1. Introduction

The Philippines sources its water from surface water (rivers, lakes, reservoirs) and groundwater resources, which spread over approximately 50,000 km

2. Groundwater provides more than 50% of potable water and 85% of the channeled water supply in the country [

1]. Despite 91% of the population having access to essential water services, this does not always guarantee safe drinking water [

2].

Water quality is crucial to modern life. In determining water quality levels, physical, chemical, and microbiological parameters are used. Effective water quality monitoring significantly improves public health. A total of 92.5% of Central Luzon families in the Philippines have access to basic drinking water services, highlighting the importance of quality monitoring as over 50% of households rely on refilling stations [

3].

Traditionally, water quality monitoring in developing countries involves manual collection and laboratory analysis, a method prone to delays and inefficiencies [

4]. In the Philippines, the Department of Health’s Administrative Order No. 2017–0010 outlines drinking water standards, requiring water to be clear, pleasant-tasting, and free from harmful contaminants. It also indicates the measurement of physical and chemical parameters, specifically turbidity, total dissolved solids, and pH. The standard values for turbidity must be less than or equal to 5.0 NTU, TDS must be less than or equal to 10 mg/L, and pH levels must be between five and seven. The ability to determine TDS, turbidity, and pH is essential to secure the water quality. TDS is measured based on the number of dissolved solids in water, with higher levels indicating potential pollutants [

5]. Turbidity indicates water clarity and potential microbial contamination [

6], while pH levels affect water safety, with extreme acidity or alkalinity posing health risks [

7].

With the high costs associated with domestic purifiers and bottled water, many people are using water refilling stations. These stations provide safe drinking water, despite management and environmental challenges [

8]. The water refilling stations must ensure water quality by conducting regular TDS monitoring and monthly third-party tests for coliform bacteria, pH, and turbidity. If high TDS levels are detected, corrective measures, including softener recharging and membrane replacement, are promptly implemented to maintain water safety.

In this study, we explored the continuous monitoring of TDS, turbidity, and pH in water to ensure the safety and quality of water from water refilling stations.

3. Methodology

We developed a system to monitor pH, TDS, and turbidity in drinking water. Data collected from sensors are transmitted and processed by microcontrollers to update the database and display water quality parameters on an ASP.NET Web Application developed using the .NET Framework and C#. The dashboard presents real-time updates for the Crystal Clear water refilling station, which was the study site [

20,

21]. We used modified prototyping with IoT. It is based on the Nurun Process [

22], which integrates IoT devices with Arduino microcontrollers.

Figure 1 demonstrates the three-part research scheme of this study.

The initial stage of the Nurun process is to investigate the feasibility of the system through interviews, observations, and a review of relevant literature. After the investigation, a device was developed and implemented in the model stage. In the model stage, a prototype is tested and modified. Diagrams showing entity relationships, data flow, and circuits are drawn to design and implement the device or a system effectively.

The test involves user acceptability (UA) in two stages: alpha testing involving internal testing for functionality, sensor calibration, data accuracy, and error handling, and beta testing to identify issues, gather feedback, and assess adaptability. In the realize stage, stakeholders tested the prototype and completed the UA questionnaire. The collected data were analyzed to determine whether the system met its objectives and operated as intended.

We developed a prototype of a water quality monitoring system for water refilling stations. Tests were conducted to ensure the system and enhance accuracies and reliabilities. These tests included self-calibration testing to verify the accuracy of the measurements, isolation testing to assess the system’s stability, third-party testing for external validation, stress testing to evaluate how the system performs under extreme conditions, and compatibility testing to ensure the system integrates seamlessly with existing infrastructure.

