1. Introduction

Marine engineering structures (such as offshore platforms, submarine pipelines, and cross-sea bridges) serve as core infrastructure for marine resource development, energy transportation, and marine space utilization [

1]. Their structural integrity directly relates to the safe operation of marine engineering and the safety of personnel and property. However, these structures operate long-term in complex marine environments characterized by high humidity, strong corrosion, wave impacts, and seismic loads, making them prone to cumulative damage such as crack propagation, material corrosion, and structural deformation. Failure to monitor and warn of these issues in a timely manner may lead to catastrophic accidents. According to statistics from the International Marine Engineering Safety Database, approximately 65% of marine engineering accidents caused by structural damage in the past decade were related to delayed monitoring or inaccurate diagnosis, resulting in annual economic losses exceeding tens of billions of USD [

2,

3]. Therefore, developing a high-precision, real-time structural health monitoring system holds significant practical importance for the full-lifecycle safety management of marine engineering.

Traditional marine structure monitoring methods mostly rely on single-modal sensing technologies (e.g., single vibration sensors or stress sensors) and centralized data processing models [

4,

5]. Single-modal sensing can only capture changes in local physical quantities of structures, failing to comprehensively reflect the coupling characteristics of multi-type damages, leading to prominent one-sidedness in damage identification. Centralized data processing requires transmitting massive sensing data to cloud servers for analysis, which not only faces data transmission delays in complex marine environments (especially in far-sea scenarios, where delays can reach seconds or even minutes) but also increases the system’s dependence on network stability due to centralized data storage and processing, resulting in weak anti-interference capabilities. Additionally, high humidity and strong corrosion environments easily cause aging and the failure of wired sensor network cabling, further limiting the engineering applicability of traditional methods. These limitations make existing systems unable to meet the core requirement of “early detection, early diagnosis, and early warning” for structural damages in complex marine environments.

To address the shortcomings of traditional monitoring methods, this study aims to develop an intelligent monitoring system for marine structural damage based on multimodal sensor fusion and edge computing, achieving high-precision real-time diagnosis of typical damages such as cracks, corrosion, and deformation [

6,

7,

8]. Specific objectives include the following: (1) realizing comprehensive perception of multi-physical field information (stress, vibration, acoustic characteristics, and strain, etc.) through the design of a multimodal sensor network; (2) completing real-time data processing and damage diagnosis at the edge layer close to sensing nodes based on edge computing technology, controlling system response delays within milliseconds [

9,

10]; and (3) improving the robustness of damage identification under complex working conditions through multi-source data fusion algorithms, enabling the recognition accuracy of typical damages to exceed 90%.

The innovations of this study are mainly reflected in three aspects: first, breaking through the limitations of single-modal sensing, constructing a multimodal sensor collaborative perception mechanism adapted to marine environments, and achieving the complementary collection of multi-physical field data; second, integrating edge computing with deep learning, designing lightweight intelligent diagnosis models to solve the bottlenecks of real-time performance and anti-interference in centralized processing; third, combining D-S evidence theory with deep learning feature fusion to enhance the ability to analyze damage characteristics from multi-source heterogeneous data under complex coupling conditions, providing an integrated “perception–transmission–computation–diagnosis” edge intelligence solution for marine engineering structural health monitoring.

2. Development of Marine Structure Health Monitoring Technology

Structural health monitoring (SHM), as a core technology for ensuring the safety of marine engineering, has a development process closely related to the progress of sensor technology and data processing methods. Early monitoring relied on manual inspection and single-point sensing, such as checking the corrosion condition of submarine pipelines through regular diving operations or using strain gauges to single-point monitor the stress at key nodes of the platform. However, these methods have problems such as limited coverage and poor data timeliness, making it difficult to meet the dynamic monitoring requirements of large and complex structures [

11].

With the development of sensor technology, single-modal sensor networks have gradually been applied in marine engineering, such as modal analysis methods based on vibration sensors (identifying damage through changes in the natural frequency of the structure) and strain monitoring technology based on optical fiber sensors (achieving distributed strain measurement by utilizing the modulation characteristics of optical signals) [

12,

13]. However, single-modal sensing can only reflect the changes in a certain physical dimension of the structure (such as vibration mode or local strain), while marine structure damage often manifests as multi-physical field coupling characteristics (such as the degradation of material mechanical properties due to corrosion, accompanied by changes in vibration characteristics), making it difficult to precisely distinguish damage types and quantify the degree of damage from a single data source. For instance, Reed et al. pointed out that when cracks are identified solely through vibration signals, they are easily confused with vibration anomalies caused by the settlement of structural foundations, with a misjudgment rate of over 25% [

14].

In terms of data processing mode, traditional SHM systems mostly adopt a centralized architecture of “sensor–cloud”, that is, sensor data are transmitted to the cloud server through wired or wireless means, and then damage diagnosis is carried out using machine learning or numerical simulation methods [

15]. However, the particularity of the marine environment poses a severe challenge to this architecture.

Transmission delay issue: Suppose the sensor network contains N nodes, the sampling frequency of each node is f

s (unit: Hz), and the amount of data sampled at a single time is D (unit: Byte). Then, the total data transmission rate of the system is as follows:

For large structures such as offshore platforms, N can usually reach 100–500, f

s is 100-1000 Hz, and D is 32–128 bytes. Substituting it results in R

total as 3.2 × 10

4–6.4 × 10

7 Byte/s (approximately 0.3–600 Mbps). In far-sea scenarios, wireless communication bandwidth is usually limited (for example, satellite communication bandwidth is only 1–10 Mbps), which can easily lead to data transmission delay t

trans. Its approximate expression is as follows:

Here, B represents the communication bandwidth and η represents the transmission efficiency (in marine environments, η is usually less than 0.5 due to interference). When N = 200, fs = 500 Hz, D = 64 Byte, B = 5 Mbps, and η = 0.3, ttrans ≈ 4.27 s, far exceeding the millisecond-level requirement of real-time diagnosis.

Weak anti-interference ability: The strong electromagnetic interference and high salt spray corrosion in the marine environment can easily lead to data packet loss. Let the packet loss rate be p, then the amount of valid data received by the cloud is . Centralized processing requires modeling based on complete data. When p > 0.1, the error of damage feature extraction will increase significantly. However, actual measurements show that the p of far-sea wireless transmission often reaches 0.15–0.3.

