A Parametric Study Investigating the Effect of Bead Morphologies of SS316L Through the GMAW Process †

Abstract

1. Introduction

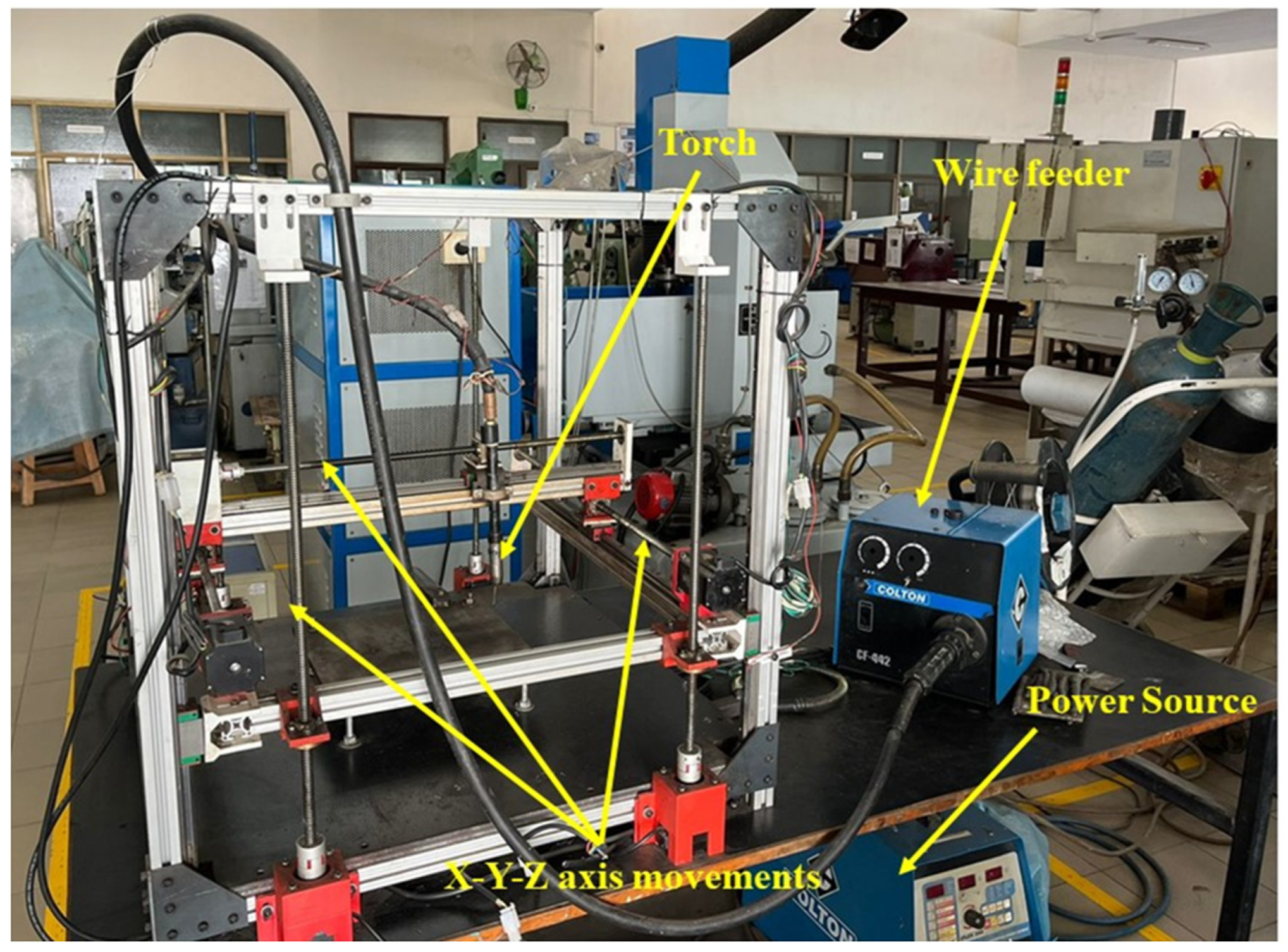

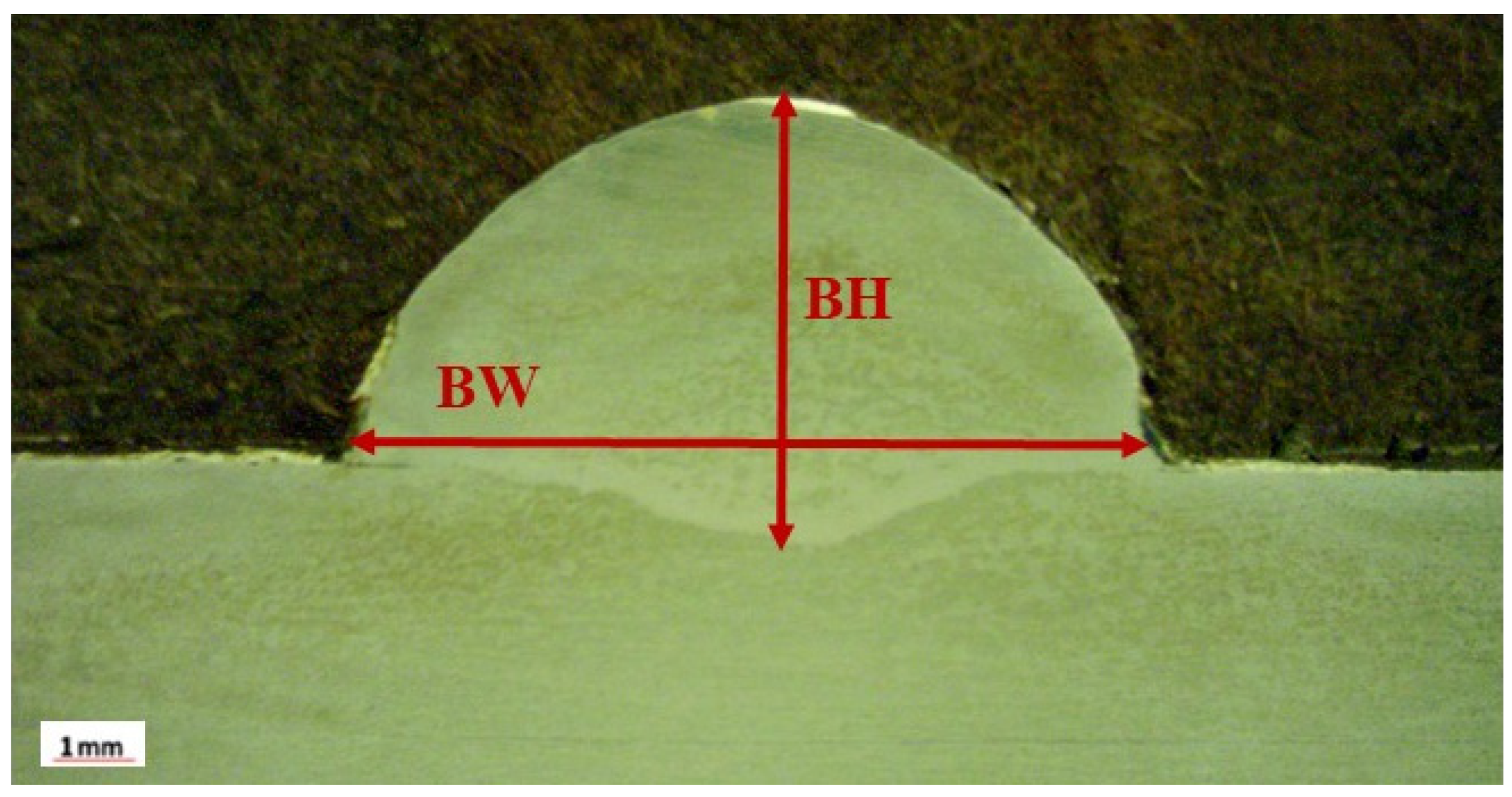

2. Experimental Section

3. Results and Discussion

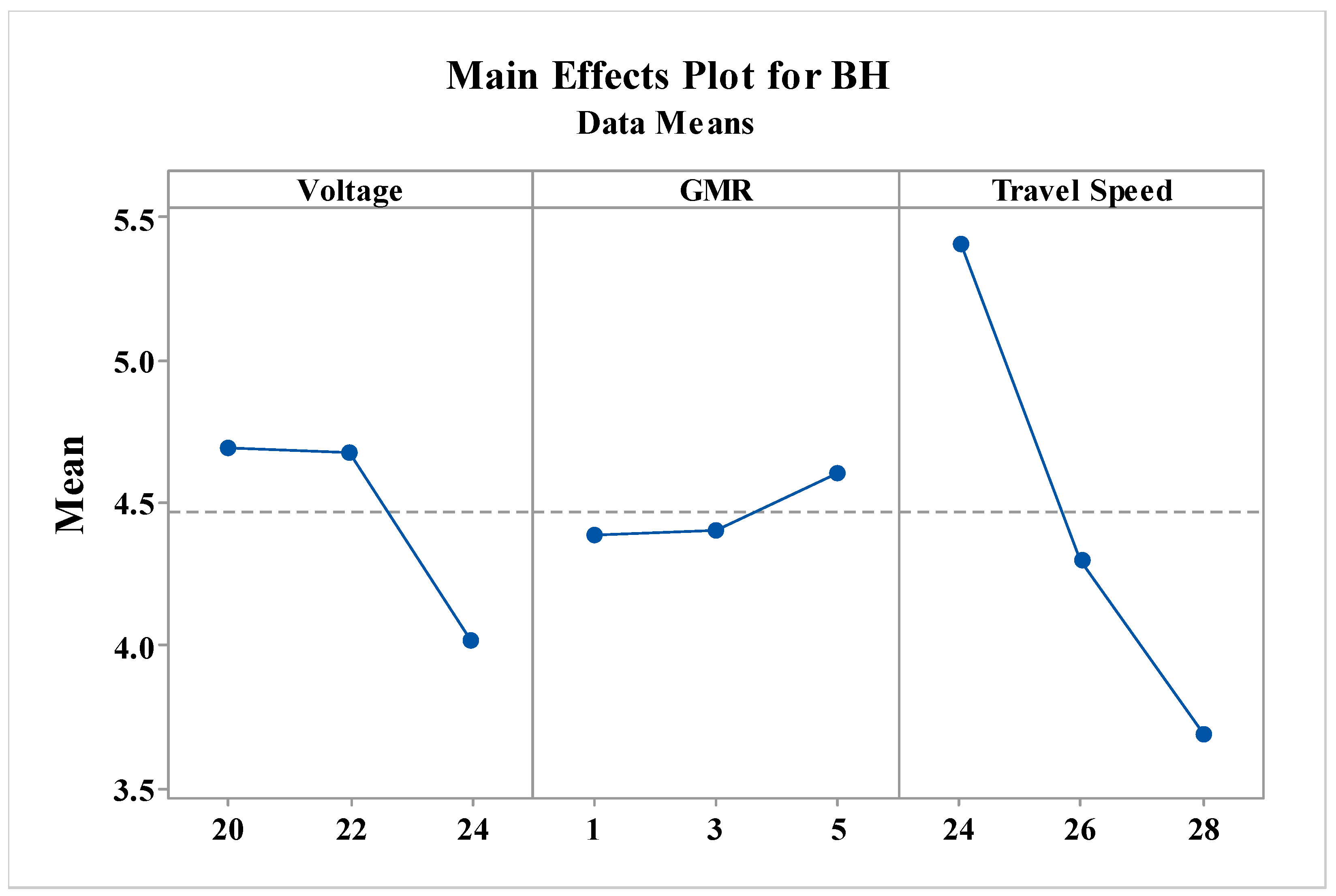

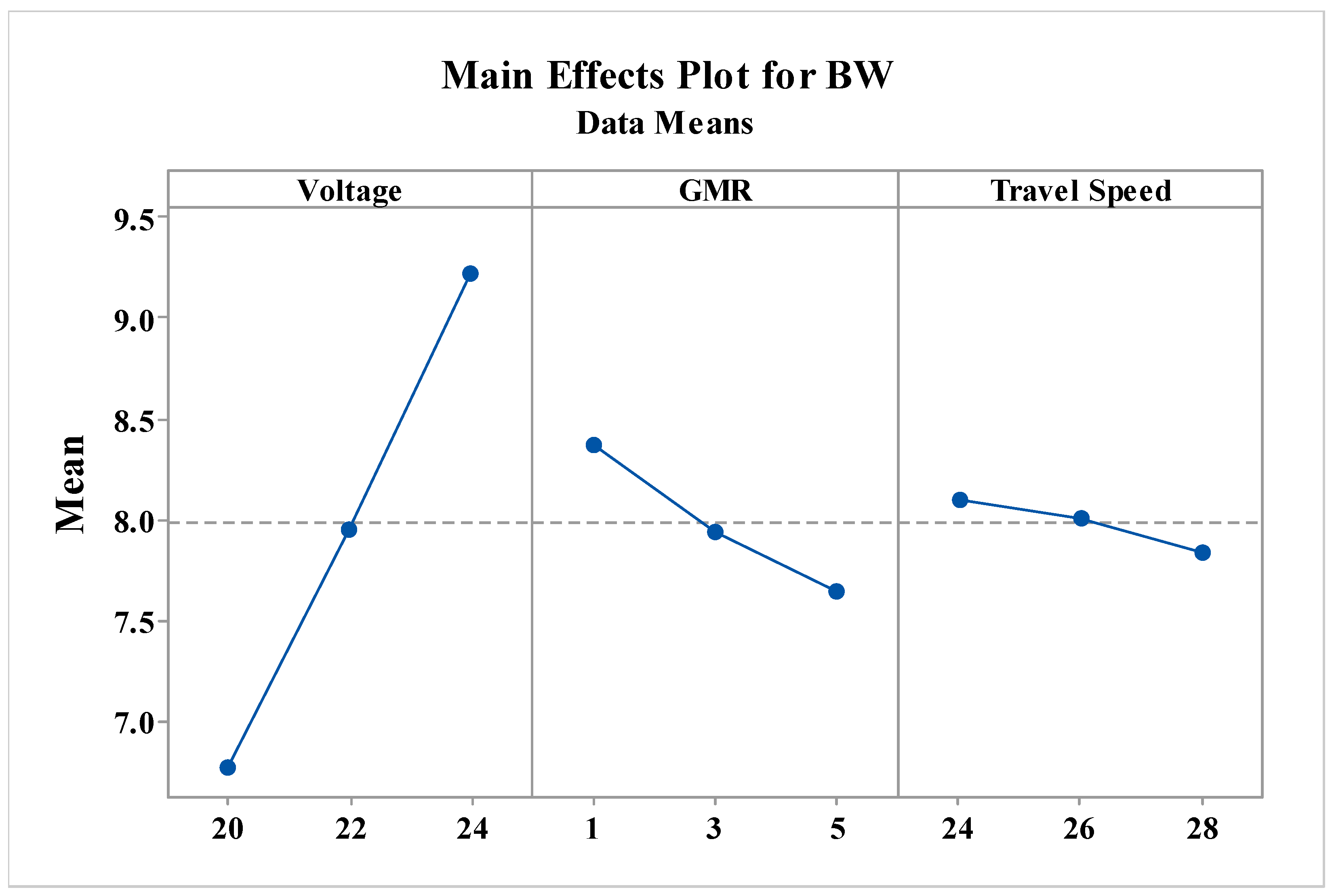

3.1. Main Effect Plots

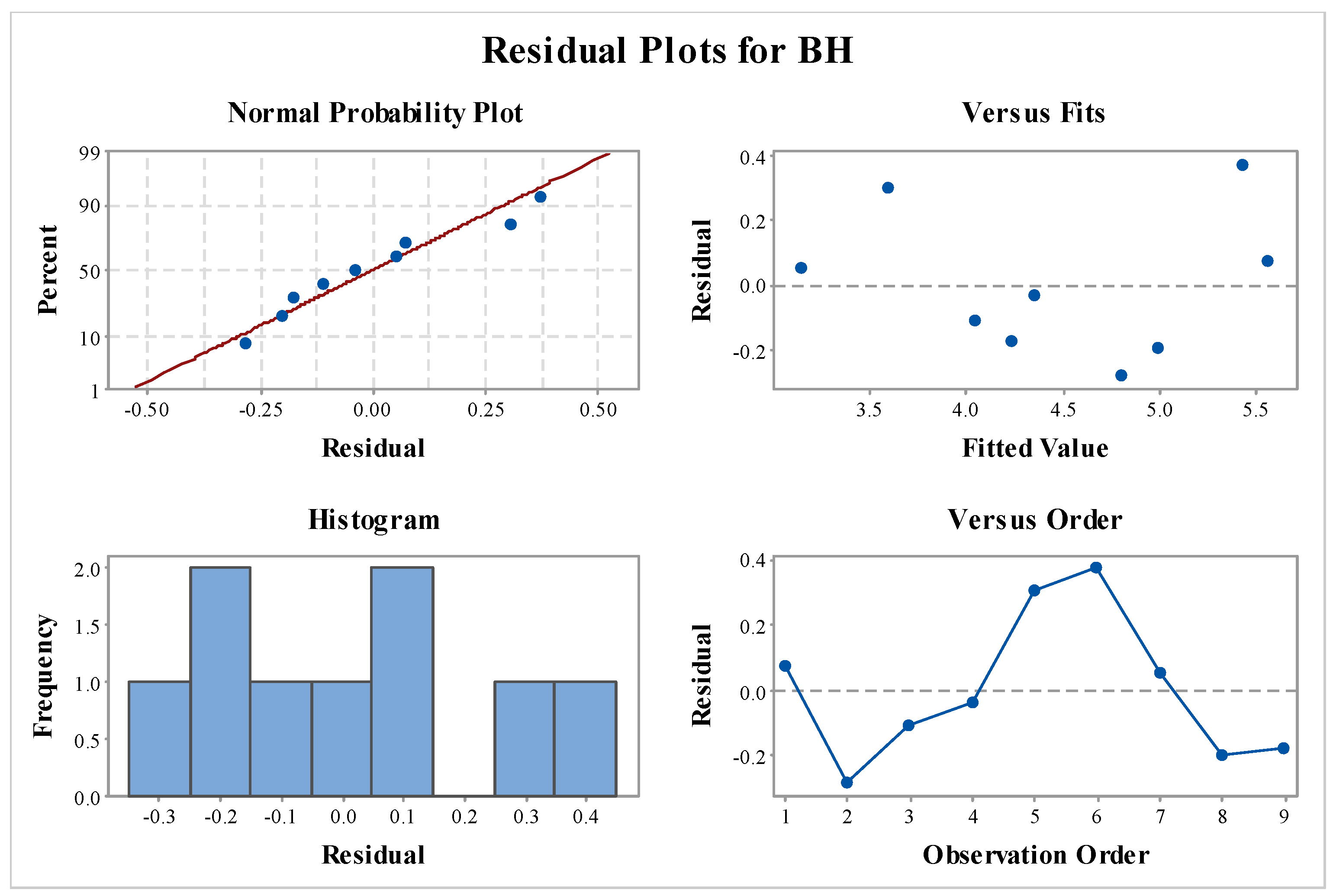

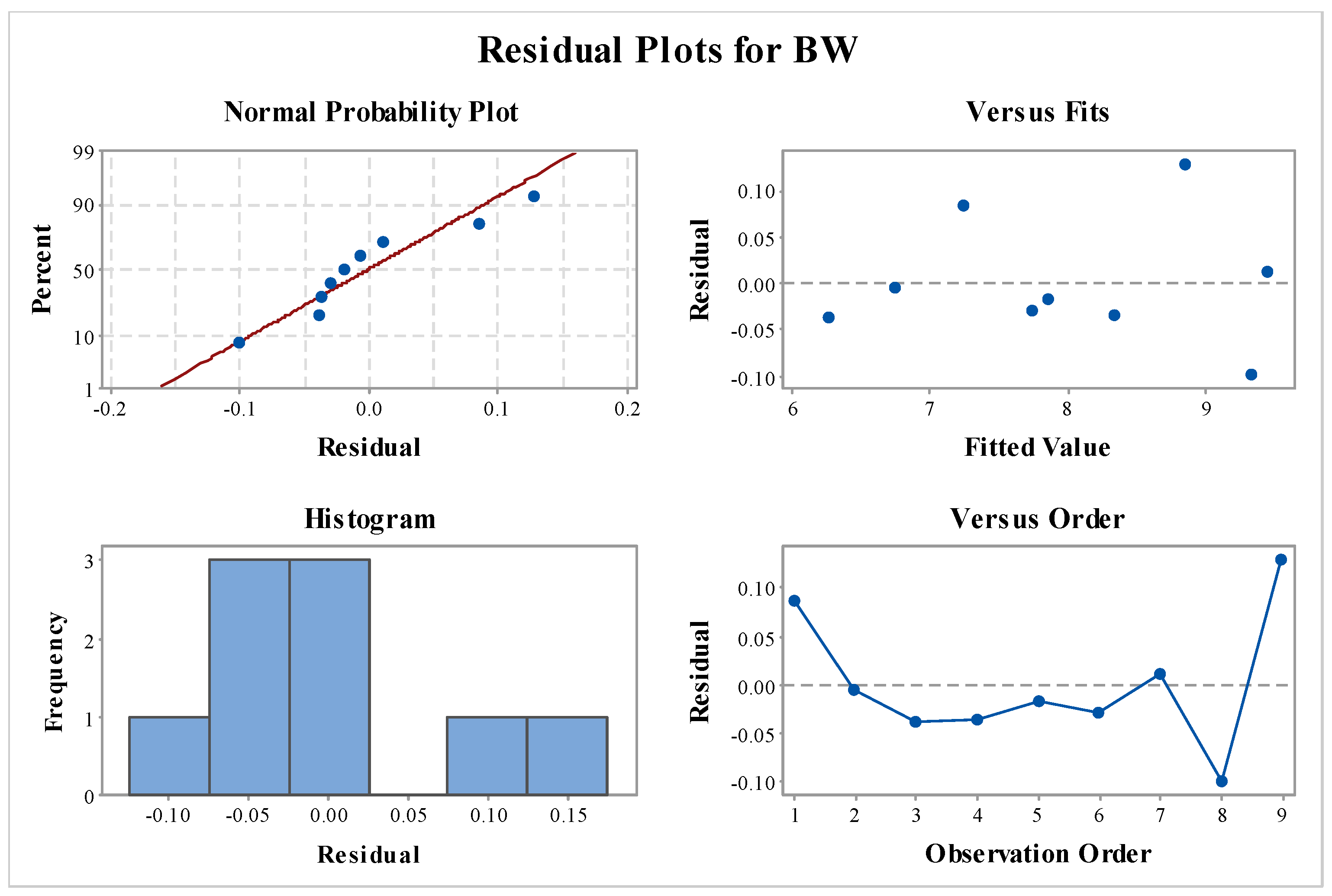

3.2. Analysis of Variance for BH and BW

