Abstract

Since increasing attention has been given to predictive maintenance (PdM) of industrial equipment, in order to enhance operational efficiency, improve reliability, and reduce downtime, this powerful strategy offers significant benefits, holds clearly great promises, and is now regarded as a key for future perspective in Industry 4.0. There are various approaches to PdM, each offering its own set of advantages and disadvantages which are single and hybrid approaches to carrying out diagnostics and prognostics in PdM. In this paper we will compare these approaches according to different aspects such as complexity of data and interpretability of results. Moreover, we also discuss the barriers to successful adoption, such as data quality, system complexity, and the need for workforce training. Finally, this paper concludes by identifying future research directions in response to scientific problems, which will drive the next wave of innovation in predictive maintenance solutions.

1. Introduction

Industry 4.0 is revolutionized by the digitalization of industrial processes through new technologies such as Artificial Intelligence (AI), the Internet of Things (IoT), cloud computing and big data into industrial processes. These technologies have significantly transformed manufacturing and especially industrial maintenance practices. Predictive maintenance (PdM) is not a new field; indeed, some of its practices can be traced back to the 1940s, according ref. [1]. The past 30 years have seen a steady rise in PdM research interest; however, maintenance organizations across industries are at different stages of maturity. According to Zhu [2], some use reactive maintenance (RM), which fixes problems after they occur at the cost of unscheduled downtime, while others use preventive maintenance (PM), scheduled checks at regular intervals based on estimates and statistics recommendations, which could lead to unnecessary maintenance or missed opportunities for intervention, so organizations run the risk of performing too much maintenance or not enough. Advanced ones are already employing predictive maintenance (PdM), which tracks equipment health to anticipate failures before the asset breaks down, thereby minimizing unplanned downtime, avoiding costly repairs, and optimizing the performance of valuable assets. Thus, PdM can be defined as a strategy that aims to determine when maintenance operations should be performed [3].

To estimate precisely when maintenance should occur, PdM focuses on the current health state of the equipment using different models to carry out diagnostics and prognostics. Though not entirely exclusive, these two scopes are complementary: it is necessary to carry out the diagnosis first to make a prognosis.

The first task of Pdm is data-acquisition, where real-time data from various sources are collected and pre-processed; then, diagnostic analyses are performed on the acquired data to identify the failure mode; and finally, prognostic forecasts are performed to determine the health state of equipment by predicting when a component is likely to fail, thereby estimating its remaining useful life (RUL) and determining its future condition by analyzing degradation patterns of the monitored system.

This paper aims to perform a review of the different approaches used for diagnostics and prognostics in PdM which are single approaches and hybrid approaches. In Section 1, we present briefly the research methodology employed in this review. Section 2 discusses the different models used according to this classification and, provides a look at their applications over the last 5 years. Section 3 addresses the comparison between models and highlights challenges and limitations of PdM.

In this context, we analyze articles from renowned bibliographic databases such as Scopus, Web of Science and others. We have only selected studies between 2019 and 2024 on predictive maintenance and algorithms most commonly used in the approaches studied in this review in order to build our work on the most current data, relying on the latest developments and findings in this field.

To structure our approach and select the most relevant articles, we did not limit our search to a specific field of application, given that all industries are concerned by maintenance. However, we relied on the diversity of the algorithms used in the different studies in question to conclude with a complete comparison of the use of each of them. Hence, we establish the following research questions to evaluate the contributions of previous studies and capitalize on their results: What are the existing studies, approaches, and models applied in the context of predictive maintenance? What are the unresolved challenges and limitations in these studies? How do they choose the right algorithm for the right application? What are the advantages and disadvantages of using each of them?

These questions guided our literature review, whose purpose is to analyze and compare the different approaches used in PdM and highlight the advantages and limitations of these models.

