Abstract

Zirconia, also known as zirconium dioxide ZrO2, is well known for its good mechanical properties, like its inertness, good wear resistance, high temperature resistance and good strength. To enhance the mechanical properties of many materials, a technique known as transformation toughening is widely used today. This research focuses on achieving an optimized composition of zirconia and alumina Al2O3 to achieve zirconia-toughened alumina ZTA with a maximum density and other mechanical properties using a cost-effective and time-efficient approach. Doing so will make it possible to make more and more use of this valuable ceramic. The curing of zirconia and alumina samples with 3d—printing resins in silicone dies was performed so that we could obtain the optimum ratio of the resin and ZTA powder that would produce the most desirable results and properties. For 3d printing, ZTA samples with 19% zirconia ZrO2 were used with alumina at two different temperatures (i.e., Sample 1, consisting of three pellets weighing 5–6 g, was sintered at 1500 °C, and Sample 2, also containing three pellets weighing 5 g (approx.), was sintered at 1600 °C). The green-state preparation of these samples (Sample 1 and Sample 2) was performed using milling media of WC balls/ethanol and a milling ratio of 1:3, and a milling time of 4 h 100 rpm was used while drying at 80 °C for 5.5 h. The relative density (70%) and Vickers hardness (14–17 GPa) were obtained for Al2O3/ZrO2/MgO samples. Mechanical properties like hardness and strength strongly depend on the holding time, the rate of the temperature increase while sintering and the sintering temperature itself.

1. Introduction

In mechanical, chemical and electrical engineering the useful properties of ceramics are becoming more important day by day. Oxides of ceramics are used in many industries, such as mining, aerospace, electronics and medicines [1,2]. Toughened alumina (ZTA) ceramic is being used in orthopedic femoral heads implants and mechanically coupled for hip joint replacements [3]. Ceramics like zirconia (ZrO2) and alumina (Al2O3) have gained a major place among oxides because of their high hardness and exceptional strength, as well as their resistance to corrosion and heat. High strength and good hardness are the fundamental properties of alumina-based ceramics. Even though ceramics show good wear resistance, their fracture toughness is comparatively low. Zirconia particles (tetragonal) can be added to significantly increase the fracture toughness and strength. This addition of ZrO2 to Al2O3 reduces the occurrence of fractures and results in increasing toughness.

Generally, ceramics have been considered as an alternative to metal implants in medicine. Zirconia ceramics have gained special attention when it comes to dentistry because of their mechanical characteristics, bio-acceptability, similar color to natural teeth and excellent antibacterial response.

Orthopedics, trauma surgery (prosthetic head, skeleton fragments, bone defect elements) and dental medicines (implants and crowns) are some of the broad applications of zirconia-based ceramics. By modifying the structure parameters and the composition, the mechanical and frictional properties of the ceramics can be modified significantly. The manipulation of the structure by varying the composition of the matrix and its resulting properties is of significant interest when it comes to composite structure formation.

The main goals of this research are

- To lower the sintering temperature of ZTA by adding a suitable additive (MgO).

- To observe the change in the properties of ZTA using an optimum ratio of zirconia (ZrO2).

- To observe the pressureless sintering of ZTA.

Although it retains many properties (corrosion resistance at very high temperature), zirconia does exhibit structural changes that limit its use to perhaps only 500 °C. At this temperature it also becomes electrically conductive. The volume growth because of the zirconia transformation is nearly 3–4%, which enhances the matrix stress [4]. So the stabilization of zirconia is performed to make the most of its excellent properties. Ceramics based upon zirconia can be stabilized in cubic or tetragonal phases depending on the percentage of the reinforcements (CaO, MgO, Y2O3) and the temperature being used during their heat treatments, i.e., sintering. A considerable volume change occurs when a tetragonal–monoclinic transformation of zirconia occurs.

A technique known as ceramic injection molding was used to fabricate zirconia micro-parts due to their small size and complex shape. This technique was not only cost effective but also produced satisfactory results. Ceramic injection molding (CIM) was first applied in the 1920s to manufacture the bodies of spark plugs. Piotter et al. used micro-injection molding techniques to manufacture zirconia-based ceramics [5] and recommended the micro-injection molding technique for the widespread fabrication of complex parts. Muller and coworkers also manufactured and determined the bending strength of zirconia-based ceramic microbeams by using micro-injection molding [6,7,8,9].