Therefore, the bottlenecks in real-time performance and robustness of the existing centralized architecture have become the core obstacles restricting the precise monitoring of marine structure damage.

3. Multimodal Sensor Fusion and Edge Computing

3.1. Research Progress on Multimodal Sensor Fusion

Multimodal sensor fusion, by integrating complementary information from different types of sensors, can effectively enhance the comprehensiveness and accuracy of state perception in complex scenarios and has been widely applied in fields such as aerospace and civil engineering. In the field of structural health monitoring, research on multimodal fusion mainly focuses on three dimensions: the data layer, the feature layer, and the decision-making layer.

Data-layer fusion emphasizes the direct correlation of raw data (such as time synchronization and spatial registration), for instance, aligning vibration acceleration signals with strain signals on the time axis to capture the multi-physical field synchronous response when damage occurs [

16].

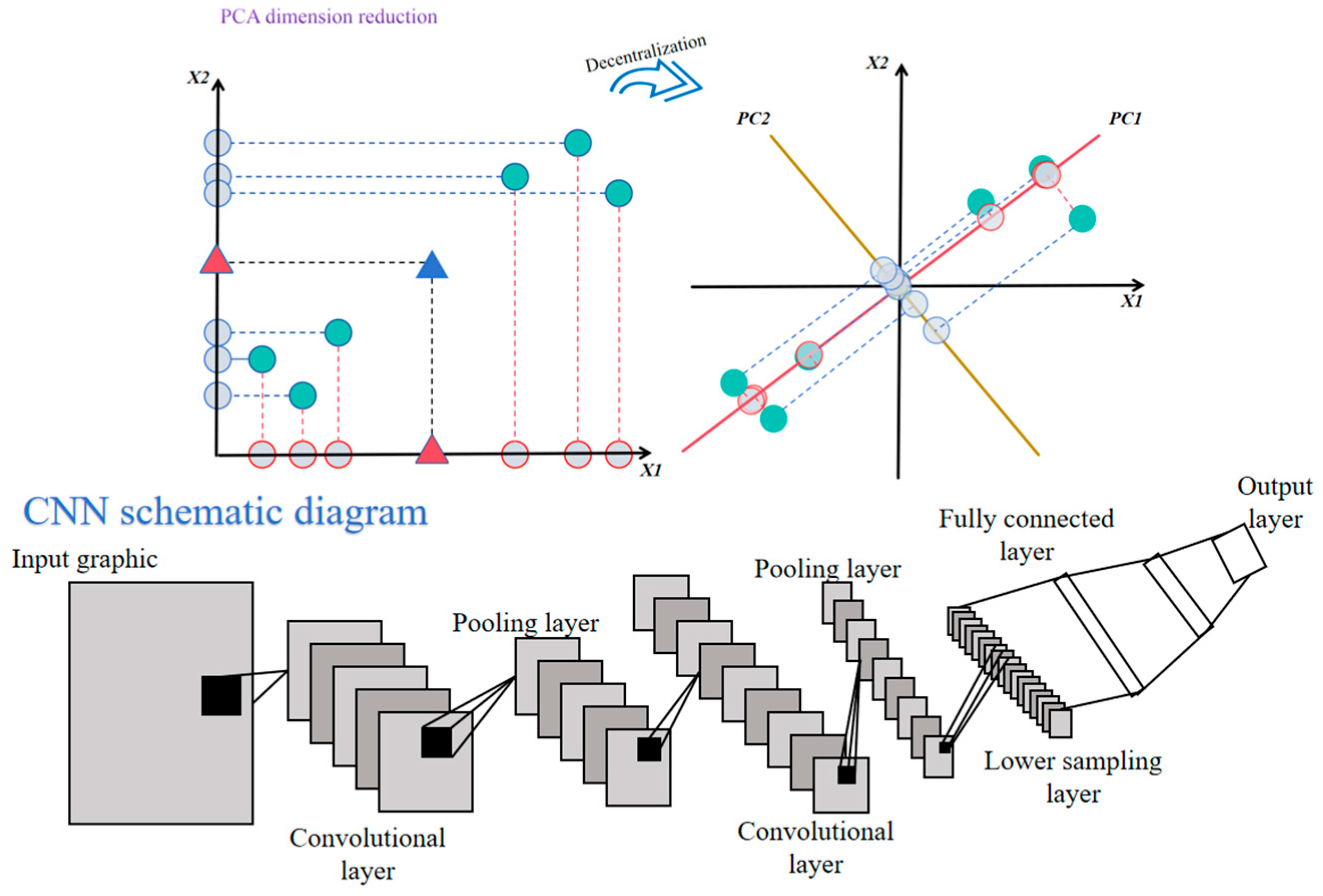

Feature-layer fusion extracts high-dimensional features from each modal data and fuses them (such as concatenation and weighted summation). Typical methods, as shown in

Figure 1, include feature dimension reduction fusion based on principal component analysis (PCA) and cross-modal feature mapping based on a convolutional neural network (CNN), etc. [

17].

