Abstract

In this study, a fuzzy-logic-based decision support model is developed to predict the fatigue life of load-bearing system elements such as torque arm. Traditional methods for fatigue life prediction are mostly based on certain mathematical expressions and fixed parameters and do not adequately take into account the uncertainties caused by many factors such as material structure, surface condition, loading pattern and heat treatment. In order to overcome these deficiencies, the fuzzy logic method is preferred. The model is based on a fuzzy logic system and predicts outputs according to specific input conditions using rules derived from expert knowledge and experience. The input parameters of the model are material type, surface hardness, maximum applied stress level, and type of heat treatment. Although these parameters can be expressed numerically in the classical sense, the relationship between them is often imprecise and based on experience and engineering interpretation. Therefore, a more realistic and flexible prediction model has been created with the linguistic variables and rule-based approach of fuzzy logic.

1. Introduction

Torque rods, which are critical components for heavy vehicle suspension systems, are subjected to significant stresses and cyclic loading and play a structurally important role in vehicles. Torque rods are especially used to keep the position of the rear axle fixed relative to the chassis, transmit torque moments to the chassis, and limit the forward and reverse movements of the axle. Torque rods are designed to absorb longitudinal stresses caused by acceleration and deceleration of heavy vehicles. These stresses can lead to significant forces acting on the suspension system, potentially causing instability or component failure. Torque rods help to distribute and reduce these forces, making the vehicle run more smoothly [1,2,3,4]. Since these components are subjected to continuously varying axial, bending, and torsional loads, they have to be especially resistant to fatigue damage. This makes fatigue life prediction a priority engineering problem in the design of torque rods. In this direction, there are various studies in the literature on the fatigue resistance of torque rods. The mechanical behavior of an automobile torque rod is investigated using the finite element method (FEM) for the dynamic analysis of torque rods, and the parameters that will contribute to design optimization are determined [5]. Similarly, a torque component optimized for additive manufacturing is analyzed by XFEM (extended finite element method) for fatigue life prediction, and the fatigue performance of such designs is evaluated [6]. In addition, the fatigue strength of structural elements subjected to torsion is evaluated under various geometric and structural configurations, and design recommendations are developed to improve performance [7]. In these fatigue life prediction studies, loading conditions and geometry are considered geometrically and limited to models with fixed parameters. Factors such as manufacturing variations, heat treatment uncertainties, and the resulting changing material microstructure are often left out of the models.

Fuzzy logic is a mathematical framework that enables reasoning with uncertain, vague, or imprecise information, moving beyond traditional binary true/false logic. It is introduced by Lotfi A. Zadeh in 1965 and is characterized by degrees of truth represented as membership in fuzzy sets [8]. This approach allows for more nuanced decision making in various applications, including control systems and artificial intelligence [9,10,11,12]. While the studies carried out up to the present on the prediction of fatigue life by fuzzy logic method depend on load and load type (tensile and compression, bending and torsion) and material geometry or shape, there is not any attempt on the fuzzy-logic-method-related structure and properties of materials for assessment of fatigue life. Therefore, the fuzzy-logic-based prediction model proposed in this study aims to fill an important gap in the literature since it can directly model these uncertainties.

