1. Introduction

With the advent of Industry 5.0, the integration of Artificial Intelligence (AI) into industry systems is a major step towards intelligent, adaptive, robust, and human-oriented production environments [

1,

2,

3]. It is a consequence of increasing requirements in operational efficiency, sustainability, and responsiveness across aerospace, energy, and precision manufacturing sectors [

4,

5,

6].

A wide range of AI techniques—Machine Learning (ML), Deep Learning (DL), Reinforcement Learning (RL), and Federated Learning (FL)—have demonstrated significant value across industrial functions including predictive maintenance, quality inspection, real-time monitoring, and autonomous decision-making [

7,

8,

9,

10,

11]. These models enable the detection of anomalies, prediction of failures, and dynamic adaptation of processes, thereby reducing downtime and enhancing product consistency [

12,

13,

14].

However, practical implementation faces persistent challenges. These include the heterogeneity and lack of standardization in industrial data [

15,

16], difficulties in interpreting complex models [

17,

18], and integration issues across digital platforms [

19,

20]. Additionally, although Federated Learning preserves data privacy and supports collaborative intelligence, it introduces concerns about fairness, trust, and vulnerability to adversarial threats [

21,

22].

Parallel to that, Reinforcement Learning is gaining momentum as a method of optimization of complex tasks like scheduling and resource allocation in uncertain environments [

9,

23]. Applications of Explainable AI (XAI) are on the rise to offer decision transparency and regulatory requirements in mission-critical applications [

17,

18]. Effort is also centered around developing self-healing systems [

24].

This paper is a systematic overview of 40 recent contributions to map the capabilities, limitations, and trends of AI in key industry-related processes. It highlights areas such as predictive maintenance [

7,

25], intelligent control [

26], digitalization [

27], and cybersecurity [

28]. The utmost importance has been given to the place of trustworthy FL, scalable architectures, and human–AI collaboration to achieve secure, explainable, and resilient industrial environments with the emergence of Industry 5.0.

The sections of the paper are arranged as follows:

Section 2 describes the criteria for article selection and the process of synthesis.

Section 3 outlines the terminology of the subject of the article.

Section 4 exhibits results of the literature review and challenges and methodologies of this subject.

Section 5 summarizes this article and future prospects.

2. Materials and Methods

2.1. Literature Selection and Review Process

This review examined peer-reviewed journal articles, conference papers, and authoritative reports on the development of Artificial Intelligence (AI) to make manufacturing processes smoother. Sources were retrieved from top databases such as Scopus, Web of Science, and Google Scholar and publishers like Springer, Elsevier, IEEE, and Wiley. The choice was confined to publications over the past seven years to keep the articles current. The keywords were searched through combinations of search words such as “Artificial Intelligence,” “Predictive Maintenance,” “Machine Learning,” “Quality Control,” “Federated Learning,” and “Reinforcement Learning” applied to “industry” variations. The inclusion criteria were studies on AI-based methods used in predictive maintenance, quality inspection, and intelligent decision-making in manufacturing.

2.2. Data Extraction and Synthesis

From each chosen publication, relevant information was gathered, such as AI methods used, addressed industrial applications, sources of data, and outcomes reported. Extracted data were organized in a systematic way in order for comparisons among studies to be examined analytically. An emphasis on finding similarities and differences in applications of AI, as well as measuring effectiveness and limitations reported, allowed for successful structured synthesis of findings, highlighting trends as well as gaps in the literature base.

2.3. Ethical Considerations

This research, based on publicly available material and not requiring formal ethical approval, has been carefully referenced to ensure original authorship and academic integrity.

2.4. Review Questions

To start the article topic, we formulated the following questions to be covered by our literature review (

Table 1).

3. Synopsis of Terminology

In the context of integrating Artificial Intelligence into critical industrial processes, we have several fundamental concepts and terminologies, including the following:

3.1. Artificial Intelligence (AI)

Artificial Intelligence refers to the use of data-driven algorithms—such as Machine Learning, Deep Learning, Reinforcement Learning, and Federated Learning—to automate, monitor, and optimize industrial operations. Key applications include predictive maintenance [

7,

10], process planning [

9], quality control [

11,

13], and energy efficiency [

6], aiming to reduce costs and enhance decision-making in complex environments [

1,

2,

15].

