Application of the 5S Technique of Lean Manufacturing to Organize a Laboratory Space and Enhance Productivity Towards a Green University †

Abstract

1. Introduction

- Insufficient interest from senior management.

- Inability of top management to foster and support teamwork initiatives.

- Limited availability of necessary resources.

- Lack of efficient communication channels within the organization.

- Low employee motivation.

- Inadequate training provided to employees.

- Absence of a Kaizen mindset and teamwork culture among employees.

- Some employees perceive that their primary responsibility is productivity rather than organization and cleanliness.

- Secure commitment from top management.

- Educating everyone on 5S principles.

- Develop a promotional campaign.

- Maintain records.

- Provide 5S training for implementation.

- Assess the 5S program’s effectiveness and conduct regular audits.

2. Literature Review

3. Problem Statement and Objectives

- To identify sources of waste in a disorganized lab environment.

- To successfully implement the 5S methodology to reduce waste, improve workflow, and maintain a clean and organized workspace.

- To implement visual management to enhance workflow transparency and improve lab efficiency.

- To remove identified inefficiencies to finally improve the efficiency of the lab.

- To provide recommendations for labs on effectively implementing lean manufacturing techniques to optimize their operations.

4. Methodology

- Why did this happen? The lab suffered from low storage density, clutter, and a dangerous environment for occupants.

- Why did this arise within the lab? There was no system for cleaning or removing unnecessary items.

- Why were procedures not being changed? No standard operating procedures existed to maintain cleanliness or organization.

- Why has no new system been implemented? Establishing such a system is a difficult task without proper guidance.

- Why is it difficult to organize the lab? Success requires the implementation of structured lean tools like 5S, which had not yet been introduced.

4.1. Implementation of Seiri

- Step 1

- All tools, equipment, and materials in the lab were evaluated and categorized based on their utility. The items were divided into three groups: items essential for current projects, items that could be used but were not currently needed, and broken, obsolete, or unnecessary items.

- Items that were broken or outdated were marked for removal, while those still functional but not needed were temporarily set aside for storage in another location.

- Step 2

- Some items like basin, cabinet door, and glasses, while in good condition, did not belong to the lab under investigation due to their irrelevance to ongoing projects. These items were sorted and relocated to designated storage areas of which in this case was floor storage.

- Step 3

- Once all non-essential items such as extra small tables and chairs were removed, the remaining equipment and tools were placed in a signeted areas for better arrangements to create a cleaner and more spacious environment. This allowed for easier movement and improved the overall workflow for students and lab staff.

- Step 4

- The necessary materials were placed on the table for easy reach, and the less used materials were placed on the floor and the one that are to be removed from the lab were placed outside.

