Abstract

3D printing has grown rapidly and is now widely used in many industries, including the automotive sector. Most 3D printing filaments are made from virgin PLA (polylactic acid); however, at the same time, the packaging industry produces large amounts of PLA waste, which is often not recycled properly. Turning this waste into good-quality 3D printing filament could be an eco-friendly alternative to traditional materials and support sustainability in the automotive supply chain. This research investigates whether the original PLA packaging material can be used for 3D printing at all by testing its printability and mechanical properties compared to commercial PLA filaments. Two types of original packaging PLA were chosen and processed into 3D printing filaments, which were then tested. The results show that packaging PLA filaments have mechanical properties similar to or even better than commercial PLA filaments, proving that they can be a useful material for 3D printing.

1. Introduction

The appearance and expansion of 3D printing have influenced all industries. Not only has it helped engineers speed up product design steps, but it has also become a cost-effective and time-saving way to improve manufacturing. Three-dimensional printing has helped manufacturers optimize their supply chains, making it easier to provide mass production in the available global market [1,2,3,4].

The raw materials for 3D printing are mostly polymers with very good and versatile properties; however, most of these materials are produced for other sectors, and few are recycled. Unfortunately, most end up in the environment. The largest part of this comes from packaging [5], and this could be partly reduced mainly through selective collection [6,7] and the use of biopolymers such as PLA (polylactic acid). PLA has good mechanical strength and is quite common in packaging technology and 3D printing [8]. It has not been widely implemented in engineering applications because it has some serious drawbacks, one of them is its brittleness, which leads to low impact resistance [9].

Collected PLA packaging materials can be composted under industrial conditions and degraded to avoid their appearance in waste, but the degradation process takes time, and we lose them as a raw material. Normal hydrocarbon-based plastics can be recycled several times [10], and this action would also be favorable in the case of biopolymers. This would allow us to obtain usable feedstock much sooner, which could be used in other areas. Research into the use of recycled PET as printing material is already underway, and the results are promising [11,12].

In 3D printing, PLA is one of the raw materials for the material extrusion process, and due to its easy handling, it has become one of the most widely used printing materials, not only in industry but also among general users [13,14]. PLA raw material manufacturers are producing and marketing types specifically for 3D printing [15], while the packaging industry releases a lot of PLAs due to its short life cycle [16,17]. For both environmental and economic reasons, it is worth investigating the suitability of PLA types used in packaging technology to produce printing filaments and printed products for different industrial sectors, such as the automotive industry.

In the automotive industry, 3D-printed PLA is mostly used to produce prototype parts and functional test products, such as interior trim, ducts, and fit-test components [18]. In addition, manufacturing support tools, such as fixtures, templates, and punching/cutting tools for thin sheets (in cases of small-series or pre-series setup), can also be printed [19]. Using PLA filament, prototype specimens have already been produced for permeability testing and it was applied to investigate the filling process in hydrogen vehicles [20].

This article is the first step in a larger research project. The long-term plan is to make filaments from recycled packaging waste, but first, it must be tested whether the selected raw materials are suitable for this purpose, and for that, original materials are required. In this study, two types of original packaging PLA were used to produce filaments and were compared with commercially available PLA filaments through mechanical testing of the printed test specimens. The study investigated whether the packaging types are suitable for filament production and whether the strength of the test specimens made from them approximates that of the test specimens made from commercial filament.

2. Materials and Methods

2.1. Materials

Natureworks Ingeo 7032D, recommended for bottle production by injection blow molding, and 4032D, offered for film manufacturing, were tested as packaging materials.

From the commercial filaments, a black and a white Herz brand and a green Philament brand were selected. An iPLA brand-name material was also selected, which was recommended for filament production and was available in pellet form.

