Abstract

Most African countries are acquiring new technologies to provide awareness and vocational training to trigger innovation in various areas, including manufacturing. However, the existing method that emphasizes least cost by bidders has been found to be deficient. This study conducts a literature review and identifies some CoBots based on the suitability of their properties to West Africa. A hybrid Multi-Criteria Decision-Making approach, comprising the Fuzzy Analytical Hierarchical Process and Interval Technique for Order of Preference by Similarity to Ideal Solution, together combined as FAHP-I-TOPSIS, was selected. This method was modeled and tested as a case study where data were collected from eight Robotics experts from West African countries. The data were analyzed through pairwise comparison and ranking to arrive at the most suitable training CoBot out of five alternatives, and six criteria were considered. Robot (R3) was selected, which, on average, satisfies their priority for Program Flexibility and Economic Cost criteria, because the robot is moderately costly and flexible in programming, too.

1. Introduction

Selecting collaborative robots for educational training and research, particularly those involving international collaboration, is a challenging task. Robots for industrial use are expensive and characterized by several features based on the applications, necessitating the careful selection of appropriate ones for the targeted applications [1]. Consequently, a good robot designed to provide high-quality and effective industrial education will surely be complex because the flexibility to learn multiple industrial operations would be incorporated into it. According to Evripidou et al. (2022), when selecting a robot for a specific application, over 75 attributes can be considered [2]. In this digital transformation era, more robot manufacturers have emerged, producing robots with different configurations and conflicting criteria [3], yielding an increase in the number of alternatives that end-users select from [4]. These robots have undoubtedly enhanced production and quality systems since the First Industrial Revolution. This is especially true in the automotive sector, which has been among the major users of robots, with 119,405 new robots installed in 2021 and a Compound Annual Growth Rate (CAGR) of 42% [5]. The West African region is trying to pull through the recent trends in technology. Training centers have been established alongside recent multidisciplinary IT programs like Mechatronics, Robotics, and Artificial Intelligence to help bridge the skill gap and provide employment for its youths, as they constitute 65% of the population [6]. Robot selection methods are classified into three categories: MCDM, integrated approaches (hybrids of multiple methods), and the general category of solutions where mathematical, statistical, and computer-assisted models are mostly used [3,7]. Veza et al. (2022) also showed that the Analytic Hierarchy Process, followed by the Technique for Order of Preference by Similarity to Ideal Solution, is the most popular MCDM method, according to their survey [8]. Recent developments in MCDM have yielded several upgrades to the classical methods, with the emergence of hybrid approaches, through the combination of traditional MCDM methods, to maximize their strengths and overcome their weaknesses [9]. Consequently, hybrid MCDM methods have been improved by combining variants of classical approaches. C & Subramaniam (2024) [10] used an AHP and TOPSIS hybrid (AHP-TOPSIS) for CoBot selection, meant for the fuel filter assembly process while Kong & Zhang (2024) utilized FAHP-I-TOPSIS, where Fuzzy AHP (FAHP) and Interval TOPSIS (I-TOPSIS) variants of the AHP and TOPSIS were combined to conduct a risk assessment of water inrush accidents during tunnel construction [11]. However, only limited research was found using the MCDM robot selection approach for educational purposes, and no such robot selection approach was found with a focus on West frica. Additionally, no usage of FAHP-I-TOPSIS for robot selection was found. We introduced and applied the hybrid FAHP-I-TOPSIS for robot selection.