3.2. Machine Learning (ML)

Machine Learning uses statistical models to enable systems to learn from historical and real-time data, without explicit programming [

1,

29]. Using in fault detection [

13,

25], preventive maintenance [

7,

10], process optimization [

30], quality prediction [

11] and for anomaly detection [

12]. These applications improve efficiency, reliability, and decision-making in industrial environments [

2,

31].

3.3. Deep Learning (DL)

Deep Learning utilizes sophisticated neural networks to process industrial data of high dimensionality in real or near-real time [

1,

13]. The models support precise fault detection, classification of defects, predictive diagnosis, and visual inspection, primarily in life-critical industries like energy, aerospace, and chemical manufacturing [

4,

11,

25]. DL improves control, monitoring, and decision-making by uncovering intricate patterns, and work on explainability enhances trust and transparency.

3.4. Predictive Maintenance

Predictive maintenance is the application of AI and ML methods to process equipment sensor data to anticipate and avoid machine failures prior to their occurrence. This prevents downtime and maintenance expenses in manufacturing processes [

7].

3.5. Smart Manufacturing

Smart manufacturing is a strategy that employs computer-integrated manufacturing, flexibility, and spontaneous design changes, employing digital information technology and flexible technical labor. It is centered on streamlined production and recycling, and generally applies technologies like big data processing, industrial connectivity, and advanced robots [

1,

15].

3.6. Industry 4.0

Also referred to as the Fourth Industrial Revolution, it is the current trend of automation and data exchange in manufacturing technologies. It includes cyber–physical systems, the Internet of Things (IoT), cloud computing, and AI, leading to smart factories with enhanced flexibility and efficiency [

1].

3.7. Industry 5.0

Industry 5.0 builds upon the technological advancements of Industry 4.0 by fostering a deeper collaboration between humans and intelligent machines. This new phase emphasizes human-centric manufacturing processes, aiming to integrate advanced AI, collaborative robotics, and mass customization. The focus shifts from pure automation to creating sustainable, resilient, and personalized production systems that place human creativity and well-being at the core of industrial innovation [

1,

15].

3.8. Cyber–Physical Systems (CPSs)

Computer-based algorithms control and monitor mechanisms in CPSs, which are highly integrated with the internet and its users. CPSs in manufacturing allow physical operations to become highly interdependent with processes based on computing, allowing for sophisticated automation and control [

15].

3.9. Internet of Things (IoT)

The Internet of Things is an interconnection of physical devices equipped with sensors, software, and other technologies for linking and sharing data with other devices and systems through the internet. In manufacturing, IoT supports monitoring and controlling production in real time [

7].

3.10. Supervised Learning

Supervised learning is used in training models using datasets, in which known outputs are already available. It is frequently used in manufacturing for defect identification, quality forecasting, and process categorization [

1].

3.11. Unsupervised Learning

Unsupervised learning works with unlabeled data in an attempt to reveal hidden patterns such as clusters or outliers. In an industrial setup, it is useful in data exploration, in finding patterns, or fault detection—without predefined labeling [

1].

3.12. Semi-Supervised Learning

Semi-supervised learning combines an allotment of labeled data with an immense pool of unlabeled data. The method enhances the generalization power of a model while reducing labeling effort and expenses when working with huge datasets—proving very helpful in industrial use [

1].

3.13. Reinforcement Learning

Reinforcement Learning is a form of Machine Learning in which an agent improves by trial and error—through taking actions and getting rewarded or punished. In manufacturing, it is applied to optimize complicated operations and make better decisions with experience over time [

9].

3.14. Federated Learning

Federated learning is the learning methodology by which models are trained on different distributed devices or edge servers holding local data—without the data being shared in reality. It enhances data privacy and protection and is thus well-suited to collaborative industrial environments.

Table 2 provides an overview of the Machine Learning paradigms, highlighting how supervised, unsupervised, semi-supervised, reinforcement, and federated learning contribute to various industrial tasks, including classification, fault detection, condition monitoring and adaptive decision-making.

3.15. Explainable AI (XAI)

Explainable AI refers to methods that explain AI system decisions in understandable human language. In the manufacturing industry, XAI ensures transparency, promotes trustworthiness, and complies with industry standards [

21].

3.16. Critical Industrial Processes

Critical industrial processes are vital operations within a manufacturing system that directly influence production effectiveness, product quality, and safety. Identifying and monitoring Critical Process Parameters (CPPs) are important to maintain these processes within predetermined limits and peak performance operation [

1,

16].

