An Overview of the Transformation Towards Quality 4.0: Technological Needs, Challenges, and Benefits †

Abstract

1. Introduction

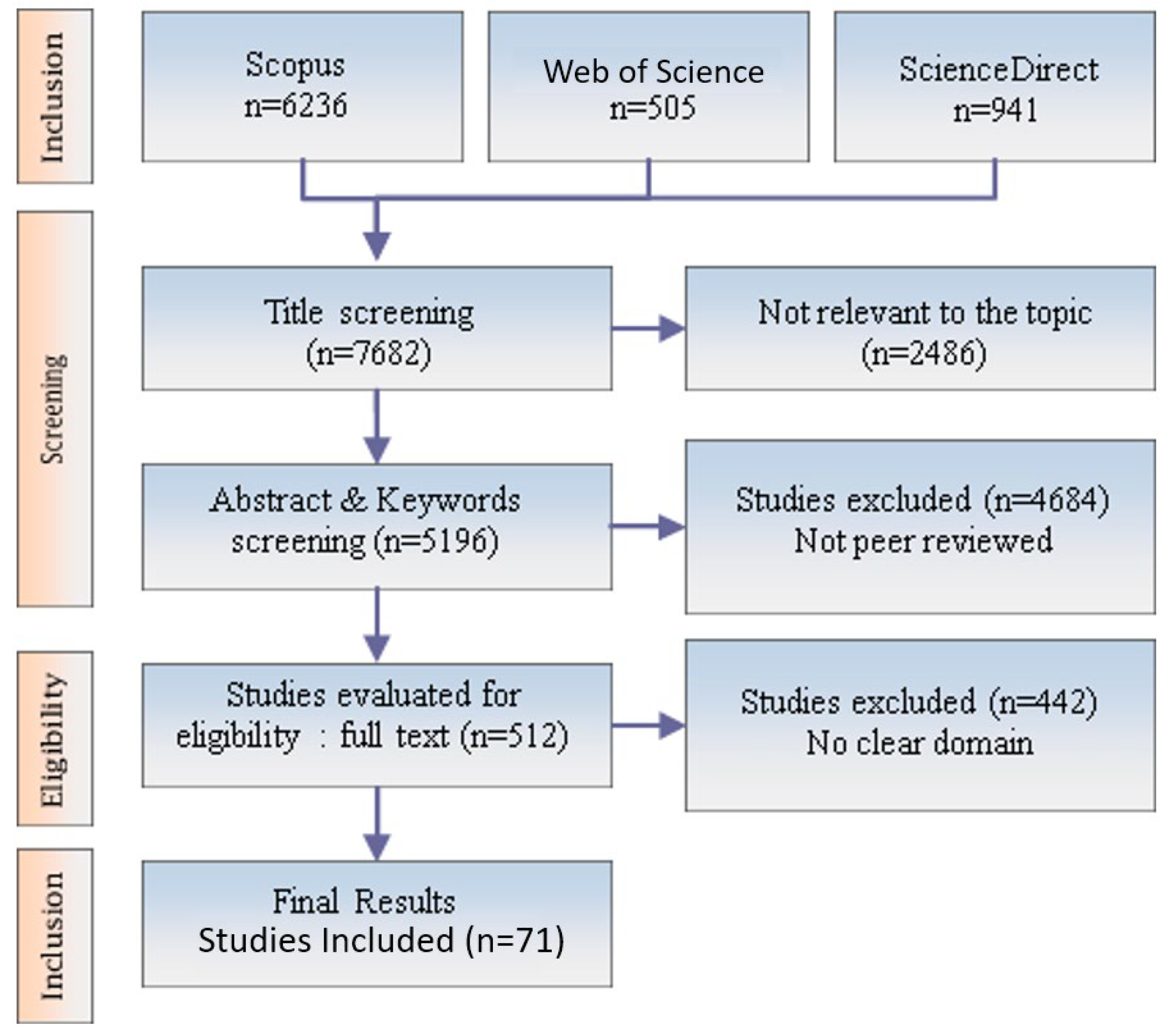

2. Methodology

2.1. Research Question

- RQ1: What Industry 4.0 technologies are most frequently adopted in quality management systems?

