Abstract

Construction projects face growing public environmental awareness, a shortage of skilled workers, and increasingly stringent legal regulations. Although construction technologies are advancing, construction progress management remains context-dependent, involving a complex construction process with numerous variables and uncertainties. Therefore, an effective management model is necessary to control construction progress. By applying statistical methods, we enhanced the efficiency and accuracy of construction progress management. By utilizing artificial intelligence and big data analytics, we established a management program that empowers construction management teams to predict construction progress conveniently, manage human resources effectively, identify risk management issues, and control costs. The program improves the success rate of on-time project completion and the efficient use of resources.

1. Introduction

Recent construction projects have faced the pressure of public environmental awareness, a shortage of human resources, and stringent laws and regulations. Despite the continuous advancement of construction technology, construction progress management still depends on a complex construction process full of variables and uncertainties. Therefore, an effective management model is needed to control the construction progress.

In this study, we developed a management program so that the construction management team conveniently predicts the construction progress, effectively manages manpower, identifies risks, and controls costs. Cloud computing and big data analytics were employed in the program to improve the efficiency and accuracy of construction progress management. The program increases the success rate of on-schedule completion of the project and the efficiency of effective resource utilization.

2. Literature Review

As the construction industry advances toward digital transformation, cloud computing technologies have emerged as essential tools for enhancing construction progress management. A growing body of literature highlights the practical advantages of cloud platforms, including real-time data transmission, remote collaboration, and centralized information integration.

In addition to allowing real-time review and export of results into standardized forms required by the client, the system can also connect to a cloud database for big data analysis. Users can view statistical reports on mobile devices to stay updated on the latest site progress, quality, and occupational safety and health management information [1]. With the advancement and maturation of cloud technology and mobile devices, industries have been promoting e-commerce platforms and adopting information technology to integrate large volumes of data. This emerging trend is having an increasingly significant impact on various sectors, including the construction industry [2]. The rapid advancements in digital technology for data processing have made big data an indispensable part of various research fields [3]. In the construction industry, information technology has become a key factor influencing the core competitiveness of construction enterprises [4].

In summary, the adoption of cloud technology in the construction sector has been shown to improve the timeliness and accuracy of data while enhancing cross-functional collaboration and progress monitoring. Looking forward, the integration of statistical analysis and artificial intelligence (AI) is expected to further advance the predictive capabilities and decision-making effectiveness of progress management systems.