The most reliable and promising toughening mechanism used for ceramics involves the transformation of phases; this technique is commonly known as transformation toughening. Ceramics such as Al2O3 can be toughened by incorporating ZrO2, which enhances crack resistance via transformation toughening. A very interesting phenomenon known as phase transformation plays an important role in defining the strength of zirconia. When the temperature of pure zirconia drops below 1150 °C, it undergoes a phase transformation from tetragonal to monoclinic, accompanied by a volume expansion of approximately 3% [10,11,12,13,14,15]. This expansion in the volume can be further used to disperse very fine tetragonal particles in the matrix of cubic alumina or zirconia. The nano-size (i.e., 200–400 nm) and contact of these fine particles with the matrix induce the tetragonal structure to stay stable and non-reactive at room temperature. This cumulative volume increase applies a closing force on the propagating crack in addition to a resistance to the propagation of the crack responsible for the increase in the crack length.

Garvie R. C and Nicholson P.S conducted a phase analysis of zirconia systems in 1972 [16]. Mechanistically this toughening mechanism can be described as a crack shielding process, as described by McMeeking and Evans [17]. Hutchinson [18] suggested that the toughening comes from a reduction in the elastic modulus in the transformed areas as energy dissipates during transformation, increasing the crack shielding around the growing crack. Micro-crack toughening again occurs due to a variation in thermal expansion, and in the case of zirconia this is likely due to the phase transformation in response to a localized residual tension [19]. The micro-cracks occur along the lowest fracture energy paths, locally relieving the residual tension.

The sintering of ceramics involves the consolidation of ceramics (powdered) by heating the green part to a high temperature below the melting point. Theoretical as well as experimental proof of sintering techniques came in the early years of the 1900s. Sintering is described as a “processing technique used to produce density-controlled materials by utilizing thermal energy”. In this process the material of the separate particles diffuses to the neighboring powder particles. The driving force in solid-state sintering is the reduction in the total interfacial energy of the particles. The pores that were present in the green state diminish or even close during the diffusion process. This results in densification, hence improving the mechanical properties of the part. “Sintering of nanoparticles generally results in better densification compared to fine particles due to their lower size but it has some cons such as higher sintering stress, and concurrent grain growth [20].”

Magnesium Oxide (MgO) is a very common additive when it comes to the sintering of ceramics as it enhances densification and improves (modifies) the microstructure of ceramics. It also lowers the sintering temperature of ceramics (ceramics are sintered at fairly high temperatures).

Advanced sintering techniques such as Hot-Press Sintering [21], Spark Plasma Sintering [22,23] and Pulsed Electric Current Sintering [24,25] are commonly used for nano-structured ceramics.

Research Strategy

The following are the processes and procedures that have been used in order to achieve the research objectives.

- The preparation of green powders by mixing an optimum ratio of zirconia in alumina powder.

- Ball milling of the mixed powder to ensure a homogenous mixture and reduce the particle size.

- The compaction of the powder to obtain cylindrical pellets and measure the green state density.

- Mixing the powder with the 3d-printed resin with different ratios.

- Sintering at different temperatures, i.e., 1500 °C and 1600 °C.

- Measuring the properties of sintered ZTA samples (density and hardness).

2. Materials and Methods

In this section we will discuss the materials and equipment used for the preparation of zirconia-toughened alumina (ZTA) for the purpose of examining its mechanical properties.

2.1. Materials Used

- Pure alumina powder (99% Al2O3).

- Zirconia powder (ZrO2).

- Magnesium Oxide powder (MgO).

- Stearic Acid (C18H36O2) as a binder.

- Pure ethanol (99% C2H5OH).

- 3d—printing UV-sensitive resin (UV wavelength 405 nm).

The composition of the resin is given in Table 1.

Table 1.

Composition of 3d-printed resin.

Physical and chemical properties of the resin are given in Table 2.

Table 2.

Properties of Resin.

