Statistical Analysis of Burr Width and Height in Conventional Speed Micro-Milling of Titanium Alloy (Ti-6Al-4V) by Varying Cutting Parameters Under Different Lubrication Methods: Dry, MQL and Wet †

Abstract

1. Introduction

2. Materials and Methods

2.1. Workpiece Material

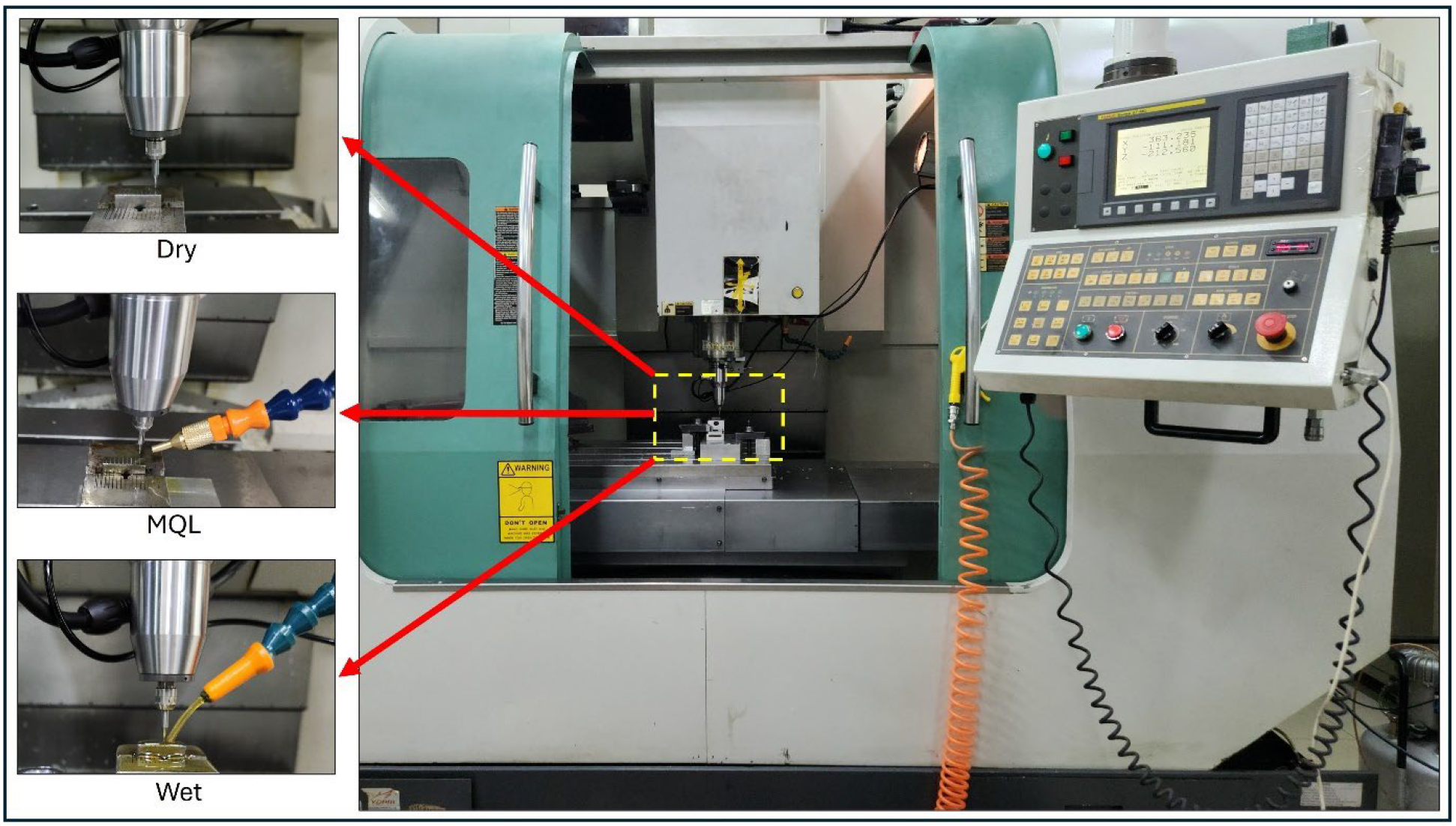

2.2. Experimental Setup

2.3. Design of Experiments

3. Results and Discussion

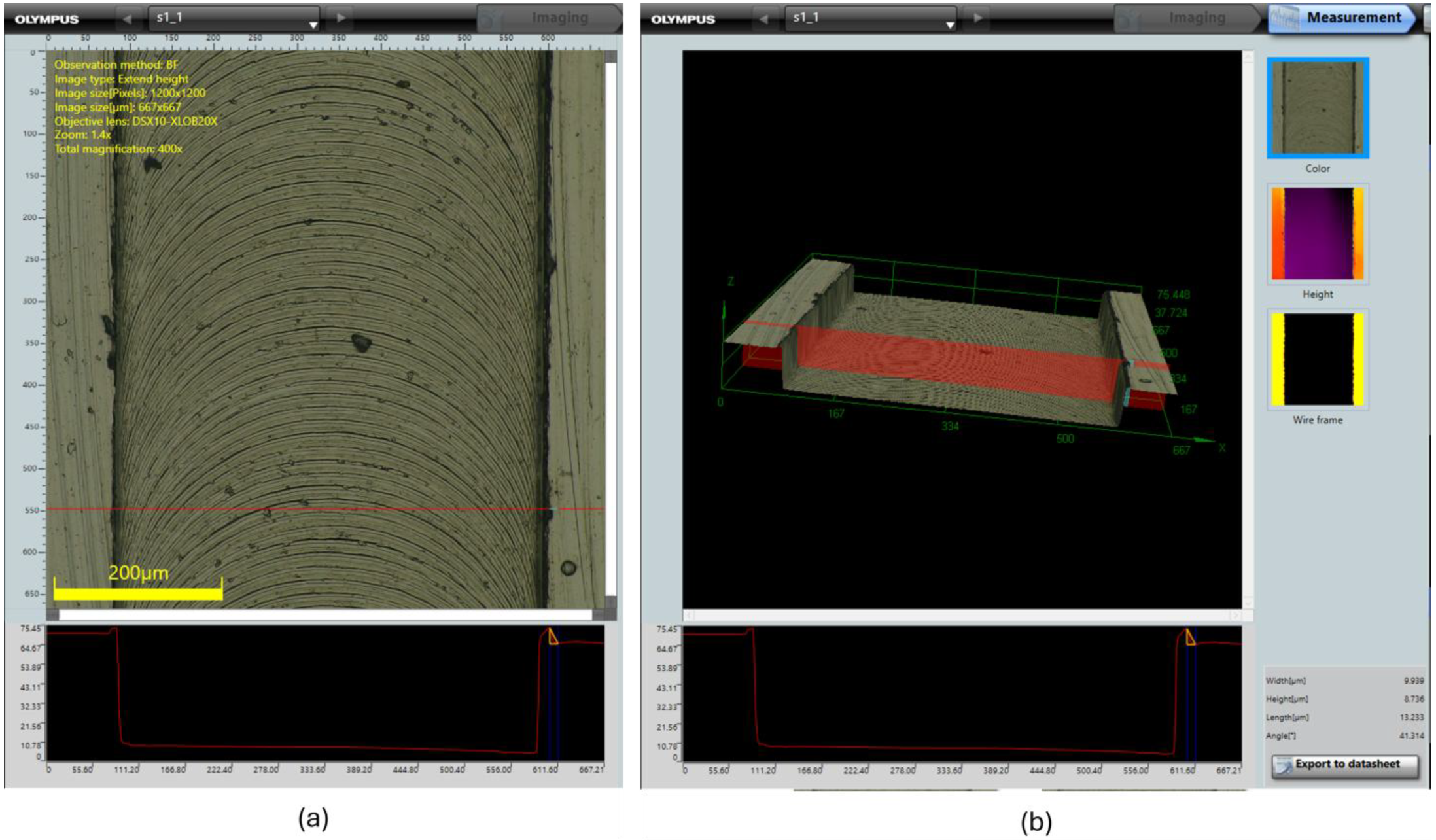

