Abstract

The aim of the current study is to optimize the bead geometries of 80B2, namely, the bead height (BH) and bead width (BW), utilizing a mild steel substrate and a wire-arc additive manufacturing (WAAM) technique based on gas metal arc welding (GMAW). Single-layer depositions with different wire feed speed (WFS), voltage (V), and travel speed (TS) were accomplished by applying the Box–Behnken design methodology. Multivariable nonlinear regression models were developed and validated through ANOVA, revealing WFS as the most significant parameter influencing both BW and BH. The minimal influence of the error factor on each response proved the accuracy of the ANOVA findings. The favorable assessment of residual plots confirmed the appropriateness and reliability of the developed regression equations and ANOVA results. A metaheuristic Passing Vehicle Search (PVS) algorithm was applied for single-objective and multi-objective optimization, yielding a minimum BW of 5.874 mm and a maximum BH of 14.153 mm. Main effect and residual plots confirmed the accuracy and reliability of the predictive models. The parametric settings of WFS: 18 mm/min, TS: 7 mm/s, V: 19 V were obtained for simultaneous optimization of BW with 7.78 mm and BH with 10.87 mm. Pareto points were also generated, which provide non-dominated unique solutions. The study emphasizes the critical role of precise process parameter control in improving WAAM build quality and offers a robust framework for optimizing bead morphology, ultimately enhancing the efficiency and applicability of WAAM for structural component fabrication. These optimized parameters will be used in the future to manufacture a thin-walled, multi-layered structure.

1. Introduction

Compared to other alloy steels, low-alloy steels are distinguished by the inclusion of a limited amount of alloying elements [1]. With the addition of these elements, specific properties such as toughness, strength, and corrosion resistance are enhanced [2]. Due to their excellent mechanical properties, low-alloy steels are used in a variety of industries [3,4]. Furthermore, owing to their exceptional strength-to-weight ratio and wear resistance, low-alloy steels are often employed in the automotive sector to manufacture components such as engine blocks, gearbox gears, and suspension parts [5,6]. The 80B2 low-alloy steel offers a balanced composition of carbon, chromium, and molybdenum. Its favorable properties—such as excellent strength, toughness, and wear resistance—make it suitable for applications that demand high mechanical performance under moderate thermal and loading conditions [7,8]. Due to the weldability and hardenability of 80B2 low-alloy steel, it is widely preferred for fabricating various components such as shafts, gears, and high-strength fasteners [9,10]. The presence of chromium and molybdenum enhances corrosion and oxidation resistance, as well as strength and hardening, respectively [11]. Owing to these features, 80B2 is also used in the construction and automotive industries. Its compatibility with arc-based welding and additive manufacturing processes further broadens its applicability in producing complex and durable metal structures. Additive manufacturing (AM) is a suitable technique for fabricating parts for various applications [12,13].

Wire-arc additive manufacturing (WAAM) is a type of directed energy deposition (DED) additive manufacturing process that uses an electric arc to melt metal feedstock wire, which is then deposited layer by layer to build a component [14,15]. Compared to other AM processes, WAAM offers several advantages, including high deposition rates, scalability, cost-effectiveness, and the ability to produce large-scale, precision-tailored metal components [16,17,18]. WAAM is utilized across multiple industries, including the energy, automotive, aerospace, and marine sectors [19,20,21]. Among the various arc and energy sources, the gas metal arc welding (GMAW) process offers a significantly higher deposition rate, typically 2–3 times greater than other processes [22,23,24]. It enables the fabrication of intricate geometries with lower operating costs, reduces equipment expenses, and is well-suited for mass production [25,26,27]. The GMAW-based WAAM process also demonstrates favorable mechanical properties, efficient fabrication of large-scale components, and cost-effective equipment requirements [28,29]. The GMAW process utilizes shielding gas and a continuous wire electrode to form a weld pool between the electrode and the workpiece [30]. GMAW-based wire-arc additive manufacturing (WAAM) produces components layer by layer by integrating additive manufacturing principles with GMAW techniques. Desired deposition characteristics—such as bead shape, deposition rate, and metallurgical properties—can be achieved by optimizing process parameters such as the welding current, travel speed (TS), voltage, wire feed speed (WFS), and shielding gas composition [22]. This process accommodates a wide range of materials, including stainless steels, carbon steels, aluminum alloys, and nickel-based superalloys, making it a versatile production technology for various industrial sectors [31]. The optimal selection of process parameters significantly influences weld bead geometry. Therefore, optimizing the input variables of the WAAM process is essential, as it directly affects the quality and performance of the fabricated parts. The Passing Vehicle Search (PVS) algorithm is a metaheuristic optimization technique known for its simplicity and ease of implementation. It has been successfully applied in previous studies to solve complex engineering problems [32,33,34,35].

Vora et al. [7] investigated the optimization of bead morphology using additive manufacturing techniques, focusing on the additive synthesis of 2.25Cr–1.0Mo steel using metal-cored wires in the GMAW process. One of the key conclusions of the study was that bead morphology could be successfully adjusted in GMAW-based WAAM, particularly for 2.25Cr–1.0Mo steel components. The report offers valuable insights into enhancing the quality and efficiency of additive manufacturing processes. By utilizing metal-cored wires and strategically modifying bead shape, the study advances WAAM technology and emphasizes the importance of achieving high-quality components in the fabrication of 2.25Cr–1.0Mo steel. For algorithm development, process variable levels were set as follows: wire feed speed (WFS) from 4 to 6 mm/min, voltage from 19 to 21 V, and travel speed (TS) from 425 to 485 mm/min. In the case of single-objective optimization, the minimum bead width (BW) achieved was 4.73 mm, while the maximum bead height (BH) was 7.81 mm. Chaudhari et al. [36] focused on optimizing WAAM parameters using GMAW for bead formation on an SS 316L substrate. Their results indicated that WFS, followed by voltage and TS, are the most significant parameters influencing bead width and height. The regression models developed were validated through ANOVA, confirming their accuracy in predicting bead characteristics. Using the Heat Transfer Search (HTS) algorithm, the study identified optimal combinations of process parameters suitable for fabricating multi-layer structures. Their systematic approach to parameter optimization offers valuable insights for improving bead morphology in additive manufacturing. By applying regression analysis and ANOVA, the study enhances the understanding of the relationships between process parameters and deposition characteristics, contributing to the advancement of WAAM in terms of quality and efficiency. Additionally, Chaudhari et al. [9] examined the mechanical properties and microstructure at various locations within the fabricated components. The study highlighted the importance of optimized process parameters in producing high-quality multi-walled structures using GMAW-based WAAM. Overall, the research demonstrated the potential of this technique for producing structurally sound components with desirable microstructural and mechanical properties, supporting its application in various industrial sectors.