2.2. Powder Development

2.2.1. Ceramic Composition

In order to obtain ZTA, a composition of 76% Al2O3/19% ZrO2/5% MgO was used, in which we have a total of 33.66 g of ZrO2, 134.64 g of Al2O3 according to the unitary method and 8.857689 g of MgO according to the unitary method. MgO is used to decrease the sintering temperature of the alumina and zirconia mixture and ensure the densification of the sintered product.

2.2.2. Ball Milling

Ball milling is mainly performed to decrease the particle size and ensure the homogenous mixing of the powders. The milling parameters used with the samples of 76% Al2O3, 19% ZrO2 and 5% MgO are given in Table 3.

Table 3.

Parameters of ball milling.

2.3. Green State Pressing

Hydraulic pressing machine was used to press the green ceramic samples. A steel die with a diameter of 15 mm was used. Pressing was performed to form cylindrical pellet samples of green-state ZTA with a load of 6.5 ton and pressure of 368 MPA. It has a 15 mm die and 6.5 tons of force.

2.4. Sintering

The green samples are sintered to achieve high-density and high-strength ceramics from their perspective ceramic powders. Ceramic sintering involves different stages to obtain a high-density product. Some of these stages involve mixing the powder, addition of binder, shape (pellets) formation and sintering.

In this research, pressureless and cost-effective sintering is used. This type of sintering involves 4 different stages: powder preparation, shaping, sintering and cooling. We start with fine, high-purity particles (sometimes with sintering aids). The powder is then shaped using die pressing or injection molding; after that it is sintered at a desirable temperature and then cooled to obtain the final enhanced product.

Sintering of solids consists of three main stages (initial, intermediate and final), which serve their own purposes. In the initial stage, neck growth occurs, which causes an increase in interparticle area of contact, hence obtaining 70% of the density. In the intermediate stage, grain boundaries are formed, achieving 90% of the relative density. In the final stage grain growth is very fast, and the pore phase weakens.

2.5. Furnace

For the sintering of ceramics, high temperatures up to 1800 °C are required. So, a suitable furnace is required to attain such a high temperature.

Box Chamber Furnace

To sinter alumina powder and resin–powder samples, box chamber furnace was used (Figure 1). The furnace has a maximum operating temperature of 1800 °C. The gradient rate was 8 °C per min, and sintering was performed at 1400 °C for 4 h. Similarly, the cooling was also conducted at 8 °C per min. The calibrations were performed before the sintering operations.

Figure 1.

Box chamber furnace.

To sinter 0.76 Al2O3/0.19 ZrO2/0.05 MgO samples, another box chamber furnace was used. The maximum operating temperature of the furnace was 1900 °C. Sintering of these samples was conducted at two different temperatures (1500 °C and 1600 °C). The sintering time was 4 h, and the temperature gradient rate was 8 °C per min.

2.6. Density Measurement

One of the most important things that is responsible in determining the mechanical properties of the material is the relative density. Relative density provides a lot of information about the strength and behavior of the materials. Relative density also significantly influences the mechanical properties of ceramics. As the relative density increases, it minimizes the number of pores or voids, hence improving the strength and hardness of the material. These voids tend to reduce the strength of the material because they act as stress concentrators. However, the hardness increases up to a certain point as the relative density increases. Higher relative density also increases the fracture toughness of the material, hence improving the strength of the material.

To determine the relative density, theoretical density is first calculated. The ratio of the experimental or real-time density to the theoretical density gives us the relative density of the material.

Relative density of both the green and sintered samples is calculated by using the Archimedes’ principle and is compared to see whether the sintering was effective. Achieving the highest possible relative density is one of the main reasons for the sintering process.

2.7. Hardness Measurement

Hardness is defined as the resistance of a material to indentation. There are many methods by which we can calculate the hardness of a material. In our case we used the Vickers hardness test.

The Vickers hardness test is often preferred over other hardness tests, as it is much easier to use. The required calculations as per ASTM E384 are independent of the indenter’s size, and the indenter can be used for all the materials. It has one of the widest scales among hardness tests. The unit of hardness given by this test is HV or DPH but can be converted into Pascals (Pa). This should not be confused with pressure or stress, as the same unit (Pa) is used for pressure also.