- RQ2: What are the main challenges encountered in implementing Quality 4.0?

- RQ3: What benefits are associated with the adoption of Quality 4.0?

“Quality 4.0” OR “Intelligent Quality” OR “Smart Quality Management” OR “Quality Transformation” OR “Evolution of Quality Management”).

2.2. Study Selection

3. Results

3.1. Industry 4.0 Technologies Used in Quality Management Systems

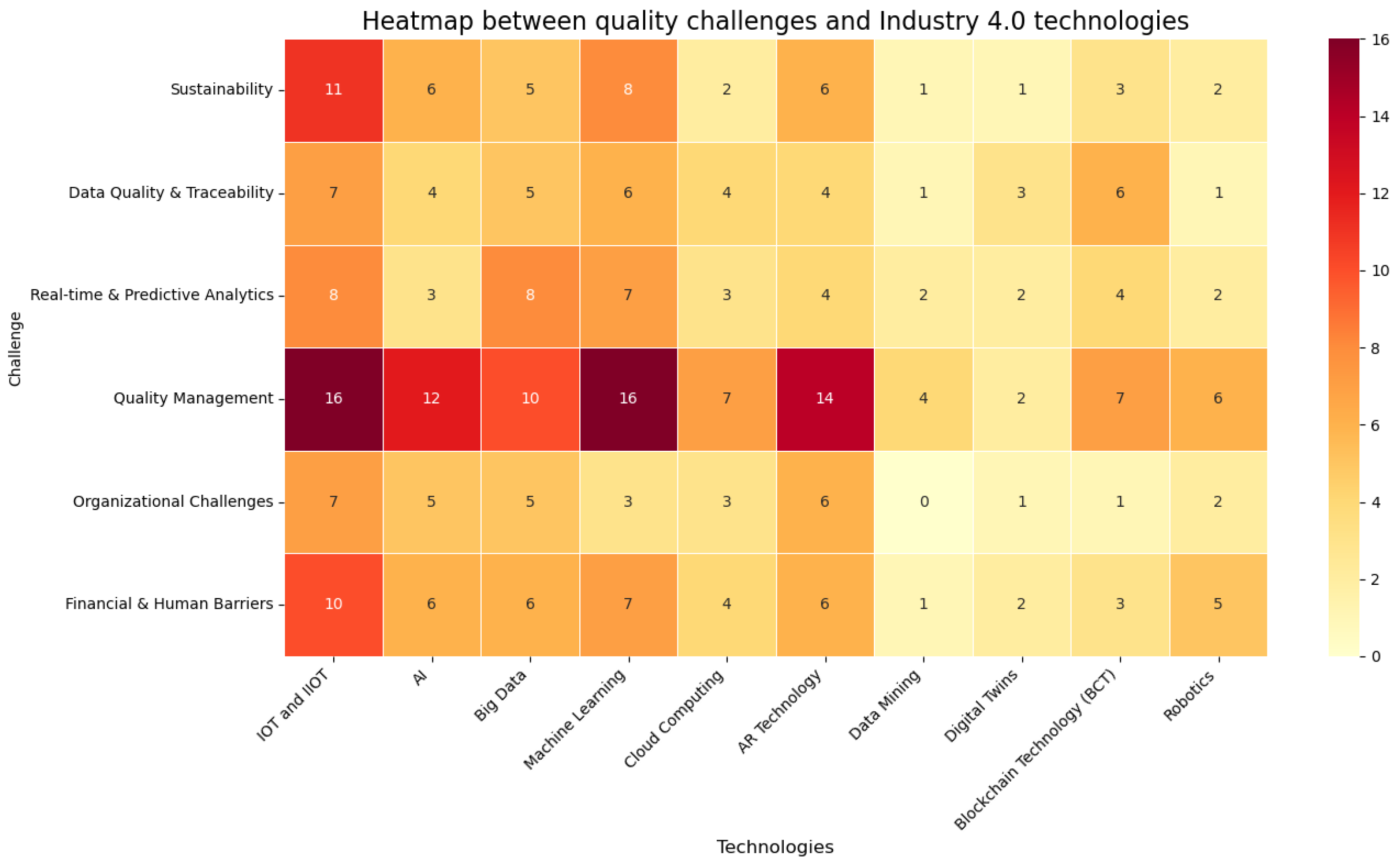

3.2. Quality 4.0 Challenges

3.3. Benefits of Implementing Quality 4.0

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| QMSs | Quality management systems |

| PRISMA | Preferred reporting items for systematic reviews and meta-analyses |

| SLR | Systematic literature review |

References

- Wang, W.; Li, Q.; Zhu, F. Association rules combined fuzzy decision quality control technology in intelligent manufacturing. Intell. Syst. Appl. 2024, 21, 200331. [Google Scholar] [CrossRef]

- Verma, V.K.; Rastogi, R. How Do Stakeholders Perceive Transit Service Quality Attributes?—A study through Fuzzy-AHP. Expert Syst. Appl. 2024, 238, 122043. [Google Scholar] [CrossRef]

- Szelążek, M.; Bobek, S.; Nalepa, G.J. Semantic data mining-based decision support for quality assessment in steel industry. Expert Syst. 2024, 41, e13319. [Google Scholar] [CrossRef]

- Narkhede, G.; Mahajan, S.; Narkhede, R.; Chaudhari, T. Significance of Industry 4.0 technologies in major work functions of manufacturing for sustainable development of small and medium-sized enterprises. Bus. Strategy Dev. 2024, 7, e325. [Google Scholar] [CrossRef]