The filaments from the two Ingeo and iPLA were prepared by a Brabender Plasto-graph and an IDMX mixer (DMX Mixer Inc.; Boston, MA, USA) using a Collin (Dr. Collin GmbH.; Ebersberg, Germany) extruder line. Before extrusion, PLA was dried at 60 °C and 4 h. The temperatures of the extruder were 190, 200, 210, and 220 °C (from hopper to die), and the rate of the screw was 40 rpm. The temperature of the mixer was 210 °C, and the rate of the screw was 12.5 RPM.

The diameter of both the purchased and manufactured filaments was 1.75 mm.

2.2. Printing Parameters

For 3D printing, a Craftbot PLUS (CraftUnique Ltd.; Budapest, Hungary) material extrusion 3D printer was used. For the investigation, two types of printing structure (direction) were chosen. In the first structure, the melted filaments were laid parallel to the longitudinal axis of the specimen, resulting in a so-called parallel orientation. In the case of the second structure, one layer was 45° to the longitudinal axis of the sample, and the next layer was perpendicular to the previous one, forming a structure of (+/−)45° orientation. The printing temperature was 230 °C and the printing rate was 30 mm/s, except for the green Philament, where 205 and 225 °C and 40 mm/s were used. The filling was 100% in all cases.

2.3. Characterization Methods

Two shapes were printed for the measurements, dog-bone-shaped specimens for tensile tests and rectangular specimens for impact tests. In both cases, the investigated cross-section was 4 × 10 mm. The tensile test was performed by an Instron 3366 (Instron Corporation, Norwood, MA, USA) universal testing machine with a 10 mm/min measuring rate, except for the green Philament, where 50 mm/min was set. The Charpy impact test was performed by a Ceast Impactor II (Instron Corporation, Norwood, MA, USA) with a 5 J hammer.

Results for the Ingeo 7032D parallel and the green Philament are from previous research [21,22]. These results were used to extend the range of comparisons and to draw partial attention to the importance of the printing parameters, not just the raw materials, because users can set them freely.

3. Results and Discussion

Table 1 presents the identification of the samples, filament types, and printing orientations. Printing temperature varied between 205 and 230 °C depending on the requirements of the actual filament, and either parallel or (+/−)45° orientation was applied.

Table 1.

Identification of the samples and printing parameters.

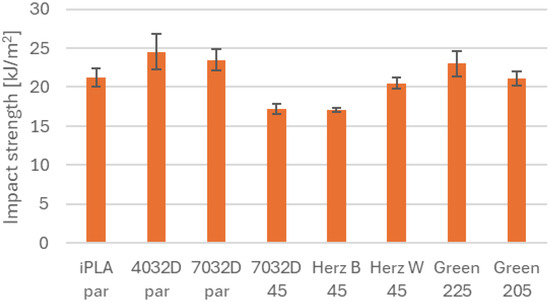

Figure 1 illustrates the values of the impact strength. Comparing the values of the packaging materials with the values of the factory materials, it can be concluded that not only do they fit the average, but the samples printed with parallel orientation also show a slight increase. Comparing the two packaging materials, 4032D has a slightly higher value than 7032D.

Figure 1.

Impact strength values of the tested materials.

The results also highlight that the choice and optimization of the right parameters are of high importance in 3D printing, often more important than the main properties of the starting materials. The averages for 7032D parallel, 4032D parallel, and Green 225 °C are nearly similar. However, if the parameters are changed, printing 7032D at 45° or Green at a lower temperature, a reduced impact strength is observed.

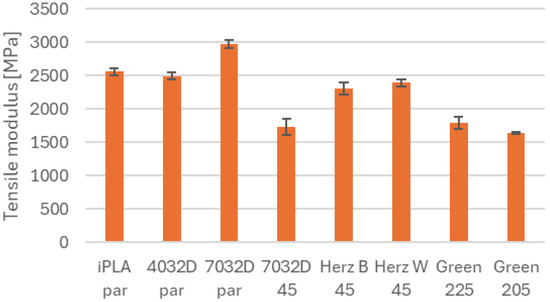

Figure 2 displays the tensile modulus values. Among the samples, the Ingeo 7032D with parallel orientation stands out. The 4032D, the iPLA, and the Herz types have similar stiffness. The green Philament has a similar value to the 45° Ingeo 7032D, they have the same printing orientation. The materials that perform better in impact strength are more flexible and therefore have a lower tensile modulus, except for the parallel 7032D, which has a higher impact strength in addition to its stiffer structure.

