Oscillatory Shear Rheology of PE/PP/MWCNT Nanocomposites †

Abstract

1. Introduction

2. Materials and Methods

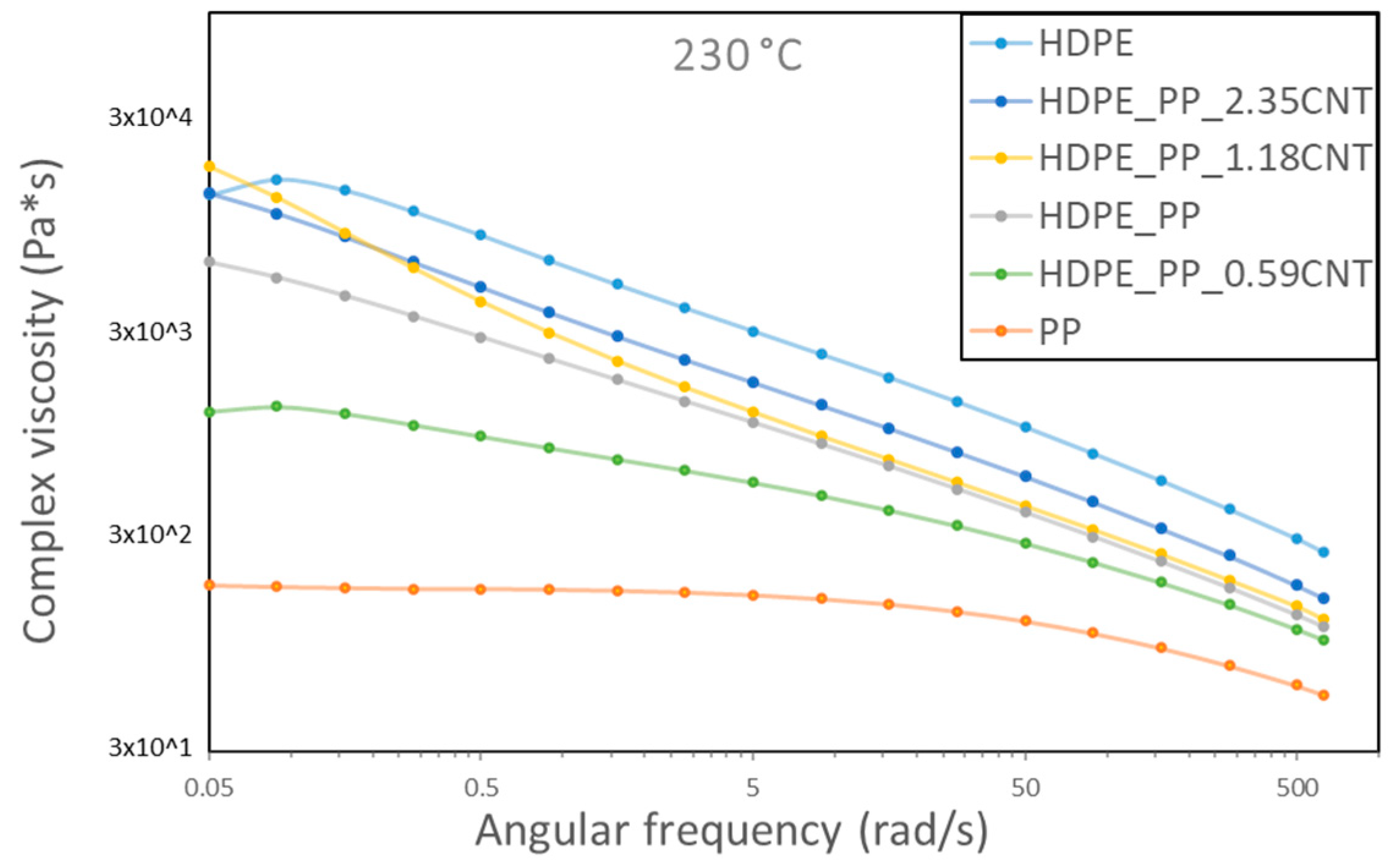