3. Research Methods

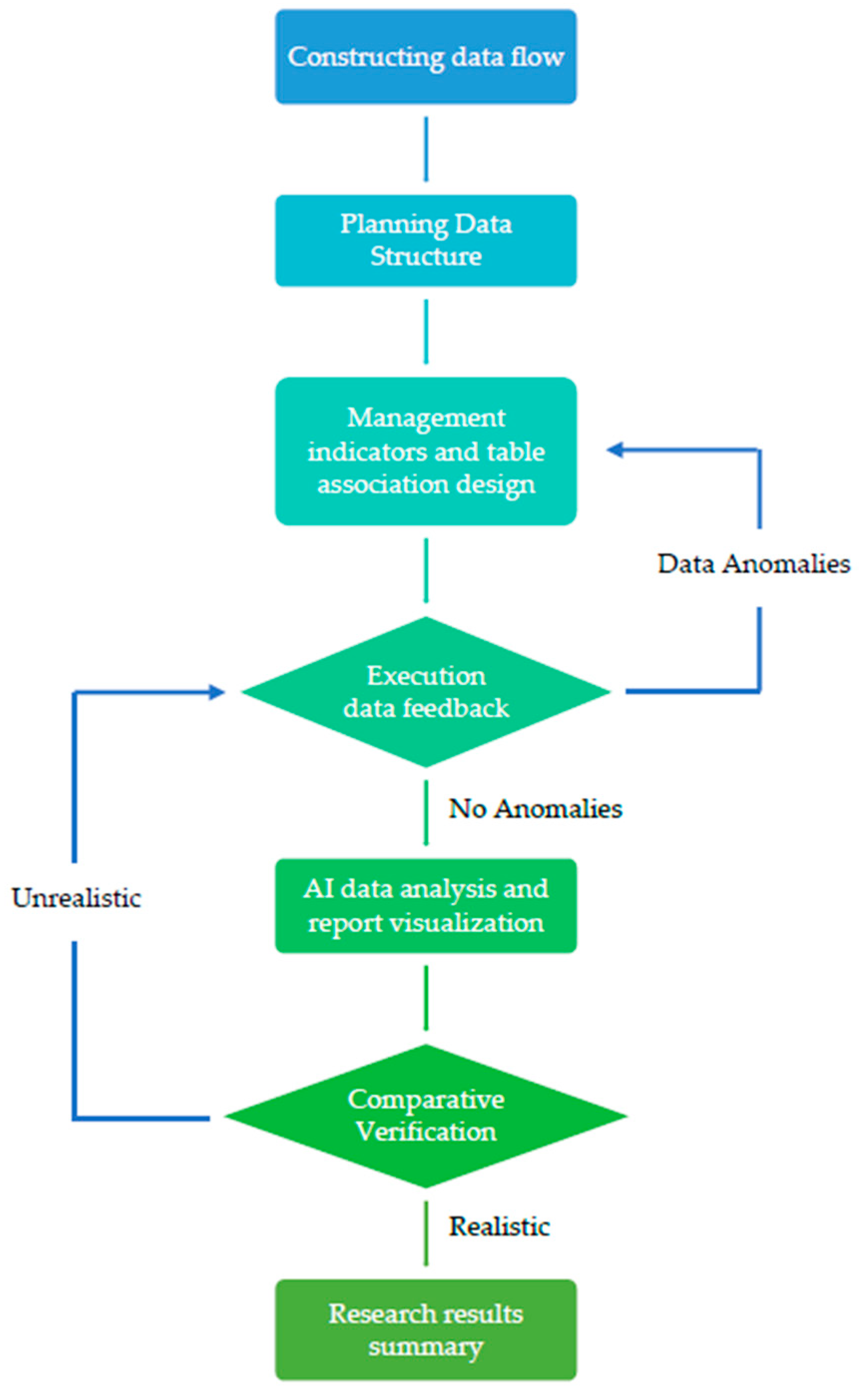

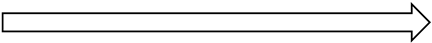

We employed cloud-based spreadsheets. The developed program includes the construction of a data flow process, the design of a data structure for management indicators, and the incorporation of feedback from the execution team (Figure 1). Data is analyzed and compared with that in real-world conditions to evaluate the system’s practicality and effectiveness in site management.

Figure 1.

Research flow in this study.

3.1. Data Flow

The data process comprises four stages (Table 1): planning spreadsheet fields, onsite data entry by the execution team, automatic data aggregation by the cloud system, and visual dashboard generation through statistical analysis. This structure emphasizes real-time reporting and seamless data application to enable a practical and streamlined approach to construction data management.

Table 1.

Data collection and analysis process.

