Towards Autonomous Raised Bed Flower Pollination with IoT and Robotics †

Abstract

1. Introduction

2. Literature Review

2.1. Importance of Pollination in Agriculture

2.2. Decline of Natural Pollinators

2.3. Existing Pollination Methods in Greenhouse Cultivation

2.4. Advances in Autonomous and Robotic Pollination

2.5. Pollination in the Sri Lankan Agricultural Context

2.6. Comparison with State of the Art

3. Methodology

3.1. System Overview

3.2. Image Processing Model

3.3. Arm Angle Calculation

- Rover Y Movement, if the rover is at position Ry (in world Y-axis), and a flower is detected at image Y coordinate Yi, then the world Y-coordinate of the flower is

- If the rover moves forward between Image 1 and Image 2:

- Therefore, the traveled distance is

- Arm X Movement, the flower position in X-axis determines how much the arm should move left or right. If the arm base is at Xbase, and flower detected at image X coordinate Xi, then

- If Xarm > 0 the arm moves right, whereas Xarm < 0 indicates leftward motion.

- The arm must rotate to point towards the flower. Let the arm base be at (Xbase, Ybase) and the flower coordinates be (Xi, Yi). The angle is

- This angle is relative to the horizontal axis.

- Pollination on Targeted flower Position

- The arm must move to the position

- Iterative algorithm for each captured image, for each flower (Xi, Yi):

- Convert to world Y:

- 2.

- Compute arm displacement:

- 3.

- Compute arm angle

- 4.

- Move rover forward:

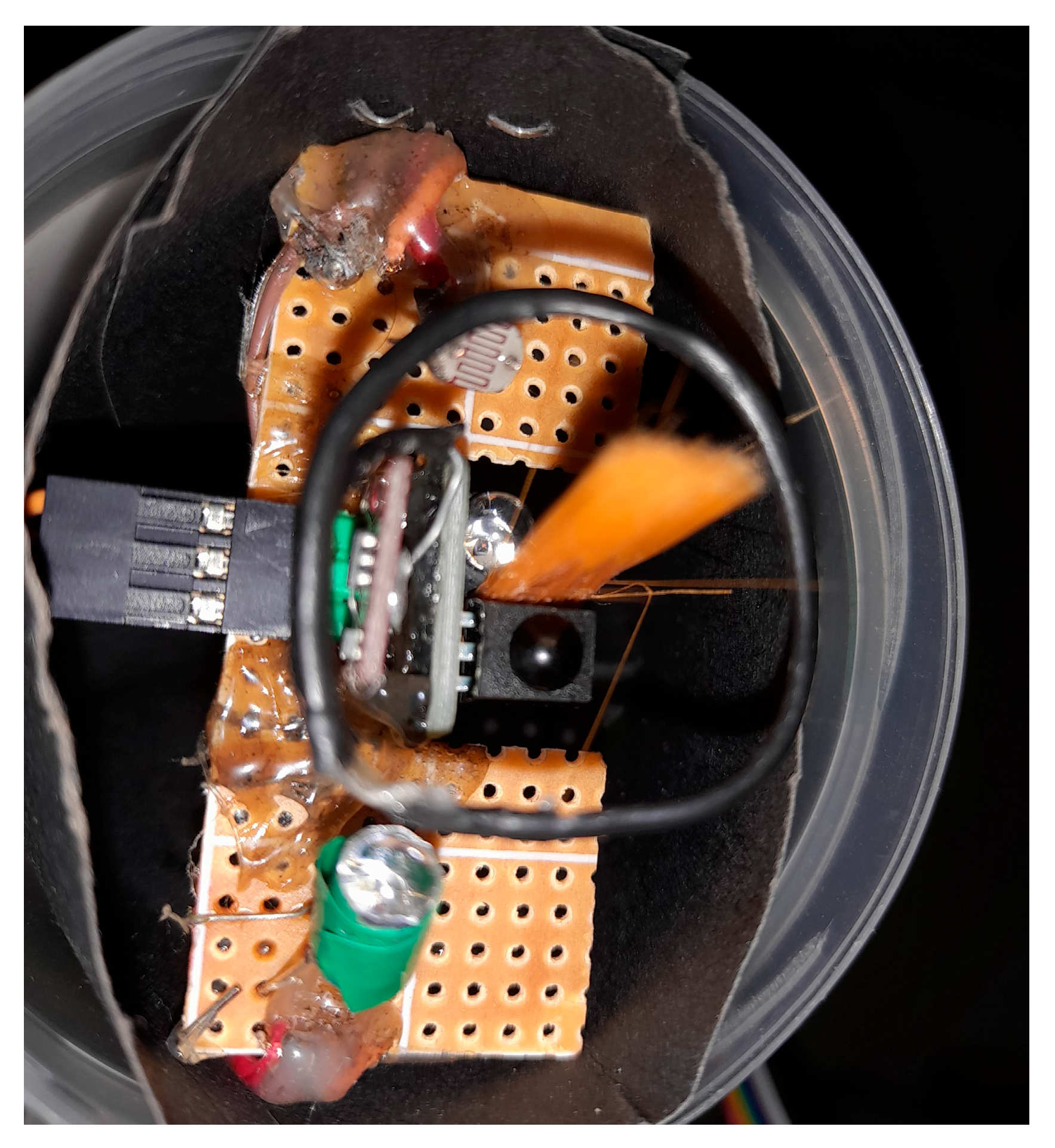

3.4. Pollination End and the Sensor Setup

3.5. Sensor Design Considerations

4. Result

4.1. Sensor Module Performance

4.2. Model Detection Performance

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Agriculture Data Bulletin—February 2025. Central Bank of Sri Lanka. 10 May 2025. Available online: https://www.cbsl.gov.lk/sites/default/files/cbslweb_documents/statistics/agriculture_data_bulletin_2025_february_e.pdf (accessed on 21 May 2025).

