Implementation of Industry 5.0 in SME: Scoping Review †

Abstract

1. Introduction

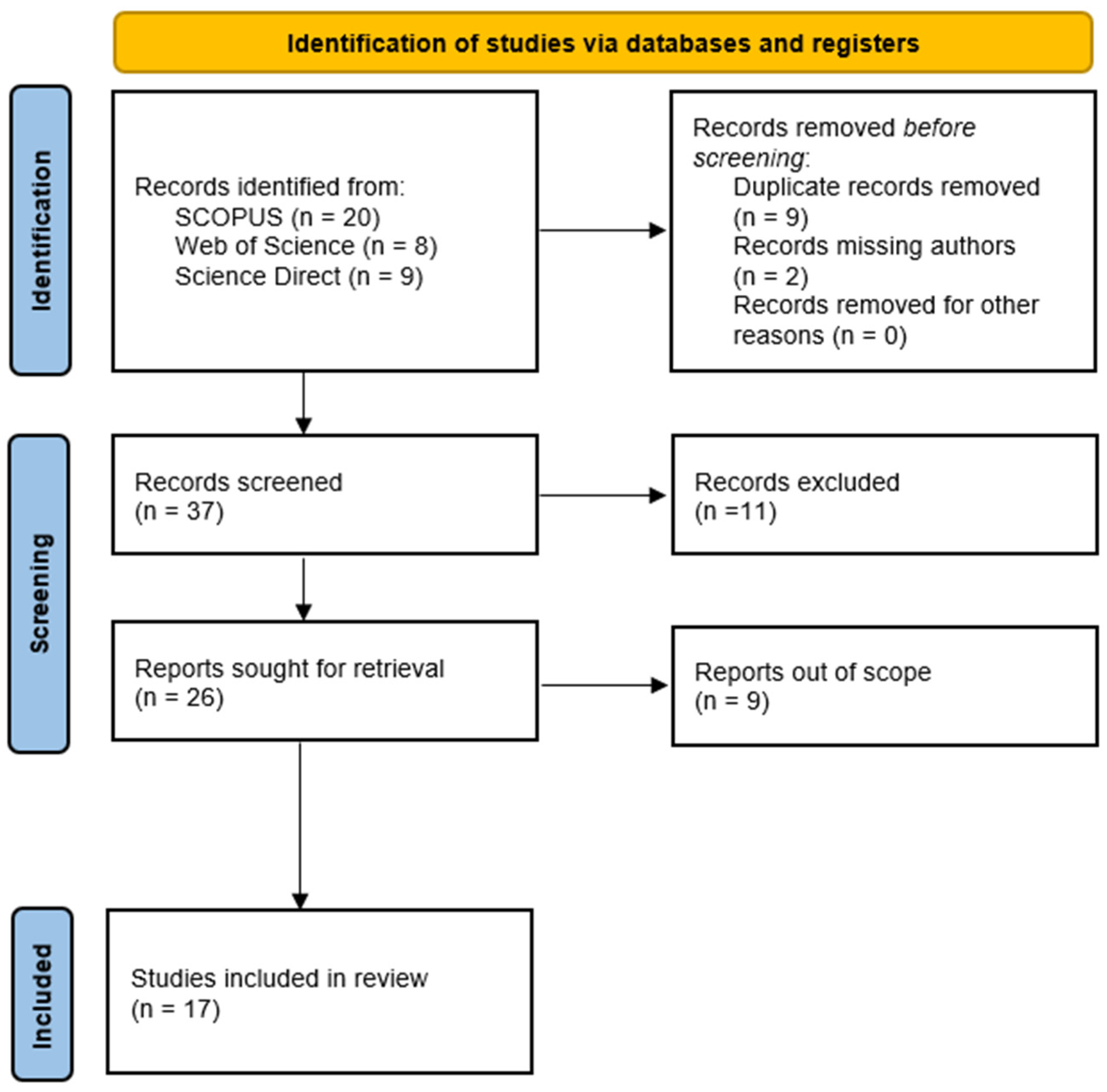

2. Material and Methods

2.1. Identification

2.2. Screening

3. Results

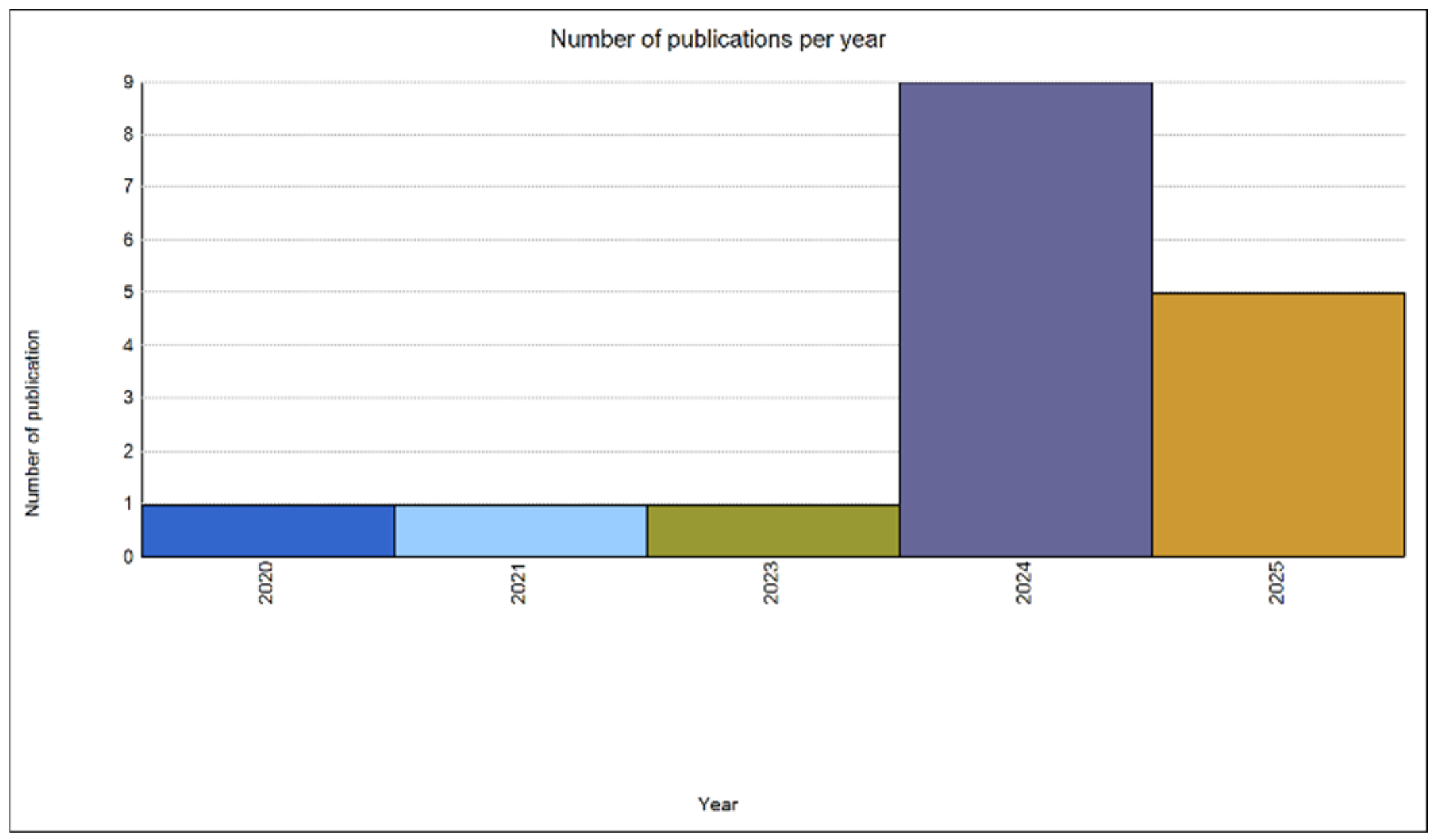

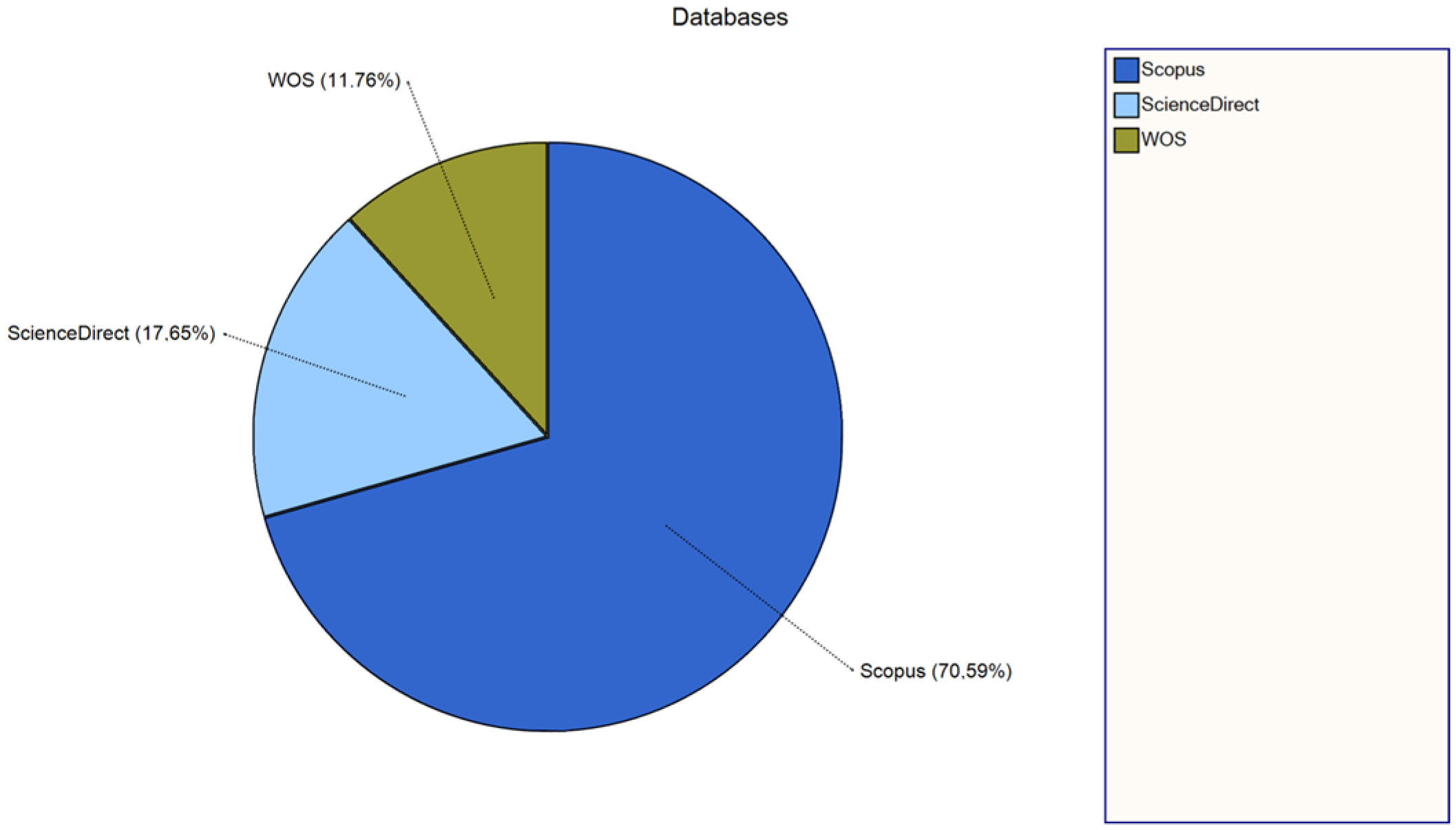

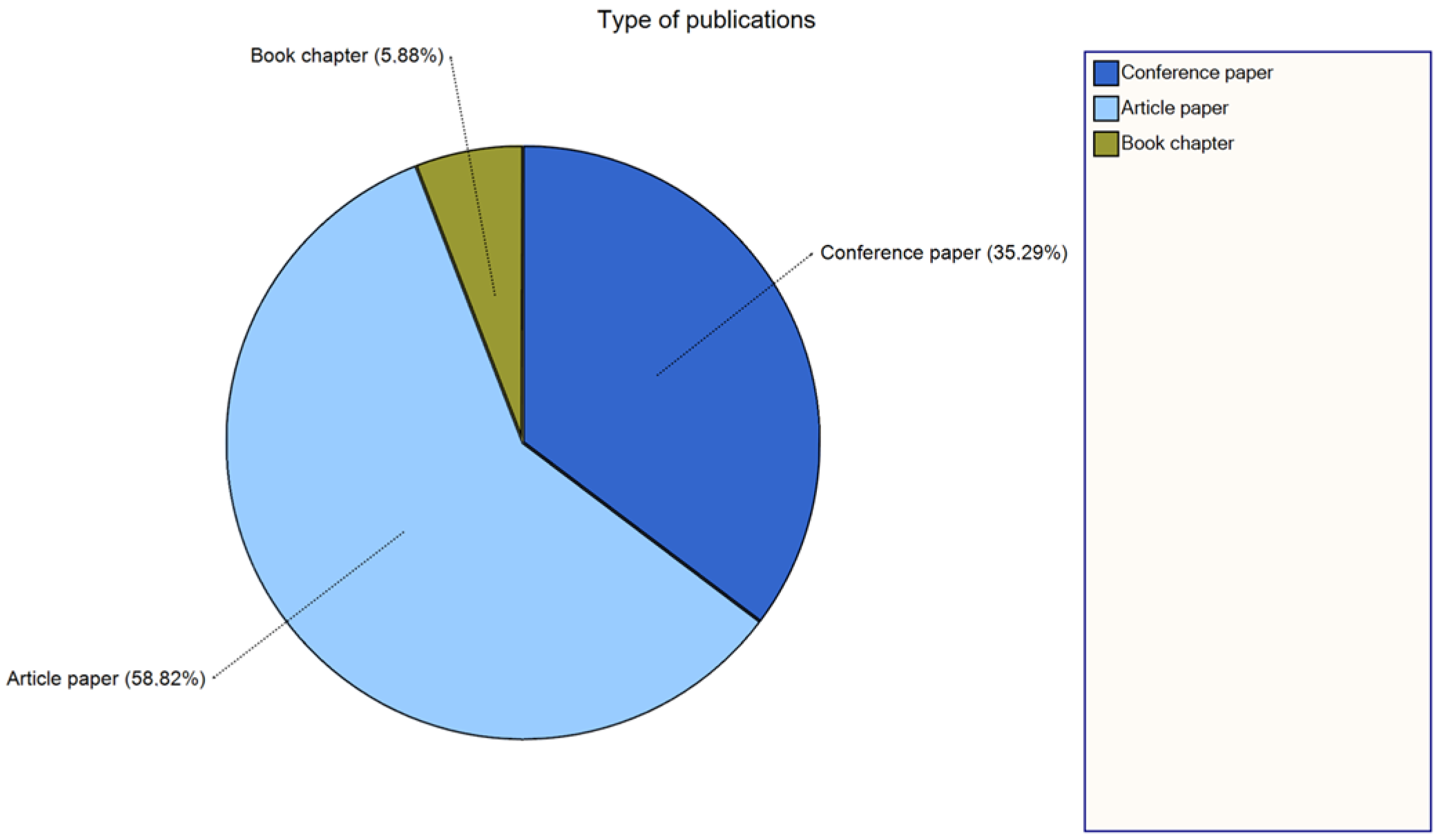

3.1. Publication Venues and Years

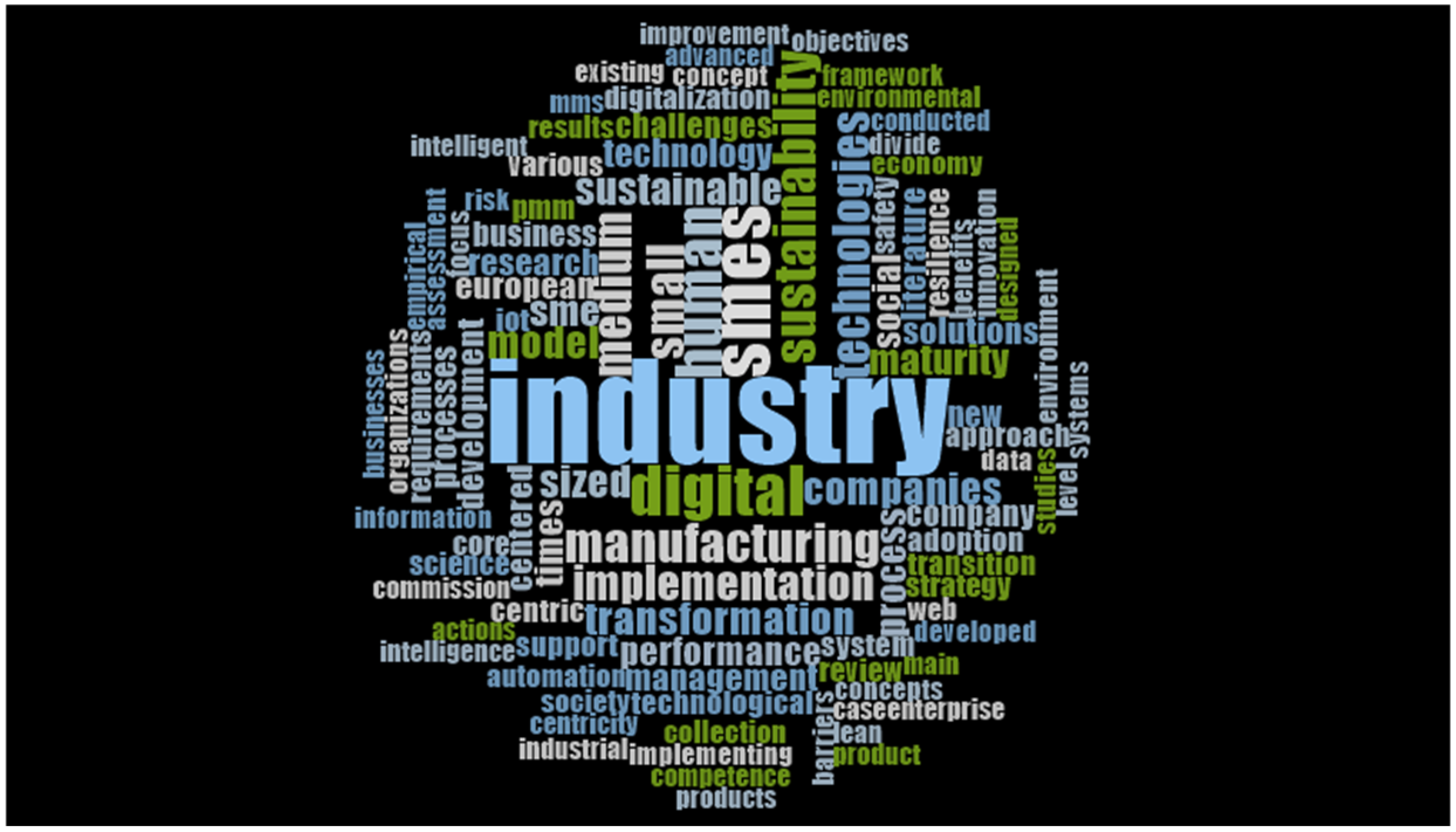

