Influence of T6 Heat Treatment on Densification, Mechanical, and Wear Behavior of Plantain Peel Ash Reinforced Aluminum Matrix Composites †

Abstract

1. Introduction

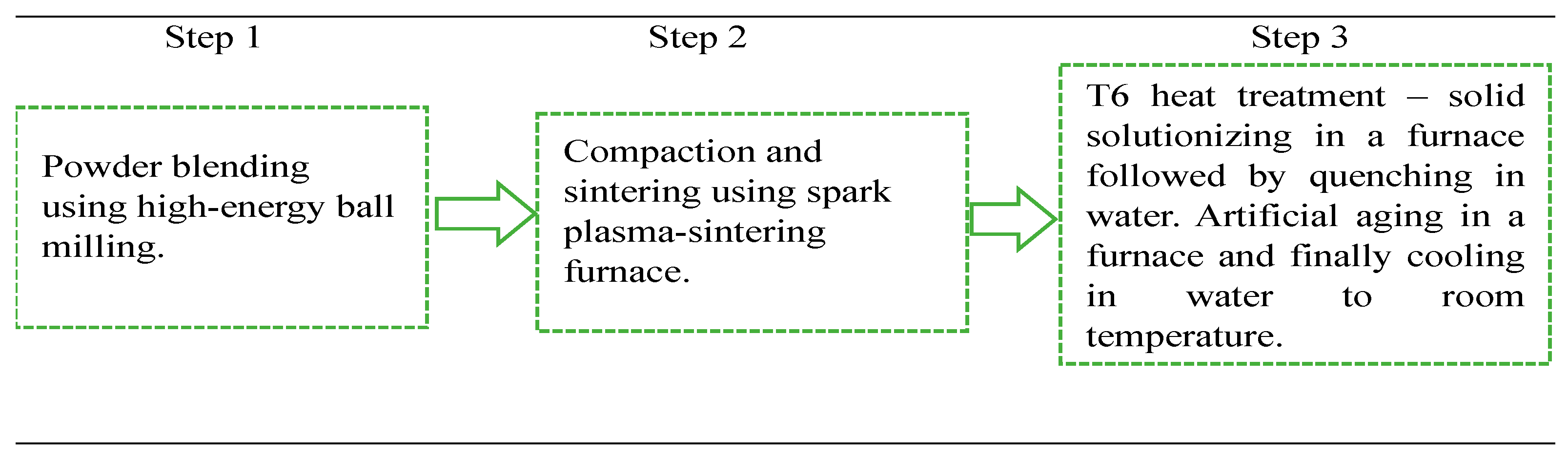

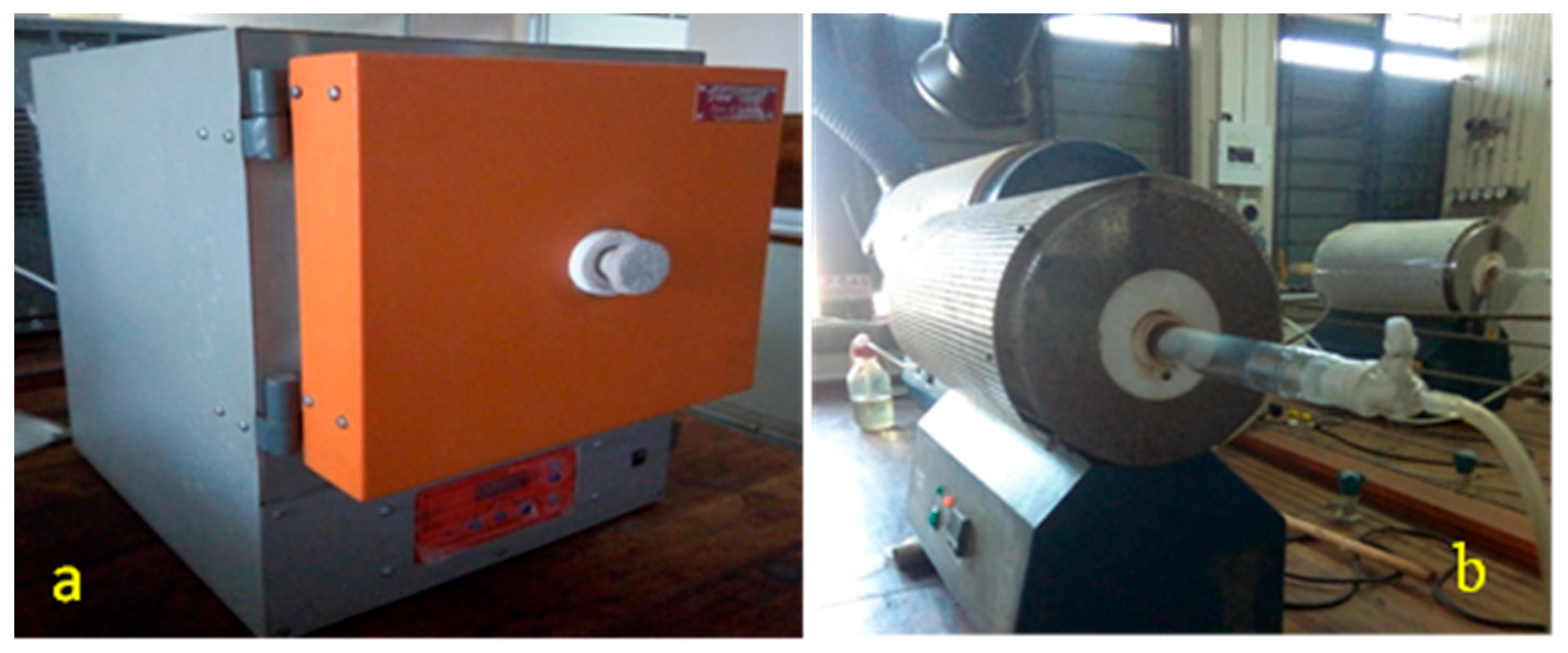

2. Materials and Methods

2.1. Heat Treatment of the Fabricated Composite Samples

| Al Matrix Composites | Solutionizing and Aging Temp. and Time (°C, h) | Designation |