2. Single and Hybrid Approaches

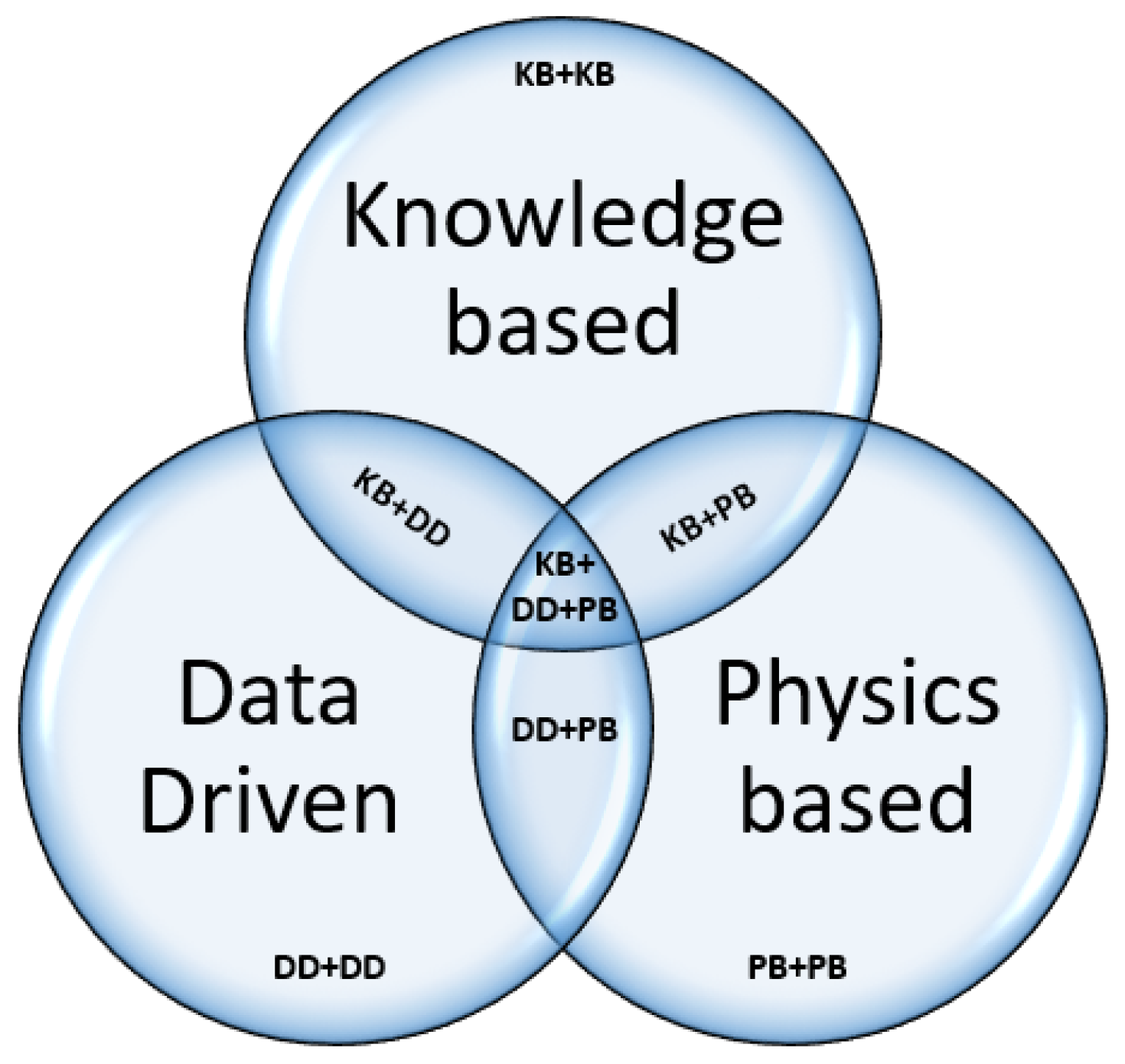

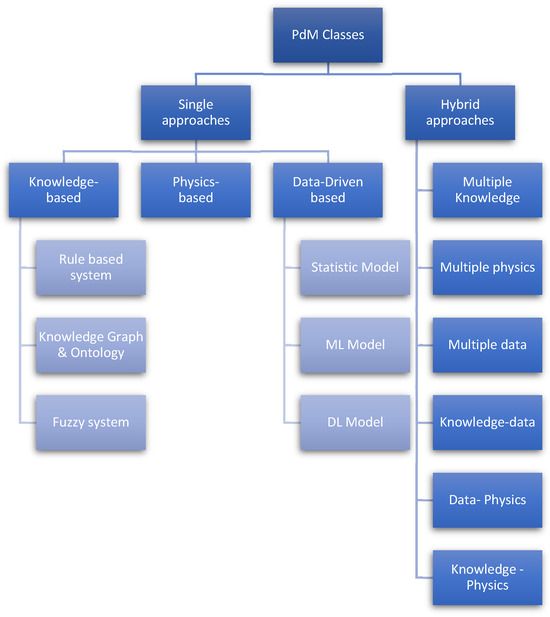

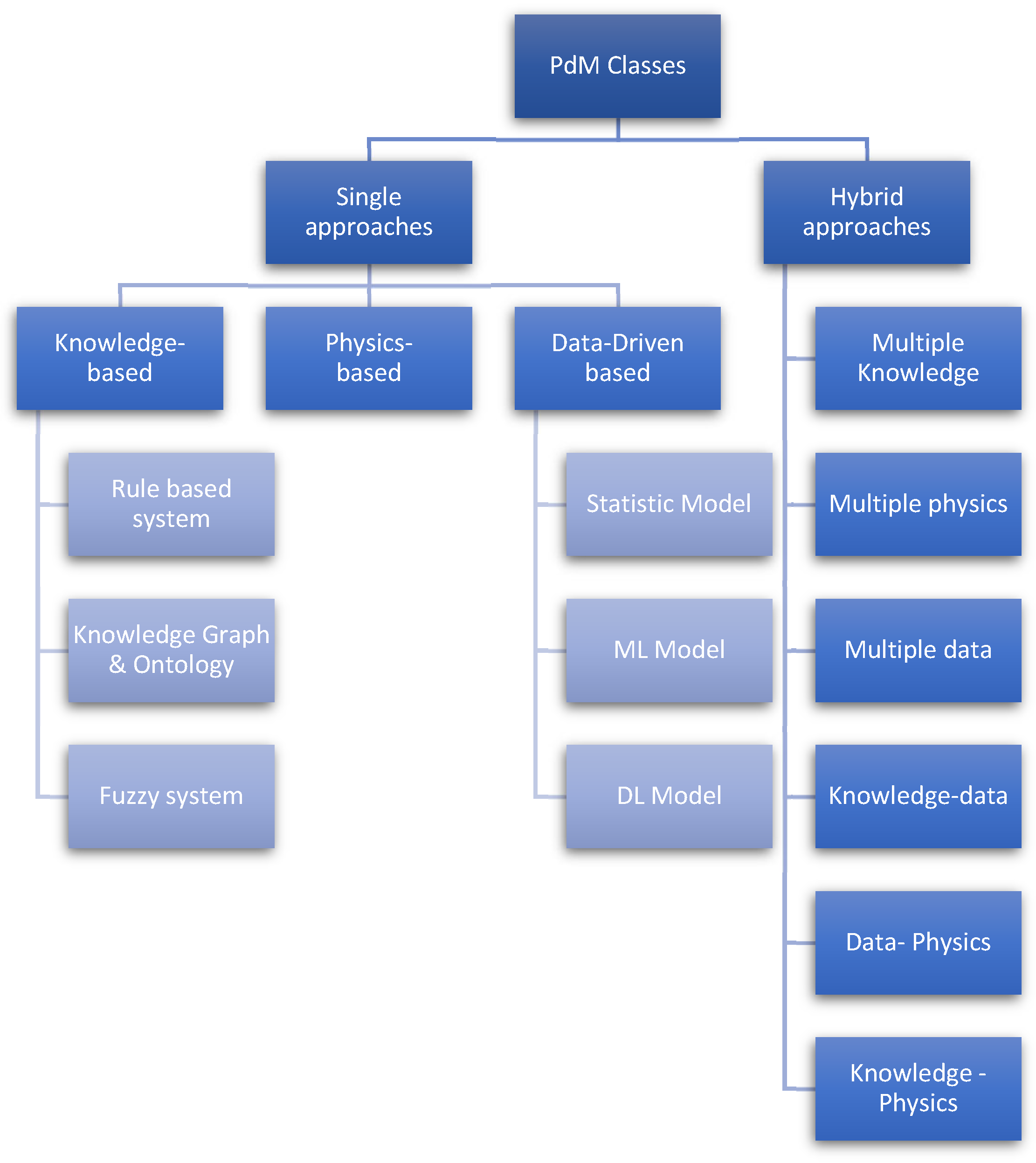

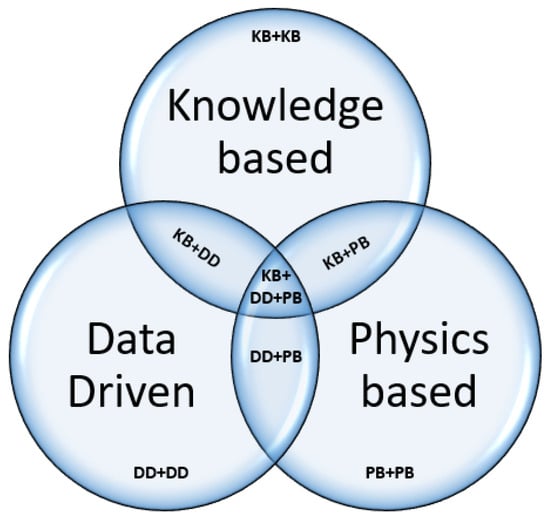

Numerous research studies have investigated various model architectures to perform diagnostics, and prognostics. Two main approaches, illustrated in Figure 1, can be extracted from the systematic review carried out by the following [3]:

- Single-model approach: This approach can be classified into three distinct categories: physics-based (utilizes the physical model of the system for prediction), knowledge-based (uses historical data for prediction of imminent faults), and data-driven (uses collected data from the installed sensors in the machinery).

- Multi-model approach: Called the hybrid approach, it leverages two or three of the previously mentioned models (different configurations are possible).

Figure 1.

Classification of the different approaches of PdM.

Figure 1.

Classification of the different approaches of PdM.

In this section, we report an overview of these categories. The structure of this section is summarized in Figure 1.

2.1. Physics-Based Models

Physics-based models employ mathematical and physical principles to assess system degradation, calculate its RUL, and describe quantitatively the behavior of failure mode [4] through physics modeled computational simulations [3,5,6]. Ref [7] develops an empirical degradation model for predicting lithium-ion battery RUL to enhance the reliability and safety of battery-operated systems. In [8], Tiwari introduces an application of three Gaussian Process Regression (GPR) models for monitoring bearing degradation features and evaluating their RUL.

Physical models do not require a large dataset and offer a precise description of degradation behavior and an optimal RUL prediction accuracy. However, they are challenging to implement in real-world scenarios and infeasible in practical applications, particularly when degradation patterns are unclear and unobservable.

2.2. Knowledge-Based Models

A knowledge-based model relies on knowledge and experience, typically rules, cases, or facts gathered over years of industrial system maintenance tasks. These empirical data can be incorporated into a computational model to facilitate decision-making by evaluating the correspondence between new operational data and the database from previous recorded situations [9,10], which enables fault detection, degradation description, and system failure prediction. In other words, this type of model predicts future failures based on past events by comparing the current situation and the previously recorded failures database.