2. Materials and Methods

In this study, a fuzzy-logic-based decision support model is developed to predict the fatigue life of torque rods used in heavy vehicles more realistically. Material type (e.g., SAE 1040, 42CrMo4), surface hardness (HRC), maximum stress level (MPa), and type of heat treatment applied are considered as input parameters in the model. These parameters are defined with three-level fuzzy sets (low, medium, high) and a fuzzy inference system is developed in MATLAB R2023b environment with a rule base formed as IF-THEN. Triangular membership functions are used for each of the input parameters. The triangular membership function is a simple and easy-to-calculate method for describing the degree to which a variable belongs to a given fuzzy set. The function is defined by an origin, a peak, and an end point. Triangular membership functions are suitable for data that can be easily transformed into linguistic categories such as low, medium, and high. The decision structure of the model is specified by a rule base consisting of rules written in IF-THEN format. These rules decide whether the input parameters (material type, surface hardness, stress level, and type of heat treatment) fulfil a certain condition. Each input variable is assigned to fuzzy sets (low, medium, high, etc.) and inferences are made based on these sets. The Mamdani method is preferred in this study. In this method, rules and membership functions based on engineering judgment and expert knowledge are created using linguistic expressions (e.g., low, medium, high) for input variables. Mamdani offers a more flexible and intuitive modeling with linguistic rules. For engineering problems such as the fatigue life of a torque rod, rules defined with linguistic expressions provide more realistic and understandable results [13,14,15,16]. In the Sugeno method, outputs are usually determined by mathematical formulas. By providing a wider range of decisions, Mamdani improves both the accuracy and visualization of the model, leading to more reliable results [17,18,19]. Therefore, Mamdani is the more appropriate choice. Material type, surface hardness (HRC), and maximum stress level (MPa) are determined as input parameters. The material type is one of the most important factors determining the fatigue life of the torque rod. Each material has different microstructural properties, chemical composition, and mechanical behavior. Surface hardness defines the mechanical resistance of the outer surface of the torque rod and is directly related to wear resistance. The maximum stress level determines the limit at which the highest load on the torque rod can be carried by the material. Fatigue life is inversely proportional to the height of the stress level. The heat treatment applied in torque rod production directly improves the fatigue life of the material by affecting the grain size, hardness, and modulus of elasticity in the internal structure of the steel. The output parameter of the model is defined as the fatigue life (or fatigue strength) of the torque rod. The purpose of the model is to predict this output and obtain accurate results. In this study, fatigue life was categorized as follows: short (0–200,000 cycles), medium (200,000–500,000 cycles), and long (500,000–1,000,000 cycles) according to the original equipment manufacturers (OEM), who determine the ranges. This classification provides a practical understanding of expected component durability. The fatigue life of a material predicts how long the material will last under its configuration and operating conditions, and when fracture or wear will occur at the end of that time. However, fatigue tests are divided to two categories as high cycle fatigue (HCF) and low cycle fatigue (LCF) in material science. If the load applied to a sample is higher than the yield strength of the sample material, the test is low-cycle-fatigue. In a high-cycle-fatigue test, the stress is lower than that of the material.

