Need Assessment for Implementation of Digital Transformation Practices Through the Capacity Building †

Abstract

1. Introduction

Motivation for This Study

- Systematically synthesizing barriers across the nine I4.0 pillars into 45 critical factors.

- Empirically validating barrier interdependencies via PLS-SEM.

- Advancing a sustainability-aligned maturity model for context-specific digital transformation.

2. Literature Review

Research Gap

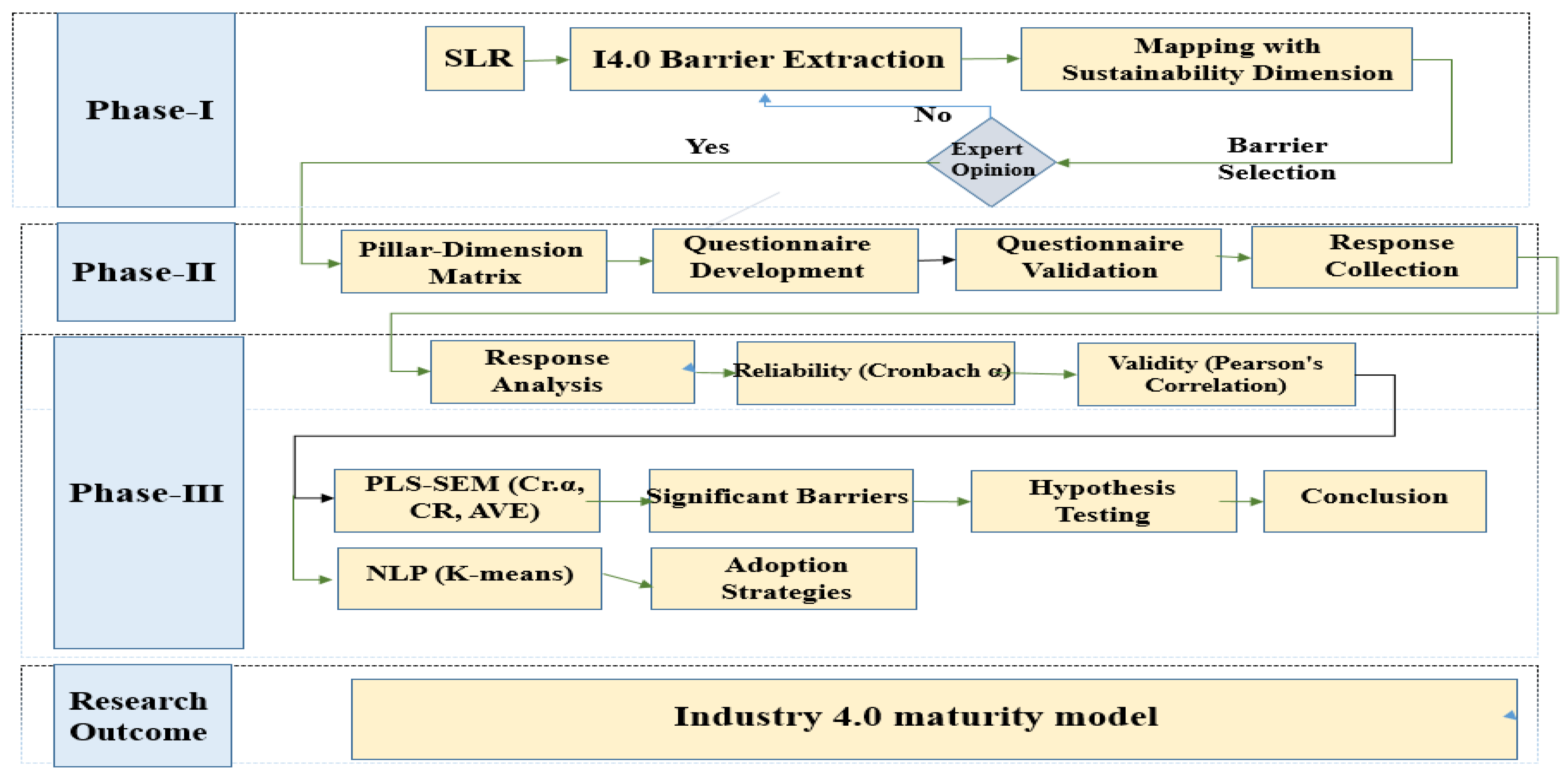

3. Research Design

3.1. Phase I (Factor Selection for Study)

3.2. Phase II (Questionnaire Development and Response Collection)

3.3. Phase III (Data Analysis)

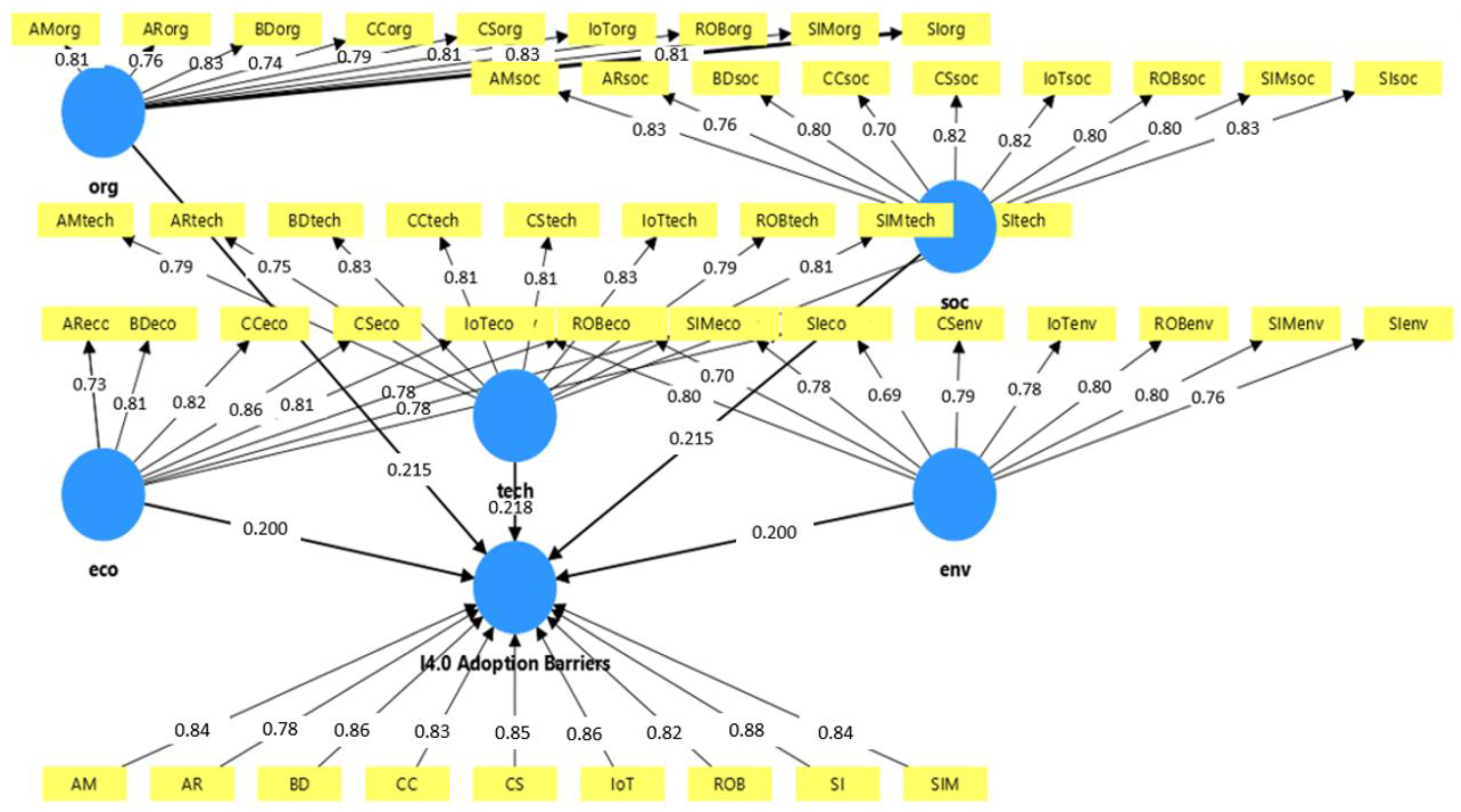

Proposed Hypotheses for the Research

4. Results and Discussion

- Y = I4.0 Adoption Barriers

- a = Constant

- x1 = Economic Barriers

- x2 = Environmental Barriers

- x3 = Organizational Barriers

- x4 = Social Barriers

- x5 = Technological Barriers

- ζ = Error term

4.1. Most Significant Barriers

4.2. Capacity Building Strategies

4.3. Proposed Maturity Model