The knowledge-based models can be categorized into rule-based, case-based and fuzzy knowledge-based models.

2.2.1. Rule-Based Systems

This model uses a combination of knowledge-based housing rules and the training data to create a series of iterative “IF-THEN” rules. It mainly consists of the following two kinds of rules: (1) “IF”: features in this part of the rules are used as inputs here, called active rules; they are based on expertise and provide reactive behavior. (2) “THEN”: this part of the rules populates the results as outputs called deductive rules. They are compared with existing rules or stored data and generate new information to solve the problem. In a practical case study [11], Antomarioni carried out an experimental application in an oil refinery, using maintenance-based models to reduce equipment failure risk. They associated a data mining tool for failure prediction and an integer programming model designed to enhance system reliability under time and cost constraints.

2.2.2. Case-Based Systems—Knowledge Graphs and Ontologies

There are two main topics in this model, which are synonymous knowledge graph and ontology. The system here learns from previous equipment behavior and compares the current situation with the past cases stored in a database to find similarities and identify potential future failures.

Many publications about ontology-based knowledge are [12,13,14,15]. Liang proposed an ontology-based solution for many automotive systems to enable them to connect and exchange information without any restriction in order to enhance decision-making and knowledge management [12]. Polenghi [13], for his part, adopts the ORMA (Ontology for Reliability-centered MAintenance) approach. Canito explores existing ontologies and semantic integration of data for both the description of sensors and the predictive maintenance and proposes an extension that bridges the gap with machine learning algorithms to train data mining models [14]. This study [15] highlights the use of case-based systems to facilitate knowledge management in aerospace production. Cho [16], uses semantic technology to manage and integrate data in Industry 4.0 applications (PdM) in combination with Digital Twin.

2.2.3. Fuzzy Knowledge-Based Systems

Fuzzy logic is a mathematical system, that uses a similar conditional structure of IF-THEN like rule-based models and that allows flexible decision-making, like a human perception, rather than relying on binary logic in which a statement can only be true or false. In this context, fuzzy systems are developed to provide an intermediate value to quantify the degree of truth or falsity of a statement.

Fuzzy knowledge-based systems are used in predictive maintenance because they can assure a better description of vague data, imprecise knowledge, and fuzzy situations. Baban [17] implemented a fuzzy-logic approach combined with vibration monitoring for failure detection in textile machines. Alexandrino [18] utilizes a fuzzy decision-making approach to determine the optimal solution among multiple genetic algorithms. Research studies [19,20] build a model for predictive maintenance by implementing fuzzy logic systems to assess rotating machinery efficiency.

2.3. Data-Driven Models

With the large amount of data volume and the complexity in data acquisition, many advances have been made on data-driven models and approaches for PdM in the last decade [21]. These models learn the behavior directly from machine operation data by evaluating its condition in real time using advanced monitoring approaches. The machine condition monitoring and maintenance decision-making process are the foundations of the data-driven maintenance technique [17]. Information collected from data is used to identify the failure, perform a health perception of the system [21], and predict its RUL. Despite all this performance, data-driven models depend on the dataset volume and its training quality. To address this challenge and improve PdM predictions, Hallaji [22] has used a new data augmentation solution, converting pump bearing fault signals to images, then applying multiple image augmentation methods to generate a robust training model with high accuracy.

Data-driven models can be classified into the following three categories: statistical models, ML, and DL models. In the first subcategory, several models are developed to monitor the degradation trajectory in a probabilistic way. Traditional machine learning methods, such as support vector machines (SVMs), random forests (RFs), and artificial neural networks (ANNs), are often used to extract features for predicting machine remaining useful life (RUL). As data complexity and volume increase, deep learning techniques, with their ability to automatically learn features, have shown exceptional performance in reliability estimation based on degradation data.

2.3.1. Statistical-Based Models

This approach analyzes random variable behavior compared with historical behaviors represented by data series in order to establish a correlation with operational time or other non-random lifecycle parameters. Such models enable simultaneous equipment condition monitoring and RUL forecasting.

Several efforts have been performed to review this topic in the last 5 years; the common models that can be deduced from these works are as follows: regression analysis [9]; autoregressive [23,24]; Bayesian [25]; stochastic filtering [26] (three processes are identified here; the Gaussian processes [27,28], the Markov chains [29,30], and the Levy model [3]), particle filters and their variants [31]; hidden Markov models [32]; and time series analysis [33].

2.3.2. Machine Learning Based Models

ML is a training model based on historical and real-time input data from different sources and its output behavior, to identify potential failures and train predictive models by shifting the model to create outputs that are closely aligned with the desired result. These models can deal with the complex relationships within data that are difficult to obtain using previous models [2].

ML methods can be categorized into three areas:

- Supervised learning: Supervised ML algorithms rely usually on historical data with known outcomes to make predictions by grouping a set of rules. The labeled data would help forecast equipment failures [34]. In the context of PdM, common supervised ML methods include classification (predict discrete outcomes to classify equipment status) or regression (predict continuous outcomes, suitable for RUL prediction with high accuracy). Here, some ML algorithms developed in PdM are as follows: decision tree (DT) [35,36], random forests [37,38], support vector machine (SVM) [39].