2. Methodology

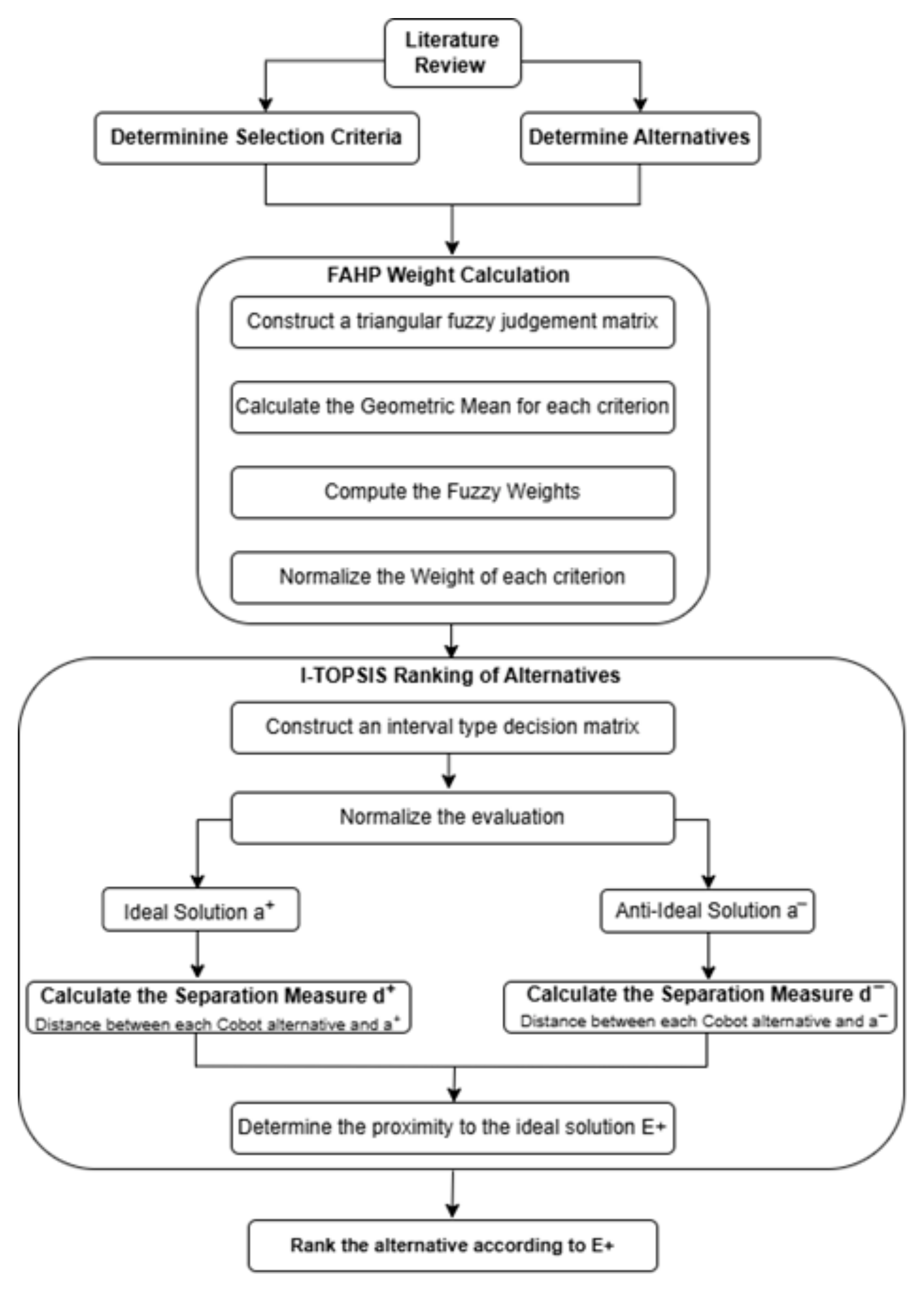

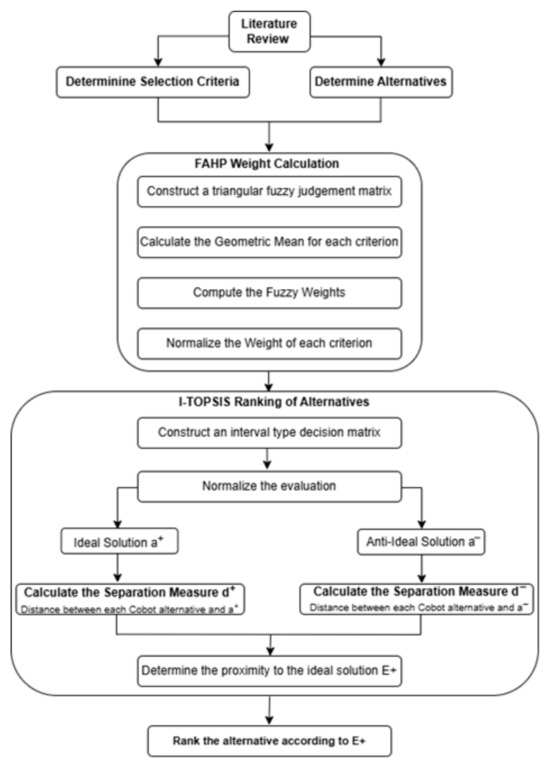

The entire methodology for selecting educational collaboration robots (CoBots) by combining the Fuzzy Analytic Hierarchy Process (FAHP) with the Interval-Type Technique for Order of Preference by Similarity to Ideal Solution (I-TOPSIS) is shown in Figure 1.

Figure 1.

Methodology framework.

By building a triangular fuzzy judgment matrix, figuring out the geometric mean, and normalizing the weights, the FAHP was used to establish the criteria weights. After constructing an interval-type decision matrix, normalizing the evaluation data, identifying the ideal and anti-ideal solutions, and computing separation measures, I-TOPSIS was utilized to rank the CoBot alternatives. To provide a methodical and reliable decision-making process, the alternatives were finally rated according to how close they were to the perfect answer.

Computational Steps

- 1.

- Determination of critical factors: Some factors were identified from the literature review and information about Africa. Similar criteria were merged to yield 6, as shown in Table 1.

Table 1. Determining critical factors from literature review.

Table 1. Determining critical factors from literature review.

- 2.

- Determination of alternatives: CoBot alternatives and their relevant criteria in this work were obtained from an online search for the best CoBots used for robot education, works of literature about CoBots, emails, and past quotations for robot purchases from some companies. However, the CoBot names were hidden during the survey to avoid biases.

- 3.

- FAHP

- i.

- Expert judgment was set to be collected via audio interviews, self-recorded responses, or Google Sheets, using the linguistic variables shown in Table 2.