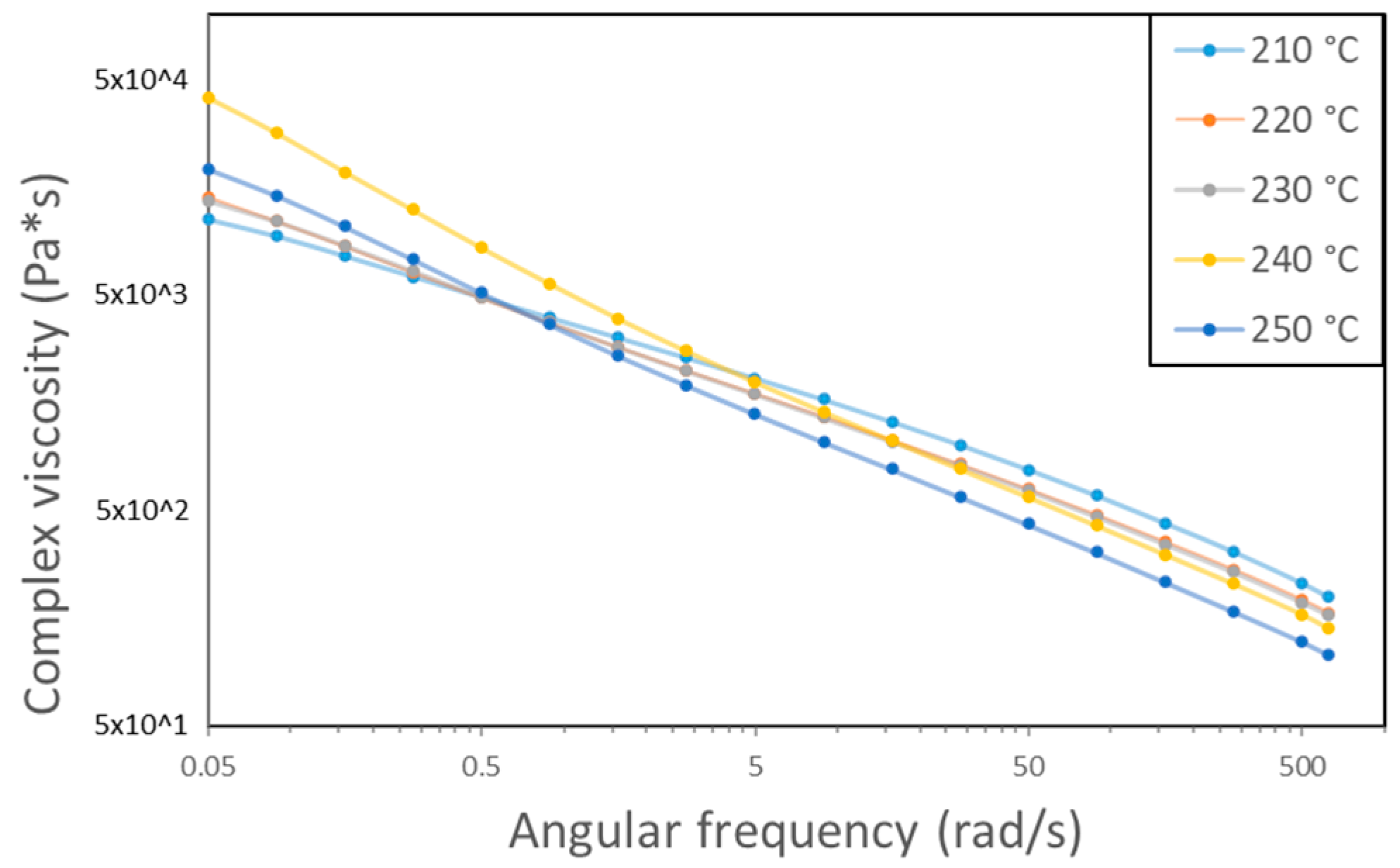

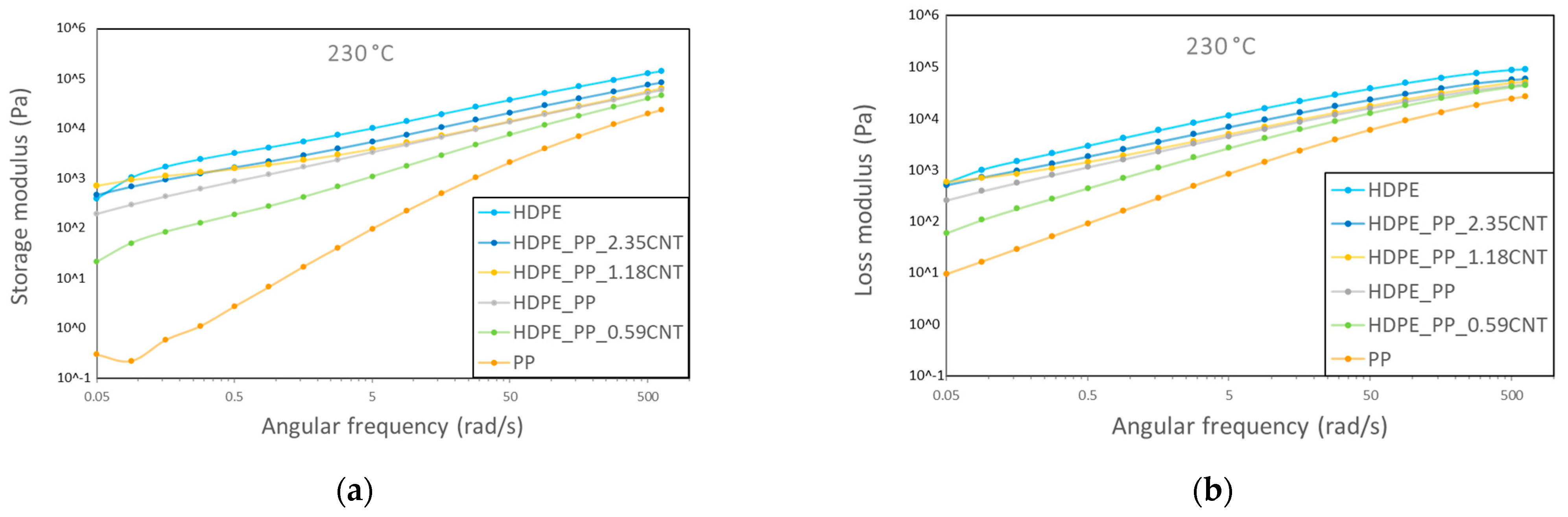

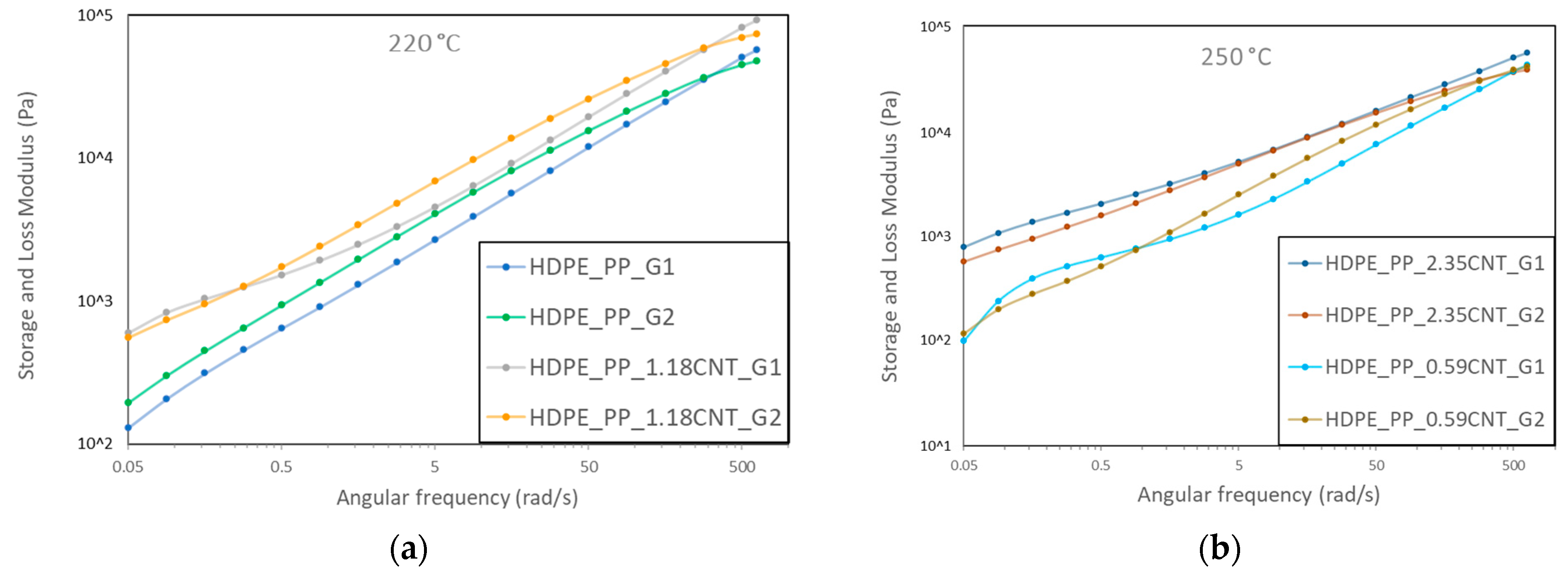

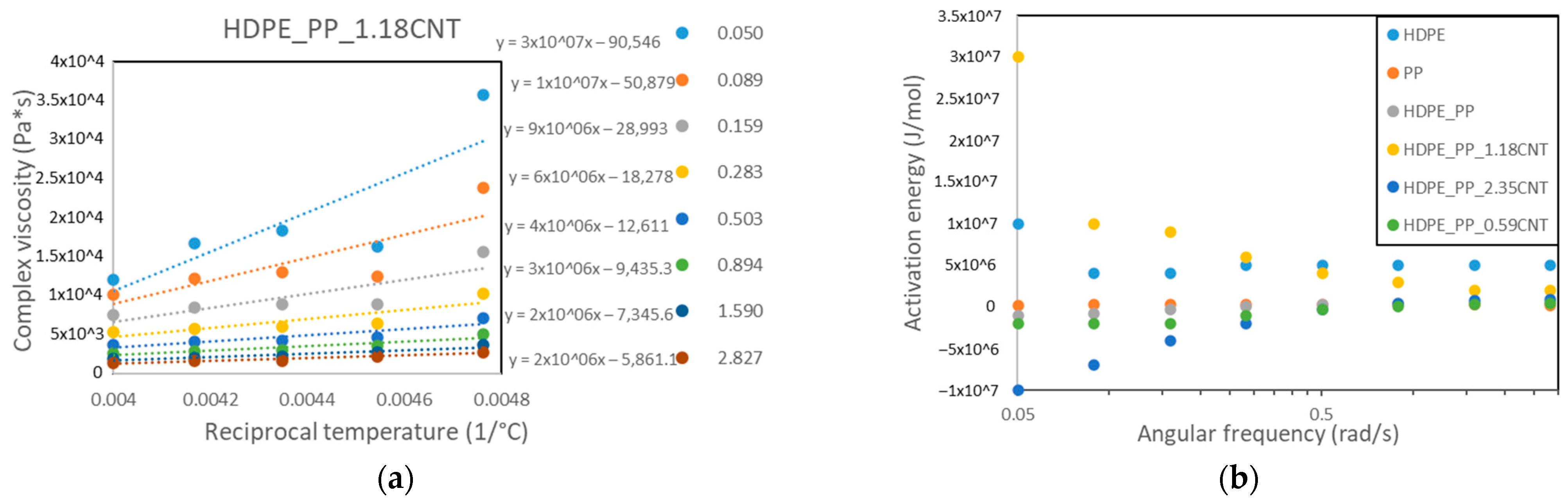

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Graziano, A.; Jaffer, S.; Sain, M. Review on modification strategies of polyethylene/polypropylene immiscible thermoplastic polymer blends for enhancing their mechanical behavior. J. Elastomers Plast. 2019, 51, 291–336. [Google Scholar] [CrossRef]