- Unsupervised learning: Unsupervised learning models rely on unlabeled data, distinguishing categories and detecting deviations from normal behavior. To group similar data points and identify outliers, clustering models, such as k-means are used [40].

- Semi-supervised learning: This approach consists of training the model using labeled data and then identifying patterns in the rest of the unlabeled data in order to improve prediction. This combination is particularly used when there is a large amount of unlabeled data and a limited amount of labeled data [41]. Zhang [42] introduces the variational autoencoder, a semi-supervised learning approach for bearing diagnosis to effectively leverage datasets with limited labeled data.

2.3.3. Deep Learning-Based Models

Machine learning algorithms present some limitations when they deal with a large amount of unstructured data and complex relationships between variables. To handle this data complexity, deep learning algorithms are used in predictive maintenance tasks to estimate RUL, detect anomalies, and enhance maintenance decisions. Wang in ref. [43] addresses the need for integrated PdM planning models by combining data-driven RUL prognostics and maintenance scheduling. The most common DL techniques related to the field of PdM are ad follows: (1) convolutional neural networks (CNNs) used in [44] for the extraction of high-level spatial inputs from sensor signal data; (2) recurrent neural networks (RNNs) are more suitable with sequential data; for example long short-term memory (LSTM) neural networks are predominantly used for the acquisition of temporal information from sensor because they can identify long-term dependencies in time-series data [45,46]; and (3) autoregressive integrated moving average (ARIMA) is employed for error detection and PdM to model equipment performance and predict future health statement from historical data by analyzing past observations and errors performance trends [23].

2.4. Hybrid Approaches

Hybrid models combine two or three types of single algorithms often a mix between physics-based, knowledge-based, and data-driven models to improve predictive accuracy and performance in complex production systems where relying on single approaches might not be effective and precise [47].

According to Jeminez [3], different types of multi-model approaches can be combined and are described in detail in his review; Figure 2, summarizes this classification.

Figure 2.

Combinations for multimodal PdM appoaches.

- Multiple physical models: The physical laws incorporated into mathematical models can enhance the precision of predictive maintenance tasks.

- Multipl knowledge-based models: These models are not often used in recent PdM research studies.

- Multiple data-driven models: They are as precise as single models, but they continue to face problems because of the difficulty of interpreting the results.

- Combination of data-driven models and knowledge-based models: Combine the strengths of both knowledge and data-driven models to improve the accuracy of decision-making systems. Human expert rules and established theories will help data-driven models to extract patterns and insights using exploration techniques.

- Combination of knowledge-based models and physics-based models: Works using this model are limited due to the complexity of mixing expert’s knowledge and mathematical laws despite the well-explicative results they can provide.

- Combination of data-driven models and physical- based models: This model is the most frequently used in research due to the high performance of data-driven models and their complementarity with the accuracy of physical model models.

- Combination of three single model approaches: This model leverages not only the advantages of each model but also the complexity of combining their outputs and results.

Recent research trends show a growing preference for the use of hybrid approaches especially, physical-based combined data-driven approaches, leveraging the strengths of both the modeling efficiency and complementarity.

3. Discussion—Challenges and Limitations

Each approach has its advantages and limitations, and the choice between single and hybrid models depends on the nature of the equipment, its specific requirements, the complexity of the system, and the availability of expertise and resources. This literature review provides a brief overview of the different approaches used in thepredictive maintenance field. In this section, we present the comparative summary of this work and deduce the following postulates:

Single approaches are easier to implement and more suitable for simpler systems where resources are limited and results are easy to understand, but they may suffer from underfitting, limited flexibility, or difficulty in handling complex data.

Knowledge-based approaches are easy to implement but less precise and flexible due to their dependence on the availability of expert experience.

Physics-based approaches are useful when mathematics and physical behavior are well understood, providing high precision but requiring significant expertise and data.

Data-driven approaches are highly flexible and can handle a large volume of complex data, but they depend on data quality and result interpretability.

Hybrid approaches are flexible, more powerful, and more effective in complex systems and changing environments. They combine the strengths of each model and provide a more adaptable solution and better performance of prediction precision and robustness. However, they require more resources, present more complexity, have difficulties in interpretation, have longer deployment times, and even have higher costs.

There is a wide choice of existing models, but none of the publications cited in this paper clearly discusses the criteria for choosing one model over another for a specific situation regarding some of its technical aspects, such as performance indicators or, operational context of external influence or constraints; they only focus on its basic functional aspects. In real-life complex systems face many failures at the same time and have to leverage heterogeneous data from different sources, which can make their fusion and modeling very difficult. Thus, there are still pertinent issues that need to be investigated and limitations that need to be overcome before adopting a successful PdM strategy.