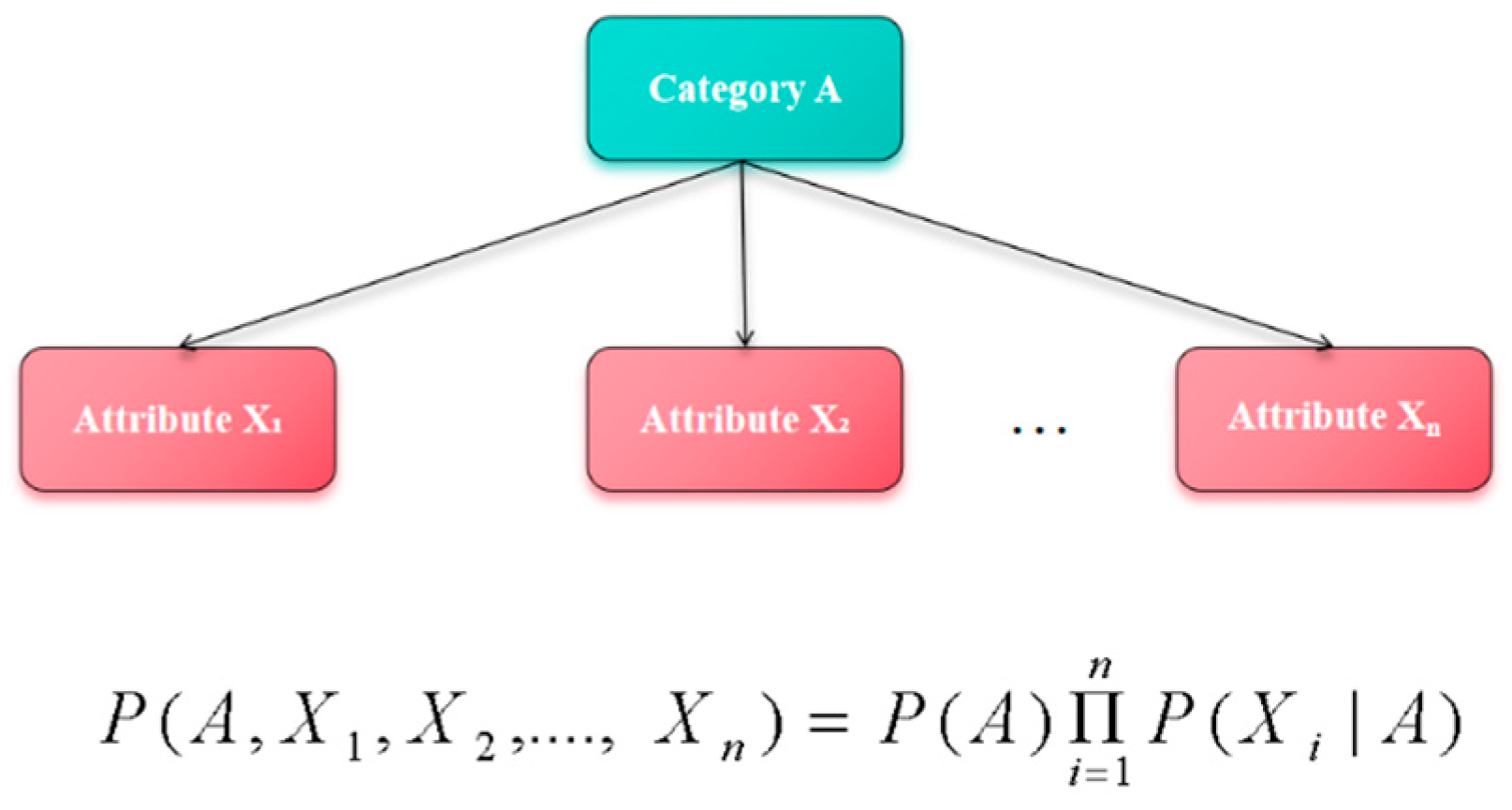

Decision-level fusion conducts a comprehensive judgment on the independent diagnostic results of each modal data. Common algorithms, as shown in

Figure 2, include Bayesian inference and D-S evidence theory, etc. Among them, D-S evidence theory stands out in multi-source decision conflict scenarios due to its ability to effectively handle uncertain information [

18].

Although multimodal fusion has significant advantages, its application in marine engineering still faces special challenges: first, the performance of sensors in marine environments is prone to interference (for example, the signal attenuation of ultrasonic sensors is severe in high-turbidity seawater), and adaptive modal selection and data preprocessing mechanisms need to be designed; second, multimodal data exhibit spatio-temporal heterogeneity (for instance, the sampling frequency of optical fiber sensors is 1 kHz, while that of corrosion sensors is 1 Hz), which increases the difficulty of fusion. At present, most related research focuses on simple nearshore structures (such as cross-sea bridges), while multimodal fusion monitoring for complex structures like deep-sea platforms and submarine pipelines is still in the exploratory stage [

19,

20,

21]. In particular, there is a lack of practical solutions that are suitable for the extreme marine environment.

3.2. Application of Edge Computing in Industrial Monitoring

Edge computing, as a distributed computing paradigm, syncs data processing and analysis functions to edge nodes close to data sources, which can significantly reduce data transmission volume and processing latency, providing a new approach to solving the real-time bottleneck of traditional centralized architectures. In the field of industrial monitoring, edge computing has been applied in scenarios such as condition monitoring of intelligent manufacturing equipment (such as real-time diagnosis of machine tool vibration) and early warning of power system faults [

22].

In the field of structural health monitoring, the application research of edge computing has gradually emerged in recent years. For instance, Rahul Kumar et al. deployed edge nodes in bridge monitoring and achieved real-time feature extraction of vibration signals through a lightweight CNN model, reducing the processing latency by 80% compared to cloud processing [

23]. Yuechun et al. combined edge computing with wireless sensor networks to achieve distributed real-time analysis of wind load responses in high-rise buildings [

24]. However, the marine environment places higher demands on the hardware reliability of edge computing nodes and high humidity and strong corrosive conditions can easily lead to the aging of edge device circuits, while structural vibrations caused by wave impacts may affect the stability of node computing power. Furthermore, marine structure monitoring needs to handle multimodal heterogeneous data. The contradiction between the limited computing power of edge nodes and complex fusion algorithms (such as the high computational overhead of the Transformer model) remains a key issue that urgently needs to be solved [

25].

4. Overall System Design

To sum up, the existing research has three deficiencies: First, single-modal sensing is difficult to cope with the coupling characteristics of multiple types of damage to marine structures. Second, centralized data processing cannot meet the real-time and robustness requirements in complex marine environments. Thirdly, the integration of multimodal fusion and edge computing is still in its infancy, lacking systematic design for marine engineering scenarios.

To this end, this study proposes a fusion framework of “multimodal sensing + edge computing” and breaks through the existing limitations through the following entry points: (1) in view of the characteristics of the marine environment, optimize the selection and distributed deployment of multimodal sensors to achieve anti-interference collection of multi-physical field information; (2) design lightweight deep learning models (such as a multi-branch Transformer) that are compatible with the computing power of edge nodes, and combine D-S evidence theory to complete real-time fusion and damage diagnosis of multi-source data at the edge layer; (3) by simulating the coupled working conditions of waves, earthquakes, and corrosion, the practicality of the system in complex scenarios is verified, providing an innovative solution for the health monitoring of Marine structures.

