1. Introduction

In recent years, the global lack of energy sources has become a major issue. This problem has led to rapid innovation in offshore wind technologies driven by renewable energy sources. The marine environment constitutes a significant renewable energy resource, increasingly exploited for sustainable energy production. Offshore wind power stands out among maritime renewable energy technologies because it combines three key advantages: an inexhaustible energy supply, rapid technological advancement, and relatively low construction costs [

1,

2]. Floating offshore wind turbines (FOWTs) are gaining increasing attention in the renewable energy industry for their suitability in deep-water installations. However, offshore wind turbines supported by a fixed-bottom substructure remain a key solution for installations in shallow to medium depths. Especially, gravity-based structure (GBS) foundations offer high stability and cost effectiveness in certain seabed conditions. Furthermore, they eliminate the need for extensive pile operations relative to monopile substructures, making them an attractive option for both new projects and retrofits.

At the same time, progress in composite materials and additive manufacturing (AM) is creating new opportunities to optimize offshore wind turbine components. For instance, fiber-reinforced polymer (FRP) composites, including glass and carbon reinforced composites, are widely used for wind turbine blades and secondary structures due to their high strength, corrosion resistance, and design flexibility [

3]. Moreover, additive manufacturing technologies, processes that involve the layer-by-layer construction of objects from a solid foundation, are being used in the renewable energy industry for the direct manufacturing of molds, prototypes, and even functional components with novel structural features [

4].

This study presents the design and construction of a scaled model of a GBS offshore wind turbine, with integrated composite materials and 3D-printed components. The 5MW NREL (National Renewable Energy Laboratory) model [

5] was scaled to fit the experimental wave basin at the University of West Attica. The hydrodynamic loads on the GBS caused by sea waves were analyzed using linear wave theory and verified through analytical calculations [

6] and numerical simulations using HAMS software [

7].