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lutfi, A.; Lai, H.S.; Ren, J.; Ghasemaghaei; Calic, G.; Chen, Q.; Preston, D.S.; Swink, M.; Maroufkhani, M.I.; Ghobakhloo, M.; et al. Drivers and Impact of Big Data Analytic Adoption in the Retail Industry: A Quantitative Investigation Applying Structural Equation Modeling. J. Retail. Consum. Serv. 2023, 70, 103129. [Google Scholar] [CrossRef]

- Grau, A.; Indri, M.; Lo Bello, L.; Sauter, T. Robots in Industry: The Past, Present, and Future of a Growing Collaboration With Humans. IEEE Ind. Electron. Mag. 2021, 15, 50–61. [Google Scholar] [CrossRef]

- Muhic, M.; Bengtsson, L.; Holmström, J. Barriers to Continuance Use of Cloud Computing: Evidence from Two Case Studies. Inf. Manag. 2023, 60, 103792. [Google Scholar] [CrossRef]

- Al-Ruithe, M.; Benkhelifa, E. Analysis and Classification of Barriers and Critical Success Factors for Implementing a Cloud Data Governance Strategy. Procedia Comput. Sci. 2017, 113, 223–232. [Google Scholar] [CrossRef]

- Creese, S.; Dutton, W.H.; Esteve-González, P. The Social and Cultural Shaping of Cybersecurity Capacity Building: A Comparative Study of Nations and Regions. Pers. Ubiquitous Comput. 2021, 25, 941–955. [Google Scholar] [CrossRef]

- Kaswan, M.S.; Rathi, R.; Reyes, J.A.G.; Antony, J. Exploration and Investigation of Green Lean Six Sigma Adoption Barriers for Manufacturing Sustainability. IEEE Trans. Eng. Manage. 2023, 70, 4079–4093. [Google Scholar] [CrossRef]