- Luo, S.; Yu, M.; Dong, Y.; Hao, Y.; Li, C.; Wu, H. Toward urban high-quality development: Evidence from more intelligent Chinese cities. Technol. Forecast. Soc. Change 2024, 200, 123108. [Google Scholar] [CrossRef]

- Hrouga, M. Towards a new conceptual digital collaborative supply chain model based on Industry 4.0 technologies: A conceptual framework. Int. J. Qual. Reliab. Manag. 2024, 41, 628–655. [Google Scholar] [CrossRef]

- Brandín, R.; Abrishami, S. IoT-BIM and blockchain integration for enhanced data traceability in offsite manufacturing. Autom. Constr. 2024, 159, 105266. [Google Scholar] [CrossRef]

- Tian, Z.; Li, J.; Liu, L.; Wu, H.; Hu, X.; Xie, M.; Zhu, Y.; Chen, X.; Ou-Yang, W. Machine learning-assisted self-powered intelligent sensing systems based on triboelectricity. Nano Energy 2023, 113, 108559. [Google Scholar] [CrossRef]

- Shvets, Y.; Hanák, T. Use of the Internet of Things in the Construction Industry and Facility Management: Usage Examples Overview. Procedia Comput. Sci. 2023, 219, 1670–1677. [Google Scholar] [CrossRef]

- Sharma, M.; Joshi, S. Digital supplier selection reinforcing supply chain quality management systems to enhance firm’s performance. TQM J. 2023, 35, 102–130. [Google Scholar]

- Sen, S.K.; Karmakar, G.C.; Pang, S. Critical Data Detection for Dynamically Adjustable Product Quality in IIoT-Enabled Manufacturing. IEEE Access 2023, 11, 49464–49480. [Google Scholar] [CrossRef]

- Salimbeni, S.; Redchuk, A.; Rousserie, H. Quality 4.0: Technologies and readiness factors in the entire value flow life cycle. Prod. Manuf. Res.-Open Access J. 2023, 11, 2238797. [Google Scholar] [CrossRef]