The application of 80B2 in additive manufacturing is scarcely explored in the existing literature, which further justifies its selection to contribute new insights into process optimization and bead morphology control in WAAM. Therefore, the aim of the present study was to investigate the optimization of bead geometries in the WAAM of 80B2 metal-cored wire—a topic that has not yet been thoroughly studied. A Box–Behnken design was employed for single-layer depositions using wire feed speed (WFS), voltage (V), and travel speed (TS) as input parameters, with bead width (BW) and bead height (BH) as output responses. To develop and evaluate a multivariable regression model, ANOVA, residual plots, and main effect plots were utilized. Additionally, the metaheuristic Passing Vehicle Search (PVS) algorithm was applied to perform both single- and multi-objective optimization. This study not only established robust regression models with high predictive accuracy but also validated them experimentally. The methodology adopted in this work offers a novel and practical framework for enhancing deposition quality in GMAW-based WAAM of low-alloy steels.

2. Materials and Methods

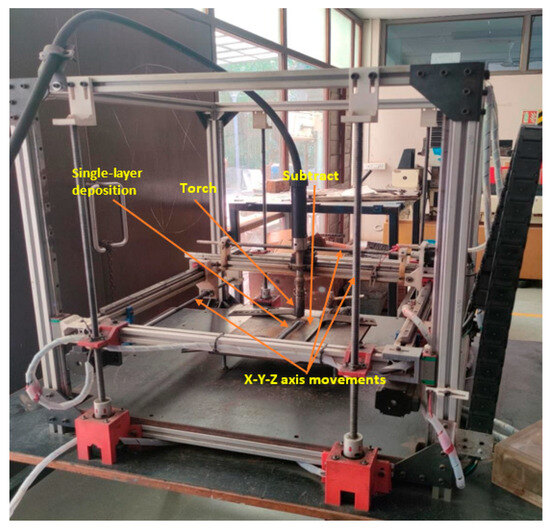

The current study implemented a wire-arc additive manufacturing (WAAM) process based on gas metal arc welding (GMAW) to deposit beads using 0.2 mm diameter metallic wire of 80B2 grade onto mild steel substrate plates. Mild steel was chosen as the substrate material due to its widespread industrial application, affordability, and compatibility with the 80B2 low-alloy steel filler wire. The chemical composition of the filler wire is provided in Table 1. The experimental setup for this study included several key components essential for the WAAM process as shown in Figure 1. These included a GMAW torch, wire feeder, controller, shielding gas system, and a mixing chamber. The machine used in the study had a build capacity of 220 × 220 × 500 mm, providing ample space for fabricating test specimens. The GMAW torch, with its mobility in the X, Y, and Z directions, enabled precise deposition of material onto the substrate. Control over the deposition process was facilitated by a controller capable of receiving input in the form of G-code through a computer interface. The metallic wire feedstock was melted using a Colton iFLEX 350 (Colton Weldtek Private Limited, Bengaluru, India) power sources to initiate the deposition process.

Table 1.

Chemical composition of low-alloy steel 80B2 wire.

Figure 1.

Experimental setup of GMAW process.

A Box–Behnken design (BBD) experimental matrix of Response Surface Methodology (RSM) was employed to systematically investigate the effects of various process parameters on deposition properties. This statistical technique allows the modeling of the relationship between input and response variables to optimize operational performance. As a fractional factorial design, BBD efficiently explores the parameter space with a reduced number of experimental runs, enabling the identification of key factors influencing process or product quality [37,38]. Based on previous studies, machine capabilities, and preliminary experiments, the input factors selected for the trials were travel speed (TS), voltage (V), and wire feed speed (WFS). The specific input factor levels used in the study are presented in Table 2. The input factors and their levels were finalized on the basis of preliminary experimental trials, the past literature, and machine limits. For the single-layer WAAM depositions, the same set of parameters was maintained: a 150 mm weld bead in length, 3 mm arc length, and a 15 L/min gas flow rate.

Table 2.

GMAW-based WAAM process parameters.

A total of fifteen experimental trials were performed, varying the input parameters at three levels in accordance with the BBD matrix, as shown in Figure 2. In each trial, the bead geometries, bead height (BH) and bead width (BW), were carefully measured to assess bead morphology. The resulting deposits were also visually inspected to ensure the absence of common defects such as lack of fusion or porosity. These pilot experiments helped establish a feasible parameter range for the subsequent phases of the study.

Figure 2.

Single-layered deposition using the BBD technique.

Optical microscopy was employed to assess the bead geometries of individual single-layer depositions. To measure the bead geometries at diverse deposition locations, three different cross-sections of the bead depositions were cut for the purpose. The average values of these variables were used in the study to increase accuracy and ensure robust findings. Metallographic samples underwent cross-sectional cutting utilizing wire-cut EDM, followed by grinding with sandpaper and polishing with a metallographic polisher. Subsequently, they underwent etching using 2% Nital reagent.

