Abstract

In this study, silicon carbide (SiC) thin films for resistive random-access memory (RRAM) devices were successfully prepared using the radio-frequency magnetron sputtering method at deposition powers of 50 and 75 W for 1 h. The aluminum (Al) top electrode of the RRAM devices was also fabricated using thermal evaporator deposition. Additionally, the electrical properties of the SiC thin film RRAM devices were determined using a B2902A mechanism. The current–voltage (I–V) curves of the as-deposited SiC thin films at 50 and 75 W power levels were measured and analyzed. Specifically, the set and reset voltages for the RRAM devices deposited at 50 and 75 W were approximately 1.2 and −1.5 V, respectively. For the annealed samples, the memory windows of the 75 W SiC thin film RRAM devices treated at 300 °C were found to be around 105.

1. Introduction

Rapid technological development has made computers, communications, and consumer electronics (3C) products integral to daily life. As manufacturing technology advances, electronic products have become portable, high-performance, and durable. Memory capacity, processing speed, and applications also have become significant. The memory devices are grouped into volatile and non-volatile categories devices. Volatile memory, such as static random access memory (SEAM) and dynamic random access memory (DRAM), requires constant power as the data are lost when power is interrupted. It has fast access and low power usage but cannot retain data without power. The non-volatile memory keeps data without power and is accessed again after power is restored. Flash memory devices are most commonly used. However, its manufacturing has limitations. In recent years, artificial intelligence (AI) technology has been used to develop advanced non-volatile memory. The next-generation non-volatile memory includes magnetic memory, ferroelectric memory, phase-change memory, and resistive random access memory (RRAM). RRAM features a simple structure, small size, fast read and write speed, low power consumption, and a low operating voltage. In non-volatile memory technology, RRAM is used as a significant memory component. The resistive random access memory (RRAM) devices exhibit a metal–insulator–metal (MIM) structure. The characteristics of RRAM include a simple structure and ease of miniaturization. It switches between a high-resistance state (HRS) and a low-resistance state (LRS) at high speeds (ns), which are presented as 0 or 1. Additionally, it operates in low current (μA–nA), with stable endurance and retention. As technology evolves, electronic products are commonly used in households. Using big data and the Internet of Things, non-volatile memory with larger capacity and faster speeds for processing and analyzing vast databases are widely used. Non-volatile memory, especially in non-volatile RRAM, is favored for its low cost, low operating voltage, and simple structure. RRAM is fabricated using the physical vapor deposition method (PVD) or chemical vapor deposition (CVD) method to create the metal–insulator–metal (MIM) structure and is considered the most promising memory, using metal oxides and rare earth elements in the switching layer [1,2,3,4,5,6,7,8,9,10,11,12,13].

2. Experiment

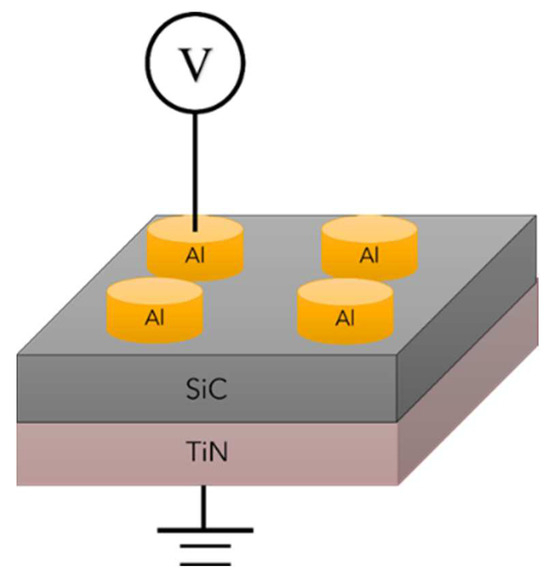

With titanium nitride (TiN) as the substrate, a silicon carbide (SiC) thin film is sputtered on the substrate as the insulating layer of RRAM. Aluminum is deposited as the electrode through evaporation to form a metal–insulator–metal (MIM) structure, as shown in Figure 1. First, the TiN substrate is cut using a diamond cutter. The cut substrate is then sequentially ultrasonically cleaned in acetone, isopropyl alcohol, and deionized water for 10 min. The cleaned substrate is dried with nitrogen gas and then placed in an oven for drying. Next, a radio frequency (RF) magnetron sputtering machine is used to deposit the SiC thin film on the TiN substrate with power settings of 50 and 75 W for 0.5, 1, and 2 h. Various measurement instruments are used to analyze the physical properties and investigate the effects on the thin film characteristics. Additionally, the electrical properties of the SiC thin film RRAM devices are determined using a B2902A mechanism. The current–voltage (I–V) curves of the as-deposited SiC thin films at 50 and 75 W are analyzed.