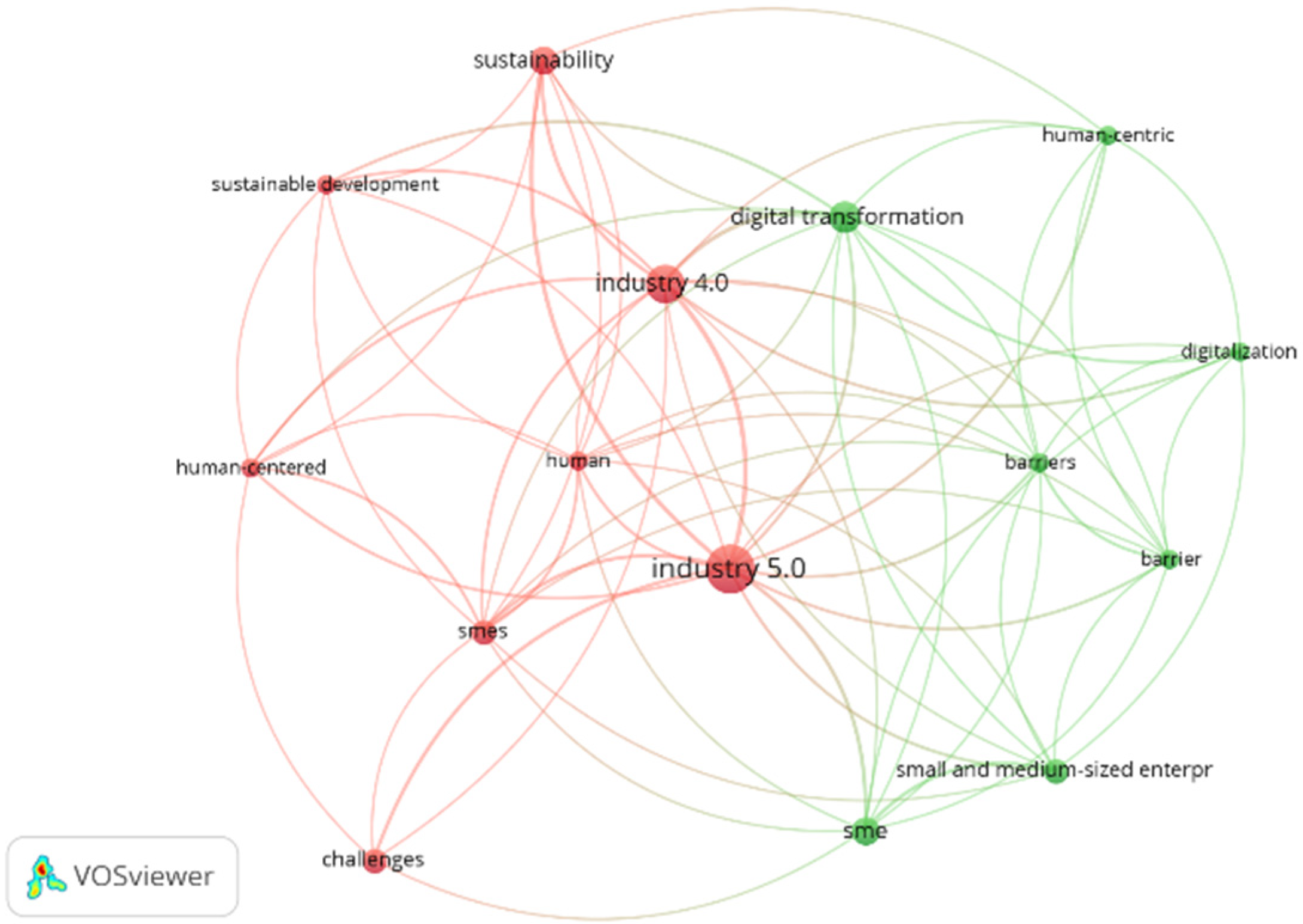

3.2. Corpus Analysis

3.3. Synthesis Grid

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ouidani, E. Factors influencing the appropriation of artificial intelligence technologies by the banking sector: Proposal of a theoretical model. Moroc. J. Quant. Qual. Res. 2023, 5, 1–16. [Google Scholar]