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, L.; Miller, J.; Vezza, J.; Mayster, M.; Raffay, M.; Justice, Q.; Al Tamimi, Z.; Hansotte, G.; Sunkara, L.D.; Bernat, J. Additive manufacturing: A comprehensive review. Sensors 2024, 24, 2668. [Google Scholar] [CrossRef] [PubMed]

- Meng, X.; Gardner, L. Hybrid construction featuring wire arc additive manufacturing: Review, concepts, challenges and opportunities. Eng. Struct. 2025, 326, 119337. [Google Scholar] [CrossRef]

- Zahidin, M.R.; Yusof, F.; Rashid, S.H.A.; Mansor, S.; Raja, S.; Jamaludin, M.F.; Manurung, Y.H.; Adenan, M.S.; Hussein, N.I.S. Research challenges, quality control and monitoring strategy for Wire Arc Additive Manufacturing. J. Mater. Res. Technol. 2023, 24, 2769–2794. [Google Scholar] [CrossRef]

- Tang, P.; Zhao, X.; Shi, H.; Hu, B.; Ding, J.; Yang, B.; Xu, W. A review of multi-axis additive manufacturing: Potential, opportunity and challenge. Addit. Manuf. 2024, 83, 104075. [Google Scholar] [CrossRef]

- Özel, T.; Shokri, H.; Loizeau, R. A Review on Wire-Fed Directed Energy Deposition Based Metal Additive Manufacturing. J. Manuf. Mater. Process. 2023, 7, 45. [Google Scholar] [CrossRef]