The surfaces of the sintered samples of ZTA were polished to ensure sharp and readable indents on the surfaces. Diamond-shaped indenters were used to produce the indents. Two indents were created on each of the samples, and their Vickers hardness was noted.

During the experiments there is a small discrepancy in masses. This is mainly due to the sample loss during the sintering process and the removal of the surface during the polishing of the final product.

The Vickers hardness is usually calculated in HV, but it can also be stated in GPa using the following conversion.

HV ≈ (0.009807 × HV) in GPa

3. Results

A variety of experiments were conducted with 5% to 19% of zirconia. With lesser compositions of zirconia most of the samples were not sintered properly and crumbled under the application of even a slight pressure.

The sintering of the cured samples of the 3d-printing resin and zirconia–alumina powder was conducted at different temperatures (from 1200 °C to 1400 °C). This did not result in a satisfactory result, and the samples crumbled.

A mixture of alumina (76%), zirconia (19%) and MgO (5%) was produced. After the ball milling and pressing of this mixture (discussed before), cylindrical pellets were created. Sintering temperatures of 1500 °C and 1600 °C were used for a duration of 4 h. The temperature gradient was 8 °C per min.

The theoretical density of the samples was calculated as

ρ = (0.76 × 3.95) + (0.19 × 5.68) + (0.05 × 3.58)

ρ = 4.2602 g/cm3

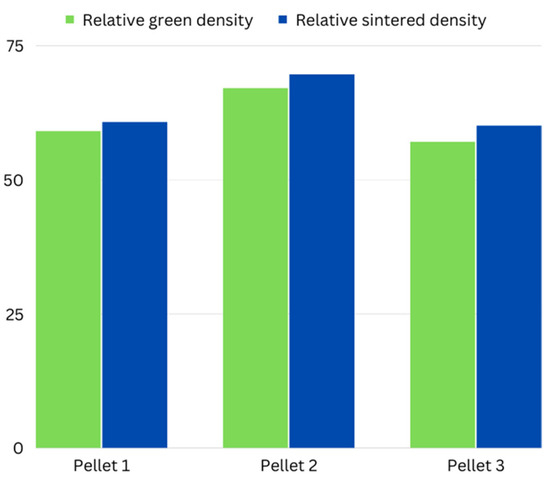

The results are shown in Table 4, and comparisons of the green and sintered density are shown in Figure 2.

Table 4.

Results at 1500 °C.

Figure 2.

Bar chart of the comparison between green and sintered density at 1500 °C.

A relative density of 60–70% was achieved in this experiment. The same experiment was repeated at 1600 °C with three more pellets, which resulted in the melting of the samples.

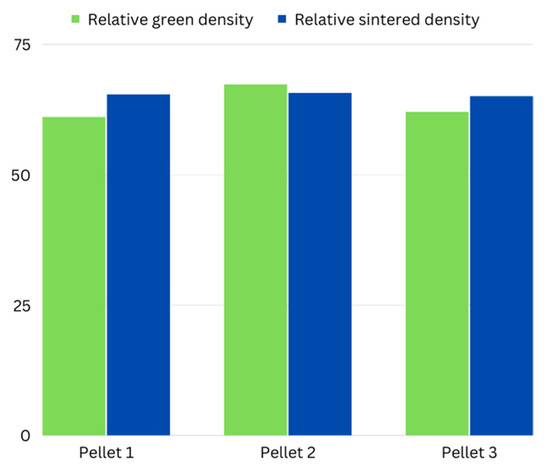

After careful measurements and conditions, another experiment was performed at 1600 °C to determine the relative sintered density of ZTA. The results are shown in Table 5, and a comparison of the green and sintered density is shown in Figure 3.

Table 5.

Results at 1600 °C.

Figure 3.

Bar chart of the comparison between green and sintered density at 1600 °C.

A relative density of approx. 65% was achieved at 1600 °C. From both the graphs, it is clear that sintering results in densification, hence improving the mechanical properties. The products were sintered properly and had a good strength. The Vickers hardness test was performed on both the samples to calculate the hardness of the sintered ZTA samples. The surfaces of the pellets were polished to insure sharp and precise indents readable by the machine. Two indents were created on each sample, and the hardness was measured. The Vickers hardness of the samples is

Vickers hardness = HV = 14–17 GPa.