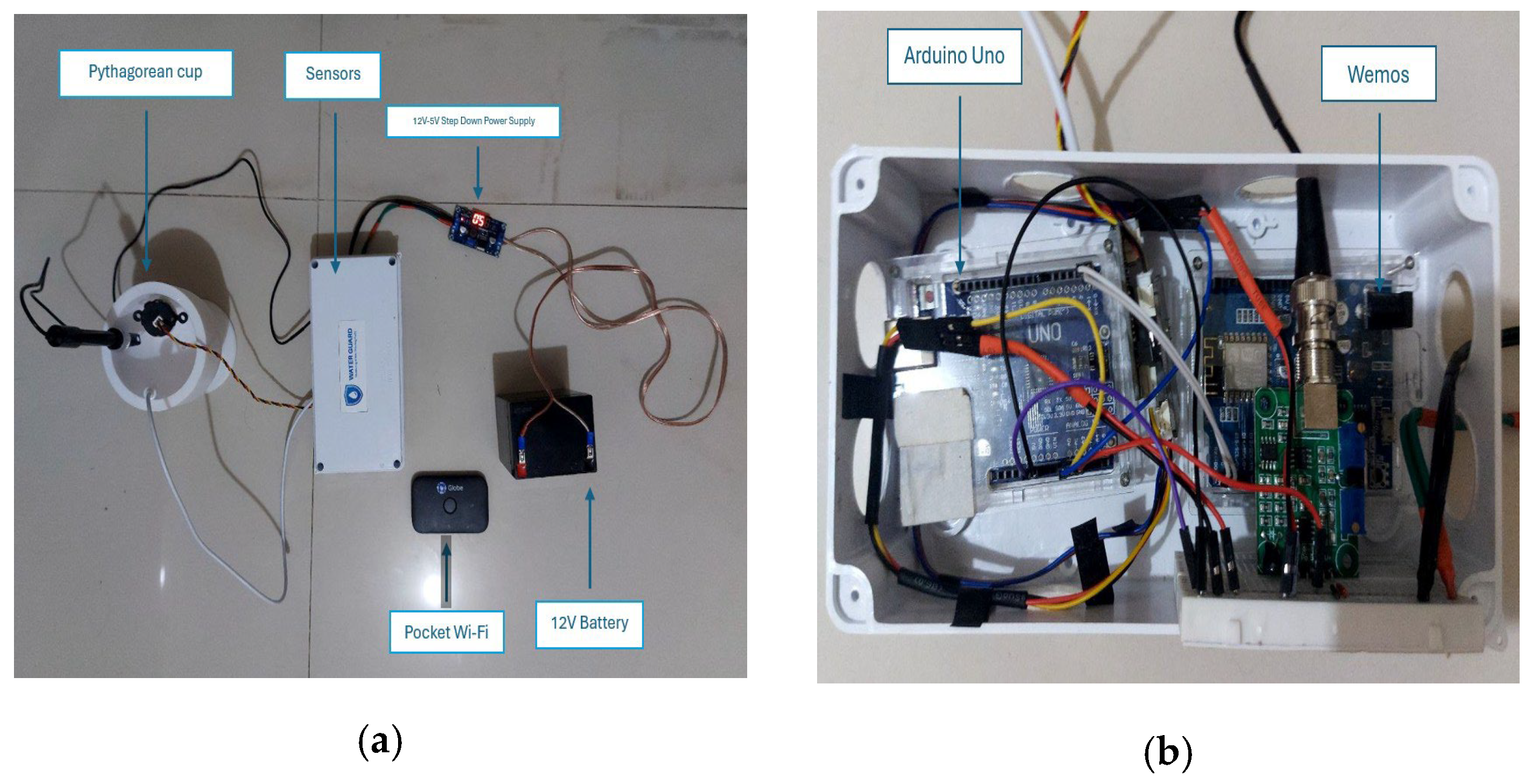

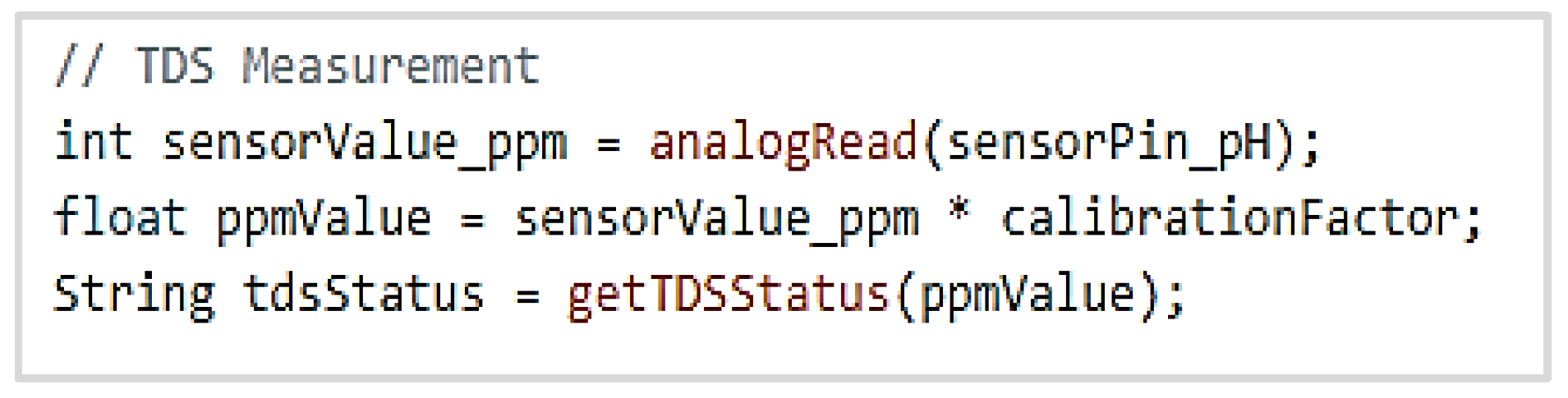

The developed system consists of the Wemos D1, Arduino Mega, pH sensor, TDS sensor, turbidity sensor, 12–5 V step-down power supply, and a 12 V–5.0 A lead–acid battery (

Figure 2).

The system included pH, TDS, and turbidity sensors, placed inside a Pythagorean cup (

Figure 3). In the cup, if water is poured beyond a certain level, it automatically drains through a hole at the bottom, preventing overflow. To protect the sensors from water and maintain their accuracy, they are enclosed in a waterproof junction box (

Figure 3) to ensure the reliability and safety of the sensors and allow precise monitoring of water quality parameters. The depths at which the sensors are placed are 1.5 cm for the TDS sensor, 2.5 cm for the turbidity sensor, and 4.2 cm for the pH sensor. Such optimized depths ensure reliable and precise measurements. The waterproof junction box also protects the step-down power supply and the battery from damage.