- Saihi, A.; Awad, M.; Ben-Daya, M. Quality 4.0: Leveraging Industry 4.0 technologies to improve quality management practices—A systematic review. Int. J. Qual. Reliab. Manag. 2023, 40, 628–650. [Google Scholar] [CrossRef]

- Sahu, A.K.; Kumar, A.; Sahu, A.K.; Sahu, N.K. Evaluation of machine tool substitute under data-driven quality management system: A hybrid decision-making approach. TQM J. 2023, 35, 234–261. [Google Scholar] [CrossRef]

- Rodríguez, F.; Chicaiza, W.D.; Sánchez, A.; Escaño, J.M. Updating digital twins: Methodology for data accuracy quality control using machine learning techniques. Comput. Ind. 2023, 151, 103958. [Google Scholar] [CrossRef]

- Rahman, M.S.; Ghosh, T.; Aurna, N.F.; Kaiser, M.S.; Anannya, M.; Hosen, A.S.M.S. Machine learning and internet of things in industry 4.0: A review. Meas. Sens. 2023, 28, 100822. [Google Scholar] [CrossRef]

- Prashar, A. Towards digitalisation of quality management: Conceptual framework and case study of auto-component manufacturer. TQM J. 2023, 35, 2436–2454. [Google Scholar] [CrossRef]

- Prashar, A. Quality management in industry 4.0 environment: A morphological analysis and research agenda. Int. J. Qual. Reliab. Manag. 2023, 40, 863–885. [Google Scholar] [CrossRef]

- Ng, S.C.H.; Ho, G.T.S.; Wu, C.H. Blockchain-IIoT-big data aided process control and quality analytics. Int. J. Prod. Econ. 2023, 261, 108871. [Google Scholar] [CrossRef]

- Muruganandham, R.; Venkatesh, K.; Devadasan, S.R.; Harish, V. TQM through the integration of blockchain with ISO 9001:2015 standard based quality management system. Total Qual. Manag. Bus. Excell. 2023, 34, 291–311. [Google Scholar] [CrossRef]

- Mondal, S.; Samaddar, K. Reinforcing the significance of human factor in achieving quality performance in data-driven supply chain management. TQM J. 2023, 35, 183–209. [Google Scholar] [CrossRef]

- Markatos, N.G.; Mousavi, A. Manufacturing quality assessment in the industry 4.0 era: A review. Total. Qual. Manag. Bus. Excel. 2023, 34, 1655–1681. [Google Scholar] [CrossRef]

- Marbouh, D.; Swarnakar, V.; Simsekler, M.C.E.; Antony, J.; Lizarelli, F.L.; Jayaraman, R.; Garza-Reyes, J.A.; Shokri, A.; Cudney, E.; Ellahham, S. Healthcare 4.0 digital technologies impact on quality of care: A systematic literature review. Total. Qual. Manag. Bus. Excel. 2023, 34, 2157–2182. [Google Scholar] [CrossRef]

- Maganga, D.P.; Taifa, I.W.R. The readiness of manufacturing industries to transit to Quality 4.0. Int. J. Qual. Reliab. Manag. 2023, 40, 1729–1752. [Google Scholar] [CrossRef]

- Maganga, D.P.; Taifa, I.W.R. Quality 4.0 transition framework for Tanzanian manufacturing industries. TQM J. 2023, 35, 1417–1448. [Google Scholar] [CrossRef]

- Maganga, D.P.; Taifa, I.W.R. Quality 4.0 conceptualisation: An emerging quality management concept for manufacturing industries. TQM J. 2023, 35, 389–413. [Google Scholar] [CrossRef]

- Laskurain-Iturbe, I.; Arana-Landin, G.; Landeta-Manzano, B.; Jimenez-Redal, R. Assessing the uptake of Industry 4.0 technologies: Barriers to their adoption and impact on quality management aspects. Int. J. Qual. Reliab. Manag. 2023, 40, 2420–2442. [Google Scholar] [CrossRef]