Optimization Using PVS Algorithm

The Passing Vehicle Search (PVS) algorithm, developed by Savsani and Savsani [39], simulates the dynamics of traffic on a two-lane roadway to identify safe overtaking opportunities. It considers several interrelated factors, including approaching traffic gaps, vehicle speed and acceleration, road conditions, overall traffic density, weather, and driver ability. While the PVS algorithm has shown promising results, further research and refinement are necessary for its application to complex and uncertain real-world traffic scenarios.

When applied to a two-lane road, the method accounts for three vehicles: the overtaking vehicle (BV), the front vehicle (FV), and the oncoming vehicle (OV). The BV can only overtake the FV if it maintains a higher speed. The algorithm evaluates the position, speed, and relative distances and velocities of the OV to determine whether an overtaking maneuver is feasible. The model considers the varying velocities of the BV, FV, and OV—denoted as V1, V2, and V3, respectively—and the associated distances between the vehicles at any given moment. The distance between the BV and FV is represented by “x,” while the distance between the FV and OV is represented by “y.” A key constraint is that overtaking is only possible when the BV’s velocity (V1) is greater than the FV’s (V2). Moreover, for a successful overtaking maneuver, the distance covered by the OV during the same time interval must be greater than the combined distance covered by the BV and FV. The PVS algorithm employs a metaheuristic optimization approach that mimics human overtaking behavior to find optimal or near-optimal solutions for a given objective function. This human-activity-based method enables efficient prediction and control of vehicle passing behavior under dynamic road conditions.

3. Results and Discussion

Table 3 presents the results for bead width (BW) and bead height (BH) obtained using the Box–Behnken design (BBD) matrix within the Response Surface Methodology (RSM) framework. For the fabrication of multi-walled structures, achieving maximum BH and minimum BW is considered ideal. Multivariable nonlinear regression models were developed to describe the relationships between the WAAM process parameters and the resulting bead geometries. These regression models were generated using Minitab v17 software. Equations (1) and (2) represent the regression equations for predicting BH and BW, respectively. They were formulated through a stepwise statistical analysis approach implemented in Minitab, enabling accurate modeling of the influence of process parameters on bead morphology.

Table 3.

Results for BW and BH bead morphologies.

3.1. Regression Equations for BW and BH

Multivariable nonlinear regression models were developed to establish the relationships between process parameters and response variables. Using the Box–Behnken design (BBD) in Minitab v17, regression equations were generated to link WAAM process variables with bead height (BH) and bead width (BW). These models enable predictions beyond the experimental matrix, offering broader insights into process behavior. The nonlinear regression equations, formulated through Response Surface Methodology (RSM) in Minitab v17, further elucidated the influence of design variables on the responses BH and BW. The validity of the regression models was confirmed through analysis of variance (ANOVA) and residual plot analysis. The equations for BH and BW were derived using a stepwise regression method and are presented as Equations (1) and (2), respectively.

BH = 86.6 − (3.48 × WFS) − (3.593 × TS) − (4.82 × V) + (0.1241 × WFS2) + (0.1085 × V2)

+ (0.1825 × TS × V)

+ (0.1825 × TS × V)

BW = 60.7 − (1.317 × WFS) − (3.117 × TS) − (4.185 × V) + (0.0582 × WFS2) + (0.0782 × TS2)

+ (0.1001 × V2) + (0.100 × TS × V)

3.2. ANOVA Analysis for BW and BH

The statistical method known as analysis of variance (ANOVA) was employed to evaluate the significance of the factors affecting the response parameters. This technique analyses the variability among different levels of the input factors to identify which factors have a statistically significant effect on the response variables. Through ANOVA, the validity and reliability of the developed regression models were assessed. Minitab v17 software was used to determine the significance of model terms at a 95% confidence level. Terms with p-values less than 0.05 were considered statistically significant and deemed to have a substantial impact on the response variables, whereas non-significant terms were excluded from further consideration [40,41]. The ANOVA results for bead width (BW) and bead height (BH) are presented in Table 4 and Table 5, respectively. The statistical evaluation revealed that the linear, interaction (two-way), and quadratic (square) terms contributed significantly to the variations in both BW and BH.

Table 4.

ANOVA results for BW response.

Table 5.

ANOVA results for BH response.

The significant impact of the entire regression equation along with the statistical significance of linear, square, and two-way interactions have been observed for the response variables of BW and BH responses. The results obtained clearly show that WFS significantly affected both BW, and BH. The minimal influence of the error factor on every response proved the accuracy of the ANOVA findings, which showed great predictive accuracy with minimum inconsistencies and statistically negligible lack of fit [42]. As a result, it was decided that the model could accurately forecast output values. The significance of the model terms and the almost perfect R2 value, which denotes expert prediction, showed that the generated regression equations were robust and accurate predictors of BW and BH values. The R2 values of the model, which were 0.9853 for BW and 0.9917 for BH, were analyzed to evaluate any effectiveness. When the R2 values are so near to unity, it indicates that the model is appropriate since a high R2 value indicates accurate predictions that are mostly in line with the actual data [43,44].