Table 2. Fuzzy scale—linguistic terms table.

Table 2. Fuzzy scale—linguistic terms table. - ii.

- The pairwise comparison matrix resembles the one shown in Equation (1), where denotes the importance of factor i compared to factor j.

- iii.

- Consistency Ratio (CR) calculation

Although CR is not necessarily needed when the FAHP is applied, it is still good to check and enhance the robustness of decision-making in cases of high discrepancy.

CR is usually calculated using the formula in Equation (2) whenever the rank of the matrix (n) is greater than 2. is expressed as shown in Equation (3); it is the maximum characteristic root of the matrix. RI represents the average random consistency index, Table 3 shows RI values based on rank of the matrix.

Table 3.

RI reference table.

To obtain the indicator , Equation (4) below is required to calculate the eigenvectors of the judgment matrix.

- iv.

- Determining the Geometric Mean for each criterion

Considering the geometric mean approach in [17], we will express the pairwise matrix as below Equation (5):

- v.

- Defuzzify to obtain the non-fuzzified weight for the criterion.

The following formula is used:

- vi.

- The normalized weight of each criterion is computed using the formula:

- vii.

- Aggregate assessment—This is calculated for each variant by multiplying the normalized weights of the criteria and variants.

- viii.

- The variant with the highest aggregate is selected as the best, as it reflects the average preferences of the decision-makers. However, since we are continuing with I-TOPSIS, this step is skipped.

- 4.

- I-TOPSIS

Expert judgment for I-TOPSIS was collected using the set of linguistic variables as in Table 4.

Table 4.

Scale—linguistic terms for I-TOPSIS.

- i.

- Decision Matrix

The initial decision matrix R for n evaluation projects and m evaluation indicators emanates from the responses. For example, the interval of the ith risk factor that corresponds to the jth risk level is represented as as shown in Equation (8)

and are the lower and upper limits of the interval.

- ii.

- Determine the positive and negative ideal solutions as shown below:

- iii.

- Compute the separation measures between the given evaluations X = , calculating , denoted as respectively, using Equation (9), where weight , obtained from the FAHP, is used:

- iv.

- Calculate the relative proximity coefficient (.

is calculated by using Equation (10):

3. Experiment and Results

A case study scenario was developed to experiment with the FAHP-I-TOPSIS approach for CoBot selection with eight experts from West African countries as a decision-making panel.