- Boretti, A. Metal additive manufacturing for internal combustion engine components: A narrative review of applications, materials, processes, challenges, and future directions. Int. J. Adv. Manuf. Technol. 2025, 139, 6355–6397. [Google Scholar] [CrossRef]

- Yang, H.; Shan, Z.; Yan, D.; Shi, J.; Shi, H.; Huang, J. Advances in digital multi-material composite sand-mold binder-jetting forming technology and equipment. Addit. Manuf. Front. 2024, 3, 200138. [Google Scholar] [CrossRef]

- Nguyen, H.D.; Pramanik, A.; Basak, A.; Dong, Y.; Prakash, C.; Debnath, S.; Shankar, S.; Jawahir, I.; Dixit, S.; Buddhi, D. A critical review on additive manufacturing of Ti-6Al-4V alloy: Microstructure and mechanical properties. J. Mater. Res. Technol. 2022, 18, 4641–4661. [Google Scholar] [CrossRef]

- Rodríguez-González, P.; Ruiz-Navas, E.M.; Gordo, E. Wire arc additive manufacturing (WAAM) for aluminum-lithium alloys: A review. Materials 2023, 16, 1375. [Google Scholar] [CrossRef]

- Evans, S.I.; Wang, J.; Qin, J.; He, Y.; Shepherd, P.; Ding, J. A review of WAAM for steel construction—Manufacturing, material and geometric properties, design, and future directions. Structures 2022, 44, 1506–1522. [Google Scholar] [CrossRef]