Figure 1.

MIM structure of SiC films used for RRAM devices.

3. Result and Discussion

Using an RF magnetron sputtering system, thin films were deposited with different powers and times. After fabricating the devices, physical and electrical analyses were conducted. The films were deposited with sputtering times of 30, 60, and 120 min at powers of 50 and 75 W. The characteristics of the RRAM were then investigated. The parameters are presented in Table 1.

Table 1.

Parameters of SiC film deposition for RRAM devices at different powers.

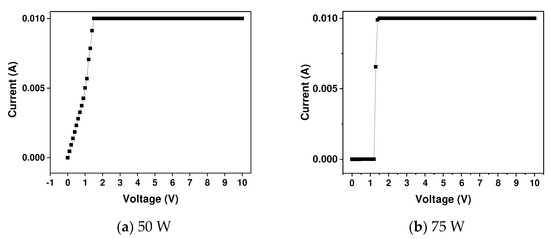

First, a positive bias was applied to the top electrode of the RRAM, causing the SiC film to switch from a high to a low resistance state, forming a conductive path, as shown in Figure 2. The forming voltage is approximately 2.5 V. To prevent the film from permanently breaking down due to excessive current during this process, the current was limited to 10 mA.

Figure 2.

Forming process of SiC films for RRAM devices at different powers.

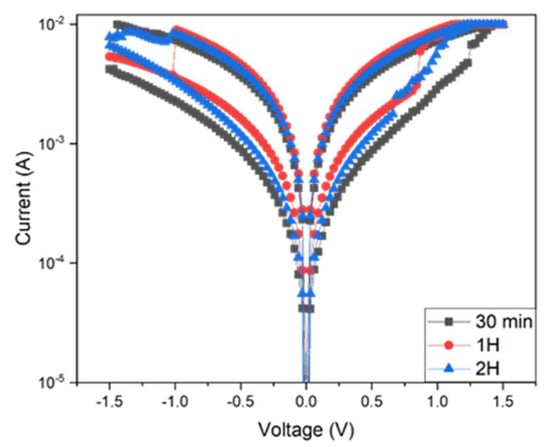

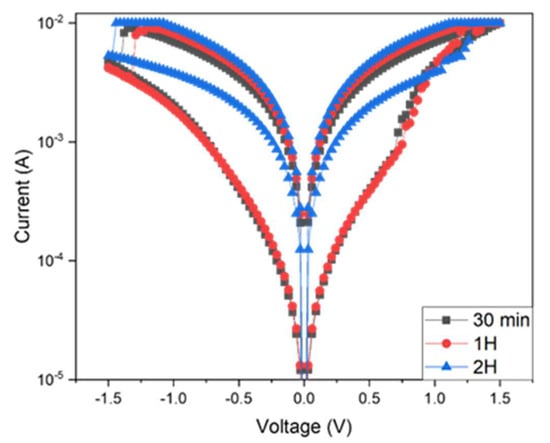

After completing the forming process, the RRAM formed a conductive path. A negative bias was then applied to reset the device, breaking the conductive filament and switching it from a low to a high-resistance state. Subsequently, the device was continuously scanned at positive and negative voltages to measure the memory window of the RRAM. Figure 3 shows the I–V curve at 50 W, measured using a bipolar method. A memory window appeared, with an on/off ratio of approximately 1 and an operating voltage of about 1.5 V. Figure 3 also shows the overlay of the I–V curves. Figure 4 shows the I–V characteristics of the device sputtered at 75 W, where a memory window also appeared with an on/off ratio of approximately 1 and an operating voltage of about 1.5 V.

Figure 3.

I–V curves of SiC films for RRAM devices at different deposition times and 50 W.

Figure 4.

I–V curves of SiC films for RRAM devices at different deposition times and 75 W.