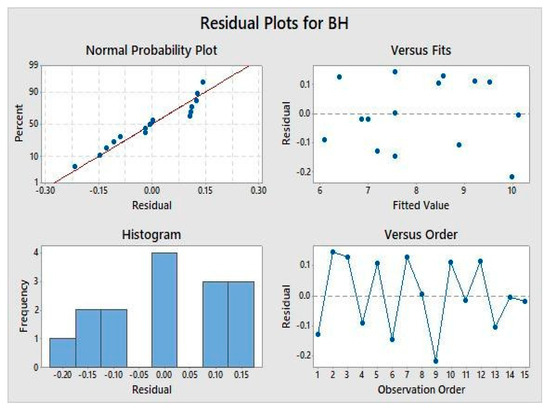

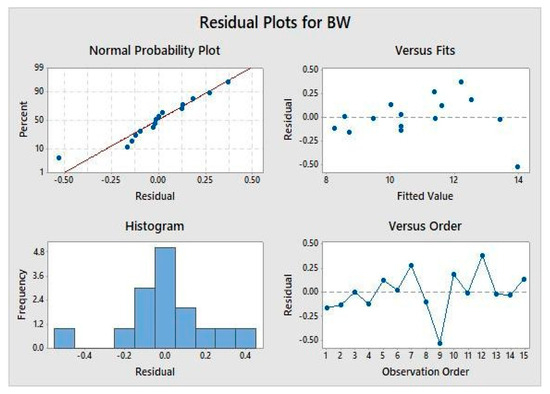

3.3. Residual Plots

The residual plots were examined to confirm the reliability of the ANOVA results [45]. ANOVA is considered an effective tool for model evaluation when these underlying assumptions are met, and residual analysis plays a critical role in this verification process [46]. Four types of residual analyses were conducted for the bead height (BH) and bead width (BW) responses, as shown in Figure 3 and Figure 4, respectively. The normal probability plots indicate that the residuals closely follow a straight line, suggesting that the residuals are normally distributed and the models are appropriate [47]. The “versus fits” plots show that residuals are randomly scattered around zero, confirming the absence of nonlinearity and constant variance issues. The histogram plots display a bell-shaped distribution, supporting the normality of the residuals and the validity of the ANOVA results. Additionally, the “versus order” plots exhibit no discernible pattern, further reinforcing the reliability of the ANOVA and enhancing confidence in the model’s predictive capability. The favorable outcomes of all four residual plots confirm the adequacy and reliability of the regression equations derived from the ANOVA analysis [48]. This validation also demonstrates that the regression models can be effectively used to predict outcomes across a range of input parameter values. Similar findings has been reported by Magabe et al. [49] and Chaudhari et al. [46] for the verification of ANOVA findings by using residual plots.

Figure 3.

Residual plot for BH.

Figure 4.

Residual plot for BW.

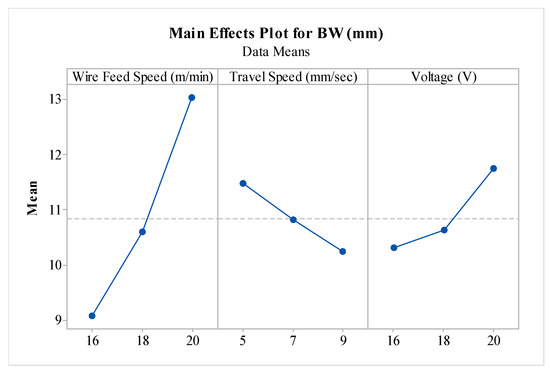

3.4. Impact of GMAW Process Parameters on Bead Morphologies of BW and BH

Figure 5 depicts the impact of design factors on the BW response. The BW of the deposition was found to be significantly impacted by an increase in WFS, which was explained by the higher deposition rate brought on by the metallic wire’s increased speed [50]. As a result, there was a rise in WFS and a reduction in BW. On the other hand, the BW vs. TS plot showed a positive connection, meaning that a rise in TS caused the BW to decrease since a faster torch speed resulted in fewer molten metal droplets being deposited [51,52]. It was also found that an increase in voltage had a detrimental effect on BW because it caused the arc to spread, which led to the deposition of bigger molten metal droplets and a wider bead overall [53,54]. The obtained trends for BW response with changes in input factors were in agreement with results reported by Vora et al. [55] and Kumar et al. [56]. The desired WAAM variable values for attaining minimal bead width were 16 V for V, 9 mm/s for TS, and 16 mm/min for WFS, based on the main effect plots.

Figure 5.

Main effect plot for BW.

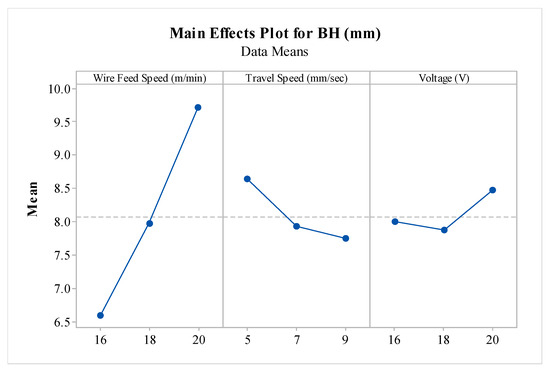

Figure 6 illustrates the influence of design factors on the bead height (BH) response. An increase in wire feed speed (WFS) resulted in a corresponding rise in BH, as WFS plays a critical role in shielding the weld pool from atmospheric contaminants. The increase in WFS leads to a higher rate of material deposition due to the accelerated delivery of molten wire from the nozzle, thereby increasing the weld bead height [57]. This explains the notable increase in BH with higher WFS values, attributed to intensified material deposition. Conversely, a decrease in BH was observed as travel speed (TS) increased from 5 mm/min to 9 mm/min. This trend can be attributed to the reduced material deposition caused by the faster movement of the welding torch, which limits the time available for material accumulation at a given point [58,59]. The influence of voltage (V) on BH was relatively minor. As the voltage increased from 16 V to 18 V, BH initially decreased and then slightly increased, indicating a weak or nonlinear effect [60,61]. The observed trends for bead width (BW) in response to variations in process parameters were consistent with findings reported by Mai et al. [62] and Dinovitzer et al. [63]. Based on the main effect plots, the optimal WAAM parameter settings for maximizing BH were identified as follows: voltage = 20 V, travel speed = 5 mm/s, and wire feed speed = 20 mm/min.

Figure 6.

Main effect plot for BH.