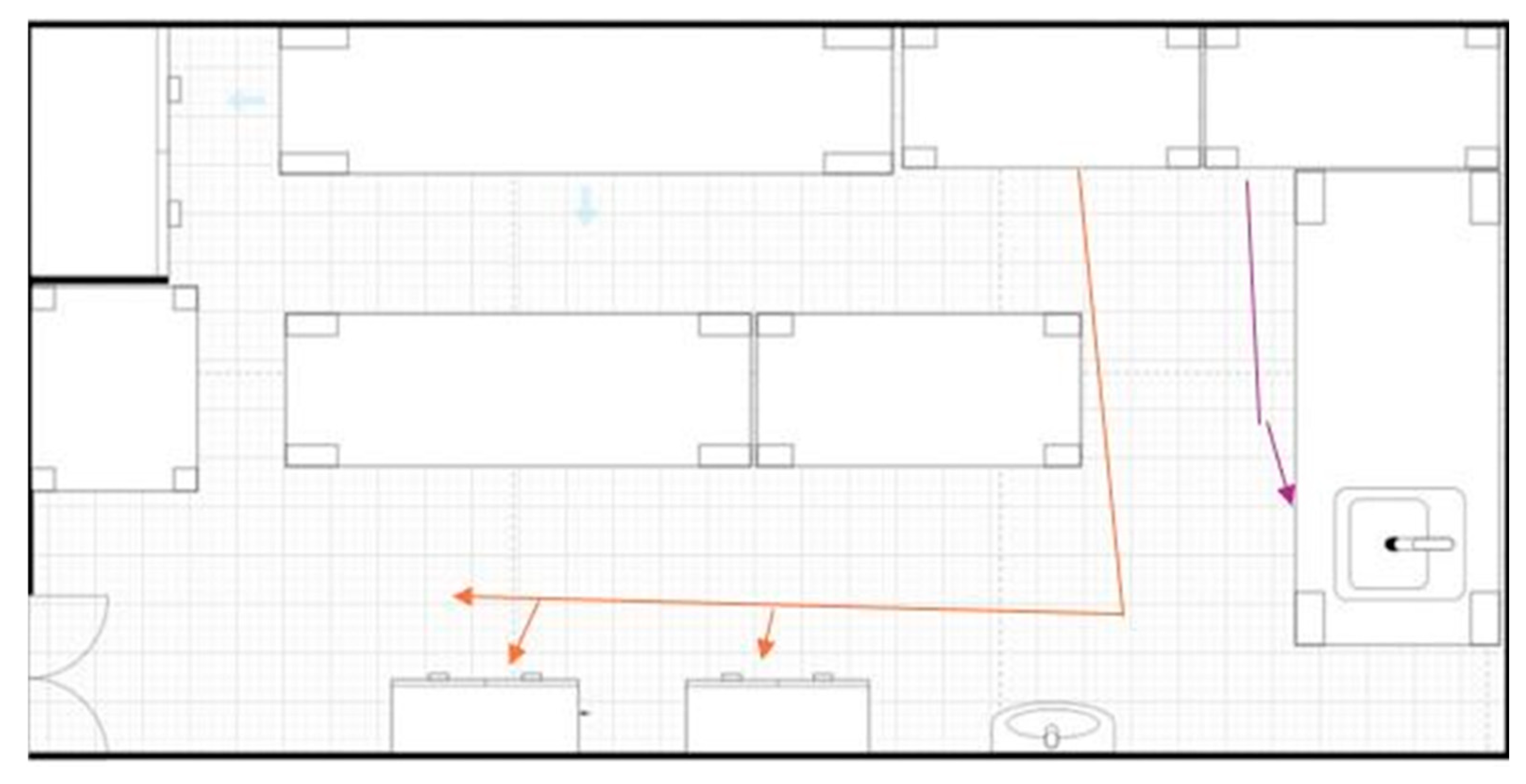

4.2. Implementation of Seiton

- Step 1

- Step 2

- Step 3

- Step 4

4.3. Implementation of Seiso

- Step 1

- Step 2

- After the cleaning equipment had been organized, we then started sweeping the floor using a broomstick and picking up the plastics and pieces of paper on the floor.

- After sweeping the floor, we then used a mop to mop the floor, ensuring that the floor is clean and efficient.

- We dusted the tables and windows to make sure the lab was clean and in good condition.

- Step 3

- After completing the cleaning procedure, the lab felt like a completely different space. The entire workshop was spotless, with everything looking bright and fresh. There was no trace of dust or stains, and the air was filled with a clean, refreshing scent. The space now felt more open and organized, giving the workshop a new, more welcoming atmosphere for all who work there.

- Step 4

4.4. Implementation of Seiketsu

- Step 1

- In the Seiketsu phase, material and tools are standardized in the lab by designating specific areas for all items that are still in use.

- This step involved more than just assigning places; it was about creating a consistent, efficient system.

- We realized that some additional materials were required to properly implement this standardization, so we carefully planned and analyzed what would work best for this lab setup.

- Step 2

- The materials used for Seiketsu included plastic bins for organizing small tools like screws, tools, and small equipment that were not used.

- Step 3

- Any misplaced or unidentified materials were tagged and relocated to their proper spots.

- The most important and frequently used items were placed in easily accessible areas, making it simple to find and use them when needed.