3.1. Case Study

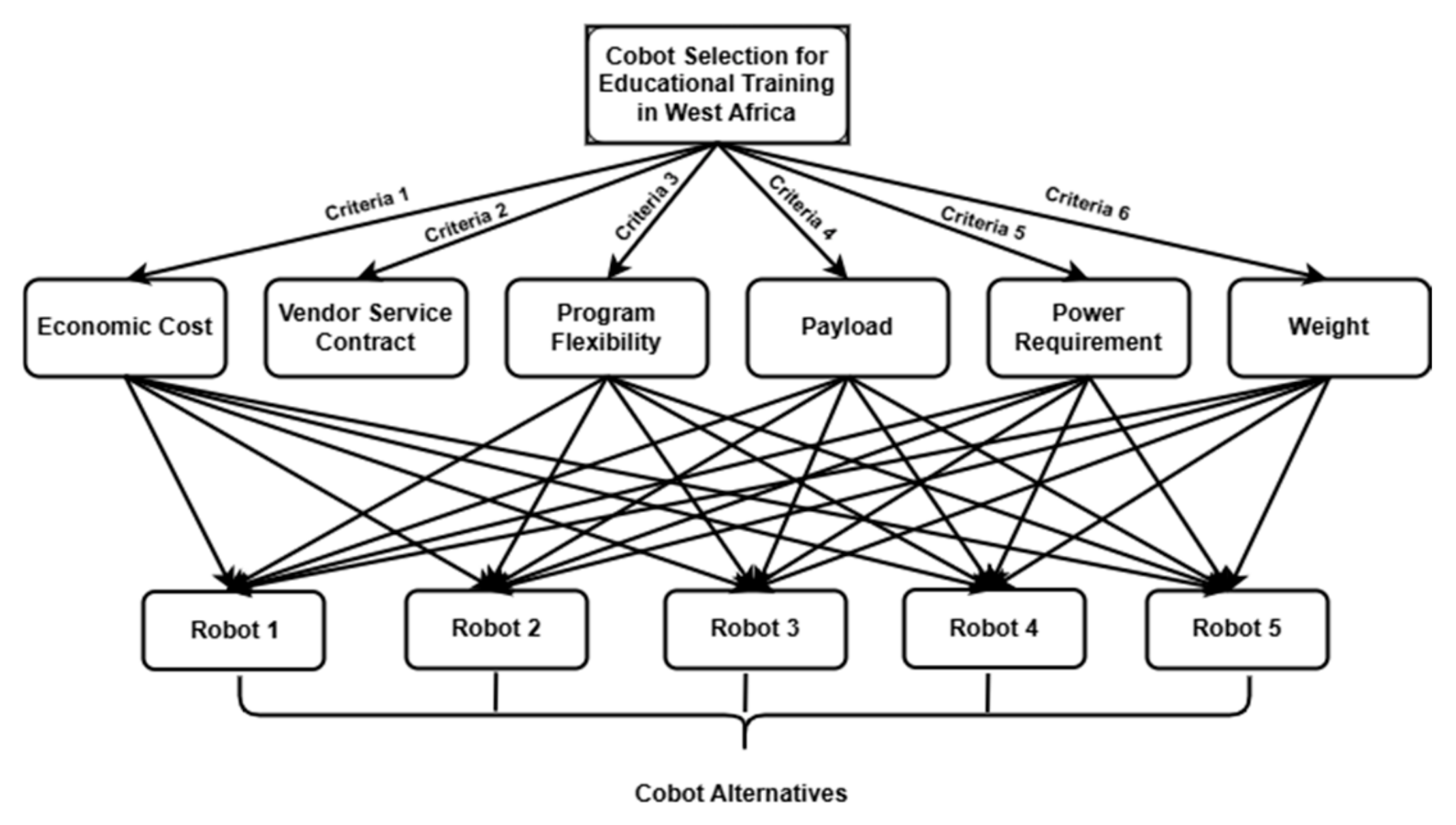

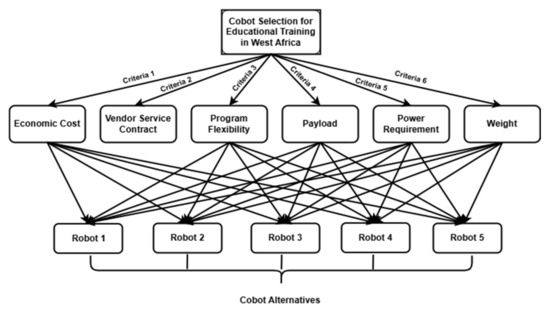

As part of their developmental agenda, the Economic Community of West African States (ECOWAS) decided to establish standard industrial training centers in all its member countries, where the youth will be empowered with digital skills for employability in industries where Advanced Manufacturing Technologies (AMT) would be deployed. There was a need to purchase collaborative robot arms and other AMT machinery for effective hands-on training focusing on operation and innovation. A total of eight experts from the Mechatronics departments and training units of public universities and research institutes in Nigeria and Ghana were contacted to contribute to the decision-making team. The team was to select the best CoBot from five alternatives, R1, R2, R3, R4, and R5, based on the quotation submitted by the suppliers. Figure 2 below shows the AHP structure for the CoBot selection process.

Figure 2.

AHP structure for the CoBot selection process.

3.2. Results and Analysis

The eight pairwise comparison matrices drawn through the responses from the experts in Table 5 utilized passed or were very close to the Consistency Ratio (CR). Each one was analyzed, and then the overall analysis was conducted.

Table 5.

Respondents.

3.2.1. FAHP

The matrices generated from responses outline the relative importance of the performance of the criteria labeled EC1-EC2-EC3, VSC1-VSC2-VSC3, etc., in the MCDM process. The comparative value between two criteria or alternatives is represented by elements within the matrix, offering insight into their relative priority or preference.

