1. Introduction

Battery testing is at the forefront of development and certification of electric vehicle (EV) components, energy storage systems, and portable electronics in the modern era. As more importance is being placed on energy efficiency, safety, and compliance with regulations, the demand for precise and versatile test systems is growing. Various standards-including ISO/IEC 17025-dictate how laboratories need to control traceability, documentation, and environment in order to maintain the validity of results [

1].

In academic and industrial labs, a broad variety of battery test procedures are employed to evaluate performance, degradation mechanisms, and safety characteristics. Typical protocols comprise charge—discharge cycling to examine capacity retention and lifetime behaviour under different electrical and thermal loads [

2], electrochemical impedance spectroscopy (EIS) to describe internal resistance and track State of Health (SoH) over time [

3], and thermal testing to simulate field extremes or impose accelerated aging [

4]. Along with conventional functional tests, numerous laboratories create customized load profiles to better replicate real-world usage patterns. These efforts are crucial for enhancing battery design, optimizing Battery Management Systems (BMSs), and meeting regulatory mandates in automotive, aerospace, and stationary energy storage applications. As discussed in [

5,

6,

7,

8,

9], such testing procedures demand strong, versatile, and reproducible systems that can keep pace with fast evolution in cell chemistry, form factor, and control strategies.

In order to facilitate sophisticated battery health estimation and reliability analysis, scalable test systems need to be able to apply user-defined load profiles under tightly controlled thermal and electrical conditions. These include programmable temperature ranges, dynamic load conditions, and the introduction of thermal shock cycles, all of which are essential to the assessment of battery behaviour in extreme or accelerated aging environments.

This article describes the development of a modular, scalable measurement system that addresses the needs of both flexible test configuration and ISO/IEC 17025 compliance. The system, created in LabVIEW, features automatic test execution, real-time monitoring, and traceable data acquisition. Specifically, the software architecture decouples test management and device control to enable reusability, ease of validation, and long-term maintainability.

2. Materials and Methods

2.1. System Overview

The development of a modular and scalable measurement system is essential for establishing an accredited laboratory for battery and electronic device testing. To meet ISO/IEC 17025 standards, the system must ensure traceability, repeatability, and flexibility while integrating diverse laboratory instruments. It is designed to support new devices and protocols over time.

Currently, the system handles programmable DC power supplies, a climate chamber, and digital/analog I/O modules, with the flexibility to integrate electronic loads and communication interfaces (CAN, Modbus, UART) without architectural changes.

The software is implemented in LabVIEW, offering high-level instrumentation control, multithreading, real-time data acquisition, and support for communication protocols (VISA, TCP/IP, Serial) as well as integration with real-time and FPGA hardware.

Recent studies have demonstrated that modular, LabVIEW-based battery test systems improve repeatability and flexibility, enabling features such as custom load profiles, thermal control, and automated SoH estimation under wide thermal conditions [

10,

11].

2.2. Modular Software Architecture

To achieve a scalable and maintainable measurement system, the software is structured around a Hardware Abstraction Layer (HAL) implemented using object-oriented LabVIEW 2025. The HAL decouples hardware-specific implementations from core test logic, enabling seamless integration of new instruments and minimizing the impact of hardware changes on the system. This modular approach ensures flexibility and supports the evolution of the laboratory setup over time [

11].

Within LabVIEW, base classes are defined for different device categories, such as power supplies, climate chambers, and communication interfaces. Derived classes encapsulate device-specific behaviours, while base classes provide common functionalities, promoting code reuse and simplifying the integration of new hardware components. Dynamic device loading from external configuration files further enhances adaptability: at startup, the system reads these files to instantiate required drivers and configure communication channels according to specified parameters.

Design patterns such as the Factory Method and Strategy Pattern are employed to manage device-specific operations. These patterns enable the dynamic selection of appropriate behaviours at runtime, reinforcing modularity, scalability, and maintainability. By combining HAL, OOP principles, dynamic configuration, and design patterns, the system achieves a robust architecture capable of supporting various devices and test scenarios.

