Experimental Investigations on Wire-Arc Additive Manufacturing of Metal-Cored Wires †

Abstract

1. Introduction

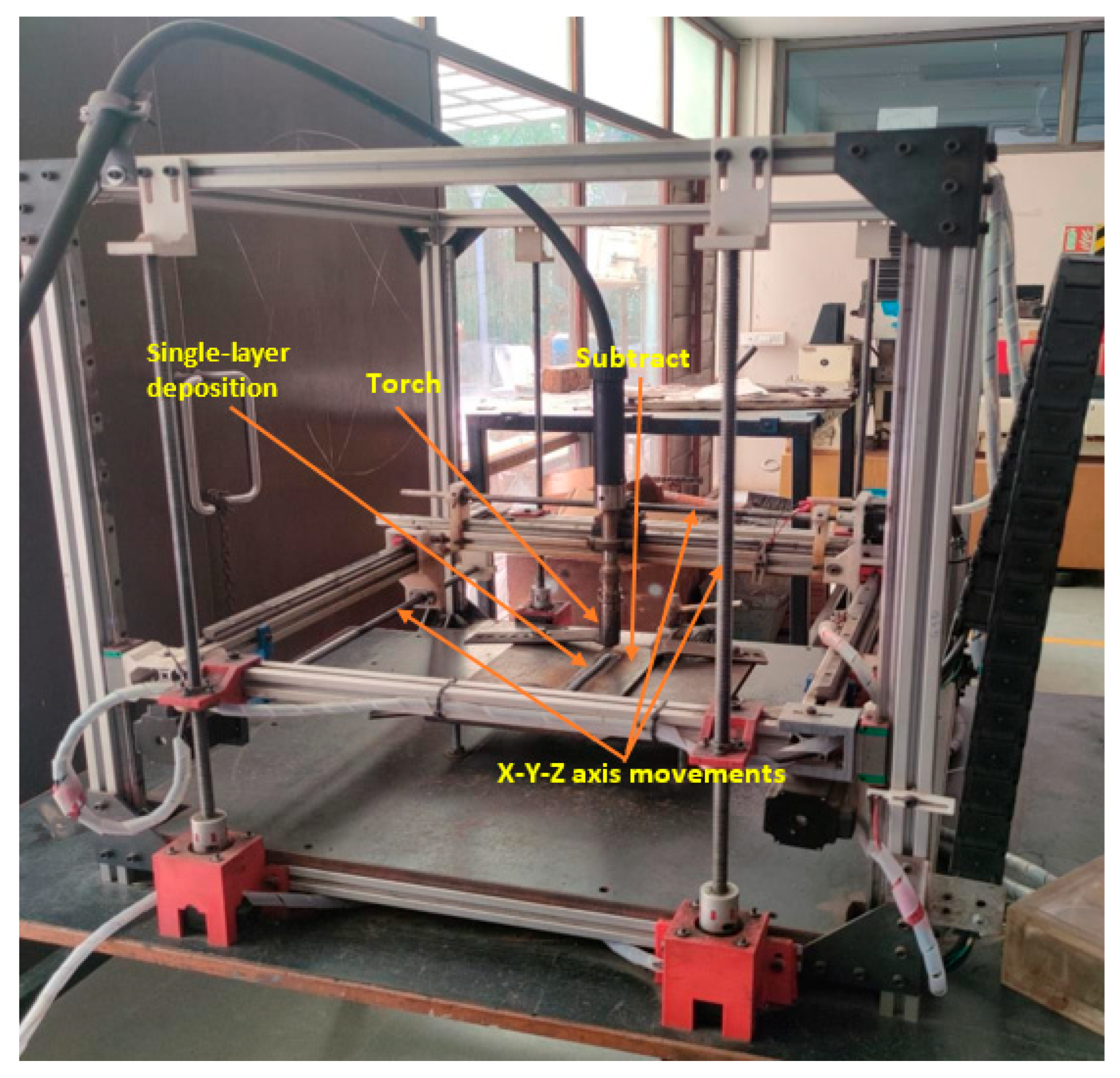

2. Materials and Methods

Optimization Using PVS Algorithm

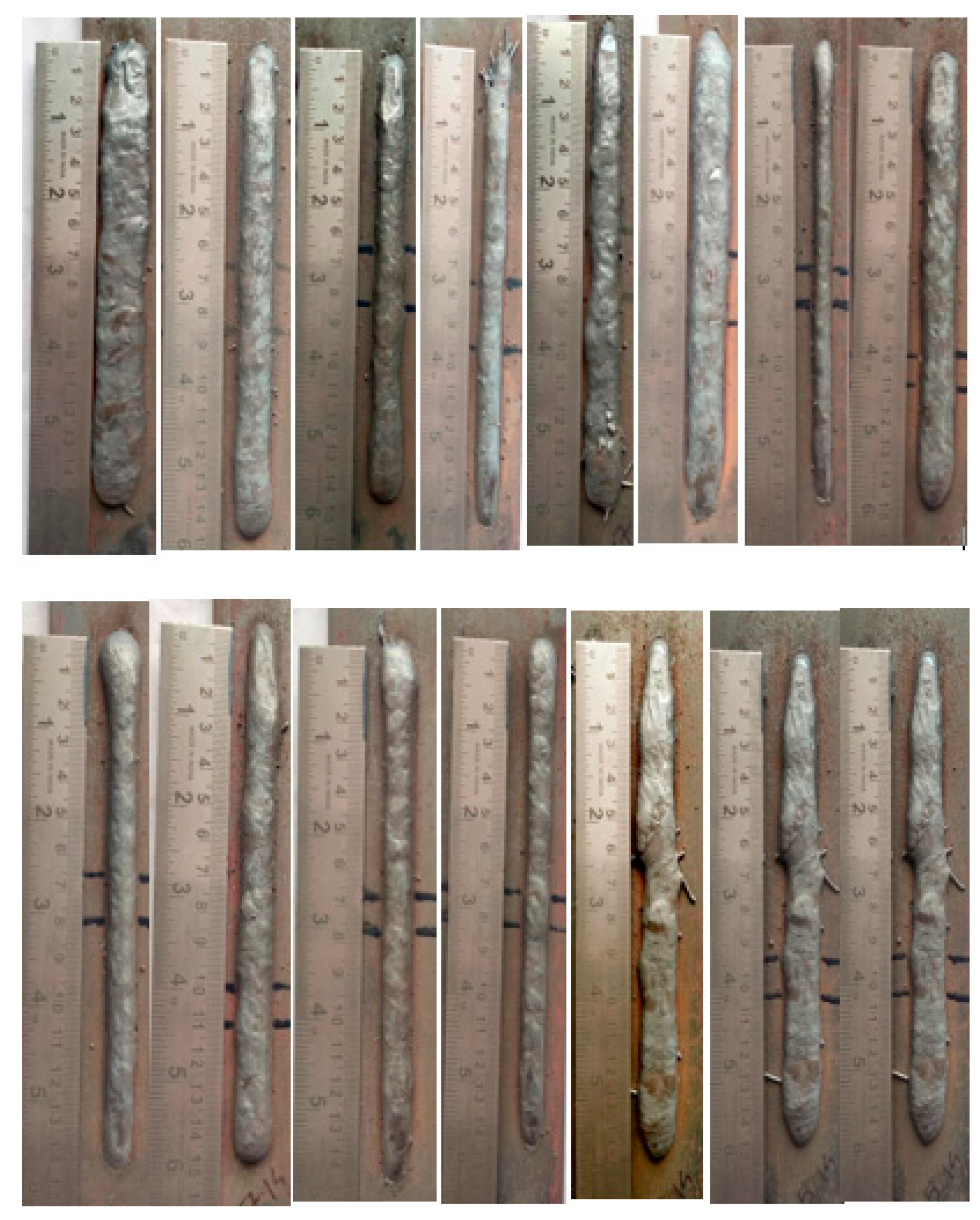

3. Results and Discussion

3.1. Regression Equations for BW and BH

+ (0.1825 × TS × V)