|---|---|---|

| Al/2Mg | 500-5 h, 180-5 h | H1 |

| Al/2Mg/5PPA | 500-5 h, 180-5 h | H2 |

| Al/2Mg/10PPA | 500-5 h, 180-5 h | H3 |

| Al/2Mg/15PPA | 500-5 h, 180-5 h | H4 |

| Al/2Mg/20PPA | 500-5 h, 180-5 h | H5 |

2.2. Characterization of the Heat-Treated Composite Samples

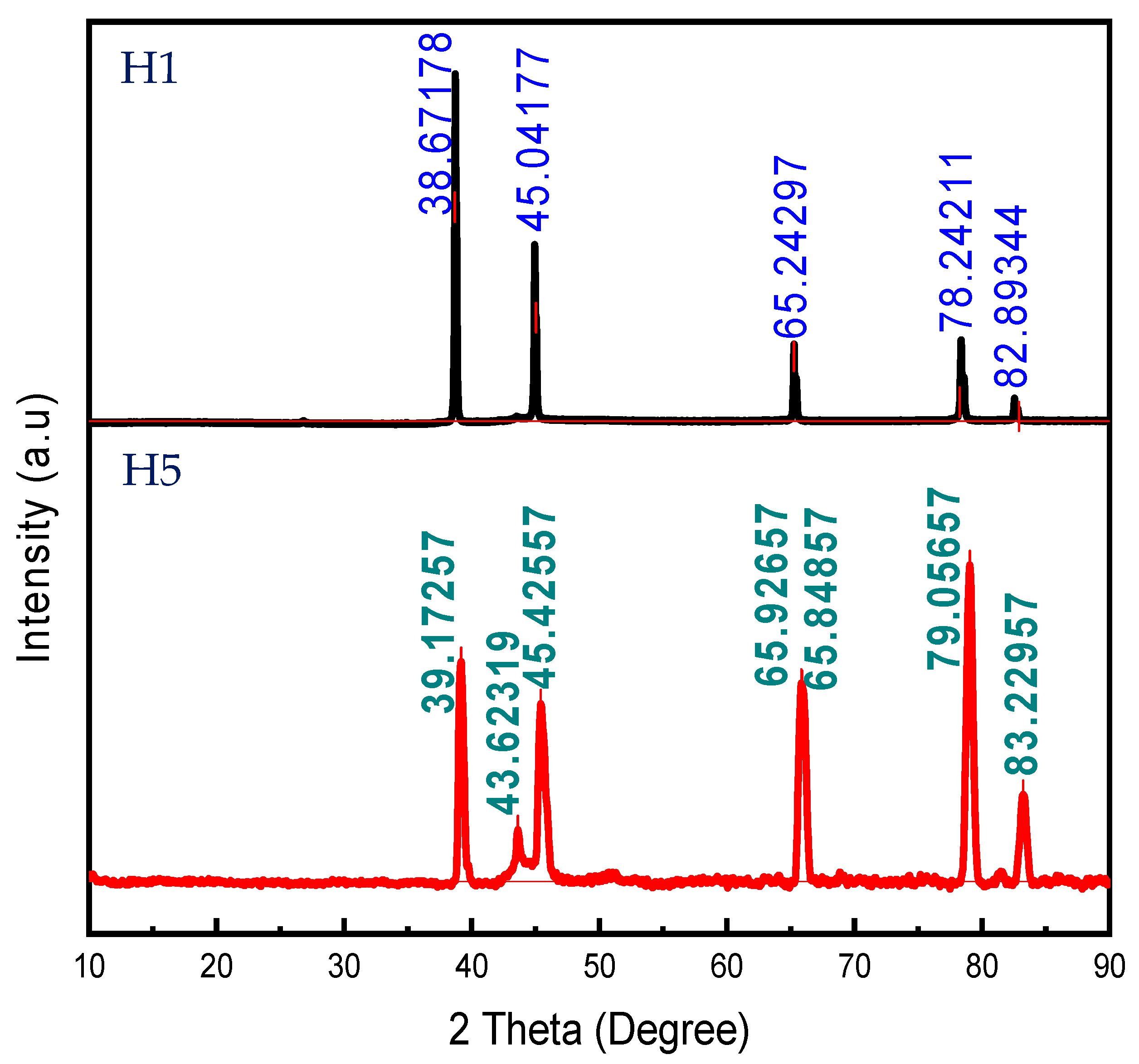

3. Results and Discussion

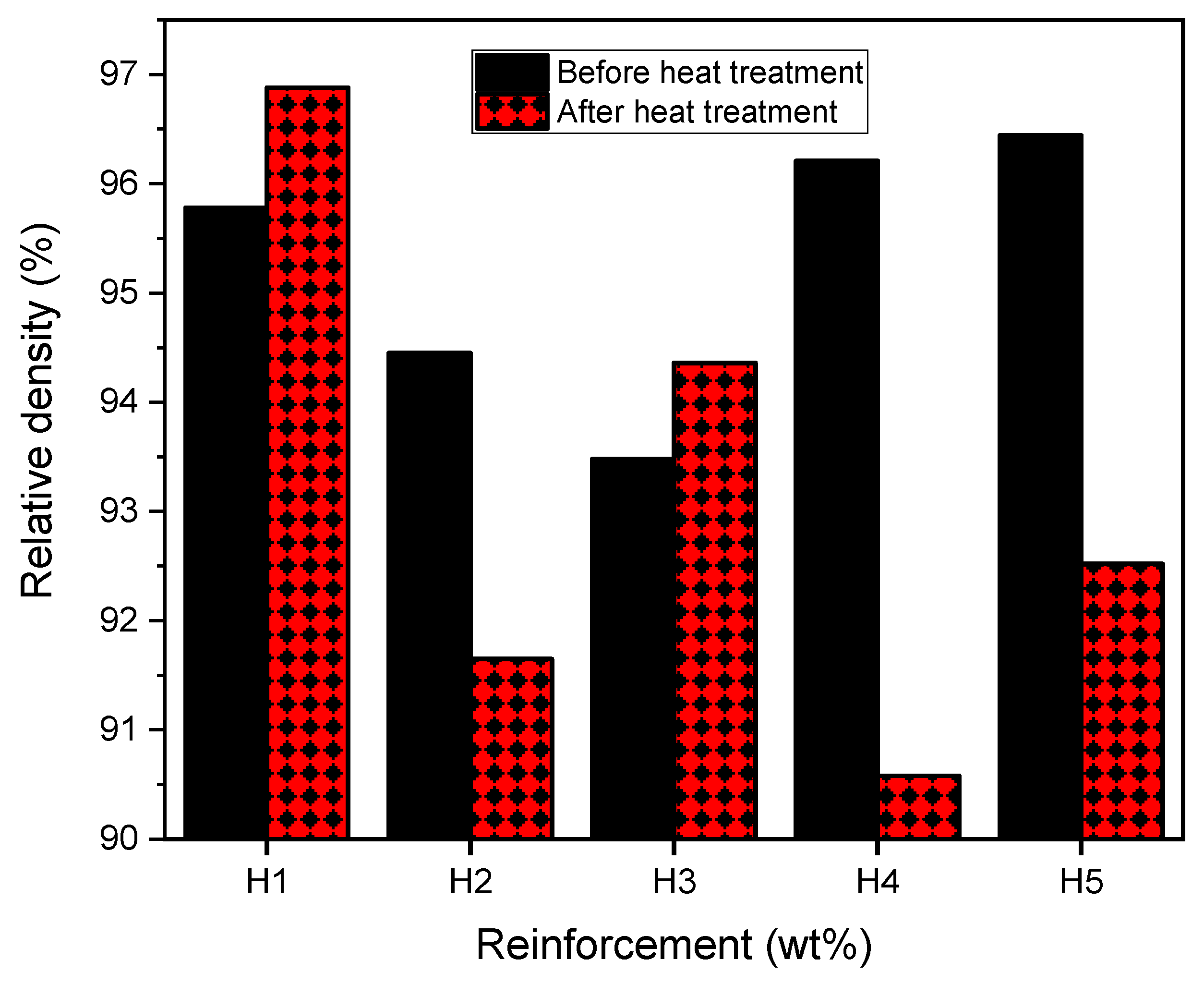

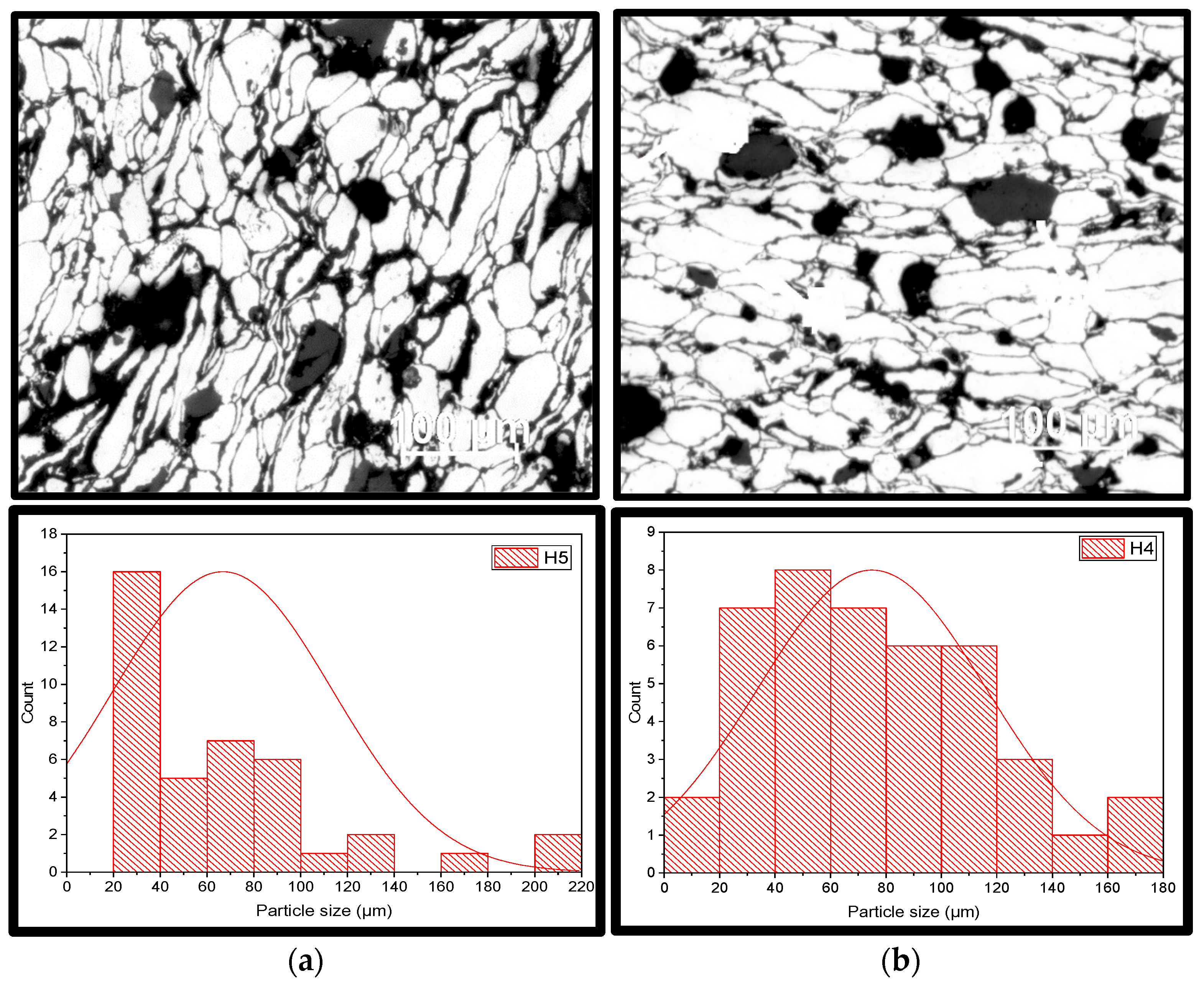

3.1. Effect of Heat Treatment on Relative Density

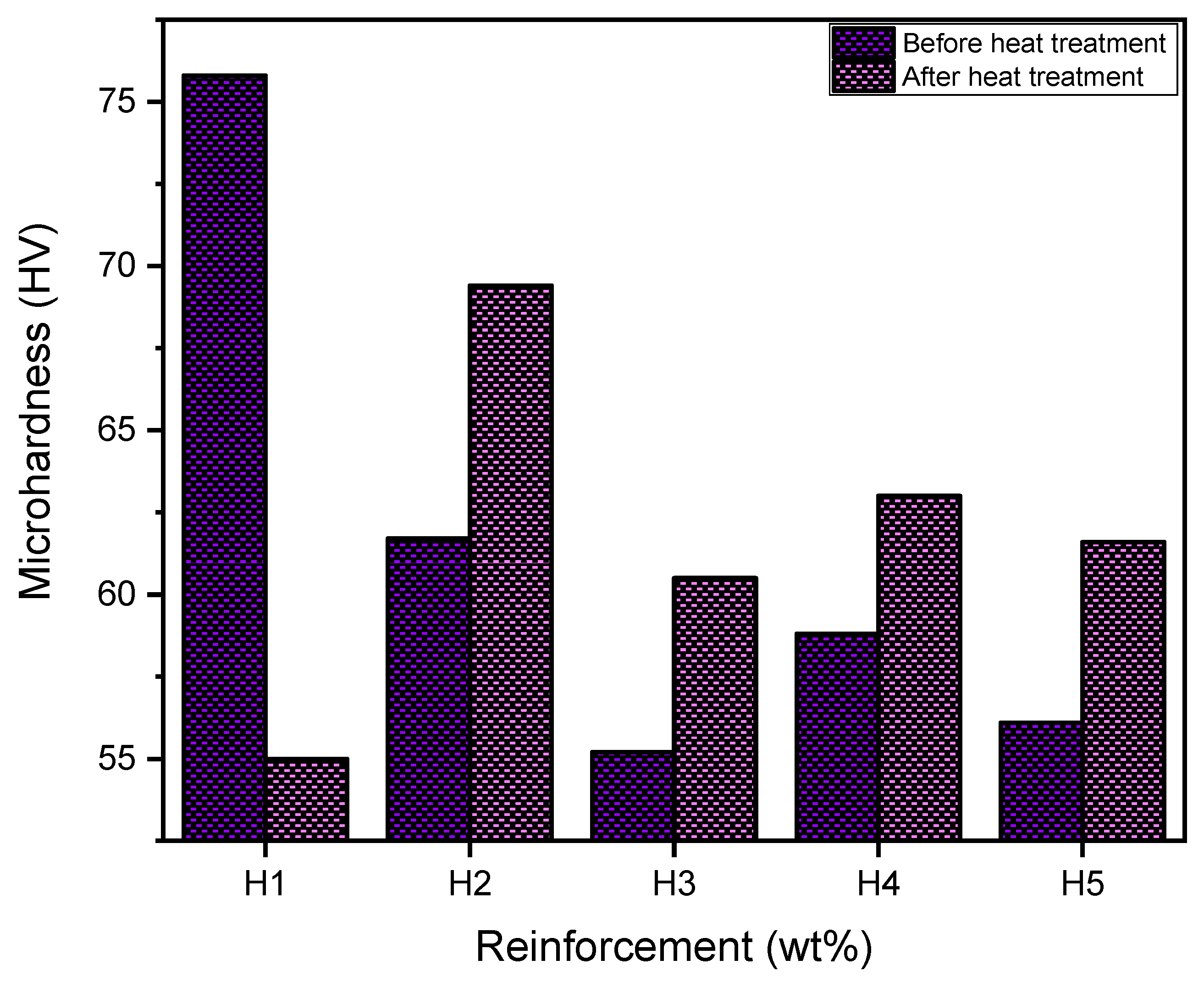

3.2. Effect of Heat Treatment on Hardness

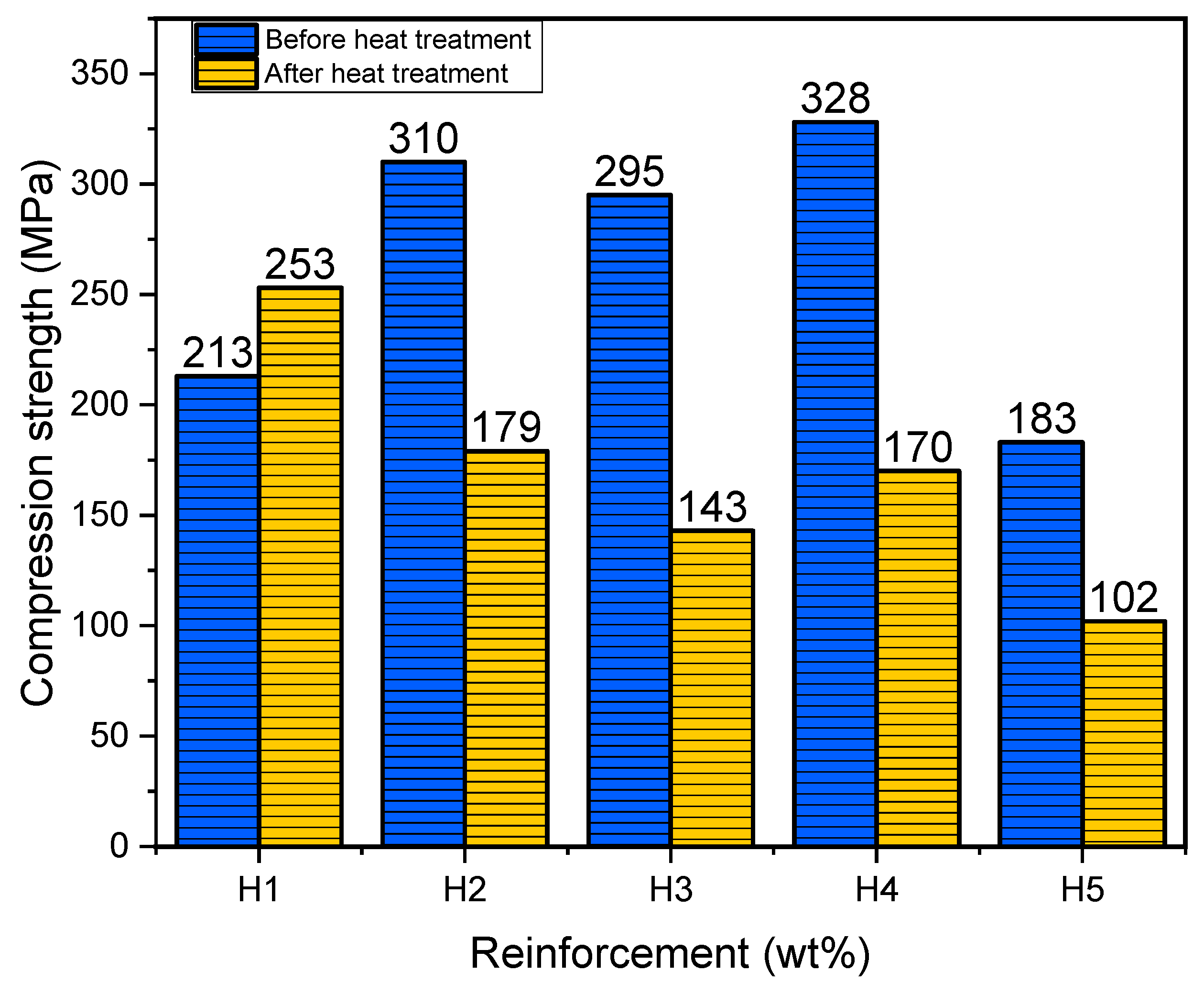

3.3. Effect of Heat Treatment on Compressive Strength

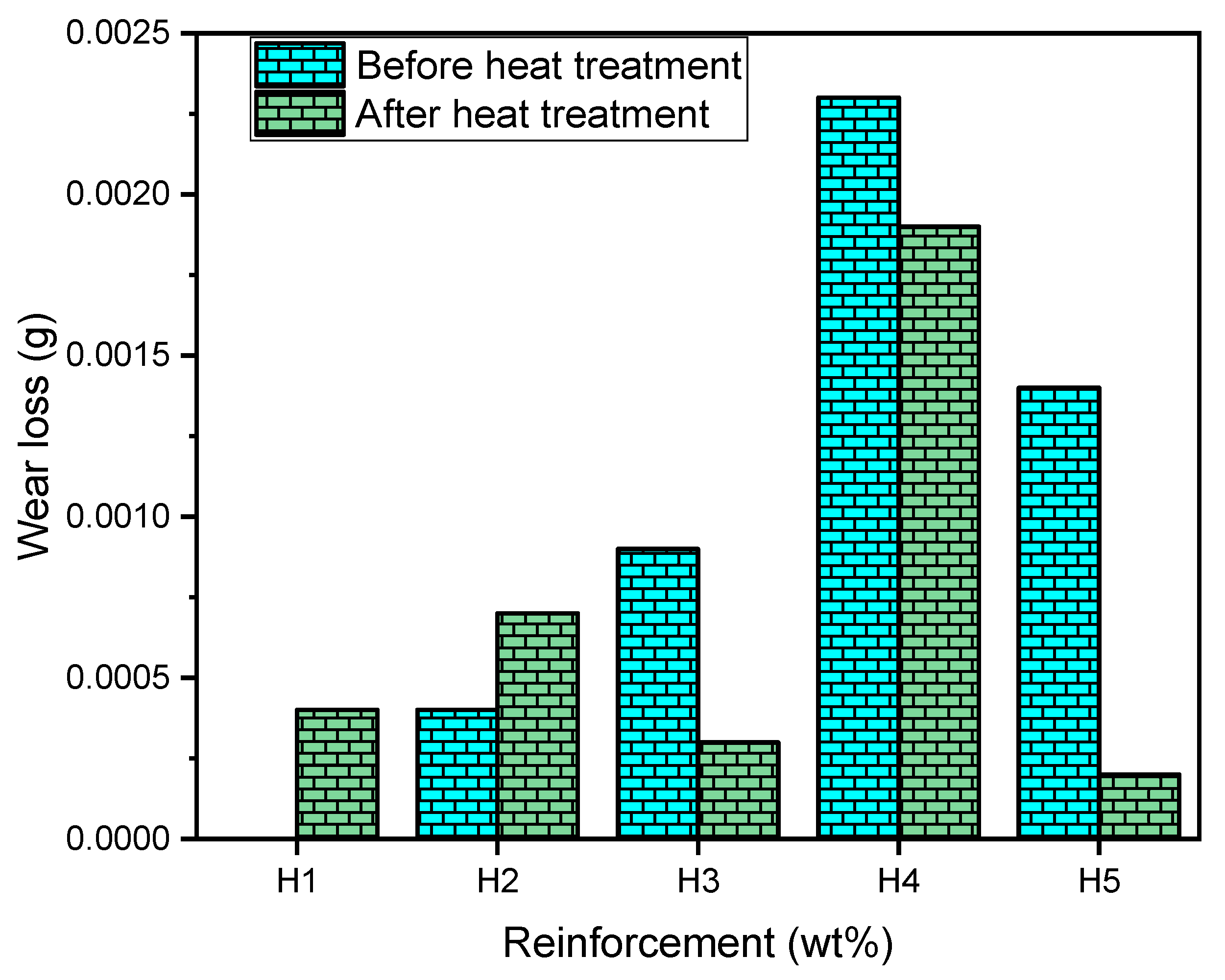

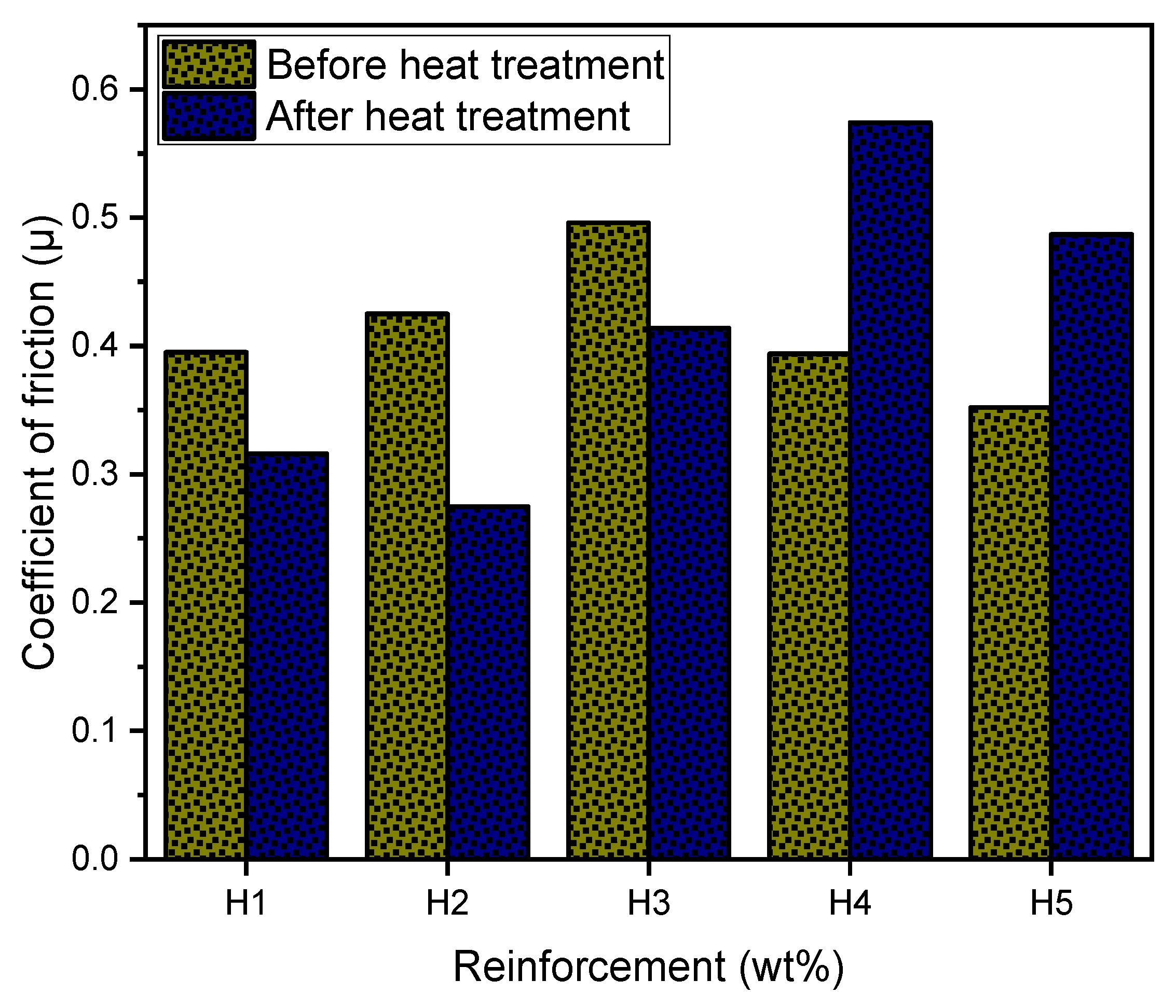

3.4. Effect of Heat Treatment on Wear Properties

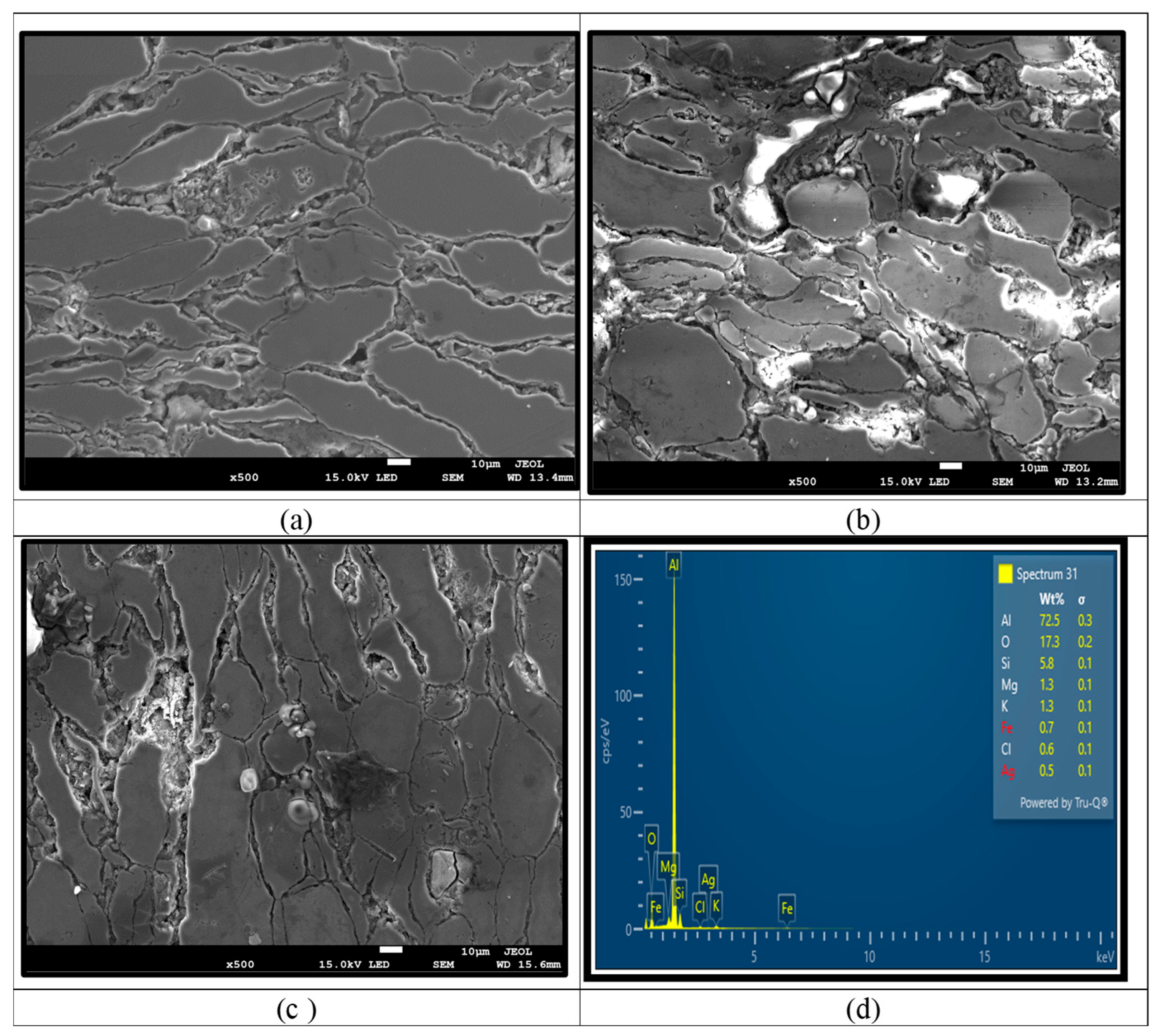

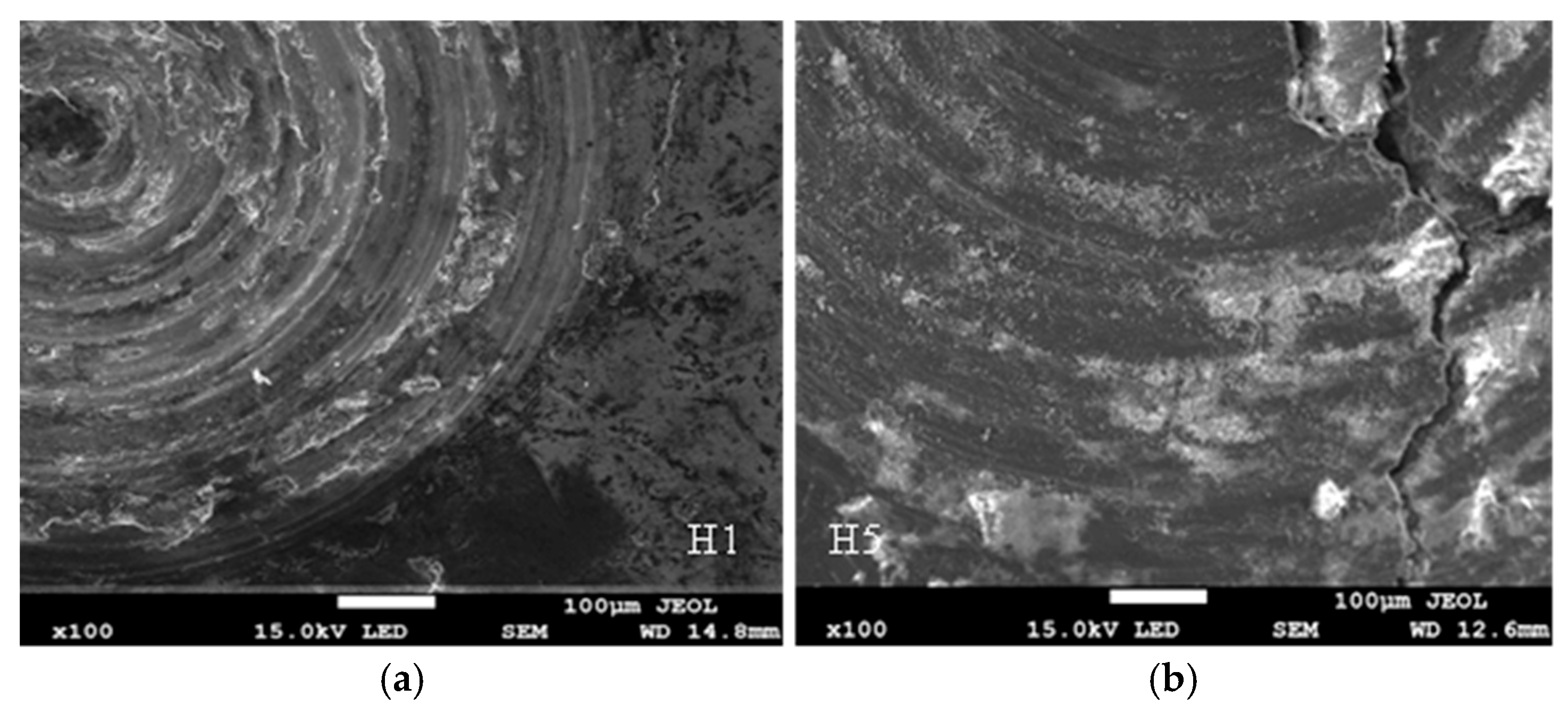