- Belina, K. Műanyagok a gépjárműiparban. 2011. Available online: www.tankonyvtar.hu (accessed on 2 July 2025).

- Nagy, D.; Kókai, E. Polymer-based nanocomposites with nanoclay. IOP Conf. Ser. Mater. Sci. Eng. 2018, 448, 012021. [Google Scholar] [CrossRef]

- Al-Saleh, M.H. Electrical, EMI shielding and tensile properties of PP/PE blends filled with GNP:CNT hybrid nanofiller. Synth. Met. 2016, 217, 322–330. [Google Scholar] [CrossRef]

- Bata, A.; Nagy, D.; Weltsch, Z. Effect of recycling on the mechanical, thermal and rheological properties of polypropylene/carbon nanotube composites. Polymers 2022, 14, 5257. [Google Scholar] [CrossRef] [PubMed]

- Lin, J.H.; Wu, C.S.; Su, K.H.; Lee, C.H.; Chen, C.Y.; Hsu, C.H.; Lou, C.W. Preparation and compatibility evaluation of polypropylene/high density polyethylene polyblends. Materials 2015, 8, 8850–8859. [Google Scholar] [CrossRef] [PubMed]

- Finlay, J.; Hill, M.J.; Barham, P.J.; Byrne, K.; Woogara, A. Mechanical properties and characterization of slowly cooled isotactic polypropylene/high-density polyethylene blends. J. Polym. Sci. B Polym. Phys. 2003, 41, 1384–1392. [Google Scholar] [CrossRef]

- Baudouin, A.C.; Bailly, C.; Devaux, J. Interface localization of carbon nanotubes in blends of two copolymers. Polym. Degrad. Stab. 2010, 95, 389–398. [Google Scholar] [CrossRef]

- Yui, H.; Wu, G.; Sano, H.; Sumita, M.; Kino, K. Morphology and electrical conductivity of injection-molded polypropylene/carbon black composites with addition of high-density polyethylene. Polymer 2006, 47, 3599–3608. [Google Scholar] [CrossRef]

- Yu, F.; Liu, Y.; Zhang, B.; Shen, T.; Zhu, Y.; Zhang, M. Anisotropic multilayer conductive networks in carbon nanotubes filled polyethylene/polypropylene blends obtained through high speed thin wall injection molding. Polymer 2013, 54, 6425–6436. [Google Scholar] [CrossRef]

- Zhang, C.; Yi, X.S.; Yui, H.; Asai, S.; Sumita, M. Selective location and double percolation of short carbon fiber filled polymer blends: High-density polyethylene/isotactic polypropylene. Mater. Lett. 1998, 36, 186–190. [Google Scholar] [CrossRef]

- Moussa, B.; Chahrazad, A. Effect of Masterbatch Type and Concentration on Carbon Nanotube Reinforced Polyolefin Blend Nanocomposites. Ph.D. Thesis, University of Calgary, Calgary, AB, Canada, 2018. Available online: https://ucalgary.scholaris.ca/items/f57eda4b-1b28-4575-8e3f-894a0e2c0049 (accessed on 2 July 2025).