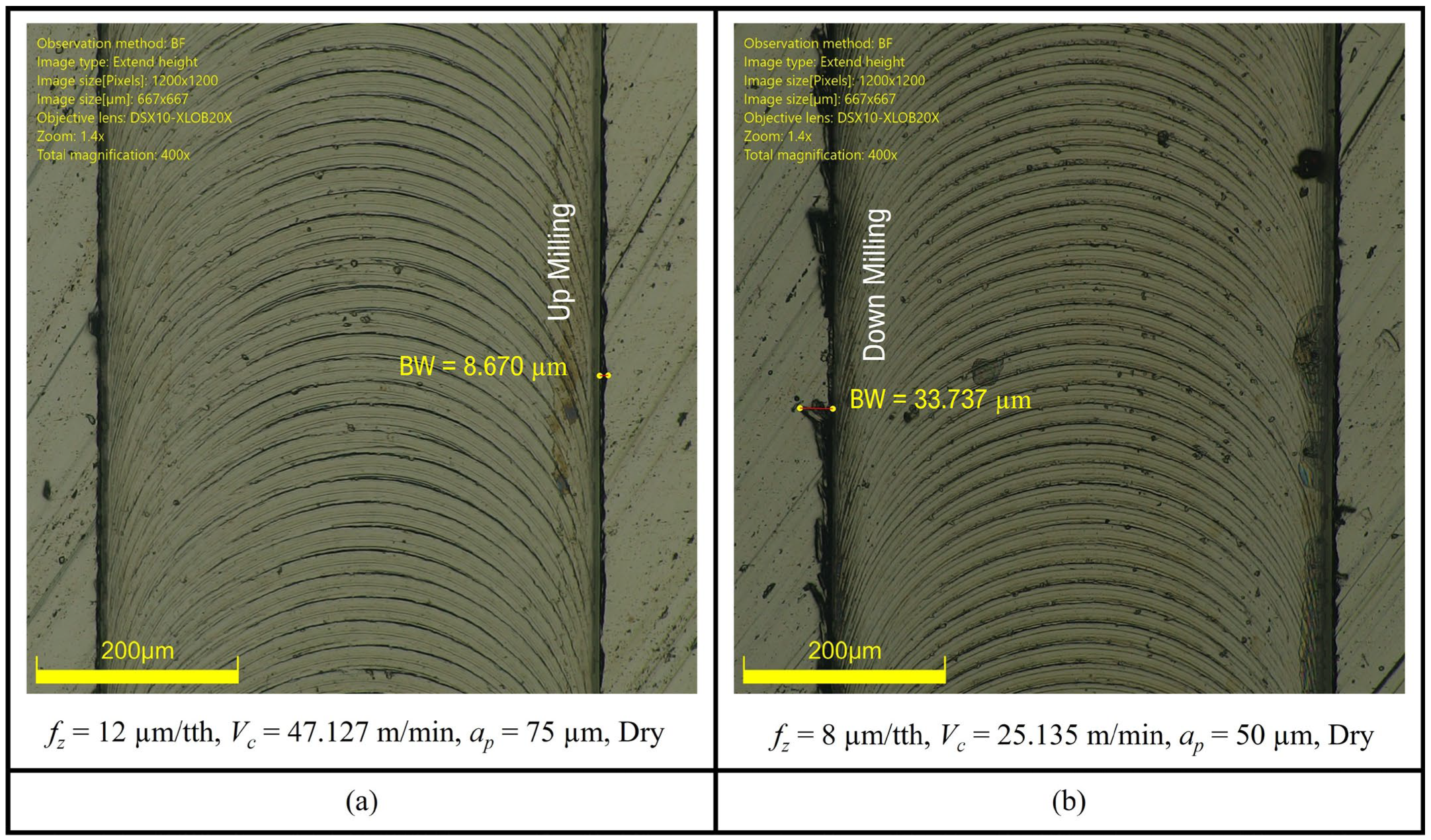

3.1. Burr Measurement

3.2. Application of ANOVA

- SS—Sum of squares;

- DoF—Degrees of freedom;

- MSSRes—Mean square of residuals;

- SST—Total sum of squares.