2. Materials and Methods

2.1. Model Properties

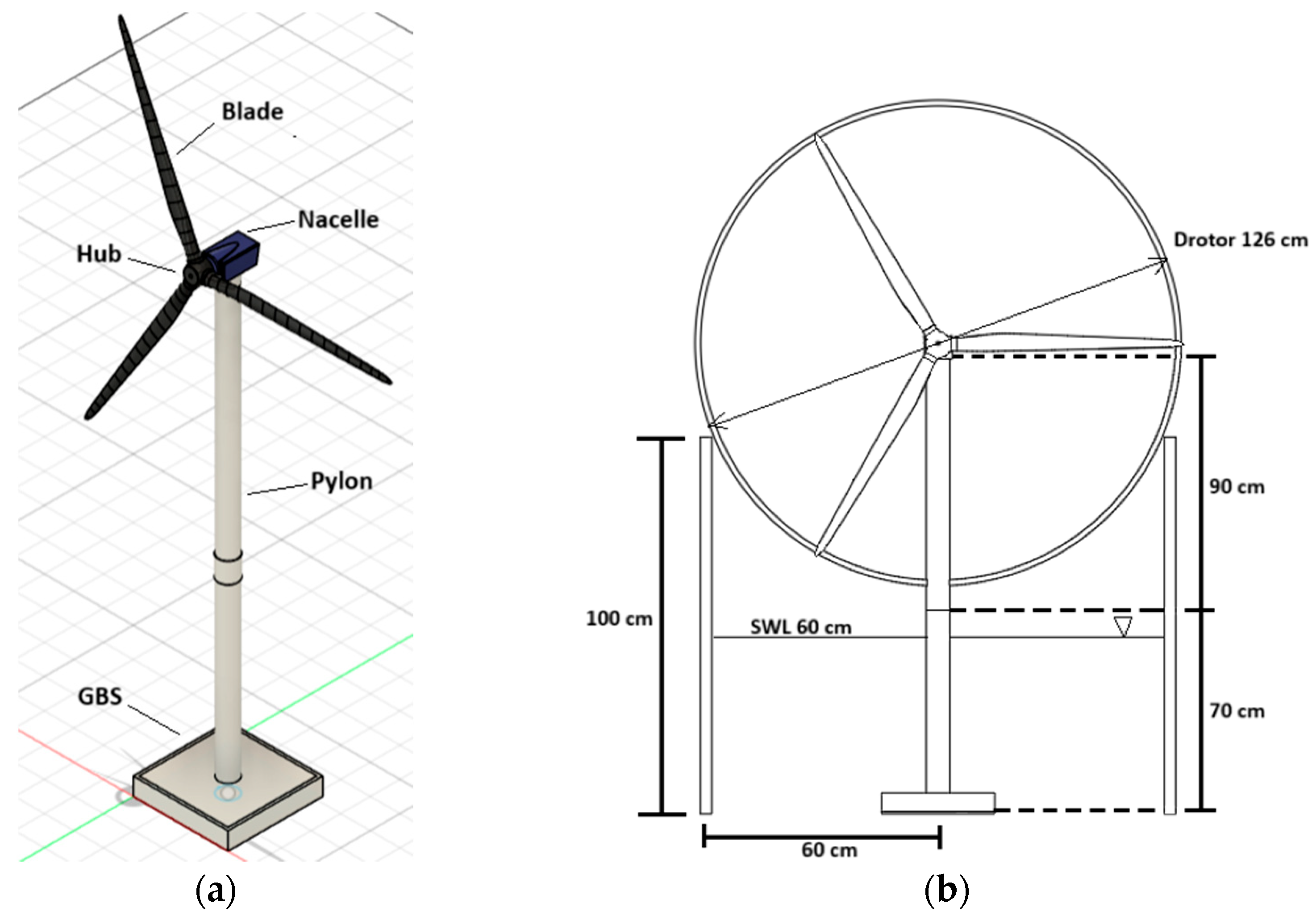

The wind turbine (WT) geometry (blades, nacelle, and hub) was based on the NREL 5MW reference [

5], scaled appropriately (1:100) for the experimental tank environment. The substructure that supports the scaled turbine consists of a central square GBS with sides measuring equal to 0.3 m and height equal to 0.05 m. The depth between the tank bottom and the still water line (SWL) is 0.6 m, and a pylon with a diameter of 0.063 m is designed to have this draught, extending 0.1 m out of the SWL. At the GBS, the wind turbine pylon, with a height of approximately 0.9 m, is mounted, along with the blades, the nacelle, and the hub. The model is illustrated in

Figure 1, and more properties are provided in

Table 1.

2.2. Model Construction Using Composite Materials

The blades of the 5MW NREL wind turbine scale model were designed to balance structural integrity, low mass, and manufacturing feasibility. Carbon fiber reinforced polymer (CFRP) was selected as the blade material due to its superior specific strength and fatigue resistance in marine applications. Additionally, the material choice was based on minimizing the contribution of the blades to the total moment of inertia, ensuring that the model will respond realistically to the wave loads.

The manufacturing process was driven by practical considerations of material efficiency. The blade molds were formed using six semi-cylindrical PVC sections with a diameter of 63 mm for every front and back view of the blades, cut appropriately according to the 5MW NREL blade’s development. Each view of the blade was laminated with two layers of carbon fiber, infused with a high-performance epoxy resin to ensure minimized porosity. After fabricating the three front and three back faces of the blades, they were joined together using an epoxy resin blend with fumed silica powder, which provided gap filling capability and high tensile strength. Moreover, to enhance rotational stiffness and maintain aerodynamic shape integrity, two polyurethane foam reinforcement joints were placed in the interior of each blade. This step improved the overall stability of the blades during operation and testing. In addition, the pylon and gravity-based structure (GBS) were constructed from a standard PVC tube and reinforced concrete, respectively.