3.5. Optimization by PVS Algorithm

The PVS method was required for response optimization since the main effect charts of the response parameters demonstrated how various WAAM variable values were required to obtain the optimal BH and BW feedback. The highest and lowest limits of the design variables were considered while applying the PVS technique, which ranged from V: 16 ≤ V ≤ 20 to TS: 5 ≤ TS ≤ 9 and WFS: 16 ≤ WFS ≤ 20. Table 6 displays the optimization results for single responses.

Table 6.

Single-response optimization.

In order to maximize the BH response, the BW response value also increased, and vice versa. To attain both the output responses, it is necessary to conduct the simultaneous optimization of BH and BW responses. With an objective function giving an equal importance to both output responses of 0.5 each, a simultaneous optimization was carried out. The objective function has shown optimal parametric settings as follows: WFS: 18 mm/min, TS: 7 mm/s, V: 19 V, with an optimized value of BH of 10.87 mm and of BW of 7.78 mm. By considering the needs of different users and their requirements, multiple Pareto points were generated through the PVS algorithm, which provides non-dominated unique solutions. For simultaneous optimizations, Pareto points were generated as shown in Table 7. These solutions offered manufacturers optimal process settings tailored to the specific requirements of achieving desired BH and BW values simultaneously. The results obtained through the PVS algorithm were further validated through experimental trials. Validation experiments confirmed the accuracy and reliability of the results obtained through the PVS algorithm, demonstrating its effectiveness in enhancing WAAM performance. The successful optimization achieved through the PVS algorithm demonstrates its ability to precisely determine the optimal process parameters for the WAAM process.

Table 7.

Pareto optimal points.

4. Conclusions

The present study investigated the influence of GMAW-based WAAM process parameters—namely, wire feed speed (WFS), travel speed (TS), and voltage (V)—on the bead geometry of single-layer depositions using 80B2 metal-cored wire on mild steel substrates. A Box–Behnken design (BBD) within the framework of Response Surface Methodology (RSM) was employed to conduct the experimental trials and develop multivariable nonlinear regression models linking the input parameters to the output responses: bead width (BW) and bead height (BH). Statistical analysis using ANOVA validated the models and identified significant factors. The statistical results revealed that WFS had the most significant impact on both BH and BW. The developed regression models demonstrated high predictive accuracy (R2 > 98%), and residual plot analyses confirmed their reliability across the experimental domain.

The Passing Vehicle Search (PVS) algorithm was successfully applied for both single- and multi-objective optimization. In single-objective optimization, the algorithm achieved a minimum BW of 5.874 mm and a maximum BH of 14.153 mm under different parameter conditions. The parametric settings of WFS: 18 mm/min, TS: 7 mm/s, and V: 19 V were obtained for the simultaneous optimization of BW with 7.78 mm and BH with 10.87 mm by giving them an equal importance with equal weightage. Furthermore, the PVS algorithm generated multiple Pareto-optimal solutions to accommodate varying user requirements, offering a set of non-dominated process parameter combinations. The optimized results obtained from the PVS algorithm were further validated through experimental trials, confirming the robustness and effectiveness of the proposed models and optimization approach. The findings underscore the critical importance of precise parameter selection for achieving the desired bead morphology.

The optimized process parameters identified in this study will be utilized in future research to fabricate thin-walled, multi-layered structures. Overall, the methodology and insights presented here offer a promising framework for enhancing structural integrity, dimensional accuracy, and process efficiency in the additive manufacturing of low-alloy steels using metal-cored wires.

Author Contributions

Conceptualization, Y.P., A.S., R.C., V.V., V.P. and J.V.; methodology, Y.P., A.S., R.C. and J.V.; software, V.P.; validation, Y.P., A.S., R.C., V.V., V.P. and J.V.; formal analysis, Y.P. and A.S.; investigation, Y.P., A.S., R.C., V.V., V.P. and J.V.; resources, Y.P., R.C., V.V., V.P. and J.V.; data curation, Y.P., V.V., R.C. and J.V.; writing—original draft preparation, Y.P., A.S., R.C. and J.V.; writing—review and editing, R.C. and J.V.; visualization, Y.P., A.S., R.C., V.V., V.P. and J.V.; supervision, R.C. and J.V.; project administration, R.C. and J.V.; funding acquisition, R.C. and J.V.; All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data presented in this study are available in this article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Tkachev, E.; Borisov, S.; Borisova, Y.; Kniaziuk, T.; Belyakov, A.; Kaibyshev, R. Austenite stabilization and precipitation of carbides during quenching and partitioning (Q&P) of low-alloyed Si–Mn steels with different carbon content. Mater. Sci. Eng. A 2024, 895, 146212. [Google Scholar]

- Liu, W.; Zhao, H.-L.; Wang, B.-X.; Tian, Y. Impact of Mo/Ni alloying on microstructural modulation and low-temperature toughness of high-strength low-alloy steel. J. Iron Steel Res. Int. 2023, 31, 1746–1762. [Google Scholar] [CrossRef]

- Che, Z.; Peng, C. Improving Support Vector Regression for Predicting Mechanical Properties in Low-Alloy Steel and Comparative Analysis. Mathematics 2024, 12, 1153. [Google Scholar] [CrossRef]

- Wang, C.; Chen, R.; Wang, C.; Zhang, Y.; Wang, X.; Chen, M. Strong and ductile low carbon low alloy steels with multiphase bimodal microstructure. Int. J. Plast. 2024, 181, 104097. [Google Scholar] [CrossRef]

- Treutler, K.; Gehling, T.; Scheck, M.; Richter, A.; Bohn, C.; Ehlers, R.; Rembe, C.; Wesling, V. Properties oriented WAAM—Microstructural and geometrical control in WAAM of low-alloy steel. Weld. World 2023, 68, 247–257. [Google Scholar] [CrossRef]

- Chen, J.; Shi, Z.; Luo, X.; Chai, F.; Pan, T.; Feng, G.; Yang, C. Micro-Alloying Effects on Microstructure and Weldability of High-Strength Low-Alloy Steel: A Review. Materials 2025, 18, 1036. [Google Scholar] [CrossRef]