3.2. ANOVA Analysis for BW and BH

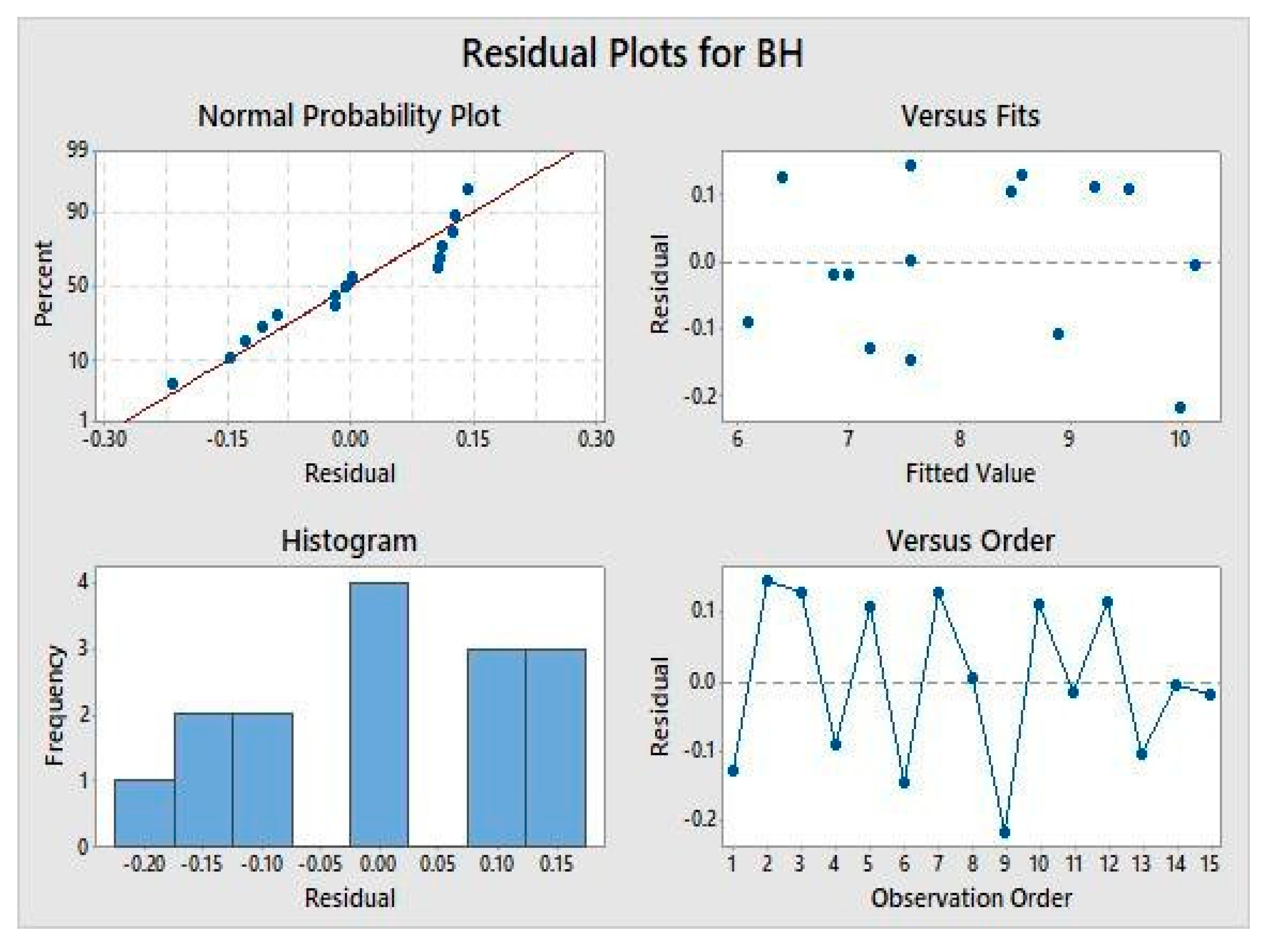

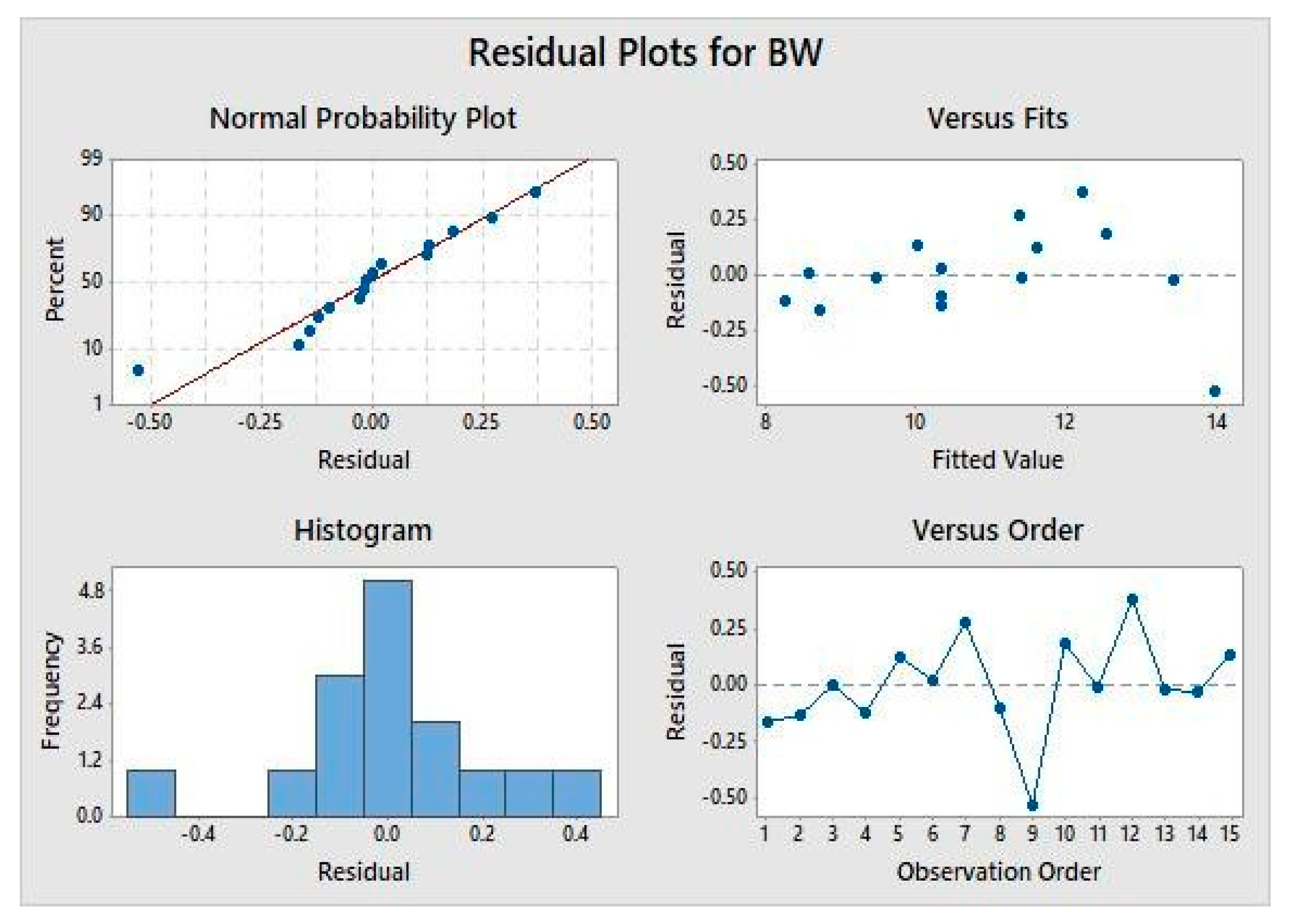

3.3. Residual Plots

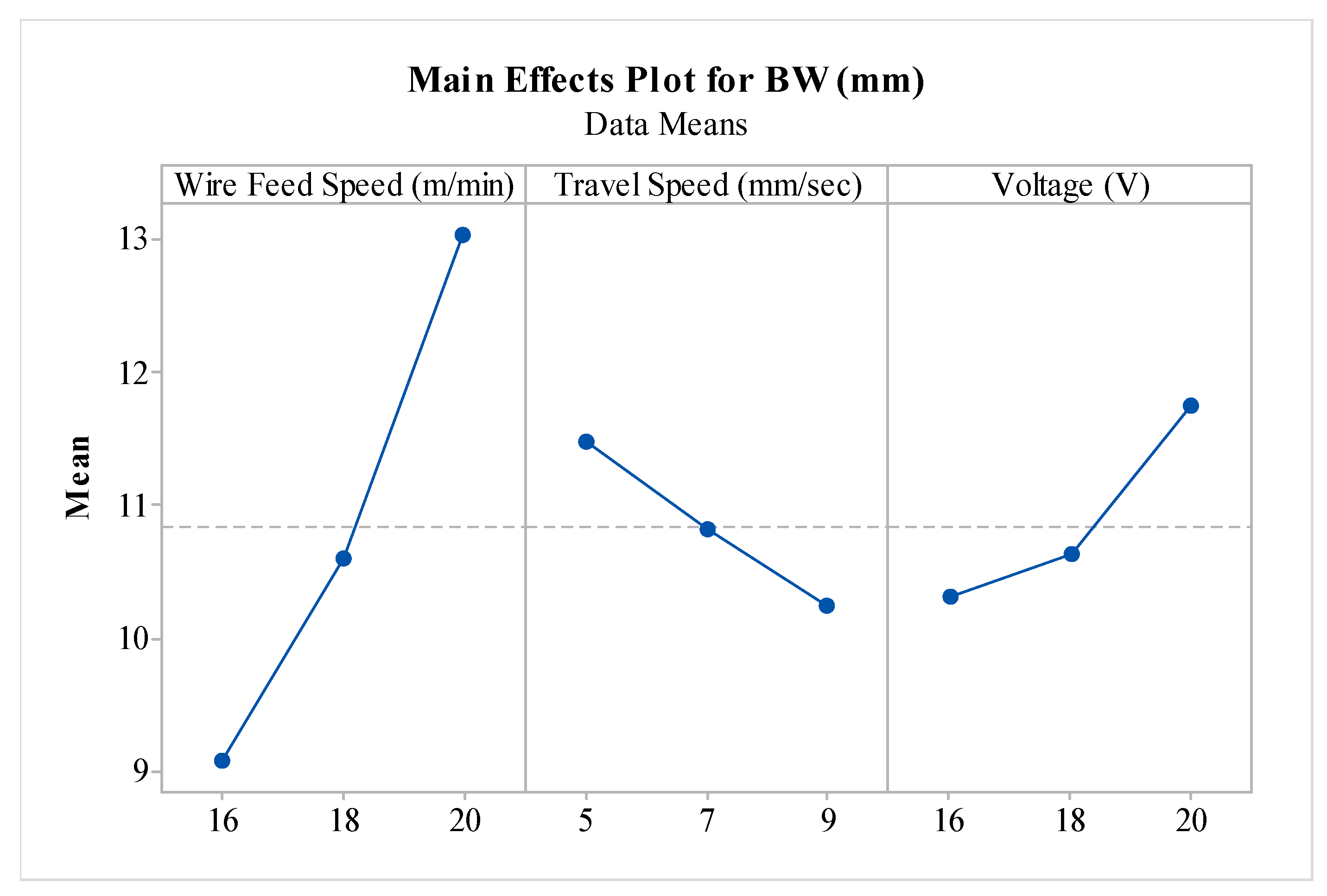

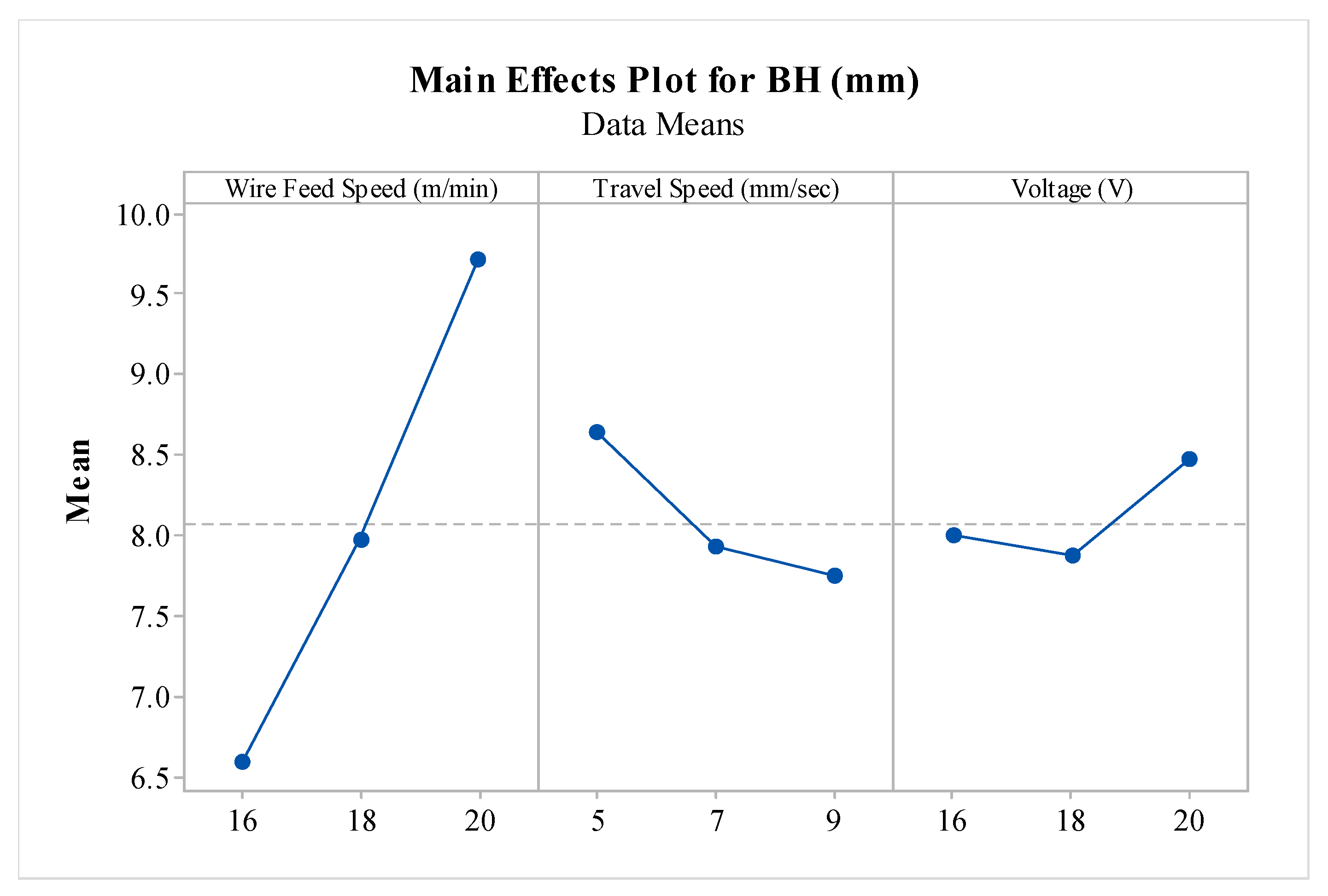

3.4. Impact of GMAW Process Parameters on Bead Morphologies of BW and BH

3.5. Optimization by PVS Algorithm

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tkachev, E.; Borisov, S.; Borisova, Y.; Kniaziuk, T.; Belyakov, A.; Kaibyshev, R. Austenite stabilization and precipitation of carbides during quenching and partitioning (Q&P) of low-alloyed Si–Mn steels with different carbon content. Mater. Sci. Eng. A 2024, 895, 146212. [Google Scholar]