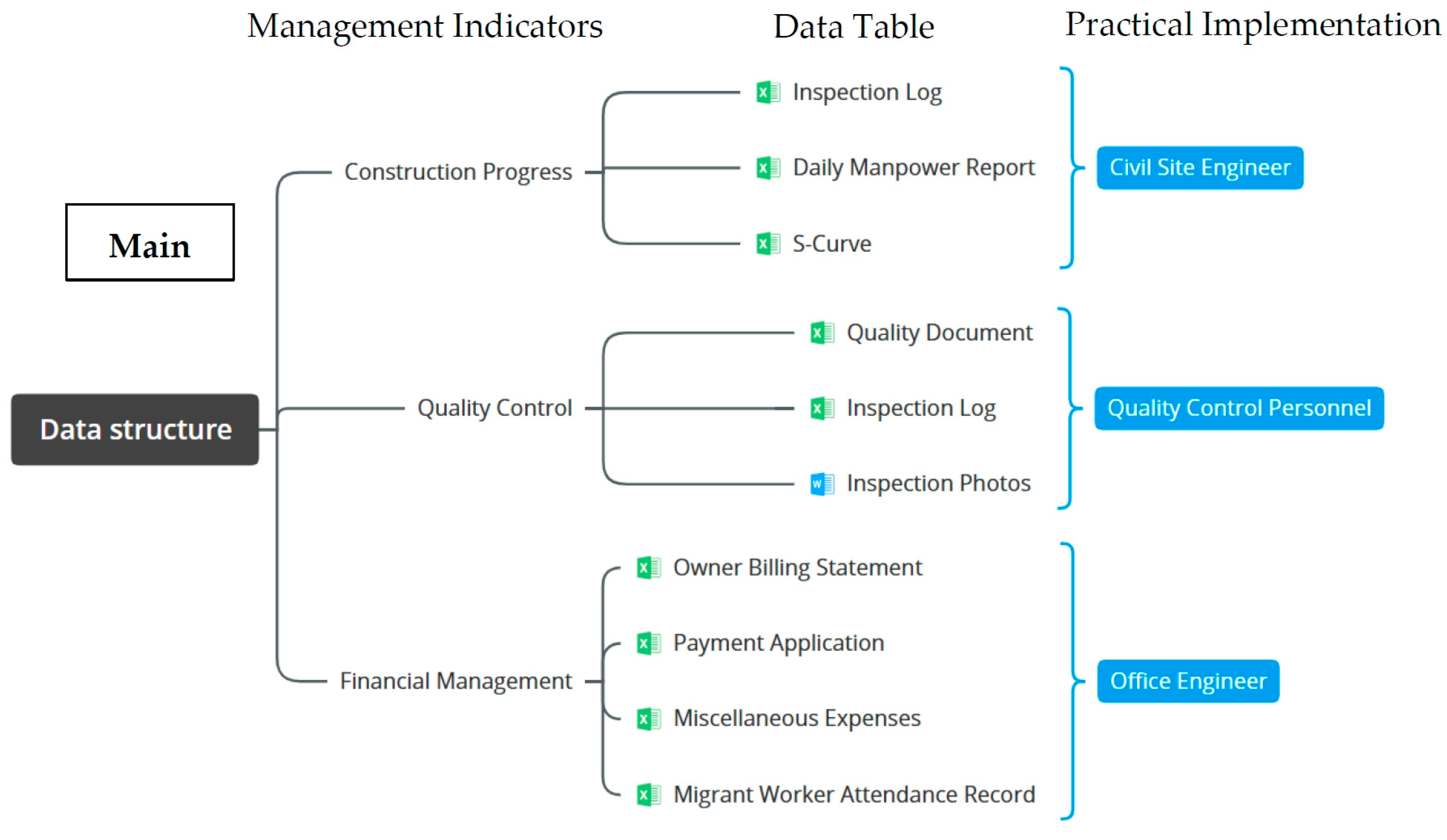

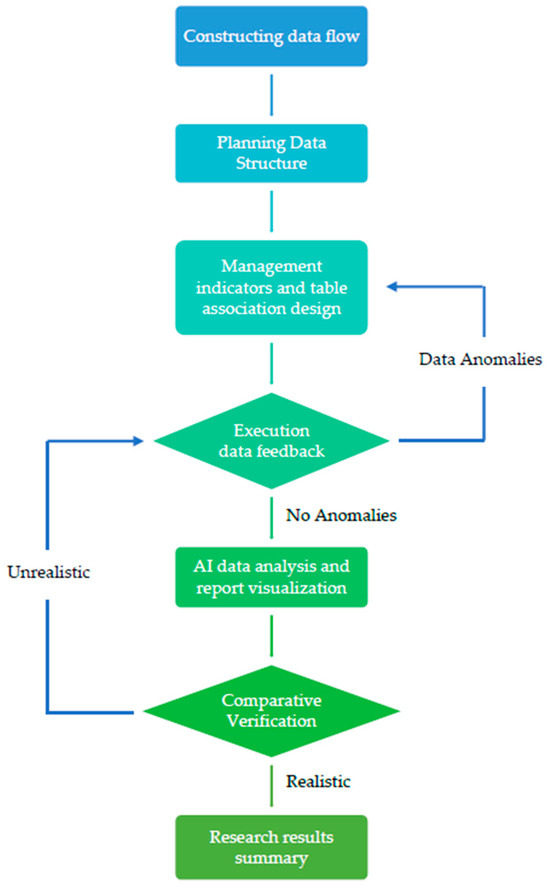

3.2. Data Structure

Responsibilities between data feedback and the execution team are clarified to ensure the timeliness and authenticity of submitted data and strengthen the basis for management decisions. Reliable, analytically valuable data are efficiently collected (Figure 2).

Figure 2.

Data structure.