- Vora, J.; Parikh, N.; Chaudhari, R.; Patel, V.K.; Paramar, H.; Pimenov, D.Y.; Giasin, K. Optimization of bead morphology for GMAW-based wire-arc additive manufacturing of 2.25 Cr-1.0 Mo steel using metal-cored wires. Appl. Sci. 2022, 12, 5060. [Google Scholar] [CrossRef]

- Kokare, S.; Shen, J.; Fonseca, P.P.; Lopes, J.G.; Machado, C.M.; Santos, T.G.; Oliveira, J.P.; Godina, R. Wire arc additive manufacturing of a high-strength low-alloy steel part: Environmental impacts, costs, and mechanical properties. Int. J. Adv. Manuf. Technol. 2024, 134, 453–475. [Google Scholar] [CrossRef]

- Chaudhari, R.; Parikh, N.; Khanna, S.; Vora, J.; Patel, V. Effect of multi-walled structure on microstructure and mechanical properties of 1.25 Cr-1.0 Mo steel fabricated by GMAW-based WAAM using metal-cored wire. J. Mater. Res. Technol. 2022, 21, 3386–3396. [Google Scholar] [CrossRef]

- Singh, A.; Khajuria, A.; Bedi, R.; Dommeti, S.G.; Shiva, S. Microstructural and Mechanical Property Analysis of High-Strength Low-Alloy Steel Tubes Fabricated Using Wire Arc-Directed Energy Deposition Technique. Met. Mater. Int. 2024, 31, 1815–1835. [Google Scholar] [CrossRef]

- Koh, S.; Lee, J.M.; Yang, B.Y.; Kim, K.Y. Effect of molybdenum and chromium addition on the susceptibility to sulfide stress cracking of high-strength, low-alloy steels. Corrosion 2007, 63, 220–230. [Google Scholar] [CrossRef]

- Gaikwad, M.U.; Gaikwad, P.U.; Ambhore, N.; Sharma, A.; Bhosale, S.S. Powder Bed Additive Manufacturing Using Machine Learning Algorithms for Multidisciplinary Applications: A Review and Outlook. Recent Pat. Mech. Eng. 2025, 18, 12–25. [Google Scholar] [CrossRef]

- Abdulhameed, O.; Al-Ahmari, A.; Ameen, W.; Mian, S.H. Additive Manufacturing: Challenges, Trends, and Applications. Adv. Mech. Eng. 2019, 11, 1687814018822880. [Google Scholar] [CrossRef]

- Nagalingam, A.P.; Shamir, M.; Tureyen, E.B.; Sharman, A.R.C.; Poyraz, O.; Yasa, E.; Hughes, J. Recent progress in wire-arc and wire-laser directed energy deposition (DED) of titanium and aluminium alloys. Int. J. Adv. Manuf. Technol. 2025, 136, 2035–2073. [Google Scholar] [CrossRef]

- Svetlizky, D.; Das, M.; Zheng, B.; Vyatskikh, A.L.; Bose, S.; Bandyopadhyay, A.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. Directed energy deposition (DED) additive manufacturing: Physical characteristics, defects, challenges and applications. Mater. Today 2021, 49, 271–295. [Google Scholar] [CrossRef]

- Sarıkaya, M.; Önler, D.B.; Dağlı, S.; Hartomacıoğlu, S.; Günay, M.; Królczyk, G.M. A review on aluminum alloys produced by wire arc additive manufacturing (WAAM): Applications, benefits, challenges and future trends. J. Mater. Res. Technol. 2024, 33, 5643–5670. [Google Scholar] [CrossRef]

- Meena, R.P.; Yuvaraj, N.; Vipin. A review on wire arc additive manufacturing based on cold metal transfer. Mater. Manuf. Process. 2024, 39, 1315–1341. [Google Scholar] [CrossRef]

- Athaib, N.H.; Haleem, A.H.; Al-Zubaidy, B. A review of wire arc additive manufacturing (WAAM) of aluminium composite, process, classification, advantages, challenges, and application. J. Phys. Conf. Ser. 2021, 1973, 12083. [Google Scholar] [CrossRef]

- Raspall, F.; Araya, S.; Pazols, M.; Valenzuela, E.; Castillo, M.; Benavides, P. Wire Arc Additive Manufacturing for Widespread Architectural Application: A Review Informed by Large-Scale Prototypes. Buildings 2025, 15, 906. [Google Scholar] [CrossRef]

- Meng, X.; Gardner, L. Hybrid construction featuring wire arc additive manufacturing: Review, concepts, challenges and opportunities. Eng. Struct. 2024, 326, 119337. [Google Scholar] [CrossRef]

- Lambiase, F.; Yanala, P.B.; Pace, F.; Andreucci, E.; Paoletti, A. A state of the art review of wire arc additive manufacturing (WAAM)–part 1: Process fundamentals, parameters and materials. Int. J. Adv. Manuf. Technol. 2025, 138, 4965–4993. [Google Scholar] [CrossRef]

- Pattanayak, S.; Sahoo, S.K. Gas metal arc welding based additive manufacturing—A review. CIRP J. Manuf. Sci. Technol. 2021, 33, 398–442. [Google Scholar] [CrossRef]

- Wang, C.; Wang, J.; Bento, J.; Ding, J.; Pardal, G.; Chen, G.; Qin, J.; Suder, W.; Williams, S. A novel cold wire gas metal arc (CW-GMA) process for high productivity additive manufacturing. Addit. Manuf. 2023, 73, 103681. [Google Scholar] [CrossRef]

- Sinha, A.K.; Pramanik, S.; Yagati, K.P. Research progress in arc based additive manufacturing of aluminium alloys–A review. Measurement 2022, 200, 111672. [Google Scholar] [CrossRef]

