Predictive Maintenance Approaches: A Systematic Literature Review †

Abstract

1. Introduction

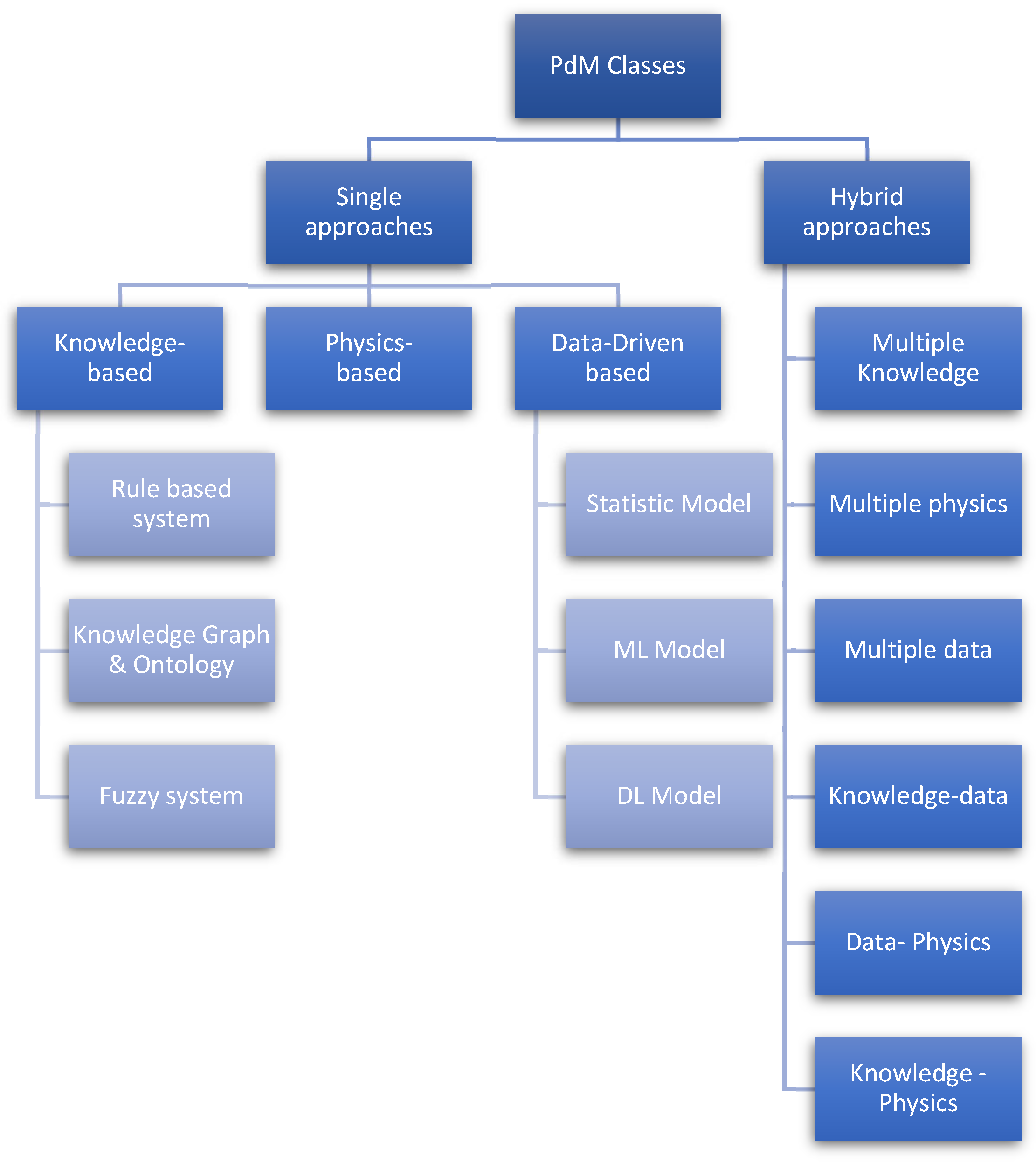

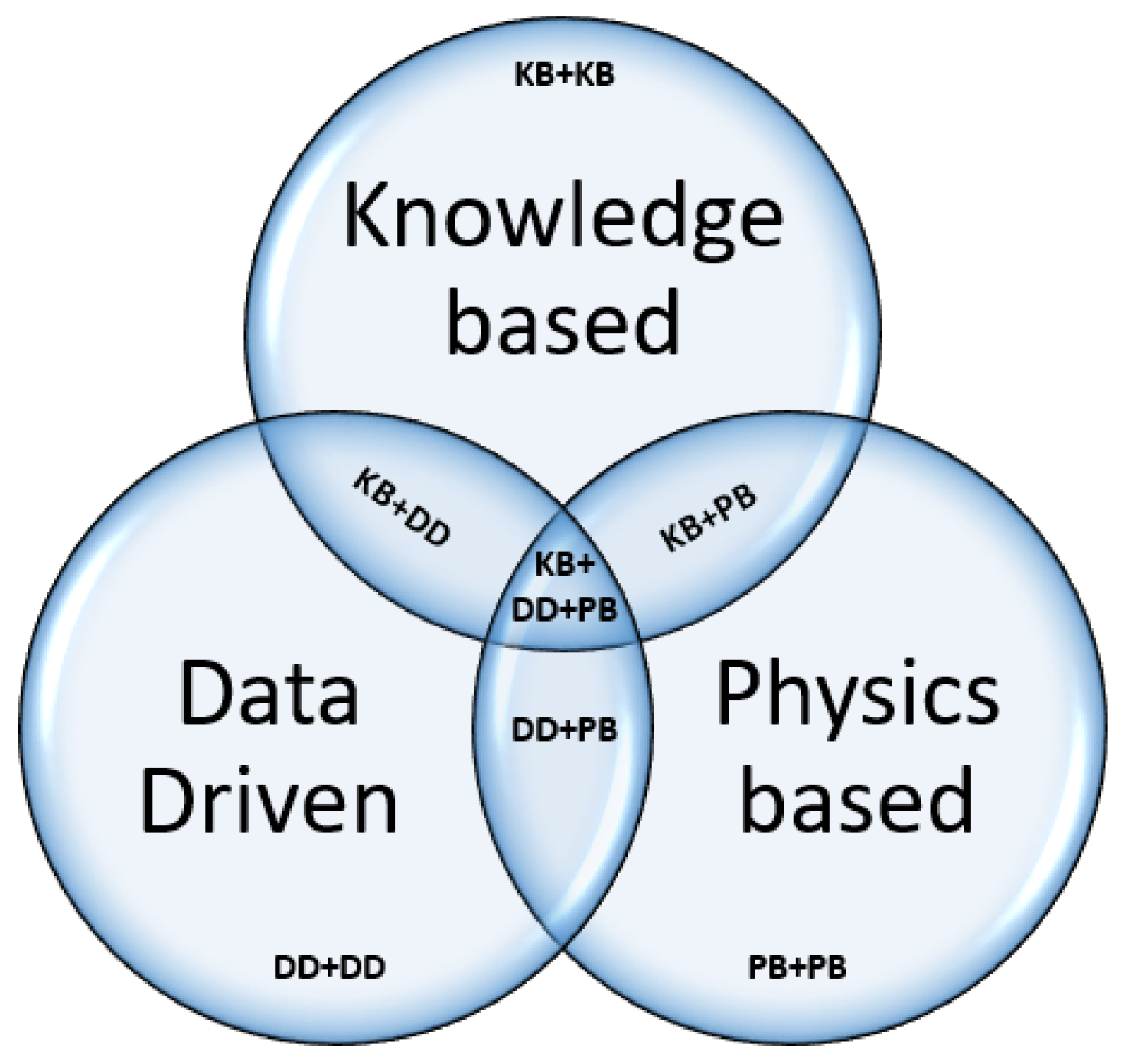

2. Single and Hybrid Approaches

- Single-model approach: This approach can be classified into three distinct categories: physics-based (utilizes the physical model of the system for prediction), knowledge-based (uses historical data for prediction of imminent faults), and data-driven (uses collected data from the installed sensors in the machinery).

- Multi-model approach: Called the hybrid approach, it leverages two or three of the previously mentioned models (different configurations are possible).

2.1. Physics-Based Models

2.2. Knowledge-Based Models

2.2.1. Rule-Based Systems

2.2.2. Case-Based Systems—Knowledge Graphs and Ontologies

2.2.3. Fuzzy Knowledge-Based Systems

2.3. Data-Driven Models

2.3.1. Statistical-Based Models

2.3.2. Machine Learning Based Models

- Supervised learning: Supervised ML algorithms rely usually on historical data with known outcomes to make predictions by grouping a set of rules. The labeled data would help forecast equipment failures [34]. In the context of PdM, common supervised ML methods include classification (predict discrete outcomes to classify equipment status) or regression (predict continuous outcomes, suitable for RUL prediction with high accuracy). Here, some ML algorithms developed in PdM are as follows: decision tree (DT) [35,36], random forests [37,38], support vector machine (SVM) [39].