This modular architecture aligns with best practices in automated test system development and recent LabVIEW–Python hybrid battery testing platforms [

11], ensuring the system remains flexible, maintainable, and compliant with ISO/IEC 17025 accreditation requirements.

2.3. Execution Engine and Test Sequences

A central feature of the measurement system is its ability to execute test sequences that define specific procedures for battery and electronics testing. Test sequences are defined in JSON format, parsed by the LabVIEW-based control software, enabling easy interpretation, external tool compatibility, and flexible automation [

12].

Each sequence consists of an ordered list of steps containing metadata such as operation type, target device, parameters (e.g., voltage, current, duration), and any required conditions or delays. The execution engine, implemented as a state machine, processes these steps sequentially or conditionally based on the defined logic. It incorporates error handling, timeout management, and logging to ensure reliability during extended test campaigns. Parallel step execution is supported, allowing synchronized control of multiple devices, such as power supplies and climate chambers, enhancing throughput and minimizing idle time.

To support test engineers, a graphical sequence editor provides drag-and-drop and tabular interfaces for constructing and visualizing sequences. Users can validate input parameters, simulate test runs before deployment, and ensure consistency across repeated experiments. This improves usability, reduces human error, and strengthens compliance with ISO/IEC 17025 standards [

12].

By combining JSON-defined sequences, a robust state-machine engine, and a user-friendly editor, the system enables standardized testing workflows, high repeatability, and adaptability to evolving testing protocols. The approach builds on established best practices in automated test systems, providing a flexible framework for future laboratory expansion.