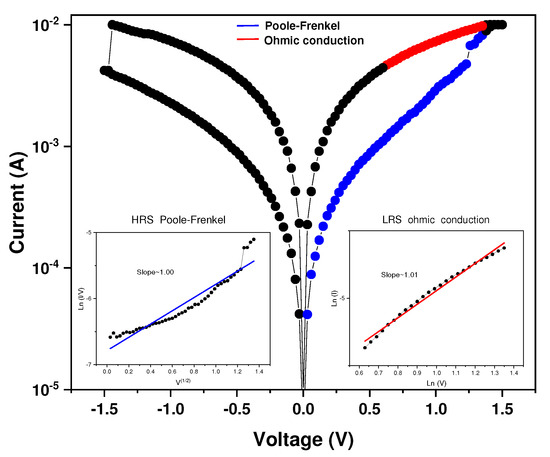

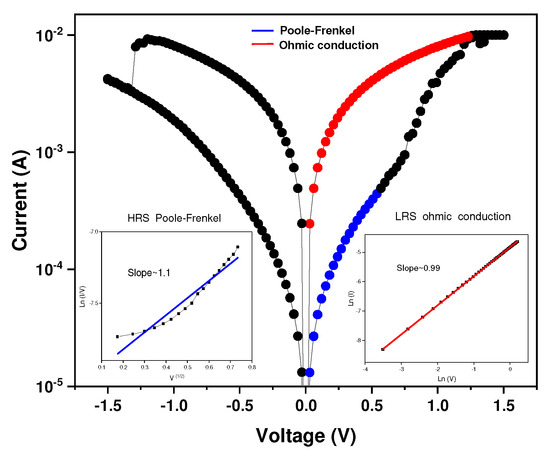

The I–V curves at 75 W are presented in Figure 5. The changes in sputtering power and time were not significant. The electrical properties were observed through the deposited process. The electrical conduction mechanism of SiC films for RRAM devices at 50 W and 30 min deposition time exhibited the Poole–Frankel mechanism of the high resistance state (HRS). In addition, the electrical conduction mechanism exhibited the ohmic conduction mechanism at the LRS.

Figure 5.

I–V curves of SiC films for RRAM devices at 50 W for 30 min deposition.

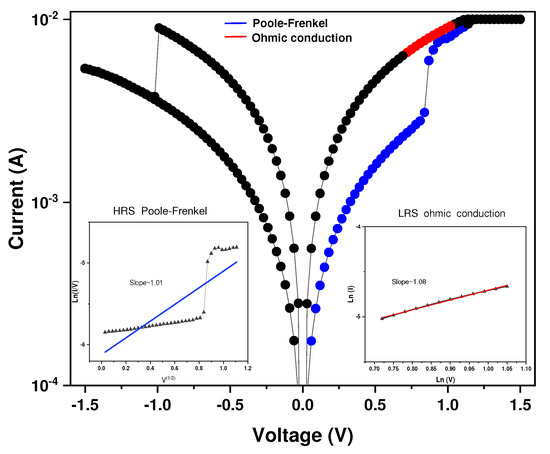

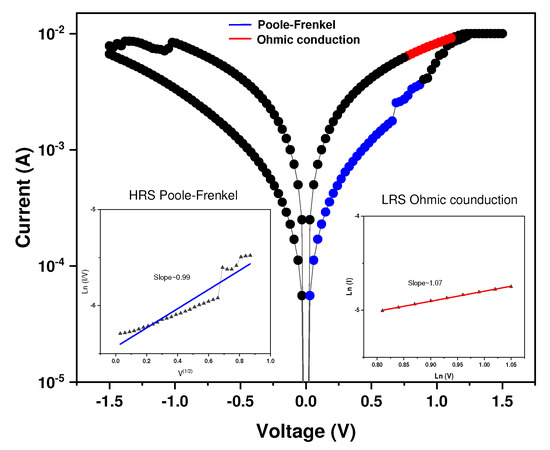

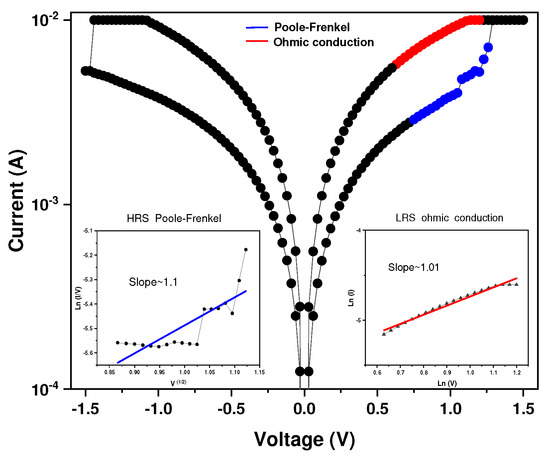

The electrical conduction mechanism of SiC films for RRAM devices at 50 W and 60 min deposition exhibited the Poole–Frankel mechanism for the HRS. In addition, the ohmic conduction mechanism for the LRS was observed (Figure 6). Figure 7 presents the electrical conduction mechanism of SiC films for RRAM devices at 50 W and 120 min deposition. The films exhibited the Poole–Frankel mechanism at the HRS, while the electrical conduction mechanism exhibited the ohmic conduction mechanism at the LRS.