- Liu, W.; Zhao, H.-L.; Wang, B.-X.; Tian, Y. Impact of Mo/Ni alloying on microstructural modulation and low-temperature toughness of high-strength low-alloy steel. J. Iron Steel Res. Int. 2023, 31, 1746–1762. [Google Scholar] [CrossRef]

- Che, Z.; Peng, C. Improving Support Vector Regression for Predicting Mechanical Properties in Low-Alloy Steel and Comparative Analysis. Mathematics 2024, 12, 1153. [Google Scholar] [CrossRef]

- Wang, C.; Chen, R.; Wang, C.; Zhang, Y.; Wang, X.; Chen, M. Strong and ductile low carbon low alloy steels with multiphase bimodal microstructure. Int. J. Plast. 2024, 181, 104097. [Google Scholar] [CrossRef]

- Treutler, K.; Gehling, T.; Scheck, M.; Richter, A.; Bohn, C.; Ehlers, R.; Rembe, C.; Wesling, V. Properties oriented WAAM—Microstructural and geometrical control in WAAM of low-alloy steel. Weld. World 2023, 68, 247–257. [Google Scholar] [CrossRef]

- Chen, J.; Shi, Z.; Luo, X.; Chai, F.; Pan, T.; Feng, G.; Yang, C. Micro-Alloying Effects on Microstructure and Weldability of High-Strength Low-Alloy Steel: A Review. Materials 2025, 18, 1036. [Google Scholar] [CrossRef]