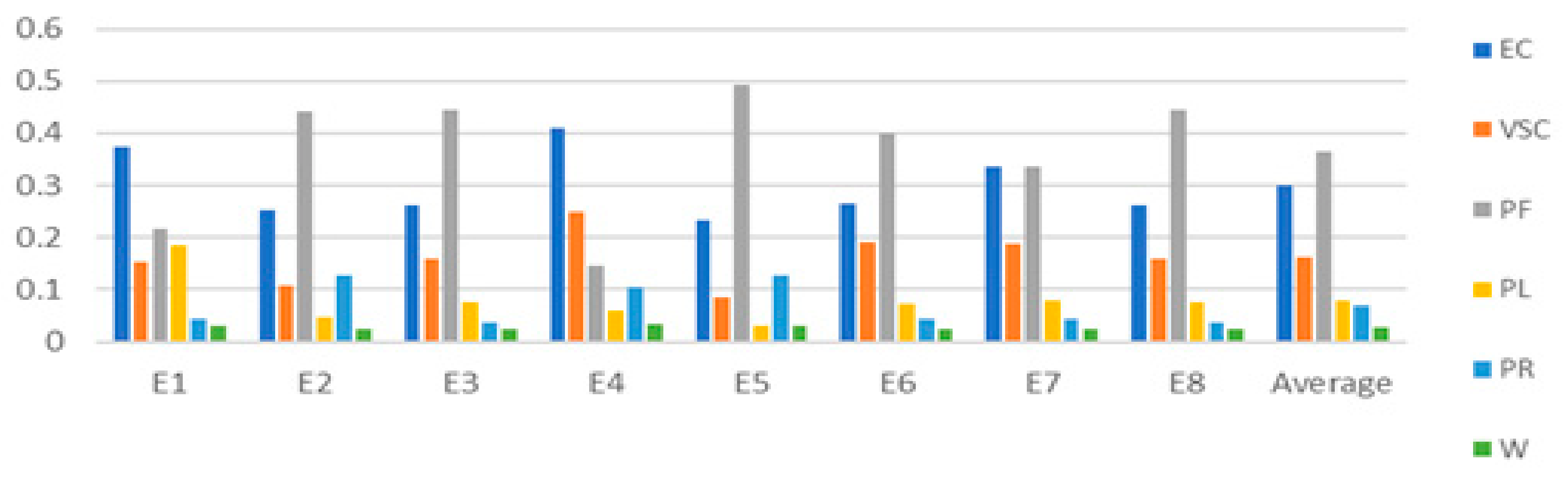

Interpretation of Final Weights

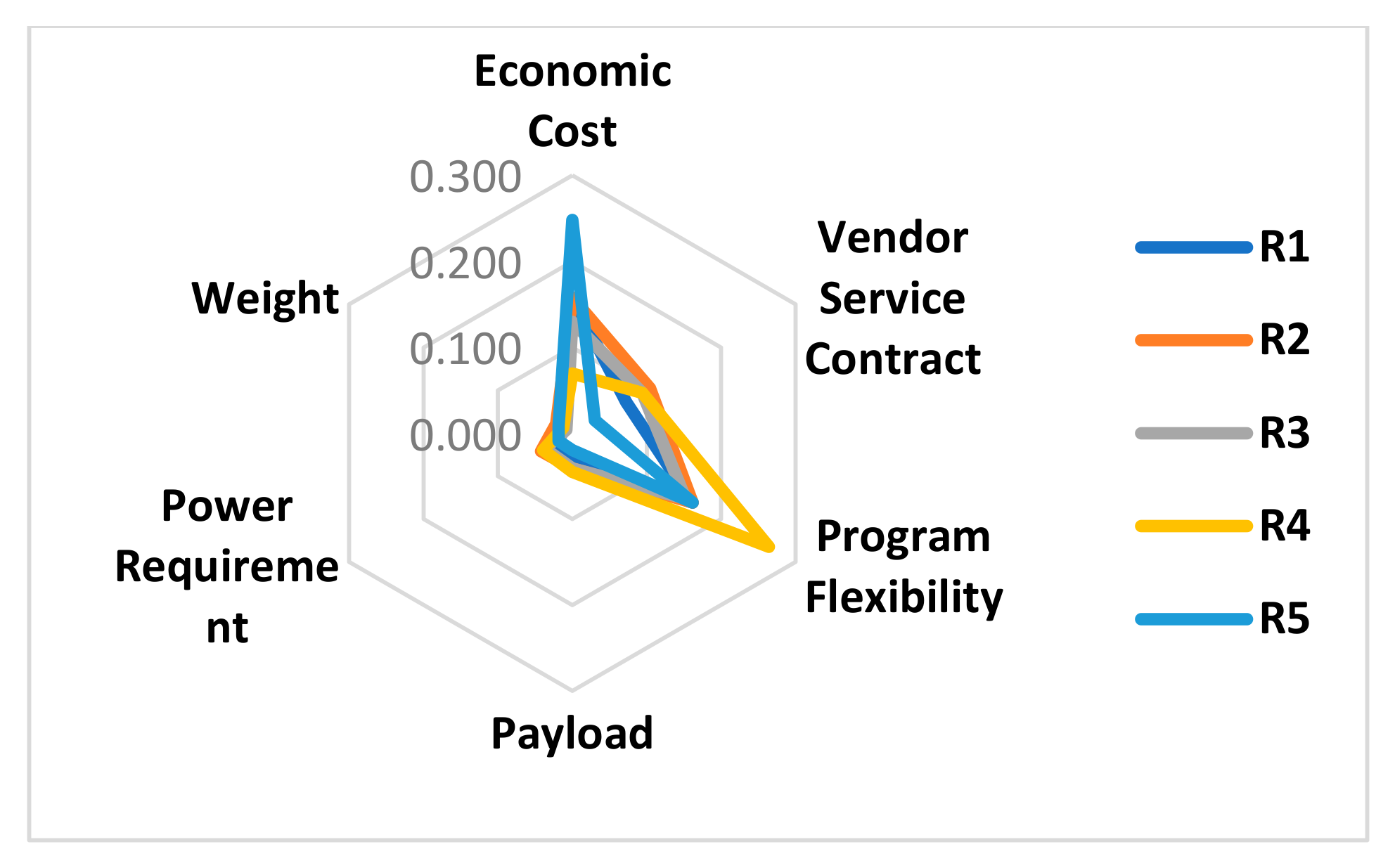

Table 6 and Figure 3 represent the final weights assigned to each criterion (or sub-criterion) after applying the FAHP methodology. These weights reflect the relative importance of each criterion in the overall decision-making process.

Table 6.

Average normalized weights.

Figure 3.

Average normalized weights.

Among the evaluated criteria, PF emerged as the most influential factor in the decision-making process, carrying the highest relative weight of 0.360, thus underscoring its critical importance. There are obvious variations in expert choices of the most influential criteria. This distribution of weights helps prioritize actions or decisions based on criteria that matter most. However, further surveys and analyses were carried out.