Figure 6.

I–V curves of SiC films for RRAM devices at 50 W for 60 min deposition.

Figure 7.

I–V curves of SiC films for RRAM devices at 50 W for 120 min deposition.

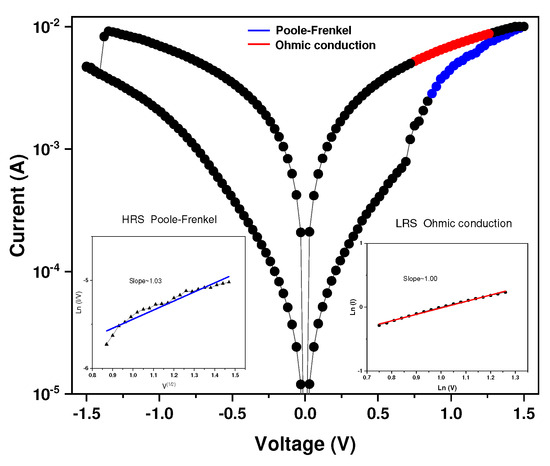

Figure 8 shows the electrical conduction mechanism of SiC films for RRAM devices at 75 W and 30 min deposition with the Poole–Frankel mechanism at the HRS. The electrical conduction mechanism exhibited the ohmic conduction mechanism at the LRS.

Figure 8.

I–V curves of SiC films for RRAM devices at 75 W for 30 min deposition.

The electrical conduction mechanism of SiC films for RRAM devices at 75 W and 60 min deposition exhibited the Poole–Frankel mechanism at the HRS state (Figure 9). The ohmic conduction mechanism was observed at the LRS. The electrical conduction mechanism of SiC films for RRAM devices for 75 W and 120 min deposition exhibited the Poole–Frankel mechanism at the HRS. The electrical conduction mechanism exhibited the ohmic conduction mechanism at the LRS (Figure 10).

Figure 9.

I–V curves of SiC films for RRAM devices at 75 W for 60 min deposition.

Figure 10.

I–V curves of SiC films for RRAM devices at 75 W for 120 min deposition.

4. Conclusions

We investigated the electrical and resistive switching properties of the deposited SiC thin film on a TiN substrate, prepared by using RF magnetron sputtering technology at different power levels (50 and 75 W) and deposition times (0.5, 1, and 2 h). The Al top electrode of thin film RRAM devices was prepared using the E-beam thermal evaporation method to form the MIM structure. The electrical and resistive switching mechanism of as-deposited treated SiC thin films was measured using precision power measurement. The as-deposited SiC thin film with 1 h deposition exhibited notable electrical and resistive switching properties. The on/off ratio was approximately 1, the operation voltage was 1.5 V, the leakage current was about 10−4 A, and the number of retention cycles was 30. The electrical transport mechanism of SiC thin films for RRAM devices demonstrated the Poole–Frenkel mechanism at the HRS and the ohmic conduction mechanism at the LRS.

Author Contributions

K.-H.C. and C.-C.H.K. conceived and designed the experiments; M.-C.K. and Y.-C.W. performed the experiments; C.-C.H.K. and K.-H.C. analyzed the data; K.-H.C. contributed rea-gents/materials/analysis tools; K.-H.C., and H.-C.C. wrote the paper. All authors have read and agreed to the published version of the manuscript.