- Vora, J.; Parikh, N.; Chaudhari, R.; Patel, V.K.; Paramar, H.; Pimenov, D.Y.; Giasin, K. Optimization of bead morphology for GMAW-based wire-arc additive manufacturing of 2.25 Cr-1.0 Mo steel using metal-cored wires. Appl. Sci. 2022, 12, 5060. [Google Scholar] [CrossRef]

- Kokare, S.; Shen, J.; Fonseca, P.P.; Lopes, J.G.; Machado, C.M.; Santos, T.G.; Oliveira, J.P.; Godina, R. Wire arc additive manufacturing of a high-strength low-alloy steel part: Environmental impacts, costs, and mechanical properties. Int. J. Adv. Manuf. Technol. 2024, 134, 453–475. [Google Scholar] [CrossRef]

- Chaudhari, R.; Parikh, N.; Khanna, S.; Vora, J.; Patel, V. Effect of multi-walled structure on microstructure and mechanical properties of 1.25 Cr-1.0 Mo steel fabricated by GMAW-based WAAM using metal-cored wire. J. Mater. Res. Technol. 2022, 21, 3386–3396. [Google Scholar] [CrossRef]

- Singh, A.; Khajuria, A.; Bedi, R.; Dommeti, S.G.; Shiva, S. Microstructural and Mechanical Property Analysis of High-Strength Low-Alloy Steel Tubes Fabricated Using Wire Arc-Directed Energy Deposition Technique. Met. Mater. Int. 2024, 31, 1815–1835. [Google Scholar] [CrossRef]

- Koh, S.; Lee, J.M.; Yang, B.Y.; Kim, K.Y. Effect of molybdenum and chromium addition on the susceptibility to sulfide stress cracking of high-strength, low-alloy steels. Corrosion 2007, 63, 220–230. [Google Scholar] [CrossRef]

- Gaikwad, M.U.; Gaikwad, P.U.; Ambhore, N.; Sharma, A.; Bhosale, S.S. Powder Bed Additive Manufacturing Using Machine Learning Algorithms for Multidisciplinary Applications: A Review and Outlook. Recent Pat. Mech. Eng. 2025, 18, 12–25. [Google Scholar] [CrossRef]

- Abdulhameed, O.; Al-Ahmari, A.; Ameen, W.; Mian, S.H. Additive Manufacturing: Challenges, Trends, and Applications. Adv. Mech. Eng. 2019, 11, 1687814018822880. [Google Scholar] [CrossRef]

- Nagalingam, A.P.; Shamir, M.; Tureyen, E.B.; Sharman, A.R.C.; Poyraz, O.; Yasa, E.; Hughes, J. Recent progress in wire-arc and wire-laser directed energy deposition (DED) of titanium and aluminium alloys. Int. J. Adv. Manuf. Technol. 2025, 136, 2035–2073. [Google Scholar] [CrossRef]

- Svetlizky, D.; Das, M.; Zheng, B.; Vyatskikh, A.L.; Bose, S.; Bandyopadhyay, A.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. Directed energy deposition (DED) additive manufacturing: Physical characteristics, defects, challenges and applications. Mater. Today 2021, 49, 271–295. [Google Scholar] [CrossRef]

- Sarıkaya, M.; Önler, D.B.; Dağlı, S.; Hartomacıoğlu, S.; Günay, M.; Królczyk, G.M. A review on aluminum alloys produced by wire arc additive manufacturing (WAAM): Applications, benefits, challenges and future trends. J. Mater. Res. Technol. 2024, 33, 5643–5670. [Google Scholar] [CrossRef]

- Meena, R.P.; Yuvaraj, N.; Vipin. A review on wire arc additive manufacturing based on cold metal transfer. Mater. Manuf. Process. 2024, 39, 1315–1341. [Google Scholar] [CrossRef]

- Athaib, N.H.; Haleem, A.H.; Al-Zubaidy, B. A review of wire arc additive manufacturing (WAAM) of aluminium composite, process, classification, advantages, challenges, and application. J. Phys. Conf. Ser. 2021, 1973, 12083. [Google Scholar] [CrossRef]

- Raspall, F.; Araya, S.; Pazols, M.; Valenzuela, E.; Castillo, M.; Benavides, P. Wire Arc Additive Manufacturing for Widespread Architectural Application: A Review Informed by Large-Scale Prototypes. Buildings 2025, 15, 906. [Google Scholar] [CrossRef]

- Meng, X.; Gardner, L. Hybrid construction featuring wire arc additive manufacturing: Review, concepts, challenges and opportunities. Eng. Struct. 2024, 326, 119337. [Google Scholar] [CrossRef]

- Lambiase, F.; Yanala, P.B.; Pace, F.; Andreucci, E.; Paoletti, A. A state of the art review of wire arc additive manufacturing (WAAM)–part 1: Process fundamentals, parameters and materials. Int. J. Adv. Manuf. Technol. 2025, 138, 4965–4993. [Google Scholar] [CrossRef]

- Pattanayak, S.; Sahoo, S.K. Gas metal arc welding based additive manufacturing—A review. CIRP J. Manuf. Sci. Technol. 2021, 33, 398–442. [Google Scholar] [CrossRef]

- Wang, C.; Wang, J.; Bento, J.; Ding, J.; Pardal, G.; Chen, G.; Qin, J.; Suder, W.; Williams, S. A novel cold wire gas metal arc (CW-GMA) process for high productivity additive manufacturing. Addit. Manuf. 2023, 73, 103681. [Google Scholar] [CrossRef]

- Sinha, A.K.; Pramanik, S.; Yagati, K.P. Research progress in arc based additive manufacturing of aluminium alloys–A review. Measurement 2022, 200, 111672. [Google Scholar] [CrossRef]

- Shah, A.; Aliyev, R.; Zeidler, H.; Krinke, S. A review of the recent developments and challenges in wire arc additive manufacturing (WAAM) process. J. Manuf. Mater. Process. 2023, 7, 97. [Google Scholar] [CrossRef]

- Foorginejad, A.; Khatibi, S.; Torshizi, H.; Emam, S.M.; Afshari, H. Enhancement of Additive Manufacturing Processes for Thin-Walled Part Production Using Gas Metal Arc Welding (GMAW) with Wavelet Transform. Appl. Sci. 2024, 14, 9909. [Google Scholar] [CrossRef]