4. Discussion

4.1. Burr Width (Up-Milling and Down-Milling)

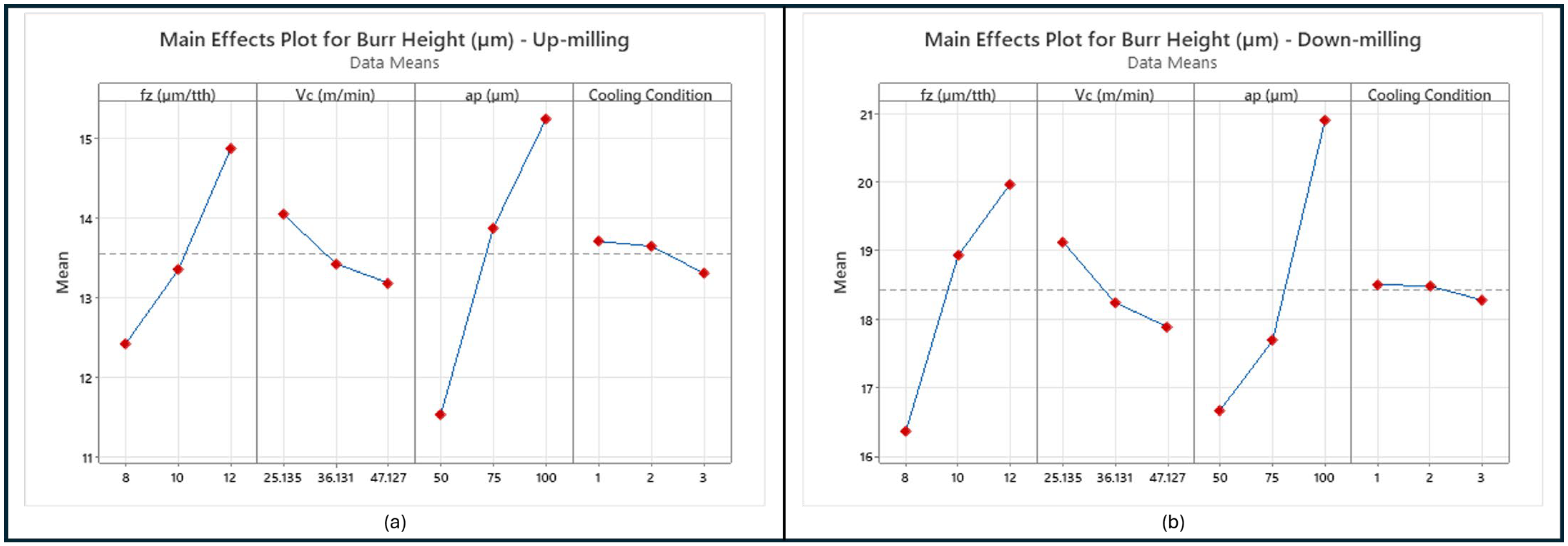

4.2. Burr Height (Up-Milling and Down-Milling)

5. Conclusions

- Feed rate, followed by cutting speed, emerged as the most significant factors influencing burr width, contributing a combined 89.06% in up-milling and 92.67% in down-milling. In contrast, the depth of cut and cooling condition had a minimal influence on burr width. Burr height, however, was primarily affected by the depth of cut and feed rate, while cutting speed and cooling condition showed negligible impact. The combined effect of depth of cut and feed rate accounted for 77.36% of the variation in burr height during up-milling and 73.95% during down-milling.

- Overall, feed rate was identified as the most influential parameter governing burr width, whereas depth of cut had the greatest impact on burr height. Therefore, precise control of these two parameters is crucial for minimizing burr formation in micro-milling operations.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Özel, T.; Thepsonthi, T.; Ulutan, D.; Kaftanolu, B. Experiments and Finite Element Simulations on Micro-Milling of Ti-6Al-4V Alloy with Uncoated and CBN Coated Micro-Tools. CIRP Ann. Manuf. Technol. 2011, 60, 85–88. [Google Scholar] [CrossRef]

- Venkatesh, V.; Swain, N.; Srinivas, G.; Kumar, P.; Barshilia, H.C. Review on the Machining Characteristics and Research Prospects of Conventional Microscale Machining Operations. Mater. Manuf. Process. 2016, 32, 235–262. [Google Scholar] [CrossRef]