- Ingaldi, M.; Ulewicz, R.; Klimecka-Tatar, D. Creation of the university curriculum in the field of Industry 4.0 with the use of modern teaching instruments—Polish case study. Procedia Comput. Sci. 2023, 217, 660–669. [Google Scholar] [CrossRef]

- Duraković, B.; Halilovic, M. Industry 4.0: The New Quality Management Paradigm in Era of the Industrial Internet of Things. JOIV Int. J. Inform. Vis. 2023, 7, 580–587. [Google Scholar] [CrossRef]

- Chiarini, A.; Cherrafi, A. Integrating ISO 9001 and Industry 4.0. An implementation guideline and PDCA model for manufacturing sector. Total. Qual. Manag. Bus. Excel. 2023, 34, 1629–1654. [Google Scholar] [CrossRef]

- Canbay, K.; Akman, G. Investigating Changes of Total Quality Management Principles in the Context of Industry 4.0: Viewpoint from an Emerging Economy. Technol. Forecast. Soc. Change 2023, 189, 122358. [Google Scholar] [CrossRef]

- Biswas, S.; Božanić, D.; Pamučar, D.; Marinković, D. A spherical fuzzy based decision making framework with Einstein aggregation for comparing preparedness of SMEs in Quality 4.0. Facta Univ. Ser. Mech. Eng. 2023, 21, 453–478. [Google Scholar] [CrossRef]

- Ardian, S.H.; Calibra, R.G.; Bafdal, N.; Bono, A.; Suryadi, E.; Nurhasanah, S. An IoT-enabled design for real-time water quality monitoring and control of greenhouse irrigation systems. INMATEH—Agric. Eng. 2023, 68, 417–426. [Google Scholar] [CrossRef]

- Akhmedova, M.S.; Meliksetyan, K.A.; Krutilin, A.A.; Boris, O.A. The role of quality management in the development of high-tech industrial enterprises in the context of Industry 4.0. Proc. Eng. Sci. 2023, 5, 207–220. [Google Scholar] [CrossRef]

- Agrawal, R.; Wankhede, V.A.; Kumar, A.; Luthra, S. A systematic and network-based analysis of data-driven quality management in supply chains and proposed future research directions. TQM J. 2023, 35, 73–101. [Google Scholar] [CrossRef]

- Zhao, R.; Luo, L.; Li, P.; Wang, J. An Industrial Heterogeneous Data Based Quality Management KPI Visualization System for Product Quality Control. Assem. Autom. 2022, 42, 796–808. [Google Scholar] [CrossRef]

- Tambare, P.; Meshram, C.; Lee, C.-C.; Ramteke, R.J.; Imoize, A.L. Performance Measurement System and Quality Management in Data-Driven Industry 4.0: A Review. Sensors 2022, 22, 224. [Google Scholar] [CrossRef]

- Singh, J.; Ahuja, I.P.S.; Singh, H.; Singh, A. Development and Implementation of Autonomous Quality Management System (AQMS) in an Automotive Manufacturing Using Quality 4.0 Concept– A Case Study. Comput. Ind. Eng. 2022, 168, 108121. [Google Scholar] [CrossRef]

- Polenta, A.; Tomassini, S.; Falcionelli, N.; Contardo, P.; Dragoni, A.F.; Sernani, P. A comparison of machine learning techniques for the quality classification of molded products. Information 2022, 13, 272. [Google Scholar] [CrossRef]

- Milošević, I.; Ruso, J.; Glogovac, M.; Arsić, S.; Rakić, A. An integrated SEM-ANN approach for predicting QMS achievements in Industry 4.0. Total Qual. Manag. Bus. Excell. 2022, 33, 1896–1912. [Google Scholar] [CrossRef]