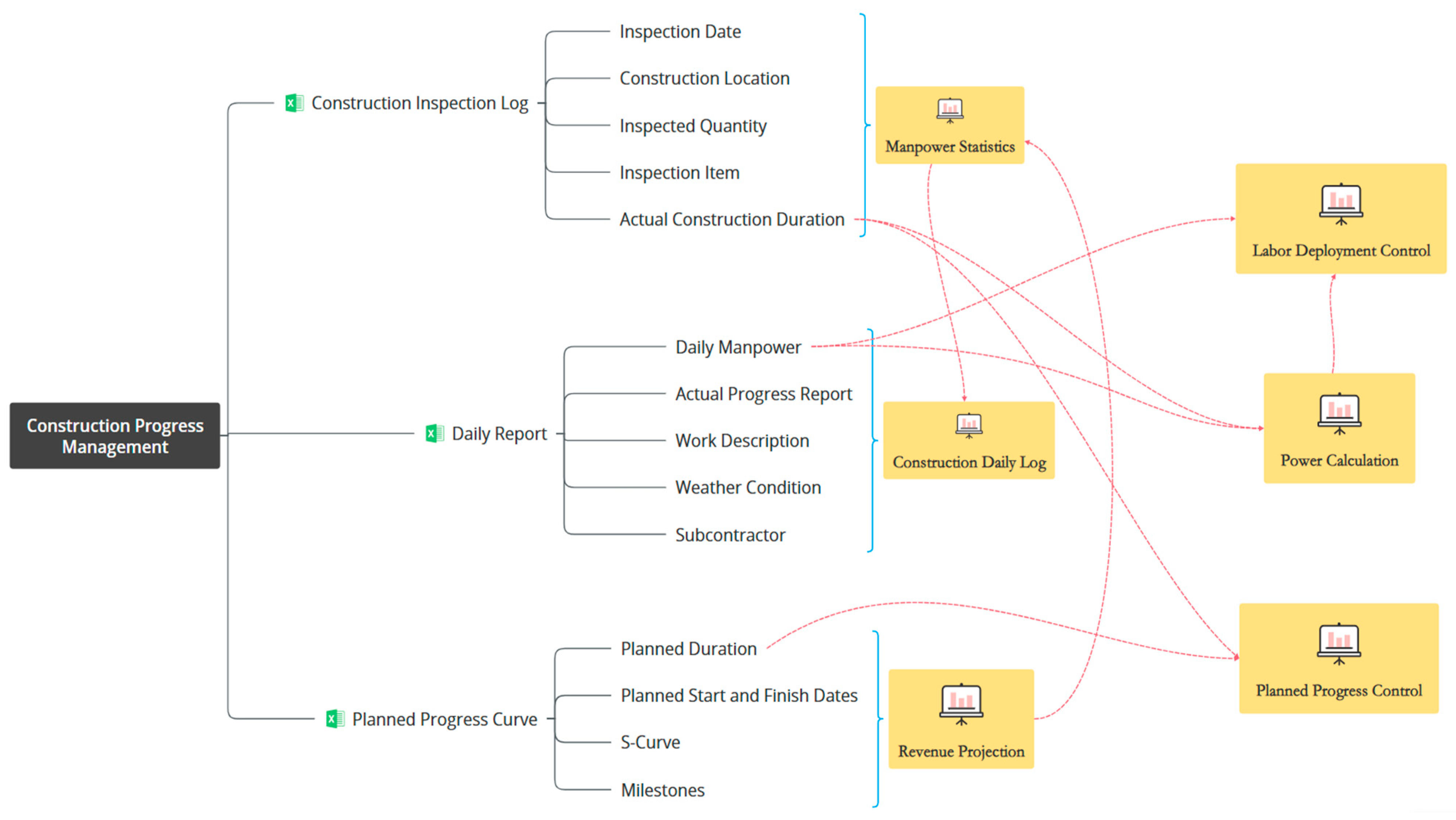

3.3. Indicator Correlation

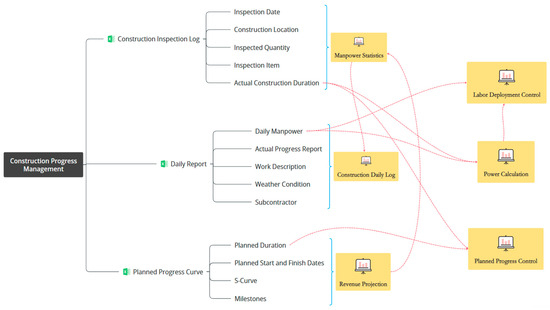

Based on required field operations and progress management practices, we identified six key progress management indicators: construction diary, labor control, productivity analysis, actual vs. planned progress, and financial management (Figure 3). These indicators are mapped to their corresponding spreadsheets for integrated tracking.

Figure 3.

Indicator correlation diagram.

3.4. Data Feedback Mechanism

The program was designed with the principle: “easy for the field to input, valuable for management to analyze.” Clearly defined data fields reduce error rates in field entry, with immediate synchronization to a cloud database. Integration with Power BI enables real-time analytical visualization.

3.5. Data Analysis and Comparison

Collected data (e.g., floor level of completed rebar inspections or formwork layout status) were compared with actual onsite construction progress to confirm consistency and detect discrepancies.

4. Results

Case Study

The “Design-Build Project of the Smart Public Housing (Phase I) in Qianzhen Asia Bay” comprises a 14-story building above ground and 2 basement levels, offering a total of 643 social housing units. The Asia Bay social housing project incorporates a range of advanced engineering practices, including the establishment of a 5G AIoT digital governance platform, environment, social, and governance (ESG) initiatives, disaster mitigation technologies, and intelligent construction management for occupational safety and health. The project management information system (PMIS) and enterprise resource planning (ERP) construction management system were used to actively track and manage various tasks through a centralized platform and ensure the safety of construction personnel and the execution of construction progress under the planned schedule.

