Real-Time Sheath Damage Detection in Multicore Wire Production Using Laser-Diffused Reflection †

Abstract

1. Introduction

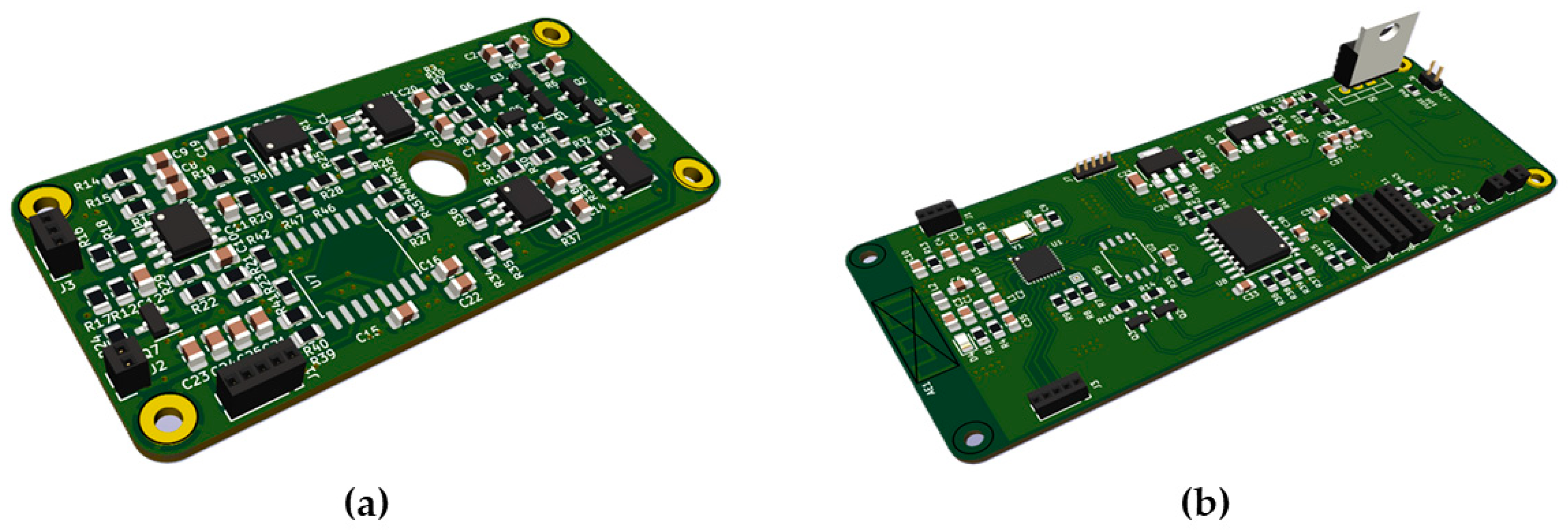

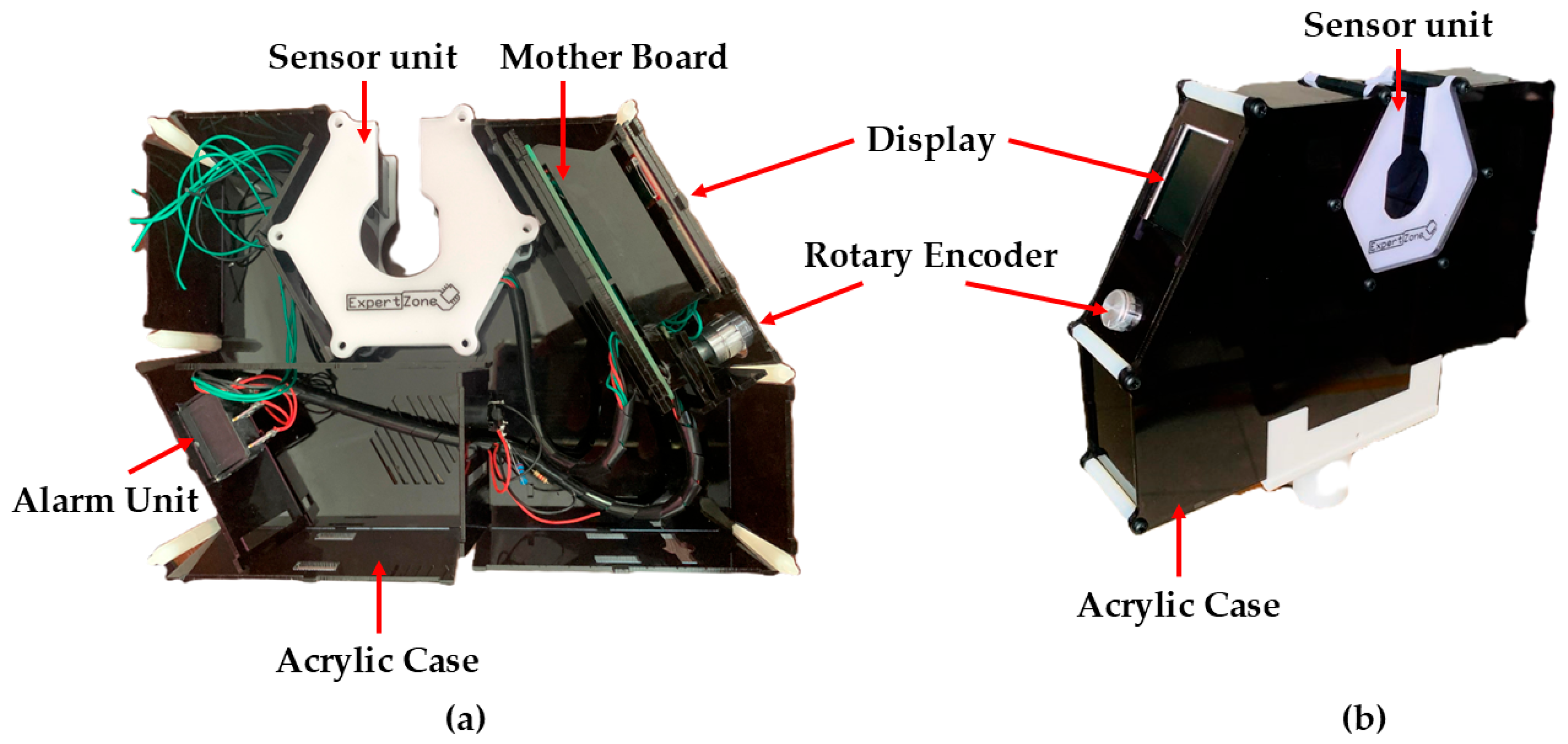

2. Methods

2.1. Color Sensing Method

2.2. Capacitive Method

2.3. Passive Infrared Method

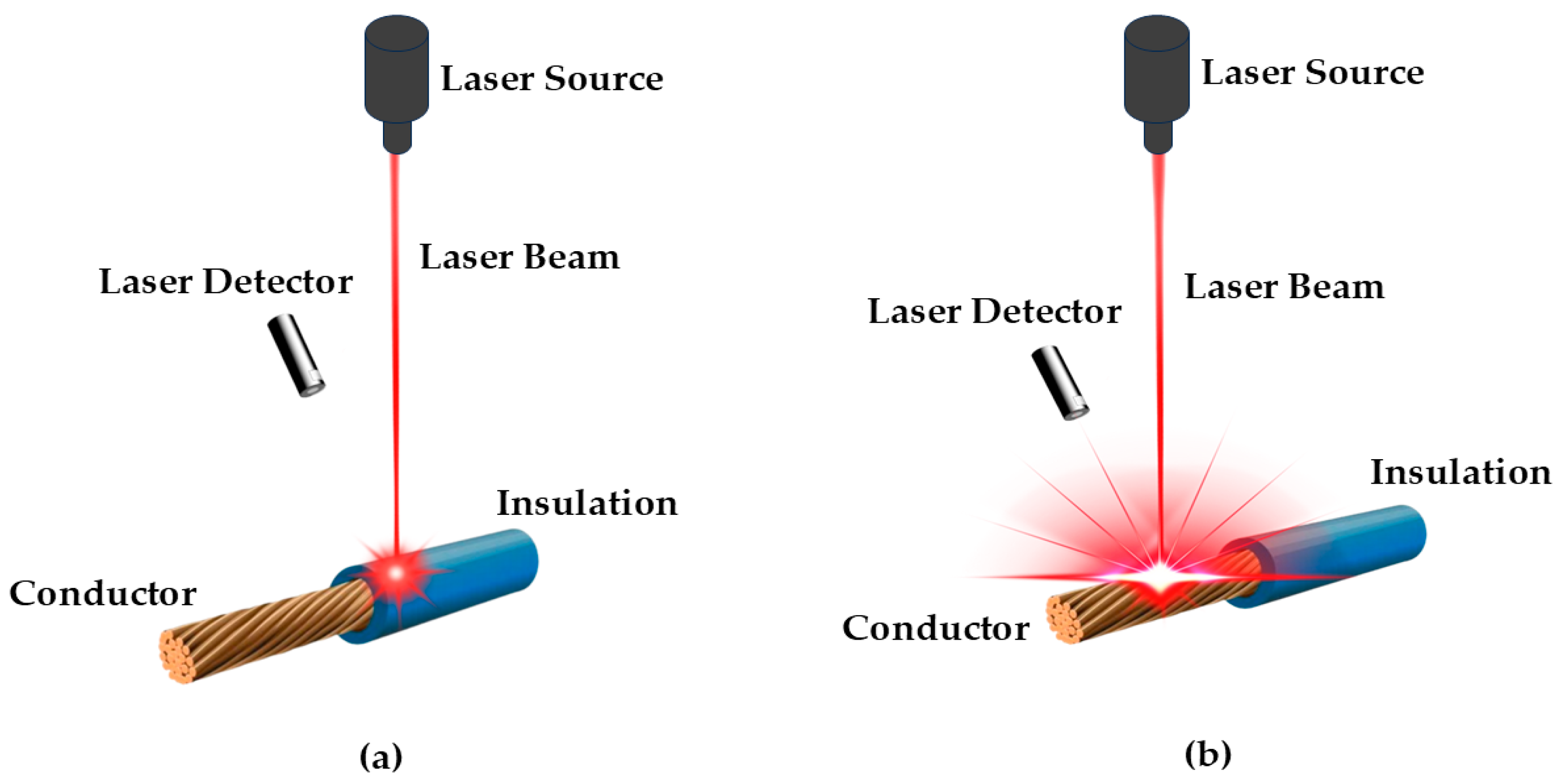

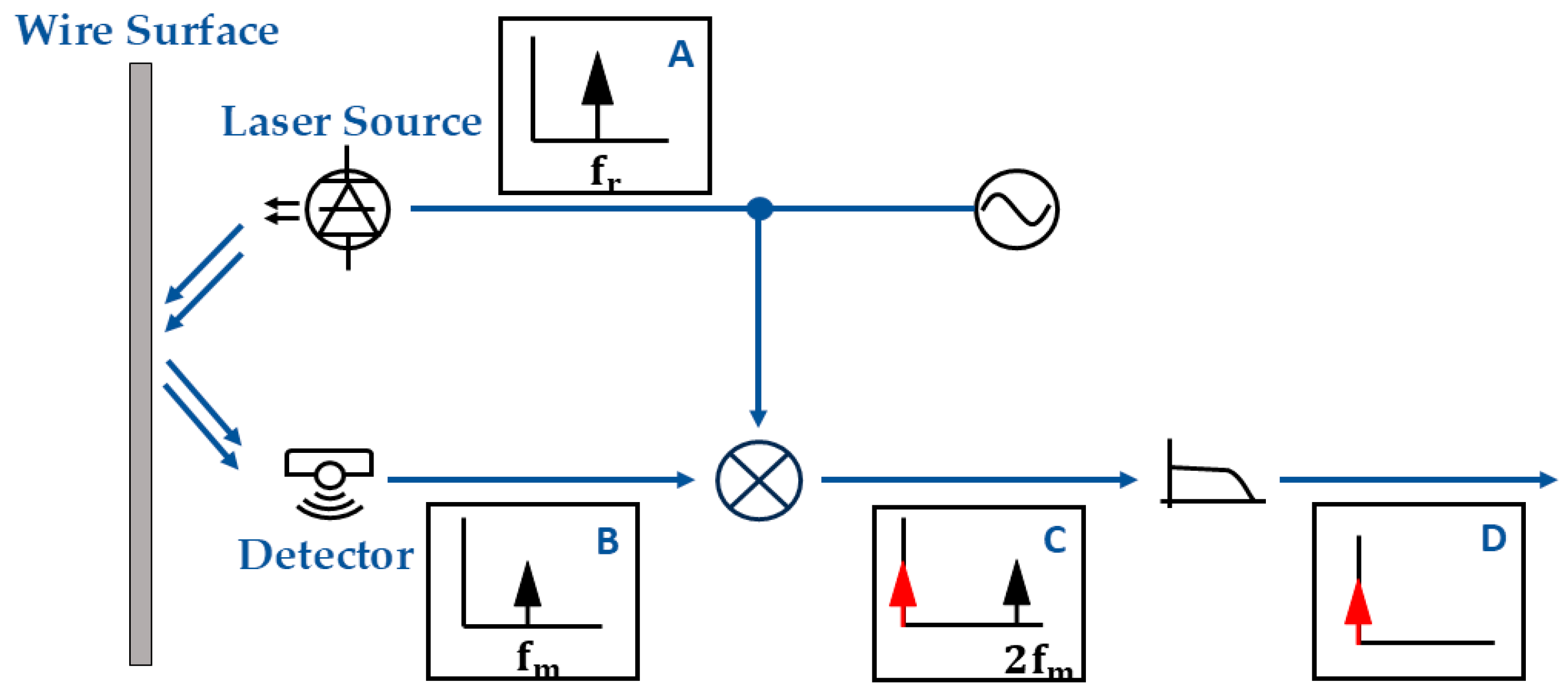