- Singh, G.; Dewangan, A.K.; Khan, M.F.; Moinuddin, S.Q. Fundamental review on gas tungsten arc welding of magnesium alloys: Challenges, innovations, and future perspectives. Weld. World 2025, 69, 2767–2787. [Google Scholar] [CrossRef]

- Kazmi, K.H.; Bara, A.K.; Sharma, S.K. Multi-objective optimisation of wire arc additive manufacturing deposition using genetic algorithm. In Thermal Claddings for Engineering Applications; CRC Press: Boca Raton, FL, USA, 2024; pp. 77–91. [Google Scholar]

- Vora, J.; Parmar, H.; Chaudhari, R.; Khanna, S.; Doshi, M.; Patel, V. Experimental investigations on mechanical properties of multi-layered structure fabricated by GMAW-based WAAM of SS316L. J. Mater. Res. Technol. 2022, 20, 2748–2757. [Google Scholar] [CrossRef]

- Arulmurugan, B.; Arunkumar, P.; Dharanikumar, S. Advances in gas tungsten and Gas metal Arc welding–A concise review. In Advanced Joining Technologies; CRC Press: Boca Raton, FL, USA, 2024; pp. 18–36. [Google Scholar]

- Treutler, K.; Wesling, V. The current state of research of wire arc additive manufacturing (WAAM): A review. Appl. Sci. 2021, 11, 8619. [Google Scholar] [CrossRef]

- Kumar, S.; Tejani, G.G.; Pholdee, N.; Bureerat, S. Multi-objective passing vehicle search algorithm for structure optimization. Expert Syst. Appl. 2021, 169, 114511. [Google Scholar] [CrossRef]

- Chentoufi, M.A.; Ellaia, R. A novel multiobjective passing vehicle search algorithm for signal timing optimization. Comput. Sci. 2021, 16, 775–792. [Google Scholar]

- Parsana, S.; Radadia, N.; Sheth, M.; Sheth, N.; Savsani, V.; Prasad, N.E.; Ramprabhu, T. Machining parameter optimization for EDM machining of Mg-RE-Zn-Zr alloy using multi-objective passing vehicle search algorithm. Arch. Civ. Mech. Eng. 2018, 18, 799–817. [Google Scholar] [CrossRef]

- Ladumor, D.P.; Trivedi, I.N.; Bhesdadiya, R.; Jangir, P. A passing vehicle search algorithm for solution of optimal power flow problems. In Proceedings of the 2017 Third International Conference on Advances in Electrical, Electronics, Information, Communication and Bio-Informatics (AEEICB), Chennai, India, 27–28 February 2017; IEEE: Piscateway, NJ, USA, 2017. [Google Scholar]

- Chaudhari, R.; Parmar, H.; Vora, J.; Patel, V.K. Parametric study and investigations of bead geometries of GMAW-based wire–arc additive manufacturing of 316L stainless steels. Metals 2022, 12, 1232. [Google Scholar] [CrossRef]

- Tukaram Sargar, N.K.G.; Jadhav, A.; Gaikwad, M.U. A Comparative Investigation of Kerf Width during CO2 and Fiber Laser Machining of SS 316L Material. Recent Pat. Mech. Eng. 2025, 18, 628–640. [Google Scholar] [CrossRef]

- Ferreira, S.C.; Bruns, R.E.; Ferreira, H.S.; Matos, G.D.; David, J.M.; Brandão, G.C.; da Silva, E.G.P.; Portugal, L.A.; dos Reis, P.S.; Souza, A.S.; et al. Box-Behnken design: An alternative for the optimization of analytical methods. Anal. Chim. Acta 2007, 597, 179–186. [Google Scholar] [CrossRef]

- Savsani, P.; Savsani, V. Passing vehicle search (PVS): A novel metaheuristic algorithm. Appl. Math. Model. 2016, 40, 3951–3978. [Google Scholar] [CrossRef]

- Al-Amin, M.; Abdul-Rani, A.M.; Ahmed, R.; Shahid, M.U.; Zohura, F.T.; Rani, M.D.B.A. Multi-objective optimization of process variables for MWCNT-added electro-discharge machining of 316L steel. Int. J. Adv. Manuf. Technol. 2021, 115, 179–198. [Google Scholar] [CrossRef]

- Gaikwad, M.U.; Krishnamoorthy, A.; Jatti, V.S. Investigation on effect of process parameter on surface integrity during electrical discharge machining of NiTi 60. Multidiscip. Model. Mater. Struct. 2020, 16, 1385–1394. [Google Scholar] [CrossRef]

- Abuabiah, M.; Weidemann, T.C.; Elahi, M.A.; Shaqour, B.; Day, R.; Plapper, P.; Bergs, T. Investigating the Impact of Process Parameters on Bead Geometry in Laser Wire-Feed Metal Additive Manufacturing. J. Manuf. Mater. Process. 2024, 8, 204. [Google Scholar] [CrossRef]

- Chaudhari, R.; Vora, J.J.; Prabu, S.S.M.; Palani, I.A.; Patel, V.K.; Parikh, D.M. Pareto optimization of WEDM process parameters for machining a NiTi shape memory alloy using a combined approach of RSM and heat transfer search algorithm. Adv. Manuf. 2019, 9, 64–80. [Google Scholar] [CrossRef]

- Ambhore, N.; Gaikwad, M.; Patil, A.; Sharma, Y.; Manikjade, A. Predictive modeling and optimization of dry turning of hardened steel. Int. J. Interact. Des. Manuf. (IJIDeM) 2024, 18, 6281–6287. [Google Scholar] [CrossRef]

- Bansal, S.; Singh, G. Multiple linear regression based analysis of weather data: Assumptions and limitations. In Proceedings of the International Conference on Advanced Communication and Intelligent Systems, Warsaw, Poland, 16–17 June 2023; Springer: Berlin/Heidelberg, Germany, 2023. [Google Scholar]

- Chaudhari, R.; Bhatt, R.; Vaghasia, V.; Raja, B.D.; Patel, V.K.; Khanna, S.; Vora, J.; Patel, V.V. A parametric study and experimental investigations of microstructure and mechanical properties of multi-layered structure of metal core wire using wire arc additive manufacturing. J. Adv. Join. Process. 2023, 8, 100160. [Google Scholar] [CrossRef]

- Chantarangsi, W.; Liu, W.; Bretz, F.; Kiatsupaibul, S.; Hayter, A.J. Normal probability plots with confidence for the residuals in linear regression. Commun. Stat.-Simul. Comput. 2018, 47, 367–379. [Google Scholar] [CrossRef]