- Shah, A.; Aliyev, R.; Zeidler, H.; Krinke, S. A review of the recent developments and challenges in wire arc additive manufacturing (WAAM) process. J. Manuf. Mater. Process. 2023, 7, 97. [Google Scholar] [CrossRef]

- Foorginejad, A.; Khatibi, S.; Torshizi, H.; Emam, S.M.; Afshari, H. Enhancement of Additive Manufacturing Processes for Thin-Walled Part Production Using Gas Metal Arc Welding (GMAW) with Wavelet Transform. Appl. Sci. 2024, 14, 9909. [Google Scholar] [CrossRef]

- Singh, G.; Dewangan, A.K.; Khan, M.F.; Moinuddin, S.Q. Fundamental review on gas tungsten arc welding of magnesium alloys: Challenges, innovations, and future perspectives. Weld. World 2025, 69, 2767–2787. [Google Scholar] [CrossRef]

- Kazmi, K.H.; Bara, A.K.; Sharma, S.K. Multi-objective optimisation of wire arc additive manufacturing deposition using genetic algorithm. In Thermal Claddings for Engineering Applications; CRC Press: Boca Raton, FL, USA, 2024; pp. 77–91. [Google Scholar]

- Vora, J.; Parmar, H.; Chaudhari, R.; Khanna, S.; Doshi, M.; Patel, V. Experimental investigations on mechanical properties of multi-layered structure fabricated by GMAW-based WAAM of SS316L. J. Mater. Res. Technol. 2022, 20, 2748–2757. [Google Scholar] [CrossRef]

- Arulmurugan, B.; Arunkumar, P.; Dharanikumar, S. Advances in gas tungsten and Gas metal Arc welding–A concise review. In Advanced Joining Technologies; CRC Press: Boca Raton, FL, USA, 2024; pp. 18–36. [Google Scholar]

- Treutler, K.; Wesling, V. The current state of research of wire arc additive manufacturing (WAAM): A review. Appl. Sci. 2021, 11, 8619. [Google Scholar] [CrossRef]

- Kumar, S.; Tejani, G.G.; Pholdee, N.; Bureerat, S. Multi-objective passing vehicle search algorithm for structure optimization. Expert Syst. Appl. 2021, 169, 114511. [Google Scholar] [CrossRef]

- Chentoufi, M.A.; Ellaia, R. A novel multiobjective passing vehicle search algorithm for signal timing optimization. Comput. Sci. 2021, 16, 775–792. [Google Scholar]

- Parsana, S.; Radadia, N.; Sheth, M.; Sheth, N.; Savsani, V.; Prasad, N.E.; Ramprabhu, T. Machining parameter optimization for EDM machining of Mg-RE-Zn-Zr alloy using multi-objective passing vehicle search algorithm. Arch. Civ. Mech. Eng. 2018, 18, 799–817. [Google Scholar] [CrossRef]

- Ladumor, D.P.; Trivedi, I.N.; Bhesdadiya, R.; Jangir, P. A passing vehicle search algorithm for solution of optimal power flow problems. In Proceedings of the 2017 Third International Conference on Advances in Electrical, Electronics, Information, Communication and Bio-Informatics (AEEICB), Chennai, India, 27–28 February 2017; IEEE: Piscateway, NJ, USA, 2017. [Google Scholar]

- Chaudhari, R.; Parmar, H.; Vora, J.; Patel, V.K. Parametric study and investigations of bead geometries of GMAW-based wire–arc additive manufacturing of 316L stainless steels. Metals 2022, 12, 1232. [Google Scholar] [CrossRef]

- Tukaram Sargar, N.K.G.; Jadhav, A.; Gaikwad, M.U. A Comparative Investigation of Kerf Width during CO2 and Fiber Laser Machining of SS 316L Material. Recent Pat. Mech. Eng. 2025, 18, 628–640. [Google Scholar] [CrossRef]

- Ferreira, S.C.; Bruns, R.E.; Ferreira, H.S.; Matos, G.D.; David, J.M.; Brandão, G.C.; da Silva, E.G.P.; Portugal, L.A.; dos Reis, P.S.; Souza, A.S.; et al. Box-Behnken design: An alternative for the optimization of analytical methods. Anal. Chim. Acta 2007, 597, 179–186. [Google Scholar] [CrossRef]

- Savsani, P.; Savsani, V. Passing vehicle search (PVS): A novel metaheuristic algorithm. Appl. Math. Model. 2016, 40, 3951–3978. [Google Scholar] [CrossRef]

- Al-Amin, M.; Abdul-Rani, A.M.; Ahmed, R.; Shahid, M.U.; Zohura, F.T.; Rani, M.D.B.A. Multi-objective optimization of process variables for MWCNT-added electro-discharge machining of 316L steel. Int. J. Adv. Manuf. Technol. 2021, 115, 179–198. [Google Scholar] [CrossRef]

- Gaikwad, M.U.; Krishnamoorthy, A.; Jatti, V.S. Investigation on effect of process parameter on surface integrity during electrical discharge machining of NiTi 60. Multidiscip. Model. Mater. Struct. 2020, 16, 1385–1394. [Google Scholar] [CrossRef]

- Abuabiah, M.; Weidemann, T.C.; Elahi, M.A.; Shaqour, B.; Day, R.; Plapper, P.; Bergs, T. Investigating the Impact of Process Parameters on Bead Geometry in Laser Wire-Feed Metal Additive Manufacturing. J. Manuf. Mater. Process. 2024, 8, 204. [Google Scholar] [CrossRef]

- Chaudhari, R.; Vora, J.J.; Prabu, S.S.M.; Palani, I.A.; Patel, V.K.; Parikh, D.M. Pareto optimization of WEDM process parameters for machining a NiTi shape memory alloy using a combined approach of RSM and heat transfer search algorithm. Adv. Manuf. 2019, 9, 64–80. [Google Scholar] [CrossRef]