Figure 2.

Tensile modulus values of the tested materials.

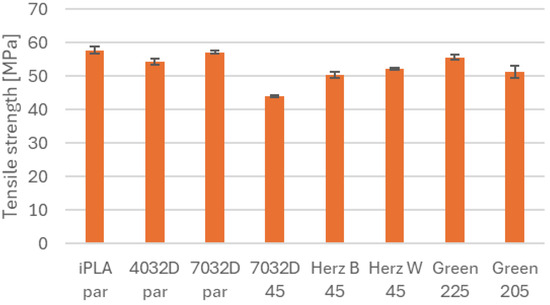

Figure 3 illustrates the change in tensile strength. The field is much more evenly balanced in terms of tensile strength, with the packaging materials fitting in with the factory materials. The 45° 7032D shows a slightly lower value, but this also confirms the importance of choosing the correct printing structure. For example, the positive effect of increasing the temperature is clearly visible in the case of the green Philament samples. The 225 °C samples had higher strength values than the 205 °C samples because the higher printing temperature improves filament welding. It is also noted that if the green Philament had been printed at a higher temperature, 230 °C, it would probably have produced slightly higher strength values, possibly reaching those of the 7032D parallel and iPLA parallel samples.

Figure 3.

Tensile strength values of the tested materials.

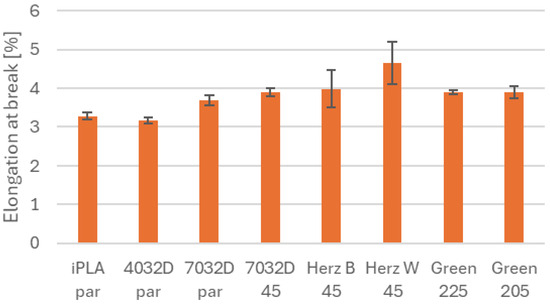

Figure 4 shows the elongation at break. Here again, the packaging samples fit well with the commercial samples. The white Herz sample can withstand the greatest elongation before the moment of break, but the width of the standard deviation field is also the largest here, which shows the instability in production, i.e., in printing. The other samples, including the packaging materials, are much more stable in production.

Figure 4.

Elongation at break values of the tested materials.

However, it should be noted that the tensile test speed for the green Philament was slightly higher than for the other samples. The higher test speed results in more brittle behavior with higher strength and lower elongation values [23,24,25,26,27]. If the green Philament had also been tested at a lower speed, slightly lower strength and higher elongation values might be expected. In this case, it is possible that they would more closely approximate the results of the Herz samples.

4. Conclusions

From the measurement results, it can be concluded that the strength values of the packaging materials not only match those of the factory filaments but in many cases even exceed them, even if only slightly. When printed in parallel orientation, both Ingeo 7032D and 4032D have better impact strength than the factory filaments. The 7032D also has a higher tensile modulus than the others, and both the 7032D and the iPLA produce a slightly higher tensile strength. The elongation at break showed that, after roughly uniform standard deviations up to that point, the factory filaments in this case showed greater differences, indicating instability in the production and printing compared to packaging materials, which are more stable in production.

The results also demonstrate the importance of selecting the correct printing direction and the building structure. In many cases, better values could be obtained using parallel orientation rather than 45°, because it was more suitable for the load directions and better able to resist tensile and impact stresses.

In addition to orientation, the printing temperature is also an important factor. In the case of the green Philament, the specimen printed at the lower temperature of 205 °C always produced lower values than the specimen printed at the higher temperature of 225 °C. So, it is safe to use higher temperatures than the recommended temperatures for factory PLAs, because the higher temperature helps the filaments to weld together, thus increasing the strength of the printed product.