Funding

This work was performed at the National Science Council Core Facilities Laboratory for Nano-Science and Nano-Technology in the Kaohsiung-Pingtung area and was supported by the National Science Council of the Republic of China under Contract No. NSTC 113-2622-E-230-001.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Li, L.; Dai, T.J.; Liu, K.; Chang, K.C.; Zhang, R.; Lin, X.; Liu, H.J.; Lai, Y.C.; Kuo, T.P. Achieving complementary resistive switching and multi-bit storage goals by modulating the dual-ion reaction through supercritical fluid-assisted ammoniation. Nanoscale 2021, 13, 14035–14040. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Chang, K.C.; Zhang, R.; Lin, X.; Lai, Y.C.; Kuo, T.P. Variable-temperature activation energy extraction to clarify the physical and chemical mechanisms of the resistive switching process. Nanoscale 2020, 12, 15721–15724. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Chang, K.C.; Ye, C.; Lin, X.; Zhang, R.; Xu, Z.; Xiong, W.; Zhou, Y.; Kuo, T.P. An Indirect Way to Achieve Comprehensive Performance Improvement of Resistive Memory: When Hafnium Meets ITO in Electrode. Nanoscale 2020, 12, 3267–3272. [Google Scholar] [CrossRef] [PubMed]

- Chang, K.C.; Dai, T.J.; Li, L.; Lin, X.N.; Zhang, S.D.; Lai, Y.C.; Liu, H.J.; Syu, Y.E. Unveiling the influence of surrounding materials and realization of multi-level storage in resistive switching memory. Nanoscale 2020, 12, 22070–22074. [Google Scholar] [CrossRef] [PubMed]

- Chang, K.C.; Zhang, R.; Chang, T.C.; Tsai, T.M.; Chu, T.J.; Chen, H.L.; Shih, C.C.; Pan, C.H.; Su, Y.T.; Wu, P.J.; et al. High performance, excellent reliability multifunctional graphene oxide doped memristor achieved by self-protective compliance current structure. In Proceedings of the IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 15–17 December 2014; pp. 33–34. [Google Scholar]

- Chen, K.-H.; Cheng, C.-M.; Wang, N.-F.; Hung, H.-W.; Li, C.-Y.; Wu, S. First Order Rate Law Analysis for Reset State in Vanadium Oxide Thin Film Resistive Random Access Memory Devices. Nanomaterials 2023, 13, 198. [Google Scholar] [CrossRef] [PubMed]

- Chen, K.-H.; Kao, M.-C.; Cheng, C.-M.; Wang, Y.-C.; Hsieh, C.-C.; Hung, G.-J. Study on Supercritical Fluid Technique for Application in Nonvolatile Resistive Random Access Memory (RRAM) Device Using SBT Ferroelectric Thin Films. In Proceedings of the 2024 IEEE Ultrasonics, Ferroelectrics, and Frequency Control Joint Symposium (UFFC-JS), Taipei, Taiwan, 22–26 September 2024. [Google Scholar] [CrossRef]

- Chen, K.-H.; Chen, Y.-C.; Chen, Z.-S.; Yang, C.-F. Temperature and frequency dependence of the ferroelectric characteristics of BaTiO3 thin films for nonvolatile memory applications. Appl. Phys. A 2007, 89, 533–536. [Google Scholar] [CrossRef]

- Zhang, R.; Young, T.-F.; Chen, M.-C.; Chen, H.-L.; Liang, S.-P.; Syu, Y.-E.; Sze, S.M.; Chang, K.-C.; Chang, T.-C.; Tsai, T.-M.; et al. Characterization of Oxygen Accumulation in Indium-Tin-Oxide for Resistance Random Access Memory. IEEE Electron. Device Lett. 2014, 35, 630–632. [Google Scholar] [CrossRef]

- Chang, K.C.; Chang, T.C.; Tsai, T.M.; Zhang, R.; Hung, Y.C.; Syu, Y.E.; Chang, Y.F.; Chen, M.C.; Chu, T.J.; Chen, H.L.; et al. Physical and chemical mechanisms in oxide-based resistance random access memory. Nano Rev. 2015, 10, 120. [Google Scholar] [CrossRef] [PubMed]

- Huang, H.; Liu, D.; Zhang, H.; Kong, X. Electronic transport and shot noise in Thue-Morse sequence graphene superlattice. Appl. Phys. 2013, 113, 043702. [Google Scholar] [CrossRef]

- Jung, J.; Lee, D.; Chae, M.; Kim, H.-D. Influence on Post-treatment Process on Optical and Electrical Properties of IZO Thin Films. Trans. Electr. Electron. Mater. 2024, 25, 347–355. [Google Scholar] [CrossRef]

- Trinidad-Urbina, R.E.; Castanedo-Perez, R.; Torres-Delgado, G.; Sanchez-Martinez, A.; Ramirez-Bon, R. Effects of rapid heat treatments on the properties of cu 2 o thin films deposited at room temperature using an ammonia-free silar technique. J. Electron. Mater. 2024, 9, 53. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).