Development of a Data-Driven Methodology for Rapid Identification of Key Performance Indicators in Motorcycle Racing †

Abstract

1. Introduction

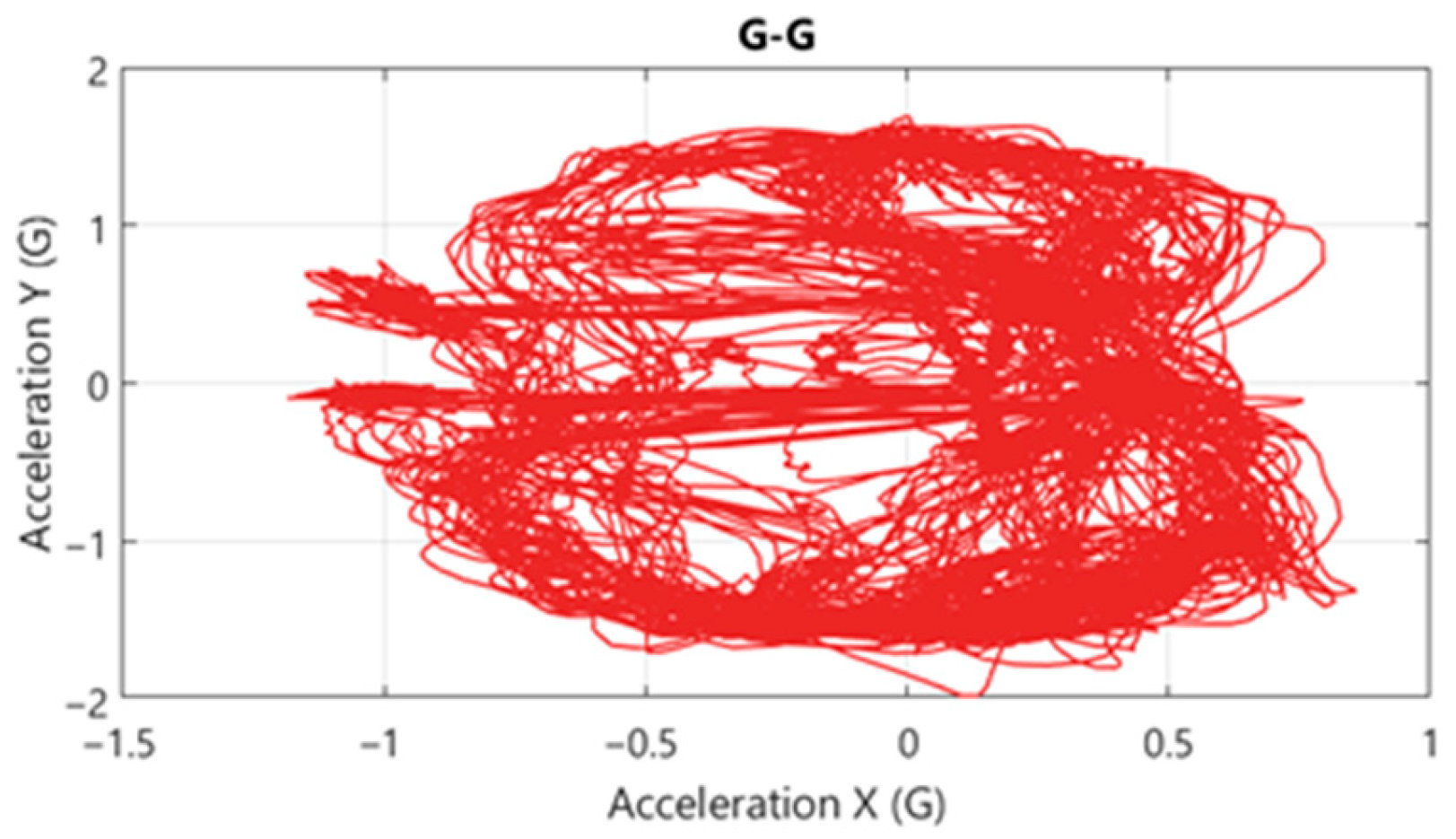

2. Methodology

2.1. Data Acquisition

- Vehicle speed (km/h)