3.17. Process Manufacturing

This refers to manufacturing goods through mixing raw materials or ingredients according to some predetermined formula or recipe. It is applied mainly in the chemical, food and beverage, and pharmaceutical industries where products are mass-produced and cannot be disassembled into what they were when made [

16].

3.18. Process Safety

This is a systematic program to maintain the integrity of high-risk operations and equipment through well-designed engineering and practices and sound operations. Its primary aim is to prevent and control incidents that potentially release dangerous materials or energy—mitigating the risk to prevent toxic exposures, fires, or explosions [

7].

3.19. Industrial Process Control

This is a manufacturing methodology employed to track, control, and optimize production processes. It uses control theory and automation technologies to make equipment operate effectively and uniformly—turning raw materials into high-quality and reliable products [

1,

15].

3.20. Efficiency of an Industrial Process

Manufacturing efficiency is the capacity to produce high-quality outputs from inputs (such as materials, labor, and energy) with very little wastage. Greater efficiency is delivered by AI and automation through real-time optimization, predictive analytics, and minimizing errors [

1].

3.21. Critical Process Parameters (CPPs)

These are critical production variables whose monitoring closely detects any divergence from regular operations or product quality. In maintaining stability and quality standards, keeping these parameters tightly controlled is necessary [

16].

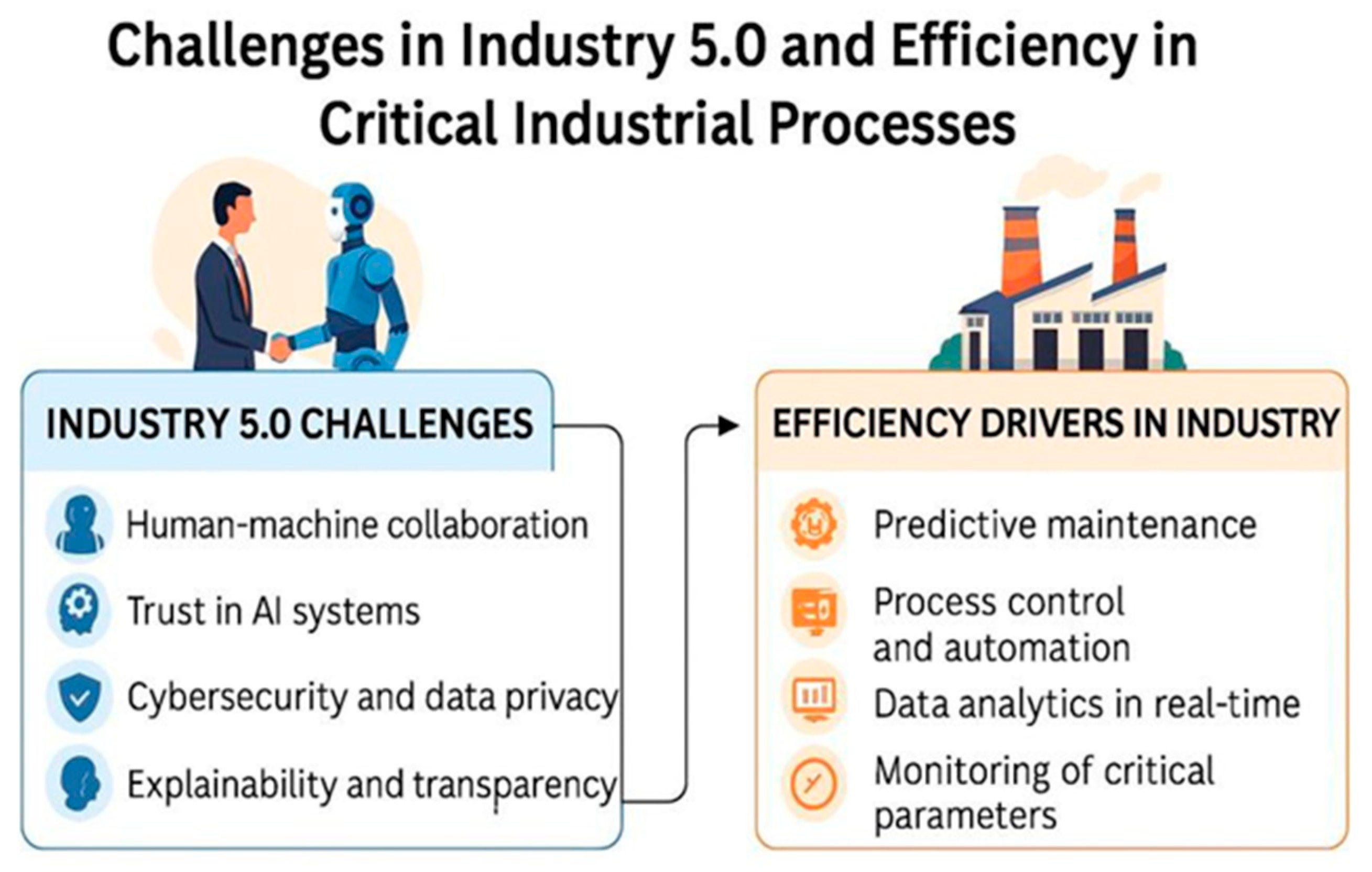

Figure 1 illustrates key Industry 5.0 challenges—such as human-machine collaboration, trust in AI systems, cybersecurity, data privacy, and the need for explainability—and links them to main efficiency drivers in critical industrial processes, including predictive maintenance, process automation, real-time data analytics, and monitoring of critical parameters.

4. Key Findings and Discussion

4.1. Research Results

New developments in Deep Learning (DL), Reinforcement Learning (RL), and Federated Learning (FL) have shown these models to be among the best AI solutions to optimize high-risk industrial processes [

1,

8,

9]. RL is superior in dynamic environments in applications like production scheduling, adaptive process control, and inventory optimization [

9,

33]. DL, with its ability to represent complex distributions of data, is extremely effective in applications like visual inspection, defect detection, and real-time quality control [

1,

11,

13]. FL is a superior solution for privacy-preserving collaborative training in geographically dispersed manufacturing locations where data exchange could be limited.

Predictive maintenance utilizing AI, backed by ML and DL methods, allows for earlier detection of faults and monitoring of conditions through sensor data in real time. These methods have registered substantial cuts in unplanned downtime and maintenance expenses [