- Thepsonthi, T.; Özel, T. Experimental and Finite Element Simulation Based Investigations on Micro-Milling Ti-6Al-4V Titanium Alloy: Effects of CBN Coating on Tool Wear. J. Mater. Process Technol. 2013, 213, 532–542. [Google Scholar] [CrossRef]

- Jaffery, S.H.I.; Khan, M.; Ali, L.; Mativenga, P.T. Statistical Analysis of Process Parameters in Micromachining of Ti-6Al-4V Alloy. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2016, 230, 1017–1034. [Google Scholar] [CrossRef]

- Venkata rao, K. A Study on Performance Characteristics and Multi Response Optimization of Process Parameters to Maximize Performance of Micro Milling for Ti-6Al-4V. J. Alloys Compd. 2019, 781, 773–782. [Google Scholar] [CrossRef]

- Ezugwu, E.O.; Wang, Z.M. Titanium Alloys and Their Machinability—A Review. J. Mater. Process Technol. 1997, 68, 262–274. [Google Scholar] [CrossRef]

- Kim, D.H.; Lee, P.-H.; Lee, S.W. Experimental Study on Machinability of Ti-6Al-4V in Micro End-Milling. In Proceedings of the World Congress on Engineering; International Association of Engineers (IAENG), London, UK, 2 June 2014. [Google Scholar]

- Thepsonthi, T.; Özel, T. Multi-Objective Process Optimization for Micro-End Milling of Ti-6Al-4V Titanium Alloy. Int. J. Adv. Manuf. Technol. 2012, 63, 903–914. [Google Scholar] [CrossRef]

- Lee, K.; Dornfeld, D.A. Micro-Burr Formation and Minimization through Process Control. Precis. Eng. 2005, 29, 246–252. [Google Scholar] [CrossRef]

- Ul Rehman, G.; Husain Imran Jaffery, S.; Khan, M.; Ali, L.; Khan, A.; Ikramullah Butt, S. Analysis of Burr Formation in Low Speed Micro-Milling of Titanium Alloy (Ti-6Al-4V). Mech. Sci. 2018, 9, 231–243. [Google Scholar] [CrossRef]

- Kiswanto, G.; Zariatin, D.L.; Ko, T.J. The Effect of Spindle Speed, Feed-Rate and Machining Time to the Surface Roughness and Burr Formation of Aluminum Alloy 1100 in Micro-Milling Operation. J. Manuf. Process. 2014, 16, 435–450. [Google Scholar] [CrossRef]

- Lekkala, R.; Bajpai, V.; Singh, R.K.; Joshi, S.S. Characterization and Modeling of Burr Formation in Micro-End Milling. Precis. Eng. 2011, 35, 625–637. [Google Scholar] [CrossRef]

- Zheng, X.; Liu, Z.; Chen, M.; Wang, X. Experimental Study on Micro-Milling of Ti6Al4V with Minimum Quantity Lubrication. Int. J. Nanomanuf. 2013, 9, 570–582. [Google Scholar] [CrossRef]

- Vazquez, E.; Gomar, J.; Ciurana, J.; Rodríguez, C.A. Analyzing Effects of Cooling and Lubrication Conditions in Micromilling of Ti6Al4V. J. Clean. Prod. 2015, 87, 906–913. [Google Scholar] [CrossRef]

- Khan, M.A.; Aziz, S.; Faraz, M.I.; Tahir, A.M.; Jaffery, S.H.I.; Jung, D.-W.; Khan, M.A.; Khan, M.A.; Aziz, S.; Faraz, M.I.; et al. Experimental Evaluation of Surface Roughness, Burr Formation, and Tool Wear during Micro-Milling of Titanium Grade 9 (Ti-3Al-2.5V) Using Statistical Evaluation Methods. Appl. Sci. 2023, 13, 12875. [Google Scholar] [CrossRef]

- Ross, P.J. Taguchi Techniques for Quality Engineering; McGraw-Hill Publication: New York, NY, USA, 1998. [Google Scholar]

- Aurich, J.C.; Dornfeld, D.; Arrazola, P.J.; Franke, V.; Leitz, L.; Min, S. Burrs—Analysis, Control and Removal. CIRP Ann. 2009, 58, 519–542. [Google Scholar] [CrossRef]