- Lekan, A.; Clinton, A.; Stella, E.; Moses, E.; Biodun, O. Construction 4.0 application: Industry 4.0, Internet of Things, and Lean construction tools’ application in quality management system of residential building projects. Buildings 2022, 12, 1557. [Google Scholar] [CrossRef]

- Lee, J.; Gore, P.; Jia, X.; Siahpour, S.; Kundu, P.; Sun, K. Stream-of-Quality methodology for industrial Internet-based manufacturing system. Manuf. Lett. 2022, 34, 58–61. [Google Scholar] [CrossRef]

- Hung, C.W.; Zhuang, Y.D.; Lee, C.H.; Wang, C.C.; Yang, H.H. Transmission power control in wireless sensor networks using fuzzy adaptive data rate. Sensors 2022, 22, 9963. [Google Scholar] [CrossRef] [PubMed]

- Huang, Z.; Shahzadi, A.; Khan, Y.D. Unfolding the impact of Quality 4.0 practices on Industry 4.0 and circular economy practices: A hybrid SEM-ANN approach. Sustainability 2022, 14, 15495. [Google Scholar] [CrossRef]

- Ho, P.T.; Albajez, J.A.; Santolaria, J.; Yagüe-Fabra, J.A. Study of augmented reality based manufacturing for further integration of quality control 4.0: A systematic literature review. Appl. Sci. 2022, 12, 1961. [Google Scholar] [CrossRef]

- Glogovac, M.; Ruso, J.; Maricic, M. ISO 9004 maturity model for quality in Industry 4.0. Total Qual. Manag. Bus. Excell. 2022, 33, 529–547. [Google Scholar] [CrossRef]

- García, L.; Garcia-Sanchez, A.J.; Asorey-Cacheda, R.; Garcia-Haro, J.; Zúñiga-Cañón, C.L. Smart air quality monitoring IoT-based infrastructure for industrial environments. Sensors 2022, 22, 9221. [Google Scholar] [CrossRef]

- Frankó, A.; Hollósi, G.; Ficzere, D.; Varga, P. Applied machine learning for IIoT and smart production—Methods to improve production quality, safety, and sustainability. Sensors 2022, 22, 9148. [Google Scholar] [CrossRef]

- Velazquez de la Hoz, J.L.; Cheng, K. Development of an intelligent quality management system for micro laser welding: An innovative framework and its implementation perspectives. Machines 2021, 9, 252. [Google Scholar] [CrossRef]

- Tasmin, R.; Rahman, N.; Jaafar, I.; Abd Hamid, N.; Ngadiman, Y. The readiness of automotive manufacturing company on Industrial 4.0 towards quality performance. Int. J. Integr. Eng. 2020, 12, 160–172. [Google Scholar] [CrossRef]

- Qeshmy, D.E.; Makdisi, J.; Ribeiro da Silva, E.H.D.; Angelis, J. Managing human errors: Augmented reality systems as a tool in the quality journey. Procedia Manuf. 2019, 28, 24–30. [Google Scholar] [CrossRef]

- Astola, P.J.; Rodríguez, P.; Botana, J.; Marcos, M. A paperless based methodology for managing Quality Control. Application to a I + D + i Supplier Company. Procedia Manuf. 2017, 13, 1066–1073. [Google Scholar] [CrossRef]

- Buer, S.-V.; Strandhagen, J.O.; Chan, F.T.S. The link between Industry 4.0 and lean manufacturing: Mapping current research and establishing a research agenda. Int. J. Prod. Res. 2018, 56, 2924–2940. [Google Scholar] [CrossRef]

- Dalenogare, L.S.; Benitez, G.B.; Ayala, N.F.; Frank, A.G. The expected contribution of Industry 4.0 technologies for industrial performance. Int. J. Prod. Econ. 2018, 204, 383–394. [Google Scholar] [CrossRef]