7,

25]. DL also facilitates autonomous fault classification and anomaly detection with less manual supervision [

11,

26]. FL, on the other hand, offers a secure method of cross-facility learning that does not compromise sensitive plant data [

22].

RL’s learning capabilities enable systems in the industrial domain to adjust to dynamic production constraints, ensuring greater system flexibility and stability [

1,

9]. Existing implementations are, nonetheless, plagued by persistent challenges that include heterogeneous data formats, restricted model interpretability, cybersecurity vulnerabilities, and model transferability across heterogeneous industrial domains [

15,

21]. In FL environments, model update integrity, fairness, and estimating client contribution are open research challenges [

8,

21].

In addition, there are no standard frameworks to measure the ROI of AI-based predictive maintenance projects that limit large-scale applications [

7]. The solution to these issues requires AI systems that are trustworthy, transparent, and scalable to fit the constraints of industry [

1,

18].

Table 3 summarizes how AI techniques enhance industrial processes: predictive maintenance lowers downtime, learning methods improve efficiency and quality control, unsupervised models detect anomalies early, and explainable AI increases transparency and trust.

4.2. Discussion and Open Challenges

Even with increased popularity, large-scale AI application in high-risk process industries remains plagued by major challenges [

1,

2]. The biggest problem is data quality and accessibility: AI models depend on large sets of labeled data, but in process industries, data tends to remain dispersed, unstructured, or unavailable due to outdated systems and privacy issues [

7,

8]. Federated Learning and synthetic data are promising solutions that are privacy-preserving [

21,

22].

Model interpretability is another barrier. Many high-performing models, especially Deep Learning, lack transparency, which limits trust in critical sectors [

1,

10]. Explainable AI (XAI) methods are being developed to address this [

17,

21].

Generalization is also challenging—models are usually required to be retrained on new equipment or environments. Transfer and meta-learning methods are being designed to enhance cross-domain adaptability [

9].

AI systems are increasingly vulnerable to cyber-attacks, including adversarial examples and data tampering. Research now focuses on adversarial robustness, secure model training, and blockchain-based traceability [

8,

28].

Ethical and legal issues are surfacing with uncertain standards of AI liability and safety. Systems emphasizing fairness, responsibility, and human control are necessary to enable trusted deployment [

1,

35].

Overcoming these challenges calls for joint efforts by researchers, industry, and regulators to create AI systems that are secure, explainable, and robust [

21].