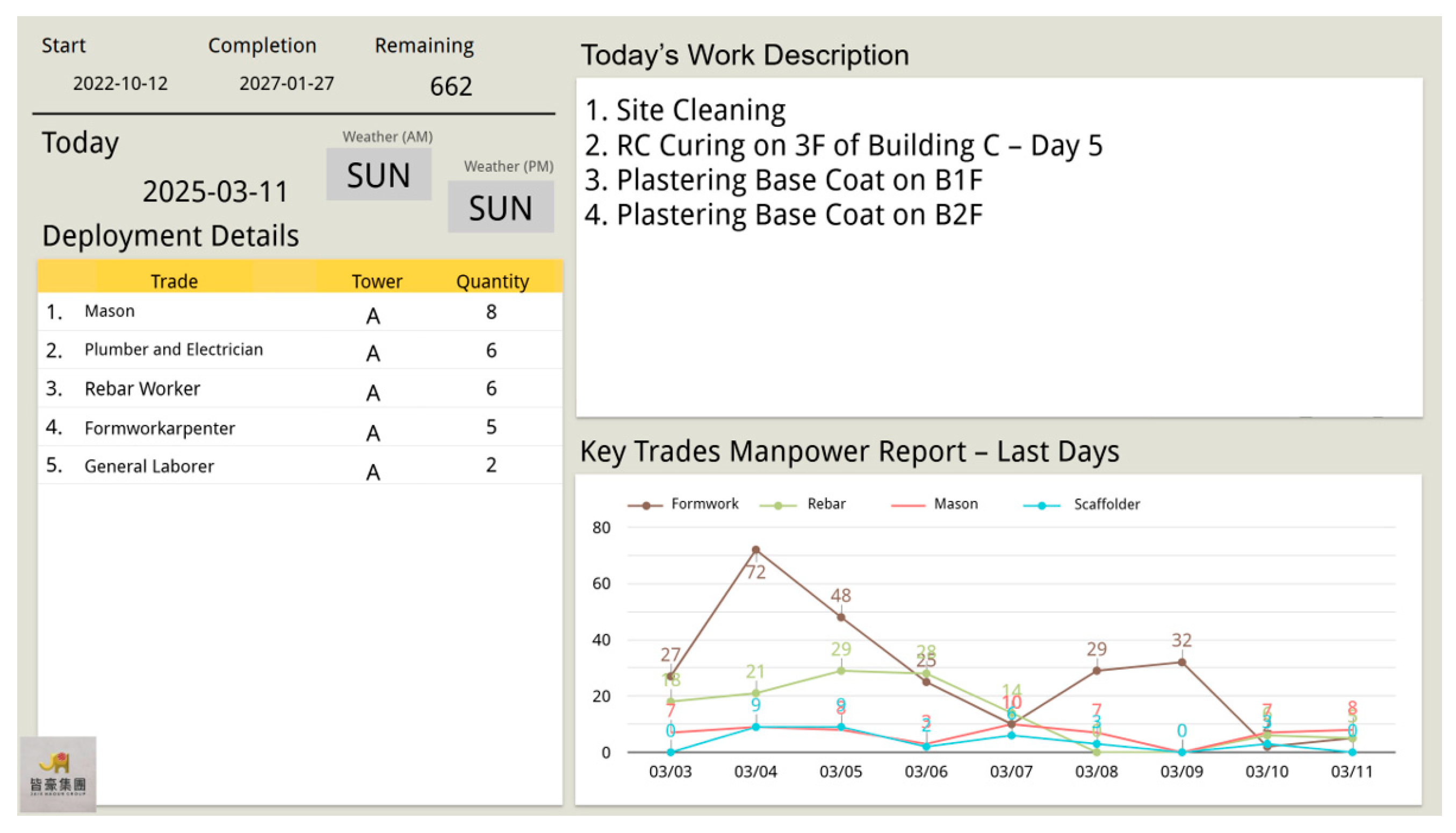

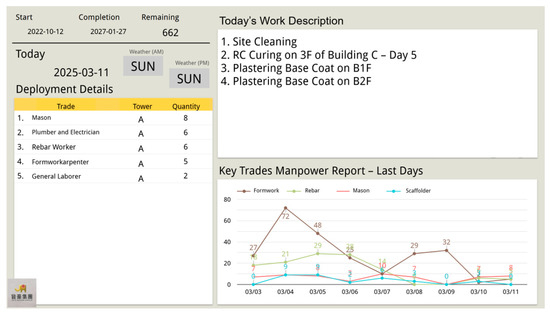

We collected daily statistical data from the construction site and stored them in the construction log (Table 2). Through toolbox meetings in the morning and closing meetings in the afternoon, we reviewed the day’s construction progress with work partners, suppliers, and supervision units to ensure that the daily construction progress was executed according to plan. The data table design needs to have a definition of columns and concise content so that the executor can fill in the form simply and clearly, and more accurate information can be collected by reducing vague words.