4. Conclusions

The main aim of this study was to study and investigate the zirconia-toughened alumina (ZTA) ceramic matrix composites at different sintering temperatures and their compatibility with the 3d—printing resin. The following conclusions were drawn from these investigations:

- The powder size and homogenous mixing play an important role in determining the properties of the final sintered product. Hence, ball milling is important to ensure small particle sizes and the homogenous mixing of the green powder.

- Different concentrations of zirconia in alumina, i.e., 5–19%, produced different results, so the right concentration of zirconia should be used.

- Increasing the sintering temperature produced better relative densities.

- Viscosity plays an important role in determining the 3d printing capability of the powder–resin mixture.

- The right balance between the viscosity and density should be considered for the powder–resin mixture.

- At 1500 °C a relative density up to 70% was obtained.

- The hardness range (i.e., 14–17 GPa) is due to the difference in the microstructure between the samples at the given temperature (i.e., 1500 °C and 1600 °C).

- The addition of MgO improved the sinterablity and densification of the samples.

- When 1.5 g of ZTA powder was mixed with 1 mL of the UV-curable resin (405 nm), the resulting mixture had an approximate volume of 2.5 cm3. The sample cured in 6 min under UV exposure, whereas the pure resin’s curing time was 4 min.

Author Contributions

Conceptualization, A.R. and O.u.R.S.; methodology, A.R. and O.u.R.S.; validation, A.R., O.u.R.S. and N.A.; formal analysis O.u.R.S. and N.A.; investigation, A.R., O.u.R.S. and N.A.; resources, A.R. and O.u.R.S.; data curation, A.R. and N.A.; writing—original draft preparation, A.R. and O.u.R.S.; writing—review and editing, O.u.R.S. and N.A.; visualization, A.R. and N.A.; supervision, O.u.R.S. and N.A.; funding, A.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available upon request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Marti, A. Inert bioceramics (AI2O3, ZrO2) for medical application. Inj. Int. J. Care Inj. 2000, 31, D33–D36. [Google Scholar]

- Mutsuddy, B.C. Influence of Powder Characteristics on the Rheology of Ceramic Injection Molding Mixtures. Proc. Brit. Ceram. Soc. 1983, 33, 117–137. [Google Scholar]

- Thomas, P.; Barnstorf, S.; Summer, B.; Willmann, G.; Przybilla, B. Immuno-allergological properties of aluminium oxide (Al2O3) ceramics and nickel sulfate in humans. Biomaterials 2003, 24, 959–966. [Google Scholar] [CrossRef] [PubMed]

- Chevalier, J. What future for zirconia as biomaterials? Biomaterials 2006, 27, 535–543. [Google Scholar] [CrossRef]

- Piotter, V.; Beck, M.B.; Ritzhaupt-Kleissl, H.J.; Ruh, A.; Hausselt, J. Recent developments in micro ceramic injection molding. Int. J. Mater. Res. 2008, 99, 1157–1162. [Google Scholar] [CrossRef]

- Rogner, J.; Okolo, B.; Kurzenhäuser, S.; Müller, M.; Bauer, W.; Ritzhaupt-Kleissl, H.J.; Kerscher, E.; Schulze, V. Relationships between process, microstructure and properties of molded zirconia micro specimens. Microsyst. Technol. 2008, 14, 1831–1837. [Google Scholar] [CrossRef]

- Kasanicka, B.; Müller, M.; Auhorn, M.; Schulze, V.; Bauer, W.; Beck, T.; Ritzhaupt-Kleissl, H.J.; Löhe, D. Correlations between production process, states and mechanical properties of microspecimens made of zirconia. Microsyst. Technol. 2006, 12, 1133–1141. [Google Scholar] [CrossRef]

- Bae, I.J.; Baik, S. Abnormal Grain Growth of Alumina. J. Am. Ceram. Soc. 1997, 80, 1149–1156. [Google Scholar] [CrossRef]