- Vogler, M.P.; DeVor, R.E.; Kapoor, S.G. On the Modeling and Analysis of Machining Performance in Micro-Endmilling, Part I: Surface Generation. J. Manuf. Sci. Eng. 2004, 126, 685–694. [Google Scholar] [CrossRef]

- Baig, A.; Jaffery, S.H.I.; Khan, M.A.; Alruqi, M. Statistical Analysis of Surface Roughness, Burr Formation and Tool Wear in High Speed Micro Milling of Inconel 600 Alloy under Cryogenic, Wet and Dry Conditions. Micromachines 2022, 14, 13. [Google Scholar] [CrossRef] [PubMed]

- Ezugwu, E.O.; Wang, Z.M.; Machado, A.R. The Machinability of Nickel-Based Alloys: A Review. J. Mater. Process Technol. 1999, 86, 1–16. [Google Scholar] [CrossRef]

| Machining Parameter | fz (µm/tth) | Vc (m/min) | ap (µm) | Cooling Condition |

|---|---|---|---|---|

| Level 1 | 8 | 25.135 | 50 | Dry |

| Level 2 | 10 | 36.131 | 75 | MQL |

| Level 3 | 12 | 47.127 | 100 | Wet |

| Test | fz (µm/tth) | Vc (m/min) | ap (µm) | Cooling Condition | N (rpm) | Vf (mm/min) | Burr Width (µm) | Burr Height (µm) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Up-Milling | Down-Milling | Up-Milling | Down-Milling | |||||||

| 1 | 8 | 25.135 | 50 | Dry | 16,000 | 256 | 32.747 | 32.901 | 11.045 | 15.401 |

| 2 | 8 | 36.131 | 75 | MQL | 23,000 | 368 | 25.387 | 27.126 | 12.712 | 15.511 |

| 3 | 8 | 47.127 | 100 | Wet | 30,000 | 480 | 23.349 | 24.580 | 13.498 | 18.176 |

| 4 | 10 | 25.135 | 75 | Wet | 16,000 | 320 | 19.749 | 27.258 | 13.922 | 18.755 |

| 5 | 10 | 36.131 | 100 | Dry | 23,000 | 460 | 13.222 | 21.951 | 15.074 | 21.319 |

| 6 | 10 | 47.127 | 50 | MQL | 30,000 | 600 | 15.827 | 21.230 | 11.050 | 16.704 |

| 7 | 12 | 25.135 | 100 | MQL | 16,000 | 384 | 13.396 | 17.616 | 17.159 | 23.236 |

| 8 | 12 | 36.131 | 50 | Wet | 23,000 | 552 | 11.154 | 14.078 | 12.485 | 17.902 |

| 9 | 12 | 47.127 | 75 | Dry | 30,000 | 720 | 8.934 | 13.118 | 14.998 | 18.791 |

| Factor | DoF | Sequential SS | Adjusted SS | Adjusted MSS | F-Value | p-Value | Significance | CR (%) |

|---|---|---|---|---|---|---|---|---|

| fz (µm/tth) | 2 | 801.49 | 801.49 | 400.75 | 43.97 | 0.000 | Significant | 76.74 |

| Vc (m/min) | 2 | 128.69 | 128.69 | 64.35 | 7.06 | 0.014 | Significant | 12.32 |

| ap (µm) | 2 | 32.02 | 32.02 | 16.01 | 1.76 | 0.227 | Non-significant | 3.07 |

| Cooling Condition | 2 | 0.14 | 0.14 | 0.07 | 0.01 | 0.992 | Non-significant | 0.01 |

| Error | 7 | 82.02 | 82.02 | 9.11 | 7.85 | |||

| Total | 17 | 1044.37 | 100.00 |

| Factor | DoF | Sequential SS | Adjusted SS | Adjusted MSS | F-Value | p-Value | Significance | CR (%) |

|---|---|---|---|---|---|---|---|---|

| fz (µm/tth) | 2 | 542.47 | 542.47 | 271.24 | 54.10 | 0.000 | Significant | 74.71 |

| Vc (m/min) | 2 | 130.40 | 130.40 | 65.20 | 13.01 | 0.002 | Significant | 17.96 |