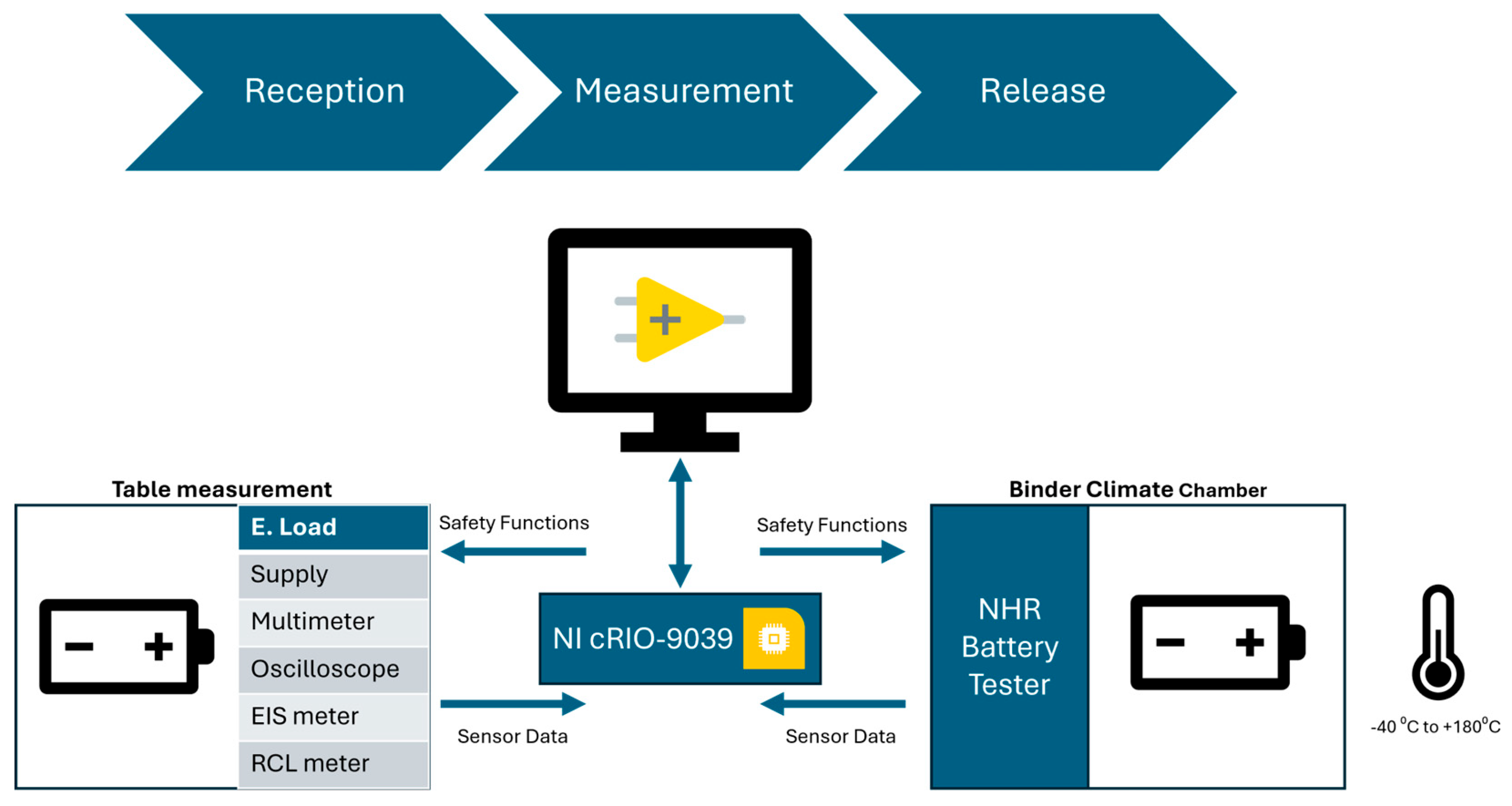

2.4. Device Integration Strategy

The versatility of the measurement system relies on its ability to integrate and control a wide range of laboratory instruments, including programmable power supplies, electronic loads, climate chambers, digital and analog I/O modules, and communication interfaces such as CAN, RS232, and Ethernet (

Figure 1). Each device type is encapsulated within a dedicated LabVIEW driver module implemented according to HAL principles. This abstraction allows standardized method calls while hiding hardware-specific details from the test execution layer, enabling commands, such as setting a voltage, to be executed on different brands of devices without modifying the test sequences.

The system supports both synchronous and asynchronous device interactions, coordinated through a real-time scheduling engine. Synchronous operation allows tasks such as starting a battery discharge while adjusting the chamber temperature, whereas asynchronous tasks, like ambient data logging, run in the background. Synchronization is achieved using timestamp alignment and shared trigger events managed by the LabVIEW core.

Device configuration is handled via JSON files, allowing test engineers to define hardware properties including addresses, communication protocols, and calibration factors. This strategy reduces the need for code modifications when adding or replacing equipment and aligns with best practices in modular test systems.

The system architecture (seen in

Figure 1) also incorporates integrated power and thermal control, supporting realistic SoH and safety assessments, including thermal shock cycles. Future extensions are planned for high-speed data acquisition modules and battery cycling units, ensuring adaptability to evolving industry requirements and compliance with ISO/IEC 17025 standards.

3. Results

3.1. Initial System Deployment

The first stage of system validation focused on integrating and coordinating two key laboratory instruments: the NHR battery tester cabinet and a Binder climate chamber. Through the JSON-based test sequence engine, automated charge–discharge cycles were successfully executed under varying thermal conditions. The system managed real-time parameter configuration and logging without requiring manual intervention, demonstrating the intended modular behaviour in a controlled setup.

The test environment verified that synchronized operation, such as simultaneous temperature regulation and current control, was possible via the software’s abstraction layer. This confirmed both functional compatibility and the practical applicability of the architecture in multi-instrument workflows.

3.2. Expansion and Hardware Compatibility

Following the successful initial deployment, additional devices were procured and gradually integrated, including digital multimeters, programmable power supplies, oscilloscopes, and communication interfaces (e.g., CAN, RS232, Ethernet). Early-stage functionality tests with these instruments validated the robustness of the HAL, which permitted seamless communication and control regardless of manufacturer or interface type.

The new devices were integrated into the same control framework with only minimal configuration file updates, requiring no core modifications to the test sequence engine. This supported the primary design goal of minimal reconfiguration for system scalability.

3.3. Sequence Execution and Usability Feedback

The JSON-based test sequence engine successfully executed complex multi-step test protocols. These sequences defined parameters such as voltage levels, current limits, step durations, and conditional delays. The execution engine functioned reliably, with correct command dispatching, timeout handling, and error logging during runtime.