2.4. Laser Reflection Method

3. Results and Discussion

4. Conclusions and Future Work

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dhanushka, S.; Hasaranga, C.; Kahatapitiya, N.S.; Wijesinghe, R.E.; Wijethunge, A. Efficient Battery Management and Workflow Optimization in Warehouse Robotics Through Advanced Localization and Communication Systems. Eng. Proc. 2024, 82, 50. [Google Scholar]

- Goyal, A.; Thakur, A. An Overview of Drive by Wire Technology for Automobiles. In Proceedings of the 2019 International Conference on Automation, Computational and Technology Management (ICACTM), London, UK, 24–26 April 2019; pp. 108–110. [Google Scholar]

- Abdhul Rahuman, M.A.; Kahatapitiya, N.S.; Amarakoon, V.N.; Wijenayake, U.; Silva, B.N.; Jeon, M.; Kim, J.; Ravichandran, N.K.; Wijesinghe, R.E. Recent Technological Progress of Fiber-Optical Sensors for Bio-Mechatronics Applications. Technologies 2023, 11, 157. [Google Scholar] [CrossRef]

- Zhang, Y.; Tang, K.; Liu, Z.; Chen, Y. Experimental Study on Thermal and Fire Behaviors of Energized PE-Insulated Wires under Overload Currents. J. Therm. Anal. Calorim. 2021, 145, 345–351. [Google Scholar] [CrossRef]