- Raj, R.; Kumar, V.; Verma, P. Big Data Analytics in Mitigating Challenges of Sustainable Manufacturing Supply Chain. Oper. Manag. Res. 2023, 16, 1886–1900. [Google Scholar] [CrossRef]

- Aquino, S.; Rapaccini, M.; Adrodegari, F.; Pezzotta, G. Augmented Reality for Industrial Services Provision: The Factors Influencing a Successful Adoption in Manufacturing Companies. J. Manuf. Technol. Manag. 2023, 34, 601–620. [Google Scholar] [CrossRef]

- Souza, S.R.D.L.S.; Macêdo, R.D.J.; De Oliveira, V.P.; Santos, W.D.S.; Alves, L.R.G.; Lordelo, S.N.D.B.; Winkler, I. Augmented Reality in Education for Industry 4.0: What Are the Barriers to Adoption? Cuad. Ed. Desar. 2023, 15, 481–505. [Google Scholar] [CrossRef]

- Cheng, M.; Liu, G.; Xu, Y.; Chi, M. What hinders internet of things (IoT) adoption in the Chinese construction industry: A mixed-method. J. Civ. Eng. Manag. 2024, 30, 1–18. [Google Scholar] [CrossRef]

- Basit, A.; Qazi, T.F.; Niazi, A.A.K.; Niazi, I.A.K. Structural Analysis of the Barriers to Address Cyber Security Challenges. J. Policy Res. 2023, 9, 221–236. [Google Scholar] [CrossRef]