A prototype of the visual sequence editor was also tested by early users. Although still under development, it significantly improved usability by enabling drag-and-drop test creation and tabular overview of procedure logic. User feedback highlighted its potential to reduce configuration errors and simplify training for test engineers unfamiliar with LabVIEW or software development.

3.4. System Responsiveness and Reliability

The response time of the system remained within acceptable bounds during real-time testing. All devices responded correctly to commands, and recorded measurement values matched expected outputs with high consistency. Even under multi-instrument test scenarios, the scheduling and logging modules maintained synchronized execution without observable data loss or communication delays.

The abstraction layer proved resilient to device-level failures. In cases where communication errors were artificially introduced (e.g., simulated disconnection), the system triggered error routines and maintained log integrity, which is essential for auditability in accredited environments.

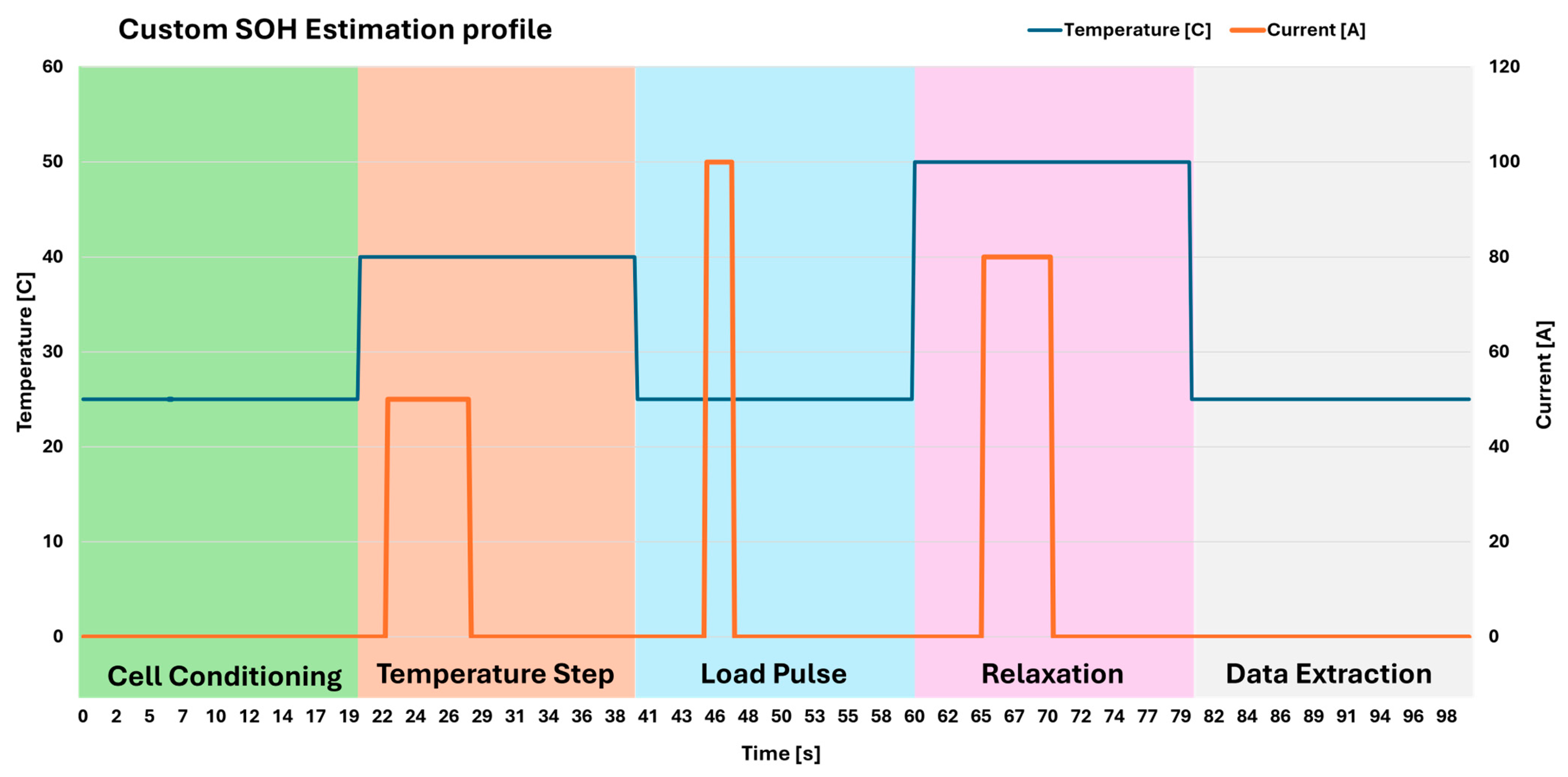

3.5. Custom Measurement Procedures for Accelerated SoH Estimation

In addition to conventional charge–discharge cycling and long-term degradation tests, the system was validated for executing custom measurement procedures designed to accelerate SoH estimation. These methods rely on short-duration load pulses, dynamic current profiles, and impedance-based measurements rather than extended cycling campaigns.

The JSON-based test sequence engine allowed these procedures to be implemented with minimal additional coding effort, combining rapid electrical excitation with synchronized thermal control. For example, short high-current pulses followed by relaxation phases enabled the extraction of internal resistance and voltage recovery characteristics, key indicators of cell aging. Similarly, impedance measurements performed under controlled temperature variations provided early insights into degradation trends.

The system architecture allows the execution of specialized measurement procedures, including stress tests such as rapid load changes and thermal shocks, which are planned to be used for accelerated determination of the SoH such as in

Figure 2. These capabilities open the way for developing novel diagnostic methods.

4. Discussion