- Longitudinal and lateral acceleration (m/s2)

- Suspension travel (mm)

- Throttle position (%)

- Brake pressure (bar)

- Gear selection

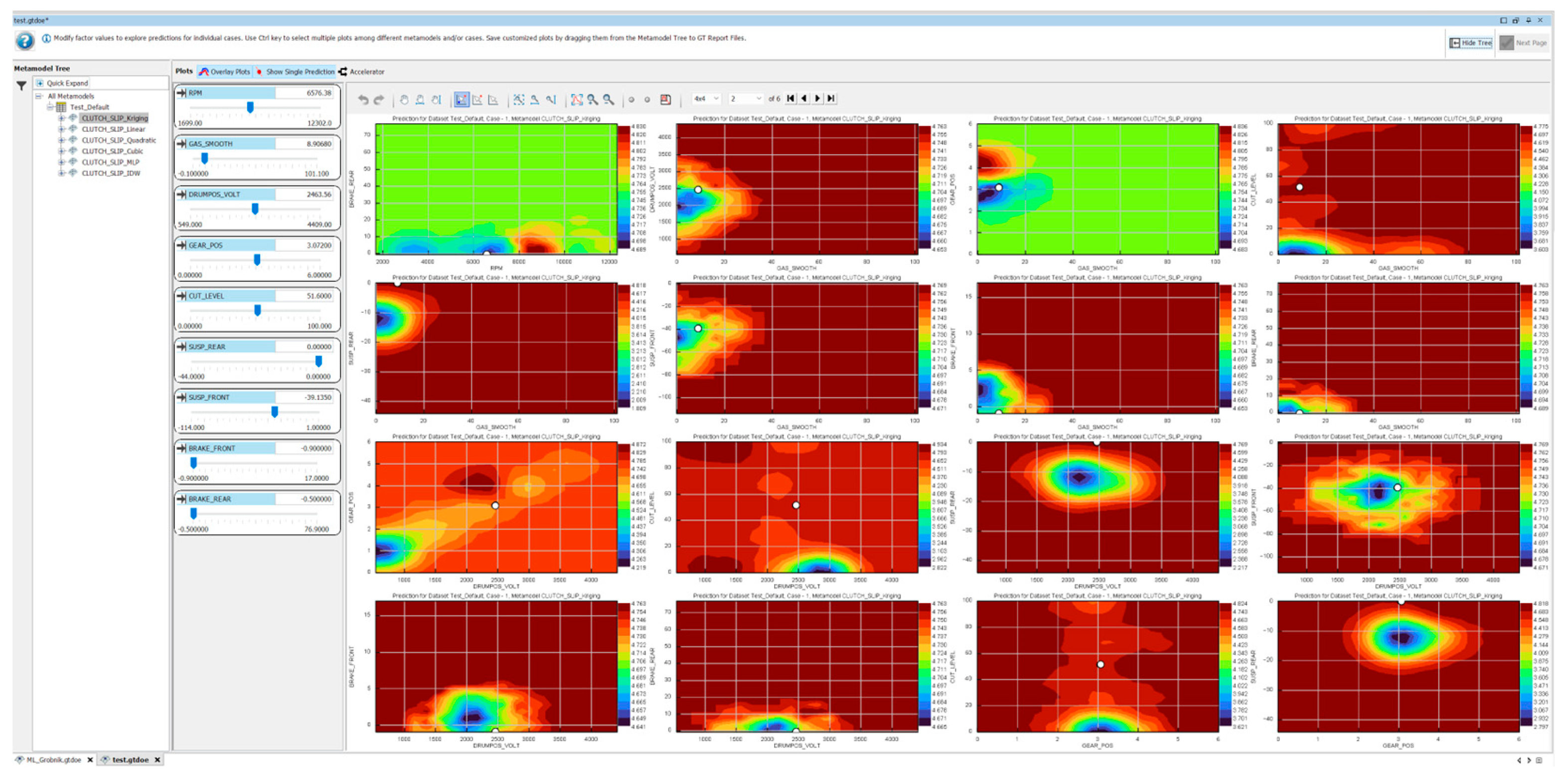

2.2. Application of Neural Networks for Preliminary