In summary, the selected packaging materials are suitable for producing printing filaments. The strength values of the test specimens made from them are well within the range of commercial filaments. They are therefore suitable as a basis for further research. The next step is to find out how reprocessing will affect their printability and strength. This will show whether it is worth reusing the used packaging materials as printing materials, offering a more environmentally friendly alternative.

Author Contributions

Conceptualization, B.Á.; methodology, B.Á.; software, P.H.; validation, B.Á., D.A.N. and F.P.; formal analysis, D.A.N.; investigation, P.H.; resources, B.Á. and L.T.; data curation, F.P.; writing—original draft preparation, B.Á.; writing—review and editing, B.Á., L.T., and E.V.; visualization, F.P.; supervision, L.T. and E.V.; project administration, B.Á. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Elakkad, A.S. 3D Technology in the Automotive Industry. Int. J. Eng. Res. Technol. 2019, 8, 110–122. [Google Scholar] [CrossRef]

- Xue, B. 3D Printing is Empowering the Automotive Industry. Appl. Comput. Eng. 2025, 140, 53–58. [Google Scholar] [CrossRef]

- Bognár, A.; Kun, K. Design of a Heating Unit for Photopolymerization-Based 3D Printing Technology. In Proceedings of the 38th International Colloquium on Advanced Manufacturing and Repair Technologies in Vehicle Industry; Vehovszky, B., Hlinka, J., Eds.; Gépipari Tudományos Egyesület (GTE): Budapest, Hungary, 2023; pp. 46–50. [Google Scholar]

- Bognár, A.; Kun, K.; Zsidai, L. Heating Unit Design for VAT Photopolymerization Process in Stereolithography 3D Printing. Mech. Eng. Lett. R D 2024, 25, 68–75. [Google Scholar]

- Ncube, L.K.; Ude, A.U.; Ogunmuyiwa, E.N.; Zulkifli, R.; Beas, I.N. An Overview of Plastic Waste Generation and Management in Food Packaging Industries. Recycling 2021, 6, 12. [Google Scholar] [CrossRef]

- Ronkay, F.; Dobrovszky, K.; Toldy, A. Műanyagok Újrahasznosítása; Printer Kiadó: Budapest, Hungary, 2014. [Google Scholar]

- Nagy, B. Újrahasznosítási Ismeretek; Szent István Egyetem: Gödöllő, Hungary, 2011. [Google Scholar]

- Murariu, M.; Dubois, P. PLA Composites: From Production to Properties. Adv. Drug Deliv. Rev. 2016, 107, 17–46. [Google Scholar] [CrossRef] [PubMed]

- Lim, L.T.; Auras, R.; Rubino, M. Processing Technologies for Poly(Lactic Acid). Prog. Polym. Sci. 2008, 33, 820–852. [Google Scholar] [CrossRef]

- Rosli, N.A.; Ahmad, I. Mechanical Properties of Recycled Plastics. In Recycled Plastic Biocomposites; Springer: Singapore, 2021; pp. 239–258. [Google Scholar] [CrossRef]

- Toth, L.; Slezák, E.; Bocz, K.; Ronkay, F. Progress in 3D Printing of Recycled PET. Mater. Today Sustain. 2024, 26, 100757. [Google Scholar] [CrossRef]

- Schneevogt, H.; Stelzner, K.; Yilmaz, B.; Abali, B.E.; Klunker, A.; Völlmecke, C. Sustainability in Additive Manufacturing: Exploring the Mechanical Potential of Recycled PET Filaments. Compos. Adv. Mater. 2021, 30, 26349833211000063. [Google Scholar] [CrossRef]

- Mohd Pu’ad, N.A.S.; Abdul Haq, R.H.; Mohd Noh, H.; Abdullah, H.Z.; Idris, M.I.; Lee, T.C. Review on the Fabrication of Fused Deposition Modelling (FDM) Composite Filament for Biomedical Applications. Mater. Today Proc. 2020, 29, 228–232. [Google Scholar] [CrossRef]