- Hasani, T.; O’Reilly, N.; Dehghantanha, A.; Rezania, D.; Levallet, N. Evaluating the Adoption of Cybersecurity and Its Influence on Organizational Performance. SN Bus. Econ. 2023, 3, 97. [Google Scholar] [CrossRef]

- Gaikwad, S.K.; Paul, A.; Moktadir, M.A.; Paul, S.K.; Chowdhury, P. Analyzing Barriers and Strategies for Implementing Lean Six Sigma in the Context of Indian SMEs. Benchmarking Int. J. 2020, 27, 2365–2399. [Google Scholar] [CrossRef]

- Aguero, C. Inside the Virtual Robotics Challenge: Simulating Real-Time Robotic Disaster Response. IEEE Trans. Autom. Sci. Eng. 2015, 12, 494–506. [Google Scholar] [CrossRef]

- Sanchez, M.; Exposito, E.; Aguilar, J. Industry 4.0: Survey from a System Integration Perspective. Int. J. Comput. Integr. Manuf. 2020, 33, 1017–1041. [Google Scholar] [CrossRef]

- Waqar, A.; Khan, M.B.; Shafiq, N.; Skrzypkowski, K.; Zagórski, K.; Zagórska, A. Assessment of Challenges to the Adoption of IOT for the Safety Management of Small Construction Projects in Malaysia: Structural Equation Modeling Approach. Appl. Sci. 2023, 13, 3340. [Google Scholar] [CrossRef]

- Hong, J.; Akotia, J.; Charles, E. Virtual Reality in Construction Activities: Barriers for Adoption in China. Constr. Econ. Build. 2024, 24, 77–93. [Google Scholar] [CrossRef]

- Yeh, C.-C.; Chen, Y.-F. Critical Success Factors for Adoption of 3D Printing. Technol. Forecast. Soc. Chang. 2018, 132, 209–216. [Google Scholar] [CrossRef]

- Abdelmegid, M.A.; González, V.A.; Poshdar, M.; O’Sullivan, M.; Walker, C.G.; Ying, F. Barriers to Adopting Simulation Modelling in Construction Industry. Autom. Constr. 2020, 111, 103046. [Google Scholar] [CrossRef]

- Maroufkhani, P.; Iranmanesh, M.; Ghobakhloo, M. Determinants of Big Data Analytics Adoption in Small and Medium-Sized Enterprises (SMEs). Ind. Manag. Data Syst. 2023, 123, 278–301. [Google Scholar] [CrossRef]

- Omer, M.M.; Kineber, A.F.; Oke, A.E.; Kingsley, C.; Alyanbaawi, A.; Rached, E.F.; Elmansoury, A. Barriers to Using Cloud Computing in Sustainable Construction in Nigeria: A Fuzzy Synthetic Evaluation. Mathematics 2023, 11, 1037. [Google Scholar] [CrossRef]

- Khattak, A.S.; Ali, M.K.; Al Awadh, M. A Multidimensional Evaluation of Technology-Enabled Assessment Methods during Online Education in Developing Countries. Sustainability 2022, 14, 10387. [Google Scholar] [CrossRef]

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 Technologies: Implementation Patterns in Manufacturing Companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Hajoary, P.K. Industry 4.0 Maturity and Readiness Models: A Systematic Literature Review and Future Framework. Int. J. Innov. Technol. Manag. 2020, 17, 2030005. [Google Scholar] [CrossRef]

| Industry 4.0 Pillar | Sustainability Dimension | ||||

|---|---|---|---|---|---|

| Economic | Environmental | Organizational | Social | Technological | |

| Cloud Computing | Operational Costs | External Pressure | Lack of Management Support | Power Distance | High Complexity |

| Cybersecurity | Cyber Threat Costs | Advanced Cyber Threats | Organizational Flexibility | Privacy Awareness | Performance Barriers |

| System Integration | Implementation Costs | Operational Disruption Risk | Consultant Availability Issues | Cultural Fragmentation | Process Metrics Issues |

| Big Data | Financial Assistance Uncertainty | External Support Issues | Organizational Readiness | Traceability Challenges | Technological Advantage |