Selection of Influential Parameters

2.3. KPI Identification Algorithms

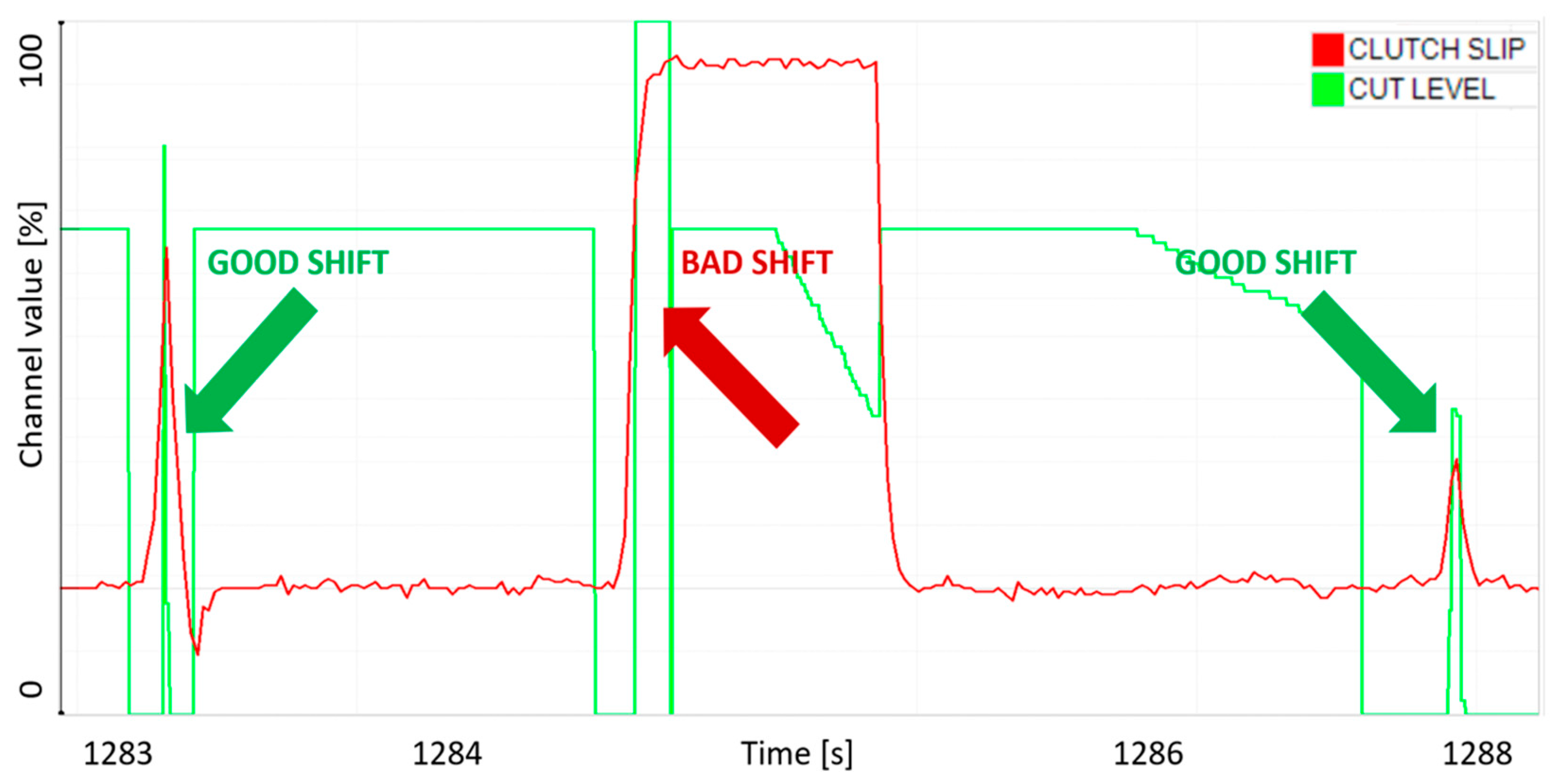

- Gear Shift Delay (ms): The temporal delay between the rider’s gear shift command and the actual gear change.