- Katumo, D.M.; Liang, H.; Ochola, A.C.; Lv, M.; Wang, Q.-F.; Yang, C.-F. Pollinator diversity benefits natural and agricultural ecosystems, environmental health, and human welfare. Plant Divers. 2022, 44, 429–435. [Google Scholar] [CrossRef] [PubMed]

- Van Dyk, S.; McGlasson, W.B.; Williams, M.; Spooner-Hart, R.; Holford, P. Vanilla planifolia: Artificial and insect pollination, floral guides and volatiles. Plants 2024, 13, 2977. [Google Scholar] [CrossRef] [PubMed]

- Cohen, H.; Smith, G.P.; Sardiñas, H.; Zorn, J.F.; McFrederick, Q.S.; Woodard, S.H.; Ponisio, L.C. Mass-flowering monoculture attracts bees, amplifying parasite prevalence. Proc. R. Soc. B Biol. Sci. 2021, 288, 20211369. [Google Scholar] [CrossRef] [PubMed]

- Rahimi, E.; Jung, C. Global Trends in Climate Suitability of Bees: Ups and Downs in a Warming World. Insects 2024, 15, 127. [Google Scholar] [CrossRef] [PubMed]

- Nader, E.A.; Kleftodimos, G.; Kyrgiakos, L.S.; Kleisiari, C.; Gallai, N.; Darwich, S.; Berchoux, T.; Vlontzos, G.; Belhouchette, H. Linking Beekeepers’ and Farmers’ Preferences towards Pollination Services in Greek Kiwi Systems. Animals 2023, 13, 806. [Google Scholar] [CrossRef] [PubMed]

- Wurz, A.; Grass, I.; Tscharntke, T. Hand pollination of global crops—A systematic review. Basic Appl. Ecol. 2021, 56, 299–321. [Google Scholar] [CrossRef]

- Miyoshi, K.; Hiraguri, T.; Shimizu, H.; Hattori, K.; Kimura, T.; Okubo, S.; Endo, K.; Shimada, T.; Shibasaki, A.; Takemura, Y. Development of Pear Pollination System Using Autonomous Drones. Agriengineering 2025, 7, 68. [Google Scholar] [CrossRef]

- Gunatilleke, M. Flower Visiting Fauna of Sri Lanka: An Inventory of Pollinators. 2020. Available online: http://envmin.nsf.gov.lk/bitstream/handle/1/555/ENV_0097.pdf?sequence=2&isAllowed=y (accessed on 21 May 2025).

| System | Environment | Mechanism | Novelty |

|---|---|---|---|

| This work (Proposed Rover) | Raised beds (open-field) | Brush + Vibration | Affordable; Modular sensor fusion; Optimized for raised beds; Event-driven; |

| BrambleBee | Greenhouse rows (bramble/raspberry/blackberry) | Soft brush robotic arm | Greenhouse-focused; high-cost; The proposed system is low-cost for open-field raised beds |

| HarvestX | Strawberry greenhouses | Robotic arms/tools | Commercial greenhouse only; The proposed system suits small/medium farms |

| Drone-based systems | Orchards/large fields | Downdraft airflow/ pollen dispersion | Effective for orchards; The proposed system is ground level precision for raised beds |

| Arugga ‘Polly’ | Tomato greenhouses | Air pulses (non-contact) | Airflow only; The proposed system uses direct pollen transfer with brush |

| Ultrasonic/vibratory devices | Indoor farms/vertical systems | Ultrasonic pollen release | Limited robustness; The proposed system ensures direct pollen transfer in open field |

| Color | Average Value |

|---|---|

| Light Blue | 93.1 |

| Gray | 77.3 |

| Black | 58.4 |

| Brown | 70.1 |

| Dark Green | 93.2 |

| Light Green | 94.0 |

| Blue | 52.5 |

| Strawberry Leaf | 117.6 |

| Strawberry Flower | 261.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karunarathna, R.T.; Wickramarathne, C.; Mohamed Alavi, M.A.; Wickrama Arachchi, C.S.; Dissanayaka, K.; Silva, B.N.; Wijesinghe, R.E. Towards Autonomous Raised Bed Flower Pollination with IoT and Robotics. Eng. Proc. 2025, 118, 55. https://doi.org/10.3390/ECSA-12-26572

Karunarathna RT, Wickramarathne C, Mohamed Alavi MA, Wickrama Arachchi CS, Dissanayaka K, Silva BN, Wijesinghe RE. Towards Autonomous Raised Bed Flower Pollination with IoT and Robotics. Engineering Proceedings. 2025; 118(1):55. https://doi.org/10.3390/ECSA-12-26572

Chicago/Turabian StyleKarunarathna, Rusira Thamuditha, Chathupa Wickramarathne, Mohamed Akmal Mohamed Alavi, Chamath Shanaka Wickrama Arachchi, Kapila Dissanayaka, Bhagya Nathali Silva, and Ruchire Eranga Wijesinghe. 2025. "Towards Autonomous Raised Bed Flower Pollination with IoT and Robotics" Engineering Proceedings 118, no. 1: 55. https://doi.org/10.3390/ECSA-12-26572

APA StyleKarunarathna, R. T., Wickramarathne, C., Mohamed Alavi, M. A., Wickrama Arachchi, C. S., Dissanayaka, K., Silva, B. N., & Wijesinghe, R. E. (2025). Towards Autonomous Raised Bed Flower Pollination with IoT and Robotics. Engineering Proceedings, 118(1), 55. https://doi.org/10.3390/ECSA-12-26572