- Ambhore, N.; Gaikwad, M.; Patil, A.; Sharma, Y.; Manikjade, A. Predictive modeling and optimization of dry turning of hardened steel. Int. J. Interact. Des. Manuf. (IJIDeM) 2024, 18, 6281–6287. [Google Scholar] [CrossRef]

- Bansal, S.; Singh, G. Multiple linear regression based analysis of weather data: Assumptions and limitations. In Proceedings of the International Conference on Advanced Communication and Intelligent Systems, Warsaw, Poland, 16–17 June 2023; Springer: Berlin/Heidelberg, Germany, 2023. [Google Scholar]

- Chaudhari, R.; Bhatt, R.; Vaghasia, V.; Raja, B.D.; Patel, V.K.; Khanna, S.; Vora, J.; Patel, V.V. A parametric study and experimental investigations of microstructure and mechanical properties of multi-layered structure of metal core wire using wire arc additive manufacturing. J. Adv. Join. Process. 2023, 8, 100160. [Google Scholar] [CrossRef]

- Chantarangsi, W.; Liu, W.; Bretz, F.; Kiatsupaibul, S.; Hayter, A.J. Normal probability plots with confidence for the residuals in linear regression. Commun. Stat.-Simul. Comput. 2018, 47, 367–379. [Google Scholar] [CrossRef]

- Moradi, M.; Beiranvand, Z.M.; Salimi, N.; Meiabadi, S.; Lawrence, J. Experimental investigation on the 3D printing of nylon reinforced by carbon fiber through fused filament fabrication process, effects of extruder temperature, and printing speed. Int. J. Polym. Sci. 2024, 2024, 1234797. [Google Scholar] [CrossRef]

- Magabe, R.; Sharma, N.; Gupta, K.; Davim, J.P. Modeling and optimization of Wire-EDM parameters for machining of Ni 55.8 Ti shape memory alloy using hybrid approach of Taguchi and NSGA-II. Int. J. Adv. Manuf. Technol. 2019, 102, 1703–1717. [Google Scholar] [CrossRef]

- Wu, B.; Pan, Z.; Ding, D.; Cuiuri, D.; Li, H.; Xu, J.; Norrish, J. A review of the wire arc additive manufacturing of metals: Properties, defects and quality improvement. J. Manuf. Process. 2018, 35, 127–139. [Google Scholar] [CrossRef]

- Paskual, A.; Álvarez, P.; Suárez, A. Study on arc welding processes for high deposition rate additive manufacturing. Procedia Cirp 2018, 68, 358–362. [Google Scholar]

- Rauch, M.; Nwankpa, U.V.; Hascoet, J.-Y. Investigation of deposition strategy on wire and arc additive manufacturing of aluminium components. J. Adv. Join. Process. 2021, 4, 100074. [Google Scholar] [CrossRef]

- Lee, S.H. Optimization of cold metal transfer-based wire arc additive manufacturing processes using gaussian process regression. Metals 2020, 10, 461. [Google Scholar] [CrossRef]

- Vaghasia, V.; Chaudhari, R.; Patel, V.K.; Vora, J. Parametric Study on Investigations of GMAW-Based WAAM Process Parameters and Effect on Microstructure and Mechanical Properties of NiTi SMA. J. Manuf. Mater. Process. 2025, 9, 58. [Google Scholar] [CrossRef]

- Vora, J.; Pandey, R.; Dodiya, P.; Patel, V.; Khanna, S.; Vaghasia, V.; Chaudhari, R. Fabrication of Multi-Walled Structure through Parametric Study of Bead Geometries of GMAW-Based WAAM Process of SS309L. Materials 2023, 16, 5147. [Google Scholar] [CrossRef]

- Kumar, V.; Mandal, A.; Das, A.K.; Kumar, S. Parametric study and characterization of wire arc additive manufactured steel structures. Int. J. Adv. Manuf. Technol. 2021, 115, 1723–1733. [Google Scholar] [CrossRef]

- Xu, W.; Lin, S.B.; Fan, C.L.; Yang, C.L. Prediction and optimization of weld bead geometry in oscillating arc narrow gap all-position GMA welding. Int. J. Adv. Manuf. Technol. 2015, 79, 183–196. [Google Scholar] [CrossRef]

- Pan, Z.; Ding, D.; Wu, B.; Cuiuri, D.; Li, H.; Norrish, J. Arc welding processes for additive manufacturing: A review. In Transactions on Intelligent Welding Manufacturing; Springer: Berlin/Heidelberg, Germany, 2018; pp. 3–24. [Google Scholar]

- Chaturvedi, M.; Scutelnicu, E.; Rusu, C.C.; Mistodie, L.R.; Mihailescu, D.; Subbiah, A.V. Wire arc additive manufacturing: Review on recent findings and challenges in industrial applications and materials characterization. Metals 2021, 11, 939. [Google Scholar] [CrossRef]

- Thakur, P.; Chapgaon, A. A review on effects of GTAW process parameters on weld. IJRASET 2016, 4, 136–140. [Google Scholar]

- Giarollo, D.F.; Mazzaferro, C.C.P.; Mazzaferro, J.A.E. Comparison between two heat source models for wire-arc additive manufacturing using GMAW process. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 7. [Google Scholar] [CrossRef]

- Mai, D.S.; Doan, T.K.; Paris, H. Wire and arc additive manufacturing of 308L stainless steel components: Optimization of processing parameters and material properties. Eng. Sci. Technol. Int. J. 2021, 24, 1015–1026. [Google Scholar] [CrossRef]

- Dinovitzer, M.; Chen, X.; Laliberte, J.; Huang, X.; Frei, H. Effect of wire and arc additive manufacturing (WAAM) process parameters on bead geometry and microstructure. Addit. Manuf. 2019, 26, 138–146. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).