4.3. Requirement Fixing of Our Approach

In order to overcome the limitations of using AI in industry, a systematic and forward-looking solution is needed. AI models need to become adaptable to evolving industry environments. The combination of Reinforcement Learning with transfer or meta-learning increases flexibility and generalization across diverse tasks [

9,

31].

Second, integrating Explainable AI (XAI) improves trust and transparency. Attention-based networks, rule-based logic, and visual interfaces help operators interpret and validate AI decisions [

1,

17,

21].

Third, cybersecurity must be reinforced. Industrial AI systems require anomaly detection, adversarial robustness, and zero-trust frameworks. Blockchain offers secure traceability in distributed environments [

8,

22,

28].

Fourth, secure and scalable data processing is essential. Federated Learning and syn-thetic data make training possible without centralizing sensitive data, which is important in regulated industries [

7,

21].

Finally, wide-scale uptake is reliant on interoperability and regulatory harmonization. It is through industry-standard development of ethical frameworks in conjunction with developers, operators, and regulators that sustainable AI deployment is facilitated [

15,

30].

Achieving these conditions allows safer, more reliable, and effective application of AI in risky industrial applications.

5. Conclusions

Artificial Intelligence (AI) is transforming industrial operations through the introduction of sophisticated automation, predictive precision, and real-time optimization. Strategies such as Machine Learning, Deep Learning, and Reinforcement Learning have fueled advancement in maintenance, quality control, and process optimization, bringing down the cost and improving operational reliability.

However, there are still major challenges. Fragmentation of data, privacy issues, and difficulty in interpreting AI models are major bottlenecks in adoption. The increased risk of cyber-attacks and the inability to scale AI into varied environments are also major challenges.

In the future, the integration of AI with the likes of edge computing, blockchain, and quantum computing has the potential to enhance security and performance. Federated Learning enables privacy-preserving collaboration, and Explainable AI builds trust and transparency. To overcome the limitations of today, a robust partnership between AI experts, engineers, and cybersecurity professionals will be needed to drive effective and accountable industrial AI deployment.

Author Contributions

Conceptualization, K.A.; methodology, K.A.; software, K.A.; validation, K.A., R.S. and W.C.; formal analysis, K.A.; investigation, K.A.; resources, K.A., R.S. and W.C.; data curation, K.A., R.S. and W.C.; writing—original draft preparation, K.A.; writing—review and editing, R.S. and W.C.; visualization, K.A., R.S. and W.C.; supervision, R.S. and W.C.; project administration, K.A., R.S. and W.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analyzed in this study.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Gao, R.X.; Krüger, J.; Merklein, M.; Möhring, H.-C.; Váncza, J. Artificial Intelligence in manufacturing: State of the art, perspectives, and future directions. CIRP Ann. Manuf. Technol. 2024, 73, 723–749. [Google Scholar] [CrossRef]

- Peres, R.S.; Jia, X.; Lee, J.; Sun, K.; Colombo, A.W.; Barata, J. Industrial artificial intelligence in Industry 4.0: Systematic review, challenges and outlook. IEEE Access 2020, 8, 220121–220139. [Google Scholar] [CrossRef]

- Banitaan, S.; Al-refai, G.; Almatarneh, S.; Alquran, H. A review on artificial intelligence in the context of Industry 4.0. Int. J. Adv. Comput. Sci. Appl. 2023, 14, 23–30. [Google Scholar] [CrossRef]

- Mao, S.; Wang, B.; Tang, Y.; Qian, F. Opportunities and challenges of artificial intelligence for green manufacturing in the process industry. Engineering 2019, 5, 995–1002. [Google Scholar] [CrossRef]

- Toderas, M. Artificial Intelligence for Sustainability: A Systematic Review and Critical Analysis of AI Applications, Challenges, and Future Directions. Sustainability 2025, 17, 8049. [Google Scholar] [CrossRef]

- Viitala, R.; Miettinen, M.; Marquez, R.; Hämäläinen, A.; Karhinen, A.; Barrios, N.; Gonzalez, R.; Pal, L.; Jameel, H.; Holmberg, K. Integration of Artificial Intelligence and Sustainable Energy Management in the Pulp and Paper Industry: A Path to Decarbonization. Renew. Sustain. Energy Rev. 2025, 218, 115809. [Google Scholar] [CrossRef]