3.5. Worn Surface Morphology After Heat Treatment

3.6. Effect of Heat Treatment on Fracture Surfaces

4. Conclusions

- Porosity increased in most of the composite samples containing PPA reinforcement, whereas it reduced in sample H1 containing no PPA reinforcement.

- The hardness property of the samples reinforced with PPA improved after the heat treatment; however, the hardness of the sample not reinforced with PPA reduced.

- After the heat treatment, the compressive strength of the samples reinforced with PPA dropped significantly, while the compressive strength of the sample not reinforced with PPA increased considerably, possibly due to strain-hardening effect.

- The wear rate for samples reinforced with higher percentage weight fraction of PPA reduced, whereas it increased for samples reinforced with little to no PPA. The wear mechanism of the composites remains abrasive wear. Fracture surface analysis shows that the composite samples exhibited ductile-brittle fracture after the heat treatment.

- Finally, it is evident from the findings that the T6 heat treatment is not designed to improve all the properties of the composites, such as strength, hardness, and wear, simultaneously. Instead, it is tailored to enhance the hardness properties of the composites.

- Further study should be conducted to compare the effects of long and short solid solutionizing time during T6 heat treatment using agro-waste and synthetic reinforced AMC.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sharma, S.; Nanda, T.; Pandey, O.P. Heat Treatment T4 and T6 Effects on the Tribological Properties of Sillimanite Mineral-Reinforced LM30 Aluminum Alloy Composites at Elevated Temperatures. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2022, 236, 946–959. [Google Scholar] [CrossRef]