- Irwin, T.; Ryan, H.M. Insulation Co-Ordination for AC Transmission and Distribution Systems. In High Voltage Engineering and Testing; Ryan, H.M., Ed.; Institution of Engineering and Technology: London, UK, 2007; pp. 55–86. ISBN 978-0-85296-775-1. [Google Scholar]

- Maraaba, L.; Al-Soufi, K.; Ssennoga, T.; Memon, A.; Worku, M.; Alhems, L. Contamination Level Monitoring Techniques for High-Voltage Insulators: A Review. Energies 2022, 15, 7656. [Google Scholar] [CrossRef]

- Wang, L.; Tu, Y.; Cao, B.; Liu, Y.; Mei, H.; Liu, L.; Yin, F. Review of Nondestructive Testing Methods for Defects in Insulating Polymers. CSEE J. Power Energy Syst. 2025, 11, 1380–1397. [Google Scholar] [CrossRef]

- Morsalin, S.; Phung, T.B.; Danikas, M.; Mawad, D. Diagnostic Challenges in Dielectric Loss Assessment and Interpretation: A Review. IET Sci. Meas. Tech. 2019, 13, 767–782. [Google Scholar] [CrossRef]

- Tan, D.Q. Differentiation of Roughness and Surface Defect Impact on Dielectric Strength of Polymeric Thin Films. IET Nanodielectr. 2020, 3, 28–31. [Google Scholar] [CrossRef]

- Inês Silva, M.; Malitckii, E.; Santos, T.G.; Vilaça, P. Review of Conventional and Advanced Non-Destructive Testing Techniques for Detection and Characterization of Small-Scale Defects. Prog. Mater. Sci. 2023, 138, 101155. [Google Scholar] [CrossRef]

- Cruz, J.D.S.; Fruett, F.; Lopes, R.D.R.; Takaki, F.L.; Tambascia, C.D.A.; Lima, E.R.D.; Giesbrecht, M. Partial Discharges Monitoring for Electric Machines Diagnosis: A Review. Energies 2022, 15, 7966. [Google Scholar] [CrossRef]

- Hussain, G.A.; Hassan, W.; Mahmood, F.; Shafiq, M.; Rehman, H.; Kay, J.A. Review on Partial Discharge Diagnostic Techniques for High Voltage Equipment in Power Systems. IEEE Access 2023, 11, 51382–51394. [Google Scholar] [CrossRef]

- Arman, A.S.; Glass, S.W.; Fifield, L.S.; Ali, M. Non-Conductor-Contact Surface Wave Reflectometry for Cable Insulation Damage Detection. IEEE Sens. J. 2022, 22, 11065–11074. [Google Scholar] [CrossRef]

- Zhang, H.; Mu, H.; Zhang, D.; Lu, X.; Yu, P.; Zhang, G. A Novel Non-Destructive Diagnosis Method for Cable Insulation Defect Based on Broadband Impedance Spectroscopy. In Proceedings of the 2020 IEEE International Conference on High Voltage Engineering and Application (ICHVE), Beijing, China, 6–10 September 2020; pp. 1–4. [Google Scholar]

- Ni, L.; Ma, Y.; Lin, Q.; Yang, J.; Jin, L. Research on Insulator Defect Detection Method Based on Image Processing and Watershed Algorithm. In Proceedings of the 2021 International Conference on Advanced Electrical Equipment and Reliable Operation (AEERO), Beijing, China, 15–17 October 2021; pp. 1–6. [Google Scholar]

- Application of Machine Learning in Wire Damage Detection for Safety Procedure|Soft Computing. Available online: https://link.springer.com/article/10.1007/s00500-022-06747-z (accessed on 3 May 2025).