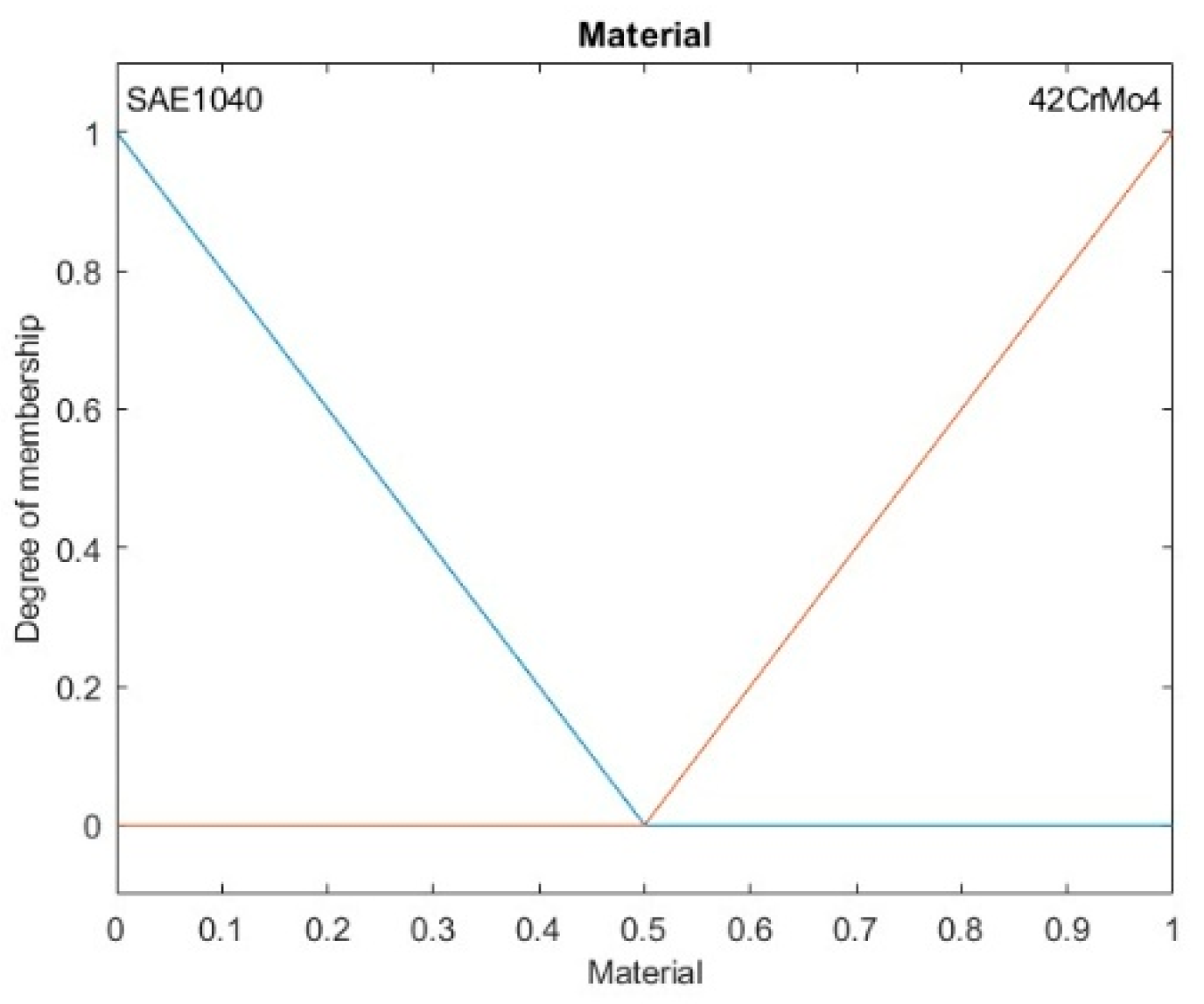

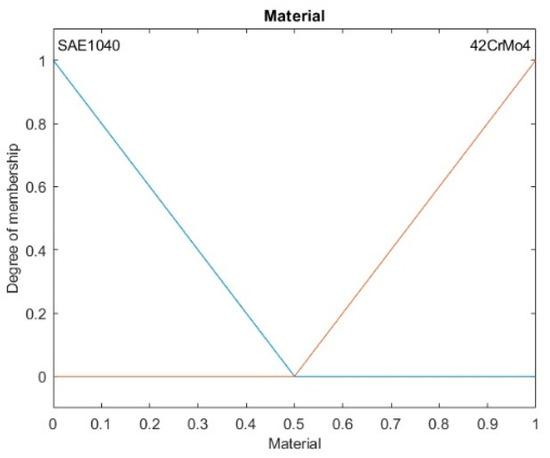

Line codes define an input variable named “Material”. It creates membership functions of this variable associated with two different material types. Thus, the system can interpret which material is used by looking at a value between 0 and 1, as shown in Figure 1.

Figure 1.

Membership function of “Material”.