- Nahavandi, S. Industry 5.0—A Human-Centric Solution. Sustainability 2019, 11, 4371. [Google Scholar] [CrossRef]

- Leng, J.; Sha, W.; Wang, B.; Zheng, P.; Zhuang, C.; Liu, Q.; Wuest, T.; Mourtzis, D.; Wang, L. Industry 5.0: Prospect and retrospect. J. Manuf. Syst. 2022, 65, 279–295. [Google Scholar] [CrossRef]

- Iakovets, A.; Balog, M.; Židek, K. Agile in the Context of Manufacturing SMEs. In Proceedings of the 6th International Conference on Design, Simulation, Manufacturing: The Innovation Exchange, DSMIE-2023, High Tatras, Slovakia, 6–9 June 2023; pp. 132–141. [Google Scholar] [CrossRef]

- Benabdelouahab, A.; Chaibi, A.; Haman, S.; Bentassil, Z.; Elouadi, A.; Moumen, A. Artificial Intelligence and Industry 4.0 Trends: A Comprehensive Review and Case Study Analysis in the Moroccan Context. In Proceedings of the 2024 International Conference on Intelligent Systems and Computer Vision (ISCV), Fez, Morocco, 24–26 April 2024; pp. 1–8. [Google Scholar] [CrossRef]

- Arora, M.; Mahale, P.; Bhalerao, K. Industry 5.0: A Solution for Leading SMEs. In Sustainable Strategic Business Infrastructure Development and Contemporary Digital Practices in Industry 5.0; Apple Academic Press eBooks: Palm Bay, FL, USA, 2024; pp. 21–32. [Google Scholar]

- Bernardo, J.; Puente, J.; León, O.; Pino, R. Assessment Model of Industry 5.0 Implementation in Small and Medium-Sized Companies in the Metal Sector, Using AHP and Fuzzy Inference Systems. In Proceedings of the 17th International Conference on Industrial Engineering and Industrial Management (ICIEIM), Madrid, Spain, 13–15 July 2022; pp. 155–160. [Google Scholar] [CrossRef]