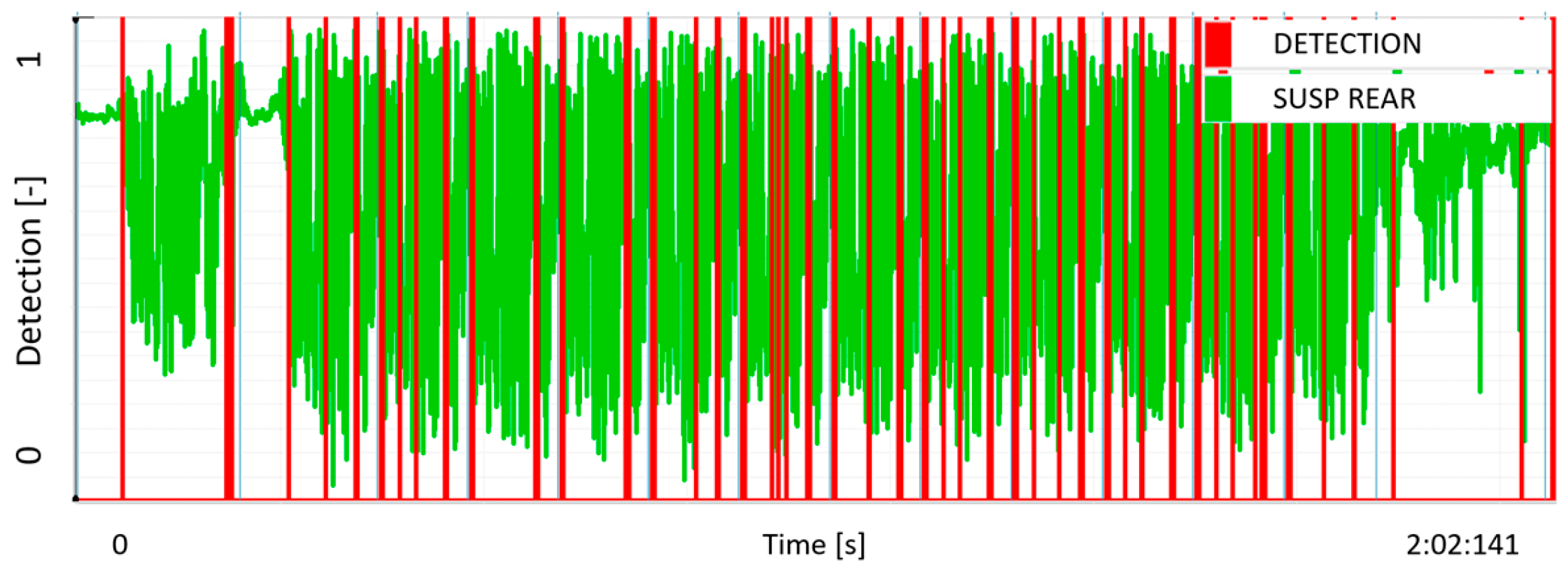

- Suspension Utilization and shock absorber hardening (mm): The maximum suspension travel observed within a given track sector, indicative of the rider’s interaction with track topography.