- Sarzyński, B.; Śnieżek, L.; Grzelak, K. Metal additive manufacturing (MAM) applications in production of vehicle parts and components—A review. Metals 2024, 14, 195. [Google Scholar] [CrossRef]

- Baghel, P.K.; Gupta, T. Optimization of parameters of pulse current gas tungsten arc welding using non conventional techniques. J. Adv. Join. Process. 2022, 6, 100124. [Google Scholar] [CrossRef]

- Elsokaty, A.; Oraby, O.; Sadek, S.; Salem, H.G. Influence of Wire Arc Additive Manufacturing Beads’ Geometry and Building Strategy: Mechanical and Structural Behavior of ER70S-6 Prismatic Blocks. J. Manuf. Mater. Process. 2023, 7, 3. [Google Scholar] [CrossRef]

- Vora, J.; Parmar, H.; Chaudhari, R.; Khanna, S.; Doshi, M.; Patel, V. Experimental investigations on mechanical properties of multi-layered structure fabricated by GMAW-based WAAM of SS316L. J. Mater. Res. Technol. 2022, 20, 2748–2757. [Google Scholar] [CrossRef]

- Pant, H.; Arora, A.; Gopakumar, G.S.; Chadha, U.; Saeidi, A.; Patterson, A.E. Applications of wire arc additive manufacturing (WAAM) for aerospace component manufacturing. Int. J. Adv. Manuf. Technol. 2023, 127, 4995–5011. [Google Scholar] [CrossRef]

- Sinha, A.K.; Pramanik, S.; Yagati, K.P. Research progress in arc based additive manufacturing of aluminium alloys—A review. Measurement 2022, 200, 111672. [Google Scholar] [CrossRef]

- Li, J.Z.; Alkahari, M.R.; Rosli, N.A.B.; Hasan, R.; Sudin, M.N.; Ramli, F.R. Review of wire arc additive manufacturing for 3D metal printing. Int. J. Autom. Technol. 2019, 13, 346–353. [Google Scholar] [CrossRef]

- Kumar, P.; Ghangas, G.; Dhull, S. Effects of WAAM Process Parameters on Mechanical and Surface Integrity: A Comprehensive Review. In Manufacturing Strategies and Systems; CRC Press: Boca Raton, FL, USA, 2025; pp. 62–84. [Google Scholar]

- Bellamkonda, P.N.; Dwivedy, M.; Sudersanan, M.; Visvalingam, B. Influence of welding processes on the microstructure and mechanical properties of duplex stainless steel parts fabricated by wire arc additive manufacturing. Met. Mater. Int. 2025, 31, 368–391. [Google Scholar] [CrossRef]

- Treutler, K.; Wesling, V. The current state of research of wire arc additive manufacturing (WAAM): A review. Appl. Sci. 2021, 11, 8619. [Google Scholar] [CrossRef]

- Horgar, A.; Fostervoll, H.; Nyhus, B.; Ren, X.; Eriksson, M.; Akselsen, O. Additive manufacturing using WAAM with AA5183 wire. J. Mater. Process. Technol. 2018, 259, 68–74. [Google Scholar] [CrossRef]

- Taheri, H.; Dababneh, F.; Weaver, G.; Butsch, B. Assessment of material property variations with resonant ultrasound spectroscopy (RUS) when using additive manufacturing to print over existing parts. J. Adv. Join. Process. 2022, 5, 100117. [Google Scholar] [CrossRef]

- Shah, A.; Aliyev, R.; Zeidler, H.; Krinke, S. A review of the recent developments and challenges in wire arc additive manufacturing (WAAM) process. J. Manuf. Mater. Process. 2023, 7, 97. [Google Scholar] [CrossRef]

- Jin, W.; Zhang, C.; Jin, S.; Tian, Y.; Wellmann, D.; Liu, W. Wire arc additive manufacturing of stainless steels: A review. Appl. Sci. 2020, 10, 1563. [Google Scholar] [CrossRef]

- Astafurov, S.; Astafurova, E. Phase composition of austenitic stainless steels in additive manufacturing: A review. Metals 2021, 11, 1052. [Google Scholar] [CrossRef]

- Zhang, D.; Liu, A.; Yin, B.; Wen, P. Additive manufacturing of duplex stainless steels—A critical review. J. Manuf. Process. 2022, 73, 496–517. [Google Scholar] [CrossRef]

- Gatto, M.L.; Santoni, A.; Santecchia, E.; Spigarelli, S.; Fiori, F.; Mengucci, P.; Cabibbo, M. The potential of duplex stainless steel processed by laser powder bed fusion for biomedical applications: A review. Metals 2023, 13, 949. [Google Scholar] [CrossRef]

- Backhouse, A.; Baddoo, N. Recent developments of stainless steels in structural applications. ce/papers 2021, 4, 2349–2355. [Google Scholar] [CrossRef]

- Wahsh, L.; ElShater, A.; Mansour, A.; Hamdy, F.; Turky, M.; Azzam, M.; ElShater, A. Parameter selection for wire arc additive manufacturing (WAAM) process. Mater. Sci. Technol. 2018, 78–85. [Google Scholar] [CrossRef]

- Chaudhari, R.; Parmar, H.; Vora, J.; Patel, V.K. Parametric study and investigations of bead geometries of GMAW-based wire–arc additive manufacturing of 316L stainless steels. Metals 2022, 12, 1232. [Google Scholar] [CrossRef]