- Moradi, M.; Beiranvand, Z.M.; Salimi, N.; Meiabadi, S.; Lawrence, J. Experimental investigation on the 3D printing of nylon reinforced by carbon fiber through fused filament fabrication process, effects of extruder temperature, and printing speed. Int. J. Polym. Sci. 2024, 2024, 1234797. [Google Scholar] [CrossRef]

- Magabe, R.; Sharma, N.; Gupta, K.; Davim, J.P. Modeling and optimization of Wire-EDM parameters for machining of Ni 55.8 Ti shape memory alloy using hybrid approach of Taguchi and NSGA-II. Int. J. Adv. Manuf. Technol. 2019, 102, 1703–1717. [Google Scholar] [CrossRef]

- Wu, B.; Pan, Z.; Ding, D.; Cuiuri, D.; Li, H.; Xu, J.; Norrish, J. A review of the wire arc additive manufacturing of metals: Properties, defects and quality improvement. J. Manuf. Process. 2018, 35, 127–139. [Google Scholar] [CrossRef]

- Paskual, A.; Álvarez, P.; Suárez, A. Study on arc welding processes for high deposition rate additive manufacturing. Procedia Cirp 2018, 68, 358–362. [Google Scholar]

- Rauch, M.; Nwankpa, U.V.; Hascoet, J.-Y. Investigation of deposition strategy on wire and arc additive manufacturing of aluminium components. J. Adv. Join. Process. 2021, 4, 100074. [Google Scholar] [CrossRef]

- Lee, S.H. Optimization of cold metal transfer-based wire arc additive manufacturing processes using gaussian process regression. Metals 2020, 10, 461. [Google Scholar] [CrossRef]

- Vaghasia, V.; Chaudhari, R.; Patel, V.K.; Vora, J. Parametric Study on Investigations of GMAW-Based WAAM Process Parameters and Effect on Microstructure and Mechanical Properties of NiTi SMA. J. Manuf. Mater. Process. 2025, 9, 58. [Google Scholar] [CrossRef]

- Vora, J.; Pandey, R.; Dodiya, P.; Patel, V.; Khanna, S.; Vaghasia, V.; Chaudhari, R. Fabrication of Multi-Walled Structure through Parametric Study of Bead Geometries of GMAW-Based WAAM Process of SS309L. Materials 2023, 16, 5147. [Google Scholar] [CrossRef]

- Kumar, V.; Mandal, A.; Das, A.K.; Kumar, S. Parametric study and characterization of wire arc additive manufactured steel structures. Int. J. Adv. Manuf. Technol. 2021, 115, 1723–1733. [Google Scholar] [CrossRef]

- Xu, W.; Lin, S.B.; Fan, C.L.; Yang, C.L. Prediction and optimization of weld bead geometry in oscillating arc narrow gap all-position GMA welding. Int. J. Adv. Manuf. Technol. 2015, 79, 183–196. [Google Scholar] [CrossRef]

- Pan, Z.; Ding, D.; Wu, B.; Cuiuri, D.; Li, H.; Norrish, J. Arc welding processes for additive manufacturing: A review. In Transactions on Intelligent Welding Manufacturing; Springer: Berlin/Heidelberg, Germany, 2018; pp. 3–24. [Google Scholar]

- Chaturvedi, M.; Scutelnicu, E.; Rusu, C.C.; Mistodie, L.R.; Mihailescu, D.; Subbiah, A.V. Wire arc additive manufacturing: Review on recent findings and challenges in industrial applications and materials characterization. Metals 2021, 11, 939. [Google Scholar] [CrossRef]

- Thakur, P.; Chapgaon, A. A review on effects of GTAW process parameters on weld. IJRASET 2016, 4, 136–140. [Google Scholar]

- Giarollo, D.F.; Mazzaferro, C.C.P.; Mazzaferro, J.A.E. Comparison between two heat source models for wire-arc additive manufacturing using GMAW process. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 7. [Google Scholar] [CrossRef]

- Mai, D.S.; Doan, T.K.; Paris, H. Wire and arc additive manufacturing of 308L stainless steel components: Optimization of processing parameters and material properties. Eng. Sci. Technol. Int. J. 2021, 24, 1015–1026. [Google Scholar] [CrossRef]

- Dinovitzer, M.; Chen, X.; Laliberte, J.; Huang, X.; Frei, H. Effect of wire and arc additive manufacturing (WAAM) process parameters on bead geometry and microstructure. Addit. Manuf. 2019, 26, 138–146. [Google Scholar] [CrossRef]

| Element | C | Mn | Si | Cr | Mo | P | S |

|---|---|---|---|---|---|---|---|

| Wt. % | 0.06–0.08 | 0.75–1.0 | 0.2–0.5 | 1.0–1.4 | 0.4–0.6 | ≤0.015 (max) | ≤0.015 (max) |