- Unsupervised learning: Unsupervised learning models rely on unlabeled data, distinguishing categories and detecting deviations from normal behavior. To group similar data points and identify outliers, clustering models, such as k-means are used [40].

- Semi-supervised learning: This approach consists of training the model using labeled data and then identifying patterns in the rest of the unlabeled data in order to improve prediction. This combination is particularly used when there is a large amount of unlabeled data and a limited amount of labeled data [41]. Zhang [42] introduces the variational autoencoder, a semi-supervised learning approach for bearing diagnosis to effectively leverage datasets with limited labeled data.

2.3.3. Deep Learning-Based Models

2.4. Hybrid Approaches

- Multiple physical models: The physical laws incorporated into mathematical models can enhance the precision of predictive maintenance tasks.

- Multipl knowledge-based models: These models are not often used in recent PdM research studies.

- Multiple data-driven models: They are as precise as single models, but they continue to face problems because of the difficulty of interpreting the results.

- Combination of data-driven models and knowledge-based models: Combine the strengths of both knowledge and data-driven models to improve the accuracy of decision-making systems. Human expert rules and established theories will help data-driven models to extract patterns and insights using exploration techniques.

- Combination of knowledge-based models and physics-based models: Works using this model are limited due to the complexity of mixing expert’s knowledge and mathematical laws despite the well-explicative results they can provide.

- Combination of data-driven models and physical- based models: This model is the most frequently used in research due to the high performance of data-driven models and their complementarity with the accuracy of physical model models.

- Combination of three single model approaches: This model leverages not only the advantages of each model but also the complexity of combining their outputs and results.

3. Discussion—Challenges and Limitations

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Prajapati, A.; Bechtel, J.; Ganesan, S. Condition Based Maintenance: A Survey. J. Qual. Maint. Eng. 2012, 18, 384–400. [Google Scholar] [CrossRef]

- Zhu, T.; Ran, Y.; Zhou, X.; Wen, Y. A survey of predictive maintenance: Systems, purposes and approaches. arXiv 2019, arXiv:1912.07383. [Google Scholar]

- Montero Jimenez, J.J.; Schwartz, S.; Vingerhoeds, R.; Grabot, B.; Salaün, M. Towards Multi-Model Approaches to Predictive Maintenance: A Systematic Literature Survey on Diagnostics and Prognostics. J. Manuf. Syst. 2020, 56, 539–557. [Google Scholar] [CrossRef]

- Downey, A.; Lui, Y.-H.; Hu, C.; Laflamme, S.; Hu, S. Physics-Based Prognostics of Lithium-Ion Battery Using Non-Linear Least Squares with Dynamic Bounds. Reliab. Eng. Syst. Saf. 2019, 182, 1–12. [Google Scholar] [CrossRef]

- Li, J.; Schaefer, D.; Milisavljevic-Syed, J. A Decision-Based Framework for Predictive Maintenance Technique Selection in Industry 4.0. Procedia CIRP 2022, 107, 77–82. [Google Scholar] [CrossRef]

- Aivaliotis, P.; Arkouli, Z.; Georgoulias, K.; Makris, S. Degradation Curves Integration in Physics-Based Models: Towards the Predictive Maintenance of Industrial Robots. Robot. Comput.-Integr. Manuf. 2021, 71, 102177. [Google Scholar] [CrossRef]

- Wu, Y.; Li, W.; Wang, Y.; Zhang, K. Remaining Useful Life Prediction of Lithium-Ion Batteries Using Neural Network and Bat-Based Particle Filter. IEEE Access 2019, 7, 54843–54854. [Google Scholar] [CrossRef]

- Tiwari, R.; Sharma, N.; Kaushik, I.; Tiwari, A.; Bhushan, B. Evolution of IoT & Data Analytics Using Deep Learning. In Proceedings of the 2019 International Conference on Computing, Communication, and Intelligent Systems (ICCCIS), Greater Noida, India, 18–19 October 2019; pp. 418–423. [Google Scholar]

- Arena, F.; Collotta, M.; Luca, L.; Ruggieri, M.; Termine, F.G. Predictive Maintenance in the Automotive Sector: A Literature Review. Math. Comput. Appl. 2022, 27, 2. [Google Scholar] [CrossRef]