- Yu, P.C.; Li, Q.F.; Fuh, J.Y.H.; Li, T.; Ho, P.W. Micro injection molding of micro gear using nano-sized zirconia powder. Microsyst. Technol. 2009, 15, 401–406. [Google Scholar] [CrossRef]

- Claussen, N.; Petzow, G. Whisker-Reinforced Zirconia-Toughened Ceramics. In Tailoring Multiphase and Composite Ceramics, 1st ed.; Tressler, R.E., Ed.; Springer: New York, NY, USA, 1986; Volume 20. [Google Scholar]

- Kriven, W.M. The Transformation Mechanism of Spherical Zirconia Particles in Alumina. In Advances in Ceramics, Vol. 12, Science and Technology of Zirconia II; American Ceramic Society, Inc.: Columbus, OH, USA, 1984; Volume 12, pp. 64–77. [Google Scholar]

- Tiegs, T.; Becher, P. Whisker-Reinforced Ceramic Composites. In Tailoring Multiphase and Composite Ceramics; Tressler, R.E., Ed.; Plenum Press: New York, NY, USA, 1986; Volume 20. [Google Scholar]

- Wang, C.J.; Huang, C.Y.; Wu, Y.C. Two-step sintering of fine alumina–zirconia ceramics. Ceram. Int. 2009, 35, 1467–1472. [Google Scholar] [CrossRef]

- Walker, L.S.; Marotto, V.R.; Rafiee, M.A.; Koratkar, N.; Corral, E.L. Toughening in Graphene Ceramic Composites. ACS Nano 2011, 5, 3182–3190. [Google Scholar] [CrossRef]

- Simpson, C.J.; Aust, K.T.; Winegard, W.C. 4 Stages of Grain Growth. Metall. Trans. 1971, 2, 987–991. [Google Scholar] [CrossRef]

- Garvie, R.C.; Hannink, R.H.J.; Pascoe, R.T. Ceramic Steel? Nature 1975, 258, 703–704. [Google Scholar] [CrossRef]

- McMeeking, R.M.; Evans, A.G. Mechanics of Transformation-Toughening in Brittle Materials. J. Am. Ceram. Soc. 1982, 65, 242–246. [Google Scholar] [CrossRef]

- Faber, K.T.; Evans, A.G. Crack Deflection Processes—I. Theory. Acta Metall. 1983, 31, 565–576. [Google Scholar] [CrossRef]

- Das, K.; Banerjee, G. Mechanical Properties and Microstructures of Reaction Sintered Mullite- Zirconia Composites in the Presence of an Additive—Dysprosia. J. Eur. Ceram. Soc. 2000, 20, 153–157. [Google Scholar] [CrossRef]

- Suryanarayana, C. Nanocrystalline Materials. Int. Mat. Rev. 1995, 40, 41–64. [Google Scholar] [CrossRef]

- He, Z.; Ma, J. Grain Growth Rate Constant of Hot-Pressed Alumina Ceramics. Mater. Lett. 2000, 44, 14–18. [Google Scholar] [CrossRef]

- Porat, R.; Berger, S.; Rosen, A. Dilatometric Study of the Sintering Mechanism of Nanocrystalline Cemented Carbides. Nano Mater. 1996, 7, 429–436. [Google Scholar] [CrossRef]

- Gao, L.; Hong, J.S.; Miyamoto, H.; Torre, D.D.L. Bending Strength and Microstructure of Al2O3 Ceramics Densified by Spark Plasma Sintering. J. Eur. Ceram. Soc. 2000, 20, 2149–2152. [Google Scholar] [CrossRef]

- Chakravarty, D.; Bysakh, S.; Muraleedharan, K.; Rao, T.N.; Sundaresan, R. Spark Plasma Sintering of Magnesia-Doped Alumina with High Hardness and Fracture Toughness. J. Am. Ceram. Soc. 2008, 91, 203–208. [Google Scholar] [CrossRef]

- Zhou, Y.; Hirao, K.; Yamauchi, Y.; Kanzaki, S. Densification and Grain Growth in Pulse Electric Current Sintering of Alumina. J. Eur. Ceram. Soc. 2004, 24, 3465–3470. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).