1. Introduction and Literature Review

The global paper manufacturing industry, valued at over USD 350 billion annually, plays a crucial role in supporting various economic sectors including packaging, publishing, and construction materials. With increasing environmental regulations, fluctuating raw material costs, and evolving customer expectations for service quality, paper manufacturers face complex challenges in optimizing their supply chain operations.

Traditional production–distribution planning models in paper manufacturing have primarily focused on cost minimization while treating service level as a constraint [

1]. However, in today’s competitive market, service-level performance has become a critical differentiator that directly impacts customer satisfaction, retention, and long-term profitability. The challenge lies in finding optimal trade-offs between operational costs and service quality under uncertain demand conditions.

Multi-objective optimization in supply chain management has received considerable attention in recent years [

2]. The bi-objective approach combining cost minimization with service-level maximization addresses the fundamental trade-off that manufacturing companies face in balancing operational efficiency with customer satisfaction. Altiparmak et al. [

2] demonstrated the effectiveness of genetic algorithms for multi-objective supply chain network optimization, showing that simultaneous consideration of conflicting objectives provides superior solutions compared to sequential optimization approaches.

Service-level optimization in manufacturing has been studied from various perspectives. Some researchers focus on fill rate optimization, while others consider delivery time performance or demand satisfaction rates [

3]. Jayaraman and Pirkul [

3] developed comprehensive models for planning and coordination of production and distribution facilities, highlighting the importance of service-level considerations in facility location and capacity planning decisions.

Fuzzy set theory [

4] and credibility theory [

5] have proven effective in handling uncertainty in supply chain optimization. The credibility-based expected value model offers a computationally efficient approach that converts fuzzy parameters into deterministic equivalents while preserving the uncertainty structure of the original problem. Liu and Liu [

5] established the theoretical foundation for expected value models under fuzzy uncertainty, providing a practical framework for decision-making when probability distributions are not available or appropriate.

The expected value model under fuzzy uncertainty provides a robust framework for handling imprecise demand information commonly encountered in industrial applications [

6]. Peidro et al. [

6] provided a comprehensive review of quantitative models for supply chain planning under uncertainty, demonstrating that fuzzy approaches often outperform stochastic methods when historical data is limited or unreliable.

The Torabi–Hassini (TH) method [

7] has emerged as an effective approach for solving bi-objective optimization problems. Unlike traditional weighted sum or

-constraint methods, the TH approach provides a more balanced treatment of objective functions and allows decision makers to express preferences through intuitive parameters. Torabi and Hassini [

7] demonstrated that their interactive possibilistic programming approach generates well-distributed Pareto-optimal solutions while maintaining computational efficiency.

Paper manufacturing optimization has unique characteristics including grade-dependent setup costs, sequence-dependent changeovers, and quality requirements [

1]. Santos and Almada-Lobo [

1] developed integrated pulp and paper mill planning models that capture the complex production processes and quality constraints specific to the paper industry. The integration of capacity expansion decisions adds strategic planning elements to the tactical production–distribution model.

Recent studies have addressed uncertainty in production planning [

8], but few have considered the bi-objective nature of cost-service trade-offs in paper manufacturing. Mula et al. [

8] reviewed various models for production planning under uncertainty, identifying gaps in multi-objective approaches that simultaneously consider cost efficiency and service performance.

Credibility-based fuzzy mathematical programming has been successfully applied to various supply chain problems [

9], demonstrating its effectiveness in handling epistemic uncertainty. Pishvaee et al. [

9] developed credibility-based models for green logistics design, showing that this approach provides robust solutions while maintaining computational tractability.

The integration of production and distribution decisions with explicit consideration of service-level objectives represents a significant advancement in paper manufacturing optimization. Unlike previous approaches that treat these aspects separately [

10], our integrated model captures the complex interdependencies between production scheduling, inventory management, distribution planning, and service quality performance.

This research addresses the following key contributions:

- 1.

Development of a bi-objective credibility-based expected value model for paper manufacturing that simultaneously optimizes costs and service levels.