- Popkova, E.G.; Ragulina, Y.V.; Bogoviz, A.V. Fundamental Differences of Transition to Industry 4.0 from Previous Industrial Revolutions. In Industry 4.0: Industrial Revolution of the 21st Century; Popkova, E.G., Ragulina, Y.V., Bogoviz, A.V., Eds.; Studies in Systems, Decision and Control; Springer International Publishing: Cham, Switzerland, 2019; Volume 169, pp. 21–29. ISBN 978-3-319-94309-1. [Google Scholar]

- Antomarioni, S.; Pisacane, O.; Potena, D.; Bevilacqua, M.; Ciarapica, F.E.; Diamantini, C. A Predictive Association Rule-Based Maintenance Policy to Minimize the Probability of Breakages: Application to an Oil Refinery. Int. J. Adv. Manuf. Technol. 2019, 105, 3661–3675. [Google Scholar] [CrossRef]

- Liang, J.S. A Process-Based Automotive Troubleshooting Service and Knowledge Management System in Collaborative Environment. Robot. Comput.-Integr. Manuf. 2020, 61, 101836. [Google Scholar] [CrossRef]

- Polenghi, A.; Roda, I.; Macchi, M.; Pozzetti, A. Ontology-Augmented Prognostics and Health Management for Shopfloor-Synchronised Joint Maintenance and Production Management Decisions. J. Ind. Inf. Integr. 2022, 27, 100286. [Google Scholar] [CrossRef]

- Canito, A.; Corchado, J.; Marreiros, G. Bridging the Gap Between Domain Ontologies for Predictive Maintenance with Machine Learning. In Trends and Applications in Information Systems and Technologies; Rocha, Á., Adeli, H., Dzemyda, G., Moreira, F., Ramalho Correia, A.M., Eds.; Advances in Intelligent Systems and Computing; Springer International Publishing: Cham, Switzerland, 2021; Volume 1366, pp. 533–543. ISBN 978-3-030-72650-8. [Google Scholar]

- Arista, R.; Mas, F.; Vallellano, C. Initial Approach to an Industrial Resources Ontology in Aerospace Assembly Lines. In Product Lifecycle Management Enabling Smart X; Nyffenegger, F., Ríos, J., Rivest, L., Bouras, A., Eds.; IFIP Advances in Information and Communication Technology; Springer International Publishing: Cham, Switzerland, 2020; Volume 594, pp. 285–294. ISBN 978-3-030-62806-2. [Google Scholar]

- Cho, S.; May, G.; Kiritsis, D. A Semantic-Driven Approach for Industry 4.0. In Proceedings of the 2019 15th International Conference on Distributed Computing in Sensor Systems (DCOSS), Santorini Island, Greece, 29–31 May 2019; pp. 347–354. [Google Scholar]

- Baban, M.; Baban, C.F.; Suteu, M.D. Maintenance Decision-Making Support for Textile Machines: A Knowledge-Based Approach Using Fuzzy Logic and Vibration Monitoring. IEEE Access 2019, 7, 83504–83514. [Google Scholar] [CrossRef]

- Alexandrino, P.D.S.L.; Gomes, G.F.; Cunha, S.S. A Robust Optimization for Damage Detection Using Multiobjective Genetic Algorithm, Neural Network and Fuzzy Decision Making. Inverse Probl. Sci. Eng. 2020, 28, 21–46. [Google Scholar] [CrossRef]

- Prommachan, W.; Pipathattakul, M.; Surin, P.; Srinoi, P. Predictive Maintenance Model for Rotating Machinery Using a Fuzzy Logic. In Proceedings of the 2022 International Conference on Power, Energy and Innovations (ICPEI), Pattaya Chonburi, Thailand, 19–21 October 2022; pp. 1–4. [Google Scholar]

- Prommachan, W.; Surin, P.; Srinoi, P.; Pipathattakul, M. A Fuzzy Logic Modelling of Predictive Maintenance in Rotating Machinery. Arch. Mater. Sci. Eng. 2024, 126, 15–22. [Google Scholar] [CrossRef]

- Zhang, W.; Yang, D.; Wang, H. Data-Driven Methods for Predictive Maintenance of Industrial Equipment: A Survey. IEEE Syst. J. 2019, 13, 2213–2227. [Google Scholar] [CrossRef]

- Hallaji, S.M.; Fang, Y.; Winfrey, B.K. Data Augmentation for Deep Learning-Based Detection of Pump Anomalous Conditions. IOP Conf. Ser. Earth Environ. Sci. 2022, 1101, 082022. [Google Scholar] [CrossRef]