Preliminary findings from the accelerated test procedures indicate that rapid load changes and thermal shock cycles can indeed reveal characteristic degradation patterns. However, the current results are still at an early stage and not yet sufficiently robust for practical application. Further validation and systematic refinement will be required to achieve reproducibility and reliability. Nevertheless, these first insights confirm that the developed measurement system is well-suited for conducting such experiments efficiently and has the potential to support the advancement of accelerated SoH diagnostic methods.

The development and initial deployment of the modular measurement platform highlight the benefits of a flexible, scalable architecture in modern testing environments. A key strength of the system lies in its ability to integrate a wide range of laboratory instruments, independent of manufacturer or communication interface, into a unified and user-friendly framework. This adaptability is particularly valuable in laboratories where instrumentation frequently changes or where multiple test campaigns must be managed in parallel. The use of JSON-based test sequences combined with a multi-threaded execution engine has proven effective for automating procedures while minimizing operator workload. Early user feedback on the graphical sequence editor has also been positive, especially in reducing setup errors and simplifying test preparation for personnel without programming expertise. Furthermore, the plug-and-play design of the device management layer has shown practical benefits, allowing new instruments to be integrated simply by updating configuration files without altering the core software. This ensures that the platform can evolve in line with laboratory needs without introducing excessive complexity.

Despite these promising results, further development remains necessary. Long-term stability testing and high-speed data acquisition trials will be essential to fully characterize the system’s performance under demanding operating conditions. In addition, features such as automated calibration routines, digital validation of test procedures, and closer integration with laboratory management systems should be introduced. These enhancements will be crucial to achieving full compliance with ISO/IEC 17025 requirements and ensuring the system’s readiness for future audits and accreditation processes.

5. Conclusions

This paper presented the design and initial validation of a modular and scalable measurement system for battery and electronics testing. The proposed architecture, based on LabVIEW with a HAL and JSON-defined test sequences, demonstrated its ability to integrate a wide range of laboratory instruments into a unified platform. The system enabled the automation of complex test procedures with minimal manual intervention, while the visual sequence editor proved especially effective in reducing setup errors and improving usability for non-programming users.