- Azadi, M.; Rezanezhad, S.; Zolfaghari, M.; Azadi, M. Investigation of Tribological and Compressive Behaviors of Al/SiO2 Nanocomposites after T6 Heat Treatment. Sādhanā 2020, 45, 1257. [Google Scholar] [CrossRef]

- Lakshmikanthan, A.; Prabhu, T.R.; Babu, U.S.; Koppad, P.G.; Gupta, M.; Krishna, M.; Bontha, S. The Effect of Heat Treatment on the Mechanical and Tribological Properties of Dual Size SiC Reinforced A357 Matrix Composites. J. Mater. Res. Technol. 2020, 9, 6434–6452. [Google Scholar] [CrossRef]

- Singh, M.; Biswas, A. Impact of Quenching on the Microstructure and Mechanical Properties of Hybrid Aluminum Matrix Composites (Al7075/SiC/TiB2). Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2025, 239, 1338. [Google Scholar] [CrossRef]

- Li, J.; Zhang, X.; Geng, L. Effect of Heat Treatment on Interfacial Bonding and Strengthening Efficiency of Graphene in GNP/Al Composites. Compos. Part A Appl. Sci. Manuf. 2019, 121, 487–498. [Google Scholar] [CrossRef]

- Fadare, D.A.; Fadara, T.G.; Akanbi, O.Y. Effect of Heat Treatment on Mechanical Properties and Microstructure of NST 37-2 Steel. J. Miner. Mater. Charact. Eng. 2011, 10, 299–308. [Google Scholar] [CrossRef]

- Pio, L.Y. Effect of T6 Heat Treatment on the Mechanical Properties of Gravity Die Cast A356 Aluminum Alloy. J. Appl. Sci. 2011, 11, 2048–2052. [Google Scholar] [CrossRef][Green Version]

- Ertugrul, O.; He, T.; Shahid, R.N.; Scudino, S. Effect of Heat Treatment on Microstructure and Mechanical Properties of Al 2024 Matrix Composites Reinforced with Ni60Nb40 Metallic Glass Particles. J. Alloys Compd. 2019, 808, 151732. [Google Scholar] [CrossRef]

- Kumar, L.V.S.; Prakrathi, S. Energy Conservation during Heat Treatment of A356 Aluminum Alloy. Int. J. Appl. Eng. Res. 2018, 13, 59–61. [Google Scholar]

- Wąsik, A.; Leszczyńska-Madej, B.; Madej, M.; Goły, M. Effect of Heat Treatment on Microstructure of Al4Cu–SiC Composites Consolidated by Powder Metallurgy Technique. J. Mater. Eng. Perform. 2020, 29, 1841–1848. [Google Scholar] [CrossRef]

- Mahan, H.M.; Konovalov, S.V.; Panchenko, I. Effect of Heat Treatment on the Mechanical Properties of the Aluminum Alloys AA2024 with Nanoparticles. Int. J. Appl. Sci. Eng. 2023, 20, 1–6. [Google Scholar] [CrossRef]

- Prathap Singh, S.; Tittu George, D.X.; Anitto Joe Xavier, A.; Abinicks Raja, G. Effect of Heat Treatment on the Hardness Behaviour of the Aluminium 6061 Alloy. Mater. Today Proc. 2023, 80, 171–175. [Google Scholar] [CrossRef]

