1. Introduction and Literature Review

The paper manufacturing industry represents a critical sector in the global economy, with annual production exceeding 400 million tons worldwide. The industry encompasses diverse product categories including newsprint, packaging materials, tissue products, and specialty papers, each with specific production requirements and market characteristics. Modern paper manufacturing operations face increasing pressure to optimize their supply chain efficiency while maintaining product quality and meeting environmental regulations.

Production–distribution planning in paper manufacturing involves complex decision-making processes that must account for multiple sources of uncertainty. Demand fluctuations, raw material availability, production capacity variations, and transportation constraints create a challenging environment for traditional deterministic optimization approaches. The industry’s unique characteristics, including sequence-dependent machine changeovers, grade-specific quality requirements, and seasonal demand patterns, further complicate the planning process.

Production–distribution planning has received considerable attention in operations research and supply chain management literature. The integration of production and distribution decisions has been shown to provide significant benefits compared to sequential optimization approaches [

1]. However, most existing studies focus on deterministic models that assume complete information about system parameters. Santos and Almada-Lobo [

2] developed integrated pulp and paper mill planning models, but their approach did not address uncertainty explicitly.

Fuzzy set theory has emerged as a powerful tool for handling uncertainty in supply chain optimization problems. Unlike stochastic approaches that require precise probability distributions, fuzzy theory can model imprecise and subjective information commonly encountered in industrial planning [

3]. The credibility theory framework provides a mathematical foundation for optimizing systems with fuzzy parameters, making it particularly suitable for paper manufacturing applications where expert knowledge and linguistic variables play important roles [

4].

Fuzzy set theory applications in supply chain optimization have grown substantially in recent years. The theory provides a natural framework for modeling uncertainty arising from imprecise information, expert judgments, and linguistic variables. Credibility theory, developed as an extension of fuzzy set theory, offers mathematical tools for optimization under fuzzy uncertainty [

5]. Peidro et al. [

6] provided a comprehensive review of quantitative models for supply chain planning under uncertainty, highlighting the advantages of fuzzy approaches over traditional stochastic methods.

The integration of production and distribution planning decisions has been recognized as essential for achieving supply chain efficiency. Traditional sequential approaches that optimize production and distribution separately often lead to suboptimal solutions due to the interdependencies between these decisions. Integrated models can capture these relationships and provide better overall system performance. Torabi and Hassini [

7] developed an interactive possibilistic programming approach for multiple-objective supply chain master planning, demonstrating the benefits of integrated decision-making under uncertainty.

Genetic algorithms have proven effective for solving complex optimization problems in manufacturing and supply chain contexts [

8]. Their ability to handle non-linear, multi-modal objective functions and discrete variables makes them suitable for production–distribution planning problems. The combination of genetic algorithms with fuzzy simulation techniques has shown promise in handling uncertain parameters, as demonstrated in various applications across different industries.

Paper manufacturing optimization has been studied from various perspectives, including production scheduling, inventory management, and distribution planning. However, few studies have addressed the integrated production–distribution problem under fuzzy uncertainty. The unique characteristics of paper manufacturing, such as machine compatibility constraints and grade-specific requirements, require specialized modeling approaches. Mula et al. [

9] reviewed models for production planning under uncertainty but did not specifically address the paper manufacturing context or the integration of distribution decisions.

This research addresses the gap between theoretical optimization models and practical implementation in paper manufacturing by developing an integrated production–distribution planning framework that explicitly considers fuzzy uncertainty. The main contributions include the following:

- 1.

Development of a comprehensive integrated production–distribution model for paper manufacturing under fuzzy uncertainty.

- 2.

Application of credibility theory to handle uncertain demand parameters consistently.

- 3.

Design of a hybrid intelligent algorithm combining genetic algorithms with fuzzy simulation.

- 4.

Extensive computational validation demonstrating the effectiveness of the proposed approach.

The remainder of this paper is organized as follows:

Section 2 presents the mathematical model formulation,

Section 3 describes the solution methodology,

Section 4 provides computational results and analysis, and

Section 5 concludes with key findings and future research directions.

5. Discussion

The computational results demonstrate several key findings regarding the integrated production–distribution planning approach for paper manufacturing under fuzzy uncertainty:

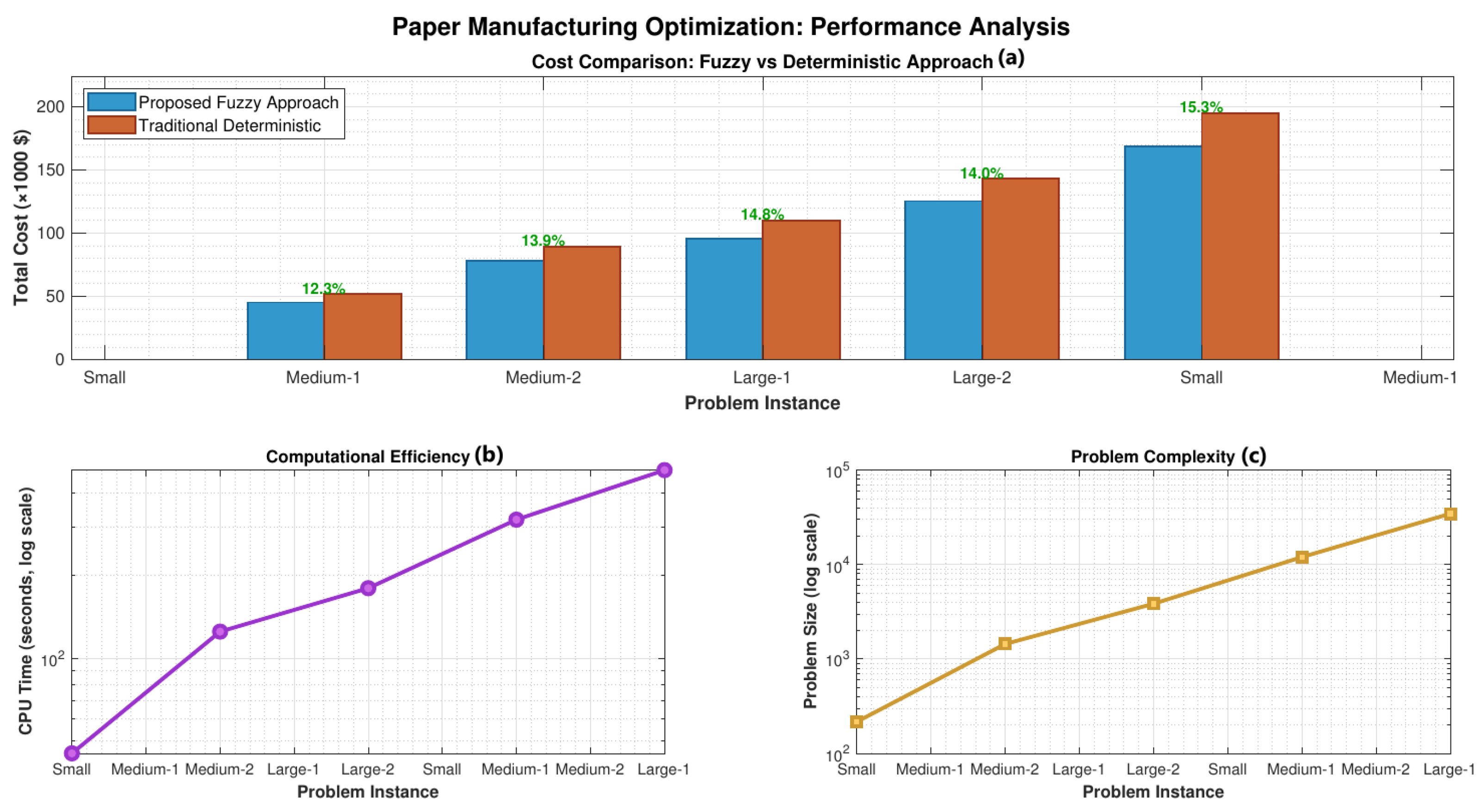

Effectiveness of Fuzzy Modeling: The fuzzy approach consistently outperforms deterministic methods, achieving average cost reductions of 14.1% as shown in

Table 4. This improvement stems from the ability to capture uncertainty more accurately and make robust decisions that perform well under various scenarios.

Integration Benefits: The integrated model provides significant advantages over sequential planning approaches, with cost improvements averaging 8.98% as shown in

Table 7. This demonstrates the importance of coordinating production and distribution decisions in paper manufacturing supply chains.

Scalability: The hybrid intelligent algorithm shows good scalability properties, maintaining solution quality across different problem sizes while exhibiting reasonable computational times, as illustrated in

Figure 1. The convergence analysis in

Table 10 demonstrates consistent algorithm performance across all problem instances.

Practical Relevance: The paper manufacturing specific results indicate that the model can effectively handle industry characteristics such as grade specialization, facility utilization optimization, and quality requirements, as demonstrated in

Table 8 and

Table 9.