4. Conclusions

This work provides a review and comparative analysis of single and hybrid approaches for PdM in Industry 4.0. Advantages and limitations of these approaches have been identified, but there are still improvements to be made to develop a tailored PdM strategy. Among the research directions that can be explored in the future are, firstly, developing extrapolation of existing solutions to complex system applications, handling the complexity of combining data from various sources, and managing the difficulty of incorporating external influence data. Secondly, exploring other technologies such as AR (Augmented Reality), VR (Virtual Reality), or Digital Twins, and investigating the integration with IoT and Edge Computing for a computational network closer to the data source. This can be a promising avenue for future research which will improve the accuracy and efficiency of PdM models and lead to reduced downtime, improved asset longevity, and minimized operational costs.

Author Contributions

Literature review, Z.E.H.; analysis, Z.E.H.; manuscript drafting, Z.E.H.; manuscript review, D.T. and Y.C.; supervision, D.T. and Y.C.; academic guidance, I.S. and O.E.B.; feedback, I.S. and O.E.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Prajapati, A.; Bechtel, J.; Ganesan, S. Condition Based Maintenance: A Survey. J. Qual. Maint. Eng. 2012, 18, 384–400. [Google Scholar] [CrossRef]

- Zhu, T.; Ran, Y.; Zhou, X.; Wen, Y. A survey of predictive maintenance: Systems, purposes and approaches. arXiv 2019, arXiv:1912.07383. [Google Scholar]

- Montero Jimenez, J.J.; Schwartz, S.; Vingerhoeds, R.; Grabot, B.; Salaün, M. Towards Multi-Model Approaches to Predictive Maintenance: A Systematic Literature Survey on Diagnostics and Prognostics. J. Manuf. Syst. 2020, 56, 539–557. [Google Scholar] [CrossRef]

- Downey, A.; Lui, Y.-H.; Hu, C.; Laflamme, S.; Hu, S. Physics-Based Prognostics of Lithium-Ion Battery Using Non-Linear Least Squares with Dynamic Bounds. Reliab. Eng. Syst. Saf. 2019, 182, 1–12. [Google Scholar] [CrossRef]

- Li, J.; Schaefer, D.; Milisavljevic-Syed, J. A Decision-Based Framework for Predictive Maintenance Technique Selection in Industry 4.0. Procedia CIRP 2022, 107, 77–82. [Google Scholar] [CrossRef]

- Aivaliotis, P.; Arkouli, Z.; Georgoulias, K.; Makris, S. Degradation Curves Integration in Physics-Based Models: Towards the Predictive Maintenance of Industrial Robots. Robot. Comput.-Integr. Manuf. 2021, 71, 102177. [Google Scholar] [CrossRef]

- Wu, Y.; Li, W.; Wang, Y.; Zhang, K. Remaining Useful Life Prediction of Lithium-Ion Batteries Using Neural Network and Bat-Based Particle Filter. IEEE Access 2019, 7, 54843–54854. [Google Scholar] [CrossRef]

- Tiwari, R.; Sharma, N.; Kaushik, I.; Tiwari, A.; Bhushan, B. Evolution of IoT & Data Analytics Using Deep Learning. In Proceedings of the 2019 International Conference on Computing, Communication, and Intelligent Systems (ICCCIS), Greater Noida, India, 18–19 October 2019; pp. 418–423. [Google Scholar]

- Arena, F.; Collotta, M.; Luca, L.; Ruggieri, M.; Termine, F.G. Predictive Maintenance in the Automotive Sector: A Literature Review. Math. Comput. Appl. 2022, 27, 2. [Google Scholar] [CrossRef]

- Popkova, E.G.; Ragulina, Y.V.; Bogoviz, A.V. Fundamental Differences of Transition to Industry 4.0 from Previous Industrial Revolutions. In Industry 4.0: Industrial Revolution of the 21st Century; Popkova, E.G., Ragulina, Y.V., Bogoviz, A.V., Eds.; Studies in Systems, Decision and Control; Springer International Publishing: Cham, Switzerland, 2019; Volume 169, pp. 21–29. ISBN 978-3-319-94309-1. [Google Scholar]

- Antomarioni, S.; Pisacane, O.; Potena, D.; Bevilacqua, M.; Ciarapica, F.E.; Diamantini, C. A Predictive Association Rule-Based Maintenance Policy to Minimize the Probability of Breakages: Application to an Oil Refinery. Int. J. Adv. Manuf. Technol. 2019, 105, 3661–3675. [Google Scholar] [CrossRef]

- Liang, J.S. A Process-Based Automotive Troubleshooting Service and Knowledge Management System in Collaborative Environment. Robot. Comput.-Integr. Manuf. 2020, 61, 101836. [Google Scholar] [CrossRef]

- Polenghi, A.; Roda, I.; Macchi, M.; Pozzetti, A. Ontology-Augmented Prognostics and Health Management for Shopfloor-Synchronised Joint Maintenance and Production Management Decisions. J. Ind. Inf. Integr. 2022, 27, 100286. [Google Scholar] [CrossRef]

- Canito, A.; Corchado, J.; Marreiros, G. Bridging the Gap Between Domain Ontologies for Predictive Maintenance with Machine Learning. In Trends and Applications in Information Systems and Technologies; Rocha, Á., Adeli, H., Dzemyda, G., Moreira, F., Ramalho Correia, A.M., Eds.; Advances in Intelligent Systems and Computing; Springer International Publishing: Cham, Switzerland, 2021; Volume 1366, pp. 533–543. ISBN 978-3-030-72650-8. [Google Scholar]