Table 2.

Quantity records.

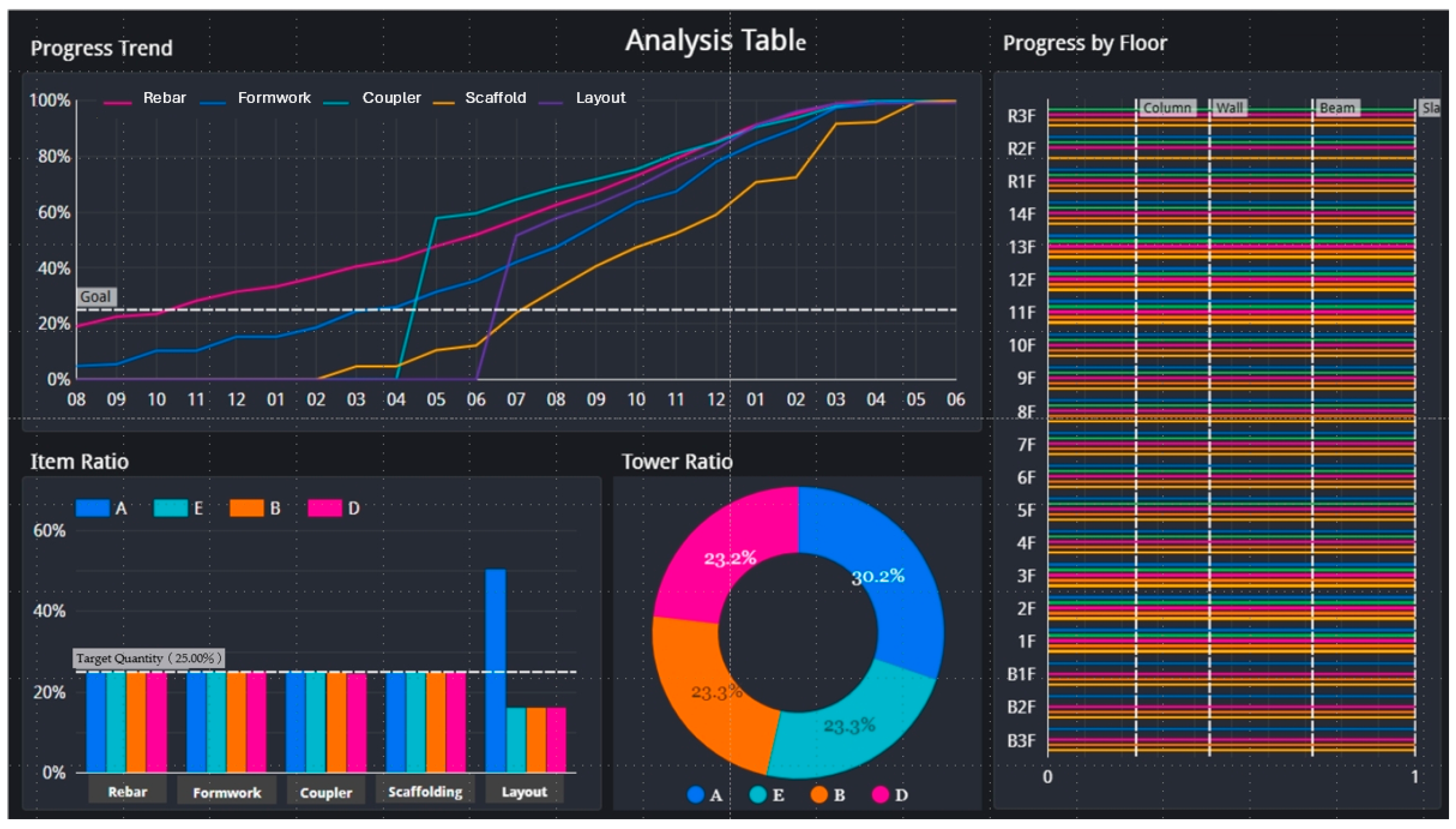

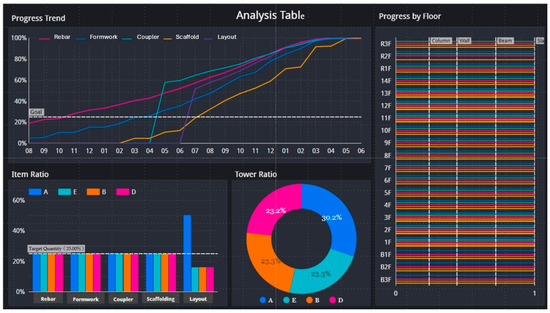

To verify the accuracy of the data, the system output results were compared with the on-site progress to confirm the consistency of the execution data with the current situation (Table 3). The comparison results serve as the basis for the calibration of future forecasting models and decision-making (Figure 4 and Figure 5).

Table 3.

Progress control report.

Figure 4.

Work rate analysis.

Figure 5.

Daily work analysis.

5. Conclusions

A progress verification program was developed in this study for data inspection to effectively identify potential construction risks and deviations. The program was applied to the “New Turnkey Project of Yawan Smart Public Housing (Phase I) in Qianzhen District, Kaohsiung City”. The results offered evidence to ensure the project completion on time and meet quality standards. Although construction work is still ongoing, the current case study and practical applications have been integrated into construction management. Cloud-based spreadsheet tools and statistical analysis methods were introduced, utilizing software such as Microsoft Forms, Excel Online, Google Sheets, and Power BI. These tools enhance the immediacy of information feedback and the consistency of management practices, assisting turnkey contractors in swiftly understanding the current conditions of the construction site, thereby enabling precise management and resource allocation.

Using cloud-based spreadsheet tools and statistical analysis methods, a construction progress management program showed its effectiveness and timeliness, accuracy, and practicality. It is necessary to collect and compile engineering management data and apply cloud computing and big data analytics