3.2.2. I-TOPSIS

The TOPSIS analysis was performed on five alternatives (R1 to R5) and six criteria (EC, VSC, PF, PL, PR, and W). Due to the intervals, most stages had upper and lower bounds until the separation measure (d) stage, where their averages were applied to the original TOPSIS formula. The criteria weights obtained from the AHP method were also utilized.

First, the vector normalization method was used to normalize the decision matrix. This guarantees that the various criteria are on a similar scale. The weighted normalized decision matrix was then obtained by multiplying the normalized decision matrix by the weights of the respective criteria. Then, using the maximum and minimum values for each criterion in the weighted normalized choice matrix, the ideal (a+) and negative ideal (a−) solutions are identified. Each alternative’s Euclidean distances, (d+) and (d−), from the ideal solutions are computed. The ratio of the distance from the negative ideal solution to the sum of the distances from the ideal and negative ideal solutions was then used to determine each alternative’s relative proximity to the ideal solution (E+), as indicated in Table 7.

Table 7.

Final ranking I-TOPSIS.

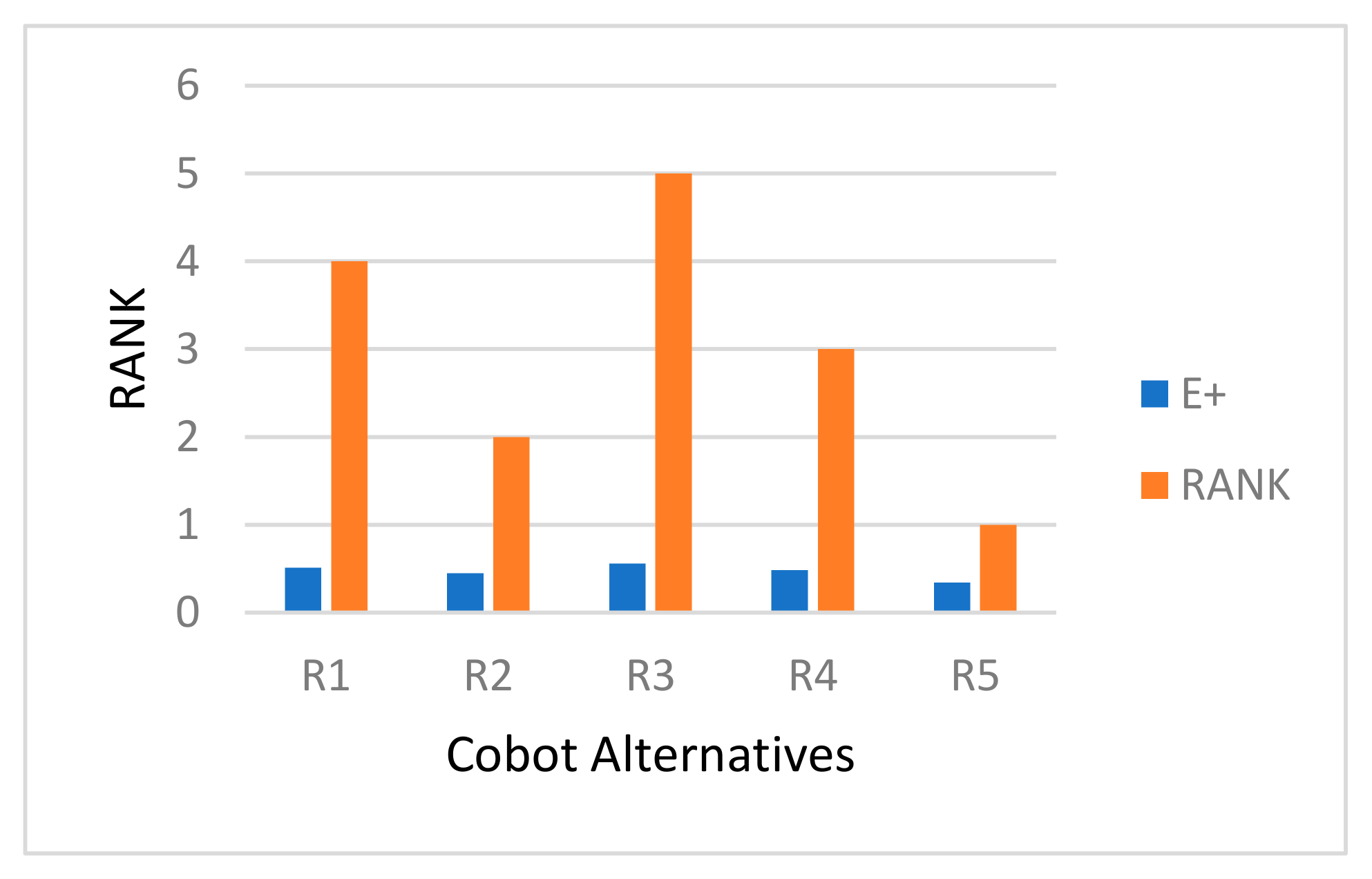

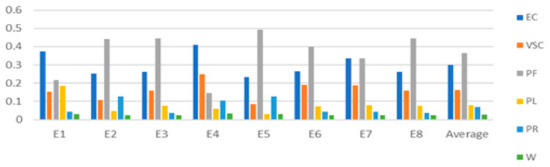

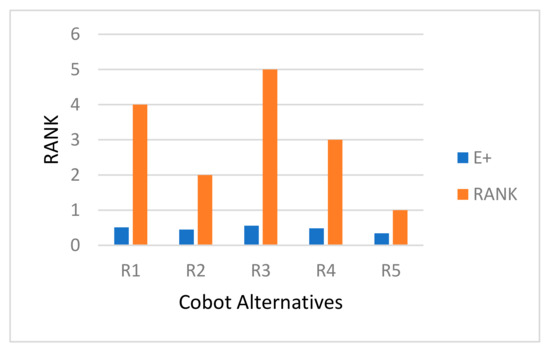

The best option is indicated by the option with the highest relative closeness value, which is used to rank the alternatives. With the highest rank and relative proximity score (E+), R3 is the best option. It is the most favored option. This indicates that it is the one that is most similar to the ideal solution and the one that is most dissimilar from the negative perfect solution. R1 is the second-best option, followed by R4 and R2 as shown in Figure 4.

Figure 4.

FAHP-I-TOPSIS final ranking.

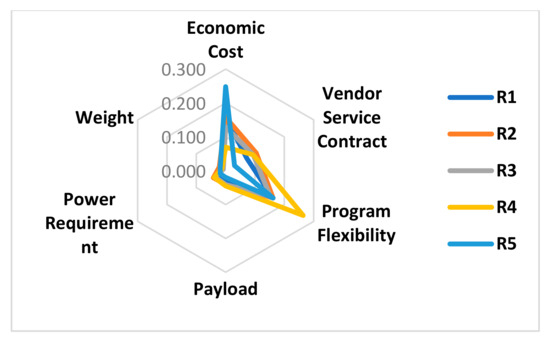

The resulting outcome can support decision-making in selecting the optimal CoBot for educational training in West Africa, involving the six criteria. Figure 5 shows how the CoBots are ranked with each selection criterion. The best robot, R3, is not the best even in terms of the most influential criterion (Program Flexibility). However, it satisfies the criteria preferences of the experts on average.

Figure 5.

Suitable alternative in each criterion.

4. Conclusions