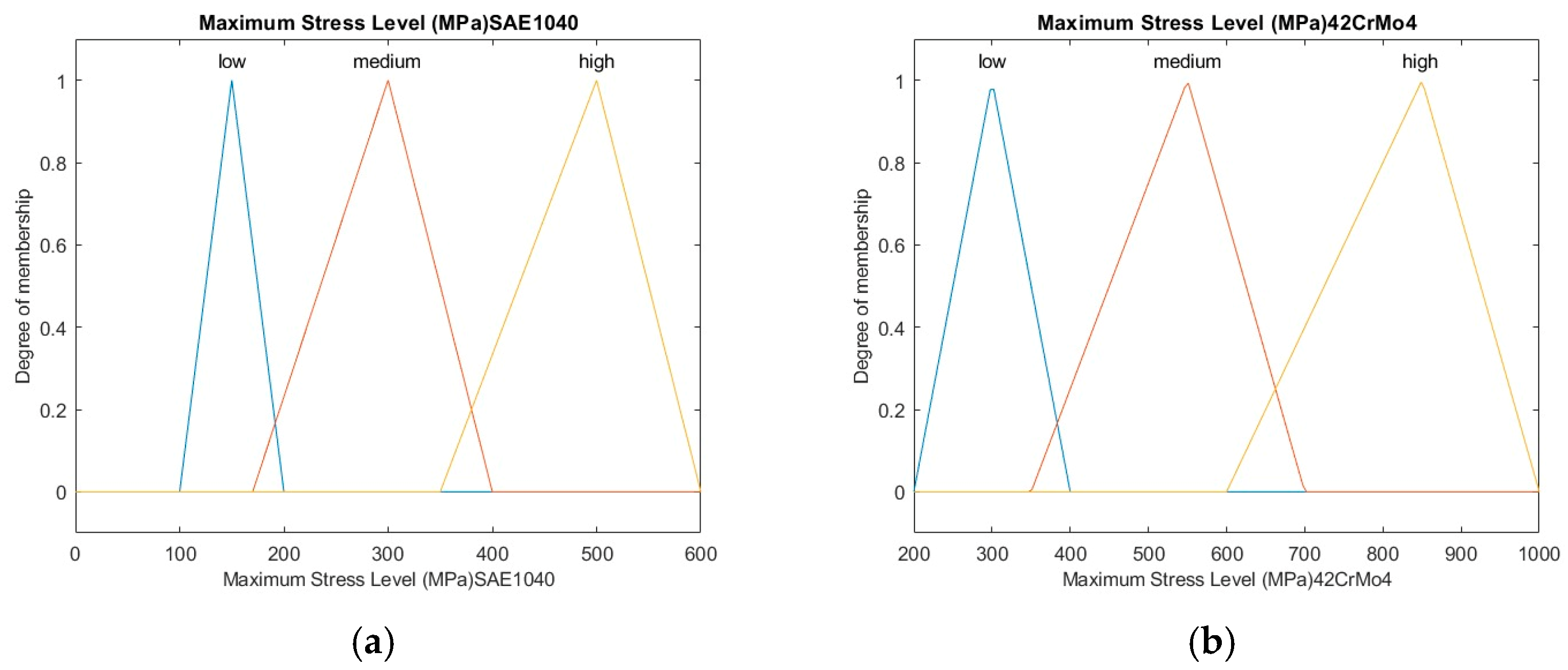

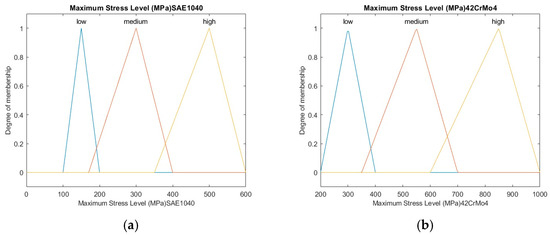

The maximum stress value for C40 (SAE1040) steel is defined as the input variable and evaluated in the range of 100–600 MPa. This value is categorized into “Low”, “Medium”, or “High” levels. The maximum stress value for 42CrMo4 (SAE4140) steel is defined as the input variable and evaluated in the range of 200–1000 MPa as well. This variable is divided into three levels as “Low”, “Medium”, and “High” using triangular membership functions. Related membership function graphs are given below, in Figure 2a,b.

Figure 2.

(a) Membership function of “SAE 1040” and (b) membership function of “42CrMo4”.