to improve the efficiency and accuracy of construction progress management. The management program enables turnkey contractors to effectively predict construction progress, manage manpower, identify risks, and control costs, ultimately enhancing the success rate of on-schedule project completion and the efficiency of resource utilization.

Author Contributions

Conceptualization, C.-F.C. and H.-H.L.; methodology, C.-F.C.; software, C.-F.C.; validation, C.-F.C.; formal analysis, C.-F.C.; investigation, C.-F.C.; resources, C.-F.C.; data curation, C.-F.C.; writing—original draft preparation, C.-F.C.; writing—review and editing, H.-H.L.; visualization, C.-F.C.; supervision, H.-H.L.; project administration, C.-F.C.; funding acquisition, C.-F.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are not publicly available due to internal company restrictions.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Chen, Y.-T.; Chung, T.-H. Using Cloud Technology for Construction Mobile Device Inspection and Big Data Statistics. China Civ. Eng. J. 2022, 34, 479–488. [Google Scholar] [CrossRef]

- Hsu, M.-S. Systems Analysis and Design to Construction Project Scheduling Management System. Master’s Thesis, National Yunlin University of Science and Technology, Yunlin, Taiwan, 15 July 2016. [Google Scholar]

- Munawar, H.S.; Ullah, F.; Qayyum, S.; Shahzad, D. Big Data in Construction: Current Applications and Future Opportunities. Big Data Cogn. Computing. 2022, 6, 18. [Google Scholar] [CrossRef]

- Pei, L. Application of Big Data Technology in Construction Organization and Management of Engineering Projects. In Proceedings of the 3rd International Symposium on Big Data and Applied Statistics, Kunming, China, 10–12 July 2020; p. 012002. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).