- Belotti, L.P.; Van Dommelen, J.; Geers, M.; Goulas, C.; Ya, W.; Hoefnagels, J. Microstructural characterisation of thick-walled wire arc additively manufactured stainless steel. J. Mater. Process. Technol. 2022, 299, 117373. [Google Scholar] [CrossRef]

- Kumar, V.; Mandal, A.; Das, A.K.; Kumar, S. Parametric study and characterization of wire arc additive manufactured steel structures. Int. J. Adv. Manuf. Technol. 2021, 115, 1723–1733. [Google Scholar] [CrossRef]

- Mai, D.S.; Doan, T.K.; Paris, H. Wire and arc additive manufacturing of 308L stainless steel components: Optimization of processing parameters and material properties. Eng. Sci. Technol. Int. J. 2021, 24, 1015–1026. [Google Scholar] [CrossRef]

- Chaudhari, R.; Bhatt, R.; Vaghasia, V.; Raja, B.D.; Patel, V.K.; Khanna, S.; Vora, J.; Patel, V.V. A parametric study and experimental investigations of microstructure and mechanical properties of multi-layered structure of metal core wire using wire arc additive manufacturing. J. Adv. Join. Process. 2023, 8, 100160. [Google Scholar] [CrossRef]

- Jagdale, M.; Ambhore, N.; Chaudhari, R.; Kulkarni, A.; Abdullah, M. Experimental investigation of process parameters in Wire-EDM of Ti-6Al-4 V. Sci. Rep. 2025, 15, 5652. [Google Scholar] [CrossRef]

- Chen, H.-J.; Lin, H.-C.; Tang, C.-W. Application of the Taguchi method for optimizing the process parameters of producing controlled low-strength materials by using dimension stone sludge and lightweight aggregates. Sustainability 2021, 13, 5576. [Google Scholar] [CrossRef]

- Majumder, H.; Maity, K. Prediction and optimization of surface roughness and micro-hardness using grnn and MOORA-fuzzy-a MCDM approach for nitinol in WEDM. Measurement 2018, 118, 1–13. [Google Scholar] [CrossRef]

- Saha, A.; Majumder, H. Multi-attribute optimisation of submerged arc welding process parameters using Taguchi GRA-PCA hybrid approach. Aust. J. Mech. Eng. 2022, 20, 1207–1212. [Google Scholar] [CrossRef]

- Wu, B.; Pan, Z.; Ding, D.; Cuiuri, D.; Li, H.; Xu, J.; Norrish, J. A review of the wire arc additive manufacturing of metals: Properties, defects and quality improvement. J. Manuf. Process. 2018, 35, 127–139. [Google Scholar] [CrossRef]

- Giarollo, D.F.; Mazzaferro, C.C.P.; Mazzaferro, J.A.E. Comparison between two heat source models for wire-arc additive manufacturing using GMAW process. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 7. [Google Scholar] [CrossRef]

- Pan, Z.; Ding, D.; Wu, B.; Cuiuri, D.; Li, H.; Norrish, J. Arc welding processes for additive manufacturing: A review. In Transactions on Intelligent Welding Manufacturing; Springer: Singapore, 2018; pp. 3–24. [Google Scholar]

- Chaturvedi, M.; Scutelnicu, E.; Rusu, C.C.; Mistodie, L.R.; Mihailescu, D.; Subbiah, A.V. Wire arc additive manufacturing: Review on recent findings and challenges in industrial applications and materials characterization. Metals 2021, 11, 939. [Google Scholar] [CrossRef]

- Paskual, A.; Álvarez, P.; Suárez, A. Study on arc welding processes for high deposition rate additive manufacturing. Procedia CIRP 2018, 68, 358–362. [Google Scholar] [CrossRef]

- Rauch, M.; Nwankpa, U.V.; Hascoet, J.-Y. Investigation of deposition strategy on wire and arc additive manufacturing of aluminium components. J. Adv. Join. Process. 2021, 4, 100074. [Google Scholar] [CrossRef]

- Lee, S.H. Optimization of cold metal transfer-based wire arc additive manufacturing processes using gaussian process regression. Metals 2020, 10, 461. [Google Scholar] [CrossRef]

- Vaghasia, V.; Chaudhari, R.; Patel, V.K.; Vora, J. Parametric Study on Investigations of GMAW-Based WAAM Process Parameters and Effect on Microstructure and Mechanical Properties of NiTi SMA. J. Manuf. Mater. Process. 2025, 9, 58. [Google Scholar] [CrossRef]

- Chaudhari, R.; Vora, J.J.; Mani Prabu, S.; Palani, I.; Patel, V.K.; Parikh, D.; de Lacalle, L.N.L. Multi-response optimization of WEDM process parameters for machining of superelastic nitinol shape-memory alloy using a heat-transfer search algorithm. Materials 2019, 12, 1277. [Google Scholar] [CrossRef]

- Sinha, A.; Majumder, A.; Barma, J.D.; Majumder, H. Investigation of surface defects of EDMed monel 400 and process optimization using K-fold NN-integrated MOBO. Surf. Rev. Lett. 2025, 2550174. [Google Scholar] [CrossRef]