- Rayhan, K.M.; Roy, S.D.; Sadid, M.F.H.; Ahmed, K.F.; Shatil, A.H. Surface Damage Detection of Line Insulators Using Deep Learning Algorithms to Avoid Insulation Failure. In Proceedings of the 2023 3rd International Conference on Robotics, Electrical and Signal Processing Techniques (ICREST), Dhaka, Bangladesh, 7–8 January 2023; pp. 238–243. [Google Scholar]

- Panie, G.I.E.; Mutiara, A.B. Development of robotic arm for color-based goods sorter in factory using TCS3200 sensor with a web-based monitoring system. In Proceedings of the 2018 Third International Conference on Informatics and Computing (ICIC); IEEE: Palembang, Indonesia, 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Sheldon, R.T.; Bowler, N. An Interdigital Capacitive Sensor for Nondestructive Evaluation of Wire Insulation. IEEE Sens. J. 2014, 14, 961–970. [Google Scholar] [CrossRef]

- Amuta, E.O.; Sobola, G.O.; Eseabasi, O.; Dike, H.N.; Matthew, S.; Agbetuyi, A.F.; Wara, S.T. Motion Detection System Using Passive Infrared Technology. IOP Conf. Ser. Earth Environ. Sci. 2024, 1342, 012001. [Google Scholar] [CrossRef]

- KiCad. Available online: https://www.kicad.org/ (accessed on 1 August 2025).

| Color | With Sheath (V) | Exposed Copper (V) |

|---|---|---|

| Maroon | 1.50 | 2.10 |

| Red | 2.79 | 2.10 |

| Black | 1.29 | 2.10 |

| Green | 1.29 | 2.10 |

| White | 3.38 | 2.10 |

| Trial No. | Detected | Not Detected |

|---|---|---|

| 01 | 8 | 2 |

| 02 | 9 | 1 |

| 03 | 9 | 1 |

| 04 | 8 | 2 |

| 05 | 5 | 0 |

| 06 | 8 | 2 |

| 07 | 5 | 0 |

| 08 | 4 | 1 |

| 09 | 4 | 1 |

| 10 | 3 | 2 |

| 11 | 4 | 1 |

| Total | 67 | 13 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Damith, N.; Kulasinghe, A.; Gunasekara, T.; Ranaweera, N.; Kahatapitiya, N.S.; Hettiarachchi, H.; Wijenayake, U.; Silva, B.N.; Jeon, M.; Kim, J.; et al. Real-Time Sheath Damage Detection in Multicore Wire Production Using Laser-Diffused Reflection. Eng. Proc. 2025, 118, 59. https://doi.org/10.3390/ECSA-12-26550

Damith N, Kulasinghe A, Gunasekara T, Ranaweera N, Kahatapitiya NS, Hettiarachchi H, Wijenayake U, Silva BN, Jeon M, Kim J, et al. Real-Time Sheath Damage Detection in Multicore Wire Production Using Laser-Diffused Reflection. Engineering Proceedings. 2025; 118(1):59. https://doi.org/10.3390/ECSA-12-26550

Chicago/Turabian StyleDamith, Nisala, Aruna Kulasinghe, Teshan Gunasekara, Narmada Ranaweera, Nipun Shantha Kahatapitiya, Hansa Hettiarachchi, Udaya Wijenayake, Bhagya Nathali Silva, Mansik Jeon, Jeehyun Kim, and et al. 2025. "Real-Time Sheath Damage Detection in Multicore Wire Production Using Laser-Diffused Reflection" Engineering Proceedings 118, no. 1: 59. https://doi.org/10.3390/ECSA-12-26550

APA StyleDamith, N., Kulasinghe, A., Gunasekara, T., Ranaweera, N., Kahatapitiya, N. S., Hettiarachchi, H., Wijenayake, U., Silva, B. N., Jeon, M., Kim, J., Wijesinghe, R. E., & Dharmaweera, N. (2025). Real-Time Sheath Damage Detection in Multicore Wire Production Using Laser-Diffused Reflection. Engineering Proceedings, 118(1), 59. https://doi.org/10.3390/ECSA-12-26550