Enhancing Sweeping Frequency and Jet Impingement Cooling in Fluidic Oscillators via Bleed-Feed Channel Width Variation †

Abstract

1. Introduction

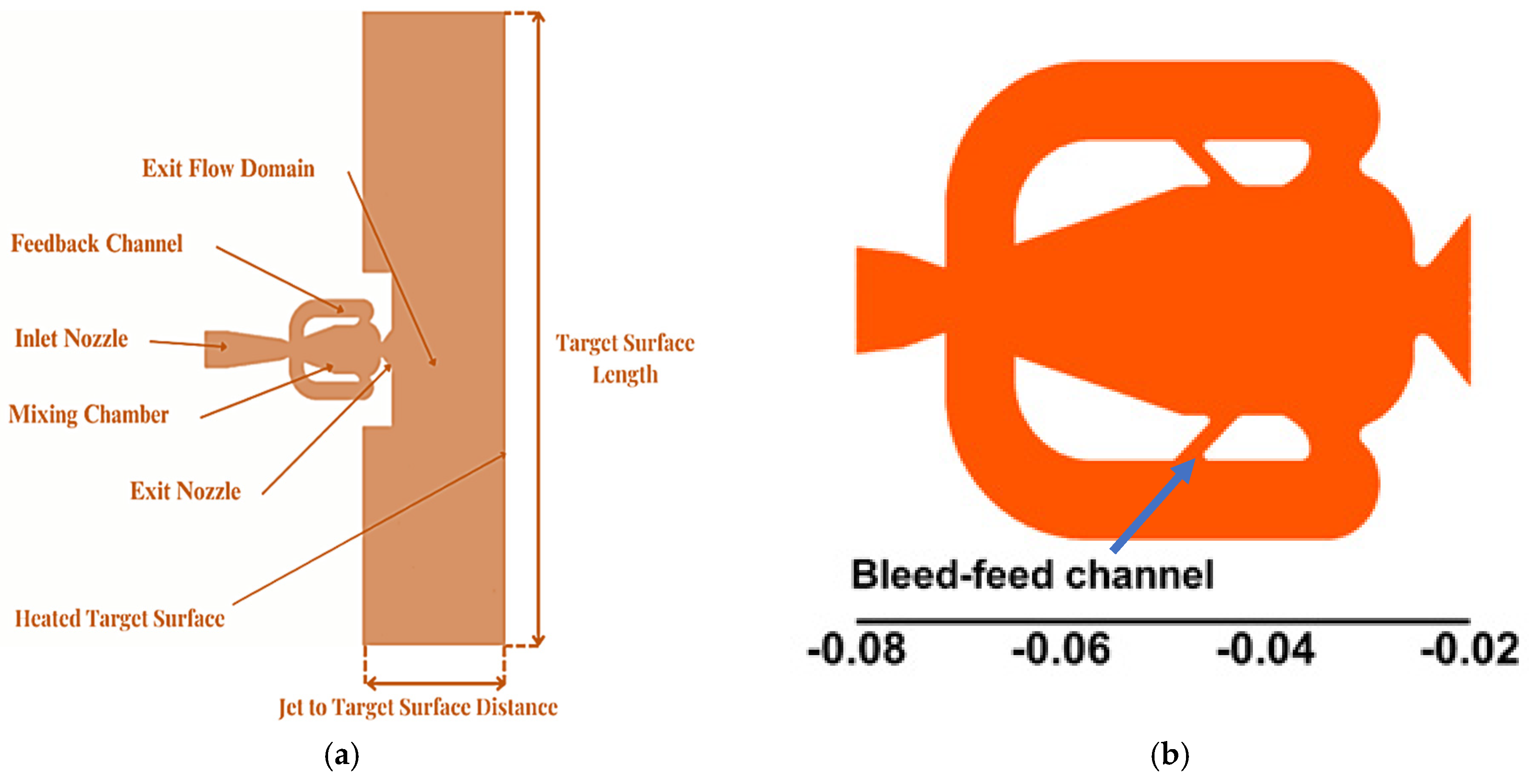

2. Numerical Methodology

3. Grid Independence and Model Validation

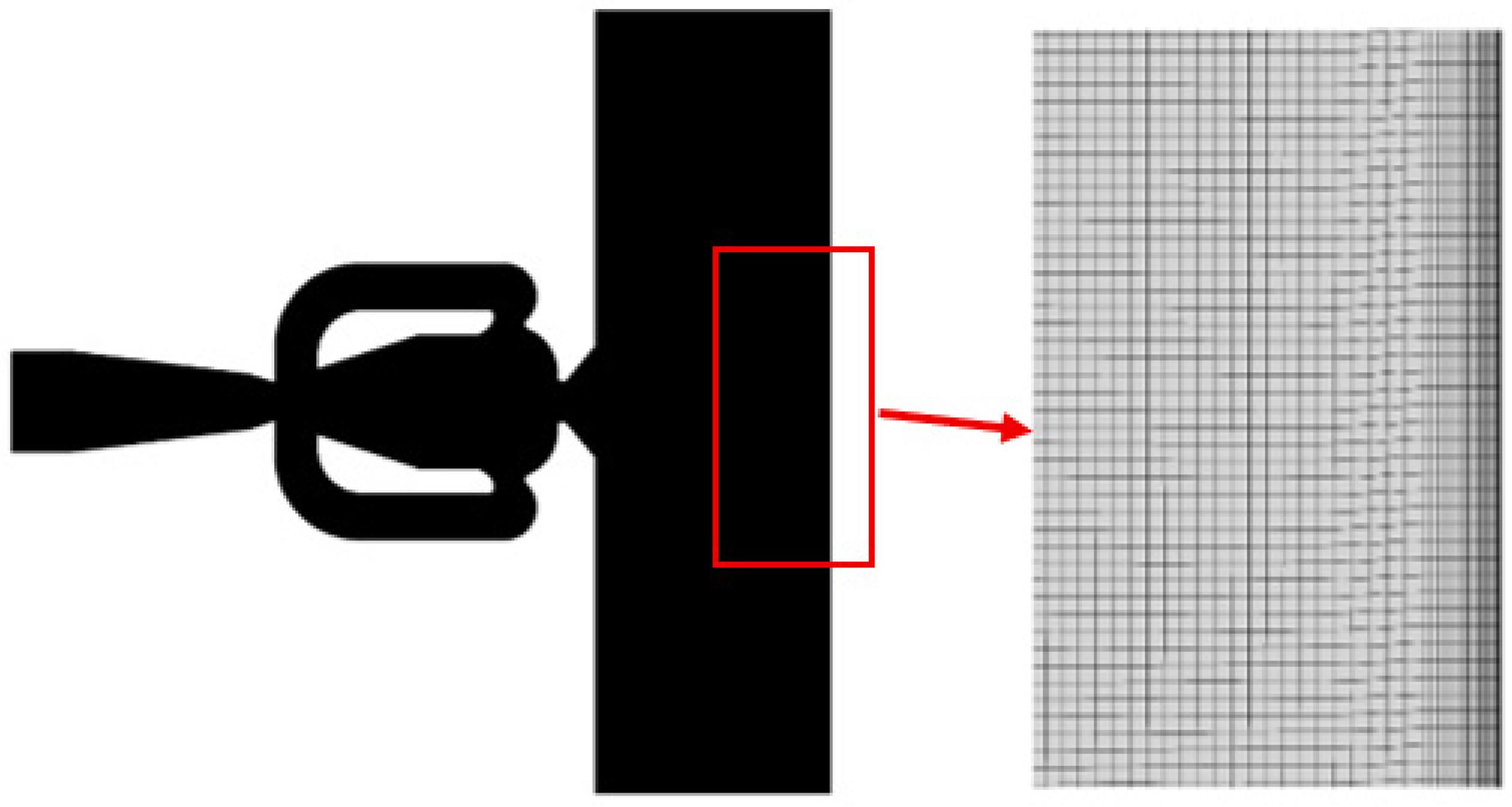

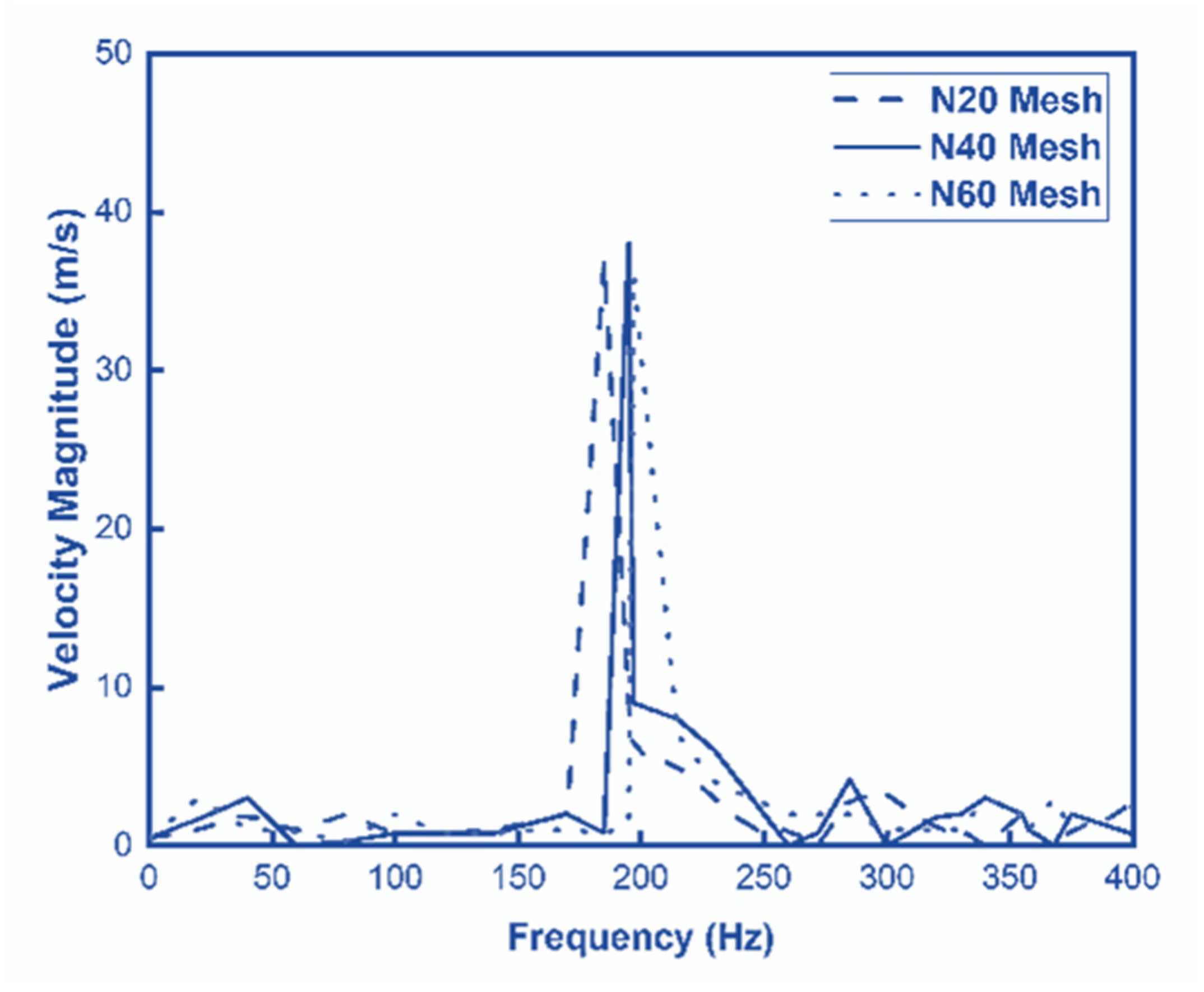

3.1. Grid Independence

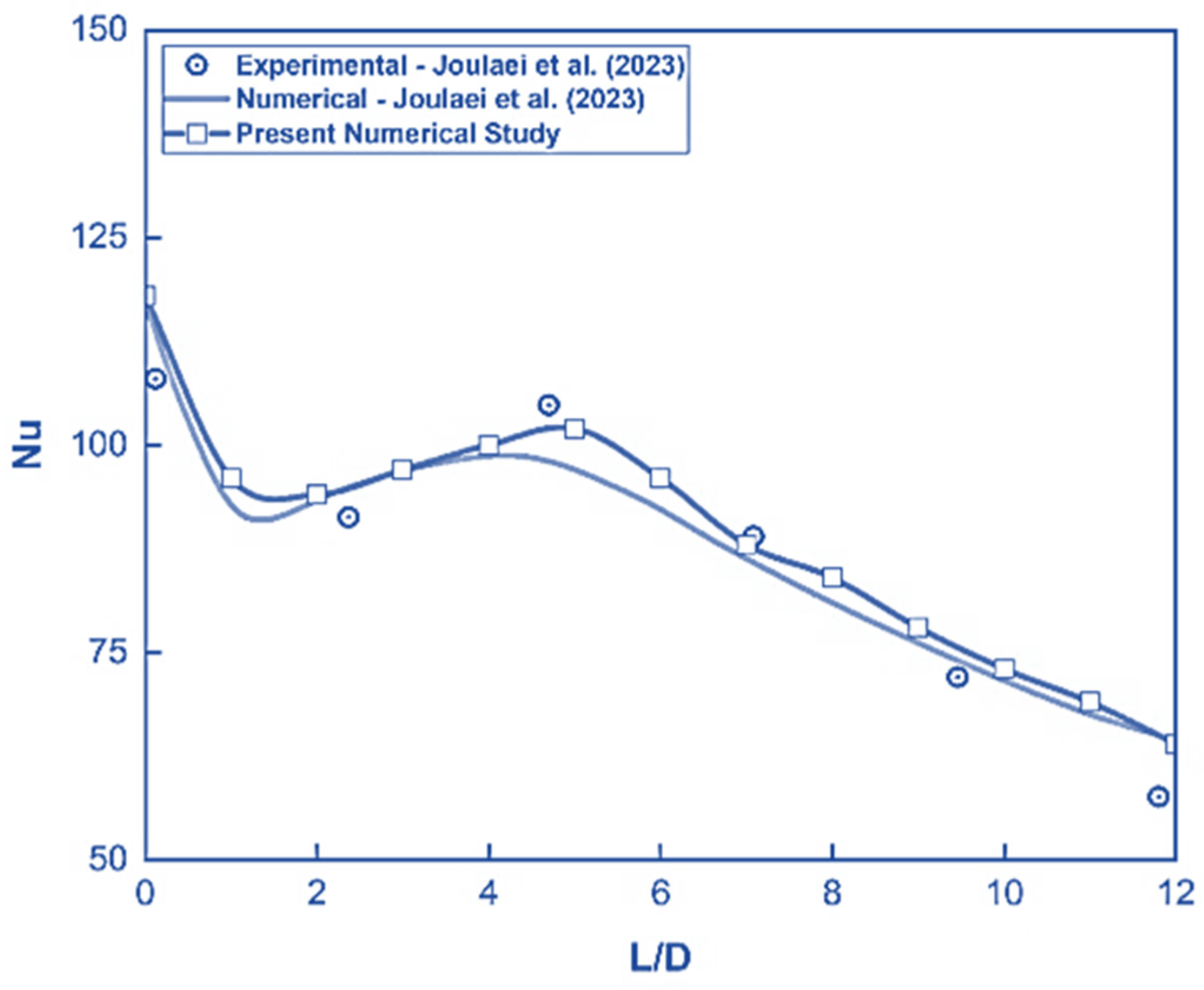

3.2. Model Validation

4. Results and Discussion

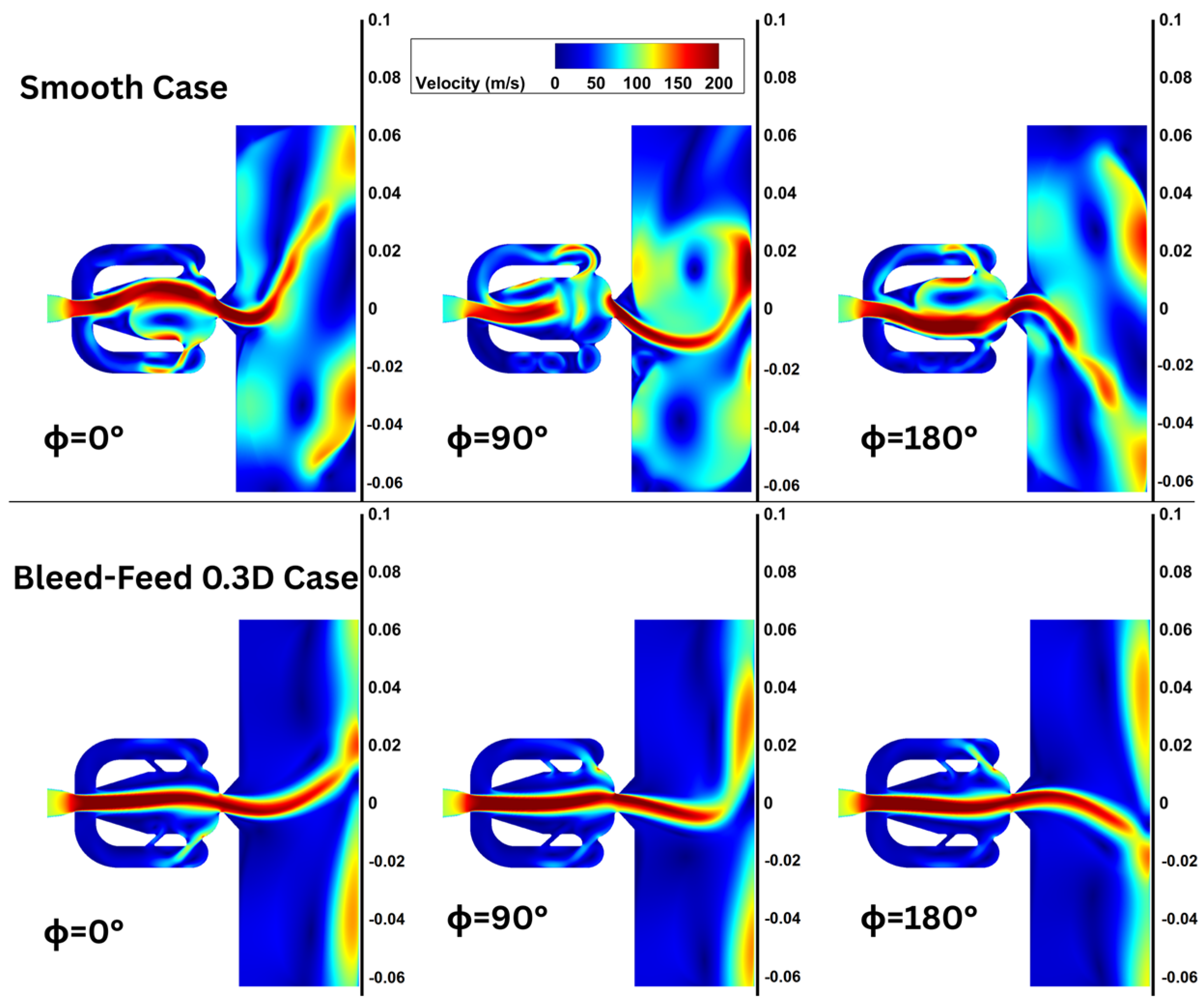

4.1. Impact of Bleed-Feed Channel Width on Frequency