This study presented a hybrid Multi-Criteria Decision-Making (MCDM) approach using the Fuzzy Analytic Hierarchy Process (FAHP) and Interval Technique for Order of Preference by Similarity to Ideal Solution (I-TOPSIS) to support the selection of the most suitable collaborative robot (CoBot) for educational training in West African countries. Six evaluation criteria were identified from the literature and expert validation: Economic Cost (EC), Program Flexibility (PF), Vendor’s Service Contract (VSC), Payload (PL), Power Requirement (PR), and Weight (W). Eight domain experts participated in the assessment through interviews, self-recorded responses, and Google Sheets. The FAHP analysis revealed that Program Flexibility (PF) was the most influential criterion, with an average normalized weight of 0.365, followed by Economic Cost (EC), with 0.300, and Vendor’s Service Contract (VSC), with 0.161. Using these weights, the I-TOPSIS method was applied to rank five CoBot alternatives. Robot R3 emerged as the optimal choice, achieving the highest relative closeness value (E+ = 0.561) and the lowest distance from the ideal solution (d+ = 0.0674). Although R3 was not ranked highest in every individual criterion, it consistently satisfied the experts’ collective preferences, particularly in the most important areas of Program Flexibility and economic feasibility. The methodology and results demonstrated a systematic and scalable decision-support framework that policymakers and institutions can adapt for technology acquisition in skill-development initiatives across the West African region.

Author Contributions

Conceptualization, D.Y.U. and Y.A.; methodology, D.Y.U.; software, A.K. and D.Y.U.; validation, A.K. and D.Y.U.; formal analysis, A.K. and D.Y.U.; writing—review and editing, A.K. and D.Y.U.; visualization, A.K. and D.Y.U.; supervision, Y.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research receives no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data that support the findings of this study is available from the corresponding author upon reasonable request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Bui, H.-A.; Nguyen, X.-T. A novel multicriteria decision-making process for selecting spot welding robot with removal effects of criteria techniques. Int. J. Interact. Des. Manuf. (IJIDeM) 2024, 18, 1033–1052. [Google Scholar] [CrossRef]

- Evripidou, S.; Doitsidis, L.; Tsinarakis, G.; Zinonos, Z.; Chatzichristofis, S.A. Selecting a robotic platform for education. In Proceedings of the 2022 IEEE International Conference On Consumer Electronics (ICCE), Las Vegas, NV, USA, 7–9 January 2022; pp. 1–6. [Google Scholar]

- Parameshwaran, R.; Kumar, S.P.; Saravanakumar, K. An integrated fuzzy MCDM based approach for robot selection considering objective and subjective criteria. Appl. Soft Comput. 2015, 26, 31–41. [Google Scholar] [CrossRef]