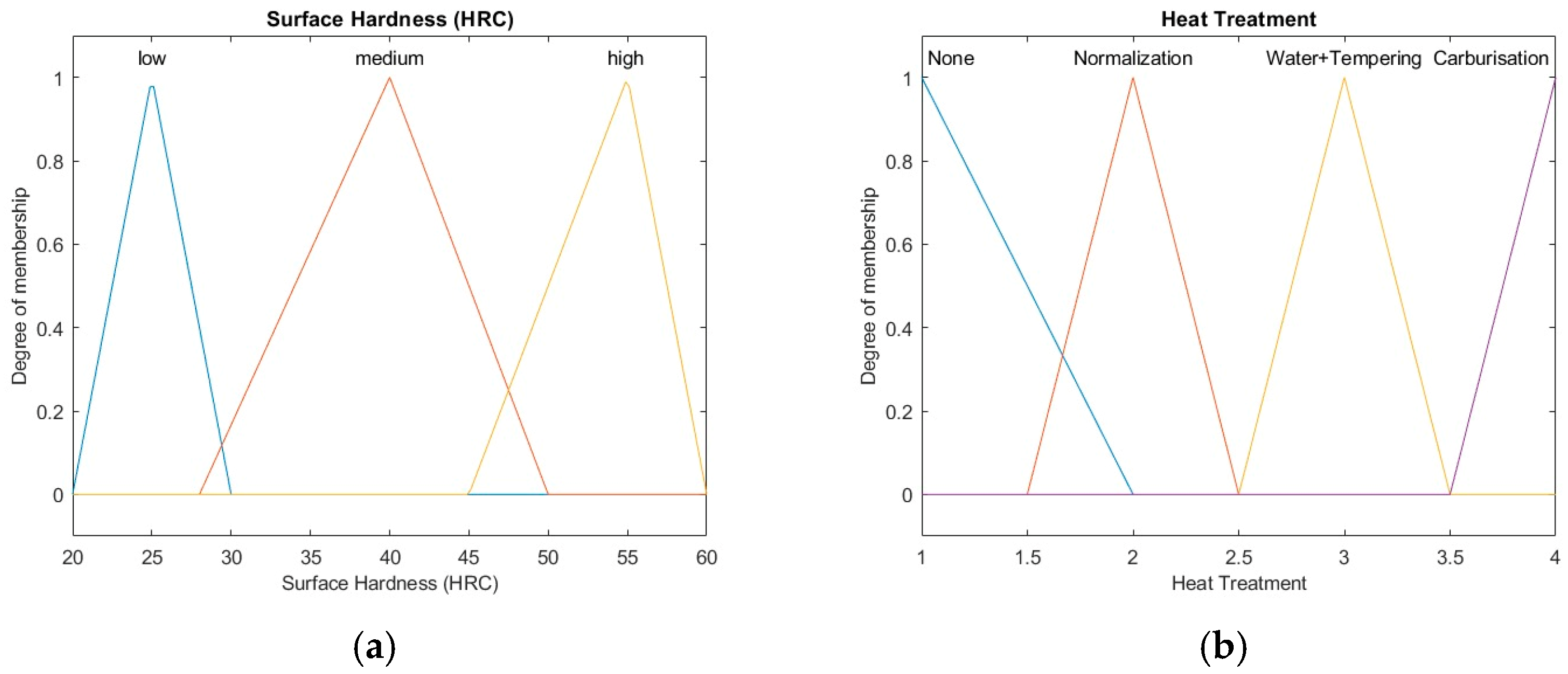

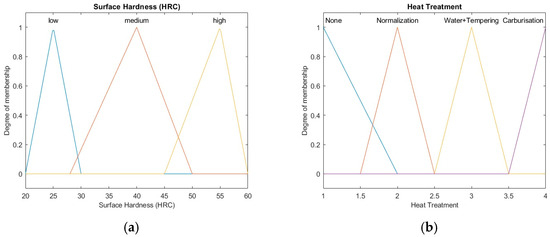

The surface hardness parameter of the torque rod is included in the system as an input variable defined in the range of 20–60 HRC. The type of heat treatment applied to the torque rod is defined as another input parameter. This variable is defined in the numerical range (1–4) and expressed by triangular membership functions for four different treatment types. “None” (1), ‘Normalization’ (2), ‘Quenching and tempering’ (3), and ‘Carburizing’ (4) processes are represented by separate fuzzy sets in the model. Images of the membership functions are shown, respectively, in Figure 3a,b.

Figure 3.

(a) Membership function of “Surface Hardness” (b) membership function of “Heat Treatment”.