- Bansal, S.; Singh, G. (Eds.) Multiple linear regression based analysis of weather data: Assumptions and limitations. In Proceedings of the International Conference on Advanced Communication and Intelligent Systems, Warsaw, Poland, 16–17 June 2023; Springer: Cham, Switzerland, 2023. [Google Scholar]

- Magabe, R.; Sharma, N.; Gupta, K.; Paulo Davim, J. Modeling and optimization of Wire-EDM parameters for machining of Ni 55.8 Ti shape memory alloy using hybrid approach of Taguchi and NSGA-II. Int. J. Adv. Manuf. Technol. 2019, 102, 1703–1717. [Google Scholar] [CrossRef]

- Chantarangsi, W.; Liu, W.; Bretz, F.; Kiatsupaibul, S.; Hayter, A.J. Normal probability plots with confidence for the residuals in linear regression. Commun. Stat.-Simul. Comput. 2018, 47, 367–379. [Google Scholar] [CrossRef]

- Vora, J.; Shah, Y.; Khanna, S.; Patel, V.K.; Jagdale, M.; Chaudhari, R. Multi-response optimization and influence of expanded graphite on performance of WEDM process of Ti6Al4V. J. Manuf. Mater. Process. 2023, 7, 111. [Google Scholar] [CrossRef]

| Elem. | Cr | Ni | Mo | Mn | Si | C | P | S | N | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| Wt. % | 17.09 | 10.61 | 2.38 | 1.17 | 0.59 | 0.013 | 0.011 | 0.011 | 0.09 | Bal. |

| WAAM Input Parameters | Unit | Values |

|---|---|---|

| Travel Speed (mm/s) | mm/s | 20; 22; 24 |

| Voltage (V) | V | 24; 26; 28 |

| Gas Mixture Ratio | - | 1; 3; 5 |

| Sr. No. | Voltage (V) | GMR | Travel Speed (mm/s) | BH (mm) | BW (mm) |

|---|---|---|---|---|---|

| 1 | 20 | 1 | 24 | 5.63 | 7.33 |

| 2 | 20 | 3 | 26 | 4.52 | 6.75 |

| 3 | 20 | 5 | 28 | 3.94 | 6.23 |

| 4 | 22 | 1 | 26 | 4.32 | 8.31 |

| 5 | 22 | 3 | 28 | 3.91 | 7.84 |

| 6 | 22 | 5 | 24 | 5.81 | 7.72 |

| 7 | 24 | 1 | 28 | 3.21 | 9.46 |

| 8 | 24 | 3 | 24 | 4.79 | 9.24 |

| 9 | 24 | 5 | 26 | 4.06 | 8.98 |

| Source | DF | SS | MS | F | P | Significance | % Contr. |

|---|---|---|---|---|---|---|---|

| For BH | |||||||

| Regression | 3 | 5.2120 | 1.7373 | 21.37 | 0.003 | Significant | |

| TS | 1 | 4.4548 | 4.4548 | 54.79 | 0.001 | Significant | 81.48% |

| Voltage | 1 | 0.6868 | 0.6868 | 8.45 | 0.034 | Significant | 15.91% |

| GMR | 1 | 0.0704 | 0.0704 | 0.87 | 0.395 | Insignificant | 1.53% |

| Error | 5 | 0.4066 | 0.0813 | 1.08% | |||

| Total | 8 | 5.6186 | |||||

| R2 = 92.76%; R2 (Adj.) = 88.42%. | |||||||

| For BW | |||||||

| Regression | 3 | 9.9339 | 3.3113 | 436.59 | 0.000 | Significant | |

| TS | 1 | 0.0962 | 0.0962 | 12.69 | 0.016 | Significant | 0.96% |

| Voltage | 1 | 9.0528 | 9.0528 | 1193.6 | 0.000 | Significant | 90.78% |

| GMR | 1 | 0.7848 | 0.7848 | 103.48 | 0.000 | Significance | 7.87% |

| Error | 5 | 0.0379 | 0.0075 | 0.39% | |||

| Total | 8 | 9.9718 | |||||

| R2 = 99.62%; R2 (Adj.) = 99.39%. | |||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vaghasia, V.; Vora, J.; Jagdale, M.; Shinde, Y.; Chaudhari, R. A Parametric Study Investigating the Effect of Bead Morphologies of SS316L Through the GMAW Process. Eng. Proc. 2025, 114, 13. https://doi.org/10.3390/engproc2025114013

Vaghasia V, Vora J, Jagdale M, Shinde Y, Chaudhari R. A Parametric Study Investigating the Effect of Bead Morphologies of SS316L Through the GMAW Process. Engineering Proceedings. 2025; 114(1):13. https://doi.org/10.3390/engproc2025114013

Chicago/Turabian StyleVaghasia, Vatsal, Jay Vora, Manoj Jagdale, Yogita Shinde, and Rakesh Chaudhari. 2025. "A Parametric Study Investigating the Effect of Bead Morphologies of SS316L Through the GMAW Process" Engineering Proceedings 114, no. 1: 13. https://doi.org/10.3390/engproc2025114013

APA StyleVaghasia, V., Vora, J., Jagdale, M., Shinde, Y., & Chaudhari, R. (2025). A Parametric Study Investigating the Effect of Bead Morphologies of SS316L Through the GMAW Process. Engineering Proceedings, 114(1), 13. https://doi.org/10.3390/engproc2025114013