However, in order to break through the limitations of traditional Marine structure monitoring systems in terms of comprehensive perception, real-time performance, and environmental adaptability, this study constructs an integrated intelligent monitoring system of “perception–transmission–computing–diagnosis”. The core lies in achieving all-round perception of the structural state through multimodal sensing and low-latency processing of data relying on edge computing. Ultimately, precise damage identification under complex working conditions was achieved. This chapter elaborates in detail on the overall architecture of the system, the functional design of each layer, and the key technical indicators.

4.1. System Architecture Design

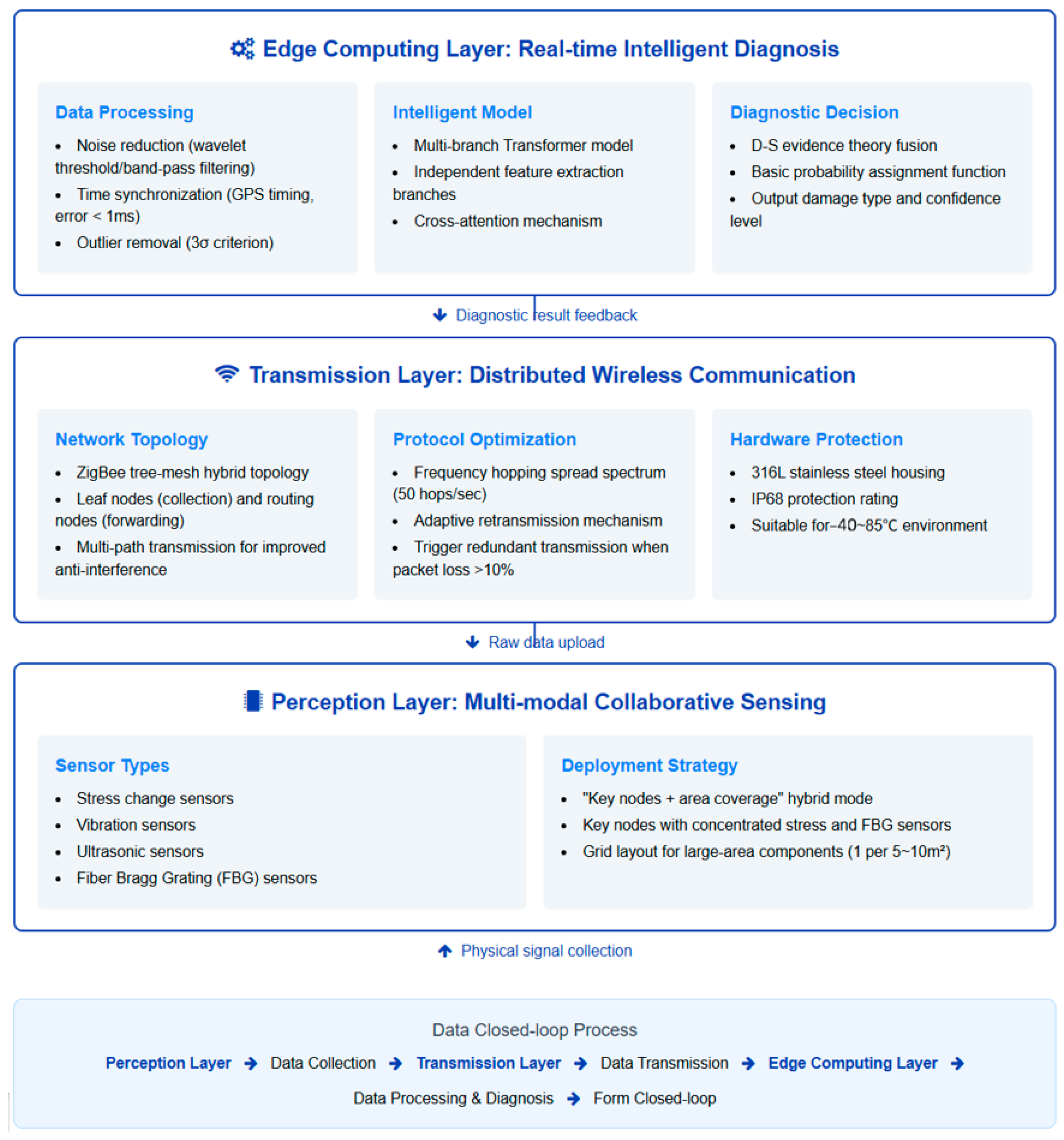

This system adopts a hierarchical architecture design, which is divided into the perception layer, transmission layer, and edge computing layer from bottom to top. Each layer collaborates to achieve a closed-loop process of “data collection–transmission–processing–diagnosis” (as shown in

Figure 3). This architecture reduces the reliance on cloud computing and long-distance communication by sinking data processing capabilities to edge nodes. At the same time, it utilizes multimodal sensing to make up for the information deficiency of a single data source, thereby adapting to the complex demands of the marine environment.

The perception layer serves as the “nerve ending” of the system, responsible for collecting multi-physical field parameters of marine structures and providing raw data support for damage diagnosis. The core of its design lies in the selection of multimodal sensors and their optimized spatial deployment, specifically including the following:

Sensor types: Based on the physical characteristics of typical damages (cracks, corrosion, and deformation) in marine structures, four types of core sensors are selected:

- (1)

Stress change sensors [

26]: Monitor stress concentration at key nodes of the structure to reflect deformation and load response;

- (2)

Vibration sensors [

27]: Collect structural vibration acceleration signals to capture modal changes caused by cracks or stiffness degradation;

- (3)

Ultrasonic sensors [

28]: Analyze the location and size of surface and near-surface corrosion and cracks through echo signal analysis;

- (4)

Fiber Bragg grating (FBG) sensors [

29]: Realize distributed strain monitoring to reflect the overall deformation trend of the structure.

Deployment strategy: Adopt a hybrid deployment mode of “key nodes + regional coverage”; stress and FBG sensors are centrally deployed at vulnerable key nodes of the structure such as welds and support points (e.g., the joints between chord members and diagonal members of jacket platforms); vibration and ultrasonic sensors are arranged in a grid pattern on large-area components (e.g., deck and riser surfaces) with a density of one sensor per 5~10 m2 to ensure the spatial correlation of damage signals.