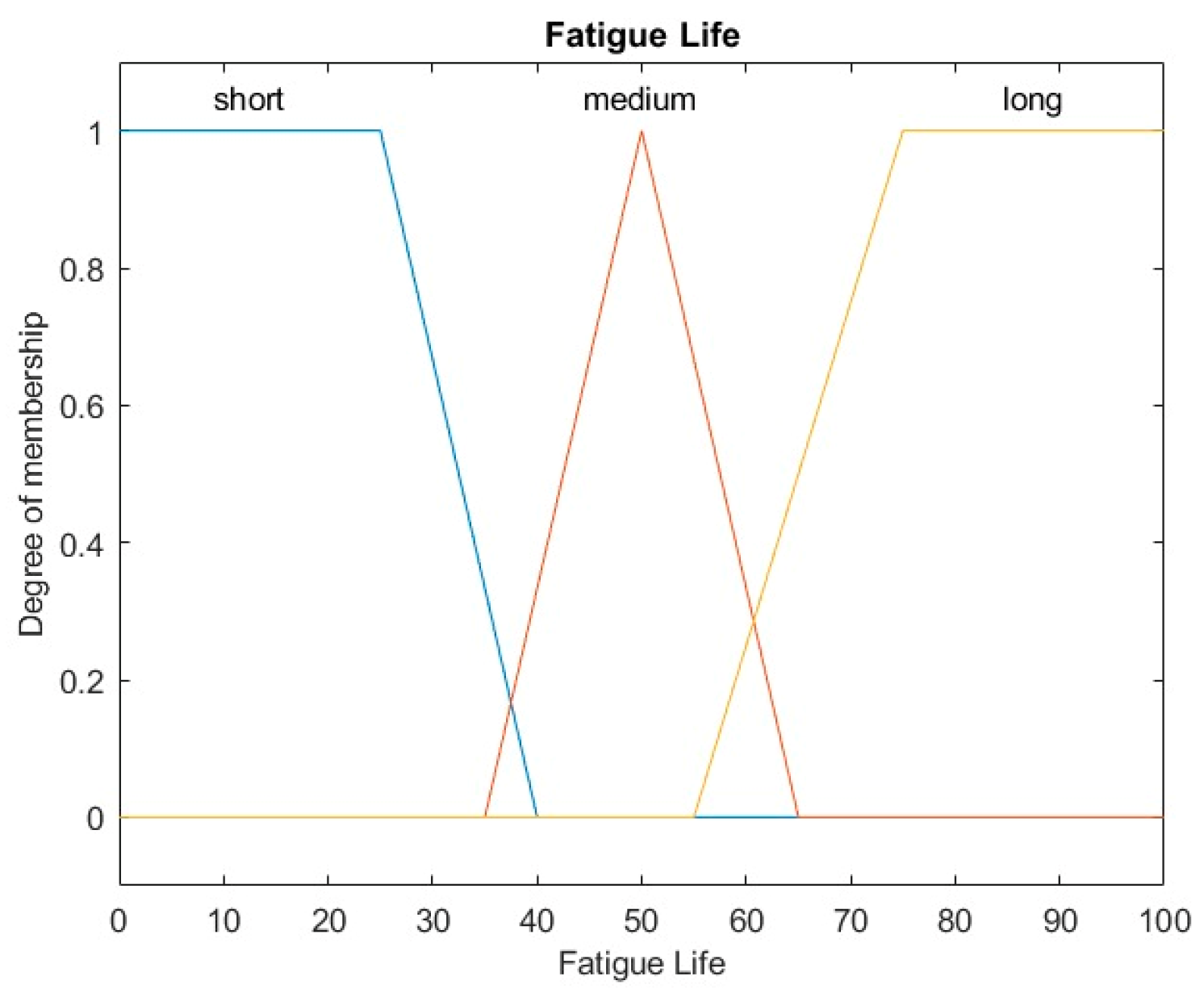

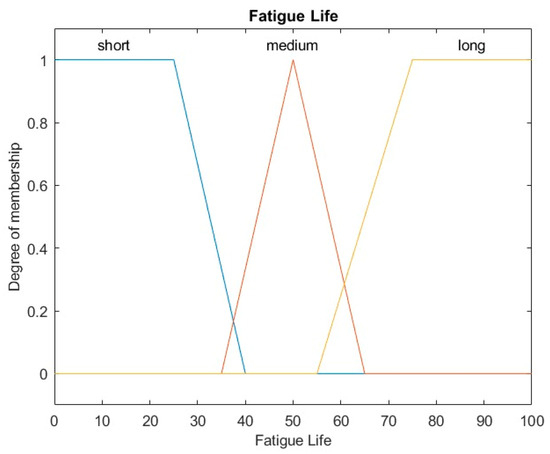

The output variable is the estimated fatigue life of the torque rod and is defined in the range of (0–100). The fatigue life is classified in three different levels: “Short”, “Medium”, and “Long”. The range (0–40) is used for “Short” life, the range (35–65) for “Medium” life, and the range (60–100) for “Long” life. This structure gives smoothness and flexibility in the transition regions to provide a more precise estimation of lifetime. A fatigue life membership function graph is illustrated in Figure 4.