- Mekonnen, K.T.; Fanta, G.M.; Tilinti, B.Z.; Regasa, M.B. Polylactic Acid Based Biocomposite for 3D Printing: A Review. Compos. Mater. 2024, 8, 57–71. [Google Scholar] [CrossRef]

- Resinex.hu. Natureworks Ingeo PLA Sorozatok. Available online: https://www.resinex.hu/termekek/natureworks-ingeo.html (accessed on 17 May 2023).

- Ncube, L.K.; Ude, A.U.; Ogunmuyiwa, E.N.; Zulkifli, R.; Beas, I.N. Environmental Impact of Food Packaging Materials: A Review of Contemporary Development from Conventional Plastics to Polylactic Acid-Based Materials. Materials 2020, 13, 4994. [Google Scholar] [CrossRef] [PubMed]

- Swetha, T.A.; Bora, A.; Mohanrasu, K.; Balaji, P.; Raja, R.; Ponnuchamy, K.; Muthusamy, G.; Arun, A. A Comprehensive Review on Polylactic Acid (PLA)—Synthesis, Processing and Application in Food Packaging. Int. J. Biol. Macromol. 2023, 234, 123715. [Google Scholar] [CrossRef] [PubMed]

- Tümer, E.H.; Erbil, H.Y. Extrusion-Based 3D Printing Applications of PLA Composites: A Review. Coatings 2021, 11, 390. [Google Scholar] [CrossRef]

- Szalai, S.; Szívós, B.F.; Nemes, V.; Szabó, G.; Kurhan, D.; Sysyn, M.; Fischer, S. Investigation of FDM-Based 3D Printing for Optimized Tooling in Automotive and Electronics Sheet Metal Cutting. Appl. Sci. 2025, 15, 442. [Google Scholar] [CrossRef]

- Cavender, K.; Evans, C.; Haney, J.; Leachman, J. Design of a Helium Vapor Shroud for Liquid Hydrogen Fueling of an Unmanned Aerial Vehicle (UAV). IOP Conf. Ser. Mater. Sci. Eng. 2017, 278, 012004. [Google Scholar] [CrossRef]

- Ádám, B.; Polgár, B.; Nagy, D. The Effect of Different Printing Parameters on Mechanical and Thermal Properties of PLA Specimens. Gradus 2020, 7, 166–173. [Google Scholar] [CrossRef]

- Ádám, B.; Weltsch, Z. Thermal and Mechanical Assessment of PLA-SEBS and PLA-SEBS-CNT Biopolymer Blends for 3D Printing. Appl. Sci. 2021, 11, 6218. [Google Scholar] [CrossRef]

- Zhan, J.; Cai, J.; Hasani, R. Effects of Testing Speed on the Tensile and Mode I Fracture Behavior of Specimens Printed through the Fused Deposition Modeling Technique. Sci. Rep. 2024, 14, 3960. [Google Scholar] [CrossRef] [PubMed]

- Balasubramanian, M.; Saravanan, R.; Shanmugam, V. Impact of Strain Rate on Mechanical Properties of Polylactic Acid Fabricated by Fusion Deposition Modeling. Polym. Adv. Technol. 2024, 35, e6335. [Google Scholar] [CrossRef]

- Ospina, S.; Hess, M.; Lopez, B. Room Temperature Monte Carlo Study of the Mechanical Properties of Thermoplastic Polymers. e-Polymers 2004, 4, 024. [Google Scholar] [CrossRef]

- Pukánszky, B.; Móczó, J. Műanyagok; Typotex: Budapest, Hungary, 2011; ISBN 978-963-279-481-5. [Google Scholar]

- Czél, G.; Kollár, M. Anyagvizsgálati Praktikum; Sunplant Kft: Miskolc, Hungary, 2008; ISBN 978-963-064-2163. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).