Furthermore, due to the necessity for high mechanical strength and low weight, the hub of the wind turbine model was also fabricated using CFRP. For the fabrication of the hub, a manual lay-up process was employed. As before, three layers of carbon fiber, infused with epoxy resin, were carefully applied over a conical shape mold ensuring a proper wind flow and an appropriate aerodynamic response of the turbine system. The final construction of the blades and the hub is illustrated in

Figure 2.

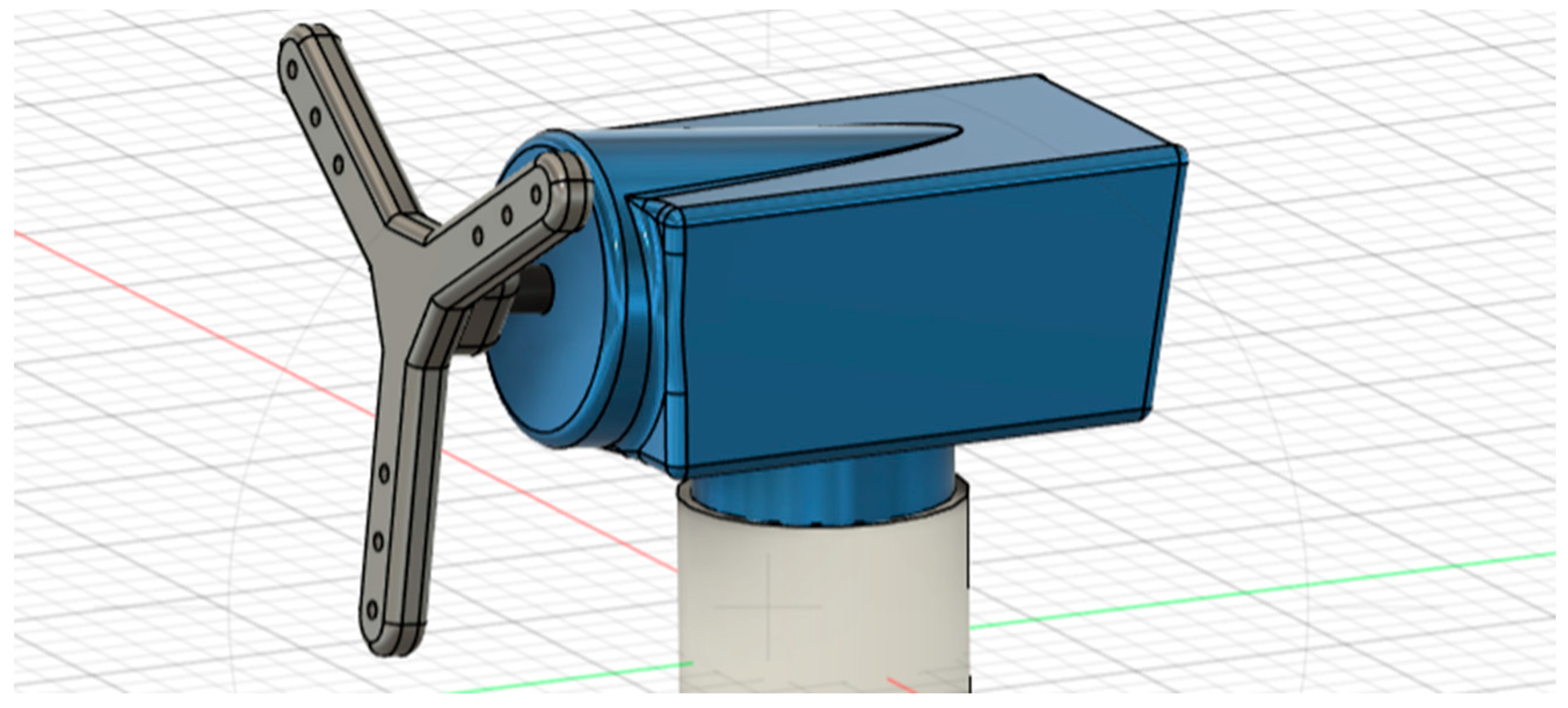

2.3. Model Construction Using Additive Manufacturing

In order to enhance the precision, modularity, and fabrication efficiency of the scale wind turbine model, key structural components such as the nacelle and a component for the connection of the blades (a blade connector) were produced using additive manufacturing techniques [

8,

9]. Both components were manufactured using the UltiMaker S5 3D printer (UltiMaker, Utrecht, The Netherlands), which employs FFF (Fused Filament Fabrication) technology.