Figure 4.

Membership function of “Fatigue Life”.

Membership functions are defined to overlap, taking into account the transitivity of the value ranges. This makes the defuzzification process more flexible and realistic. The decision mechanism of the model is built with a rule base consisting of rules in the IF-THEN format. Each rule produces an output corresponding to certain combinations of input variables. The rules in the defined ruleList matrix are added to the fuzzy inference system (FIS) through the addRule function. The rules are activated by adding the priority coefficient and “AND” logic parameters at the end of each rule.

3. Results and Discussion

In this study, a fuzzy-logic-based model was developed to estimate the fatigue life of torque arms used in heavy-duty vehicles. The model takes into account four main input parameters: material type, maximum stress level, surface hardness, and applied heat treatment. These inputs were combined using a rule base created with engineering knowledge, allowing the system to deal with uncertainties that are often present in real-world manufacturing and service conditions.

A Mamdani-type fuzzy inference system was used in the model. All input parameters were represented by triangular membership functions at three levels (low, medium, high), and the output—fatigue life—was classified as short, medium, or long. The rules connecting the inputs to the output were designed based on expert judgment.

At the time of developing this model, no experimental fatigue data were available. However, the system was intentionally built to be ready for future updates once real fatigue test results become accessible. For now, it provides a theoretical base that can be used during the early stages of design or material selection where experimental data might not yet be available.

In the future, the model will be improved by comparing its results with actual fatigue test data and field results from components in service. These comparisons will help fine-tune the membership functions and rule weights, increasing the model’s accuracy and practical value.

4. Conclusions

The fuzzy logic model presented in this study provides an effective approach to predicting the fatigue life of torque arms under varying and uncertain conditions. It addresses limitations of traditional methods by incorporating expert engineering knowledge and handling uncertainties in input parameters. Studies on fatigue life prediction using fuzzy logic are limited to material geometry and load. However, this study has shown that the fuzzy logic method can also be employed if the material structure and properties that affect fatigue life are used as input.

Future work will focus on validating the model with experimental data and refining membership functions and rule weights for enhanced accuracy.

Author Contributions

Conceptualization, M.A.; methodology, C.B. and F.D.; software, C.B.; validation, C.B., M.A. and F.D.; formal analysis, C.B., M.A. and F.D.; investigation, C.B. and F.D.; resources, C.B. and F.D.; data curation, C.B.; writing-original draft preparation, C.B. and F.D.; visualition, C.B.; supervision, F.D.; project administration, C.B. All authors have accepted responsibility for the entire content of this manuscript and consented to it submission to the journal, reviewed all the results, and approved the final version of the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external fundings.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are obtained in the article.

Acknowledgments

This research was carried out thanks to the ACV Suspension Systems.

Conflicts of Interest

R&D Center, ACV Suspension Systems Company has no commercial conflict of interest.

References

- Yarrow, N.S.; Milburn, N.F.; Burgess, M.J. Vehicle Suspension Torque Arm Assembly. U.S. Patent 5509684A, 21 August 1995. [Google Scholar]

- Raider, J.E. Heavy Vehicle Suspension with Unitized Narrow Profile Bolster Beam Hanger Assembly and Outboard Spring Mount. U.S. Patent 4718692, 7 October 1986. [Google Scholar]

- Sampson, D.J.M.; Cebon, D. Achievable Roll Stability of Heavy Road Vehicles. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2003, 217, 269–287. [Google Scholar] [CrossRef]