- Erol, S.; Schumacher, A.; Sihn, W. Strategic guidance towards Industry 4.0—A three-stage process model. Procedia CIRP 2016, 57, 522–527. [Google Scholar]

- Nascimento, D.L.; Alencastro, V.; Quelhas, O.L.G.; Caiado, R.G.G.; Garza-Reyes, J.A.; Lins, L.M.P. Exploring Industry 4.0 technologies to improve quality in manufacturing: A systematic literature review. Comput. Ind. Eng. 2019, 137, 106024. [Google Scholar]

- Mhlongo, N.; Nyembwe, K. Application of the Delphi Technique for the Successful Adoption of Quality Management 4.0 in the South African Manufacturing Sector. S. Afr. J. Ind. Eng. 2024, 35, 28–42. [Google Scholar] [CrossRef]

- Sony, M.; Naik, S. Critical factors for the successful implementation of Industry 4.0: A review and future research direction. Prod. Plan. Control 2019, 31, 799–815. [Google Scholar] [CrossRef]

- Dash, A.; Pant, P.; Sarmah, S.P.; Tiwari, M.K. The Impact of IoT on Manufacturing Firm Performance: The Moderating Role of Firm-Level IoT Commitment and Expertise. Int. J. Prod. Res. 2023, 62, 3120–3145. [Google Scholar] [CrossRef]

- Kang, H.S.; Lee, J.Y.; Kim, H.; Park, J.H.; Son, J.Y.; Do, N. Smart manufacturing: Past research, present findings, and future directions. Int. J. Precis. Eng. Manuf.-Green Technol. 2016, 3, 111–128. [Google Scholar] [CrossRef]

- Tanane, B.; Bentaha, M.-L.; Dafflon, B.; Moalla, N. Bridging the Gap between Industry 4.0 and Manufacturing SMEs: A Framework for an End-to-End Total Manufacturing Quality 4.0’s Implementation and Adoption. J. Ind. Inf. Integr. 2025, 45, 100833. [Google Scholar] [CrossRef]

- Moeuf, A.; Pellerin, R.; Lamouri, S.; Tamayo-Giraldo, S.; Barbaray, R. The industrial management of SMEs in the era of Industry 4.0. Int. J. Prod. Res. 2018, 56, 1118–1136. [Google Scholar] [CrossRef]

- Qin, J.; Liu, Y.; Grosvenor, R. A Categorical Framework of Manufacturing for Industry 4.0 and Beyond. Procedia CIRP 2016, 52, 173–178. [Google Scholar] [CrossRef]

- Brettel, M.; Friederichsen, N.; Keller, M.A.; Rosenberg, M. How Virtualization, Decentralization and Network Building Change the Manufacturing Landscape: An Industry 4.0 Perspective. World Acad. Sci. Eng. Technol. Int. J. Mech. Aerosp. Ind. Mechatron. Manuf. Eng. 2014, 8, 37–44. [Google Scholar] [CrossRef]

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 technologies: Implementation patterns in manufacturing companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Prause, M. Challenges of Industry 4.0 Technology Adoption for SMEs: The Case of Japan. Sustainability 2019, 11, 5807. [Google Scholar] [CrossRef]

- Szozda, N. Industry 4.0 and its impact on the functioning of supply chains. LogForum 2017, 13, 401–414. [Google Scholar] [CrossRef]

- Dombrowski, U.; Wagner, T. Mental Strain as Field of Action in the 4th Industrial Revolution. Procedia CIRP 2014, 17, 100–105. [Google Scholar] [CrossRef]

- Neirotti, P.; Ricci, A.; Tubiana, M. Industry 4.0 Digital Technologies and International Performance: The Role of Family Management in Italian Firms. Int. J. Prod. Econ. 2025, 277, 109765. [Google Scholar] [CrossRef]

- Kamble, S.; Gunasekaran, A.; Dhone, N.C. Industry 4.0 and Lean Manufacturing Practices for Sustainable Organisational Performance in Indian Manufacturing Companies. Int. J. Prod. Res. 2020, 58, 1319–1337. [Google Scholar] [CrossRef]