Figure 3 illustrates the connection of the two components manufactured using additive manufacturing to the shaft and the pylon.

Firstly, the nacelle was designed in Autodesk Fusion 360 [

10] based on the 1:100 scale geometry of the NREL 5MW reference [

5]. A central hole for the shaft and an external overhang for the pylon connection were incorporated into the design. The overall geometry provided structural support for turbine rotation while reducing unnecessary mass. The component was fabricated using polylactic acid (PLA) material, together with polyvinyl alcohol (PVA) water-soluble support material, to enable accurate production of internal holes, external overhangs, and final structural details. Moreover, printing parameters were determined through experimental testing using Ultimaker Cura software version 5.9.0. [

11] to balance surface quality with mechanical integrity and successful 3D printing. Additionally, post-processing included removal of the PVA support and the light finishing of critical contact surfaces. The nacelle’s printing parameters are provided in

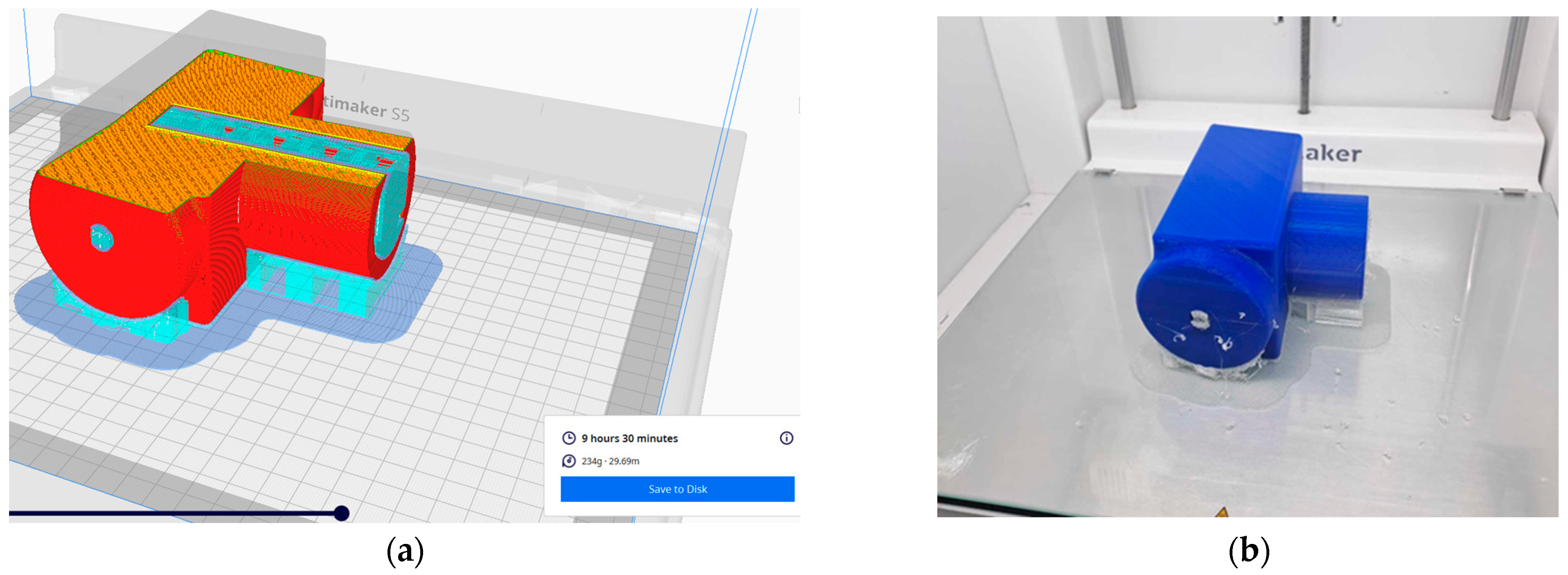

Table 2, and images of the 3D printing process are shown in

Figure 4.