- Vu, V.T.; Sename, O.; Dugard, L.; Gáspár, P. Enhancing Roll Stability of Heavy Vehicle by LQR Active Anti-Roll Bar Control Using Electronic Servo-Valve Hydraulic Actuators. Veh. Syst. Dyn. 2017, 55, 1405–1429. [Google Scholar] [CrossRef]

- Duraisivam, S.; Suresh, P.; Saravanan, A.; Jamuna, E. Static, fatigue and dynamic analysis of automobile torque arm using FEM. AIP Conf. Proc. 2021, 2408, 020012. [Google Scholar] [CrossRef]

- Raičević, N.; Grbović, A.; Kastratović, G.; Vidanović, N.; Sedmak, A. Fatigue life prediction of topologically optimized torque link adjusted for additive manufacturing. Int. J. Fatigue 2023, 176, 107907. [Google Scholar] [CrossRef]

- Yan, S.; Tao, F.; Jia, C.; Liu, G. Fatigue Life Prediction and Structural Optimization on Torsion Shaft of Tracked Vehicle, In Proceedings of the 2017 7th International Conference on Manufacturing Science and Engineering (ICMSE 2017), Zhuhai, China, 11–12 March 2017. [CrossRef][Green Version]

- Zadeh, L.A. Fuzzy Sets. Information and Control 1965, 8, 338–353. [Google Scholar] [CrossRef]

- Swathi, M. Fuzzy Logic. Int. J. Innov. Res. Inf. Secur. 2023, 9, 147–152. [Google Scholar] [CrossRef]

- Chrysafiadi, K. Comparative Discussion. In Fuzzy Logic-Based Software Systems. Learning and Analytics in Intelligent Systems; Springer: Cham, Switzerland, 2023; Volume 34, pp. 131–139. [Google Scholar] [CrossRef]

- Fletcher, K.F.B. Fuzzy Logic and Markov Kernels. arXiv 2023, arXiv:2303.03725. [Google Scholar] [CrossRef]

- Chrysafiadi, K. Fuzzy Logic. In Fuzzy Logic-Based Software Systems. Learning and Analytics in Intelligent Systems; Springer: Cham, Switzerland, 2023; Volume 34, pp. 2–24. [Google Scholar] [CrossRef]

- Tri, N.M.; Khoat, N.N. Research on a Sugeno Fuzzy Logic Controller Compared to a Mamdani-Based PI-Type Fuzzy Logic Inference Model. Univ. Danang—J. Sci. Technol. 2022, 20, 57–62. [Google Scholar] [CrossRef]

- Firdausy, M.A.; Utami, E.; Hartanto, A.D. Comparison Analysis of Fuzzy Sugeno & Fuzzy Mamdani for Household Lights. In Proceeding of the International Conference on Information Science and Technology Innovation (ICoSTEC), Batam, Indonesia, 3–4 February 2022; pp. 30–34. [Google Scholar]

- Zhong, F.; Zhong, Y.-N. Application Research of Mamdani and Sugeno Type Fuzzy Inference. J. Hubei Univ. Technol. 2005, 20, 28–30. Available online: https://wk.baidu.com/view/b1f58766be23482fb4da4c6c (accessed on 5 September 2025). (In Chinese).

- Marbun, M. Analysis of Application of Fuzzy Grid Partition on Mamdani Method Fuzzy Inference System. JUSIKOM PRIMA 2022, 6, 68–74. [Google Scholar] [CrossRef]

- Uppalapati, S.; Kaur, D. Design and Implementation of a Mamdani Fuzzy Inference System on an FPGA. In Proceedings of the NAFIPS 2009—2009 Annual Meeting of the North American Fuzzy Information Processing Society, Cincinnati, OH, USA, 14–17 June 2009; pp. 1–6. [Google Scholar] [CrossRef]

- Hamzah, M.H.M.; Thamrin, N.M.; Tajjudin, M. Robotic Arm Position Control Using Mamdani Fuzzy Logic on Arduino Microcontroller. J. Mech. Eng. 2022, 19, 235–255. [Google Scholar] [CrossRef]

- Kizito, A.E.; Ojei, E.; Okpor, M.D. A Fuzzy Logic-Based Automobile Fault Detection System Using Mamdani Algorithm. Int. J. Sci. Res. Manag. 2024, 12, 1081–1093. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).