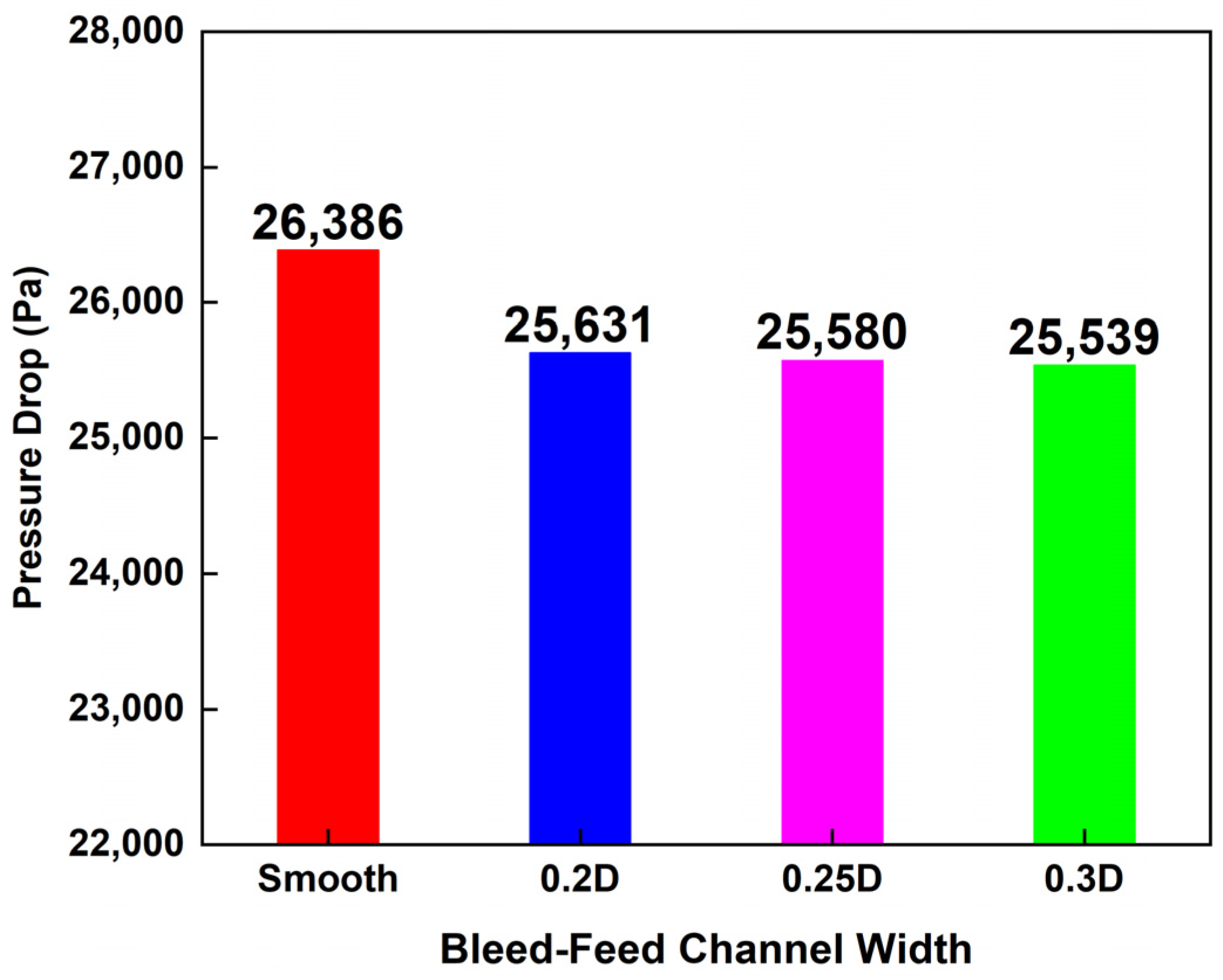

4.2. Impact of Bleed-Feed Channel Width on Pressure Drop

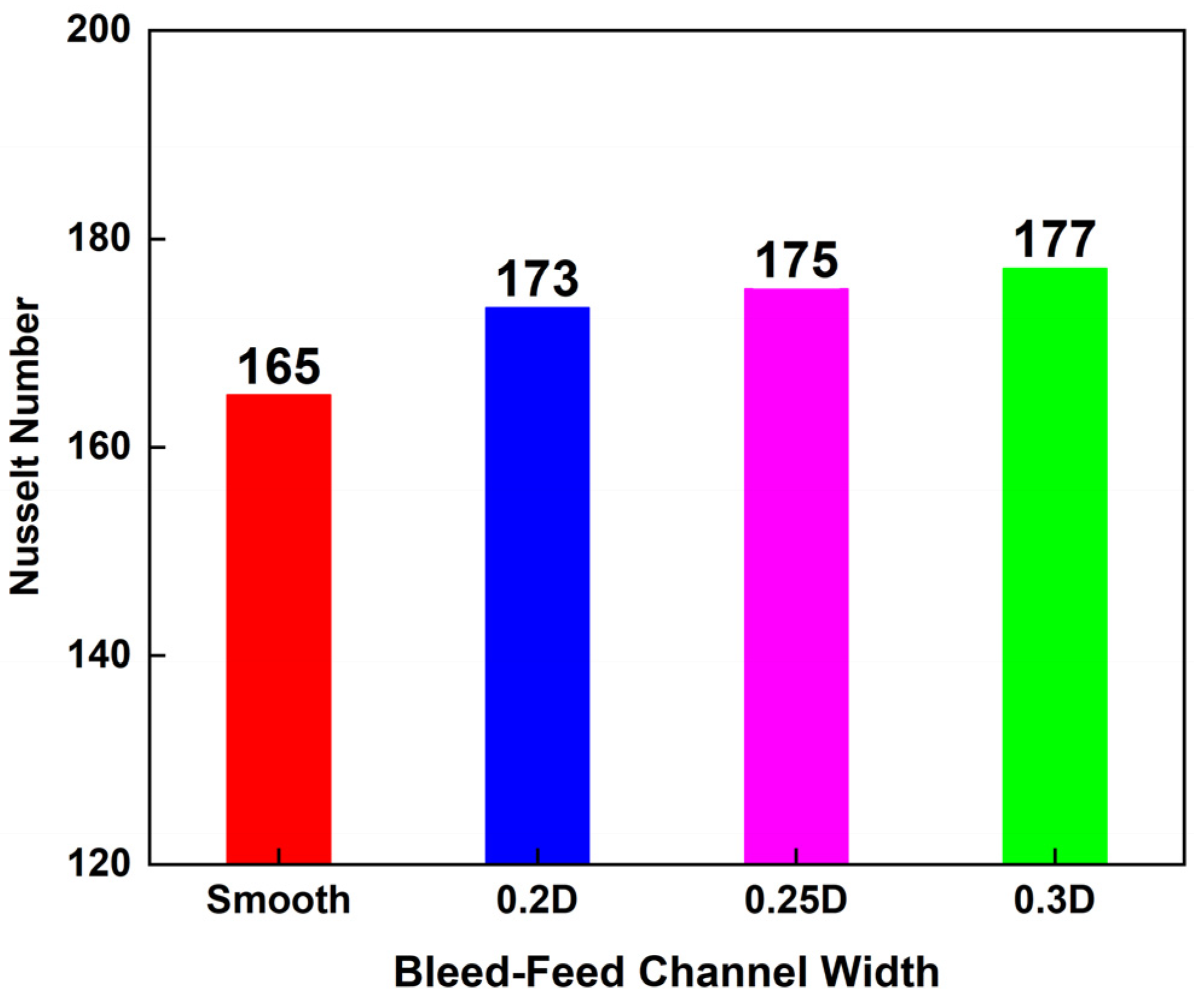

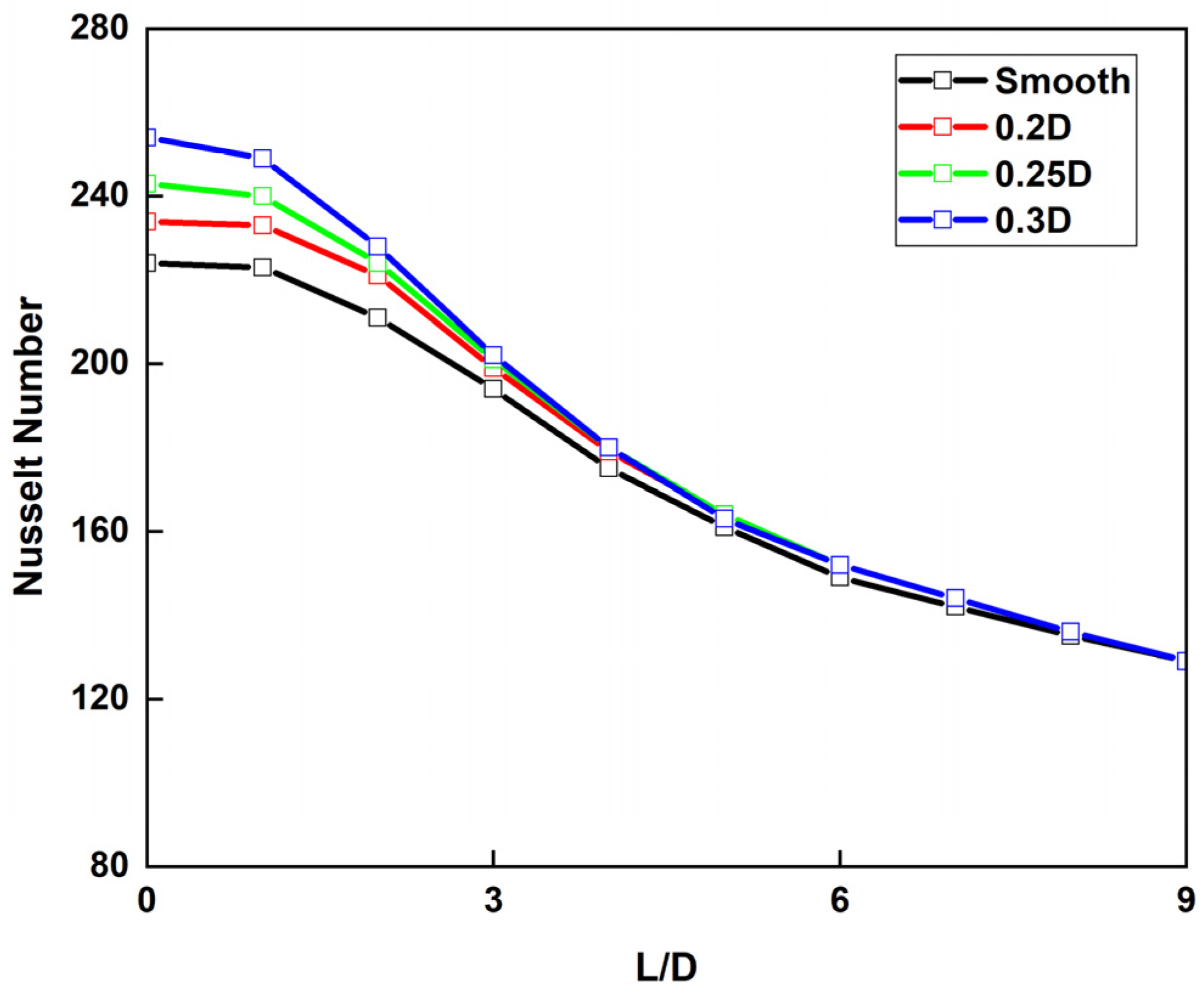

4.3. Impact of Bleed-Feed Channel Width on Nusselt Number

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Raghu, S. Feedback-Free Fluidic Oscillator and Method. U.S. Patent US 6,253,782 B1, 3 July 2001. [Google Scholar]

- Jafarian Amiri, A.; Farhadi, M. Numerical Investigation of a Single Feedback Loop Oscillator