4.5. Implementation of Shitsuke

- Step 1

- Step 2

- Step 3

5. Results and Discussion

6. Conclusions

- Improved lab organization and space management have been achieved by strategically placing tools and materials at their designated spots with a more efficient workflow. Further, this reconfiguration reduced the time spent searching for equipment and minimized movement between workstations, leading to a notable boost in the lab’s productivity and functionality.

- Total time taken to complete tasks before 4S implementation was 1069 s, whereas post-implementation, it was reduced to 437 s.

- A 78.6 sec improvement per task on average has been achieved by 5S implementation, as the average time per task before implementation was 133.2 s and after implementation 54.6 s. A total of 632 s per week in savings has been achieved.

- Improvement in operating efficiency with 54.08% has been achieved by 5S, as it was 37.42% before implementation and 91.5% after implementation.

- All users have been successfully trained on maintaining the labs and the importance of the implementation of 5S. Schedules related to maintaining 5S implementation were created and communicated to the users.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ribeiro, P.; Sá, J.C.; Ferreira, L.P.; Silva, F.J.G.; Pereira, M.T.; Santos, G. The Impact of the Application of Lean Tools for Improvement of Process in a Plastic Company: A case study. Procedia Manuf. 2019, 38, 765–775. [Google Scholar] [CrossRef]

- Taylor, A. Lean management practices in food manufacturing: A systematic review. J. Food Prod. Eff. 2019, 34, 120–135. [Google Scholar]

- Chiromo, F.; Msibi, N. Internal audit program planning and implementation determinants of an automotive company’s ISO 9001 quality system. J. Appl. Res. Ind. Eng. 2023, 10, 492–505. [Google Scholar]

- Rahmanasari, D.; Sutopo, W.; Rohani, J.M. Implementation of Lean Manufacturing Process to Reduce Waste: A Case Study. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1096, 012006. [Google Scholar] [CrossRef]

- Muotka, S.; Togiani, A.; Varis, J. A Design Thinking Approach: Applying 5S Methodology Effectively in an Industrial Work Environment. Procedia CIRP 2023, 119, 363–370. [Google Scholar] [CrossRef]

- Marcelino, S.M.; Lima, T.M.; Gaspar, P.D. Lean Laboratory—Designing an Application of Lean for Teaching and Research Laboratories. Designs 2023, 7, 17. [Google Scholar] [CrossRef]

- Sharma, K.M.; Lata, S. Effectuation of Lean Tool “5S” on Materials and Work Space Efficiency in a Copper Wire Drawing Micro-Scale Industry in India. Mater. Today Proc. 2018, 5, 4678–4683. [Google Scholar] [CrossRef]

- Mazur, M.; Korenko, M.; Zitnak, M.; Shchur, T.; Kielbasa, P.; Dostal, P.; Dzhidzhora, O.; Idzikowski, A. Implementation and Benefits of the 5S Method in Improving Workplace Organisation—A Case Study. Manag. Syst. Prod. Eng. 2024, 32, 498–507. [Google Scholar] [CrossRef]

- Bhamu, J.; Sangwan, K.S. Lean manufacturing: Literature review and research issues. Int. J. Oper. Prod. Manag. 2019, 34, 876–940. [Google Scholar] [CrossRef]

- Chen, S.; Ma, X.; Yang, L. Impact of lean tools on safety and productivity: A case study of automotive industry. J. Manuf. Syst. 2020, 54, 179–190. [Google Scholar]

- Gupta, S.; Jain, P.K. Application of 5S methodology in SME: A case study. J. Ind. Eng. Manag. 2021, 14, 325–344. [Google Scholar]

- Rahman, S.; Islam, R.; Hasan, M. Adapting 5S principles in small-scale manufacturing: A comparative study. Prod. Plan. Control 2022, 33, 710–722. [Google Scholar]

- Johnson, A.; Roberts, D.; Lee, S. Application of 5S in healthcare: A case study on improving efficiency and reducing errors in medical supply management. Int. J. Healthc. Manag. 2019, 12, 198–208. [Google Scholar]