- Benhanifia, A.; Ben Cheikh, Z.; Oliveira, P.M.; Valente, A.; Lima, J. Systematic review of predictive maintenance practices in the manufacturing sector. Intell. Syst. Appl. 2025, 26, 200501. [Google Scholar] [CrossRef]

- Pruckovskaja, V.; Weissenfeld, A.; Heistracher, C.; Graser, A.; Kafka, J.; Leputsch, P. Federated Learning for Predictive Maintenance and Quality Inspection in Industrial Applications. In Proceedings of the 2023 Prognostics and Health Management Conference (PHM), Paris, France, 31 May–2 June 2023. [Google Scholar]

- Farooq, A.; Iqbal, K. A Survey of Reinforcement Learning for Optimization in Automation. In Proceedings of the 2024 IEEE 20th International Conference on Automation Science and Engineering (CASE), Bari, Italy, 28 August–1 September 2024. [Google Scholar]

- Patil, D. Artificial Intelligence-Driven Predictive Maintenance In Manufacturing: Enhancing Operational Efficiency, Minimizing Downtime, And Optimizing Resource Utilization. J. Manuf. Syst. 2024, 72, 134–145. [Google Scholar]

- Ettalibi, A.; Elouadia, A.; Mansour, M. AI and Computer Vision-based Real-time Quality Control: A Review of Industrial Applications. Procedia Comput. Sci. 2024, 231, 212–220. [Google Scholar] [CrossRef]

- Zhou, H.; Yang, H.; Li, H.; Ma, Y.; Yu, S.; Shi, J.; Cheng, J.; Gao, P.; Yu, B.; Miao, Z.; et al. Advancements in Machine Learning for Material Design and Process Optimization in Additive Manufacturing. China Foundry 2024, 21, 101–115. [Google Scholar] [CrossRef]

- Tao, X.; Gong, X.; Zhang, X.; Yan, S.; Adak, C. Deep Learning for Unsupervised Anomaly Localization in Industrial Images: A Survey. IEEE Trans. Instrum. Meas. 2022, 71, 1–21. [Google Scholar] [CrossRef]

- Ahmad, H.M.; Rahimi, A. Deep Learning Methods for Object Detection in Smart Manufacturing: A Survey. J. Manuf. Syst. 2022, 64, 181–196. [Google Scholar] [CrossRef]

- Senkus, P.; Glabiszewski, W.; Wysokińska-Senkus, A.; Pańka, A. Process Definitions—Critical Literature Review. Eur. Res. Stud. J. 2021, 24, 241–255. [Google Scholar] [CrossRef]

- Velioglu, R.; Göpfert, J.P.; Artelt, A.; Hammer, B. Explainable artificial intelligence for improved modeling of processes. arXiv 2022, arXiv:2212.00695. [Google Scholar] [CrossRef]

- Moosavi, S.; Farajzadeh-Zanjani, M.; Razavi-Far, R.; Palade, V.; Saif, M. Explainable AI in Manufacturing and Industrial Cyber–Physical Systems: A Survey. Electronics 2024, 13, 3497. [Google Scholar] [CrossRef]

- Huang, Z.; Shen, Y.; Li, J.; Marcel, F.; Brecher, C. A Survey on AI-Driven Digital Twins in Industry 4.0: Smart Manufacturing and Advanced Robotics. Sensors 2021, 21, 6340. [Google Scholar] [CrossRef]

- Tariq, A.; Serhani, M.A.; Sallabi, F.; Qayyum, T.; Barka, E.S.; Shuaib, K.A. Trustworthy Federated Learning: A Survey. arXiv 2023, arXiv:2305.11537. [Google Scholar] [CrossRef]

- Dritsas, E.; Trigka, M. Federated Learning for IoT: A Survey of Techniques, Challenges, and Applications. J. Sens. Actuator Netw. 2025, 14, 9. [Google Scholar] [CrossRef]

- Olawale, M.; Ayeh, A.A.; Adekola, F.; Precious, A.S.; Joshua, O.; Oladosu, T. A review on the intersection of artificial intelligence on building resilient infrastructure, promoting inclusive and sustainable industrialization and fostering innovation. Int. J. Eng. Mod. Technol. 2023, 9, 44–74. [Google Scholar] [CrossRef]