with Two Outlet Channels. Chem. Eng. Res. Des. 2019, 150, 206–217. [Google Scholar] [CrossRef]

- Hussain, L.; Khan, M.M. Recent Progress in Flow Control and Heat Transfer Enhancement of Impinging Sweeping Jets Using Double Feedback Fluidic Oscillators: A Review. J. Heat Transf. 2022, 144, 120802. [Google Scholar] [CrossRef]

- Stouffer, R. Oscillating Spray Device. U.S. Patent 4,151,955, 1 May 1979. [Google Scholar]

- Greenblatt, D.; Whalen, E.A.; Wygnanski, I.J. Introduction to the Flow Control Virtual Collection. AIAA J. 2019, 57, 3111–3114. [Google Scholar] [CrossRef]

- Schmidt, H.J.; Woszidlo, R.; Nayeri, C.N.; Paschereit, C.O. Separation Control with Fluidic Oscillators in Water. Exp. Fluids 2017, 58, 135. [Google Scholar] [CrossRef]

- Raman, G.; Raghu, S. Cavity Resonance Suppression Using Miniature Fluidic Oscillators. AIAA J. 2004, 42, 10–13. [Google Scholar] [CrossRef]

- Madadkon, H.; Fadaie, A.; Nili-Ahmadabadi, M. Experimental and Numerical Investigation of Unsteady Turbulent Flow in a Fluidic Oscillator Flow Meter with Extraction