- Shahriar, M.M.; Parvez, M.S.; Islam, M.A.; Talapatra, S. Implementation of 5S in a plastic bag manufacturing industry: A case study. Clean. Eng. Technol. 2022, 8, 100488. [Google Scholar] [CrossRef]

- Choomlucksana, J.; Ongsaranakorn, M. Improving the productivity of sheet metal stamping subassembly area using the application of lean manufacturing principles. Procedia Manuf. 2015, 2, 102–107. [Google Scholar] [CrossRef]

- Senthilkumar, K.M.; Akila, K.; Arun, K.K.; Prabhu, S.; Selvakumar, C. Implementation of 5S practices in a small-scale manufacturing industries. Mater. Today Proc. 2022, 62, 1913–1916. [Google Scholar] [CrossRef]

- Subburaman, K. A Case study of 5S Implementation in Inspection Process. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Bangkok, Thailand, 5–7 March 2019; pp. 1514–1519. [Google Scholar]

- Sari, A.D.; Rahmillah, F.I.; Aji, B.P. Implementation of 5S Method for Ergonomic Laboratory. IOP Conf. Ser. Mater. Sci. Eng. 2017, 215, 012032. [Google Scholar] [CrossRef]

- Jiménez, M.; Romero, L.; Domínguez, M.; Espinosa, M.D.M. 5S methodology implementation in the laboratories of an industrial engineering university school. Saf. Sci. 2015, 78, 163–172. [Google Scholar] [CrossRef]

| Activity | Before (s) |

|---|---|

| Reaching for the cabinets | 74 |

| Searching for equipment | 240 |

| Walking to the workstation | 90 |

| Arranging tools at the workstation | 180 |

| Returning tools to their location | 110 |

| Cleaning the workstation after use | 150 |

| Fetching materials from storage | 95 |

| Setting up equipment for a task | 130 |

| Total | 1069 |

| Activity | After (s) |

|---|---|

| Reaching for the cabinets | 35 |

| Searching for equipment | 62 |

| Walking to the workstation | 45 |

| Arranging tools at the workstation | 80 |

| Returning tools to their location | 50 |

| Cleaning the workstation after use | 70 |

| Fetching materials from storage | 40 |

| Setting up equipment for a task | 55 |

| Total | 437 |

| 5S Tasks | Daily | Weekly | Monthly | Quarterly |

|---|---|---|---|---|

| Inventory review- are all the items in the lab essential | ||||

| Tables and cabinets cleaning | ||||

| Floor cleaning | ||||

| Tools and equipment cleaned and put away | ||||

| clearing dust | ||||

| Ensure labels are clear and visible | ||||

| Conduct 5S audits |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mabusela, L.; Nkosi, M.; Gupta, K. Application of the 5S Technique of Lean Manufacturing to Organize a Laboratory Space and Enhance Productivity Towards a Green University. Eng. Proc. 2025, 114, 12. https://doi.org/10.3390/engproc2025114012

Mabusela L, Nkosi M, Gupta K. Application of the 5S Technique of Lean Manufacturing to Organize a Laboratory Space and Enhance Productivity Towards a Green University. Engineering Proceedings. 2025; 114(1):12. https://doi.org/10.3390/engproc2025114012

Chicago/Turabian StyleMabusela, Lehlogonolo, Mfundo Nkosi, and Kapil Gupta. 2025. "Application of the 5S Technique of Lean Manufacturing to Organize a Laboratory Space and Enhance Productivity Towards a Green University" Engineering Proceedings 114, no. 1: 12. https://doi.org/10.3390/engproc2025114012

APA StyleMabusela, L., Nkosi, M., & Gupta, K. (2025). Application of the 5S Technique of Lean Manufacturing to Organize a Laboratory Space and Enhance Productivity Towards a Green University. Engineering Proceedings, 114(1), 12. https://doi.org/10.3390/engproc2025114012