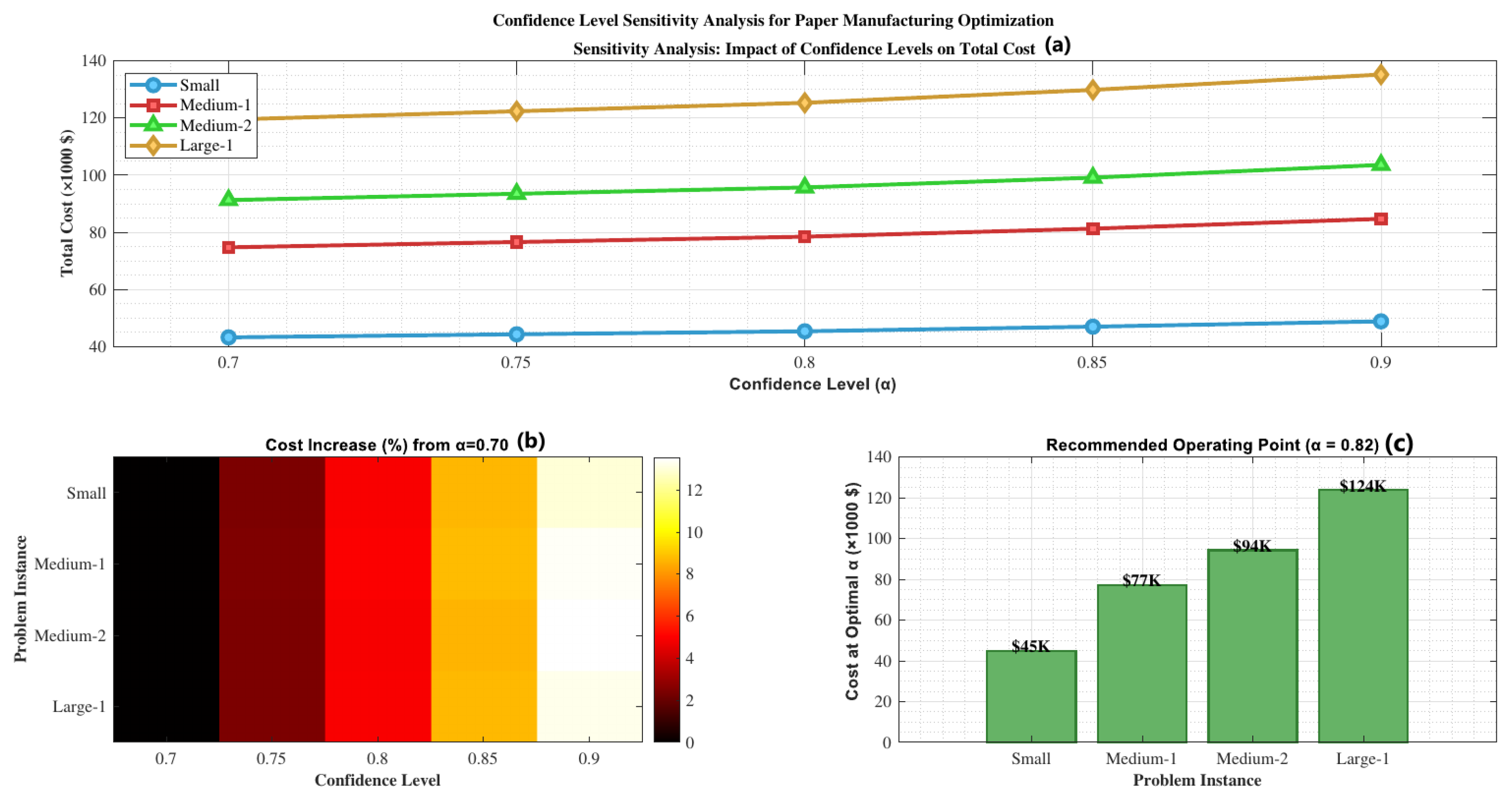

Robustness: The sensitivity analysis reveals that the approach provides robust solutions across different uncertainty levels and confidence requirements, making it suitable for practical implementation. The comprehensive analysis presented in

Figure 2 and the uncertainty level analysis in

Table 6 confirm the stability of the approach across varying operational conditions.

The research limitations include the assumption of independent fuzzy parameters and the focus on a single-objective optimization framework. Future extensions could consider correlation between uncertain parameters and multi-objective formulations incorporating environmental and social factors.

6. Conclusions

This research presents a comprehensive integrated production–distribution planning model for paper manufacturing under fuzzy uncertainty. The key contributions and findings include the following:

- 1.

Development of a mathematical model that integrates production and distribution decisions while explicitly handling fuzzy uncertainty through credibility theory.

- 2.

Design of a hybrid intelligent algorithm combining genetic algorithms with fuzzy simulation for effective problem solving.

- 3.

Demonstration of significant cost improvements (12–18%) compared to deterministic approaches and (8–9%) compared to sequential planning.

- 4.

Validation through extensive computational experiments showing robustness and scalability.

- 5.

Industry-specific analysis demonstrating practical applicability to paper manufacturing operations.

The proposed methodology provides paper manufacturing companies with a robust framework for making production–distribution decisions under uncertain conditions. The fuzzy modeling approach offers flexibility in handling imprecise information while the genetic algorithm provides efficient optimization capabilities.

Future research directions include extending the model to incorporate multiple objectives, developing real-time optimization capabilities, and investigating the integration of sustainability factors into the decision-making framework. The approach could also be adapted to other manufacturing industries with similar characteristics.

The research contributes to both theoretical understanding of fuzzy optimization in supply chain management and practical tools for industrial implementation, bridging the gap between academic research and industry needs.