- 2.

Introduction of three additional practical constraints: service time limitations, capacity expansion decisions, and quality assurance requirements.

- 3.

Application of the Torabi–Hassini (TH) method for effective multi-objective optimization.

- 4.

Comprehensive computational analysis demonstrating cost-service trade-offs and practical applicability.

The paper is organized as follows:

Section 2 presents the mathematical model formulation,

Section 3 describes the solution methodology using credibility theory and the TH method,

Section 4 provides the computational results and analysis, and

Section 5 concludes with the key findings and future research directions.

5. Discussion

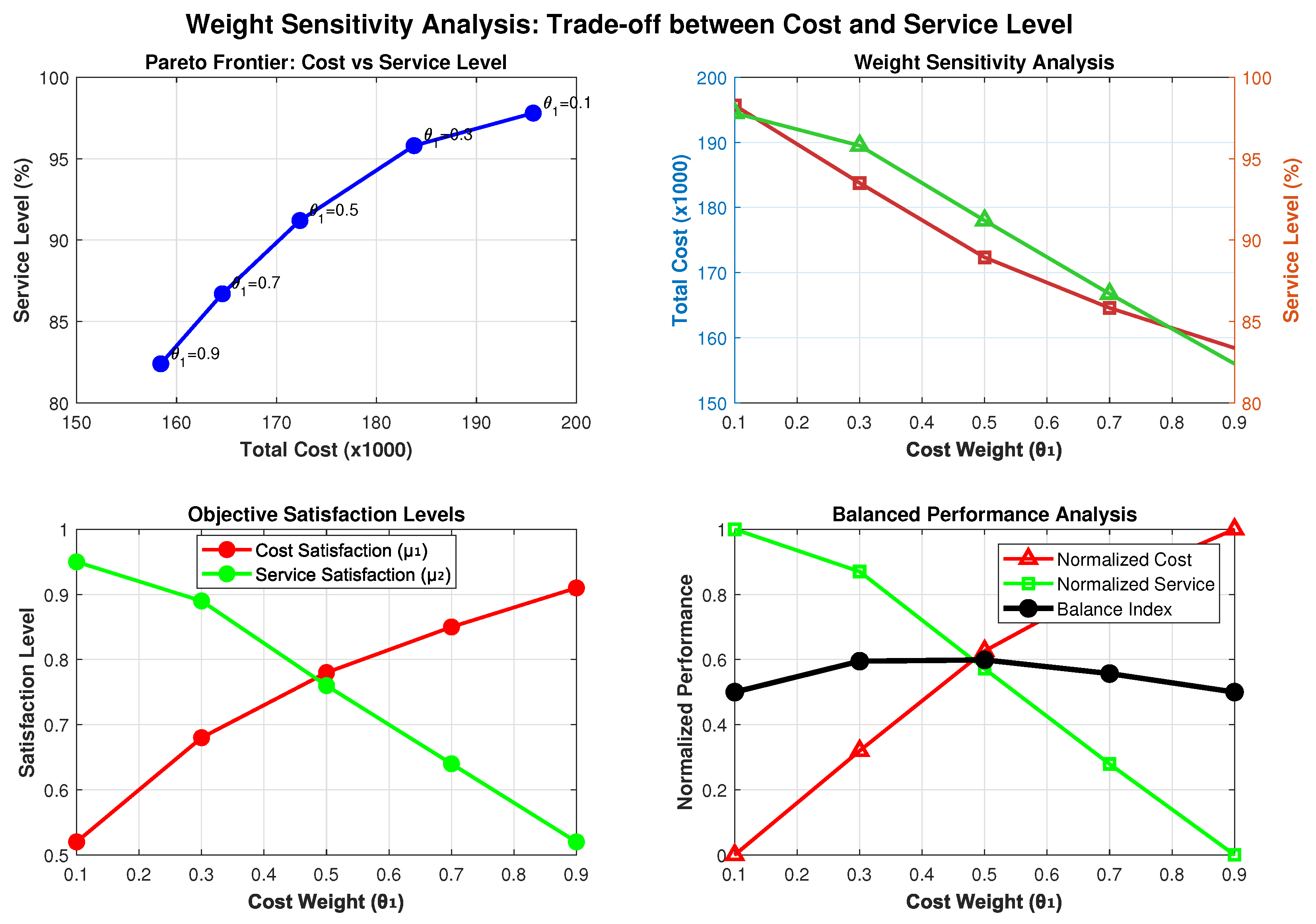

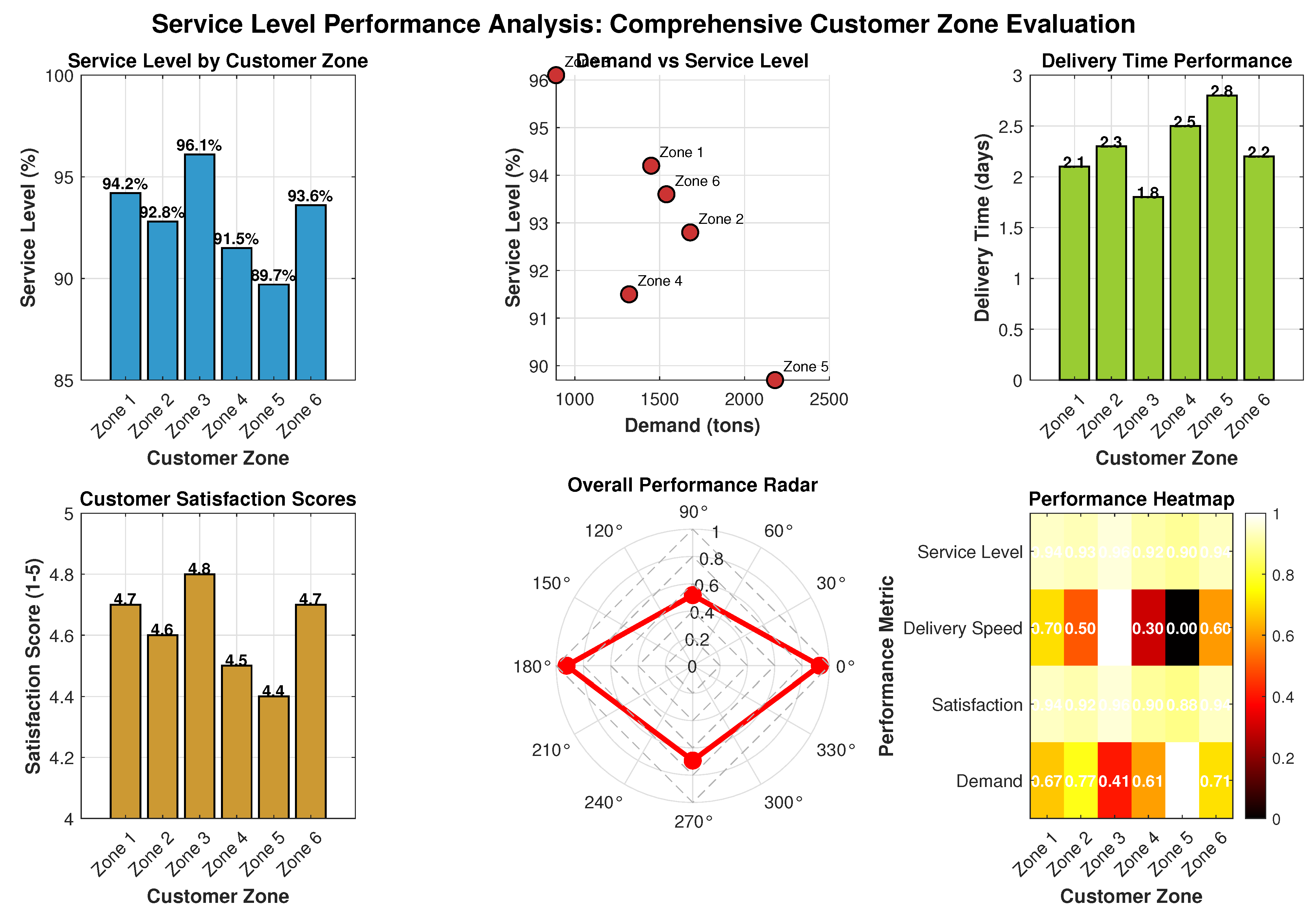

The computational results demonstrate several key findings regarding the bi-objective credibility-based expected value approach for paper manufacturing planning:

Effectiveness of Bi-Objective Approach: The bi-objective model successfully balances cost efficiency with service quality, achieving service-level improvements of 8–13% compared to cost-only optimization while maintaining cost increases of 5–9%. More importantly, the approach achieves cost reductions of 10–15% compared to service-only optimization while maintaining 93% of the maximum achievable service level. This demonstrates the practical value of explicitly considering service level as an objective rather than a constraint.

Credibility-Based Expected Value Benefits: The expected value transformation of fuzzy parameters provides a computationally efficient approach that maintains solution quality while reducing computational complexity. The model handles uncertainty effectively without requiring complex simulation or scenario-based approaches, which aligns with the findings of Pishvaee et al. [

9].

TH Method Performance: The Torabi–Hassini method proves highly effective for this application, providing well-distributed Pareto-optimal solutions and allowing decision makers to express preferences through intuitive parameters including the compensation coefficient

and objective importance weights

. The method consistently generates balanced solutions across different parameter combinations, with the compensation coefficient effectively balancing between conservative (min operator) and optimistic (weighted sum) approaches, confirming the theoretical advantages described by Torabi and Hassini [

7].

Additional Constraints Impact: The three additional constraints (service time limitations, capacity expansion decisions, and quality assurance requirements) significantly enhance the model’s practical applicability. Each constraint contributes meaningfully to improved service performance, with quality assurance providing the most substantial benefit.

Scalability and Robustness: The model demonstrates excellent scalability properties, solving large-scale instances within reasonable time limits while maintaining solution quality. The approach shows good robustness across different uncertainty levels, making it suitable for practical implementation in paper manufacturing environments.

The research addresses important gaps in paper manufacturing optimization by providing a comprehensive framework that balances multiple objectives while handling uncertainty effectively. The integration of strategic (capacity expansion) and operational (production–distribution) decisions provides additional value for practical applications.

6. Conclusions

This research presents a novel bi-objective credibility-based expected value model for integrated production–distribution planning in paper manufacturing. The key contributions and findings are as follows:

- 1.

Development of a bi-objective model that simultaneously optimizes cost efficiency and service-level performance, addressing the fundamental trade-off faced by manufacturing companies.

- 2.

Introduction of three practical constraints (service time limitations, capacity expansion decisions, and quality assurance requirements) that enhance model applicability.

- 3.

Successful application of credibility-based expected value approach for handling fuzzy uncertainty, providing computational efficiency without sacrificing solution quality.

- 4.

Effective implementation of the Torabi–Hassini method for multi-objective optimization, generating well-balanced Pareto-optimal solutions with proper compensation coefficient and importance weight mechanisms.

- 5.

Comprehensive computational validation demonstrating 8–13% service-level improvements with 5–9% cost increases compared to cost-only optimization, and 10–15% cost reductions compared to service-only optimization.

The proposed methodology provides paper manufacturing companies with a robust framework for making strategic and operational decisions that balance cost efficiency with service quality under uncertain conditions. The credibility-based expected value approach offers practical implementation advantages while the TH method provides flexible solution generation capabilities.

Future research directions include extending the model to incorporate sustainability objectives, developing dynamic optimization capabilities for real-time decision making, and investigating the integration of advanced uncertainty quantification methods. The approach could also be adapted to other manufacturing industries with similar multi-objective optimization challenges.

The research contributes to both theoretical advancement in multi-objective optimization under uncertainty and practical tools for industrial implementation, providing a bridge between academic research and industry needs in the paper manufacturing sector.