- Identification of inappropriate throttle control: Identification of locations where the driver does not use full throttle opening in places where this incorrect manipulation leads to time loss.

- Grip index

- Wheel slip

- And more

- Shifting Delay Detection:

- Suspension Utilization and shock absorber hardening:

2.4. Validation

3. Results and Discussion

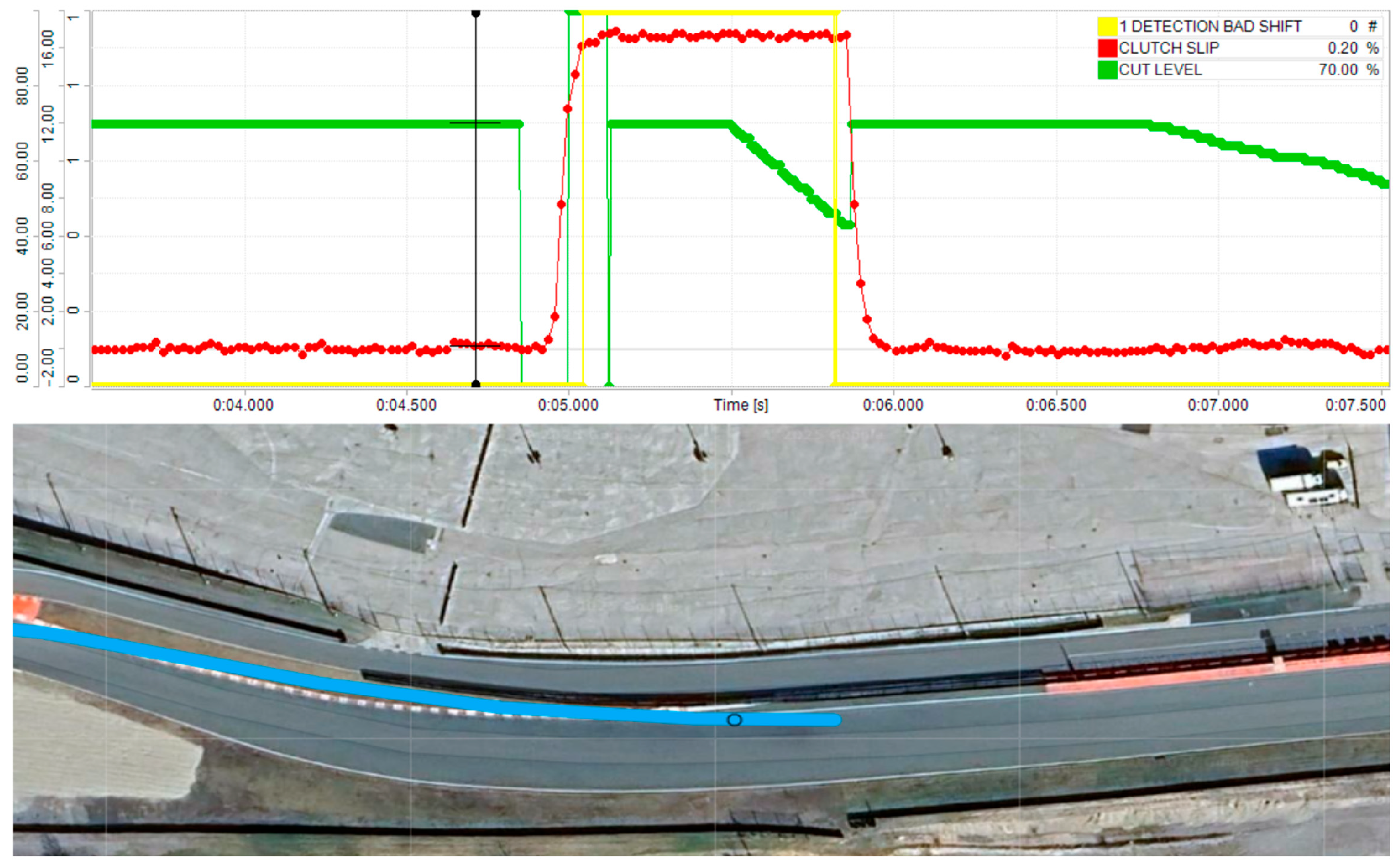

3.1. Shifting Delay Detection

3.2. Suspension Bottoming Detection

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Smith, T.; Kasantikul, V.; Ouellet, J.V.; Thom, D.; Browne, S.; Hurt, H.H., Jr. Visual Scanning of Motorcycle Riders: A Preliminary Look; Motorcycle Safety Foundation: Irvine, CA, USA, 2023. [Google Scholar]

- Cheng, W.; Gill, G.S.; Sakrani, T.; Dasu, M.; Zhou, J. Predicting motorcycle crash injury severity using weather data and alternative Bayesian multivariate crash frequency models. Accid. Anal. Prev. 2017, 108, 172–180. [Google Scholar] [CrossRef] [PubMed]

- Bhavsar, D.; Jaychandra, R.K.; Mittal, M. Data Acquisition and Performance Analysis during Real-Time Driving of a Two-Wheeler Electric Vehicle—A Case Study. World Electr. Veh. J. 2024, 15, 121. [Google Scholar] [CrossRef]

- Bartolozzi, M.; Boubezoul, A.; Bouaziz, S.; Savino, G.; Espié, S. Data-Driven Methodology for the Investigation of Riding Dynamics: A Motorcycle Case Study. IEEE Trans. Intell. Transp. Syst. 2023, 24, 10224–10237. [Google Scholar] [CrossRef]

- Choo, C. Real-Time Decision Making in Motorsports: Analytics for Improving Professional Car Race Strategy. Master’s Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2015. [Google Scholar]