The transmission layer is responsible for efficiently transmitting data from the perception layer to the edge computing layer, and it needs to meet the requirements of low power consumption, anti-interference, and easy deployment in marine environments. The key design points include the following:

- (1)

Network topology: Adopt a tree-mesh hybrid topology based on ZigBee. Sensor nodes are divided into leaf nodes (only for data collection) and routing nodes (with both data collection and forwarding functions). A mesh network is formed between routing nodes to realize multi-path transmission, thereby improving the anti-interference capability.

- (2)

Optimization of communication protocols: In response to the high-noise marine environment, Frequency-Hopping Spread Spectrum (FHSS) technology is adopted at the physical layer, with a frequency-hopping rate of 50 hops per second within the 2.4 GHz frequency band. An adaptive retransmission mechanism is introduced at the data link layer. When the packet loss rate exceeds 10%, redundant data packet transmission is automatically triggered to ensure data integrity.

- (3)

Hardware protection: The shells of sensors and routing nodes are made of 316L stainless steel, with a protection level of IP68. They can adapt to environments with a temperature range of −40~85 °C and a relative humidity of over 95%, avoiding failures caused by salt spray corrosion and seawater immersion.

The edge computing layer serves as the “brain” of the system, deployed on the edge nodes close to the sensor network (such as industrial-grade edge servers installed in platform control cabinets). It is responsible for data preprocessing, feature extraction, and damage fusion diagnosis. Its core functions include the following:

- (1)

Data preprocessing: Perform denoising on multimodal raw data (wavelet threshold denoising for vibration signals, band-pass filtering for ultrasonic signals), time synchronization (based on GPS timing with a synchronization error < 1 ms), and outlier removal (three criteria).

- (2)

Lightweight intelligent model: Deploy a multi-branch Transformer model, design independent feature extraction branches (each branch contains two layers of Transformer encoders) for four types of data: stress, vibration, ultrasonic, and FBG. Realize inter-modal feature interaction through a cross-attention mechanism and output preliminary damage identification results.

- (3)

Decision fusion: Adopt D-S evidence theory to fuse the identification results of multi-branch models, define three basic probability assignment (BPA) functions for cracks, corrosion, and deformation, and reduce the risk of misjudgment from a single modality through evidence synthesis rules (such as Dempster’s combination rule) to output the final damage type and confidence level.

4.2. System Workflow

The damage monitoring process of the system can be divided into four stages:

- (1)

Data collection stage: Various modal sensors continuously collect data at set frequencies (stress/FBG: 1 Hz, vibration: 500 Hz, and ultrasonic: 0.1 Hz), and leaf nodes send the data to nearby routing nodes;

- (2)

Data transmission stage: Routing nodes forward the aggregated data to edge nodes through the wireless mesh network, and data verification and retransmission are automatically completed during the transmission process;

- (3)

Edge processing stage: After preprocessing the received multimodal data, the edge node inputs the multi-branch Transformer model to extract damage features, and then fuses decisions through D-S evidence theory to output the damage type (crack/corrosion/deformation), location and degree (such as crack length and corrosion depth);

- (4)

Result feedback stage: If the diagnosis result shows that the damage level exceeds the preset threshold (such as crack length > 5 mm), the edge node immediately triggers a local early warning (acousto-optic alarm) and compresses the key data (damage features and diagnosis results) before uploading them to the cloud database for analysis by the remote monitoring center.

To verify the practicality of the system, the following core technical indicators are set:

- (1)

Real-time performance: The total delay from data collection to damage diagnosis is less than 500 ms (including transmission delay < 200 ms and processing delay < 300 ms);

- (2)

Accuracy: The recognition accuracy of typical damages (cracks: > 92%, corrosion: > 90%, and deformation: > 95%), with position positioning error < 0.5 m;

- (3)

Robustness: Under the coupled working conditions of wave impact (wave height 5 m), seismic load (intensity VII), and salt spray corrosion (concentration 5% NaCl), the continuous operation stability of the system is > 99% (mean time between failures > 1000 h).

5. Implementation of Key Technologies

This section focuses on the specific implementation details of the system’s core technologies, including the collaborative perception mechanism of the multimodal sensor network, the optimized design of distributed wireless transmission protocols, and the construction of lightweight intelligent algorithms in the edge computing layer, providing technical support for the real-time performance and accuracy of the system.

5.1. Formatting of Mathematical Components

In view of the multi-physical field characteristics of marine structure damage, sensor selection must meet the dual requirements of environmental adaptability and parameter matching:

- (1)

Stress change sensor: A suitable piezoresistive strain gauge is selected, which converts stress changes into voltage signals through a Wheatstone bridge. The package adopts a polyimide film moisture-proof layer, and the zero drift is <0.1% under specific humidity to ensure long-term monitoring stability.

- (2)

Vibration sensor: A MEMS accelerometer is used, with a built-in low-pass filter (cut-off frequency adjustable) to suppress high-frequency noise (>1 kHz) generated by ocean wave impact.

- (3)

Ultrasonic sensor: A suitable piezoelectric probe is selected, using the pulse-echo method. The influence of marine humidity on the propagation speed is eliminated through sound velocity correction (compensation for sound velocity differences at the seawater/air interface) (correction formula: , where is relative humidity and is the standard sound velocity).

- (4)

FBG sensor: A specific ultraviolet-written grating is used, which is connected in series through optical fiber fusion technology to form a distributed array. The wavelength resolution of the supporting demodulator reaches 1 pm, enabling strain measurement accuracy of ±1 με, and its anti-electromagnetic interference capability is adapted to the strong electromagnetic field environment in the ocean.

The temporal and spatial correlation of multimodal data is a prerequisite for fusion analysis, and synchronization protocols are required to eliminate the spatiotemporal deviations of heterogeneous sensors:

- (1)

Time synchronization [

30,

31,

32]: A hierarchical synchronization strategy based on the Precision Time Protocol is adopted. The edge node serves as the master clock and sends synchronization frames to routing nodes via wireless transmission. The routing nodes then broadcast to leaf nodes, ultimately ensuring that the sampling time deviation of all sensors is relatively small.