- Mousavi Abarghouie, S.M.R.; Reihani, S.M.S. Aging Behavior of a 2024 Al Alloy–SiCp Composite. Mater. Des. 2010, 31, 2368–2374. [Google Scholar] [CrossRef]

- Md Ali, A.; Omar, M.Z.; Salleh, M.S.; Mohamed, I.F.; Hashim, H.; Wakhi Anuar, N.F.B. Effect of Heat Treatment on the Microstructures and Mechanical Properties of Thixoformed Graphene-Reinforced Aluminum Alloy Composite. Int. J. Met. 2024, 18, 1695–1709. [Google Scholar] [CrossRef]

- Edosa, O.O.; Tekweme, F.K.; Olubambi, P.A.; Gupta, K. Microstructural Analysis, Compressive Strength, and Wear Properties of Spark-Plasma-Sintered Al–Mg–PPA Composites. Quantum Beam Sci. 2024, 8, 32. [Google Scholar] [CrossRef]

- Edosa, O.O.; Tekweme, F.K.; Olubambi, P.A.; Gupta, K. Effects of PPA Reinforcement and Sintering Parameters on the Densification and Hardness Properties of Al/Mg/PPA Composites. Materials 2025, 18, 1246. [Google Scholar] [CrossRef]

- Veeranaath, V.; Daga, U.; Sharma, P.; Kumar, Y. Analysis of the Upshot of Heat Treatment on Physical and Mechanical Behavior of Aluminum Hybrid Composites. Mater. Today Proc. 2022, 65, 81–94. [Google Scholar] [CrossRef]

- Menachery, N.; Thomas, S.; Deepanraj, B.; Senthilkumar, N. Processing of Nano reinforced Aluminum Hybrid Metal Matrix Composites and the Effect of Post-Heat Treatment: A Review. Appl. Nanosci. 2023, 13, 4075–4099. [Google Scholar] [CrossRef]

- Sawla, S.; Das, S. Combined Effect of Reinforcement and Heat Treatment on the Two Body Abrasive Wear of Aluminum Alloy and Aluminum Particle Composites. Wear 2004, 257, 555–561. [Google Scholar] [CrossRef]

- Arya, R.K.; Kumar, R.; Telang, A. Influence of Microstructure on Tribological Behaviors of Al6061 Metal Matrix Composite Reinforced with Silicon Nitride (Si3N4) and Silicon Carbide (SiC) Micro Particles. Silicon 2023, 15, 3987–4001. [Google Scholar] [CrossRef]

- Pramanik, A. Effects of Reinforcement on Wear Resistance of Aluminum Matrix Composites. Trans. Nonferrous Met. Soc. China 2016, 26, 348–358. [Google Scholar] [CrossRef]

- Ayodele, O.O.; Babalola, B.J.; Olubambi, P.A. Characterization, Nano mechanical, and Wear Attributes of Sintered Al–TiB2 Composites. J. Mater. Res. Technol. 2023, 24, 4153–4167. [Google Scholar] [CrossRef]

- Lucchetta, M.C.; Ramasamy, P.; Saporiti, F.; Eckert, J.; Audebert, F. Influence of the 1% Ti Content on Microstructure, Friction Coefficient and Contribution to the Strengthening Mechanisms in the Al20Sn1Cu Alloy. Results Eng. 2022, 15, 100506. [Google Scholar] [CrossRef]

- Raghav, G.R.; Janardhanan, S.; Sajith, E.; Chandran, V.; Sruthi, V. Mechanical and Tribological Performance of Al–Fe–SiC–Zr Hybrid Composites Produced through Powder Metallurgy Process. Mater. Res. Express 2021, 8, 115007. [Google Scholar] [CrossRef]

- Mohammad Sharifi, E.; Karimzadeh, F.; Enayati, M.H. Fabrication and Evaluation of Mechanical and Tribological Properties of Boron Carbide Reinforced Aluminum Matrix Nanocomposites. Mater. Des. 2011, 32, 3263–3271. [Google Scholar] [CrossRef]

- Shaikh, M.B.N.; Aziz, T.; Arif, S.; Ansari, A.H.; Karagiannidis, P.G.; Uddin, M. Effect of Sintering Techniques on Microstructural, Mechanical and Tribological Properties of Al–SiC Composites. Surf. Interfaces 2020, 20, 100598. [Google Scholar] [CrossRef]

- Brillon, A.; Garcia, J.; Riallant, F.; Garnier, C.; Joulain, A.; Lu, Y.; Silvain, J.F. Characterization of Al/B4C Composite Materials Fabricated by Powder Metallurgy Process Technique for Nuclear Applications. J. Nucl. Mater. 2022, 565, 153724. [Google Scholar] [CrossRef]

- Venkatesh, V.S.S.; Deoghare, A.B. Effect of Microwave Sintering on the Mechanical Characteristics of Al/Kaoline/SiC Hybrid Composite Fabricated through Powder Metallurgy Techniques. Mater. Chem. Phys. 2022, 287, 126276. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Edosa, O.O.; Kunzi Tekweme, F.; Olubambi, P.A.; Gupta, K. Influence of T6 Heat Treatment on Densification, Mechanical, and Wear Behavior of Plantain Peel Ash Reinforced Aluminum Matrix Composites. Eng. Proc. 2025, 114, 1. https://doi.org/10.3390/engproc2025114001

Edosa OO, Kunzi Tekweme F, Olubambi PA, Gupta K. Influence of T6 Heat Treatment on Densification, Mechanical, and Wear Behavior of Plantain Peel Ash Reinforced Aluminum Matrix Composites. Engineering Proceedings. 2025; 114(1):1. https://doi.org/10.3390/engproc2025114001

Chicago/Turabian StyleEdosa, Osarue Osaruene, Francis Kunzi Tekweme, Peter A. Olubambi, and Kapil Gupta. 2025. "Influence of T6 Heat Treatment on Densification, Mechanical, and Wear Behavior of Plantain Peel Ash Reinforced Aluminum Matrix Composites" Engineering Proceedings 114, no. 1: 1. https://doi.org/10.3390/engproc2025114001

APA StyleEdosa, O. O., Kunzi Tekweme, F., Olubambi, P. A., & Gupta, K. (2025). Influence of T6 Heat Treatment on Densification, Mechanical, and Wear Behavior of Plantain Peel Ash Reinforced Aluminum Matrix Composites. Engineering Proceedings, 114(1), 1. https://doi.org/10.3390/engproc2025114001