- Li, L. China’s Manufacturing Locus in 2025: With a Comparison of “Made-in-China 2025” and “Industry 4.0”. Technol. Forecast. Soc. Change 2018, 135, 66–74. [Google Scholar] [CrossRef]

| Databases of Documents | Scopus, ScienceDirect, and Web of Science |

| Methodology | Data qualitative analysis, systematic literature review, maturity model, conceptual framework, comprehensive literature review, survey-based study, and case study. |

| Total number of documents evaluated | 71 |

| Used Technologies | Reference | Total |

|---|---|---|

| IOT and IIOT | [7,9,11,12,16,19,23,29,31,36,42,44,53,57,58,69] | 16 |

| AI | [8,10,12,13,17,24,25,26,27,31] | 10 |

| Big Data | [8,19,26,30,31,50,69] | 7 |

| AR technology | [55,70,71] | 3 |

| Machine learning | [16,46,64] | 3 |

| Cloud computing | [8,12,31] | 3 |

| Data mining | [3,6] | 2 |

| Digital twins | [15,50] | 2 |

| Blockchain technology (BCT) | [7,20] | 2 |

| Robotics | [31] | 1 |

| Quality 4.0 Challenges | Reference | Total |

|---|---|---|

| Manufacturing & Supply Chains: Enhancing Supply Chain Visibility and Traceability Optimizing Quality Control in Distributed Manufacturing Managing Quality in Complex Manufacturing Processes Addressing Sustainability Considerations in Quality Management | [3,4,6,7,10,21,34] | 7 |

| Technology Implementation: Overcoming Technological Barriers Addressing Organizational Challenges Addressing Financial Constraints Addressing Cybersecurity Risks | [16,17,41,42,43,44] | 6 |

| Data Management: Ensuring Data Security and Privacy Maintaining Data Quality and Integrity Enabling Real-time Data Processing and Analytics Leveraging Data for Predictive Quality Management | [1,11,15,19,36] | 5 |

| Quality 4.0 Implementation: Redefining Quality Management Principles Fostering a Quality 4.0 Culture Integrating Quality 4.0 into Existing Systems Measuring and Evaluating Quality 4.0 Performance | [13,23,24,25] | 4 |

| Benefits of Quality 4.0 Implementation | Reference | Total |

|---|---|---|

| Improving quality performance | [53,54,55,56,57,58] | 6 |

| Real-time tracking and traceability | [59,60,61,62,63] | 5 |

| Improved customer satisfaction and personalization | [64,65,66,67,68] | 5 |

| Reduction in quality-related costs | [69,70,71] | 4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hafid, A.; Sebtaoui, F.E.; Mouchtachi, A. An Overview of the Transformation Towards Quality 4.0: Technological Needs, Challenges, and Benefits. Eng. Proc. 2025, 112, 18. https://doi.org/10.3390/engproc2025112018

Hafid A, Sebtaoui FE, Mouchtachi A. An Overview of the Transformation Towards Quality 4.0: Technological Needs, Challenges, and Benefits. Engineering Proceedings. 2025; 112(1):18. https://doi.org/10.3390/engproc2025112018

Chicago/Turabian StyleHafid, Anass, Fatima Ezzahra Sebtaoui, and Ahmed Mouchtachi. 2025. "An Overview of the Transformation Towards Quality 4.0: Technological Needs, Challenges, and Benefits" Engineering Proceedings 112, no. 1: 18. https://doi.org/10.3390/engproc2025112018

APA StyleHafid, A., Sebtaoui, F. E., & Mouchtachi, A. (2025). An Overview of the Transformation Towards Quality 4.0: Technological Needs, Challenges, and Benefits. Engineering Proceedings, 112(1), 18. https://doi.org/10.3390/engproc2025112018