- Fernandes, M.; Canito, A.; Corchado, J.M.; Marreiros, G. Fault Detection Mechanism of a Predictive Maintenance System Based on Autoregressive Integrated Moving Average Models. In Proceedings of the 16th International Conference on Distributed Computing and Artificial Intelligence, Ávila, Spain, 26–28 June 2019; Herrera, F., Matsui, K., Rodríguez-González, S., Eds.; Advances in Intelligent Systems and Computing; Springer International Publishing: Cham, Switzerland, 2020; Volume 1003, pp. 171–180. ISBN 978-3-030-23886-5. [Google Scholar]

- Diversi, R.; Lenzi, A.; Speciale, N.; Barbieri, M. An Autoregressive-Based Motor Current Signature Analysis Approach for Fault Diagnosis of Electric Motor-Driven Mechanisms. Sensors 2025, 25, 1130. [Google Scholar] [CrossRef]

- Song, R. Research on Bayesian Method and Its Application. Theor. Nat. Sci. 2025, 92, 54–59. [Google Scholar] [CrossRef]

- De Pater, I.; Reijns, A.; Mitici, M. Alarm-Based Predictive Maintenance Scheduling for Aircraft Engines with Imperfect Remaining Useful Life Prognostics. Reliab. Eng. Syst. Saf. 2022, 221, 108341. [Google Scholar] [CrossRef]

- Shao, Z.; Kumral, M. Implementing Gaussian Process Modelling in Predictive Maintenance of Mining Machineries. Min. Technol. Trans. Inst. Min. Metall. 2024, 133, 348–368. [Google Scholar] [CrossRef]

- Bera, B.; Huang, S.-C.; Lin, P.T.; Chiu, Y.-J.; Liang, J.-W. Bayesian Architecture for Predictive Monitoring of Unbalance Faults in a Turbine Rotor–Bearing System. Sensors 2024, 24, 8123. [Google Scholar] [CrossRef]

- Chinyuchin, Y.M.; Solov’ev, A.S. Application of Markov Processes for Analysis and Control of Aircraft Maintainability. Civ. Aviat. High Technol. 2020, 23, 71–83. [Google Scholar] [CrossRef]

- Guo, C.; Liang, Z. A Predictive Markov Decision Process for Optimizing Inspection and Maintenance Strategies of Partially Observable Multi-State Systems. Reliab. Eng. Syst. Saf. 2022, 226, 108683. [Google Scholar] [CrossRef]

- Xu, R.; Wang, H.; Peng, M.; Liu, Y. An Improved Regularized Particle Filter for Remaining Useful Life Prediction in Nuclear Plant Electric Gate Valves. Nucl. Eng. Technol. 2022, 54, 2107–2119. [Google Scholar] [CrossRef]

- Zhao, X.; Kang, Y.; Yan, H.; Ju, F. Semi-Supervised Constrained Hidden Markov Model Using Multiple Sensors for Remaining Useful Life Prediction and Optimal Predictive Maintenance: For Remaining Useful Life Prediction and Optimal Predictive Maintenance. Annu. Conf. PHM Soc. 2019, 11. [Google Scholar] [CrossRef]

- Ordóñez, C.; Sánchez Lasheras, F.; Roca-Pardiñas, J.; Juez, F.J.D.C. A Hybrid ARIMA–SVM Model for the Study of the Remaining Useful Life of Aircraft Engines. J. Comput. Appl. Math. 2019, 346, 184–191. [Google Scholar] [CrossRef]

- Angelopoulos, A.; Michailidis, E.T.; Nomikos, N.; Trakadas, P.; Hatziefremidis, A.; Voliotis, S.; Zahariadis, T. Tackling Faults in the Industry 4.0 Era—A Survey of Machine-Learning Solutions and Key Aspects. Sensors 2019, 20, 109. [Google Scholar] [CrossRef] [PubMed]

- Kou, L.; Qin, Y.; Zhao, X.; Fu, Y. Integrating Synthetic Minority Oversampling and Gradient Boosting Decision Tree for Bogie Fault Diagnosis in Rail Vehicles. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2019, 233, 312–325. [Google Scholar] [CrossRef]