| IoT | Extended Payback | Regulatory Barriers | Collaboration Issues | Transparency Issues | IT Infrastructure Gaps |

| Additive Manufacturing | Machine/Material Costs | Low Customization Demand | Managerial Challenges | Lack of Knowledge Systems | Printing System Size |

| Simulation | Simulation Time Issues | Project Uniqueness | Management Vision Gaps | Learning Curve Barriers | Simulation Cycle Time Issues |

| Autonomous Robots | High Costs | Data Sharing Standards Lack | Digital Readiness Issues | Robot Technology Reservations | Human–Robot Interaction Issues |

| Augmented Reality | Capital Investment Needs | Tech Approval Barriers | Leadership in Digitalization | Tech Familiarization Challenges | Interface Consistency Issues |

| Factors | Abb | Relationship | Hypothesis |

|---|---|---|---|

| Economic | ECO | ECO → I4.0 Adop. Barriers | H1: Economic constraints significantly hinder I4.0 implementation. |

| Environmental | ENV | ENV → I4.0 Adop. Barriers | H2: Environmental concerns create substantial adoption barriers. |

| Organizational | ORG | ORG → I4.0 Adop. Barriers | H3: Organizational limitations impede I4.0 technology integration. |

| Social | SOC | SOC → I4.0 Adop. Barriers | H4: Social factors present critical obstacles to adoption. |

| Technological | TECH | TECH → I4.0 Adop. Barriers | H5: Technological challenges significantly restrict I4.0 deployment. |

| Construct | Cronbach’s Alpha (0.81–0.83) | Composite Reliability > 0.80 | Average Variance Extracted > 0.5 |

|---|---|---|---|

| Eco | 0.83 | 0.84 | 0.65 |

| Env | 0.81 | 0.82 | 0.59 |

| Org | 0.82 | 0.84 | 0.63 |

| Soc | 0.81 | 0.83 | 0.63 |

| Tech | 0.83 | 0.84 | 0.64 |

| Hypothesis | Relationship | Beta-Value | Std-Error | T-Value | p-Value | Decision | CI-2.5% | CI-97.5% |

|---|---|---|---|---|---|---|---|---|

| H1 | eco → I4.0 Adoption Barriers | 0.200 | 0.007 | 4.15 | 0.00 | Supported | 0.188 | 0.213 |

| H2 | env → I4.0 Adoption Barriers | 0.200 | 0.004 | 5.36 | 0.00 | Supported | 0.194 | 0.207 |

| H3 | org → I4.0 Adoption Barriers | 0.215 | 0.004 | 2.71 | 0.00 | Supported | 0.208 | 0.225 |

| H4 | soc → I4.0 Adoption Barriers | 0.215 | 0.004 | 9.83 | 0.00 | Supported | 0.207 | 0.224 |

| H5 | tech → I4.0 Adoption Barriers | 0.218 | 0.004 | 15.69 | 0.00 | Supported | 0.209 | 0.226 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Iqbal, M.S.; Hussain, S.; Ahmad, W.; Ullah, A.; Hussain, S. Need Assessment for Implementation of Digital Transformation Practices Through the Capacity Building. Eng. Proc. 2025, 111, 1001. https://doi.org/10.3390/engproc2025111001

Iqbal MS, Hussain S, Ahmad W, Ullah A, Hussain S. Need Assessment for Implementation of Digital Transformation Practices Through the Capacity Building. Engineering Proceedings. 2025; 111(1):1001. https://doi.org/10.3390/engproc2025111001

Chicago/Turabian StyleIqbal, Muhammad Sohail, Salman Hussain, Wasim Ahmad, Abaid Ullah, and Sajjad Hussain. 2025. "Need Assessment for Implementation of Digital Transformation Practices Through the Capacity Building" Engineering Proceedings 111, no. 1: 1001. https://doi.org/10.3390/engproc2025111001

APA StyleIqbal, M. S., Hussain, S., Ahmad, W., Ullah, A., & Hussain, S. (2025). Need Assessment for Implementation of Digital Transformation Practices Through the Capacity Building. Engineering Proceedings, 111(1), 1001. https://doi.org/10.3390/engproc2025111001