| Parameter | Unit | Values |

|---|---|---|

| WFS | m/min | 16, 18, 20 |

| TS | mm/s | 5, 7, 9 |

| V | V | 16, 18, 20 |

| Std. Order | Run Order | Voltage | TS | WFS | BH | BW |

|---|---|---|---|---|---|---|

| 10 | 1 | 16 | 9 | 18 | 7.07 | 8.55 |

| 13 | 2 | 18 | 7 | 18 | 7.71 | 10.21 |

| 5 | 3 | 16 | 7 | 16 | 6.53 | 8.58 |

| 3 | 4 | 18 | 9 | 16 | 6.02 | 8.13 |

| 12 | 5 | 20 | 9 | 18 | 8.58 | 11.74 |

| 14 | 6 | 18 | 7 | 18 | 7.42 | 10.37 |

| 11 | 7 | 20 | 5 | 18 | 8.69 | 11.66 |

| 15 | 8 | 18 | 7 | 18 | 7.57 | 10.25 |

| 8 | 9 | 20 | 7 | 20 | 9.78 | 13.45 |

| 6 | 10 | 16 | 7 | 20 | 9.63 | 12.72 |

| 1 | 11 | 18 | 5 | 16 | 6.98 | 9.47 |

| 4 | 12 | 18 | 9 | 20 | 9.34 | 12.58 |

| 9 | 13 | 16 | 5 | 18 | 8.78 | 11.39 |

| 2 | 14 | 18 | 5 | 20 | 10.11 | 13.41 |

| 7 | 15 | 20 | 7 | 16 | 6.86 | 10.11 |

| Source | DF | F-Value | p-Value | Significance |

|---|---|---|---|---|

| Model | 6 | 89.35 | 0.000 | * |

| Linear | 3 | 163.26 | 0.000 | * |

| WFS | 1 | 398.39 | 0.000 | * |

| TS | 1 | 38.64 | 0.000 | * |

| Voltage | 1 | 52.75 | 0.000 | * |

| Square | 2 | 9.60 | 0.007 | * |

| WFS × WFS | 1 | 11.65 | 0.009 | * |

| Voltage × Voltage | 1 | 8.90 | 0.018 | * |

| 2-Way Interaction | 1 | 27.11 | 0.001 | * |

| TS × V | 1 | 27.11 | 0.001 | * |

| Error | 8 | - | - | |

| Lack-of-Fit | 6 | 14.79 | 0.065 | # |

| Pure Error | 2 | - | - | |

| Total | 14 | 42.7784 |

| Source | DF | F-Value | p-Value | Significance |

|---|---|---|---|---|

| Model | 7 | 119.30 | 0.000 | * |

| Linear | 3 | 258.47 | 0.000 | * |

| WFS | 1 | 702.20 | 0.000 | * |

| TS | 1 | 56.91 | 0.000 | * |

| Voltage | 1 | 16.30 | 0.005 | * |

| Square | 3 | 12.18 | 0.004 | * |

| WFS × WFS | 1 | 7.24 | 0.031 | # |

| TS × TS | 1 | 13.06 | 0.009 | * |

| Voltage × Voltage | 1 | 21.39 | 0.002 | * |

| 2-Way Interaction | 1 | 23.12 | 0.002 | * |

| TS × V | 1 | 23.12 | 0.002 | * |

| Error | 7 | - | - | |

| Lack-of-Fit | 5 | 1.44 | 0.458 | # |

| Pure Error | 2 | - | - | |

| Total | 14 | 23.3092 |

| Type of Optimization | Process Parameters WFS TS V | Responses BW BH | |||

|---|---|---|---|---|---|

| Max. BH | 20 | 9 | 20 | 10.26 | 14.15 |

| Min. BW | 19 | 7 | 18 | 5.87 | 7.28 |

| Sr. No. | V | TS | WFS | BW | BH |

|---|---|---|---|---|---|

| 1 | 16 | 9 | 16 | 7.2886 | 5.874 |

| 2 | 16 | 9 | 17 | 7.6916 | 5.8923 |

| 3 | 16 | 8 | 17 | 8.1821 | 5.9799 |

| 4 | 16 | 8 | 18 | 8.6196 | 6.0984 |

| 5 | 16 | 7 | 17 | 8.6726 | 6.2239 |

| 6 | 16 | 7 | 18 | 8.9276 | 6.2424 |

| 7 | 16 | 8 | 19 | 9.2741 | 6.4171 |

| 8 | 16 | 7 | 19 | 9.3996 | 6.4611 |

| 9 | 16 | 6 | 19 | 9.5251 | 6.6615 |

| 10 | 17 | 7 | 18 | 9.5429 | 6.846 |

| 11 | 16 | 7 | 20 | 10.0886 | 6.88 |

| 12 | 16 | 8 | 20 | 10.1456 | 6.936 |

| 13 | 16 | 9 | 20 | 10.2026 | 7.1484 |

| 14 | 17 | 7 | 20 | 10.7039 | 7.4836 |

| 15 | 17 | 8 | 20 | 10.7609 | 7.5396 |

| 16 | 17 | 9 | 20 | 10.8179 | 7.752 |

| 17 | 18 | 7 | 19 | 10.8784 | 7.7847 |

| 18 | 18 | 6 | 19 | 11.0039 | 7.9851 |

| 19 | 18 | 7 | 20 | 11.5674 | 8.2036 |

| 20 | 18 | 7 | 20 | 11.5674 | 8.2036 |

| 21 | 18 | 8 | 20 | 11.6244 | 8.2596 |

| 22 | 18 | 9 | 20 | 11.6814 | 8.472 |

| 23 | 19 | 7 | 19 | 11.9901 | 8.6211 |

| 24 | 19 | 6 | 19 | 12.1156 | 8.8215 |

| 25 | 19 | 6 | 19 | 12.1156 | 8.8215 |

| 26 | 19 | 7 | 20 | 12.6791 | 9.04 |

| 27 | 19 | 8 | 20 | 12.7361 | 9.096 |

| 28 | 19 | 9 | 20 | 12.7931 | 9.3084 |

| 29 | 20 | 7 | 18 | 12.878 | 9.3552 |

| 30 | 20 | 8 | 19 | 13.2245 | 9.5299 |

| 31 | 20 | 7 | 19 | 13.35 | 9.5739 |

| 32 | 20 | 6 | 19 | 13.4755 | 9.7743 |

| 33 | 20 | 7 | 20 | 14.039 | 9.9928 |

| 34 | 20 | 8 | 20 | 14.096 | 10.0488 |

| 35 | 20 | 9 | 20 | 14.153 | 10.2612 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Patel, Y.; Shah, A.; Chaudhari, R.; Vaghasia, V.; Patel, V.; Vora, J. Experimental Investigations on Wire-Arc Additive Manufacturing of Metal-Cored Wires. Eng. Proc. 2025, 114, 14. https://doi.org/10.3390/engproc2025114014

Patel Y, Shah A, Chaudhari R, Vaghasia V, Patel V, Vora J. Experimental Investigations on Wire-Arc Additive Manufacturing of Metal-Cored Wires. Engineering Proceedings. 2025; 114(1):14. https://doi.org/10.3390/engproc2025114014

Chicago/Turabian StylePatel, Yagna, Aagam Shah, Rakesh Chaudhari, Vatsal Vaghasia, Vivek Patel, and Jay Vora. 2025. "Experimental Investigations on Wire-Arc Additive Manufacturing of Metal-Cored Wires" Engineering Proceedings 114, no. 1: 14. https://doi.org/10.3390/engproc2025114014

APA StylePatel, Y., Shah, A., Chaudhari, R., Vaghasia, V., Patel, V., & Vora, J. (2025). Experimental Investigations on Wire-Arc Additive Manufacturing of Metal-Cored Wires. Engineering Proceedings, 114(1), 14. https://doi.org/10.3390/engproc2025114014