- Patil, S.S.; Phalle, V.M. Fault Detection of Anti-Friction Bearing Using AdaBoost Decision Tree. In Computational Intelligence: Theories, Applications and Future Directions—Volume I; Verma, N.K., Ghosh, A.K., Eds.; Advances in Intelligent Systems and Computing; Springer: Singapore, 2019; Volume 798, pp. 565–575. ISBN 978-981-13-1131-4. [Google Scholar]

- Aji, A.S.; Sashiomarda, J.A.; Handoko, D. Predictive Maintenance Magnetic Sensor Using Random Forest Method. J. Phys. Conf. Ser. 2020, 1528, 012030. [Google Scholar] [CrossRef]

- Beden, S.; Lakshmanan, K.; Giannetti, C.; Beckmann, A. Steelmaking Predictive Analytics Based on Random Forest and Semantic Reasoning. Appl. Sci. 2023, 13, 12778. [Google Scholar] [CrossRef]

- Han, H.; Cui, X.; Fan, Y.; Qing, H. Least Squares Support Vector Machine (LS-SVM)-Based Chiller Fault Diagnosis Using Fault Indicative Features. Appl. Therm. Eng. 2019, 154, 540–547. [Google Scholar] [CrossRef]

- Rodriguez, P.C.; Marti-Puig, P.; Caiafa, C.F.; Serra-Serra, M.; Cusidó, J.; Solé-Casals, J. Exploratory Analysis of SCADA Data from Wind Turbines Using the K-Means Clustering Algorithm for Predictive Maintenance Purposes. Machines 2023, 11, 270. [Google Scholar] [CrossRef]

- Ariyaluran Habeeb, R.A.; Nasaruddin, F.; Gani, A.; Targio Hashem, I.A.; Ahmed, E.; Imran, M. Real-Time Big Data Processing for Anomaly Detection: A Survey. Int. J. Inf. Manag. 2019, 45, 289–307. [Google Scholar] [CrossRef]

- Zhang, S.; Ye, F.; Wang, B.; Habetler, T.G. Semi-Supervised Bearing Fault Diagnosis and Classification Using Variational Autoencoder-Based Deep Generative Models. IEEE Sens. J. 2021, 21, 6476–6486. [Google Scholar] [CrossRef]

- Lee, J.; Mitici, M. Deep Reinforcement Learning for Predictive Aircraft Maintenance Using Probabilistic Remaining-Useful-Life Prognostics. Reliab. Eng. Syst. Saf. 2023, 230, 108908. [Google Scholar] [CrossRef]

- Mourtzis, D.; Angelopoulos, J.; Panopoulos, N. A Framework for Automatic Generation of Augmented Reality Maintenance & Repair Instructions Based on Convolutional Neural Networks. Procedia CIRP 2020, 93, 977–982. [Google Scholar] [CrossRef]

- Bampoula, X.; Siaterlis, G.; Nikolakis, N.; Alexopoulos, K. A Deep Learning Model for Predictive Maintenance in Cyber-Physical Production Systems Using LSTM Autoencoders. Sensors 2021, 21, 972. [Google Scholar] [CrossRef]

- Sang, G.M.; Xu, L.; De Vrieze, P. A Predictive Maintenance Model for Flexible Manufacturing in the Context of Industry 4.0. Front. Big Data 2021, 4, 663466. [Google Scholar] [CrossRef] [PubMed]

- Wiercioch, J. Development of a Hybrid Predictive Maintenance Model. J. Konbin 2023, 53, 141–158. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

El Hammoumi, Z.; Tebr, D.; Charkaoui, Y.; Satauri, I.; El Beqqali, O. Predictive Maintenance Approaches: A Systematic Literature Review. Eng. Proc. 2025, 112, 70. https://doi.org/10.3390/engproc2025112070

El Hammoumi Z, Tebr D, Charkaoui Y, Satauri I, El Beqqali O. Predictive Maintenance Approaches: A Systematic Literature Review. Engineering Proceedings. 2025; 112(1):70. https://doi.org/10.3390/engproc2025112070

Chicago/Turabian StyleEl Hammoumi, Zeineb, Dounia Tebr, Youssef Charkaoui, Imane Satauri, and Omar El Beqqali. 2025. "Predictive Maintenance Approaches: A Systematic Literature Review" Engineering Proceedings 112, no. 1: 70. https://doi.org/10.3390/engproc2025112070

APA StyleEl Hammoumi, Z., Tebr, D., Charkaoui, Y., Satauri, I., & El Beqqali, O. (2025). Predictive Maintenance Approaches: A Systematic Literature Review. Engineering Proceedings, 112(1), 70. https://doi.org/10.3390/engproc2025112070