- Cagno, E.; Accordini, D.; Neri, A.; Negri, E.; Macchi, M. Digital solutions for workplace safety: An empirical study on their adoption in Italian metalworking SMEs. Saf. Sci. 2024, 177, 106598. [Google Scholar] [CrossRef]

- Dossou, P.-E.; Nshokano, C. Framework for Implementing Digital Twin as an Industry 5.0 Concept to Increase the SME Performance. In Proceedings of the FAIM 2023, Porto, Portugal, 18–22 June 2023; pp. 590–600. [Google Scholar] [CrossRef]

- Grünbichler, R.; Salimbeni, S. Artificial Intelligence in Small and Medium-Sized Enterprises: Requirements and Barriers. In Proceedings of the 3rd International Symposium on Industrial Engineering and Automation ISIEA 2024, Trier, Germany, 19–20 June 2024; pp. 173–184. [Google Scholar] [CrossRef]

- Hamden, M.; Houssin, R.; Lehyani, F.; Zouari, A.; Coulibaly, A. Inventive Design for Transition to Industry 5.0 Based on Risk Management: Statement and First Proposition. In Proceedings of the 24th IFIP WG 5.4 International TRIZ Future Conference, TFC 2024, Cluj-Napoca, Romania, 6–8 November 2024; pp. 185–196. [Google Scholar] [CrossRef]

- Hansen, A.K.; Christiansen, L.; Lassen, A.H. Technology isn’t enough for Industry 4.0: On SMEs and hindrances to digital transformation. Int. J. Prod. Res. 2024, 63, 6585–6605. [Google Scholar] [CrossRef]

- Hein-Pensel, F.; Winkler, H.; Brückner, A.; Wölke, M.; Jabs, I.; Mayan, I.J.; Kirschenbaum, A.; Friedrich, J.; Zinke-Wehlmann, C. Maturity assessment for Industry 5.0: A review of existing maturity models. J. Manuf. Syst. 2023, 66, 200–210. [Google Scholar] [CrossRef]

- Kononova, N.; Juraschek, M.; Kohlgrüber, M.; Herrmann, C. Advanced Sustainability Action Plan: Supporting manufacturing SMEs on a sustainability pathway. Procedia CIRP 2024, 122, 354–359. [Google Scholar] [CrossRef]

- Latino, M.E. A maturity model for assessing the implementation of Industry 5.0 in manufacturing SMEs: Learning from theory and practice. Technol. Forecast. Soc. Change 2025, 214, 124045. [Google Scholar] [CrossRef]

- Mladineo, M.; Ćubić, M.; Gjeldum, N.; Crnjac Žižić, M. Human-centric approach of the Lean management as an enabler of Industry 5.0 in SMEs. In Proceedings of the Conference Proceedings-Mechanical Technologies and Structural Materials 2021, Split, Croatia, 23–24 September 2021; pp. 111–117. [Google Scholar]

- Nazarejova, J.; Soltysova, Z.; Rudeichuk, T. Requirements and Barriers for Human-Centered SMEs. Sensors 2024, 24, 4681. [Google Scholar] [CrossRef] [PubMed]

- Osieczko-Potoczna, K. Reasons, benefits and challenges on the road to automated internal transportation. Acta Logist. 2024, 11, 605–613. [Google Scholar] [CrossRef]

- Saptaningtyas, W.W.E.; Rahayu, D.K. A proposed model for food manufacturing in smes: Facing industry 5.0. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Dubai, United Arab Emirates, 10–12 March 2020. [Google Scholar]

- Saunila, M.; Nasiri, M.; Ukko, J.; Gastaldi, L. Managing Social Sustainability With IoT Implementation: An Industry 5.0 Perspective. Sustain. Dev. 2025, 33, 5327–5335. [Google Scholar] [CrossRef]

- García, P.S.; Ramírez-Gutiérrez, A.G.; Matamoros, O.M.; Páez, A.L.C. Viable and Sustainable Model for Adoption of New Technologies in Industry 4.0 and 5.0: Case Study on Pellet Manufacturing. Appl. Syst. Innov. 2025, 8, 14. [Google Scholar] [CrossRef]