- Heilmeier, A.; Thomaser, A.; Graf, M.; Betz, J. Virtual Strategy Engineer: Using Artificial Neural Networks for Making Race Strategy Decisions in Circuit Motorsport. Appl. Sci. 2020, 10, 7805. [Google Scholar] [CrossRef]

- SP Race Project. Available online: https://spraceproject.cz/pages/nas-pribeh (accessed on 26 May 2025).

- Ducati Panigale V2 2024. Available online: https://www.ducati.com/us/en/bikes/panigale/panigale-v2-my24 (accessed on 26 May 2025).

| Model | Ducati Panigale V2 |

|---|---|

| Year: | 2020 |

| Category: | Supersport |

| Engine type: | V2, four-stroke |

| Engine displacement: | 955 cm2 |

| Engine power: | 116 kW (10,750 min−1) |

| Engine torque: | 104 Nm (9000 min−1) |

| Frame construction: | Aluminum monobloc |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fojtasek, J.; Bohm, M. Development of a Data-Driven Methodology for Rapid Identification of Key Performance Indicators in Motorcycle Racing. Eng. Proc. 2025, 113, 12. https://doi.org/10.3390/engproc2025113012

Fojtasek J, Bohm M. Development of a Data-Driven Methodology for Rapid Identification of Key Performance Indicators in Motorcycle Racing. Engineering Proceedings. 2025; 113(1):12. https://doi.org/10.3390/engproc2025113012

Chicago/Turabian StyleFojtasek, Jan, and Michael Bohm. 2025. "Development of a Data-Driven Methodology for Rapid Identification of Key Performance Indicators in Motorcycle Racing" Engineering Proceedings 113, no. 1: 12. https://doi.org/10.3390/engproc2025113012

APA StyleFojtasek, J., & Bohm, M. (2025). Development of a Data-Driven Methodology for Rapid Identification of Key Performance Indicators in Motorcycle Racing. Engineering Proceedings, 113(1), 12. https://doi.org/10.3390/engproc2025113012