- Arista, R.; Mas, F.; Vallellano, C. Initial Approach to an Industrial Resources Ontology in Aerospace Assembly Lines. In Product Lifecycle Management Enabling Smart X; Nyffenegger, F., Ríos, J., Rivest, L., Bouras, A., Eds.; IFIP Advances in Information and Communication Technology; Springer International Publishing: Cham, Switzerland, 2020; Volume 594, pp. 285–294. ISBN 978-3-030-62806-2. [Google Scholar]

- Cho, S.; May, G.; Kiritsis, D. A Semantic-Driven Approach for Industry 4.0. In Proceedings of the 2019 15th International Conference on Distributed Computing in Sensor Systems (DCOSS), Santorini Island, Greece, 29–31 May 2019; pp. 347–354. [Google Scholar]

- Baban, M.; Baban, C.F.; Suteu, M.D. Maintenance Decision-Making Support for Textile Machines: A Knowledge-Based Approach Using Fuzzy Logic and Vibration Monitoring. IEEE Access 2019, 7, 83504–83514. [Google Scholar] [CrossRef]

- Alexandrino, P.D.S.L.; Gomes, G.F.; Cunha, S.S. A Robust Optimization for Damage Detection Using Multiobjective Genetic Algorithm, Neural Network and Fuzzy Decision Making. Inverse Probl. Sci. Eng. 2020, 28, 21–46. [Google Scholar] [CrossRef]

- Prommachan, W.; Pipathattakul, M.; Surin, P.; Srinoi, P. Predictive Maintenance Model for Rotating Machinery Using a Fuzzy Logic. In Proceedings of the 2022 International Conference on Power, Energy and Innovations (ICPEI), Pattaya Chonburi, Thailand, 19–21 October 2022; pp. 1–4. [Google Scholar]

- Prommachan, W.; Surin, P.; Srinoi, P.; Pipathattakul, M. A Fuzzy Logic Modelling of Predictive Maintenance in Rotating Machinery. Arch. Mater. Sci. Eng. 2024, 126, 15–22. [Google Scholar] [CrossRef]

- Zhang, W.; Yang, D.; Wang, H. Data-Driven Methods for Predictive Maintenance of Industrial Equipment: A Survey. IEEE Syst. J. 2019, 13, 2213–2227. [Google Scholar] [CrossRef]

- Hallaji, S.M.; Fang, Y.; Winfrey, B.K. Data Augmentation for Deep Learning-Based Detection of Pump Anomalous Conditions. IOP Conf. Ser. Earth Environ. Sci. 2022, 1101, 082022. [Google Scholar] [CrossRef]

- Fernandes, M.; Canito, A.; Corchado, J.M.; Marreiros, G. Fault Detection Mechanism of a Predictive Maintenance System Based on Autoregressive Integrated Moving Average Models. In Proceedings of the 16th International Conference on Distributed Computing and Artificial Intelligence, Ávila, Spain, 26–28 June 2019; Herrera, F., Matsui, K., Rodríguez-González, S., Eds.; Advances in Intelligent Systems and Computing; Springer International Publishing: Cham, Switzerland, 2020; Volume 1003, pp. 171–180. ISBN 978-3-030-23886-5. [Google Scholar]

- Diversi, R.; Lenzi, A.; Speciale, N.; Barbieri, M. An Autoregressive-Based Motor Current Signature Analysis Approach for Fault Diagnosis of Electric Motor-Driven Mechanisms. Sensors 2025, 25, 1130. [Google Scholar] [CrossRef]

- Song, R. Research on Bayesian Method and Its Application. Theor. Nat. Sci. 2025, 92, 54–59. [Google Scholar] [CrossRef]

- De Pater, I.; Reijns, A.; Mitici, M. Alarm-Based Predictive Maintenance Scheduling for Aircraft Engines with Imperfect Remaining Useful Life Prognostics. Reliab. Eng. Syst. Saf. 2022, 221, 108341. [Google Scholar] [CrossRef]

- Shao, Z.; Kumral, M. Implementing Gaussian Process Modelling in Predictive Maintenance of Mining Machineries. Min. Technol. Trans. Inst. Min. Metall. 2024, 133, 348–368. [Google Scholar] [CrossRef]

- Bera, B.; Huang, S.-C.; Lin, P.T.; Chiu, Y.-J.; Liang, J.-W. Bayesian Architecture for Predictive Monitoring of Unbalance Faults in a Turbine Rotor–Bearing System. Sensors 2024, 24, 8123. [Google Scholar] [CrossRef]

- Chinyuchin, Y.M.; Solov’ev, A.S. Application of Markov Processes for Analysis and Control of Aircraft Maintainability. Civ. Aviat. High Technol. 2020, 23, 71–83. [Google Scholar] [CrossRef]

- Guo, C.; Liang, Z. A Predictive Markov Decision Process for Optimizing Inspection and Maintenance Strategies of Partially Observable Multi-State Systems. Reliab. Eng. Syst. Saf. 2022, 226, 108683. [Google Scholar] [CrossRef]