| ap (µm) | 2 | 6.28 | 6.28 | 3.14 | 0.63 | 0.556 | Non-significant | 0.87 |

| Cooling condition | 2 | 1.83 | 1.83 | 0.91 | 0.18 | 0.837 | Non-significant | 0.25 |

| Error | 7 | 45.12 | 45.12 | 5.01 | 6.21 | |||

| Total | 17 | 726.10 | 100.00 |

| Factor | DoF | Sequential SS | Adjusted SS | Adjusted MSS | F-Value | p-Value | Significance | CR (%) |

|---|---|---|---|---|---|---|---|---|

| fz (µm/tth) | 2 | 18.55 | 18.55 | 9.28 | 5.60 | 0.026 | Significant | 23.54 |

| Vc (m/min) | 2 | 2.36 | 2.36 | 1.18 | 0.71 | 0.516 | Non-significant | 2.99 |

| ap (µm) | 2 | 42.42 | 42.42 | 21.21 | 12.80 | 0.002 | Significant | 53.82 |

| Cooling Condition | 2 | 0.56 | 0.56 | 0.28 | 0.17 | 0.846 | Non-significant | 0.72 |

| Error | 7 | 14.92 | 14.92 | 1.66 | 18.93 | |||

| Total | 17 | 78.81 | 100.00 |

| Factor | DoF | Sequential SS | Adjusted SS | Adjusted MSS | F-Value | p-Value | Significance | CR (%) |

|---|---|---|---|---|---|---|---|---|

| fz (µm/tth) | 2 | 41.46 | 41.46 | 20.73 | 6.17 | 0.021 | Significant | 30.57 |

| Vc (m/min) | 2 | 4.90 | 4.90 | 2.45 | 0.73 | 0.509 | Non-significant | 3.61 |

| ap (µm) | 2 | 58.84 | 58.84 | 29.42 | 8.75 | 0.008 | Significant | 43.38 |

| Cooling Condition | 2 | 0.19 | 0.19 | 0.09 | 0.03 | 0.972 | Non-significant | 0.14 |

| Error | 7 | 30.25 | 30.25 | 3.36 | 22.30 | |||

| Total | 17 | 135.64 | 100.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rehman, G.U.; Haq, M.R.u.; Masud, M.; Jaffery, S.H.I.; Khan, M.S.; Butt, S.I. Statistical Analysis of Burr Width and Height in Conventional Speed Micro-Milling of Titanium Alloy (Ti-6Al-4V) by Varying Cutting Parameters Under Different Lubrication Methods: Dry, MQL and Wet. Eng. Proc. 2025, 111, 11. https://doi.org/10.3390/engproc2025111011

Rehman GU, Haq MRu, Masud M, Jaffery SHI, Khan MS, Butt SI. Statistical Analysis of Burr Width and Height in Conventional Speed Micro-Milling of Titanium Alloy (Ti-6Al-4V) by Varying Cutting Parameters Under Different Lubrication Methods: Dry, MQL and Wet. Engineering Proceedings. 2025; 111(1):11. https://doi.org/10.3390/engproc2025111011

Chicago/Turabian StyleRehman, Gulfam Ul, Muhammad Rizwan ul Haq, Manzar Masud, Syed Husain Imran Jaffery, Muhammad Salman Khan, and Shahid Ikramullah Butt. 2025. "Statistical Analysis of Burr Width and Height in Conventional Speed Micro-Milling of Titanium Alloy (Ti-6Al-4V) by Varying Cutting Parameters Under Different Lubrication Methods: Dry, MQL and Wet" Engineering Proceedings 111, no. 1: 11. https://doi.org/10.3390/engproc2025111011

APA StyleRehman, G. U., Haq, M. R. u., Masud, M., Jaffery, S. H. I., Khan, M. S., & Butt, S. I. (2025). Statistical Analysis of Burr Width and Height in Conventional Speed Micro-Milling of Titanium Alloy (Ti-6Al-4V) by Varying Cutting Parameters Under Different Lubrication Methods: Dry, MQL and Wet. Engineering Proceedings, 111(1), 11. https://doi.org/10.3390/engproc2025111011