- Al-Saleh, M.H. Carbon nanotube-filled polypropylene/polyethylene blends: Compatibilization and electrical properties. Polym. Bull. 2016, 73, 975–987. [Google Scholar] [CrossRef]

- He, L.; Xu, Q.; Song, R.; Hua, C. Thermal and morphological characterization of composites prepared by solution crystallization method of high-density polyethylene on carbon nanotubes. Polym. Compos. 2010, 31, 913–920. [Google Scholar] [CrossRef]

- Xiao, K.Q.; Zhang, L.C.; Zarudi, I. Mechanical and rheological properties of carbon nanotube-reinforced polyethylene composites. Compos. Sci. Technol. 2007, 67, 177–182. [Google Scholar] [CrossRef]

- Gill, Y.Q.; Jin, J.; Song, M. Melt flow behavior of high density polyethylene nanocomposites with 1D, 2D and 3D nanofillers. Nanocomposites 2015, 1, 160–169. [Google Scholar] [CrossRef]

- Morcom, M.; Simon, G. Polyolefin-carbon nanotube composites. In Polymer-Carbon Nanotube Composites: Preparation, Properties and Applications; Mittal, V., Ed.; Woodhead Publishing: Cambridge, UK, 2011; pp. 511–544. [Google Scholar] [CrossRef]

- Zhang, Q.; Rastogi, S.; Chen, D.; Lippits, D.; Lemstra, P.J. Low percolation threshold in single-walled carbon nanotube/high density polyethylene composites prepared by melt processing technique. Carbon 2006, 44, 778–785. [Google Scholar] [CrossRef]

- Xu, D.; Wang, Z. Role of multi-wall carbon nanotube network in composites to crystallization of isotactic polypropylene matrix. Polymer 2008, 49, 330–338. [Google Scholar] [CrossRef]

- Pötschke, P.; Abdel-Goad, M.; Alig, I.; Dudkin, S.; Lellinger, D. Rheological and dielectrical characterization of melt mixed polycarbonate–multiwalled carbon nanotube composites. Polymer 2004, 45, 8863–8870. [Google Scholar] [CrossRef]

- Agrawal, P.; Chaudhary, M.; Patel, P.; Vashi, R.; Sharma, R. Rheological properties of high-density polyethylene/linear low-density polyethylene and high-density polyethylene/low-density polyethylene blends. Polym. Bull. 2022, 79, 2321–2343. [Google Scholar] [CrossRef]

- Tóth, G.; Nagy, D.; Bata, A.; Belina, K. Determination of polymer melts flow-activation energy as a function of wide range shear rate. J. Phys. Conf. Ser. 2018, 1045, 012040. [Google Scholar] [CrossRef]

| Identification | HDPE Ratio | PP Ratio | MWCNT Ratio |

|---|---|---|---|

| HDPE | 100% | - | - |

| PP | - | 100% | - |

| HDPE_PP | 40% | 60% | - |

| HDPE_PP_1.18CNT | 40% | 58.82% | 1.18% |

| HDPE_PP_2.35CNT | 40% | 57.65% | 2.35% |

| HDPE_PP_0.59CNT | 40% | 59.41% | 0.59% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nagy, D.A.; Ádám, B.; Varga, E.; Hansághy, P.; Palásti, F.; Tóth, L. Oscillatory Shear Rheology of PE/PP/MWCNT Nanocomposites. Eng. Proc. 2025, 113, 51. https://doi.org/10.3390/engproc2025113051

Nagy DA, Ádám B, Varga E, Hansághy P, Palásti F, Tóth L. Oscillatory Shear Rheology of PE/PP/MWCNT Nanocomposites. Engineering Proceedings. 2025; 113(1):51. https://doi.org/10.3390/engproc2025113051

Chicago/Turabian StyleNagy, Dorottya Antaliczné, Balázs Ádám, Erika Varga, Pál Hansághy, Ferenc Palásti, and László Tóth. 2025. "Oscillatory Shear Rheology of PE/PP/MWCNT Nanocomposites" Engineering Proceedings 113, no. 1: 51. https://doi.org/10.3390/engproc2025113051

APA StyleNagy, D. A., Ádám, B., Varga, E., Hansághy, P., Palásti, F., & Tóth, L. (2025). Oscillatory Shear Rheology of PE/PP/MWCNT Nanocomposites. Engineering Proceedings, 113(1), 51. https://doi.org/10.3390/engproc2025113051