- Zare, L.; Benedini, B.; Ali, M.B.; Rauch, E.; Salimbeni, S. Opportunities and Barriers for Implementing Human-Centric Manufacturing in SMEs: Results from Focus Group Workshops in Argentina. Procedia Comput. Sci. 2025, 253, 1452–1461. [Google Scholar] [CrossRef]

| Ref | Source Title | Country | Purpose of the Study |

|---|---|---|---|

| [6] | “Sustainable Strategic Business Infrastructure Development and Contemporary Digital Practices in Industry 5.0” | India | “1—researching the role of SMEs and Industry 5.0 in economic advancement, 2—investigating the opportunities and challenges of implementing Industry 5.0 in SMEs, and 3—proposing the Industry 5.0 model for SMEs.” |

| [7] | “Proceedings of the 17th international conference on industrial engineering and industrial management, icieim-xxvii congreso de ingenieria de organizacion, cio 2023” | Spain | “Identifying the factors that must be taken into account in the implementation of I5.0 by SMEs.” |

| [8] | «Safety Science» | Italy | “Exploring the digital transition and the barriers influencing the adoption of this solution” |

| [9] | “Lecture Notes in Mechanical Engineering” | France | “The formulation of a framework for the implementation of digital twin technology as an Industry 5.0 concept in the SME.” |

| [10] | “Latest advancements in mechanical engineering, vol 2, isiea 2024” | Argentina/Austria | “Defining the obstacles to the implementation of AI face SMEs in the manufacturing sector and the requirements they must meet to adopt it.” |

| [11] | “IFIP Advances in Information and Communication Technology” | France/Tunisia | “Identifying the risk management related to the digital transition of SMEs into I5.0.” |

| [12] | “International Journal of Production Research” | Denmark | “Defining how can the approach to competence development in SMEs explain patterns of slow digital transformation.” |

| [13] | «Journal of Manufacturing Systems» | Germany | “Assess the extent to which existing Industry 4.0 maturity models accommodate the specific requirements of Industry 5.0.” |

| [14] | “31st CIRP Conference on Life Cycle Engineering” | Germany | “Proposing a guided decision support method for SMEs to help them on the sustainability pathway.” |

| [15] | “Technological Forecasting and Social Change” | Italy | “Proposing a framework to evaluate the maturity of SMEs in Industry 5.0 practices and outlining improvement strategies and operational information to enhance the enterprise’s maturity.” |

| [16] | “Mechanical Technology and Structural Materials” | Croatia | “Selection of key success factors for Lean implementation of Industry 5.0 into SME.” |

| [17] | «Sensors» | Slovakia | “Identify the gaps preventing the effective integration of human centricity into industrial practices, particularly within SME.” |

| [18] | «Acta Logistica» | Poland | “Study and describing the case of a manufacturing company that decided to change the means of internal transportation to automated.” |

| [19] | “Proceedings of the International Conference on Industrial Engineering and Operations Management” | Indonesia | “Offering the process product innovation model for facing Industry 5.0 in food manufacturing SME industries.” |

| [20] | «Sustainable Development» | Finland/Italy | “Determine how the connection between IoT and social sustainability is facilitated by PMM.” |

| [21] | «Applied System Innovation» | Mexico | “Design and testing of an innovative model aimed at supporting organizations, especially SMEs, in overcoming the challenges of emerging technologies under the paradigms of Industry 4.0 and 5.0.” |

| [22] | “6th International Conference on Industry 4.0 and Smart Manufacturing” | Argentina/Italy | “Define what human-centered challenges SMEs in the manufacturing industry encounter when moving towards I5.0, and what criteria must be fulfilled to embrace it.” |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bentassil, Z.; Ben Abdelouahab, A.; Moumen, A. Implementation of Industry 5.0 in SME: Scoping Review. Eng. Proc. 2025, 112, 14. https://doi.org/10.3390/engproc2025112014

Bentassil Z, Ben Abdelouahab A, Moumen A. Implementation of Industry 5.0 in SME: Scoping Review. Engineering Proceedings. 2025; 112(1):14. https://doi.org/10.3390/engproc2025112014

Chicago/Turabian StyleBentassil, Zineb, Anass Ben Abdelouahab, and Aniss Moumen. 2025. "Implementation of Industry 5.0 in SME: Scoping Review" Engineering Proceedings 112, no. 1: 14. https://doi.org/10.3390/engproc2025112014

APA StyleBentassil, Z., Ben Abdelouahab, A., & Moumen, A. (2025). Implementation of Industry 5.0 in SME: Scoping Review. Engineering Proceedings, 112(1), 14. https://doi.org/10.3390/engproc2025112014