- Johnphill, O.; Sadiq, A.S.; Al-Obeidat, F.; Al-Khateeb, H.; Taheir, M.A.; Kaiwartya, O.; Ali, M. Self-Healing in Cyber–Physical Systems Using Machine Learning: A Critical Analysis of Theories and Tools. Future Interne 2023, 15, 244. [Google Scholar] [CrossRef]

- Cheng, X.; Chaw, J.K.; Goh, K.M.; Ting, T.T.; Sahrani, S.; Ahmad, M.N.; Abdul Kadir, R.; Ang, M.C. Systematic Literature Review on Visual Analytics of Predictive Maintenance in the Manufacturing Industry. Sensors 2022, 22, 6321. [Google Scholar] [CrossRef]

- Bortz, M.; Dadhe, K.; Engell, S.; Gepert, V.; Kockmann, N.; Müller-Pfefferkorn, R.; Schindler, T.; Urbas, L. AI in Process Industries—Current Status and Future Prospects. Chem. Ing. Tech. 2023, 95, 975–988. [Google Scholar] [CrossRef]

- Lee, J.; Bagheri, B.; Kao, H.-A. A cyber-physical systems architecture for Industry 4.0-based manufacturing systems. Manuf. Lett. 2015, 3, 18–23. [Google Scholar] [CrossRef]

- Owen, A.; Ajeigbe, K. Addressing Cybersecurity in AI-Enhanced Manufacturing Systems. Technical Report. December 2021. Available online: https://www.researchgate.net/publication/390366806_Addressing_Cybersecurity_in_AI-Enhanced_Manufacturing_Systems (accessed on 2 December 2025).

- Weichert, D.; Link, P.; Stoll, A.; Rüping, S.; Ihlenfeldt, S.; Wrobel, S. A Review of Machine Learning for the Optimization of Production Processes. Int. J. Adv. Manuf. Technol. 2019, 104, 1889–1902. [Google Scholar] [CrossRef]

- Sumarlin, T.; Kusumajaya, R.A. AI Challenges and Strategies for Business Process Optimization in Industry 4.0: Systematic Literature Review. J. Manag. Inform. 2024, 3, 195–211. [Google Scholar] [CrossRef]

- Li, N. Ethical Considerations in Artificial Intelligence: A Comprehensive Discussion from the Perspective of Computer Vision. SHS Web Conf. 2023, 179, 04024. [Google Scholar] [CrossRef]

- Kovalenko, I.; Barton, K.; Moyne, J.; Tilbury, D.M. Opportunities and Challenges to Integrate Artificial Intelligence into Manufacturing Systems. arXiv 2023, arXiv:2303.11139. [Google Scholar] [CrossRef]

- Perera, Y.S.; Ratnaweera, D.A.A.C.; Dasanayaka, C.H.; Abeykoon, C. The role of artificial intelligence-driven soft sensors in advanced sustainable process industries: A critical review. Eng. Appl. Artif. Intell. 2023, 121, 105988. [Google Scholar] [CrossRef]

- Popp, G.-P.; Racz, S.-G.; Breaz, R.-E.; Oleksik, V.-Ș.; Popp, M.-O.; Morar, D.-E.; Chicea, A.-L.; Popp, I.-O. State of the art in incremental forming: Process variants, tooling, industrial applications for complex part manufacturing and sustainability of the process. Materials 2024, 17, 5811. [Google Scholar] [CrossRef]

- Parikh, M.; Ramavath, S.K.; Prathi, S.; Sheela, K.; Handaragal, R.; Nathiya, R. Deep learning for automated defect detection in industrial manufacturing. In Proceedings of the 2025 6th International Conference on Electronics and Sustainable Communication Systems (ICESC), Coimbatore, India, 10–12 September 2025. [Google Scholar]

- Mat Pauzi, N.A.; Mustaza, S.M.; Zainal, N.; Zaman, M.H.M.; Moubark, A.M. Artificial Intelligence in Precision Agriculture: A Review. J. Kejuruter. 2025, 37, 1025–1047. [Google Scholar] [CrossRef]

- Eyo-Udo, N.L.; Apeh, C.E.; Bristol-Alagbariya, B.; Udeh, C.A.; Ewim, C.P.-M. Review of Ethical Considerations and Dilemmas in the Field of AI and Machine Learning. Int. J. Multidiscip. Res. Growth Eval. 2025, 6, 827–834. Available online: https://www.allmultidisciplinaryjournal.com/uploads/archives/20250118181128_MGE-2025-1-124.1.pdf (accessed on 2 December 2025). [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).