Subsequently, a blade-connecting component was designed to ensure the correct positioning and angular alignment of the three composite blades. The blade connector consists of three brackets with small holes for blade holding and a central hole for the shaft connection. This component was fabricated using PLA material, while no support material was required. Great attention was paid to dimensional accuracy to ensure balanced rotation and symmetrical load distribution. The blade connector’s printing parameters are provided in

Table 3 and images of the 3D printing process are shown in

Figure 5.

For both the nacelle and the blade connector, the printing parameters were determined according to the filament supplier’s recommended values, proposed values reported in the literature for the same material, and empirical printing tests made by the authors. The printed parts exhibited good surface quality and dimensional accuracy and were successfully assembled with other parts of the structure, such as the pylon and the hub. The use of additive manufacturing (AM) to produce these critical components enabled rapid prototyping and evaluation, as well as easy redesign and remanufacturing. In addition, this approach demonstrates the potential of AM for future modular and adaptable designs in the marine and offshore industries.

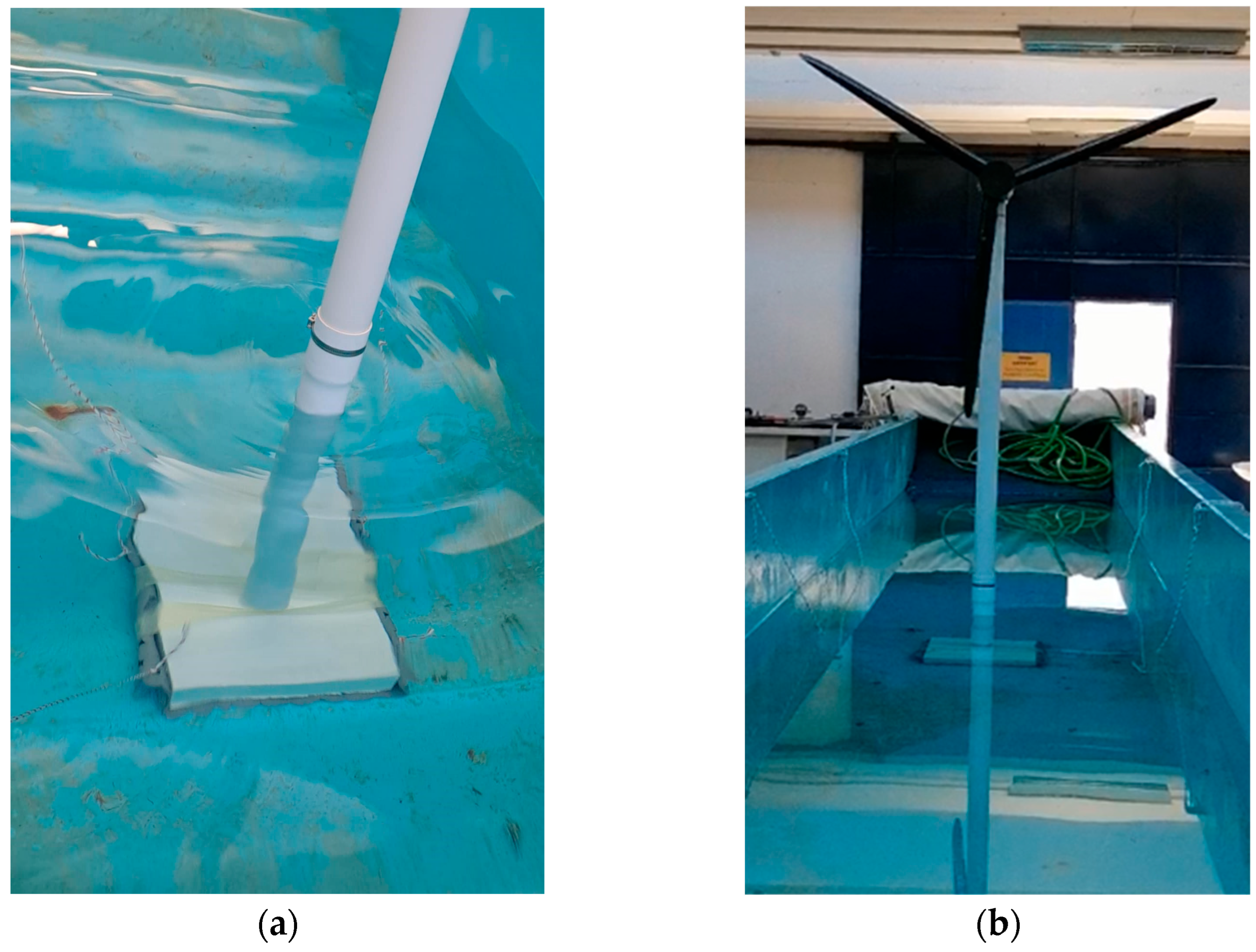

3. Model Experimental Testing

For the observation of the substructural integration of the gravity-based structure (GBS) and the hydrodynamic behavior around the scale wind turbine model, an experimental campaign was conducted in the wave basin at the University of West Attica. The main purpose of this test was to observe the response of the complete system. The fully assembled system was carefully installed in the wave basin, setting linear waves of known frequency. The model was positioned so that the GBS foundation remained fixed on the basin floor, while the visible part of the pylon and the wind turbine elements extended above the water surface of 0.6 m depth, according to the scale geometry. In