- Garg, H.; Sharaf, I.M. A new spherical aggregation function with the concept of spherical fuzzy difference for spherical fuzzy EDAS and its application to industrial robot selection. Comput. Appl. Math. 2022, 41, 212. [Google Scholar] [CrossRef]

- Mouhib, H.; Amar, S.; Elrhanimi, S.; El Abbadi, L. Maximizing efficiency and collaboration: Comparing Robots and Cobots in the Automotive Industry–A Multi-Criteria Evaluation Approach. Int. J. Ind. Eng. Manag. 2024, 15, 238–253. [Google Scholar] [CrossRef]

- AUC/OECD. Africa’s Development Dynamics 2021: Digital Transformation for Quality Jobs; OECD Publishing: France, Paris, 2021. [Google Scholar] [CrossRef]

- Chatterjee, S.; Das, P.P.; Chakraborty, S. An LOPCOW-OPTBIAS-based integrated approach for cobot selection in manufacturing assembly operations. Int. J. Multicriteria Decis. Mak. 2024, 10, 47–69. [Google Scholar] [CrossRef]

- Veza, I.; Mladineo, M.; Kutlesa, M.; Gjeldum, N.; Bilic, B.; Crnjac Zizic, M.; Aljinovic, A.; Basic, A. Selection of the cobot workstation for the learning factory by using the multi-criteria analysis. In Proceedings of the 12th Conference on Learning Factories (CLF 2022), Singapore, 11–13 April 2022. [Google Scholar]

- Ojokoh, B.; Afolayan, A. Analysis of Multi-Criteria Decision Making Methods for Contractor Selection in Nigeria. In Proceedings of the 5th Covenant University Conference on E-Governance in Nigeria (CUCEN 2018), Ota Ogun, Nigeria, 6–8 June 2018. [Google Scholar]

- Sivalingam, C.; Subramaniam, S.K. Cobot selection using hybrid AHP-TOPSIS based multi-criteria decision making technique for fuel filter assembly process. Heliyon 2024, 10, e26374. [Google Scholar]

- Kong, H.-Q.; Zhang, N. Risk assessment of water inrush accident during tunnel construction based on FAHP-I-TOPSIS. J. Clean. Prod. 2024, 449, 141744. [Google Scholar] [CrossRef]

- Mahanta, G.B.; Mohanty, B.; Rout, A.; Biswal, B.B.; Jha, A. Selection of cobot for human-robot collaboration for robotic assembly task with Best Worst MCDM techniques. In Proceedings of the 2023 IEEE 7th Conference on Information and Communication Technology (CICT), Jabalpur, India, 15–17 December 2023; pp. 1–6. [Google Scholar]

- Vahdani, B.; Mousavi, S.M.; Tavakkoli-Moghaddam, R.; Ghodratnama, A.; Mohammadi, M. Robot selection by a multiple criteria complex proportional assessment method under an interval-valued fuzzy environment. Int. J. Adv. Manuf. Technol. 2014, 73, 687–697. [Google Scholar] [CrossRef]

- Gitinavard, H.; Mousavi, S.M.; Vahdani, B. Soft computing-based new interval-valued hesitant fuzzy multi-criteria group assessment method with last aggregation to industrial decision problems. Soft Comput. 2017, 21, 3247–3265. [Google Scholar] [CrossRef]

- Petrov, I. Multi-criteria selection of industrial robots: Modelling users’ preferences in combined AHP-Entropy-TOPSIS. In Proceedings of the 2022 5th International Conference on Computing and Informatics (ICCI), New Cairo, Cairo, Egypt, 9–10 March 2022; pp. 126–131. [Google Scholar]

- Liu, H.-C.; Ren, M.-L.; Wu, J.; Lin, Q.-L. An interval 2-tuple linguistic MCDM method for robot evaluation and selection. Int. J. Prod. Res. 2014, 52, 2867–2880. [Google Scholar] [CrossRef]

- Sen, D.K.; Datta, S.; Mahapatra, S.S. Extension of TODIM for decision making in fuzzy environment: A case empirical research on selection of industrial robot. Int. J. Serv. Oper. Manag. 2017, 26, 238–276. [Google Scholar] [CrossRef]

- Hong Son, N.; Hieu, T.T. Selection of Welding Robot by Multi-Criteria Decisionmaking Method. East.-Eur. J. Enterp. Technol. 2023, 1, 66–72. [Google Scholar]

- Chodha, V.; Dubey, R.; Kumar, R.; Singh, S.; Kaur, S. Selection of industrial arc welding robot with TOPSIS and Entropy MCDM techniques. Mater. Today Proc. 2022, 50, 709–715. [Google Scholar] [CrossRef]

- Garg, C.P.; Görçün, Ö.F.; Kundu, P.; Küçükönder, H. An integrated fuzzy MCDM approach based on Bonferroni functions for selection and evaluation of industrial robots for the automobile manufacturing industry. Expert Syst. Appl. 2023, 213, 118863. [Google Scholar] [CrossRef]

- Suszyński, M.; Rogalewicz, M. Selection of an industrial robot for assembly jobs using multi-criteria decision making methods. Manag. Prod. Eng. Rev. 2020, 11, 62–72. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).