- (2)

Spatial registration [

33,

34,

35]: The spatial coordinates (x, y, z) of each sensor are pre-calibrated through a 3D structural model (such as a BIM model) and coordinate labels are embedded in data frames. The edge layer correlates multimodal data to the same physical position of the structure through coordinate mapping, solving the problem of spatial coverage overlap between vibration and ultrasonic sensors.

In response to noise interference in the marine environment, differentiated preprocessing is applied to data of different modalities:

- (1)

Stress/FBG data: Affected by temperature drift interference, polynomial fitting compensation is used (, where T is temperature, and a and b are calibration coefficients);

- (2)

Vibration data: Disturbed by random wave vibrations, wavelet threshold denoising is adopted (using db4 wavelet, decomposed into 5 layers, with the threshold function , where is the noise standard deviation and N is the data length);

- (3)

Ultrasonic data: Due to clutter generated by interface reflection, effective echo signals are extracted through band-pass filtering (1.5~3 MHz) and envelope detection (Hilbert transform).

5.2. Optimization of Distributed Wireless Transmission Protocol

To adapt to the highly interfering marine environment, the transmission layer implements three key optimizations based on the ZigBee protocol to improve the reliability and energy efficiency of data transmission.

A dynamic routing selection based on the Link Quality Indicator (LQI) is adopted, with the routing weight function defined as

where

,

, and

are weight coefficients

, p is the historical packet loss rate, and d is the node distance. Routing nodes broadcast LQI information periodically and dynamically select the path with the maximum weight.

For high-frequency data such as vibration signals (500 Hz), piecewise linear fitting compression is used; the data are divided into segments of length L, and each segment is fitted with a straight line, y = kx + b. When the fitting error e < δ (threshold set to 0.05 g), k and b are retained to replace the original data, achieving a compression ratio of 5:1 to 10:1. For co-located data from multiple nodes (e.g., stress and strain in the same area), routing nodes perform data aggregation (such as calculating mean and variance) to reduce transmission volume.

5.3. Design of Intelligent Algorithms for Edge Layer

The core of the edge computing layer is to realize real-time fusion diagnosis of multimodal data with limited computing power. The algorithm’s architecture consists of two parts: feature extraction and decision fusion.

Branch design: (1) Stress/FBG branch: the input is a time series, which is dimensionally reduced by 1D convolution and then connected to the Transformer encoder to extract long-term trend features; (2) Vibration branch: the input is a spectrogram, from which frequency domain features are extracted by 2D convolution and then encoded by the Transformer; and the (3) Ultrasonic branch: the input is the echo signal envelope, and the reflection peak features are focused through the self-attention mechanism.

Cross-modal fusion: A modal attention module is introduced to calculate the similarity matrix, , of each branch feature (where M and N are the dimensions of modal features). Feature interaction is realized through weighted summation: .

To reduce the risk of misjudgment from a single modality, D-S evidence theory is used to fuse the outputs of multiple branches [

36]:

Basic Probability Assignment (BPA): Convert the prediction probabilities P

i(A), P

i(B), and P

i(C) of each branch for damage types (crack A, corrosion B, and deformation C) into BPA:

,

(where

is the uncertainty set). Evidence synthesis: Dempster’s combination rule is used to fuse n pieces of evidence:

where

is the conflict coefficient. When

, a weighted average method is introduced to weaken highly conflicting evidence. Decision output: The X with the maximum m(X) is selected as the final result.

5.4. Implementation of Damage-Identification Process

The specific steps of the complete damage-identification process of the system are as follows:

Multimodal sensors collect data synchronously, which are preprocessed and transmitted to edge nodes through the optimized wireless protocol. The edge node inputs the data into the multi-branch Transformer to extract features such as stress trends, vibration spectra, and ultrasonic echoes. The model outputs the preliminary probabilities of each damage type, which are converted through BPA and then fused through D-S evidence theory. If the confidence of the fusion result satisfies , it outputs the damage type, location, and quantitative parameters (e.g., crack length , where is the vibration frequency offset and k is the calibration coefficient). When the damage degree exceeds the threshold, an early warning is triggered, and key data are compressed and uploaded to the cloud.

6. Conclusions and Prospects

6.1. Research Conclusions

Aiming to discuss the problems of traditional marine structure health monitoring methods, such as insufficient real-time performance, weak anti-interference abilities, and the one-sidedness of single-modal perception in complex environments, this study proposes an intelligent monitoring system based on multimodal sensing and edge computing. Through system design and the implementation of key technologies, the following core conclusions are drawn:

The multimodal sensor network realizes comprehensive perception of the multi-physical fields of the structure: Through the collaborative deployment of stress change sensors, vibration sensors, ultrasonic sensors, and FBG sensors, combined with spatiotemporal synchronization mechanisms and environment-adaptive preprocessing strategies, it effectively captures the stress concentration, vibration modal changes, surface damage, and distributed strain characteristics of marine structures under the effects of wave impact, seismic loads, and corrosion. This makes up for the one-sidedness of single-modal sensing in identifying multiple types of damage (cracks, corrosion, and deformation) and provides multi-dimensional data support for accurate diagnosis.

The optimized distributed wireless transmission protocol is adapted to the complex marine environment: The dynamic routing algorithm, segment compression, and low-power scheduling mechanism based on the ZigBee protocol solve the problems of complex wiring in traditional wired networks and the weak anti-interference ability of wireless transmission. At the same time, it meets the requirements of long-term stable operation in the marine environment with high humidity and strong corrosion.

The lightweight intelligent algorithm at the edge layer realizes real-time and high-precision diagnosis: The fusion framework of the multi-branch Transformer model and D-S evidence theory realizes the real-time extraction of multimodal features and decision fusion on edge nodes, reducing the total processing delay. Compared with centralized cloud processing, it has significant improvements in real-time performance and robustness, verifying the applicability of edge intelligence in marine monitoring scenarios.

In summary, through the three-layer collaborative design of “perception–transmission–computation”, this system constructs a low-latency and high-robustness damage monitoring solution adapted to the marine environment, providing technical support for the full-lifecycle safety management of marine engineering structures.