Preliminary experiments confirmed that the system can support both standard cycling tests and accelerated protocols, highlighting its flexibility for research and practical applications. At the same time, the results underline the need for further refinement, particularly with respect to high-speed data acquisition, long-term stability, and compliance with ISO/IEC 17025 requirements. Future developments will focus on adding automated calibration checks, enhanced validation tools, and seamless integration with laboratory management systems, ensuring the platform’s reliability in accredited environments.

Author Contributions

Conceptualization, I.K. and G.S.; methodology, I.K.; software, I.K. and G.S.; resources, G.S.; writing—original draft preparation, I.K.; writing—review and editing, I.K. and G.S.; visualization, I.K. All authors have read and agreed to the published version of the manuscript.

Funding

Project no. TKP2021-NVA-23 has been implemented with the support provided by the Ministry of Technology and Industry of Hungary from the National Research, Development and Innovation Fund, financed under the TKP2021-NVA funding scheme.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The datasets presented in this article are not readily available because they are part of an ongoing study.

Conflicts of Interest

The authors declare no conflict of interest.

References

- ISO/IEC 17025:2017; General Requirements for the Competence of Testing and Calibration Laboratories. International Organization for Standardization: Geneva, Switzerland, 2017.

- Keil, P.; Jossen, A. Charging Protocols for Lithium-Ion Batteries and Their Impact on Cycle Life-An Experimental Study with Different 18650 High-Power Cells. J. Energy Storage 2016, 6, 125–141. [Google Scholar] [CrossRef]

- Jeon, M.; Lee, E.; Park, H.; Yoon, H.; Keel, S. Effect of Thermal Abuse Conditions on Thermal Runaway of NCA 18650 Cylindrical Lithium-Ion Battery. Batteries 2022, 8, 196. [Google Scholar] [CrossRef]

- Ye, H.; Jain, G.; Schmidt, C. Thermally Accelerated Life Testing for Rechargeable Li-Ion Batteries. ECS Meet. Abstr. 2013, MA2013-02, 252. [Google Scholar] [CrossRef]

- Su, L.; Xu, Y.; Dong, Z. State-of-Health Estimation of Lithium-Ion Batteries: A Comprehensive Literature Review from Cell to Pack Levels. Energy Convers. Econ. 2024, 5, 224–242. [Google Scholar] [CrossRef]

- Berecibar, M.; Gandiaga, I.; Villarreal, I.; Omar, N.; Van Mierlo, J.; Van den Bossche, P. Critical Review of State of Health Estimation Methods of Li-Ion Batteries for Real Applications. Renew. Sustain. Energy Rev. 2016, 56, 572–587. [Google Scholar] [CrossRef]

- Schuster, S.F.; Bach, T.; Fleder, E.; Müller, J.; Brand, M.; Sextl, G.; Jossen, A. Nonlinear Aging Characteristics of Lithium-Ion Cells under Different Operational Conditions. J. Energy Storage 2015, 1, 44–53. [Google Scholar] [CrossRef]

- Deng, Z.; Hu, X.; Lin, X.; Che, Y.; Xu, L.; Guo, W. Data-Driven State of Charge Estimation for Lithium-Ion Battery Packs Based on Gaussian Process Regression. Energy 2020, 205, 118000. [Google Scholar] [CrossRef]

- Zhang, J.; Li, K. State-of-Health Estimation for Lithium-Ion Batteries in Hybrid Electric Vehicles-A Review. Energies 2024, 17, 5753. [Google Scholar] [CrossRef]

- Yli-Sorvari, J. Educational Battery Measurement System Using LabVIEW Software. Available online: http://www.theseus.fi/handle/10024/495610 (accessed on 16 October 2022).

- Marsal, E.; Martínez, N.; Pérez Vega-Leal, A.; Barrero, F.; Hamdan, M.; Satué, M.G. Automatic and Versatile Test Bench for Data Collection on Battery Cells. Energies 2025, 18, 2304. [Google Scholar] [CrossRef]

- Khalghani, S. Streamlining Electrical Battery Testing Through Automation: A Method to Automate the Testing of Automotive Batteries Employing LabVIEW, TestStand, and Ardiuno. Available online: http://www.theseus.fi/handle/10024/895537 (accessed on 14 August 2025).

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).