of Characteristics Diagrams. Modares J. Mech. Eng. 2013, 12, 30–42. [Google Scholar]

- Lacarelle, A.; Paschereit, C.O. Increasing the Passive Scalar Mixing Quality of Jets in Crossflow with Fluidics Actuators. J. Eng. Gas Turbine Power 2012, 134, 021503. [Google Scholar] [CrossRef]

- Kim, S.H.; Kim, H.D.; Kim, K.C. Measurement of Two-Dimensional Heat Transfer and Flow Characteristics of an Impinging Sweeping Jet. Int. J. Heat. Mass. Transf. 2019, 136, 415–426. [Google Scholar] [CrossRef]

- Fawzy, H.; Zheng, Q.; Ahmad, N.; Jiang, Y. Optimization of a Swirl with Impingement Compound Cooling Unit for a Gas Turbine Blade Leading Edge. Energies 2020, 13, 210. [Google Scholar] [CrossRef]

- Fawzy, H.; Zheng, Q.; Jiang, Y.; Lin, A.; Ahmad, N. Conjugate Heat Transfer of Impingement Cooling Using Conical Nozzles with Different Schemes in a Film-Cooled Blade Leading-Edge. Appl. Therm. Eng. 2020, 177, 115491. [Google Scholar] [CrossRef]

- Fawzy, H.; Zheng, Q.; Ahmad, N. Effect of Slot Area Ratio and Slot Angle on Swirl Cooling in a Gas Turbine Blade Leading Edge. J. Aerosp. Eng. 2020, 33, 04020046. [Google Scholar] [CrossRef]

- Bobusch, B.C.; Woszidlo, R.; Krüger, O.; Paschereit, C.O. Numerical Investigations on Geometric Parameters Affecting the Oscillation Properties of a Fluidic Oscillator. In Proceedings of the 21st AIAA Computational Fluid Dynamics Conference, San Diego, CA, USA, 24–27 June 2013; pp. 1–15. [Google Scholar]

- Baghaei, M.; Bergada, J.M. Fluidic Oscillators, the Effect of Some Design Modifications. Appl. Sci. 2020, 10, 2105. [Google Scholar] [CrossRef]