6.2. Research Limitations and Future Prospects

Although this study has achieved phased results by combining multimodal fusion with edge computing, there are still the following limitations: first, large-scale deployment of sensor networks (such as thousand-level nodes in super-large marine platforms) may lead to uneven computing load on edge nodes; second, the performance attenuation mechanism of sensors under extreme working conditions (such as typhoons and deep-sea high pressure) has not been fully clarified; third, the long-term prediction model of damage evolution has not been incorporated into the system, making it difficult to upgrade from “diagnosis to early warning”. Future research can be deepened in the following directions:

Dynamic edge computing power scheduling and network optimization: For large-scale sensor networks, introduce edge node clusters and load-balancing algorithms (such as task allocation based on reinforcement learning), and combine federated learning frameworks to realize distributed model training to avoid computing bottlenecks of a single node; at the same time, explore the integrated transmission of low-orbit satellites and underwater acoustic communication to solve the communication coverage problem in far-sea/deep-sea scenarios.

Enhancement of extreme environment adaptability: Develop sensor packaging technology with high pressure resistance and anti-biofouling properties, establish a quantitative relationship model between environmental parameters (temperature, pressure, and salinity) and sensor drift, and further improve data reliability through online calibration.

Damage evolution prediction and full-lifecycle management: Integrate multimodal monitoring data with structural finite element models, construct a damage growth prediction model based on Long Short-Term Memory (LSTM) networks, and realize dynamic visualization of structural health status combined with digital twin technology, providing an integrated “diagnosis–prediction–maintenance” scheme for maintenance decision making.

Cross-domain technology integration and standardization: Promote the in-depth integration of marine monitoring and Industry 4.0, formulate industry standards for multimodal sensing data interfaces and edge computing communication protocols, and promote the transformation of technical achievements into practical engineering applications.

Future research will continue to focus on the collaborative optimization of “perception accuracy–computing efficiency–environmental adaptability”, striving to provide a more universal edge intelligence solution for marine engineering structure health monitoring, and contributing to the safe and efficient development of marine resources.

Author Contributions

Conceptualization, K.Y. (Keqi Yang) and K.Y. (Kefan Yang); methodology, K.Y. (Keqi Yang); software, S.Z.; validation, Y.Z., K.Y. (Keqi Yang), and S.Z.; formal analysis, K.Y. (Kefan Yang); investigation, K.Y. (Kefan Yang); resources, D.Z.; data curation, S.Z.; writing—original draft preparation, K.Y. (Keqi Yang); writing—review and editing, Y.Z. and D.Z.; visualization, D.Z.; supervision, D.Z.; project administration, D.Z.; funding acquisition, D.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Program for Scientific Research Start-up Funds of Guangdong Ocean University, Grant No. 060302072101 and Zhanjiang Marine Youth Talent Project—Comparative Study and Optimization of Horizontal Lifting of Subsea Pipeline, Grant No. 2021E5011.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Taylor, D.A. Introduction to Marine Engineering; Elsevier: Amsterdam, The Netherlands, 1996. [Google Scholar]

- Vukelić, G.; Vizentin, G. Common case studies of marine structural failures. In Failure Analysis and Prevention; IntechOpen: London, UK, 2017. [Google Scholar]

- Ibrion, M.; Paltrinieri, N.; Nejad, A.R. Learning from failures: Accidents of marine structures on Norwegian continental shelf over 40 years time period. Eng. Fail. Anal. 2020, 111, 104487. [Google Scholar] [CrossRef]

- Socorro, A.B.; Hernaez, M.; Del Villar, I.; Corres, J.M.; Arregui, F.J.; Matias, I.R. Single-mode—Multimode—Single-mode and lossy mode resonance-based devices: A comparative study for sensing applications. Microsyst. Technol. 2016, 22, 1633–1638. [Google Scholar] [CrossRef]

- Han, L.; Newhook, J.P.; Mufti, A.A. Centralized remote structural monitoring and management of real-time data. In Nondestructive Evaluation and Health Monitoring of Aerospace Materials and Composites III; SPIE: Bellingham, WA, USA, 2004; Volume 5393. [Google Scholar]

- Silva-Campillo, A.; Pérez-Arribas, F.; Suárez-Bermejo, J.C. Health-monitoring systems for marine structures: A review. Sensors 2023, 23, 2099. [Google Scholar] [CrossRef] [PubMed]

- Luo, H.; Wang, X.; Xu, Z.; Liu, C.; Pan, J.-S. A software-defined multi-modal wireless sensor network for ocean monitoring. Int. J. Distrib. Sens. Netw. 2022, 18, 15501477211068389. [Google Scholar] [CrossRef]

- Nie, J.; Zuo, Z.; Liang, X.; Ye, M.; Song, N.; Li, X. Multimodal Issues and Key Technologies in Ocean Observation Data: A Review. IEEE J. Sel. Top. Appl. Earth Obs. Remote Sens. 2025, 18, 19333–19362. [Google Scholar] [CrossRef]

- Cao, K.; Liu, Y.; Meng, G.; Sun, Q. An overview on edge computing research. IEEE Access 2020, 8, 85714–85728. [Google Scholar] [CrossRef]

- Sharma, M.; Tomar, A.; Hazra, A. Edge computing for industry 5.0: Fundamental, applications, and research challenges. IEEE Internet Things J. 2024, 11, 19070–19093. [Google Scholar] [CrossRef]

- Selvaprasanth, P.; Malathy, R. Revolutionizing structural health monitoring in marine environment with internet of things: A comprehensive review. Innov. Infrastruct. Solut. 2025, 10, 62. [Google Scholar] [CrossRef]

- Chen, S.; Wang, J.; Zhang, C.; Li, M.; Li, N.; Wu, H.; Liu, Y.; Peng, W.; Song, Y. Marine structural health monitoring with optical fiber sensors: A review. Sensors 2023, 23, 1877. [Google Scholar] [CrossRef]

- Wu, Q.; Qu, Y.; Liu, J.; Yuan, J.; Wan, S.-P.; Wu, T.; He, X.-D.; Liub, B.; Liuc, D.; Ma, Y.; et al. Singlemode-multimode-singlemode fiber structures for sensing applications—A review. IEEE Sens. J. 2020, 21, 12734–12751. [Google Scholar] [CrossRef]