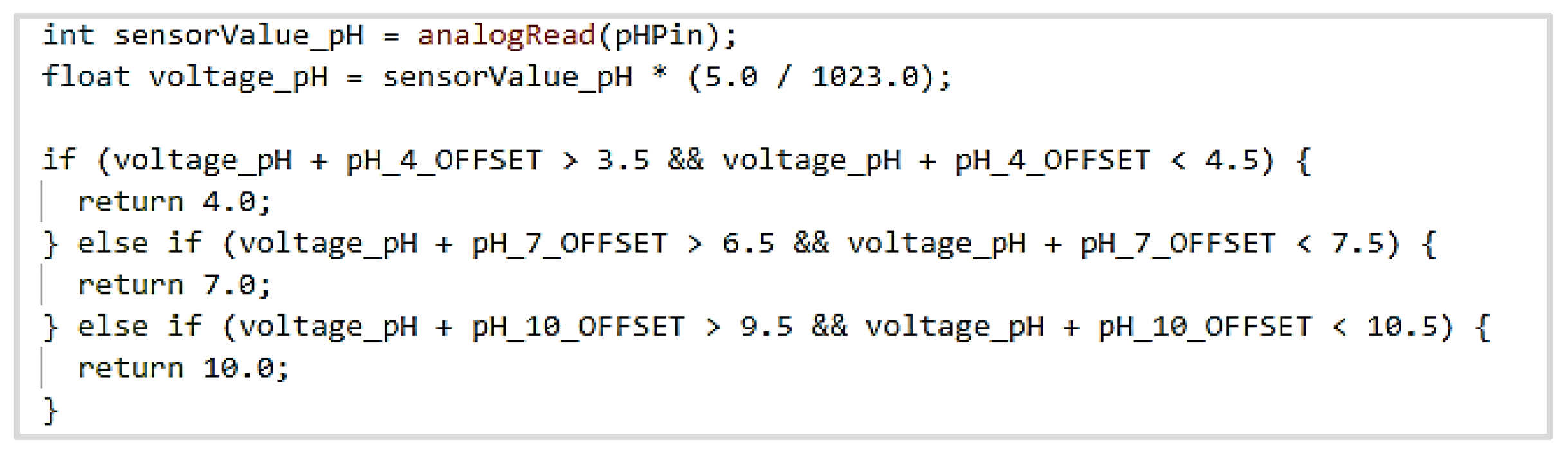

The TDS sensor is calibrated by determining the slope and offset constants. The sensor is connected to an Arduino microcontroller to read values through an analog pin (A1). The Arduino code calculates the value in ppm, displaying the raw and TDS values through serial communication (

Figure 4).

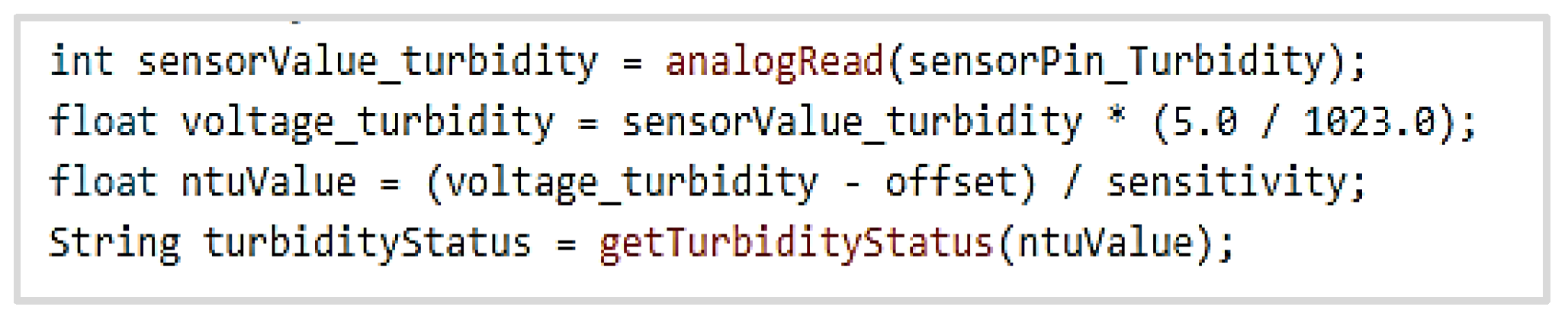

The pH sensor is calibrated by establishing the correlation between readings and actual pH values of standard solutions. A consistent voltage during calibration is maintained. The pH values are read from the analog pin (A2) and displayed if the readings are in the acceptable range (

Figure 5).

The turbidity sensor is calibrated by measuring baseline readings in clear water and a reference solution. The turbidity is calculated in the Nephelometric turbidity unit (NTU) based on the output voltage (

Figure 6).

4. Results

The six-hour test was conducted as shown in

Table 1. The system’s ability was tested by adding impurities, such as vinegar, detergent powder, mud, salt, and hot water, which were introduced into the water sample. Vinegar lowered pH, detergent increased pH, turbidity, and conductivity, mud affected turbidity, salt raised conductivity, and hot water increased temperature. The sensors accurately detected these changes, demonstrating the system’s effectiveness in real-time water quality monitoring.

A 12 h test was conducted as shown in

Table 2 to evaluate the system’s performance by intentionally altering water quality with various solutions, simulating conditions. The test results helped observe how the system detected these changes. In the 24 h test, tap water was to assess the system’s response over a longer period (

Table 3). The results provided data to evaluate the system’s effectiveness in detecting and responding to different water quality levels and validate its reliability for continuous monitoring in both controlled and real-world environments.