Figure 6, the fully assembled scale model of the 5MW NREL wind turbine is illustrated.

4. Hydrodynamic Analysis

In this section, the calculations of the first-order horizontal excitation force exerted on the wind turbine support pylon, under the action of simple harmonic waves (linear waves), are presented for the actual structure.

Figure 7 shows the horizontal wave exciting force in N/(

H/2), where

H is the height of the sea wave, as a function of ω (rad/s).

The calculations were performed using the analytical relations of [

6] and compared with those obtained from the open-source HAMS code [

7]. The HAMS program solves the hydrodynamic problem by the Boundary Element Method (BEM). More details can be found in [

7].

The formula for calculating the first-order horizontal excitation force is given by the following expression [

6]:

where

ρ is the density of water,

ω is the wave frequency,

H/2 is the wave amplitude,

φI +

φD is the incident wave and diffraction potential, respectively,

is the unit normal vector, and

is the wetted surface area of the body.

As can be seen in

Figure 7 [

6], the results of the HAMS program are very close to those obtained from the analytical solution. In the diagram, we observe that the largest value of the horizontal force modulus is presented for ω = 0.9 rad/s.

5. Discussion and Conclusions

In this study, the design, construction, and hydrodynamic analysis of a GBS, supporting a 1:100 scale model of the NREL 5MW reference wind turbine, were presented. The model integrated composite materials and additive manufacturing to simulate the behavior of a real offshore wind system under wave loading conditions. Hydrodynamic analysis was carried out using both an analytical method and numerical simulations. The numerical results showed good agreement with the analytical predictions across a range of frequencies, with the largest value of the horizontal force observed for an angular frequency equal to 0.9 rad/s.