- Reed, H.M. Stochastic and Deterministic Inverse Problem Solutions for Structural Damage Condition Assessment in a Multi-Physics Context; Cornell University: Ithaca, NY, USA, 2014. [Google Scholar]

- Webb, G.T.; Vardanega, P.J.; Middleton, C.R. Categories of SHM deployments: Technologies and capabilities. J. Bridge Eng. 2015, 20, 04014118. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, W.; Lin, S.; Quek, T.Q. Heterogeneous sensor data fusion by deep multimodal encoding. IEEE J. Sel. Top. Signal Process. 2017, 11, 479–491. [Google Scholar] [CrossRef]

- Raza, A.; Huo, H.; Fang, T. PFAF-Net: Pyramid feature network for multimodal fusion. IEEE Sens. Lett. 2020, 4, 5501704. [Google Scholar] [CrossRef]

- Fan, L.; Wang, Y.; Zhang, H.; Zeng, C.; Li, Y.; Gou, C.; Yu, H. Multimodal perception and decision-making systems for complex roads based on foundation models. IEEE Trans. Syst. Man Cybern. Syst. 2024, 54, 6561–6569. [Google Scholar] [CrossRef]

- Lahat, D.; Adali, T.; Jutten, C. Multimodal data fusion: An overview of methods, challenges, and prospects. Proc. IEEE 2015, 103, 1449–1477. [Google Scholar] [CrossRef]

- Pawłowski, M.; Wróblewska, A.; Sysko-Romańczuk, S. Effective techniques for multimodal data fusion: A comparative analysis. Sensors 2023, 23, 2381. [Google Scholar] [CrossRef]

- Gaw, N.; Yousefi, S.; Gahrooei, M.R. Multimodal data fusion for systems improvement: A review. In Handbook of Scholarly Publications from the Air Force Institute of Technology (AFIT), Volume 1, 2000–2020; CRC Press: Boca Raton, FL, USA, 2022; pp. 101–136. [Google Scholar]

- Yazdi, M. Integration of IoT and edge computing in industrial systems. In Advances in Computational Mathematics for Industrial System Reliability and Maintainability; Springer Nature: Cham, Switzerland, 2024; pp. 121–137. [Google Scholar]

- Verma, R.K.; Pattanaik, K.K.; Dissanayake, P.B.; Dammika, A.J.; Buddika, H.A.; Kaloop, M.R. Damage detection in bridge structures: An edge computing approach. arXiv 2020, arXiv:2008.06724. [Google Scholar] [CrossRef]

- Wang, Y.; Man, K.L.; Lee, K.; Hughes, D.; Guan, S.-U.; Wong, P. Application of wireless sensor network based on hierarchical edge computing structure in rapid response system. Electronics 2020, 9, 1176. [Google Scholar] [CrossRef]

- Yang, T.; Cui, Z.; Alshehri, A.H.; Wang, M.; Gao, K.; Yu, K. Distributed maritime transport communication system with reliability and safety based on blockchain and edge computing. IEEE Trans. Intell. Transp. Syst. 2022, 24, 2296–2306. [Google Scholar] [CrossRef]

- Han, B.; Ou, J. Embedded piezoresistive cement-based stress/strain sensor. Sens. Actuators A Phys. 2007, 138, 294–298. [Google Scholar] [CrossRef]

- Haroun, A.; Tarek, M.; Mosleh, M.; Ismail, F. Recent progress on triboelectric nanogenerators for vibration energy harvesting and vibration sensing. Nanomaterials 2022, 12, 2960. [Google Scholar] [CrossRef]

- Djalilov, A.; Sobirov, E.; Nazarov, O.; Urolov, S.; Gayipov, I. Study on automatic water level detection process using ultrasonic sensor. IOP Conf. Ser. Earth Environ. Sci. 2023, 1141, 012020. [Google Scholar] [CrossRef]

- Li, T.; Guo, J.; Tan, Y.; Zhou, Z. Recent advances and tendency in fiber Bragg grating-based vibration sensor: A review. IEEE Sens. J. 2020, 20, 12074–12087. [Google Scholar] [CrossRef]

- Basystiuk, O.; Rybchak, Z.; Zavushchak, I.; Marikutsa, U. Evaluation of multimodal data synchronization tools. Comput. Des. Syst. Theory Pract. 2024, 6, 104–111. [Google Scholar] [CrossRef]

- Piatkowski, J.; Karbowiak, L.; Depta, F. A lightweight algorithm for synchronized multimodal data acquisition using temporal sample alignment. Sci. Rep. 2025, 15, 22711. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Ning, K.; Pan, Z.; Shen, X.; Ni, J.; Yu, W.; Schneider, A.; Chen, H.; Nevmyvaka, Y.; Song, D. Multi-modal time series analysis: A tutorial and survey. In Proceedings of the 31st ACM SIGKDD Conference on Knowledge Discovery and Data Mining V. 2, Toronto, ON, Canada, 3–7 August 2025. [Google Scholar]

- Zhu, B.; Zhou, L.; Pu, S.; Fan, J.; Ye, Y. Advances and challenges in multimodal remote sensing image registration. IEEE J. Miniaturization Air Space Syst. 2023, 4, 165–174. [Google Scholar] [CrossRef]

- Velesaca, H.O.; Bastidas, G.; Rouhani, M.; Sappa, A.D. Multimodal image registration techniques: A comprehensive survey. Multimed. Tools Appl. 2024, 83, 63919–63947. [Google Scholar] [CrossRef]

- Hu, J.; Luo, Z.; Wang, X.; Sun, S.; Yin, Y.; Cao, K.; Song, Q.; Lyu, S.; Wu, X. End-to-end multimodal image registration via reinforcement learning. Med. Image Anal. 2021, 68, 101878. [Google Scholar] [CrossRef]

- Yuan, T.; Xu, W.; Adjallah, K.H.; Wang, H.; Xu, J. A Risk Evaluation Method Before Using a Black-Box Model Considering Sensor Failure. In Proceedings of the 2023 IEEE 12th International Conference on Intelligent Data Acquisition and Advanced Computing Systems: Technology and Applications (IDAACS), Dortmund, Germany, 7–9 September 2023; Volume 1. [Google Scholar]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).