The third-party testing was carried out in cooperation with Acculab Calibration Laboratory Inc. to guarantee that the calibration process of the developed system was accurate and reliable. The difference was low, indicating that the system developed accurately monitored every 5 min (

Table 4 and

Table 5).

We examined the difference between the system developed and the Acculab Calibration Laboratory’s system using an unpaired

t-test (

Table 6).

Compatibility testing was conducted to ensure that a website functioned correctly. The website was developed using ASP.NET Web Application with Bootstrap 4 and JavaScript. It was tested for compatibility on desktop computers and mobile browsers in Windows and Mac operating systems (

Table 7). In the Windows operating system, Chrome, Firefox, Microsoft Edge, and Opera were used while in the Mac system, Chrome, Firefox, Safari, Microsoft Edge, and Opera were used. For mobile browsers, Android and iOS devices on the Infinix HOT 20s (Android) and iPhone 11 Pro (iOS) were used (

Table 8). For Android, the website was compatible with Chrome and Firefox except for Safari. For iOS, the website was compatible with Chrome, Firefox, and Safari.

Figure 7 illustrates the connections between each component. The pH, TDS, and turbidity sensors’ power pins were connected to an LM2596 step-down adjustable power supply for voltage regulation. Their analog outputs are connected to the Arduino UNO R3 Board ATmega328’s six analog inputs. The PH-4502C Liquid PH Sensor’s analog output pin connects to two analog input pins, the TDS Sensor’s output pin to one analog input pin, and the Turbidity Analog Sensor’s output pin to zero analog input pins on the Arduino. Data are transmitted from the Arduino to the WeMos D1 through serial connections using the TX and RX pins. The RX pin of the Arduino is linked to the TX pin of the WeMos D1, and vice versa. Analog sensor readings are converted to PPM values through the microcontroller’s programmed algorithm.

Figure 8 illustrates a water quality monitoring system that employs Arduino-based microcontroller units and cloud services for data storage and visualization. The system comprises sensors, microcontroller units, power supply, and cloud services. Initially, the system utilizes three types of sensors to measure different water quality parameters: a pH sensor connected to analog pin A2, a TDS sensor connected to analog pin A1, and a turbidity sensor connected to analog pin A0. These sensors are connected to Arduino Uno, which serves as the primary microcontroller unit. The Arduino Uno processes the sensor data and then communicates with an ESP8266 module, which is a WiFi-enabled microcontroller. The ESP8266 handles the wireless transmission of processed data to cloud services.

The entire system is powered by a 12V power supply, ensuring that both the Arduino Uno and the ESP8266 module receive adequate power for their operations. Finally, the sensor data are transmitted to cloud services for further processing, storage, and visualization. The cloud service platform used in this system provides functionalities, such as data analytics, database management, and real-time monitoring. Users can access and visualize the data through display units, such as computers and smartphones, providing them with real-time insights into water quality. This integration of hardware and cloud services enables efficient and effective monitoring of water quality, making the system a valuable tool for environmental monitoring and management.

The developed software was tested in alpha and beta testing modes. Alpha Testing involves unit, integration, stress, and compatibility testing, while beta testing consists of user acceptance testing by staff, supervisor and manager. A questionnaire was developed focusing on usability, functionality, user interface, and experience (

Table 9). The overall results showed “Strongly Agree”.

5. Conclusions

We developed an IoT-based water quality monitoring system for water refilling stations, ensuring continuous and real-time monitoring of water quality parameters. The system underwent rigorous testing, including self-calibration, isolation, third-party evaluation, stress testing, and compatibility assessments. The results demonstrated a high accuracy and reliability. The system met standards for TDS, pH, and turbidity measurement, aligning with the Philippine National Standards for Drinking Water. User acceptance was high, confirming the system’s effectiveness, design, and usability while proving its ability to accurately measure and record water quality data. The process of monitoring water quality using the developed system enables the presentation of relevant reports and essential data to maintain water quality. Additionally, data visualization of historical water quality serves as a basis for service improvement.