- Woszidlo, R.; Ostermann, F.; Nayeri, C.N.; Paschereit, C.O. The Time-Resolved Natural Flow Field of a Fluidic Oscillator. Exp. Fluids 2015, 56, 125. [Google Scholar] [CrossRef]

- Tajik, A.; Kara, K.; Parezanovic, V. Sensitivity of a Fluidic Oscillator to Modifications of Feedback Channel and Mixing Chamber Geometry. Exp. Fluids 2021, 62, 250. [Google Scholar] [CrossRef]

- Hossain, M.A.; Prenter, R.; Agricola, L.M.; Lundgreen, R.K.; Ameri, A.; Gregory, J.W.; Bons, J.P.; Researcher, P. Effects of Roughness on the Performance of Fluidic. In Proceedings of the 55th AIAA Aerospace Sciences Meeting, Grapevine, TX, USA, 9–13 January 2017. [Google Scholar]

- Jeong, H.S.; Kim, K.Y. Shape Optimization of a Feedback-Channel Fluidic Oscillator. Eng. Appl. Comput. Fluid Mech. 2018, 12, 169–181. [Google Scholar] [CrossRef]

- Hussain, L.; Khan, M.M.; Ahmad, N. Flow Performance Enhancement of a Fluidic Oscillator Through the Integration of Rectangular Ribs on Coanda Surface. J. Fluids Eng. 2024, 146, 111301. [Google Scholar] [CrossRef]

- Hussain, L.; Khan, M.M.; Ahmad, N. Flow Performance Improvement of Fluidic Oscillator Through Variation in Number of Ribs on Coanda Surface. J. Fluids Eng. 2025, 147, 111201. [Google Scholar] [CrossRef]

- Hussain, L.; Khan, M.M. The Influence of Location of Coanda Surface Ribs on Fluidic Oscillator Performance. In Proceedings of the 4th International Conference on Advances in Mechanical Engineering (ICAME-24), Islamabad, Pakistan, 8 August 2024; p. 3. [Google Scholar]

- Hussain, L.; Khan, M.M.; Ahmad, N. Design Optimization of Ribbed Fluidic Oscillator Using Integrated CFD-Taguchi-GRA Method. Eur. J. Mech.—B/Fluids 2025, 113, 204284. [Google Scholar] [CrossRef]

- Hussain, L.; Khan, M.M.; Ahmad, N.; Imran, M.; Shahzad, M.W. Taguchi-Based Optimization of a Fluidic Oscillator for Enhanced Thermal-Hydraulic Performance of an Impinging Sweeping Jet. Int. Commun. Heat Mass. Transf. 2025, 166, 109176. [Google Scholar] [CrossRef]

- Joulaei, A.; Nili-Ahmadabadi, M.; Yeong Ha, M. Numerical Study of the Effect of Geometric Scaling of a Fluidic Oscillator on the Heat Transfer and Frequency of Impinging Sweeping Jet. Appl. Therm. Eng. 2023, 221, 119848. [Google Scholar] [CrossRef]

- Joulaei, A.; Nili-Ahmadabadi, M.; Chun Kim, K. Parametric Study of a Fluidic Oscillator for Heat Transfer Enhancement of a Hot Plate Impinged by a Sweeping Jet. Appl. Therm. Eng. 2022, 205, 118051. [Google Scholar] [CrossRef]

- Slupski, B.J.; Tajik, A.R.; Parezanović, V.B.; Kara, K. On the Impact of Geometry Scaling and Mass Flow Rate on the Frequency of a Sweeping Jet Actuator. FME Trans. 2019, 47, 599–607. [Google Scholar] [CrossRef]

- Alam, M.; Kara, K. The Influence of Exit Nozzle Geometry on Sweeping Jet Actuator Performance. Fluids 2022, 7, 69. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hussain, L.; Khan, M.M.; Ahmad, N.; Kifayatullah; Ahmer, T. Enhancing Sweeping Frequency and Jet Impingement Cooling in Fluidic Oscillators via Bleed-Feed Channel Width Variation. Eng. Proc. 2025, 111, 24. https://doi.org/10.3390/engproc2025111024

Hussain L, Khan MM, Ahmad N, Kifayatullah, Ahmer T. Enhancing Sweeping Frequency and Jet Impingement Cooling in Fluidic Oscillators via Bleed-Feed Channel Width Variation. Engineering Proceedings. 2025; 111(1):24. https://doi.org/10.3390/engproc2025111024

Chicago/Turabian StyleHussain, Liaqat, Muhammad Mahabat Khan, Naseem Ahmad, Kifayatullah, and Taha Ahmer. 2025. "Enhancing Sweeping Frequency and Jet Impingement Cooling in Fluidic Oscillators via Bleed-Feed Channel Width Variation" Engineering Proceedings 111, no. 1: 24. https://doi.org/10.3390/engproc2025111024

APA StyleHussain, L., Khan, M. M., Ahmad, N., Kifayatullah, & Ahmer, T. (2025). Enhancing Sweeping Frequency and Jet Impingement Cooling in Fluidic Oscillators via Bleed-Feed Channel Width Variation. Engineering Proceedings, 111(1), 24. https://doi.org/10.3390/engproc2025111024