This work demonstrates that the proposed design and construction methodology can be promising for small-scale wind turbines. Specifically, the use of carbon CFRP for the blades and hub offers a lightweight, high-strength solution for constructing specific turbine components. In addition, additive manufacturing can be used to fabricate lightweight components, such as the nacelle and blade connector, with high precision and design flexibility. Further research could include the construction of a larger-scale wind turbine model for experiments in a larger experimental tank, as well as the use of alternative materials for 3D-printed parts, such as carbon fiber reinforced polyamide or carbon fiber reinforced polylactic acid, to enhance their mechanical strength.

Author Contributions

Conceptualization, T.P.M.; methodology, T.P.M., I.I., and S.D.; software, T.P.M. and D.A.B.; validation, D.A.B., I.I., and S.D.; formal analysis, D.A.B.; investigation, D.A.B.; writing—original draft preparation, T.P.M. and D.A.B.; writing—review and editing, D.A.B., T.P.M., I.I., and S.D.; supervision, T.P.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

This work was presented at the 8th International Conference of Engineering Against Failure, Kalamata, Greece, 22–25 June 2025, and the registration fees were totally covered by the University of West Attica.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Otter, A.; Murphy, J.; Pakrashi, V.; Robertson, A.; Desmond, C. A review of modelling techniques for floating offshore wind turbines. Wind Energy 2022, 25, 831–857. [Google Scholar] [CrossRef]

- Jonkman, J.M. Dynamics of offshore floating wind turbines—Model development and verification. Wind Energy 2009, 12, 459–492. [Google Scholar] [CrossRef]

- Bere, P.; Ciobanu, R.; Ciobanu, O.; Gutu, M. Design and Manufacturing Method of GFRP Blades for Vertical Axis Wind Turbine. In IOP Conference Series: Materials Science and Engineering, World Symposium on Mechanical-Materials Engineering & Science (WMMES 2021); IOP Publishing: London, UK, 2021. [Google Scholar] [CrossRef]

- Murdy, P.; Dolson, J.; Miller, D.; Hughes, S.; Beach, R. Leveraging the Advantages of Additive Manufacturing to Produce Advanced Hybrid Composite Structures for Marine Energy Systems. Appl. Sci. 2021, 11, 1336. [Google Scholar] [CrossRef]

- Jonkman, J.; Butterfield, S.; Musial, W.; Scott, G. Definition of a 5-mw Reference Wind Turbine for Offshore System Development; Technical Report No. nrel/tp-500-38060; National Renewable Energy Laboratory: Applewood, CO, USA, 2009. [Google Scholar]

- Mazarakos, T.P. Second-Order Wave Loading and Wave Drift Damping on Floating Marine Structures. Ph.D. Thesis, School of Naval Architecture and Marine Engineering, Division of Marine Structures, Laboratory of Floating Structures and Mooring Systems, National Technical University of Athens, Athens, Greece, 2010. [Google Scholar] [CrossRef]

- Liu, Y. HAMS: A frequency-domain preprocessor for wave-structure interactions—Theory, development, and application. J. Mar. Sci. Eng. 2019, 7, 81. [Google Scholar] [CrossRef]

- Dimitrellou, S.; Strantzali, E.; Iakovidis, I. A decision-making strategy for selection of FDM-based additively manufactured thermoplastics for industrial applications based on material attributes. Sustain. Futures 2025, 9, 100640. [Google Scholar] [CrossRef]

- Ilyas, R.A.; El-Shafay, A.S.; Mastura, M.T.; Yusuf, S.M.; Byraktar, E.; Azman, A.H. Additive Manufacturing of Polymer-Fiber Composites. Materials 2022, 15, 5337. [Google Scholar] [CrossRef] [PubMed]

- Autodesk, 2025. Fusion 360, 3D CAD, CAM, CAE & PCB Cloud-Based Software. Available online: https://www.autodesk.com/products/fusion-360/overview (accessed on 10 January 2025).

- UltiMaker Cura 5.9.0. Available online: https://ultimaker.com/software/ultimaker-cura/ (accessed on 10 January 2025).

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).