- Xu, R.; Wang, H.; Peng, M.; Liu, Y. An Improved Regularized Particle Filter for Remaining Useful Life Prediction in Nuclear Plant Electric Gate Valves. Nucl. Eng. Technol. 2022, 54, 2107–2119. [Google Scholar] [CrossRef]

- Zhao, X.; Kang, Y.; Yan, H.; Ju, F. Semi-Supervised Constrained Hidden Markov Model Using Multiple Sensors for Remaining Useful Life Prediction and Optimal Predictive Maintenance: For Remaining Useful Life Prediction and Optimal Predictive Maintenance. Annu. Conf. PHM Soc. 2019, 11. [Google Scholar] [CrossRef]

- Ordóñez, C.; Sánchez Lasheras, F.; Roca-Pardiñas, J.; Juez, F.J.D.C. A Hybrid ARIMA–SVM Model for the Study of the Remaining Useful Life of Aircraft Engines. J. Comput. Appl. Math. 2019, 346, 184–191. [Google Scholar] [CrossRef]

- Angelopoulos, A.; Michailidis, E.T.; Nomikos, N.; Trakadas, P.; Hatziefremidis, A.; Voliotis, S.; Zahariadis, T. Tackling Faults in the Industry 4.0 Era—A Survey of Machine-Learning Solutions and Key Aspects. Sensors 2019, 20, 109. [Google Scholar] [CrossRef] [PubMed]

- Kou, L.; Qin, Y.; Zhao, X.; Fu, Y. Integrating Synthetic Minority Oversampling and Gradient Boosting Decision Tree for Bogie Fault Diagnosis in Rail Vehicles. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2019, 233, 312–325. [Google Scholar] [CrossRef]

- Patil, S.S.; Phalle, V.M. Fault Detection of Anti-Friction Bearing Using AdaBoost Decision Tree. In Computational Intelligence: Theories, Applications and Future Directions—Volume I; Verma, N.K., Ghosh, A.K., Eds.; Advances in Intelligent Systems and Computing; Springer: Singapore, 2019; Volume 798, pp. 565–575. ISBN 978-981-13-1131-4. [Google Scholar]

- Aji, A.S.; Sashiomarda, J.A.; Handoko, D. Predictive Maintenance Magnetic Sensor Using Random Forest Method. J. Phys. Conf. Ser. 2020, 1528, 012030. [Google Scholar] [CrossRef]

- Beden, S.; Lakshmanan, K.; Giannetti, C.; Beckmann, A. Steelmaking Predictive Analytics Based on Random Forest and Semantic Reasoning. Appl. Sci. 2023, 13, 12778. [Google Scholar] [CrossRef]

- Han, H.; Cui, X.; Fan, Y.; Qing, H. Least Squares Support Vector Machine (LS-SVM)-Based Chiller Fault Diagnosis Using Fault Indicative Features. Appl. Therm. Eng. 2019, 154, 540–547. [Google Scholar] [CrossRef]

- Rodriguez, P.C.; Marti-Puig, P.; Caiafa, C.F.; Serra-Serra, M.; Cusidó, J.; Solé-Casals, J. Exploratory Analysis of SCADA Data from Wind Turbines Using the K-Means Clustering Algorithm for Predictive Maintenance Purposes. Machines 2023, 11, 270. [Google Scholar] [CrossRef]

- Ariyaluran Habeeb, R.A.; Nasaruddin, F.; Gani, A.; Targio Hashem, I.A.; Ahmed, E.; Imran, M. Real-Time Big Data Processing for Anomaly Detection: A Survey. Int. J. Inf. Manag. 2019, 45, 289–307. [Google Scholar] [CrossRef]

- Zhang, S.; Ye, F.; Wang, B.; Habetler, T.G. Semi-Supervised Bearing Fault Diagnosis and Classification Using Variational Autoencoder-Based Deep Generative Models. IEEE Sens. J. 2021, 21, 6476–6486. [Google Scholar] [CrossRef]

- Lee, J.; Mitici, M. Deep Reinforcement Learning for Predictive Aircraft Maintenance Using Probabilistic Remaining-Useful-Life Prognostics. Reliab. Eng. Syst. Saf. 2023, 230, 108908. [Google Scholar] [CrossRef]

- Mourtzis, D.; Angelopoulos, J.; Panopoulos, N. A Framework for Automatic Generation of Augmented Reality Maintenance & Repair Instructions Based on Convolutional Neural Networks. Procedia CIRP 2020, 93, 977–982. [Google Scholar] [CrossRef]

- Bampoula, X.; Siaterlis, G.; Nikolakis, N.; Alexopoulos, K. A Deep Learning Model for Predictive Maintenance in Cyber-Physical Production Systems Using LSTM Autoencoders. Sensors 2021, 21, 972. [Google Scholar] [CrossRef]

- Sang, G.M.; Xu, L.; De Vrieze, P. A Predictive Maintenance Model for Flexible Manufacturing in the Context of Industry 4.0. Front. Big Data 2021, 4, 663466. [Google Scholar] [CrossRef] [PubMed]

- Wiercioch, J. Development of a Hybrid Predictive Maintenance Model. J. Konbin 2023, 53, 141–158. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).