Comparative Analysis of Modern Robotic Demining Complexes and Development of an Automated Mission Planning Algorithm †

Abstract

1. Introduction

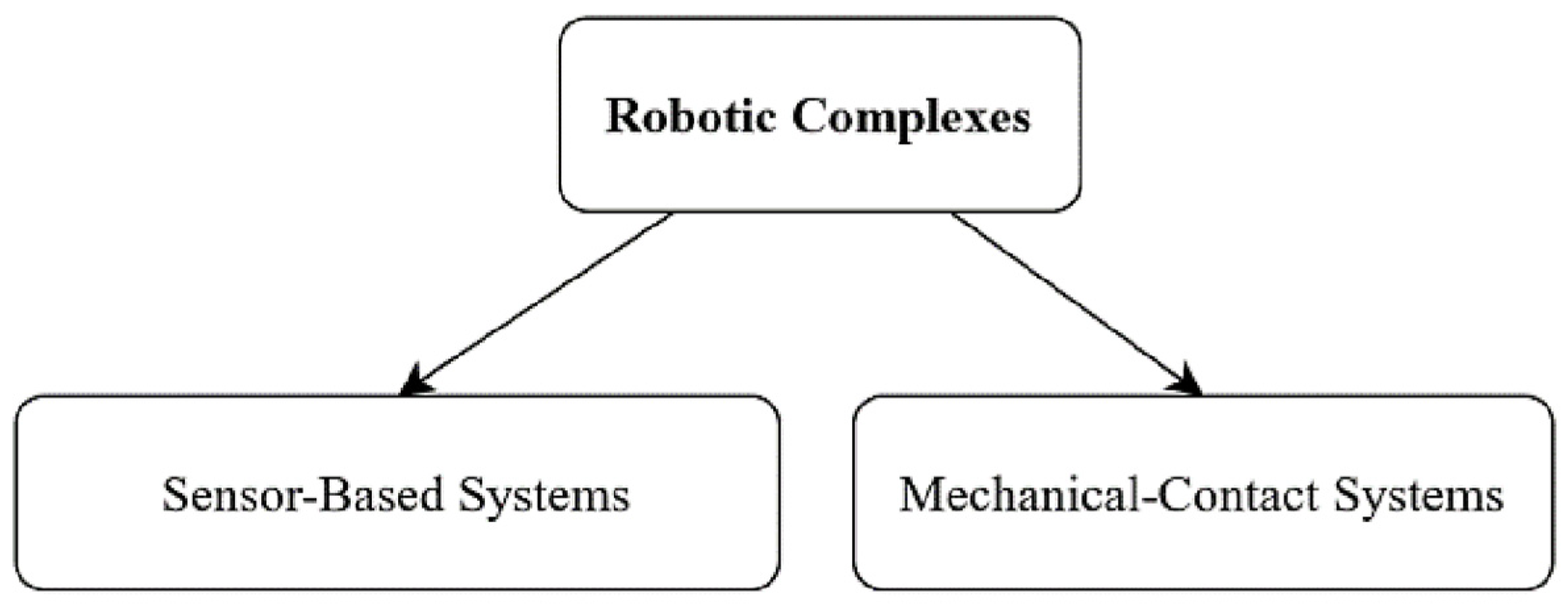

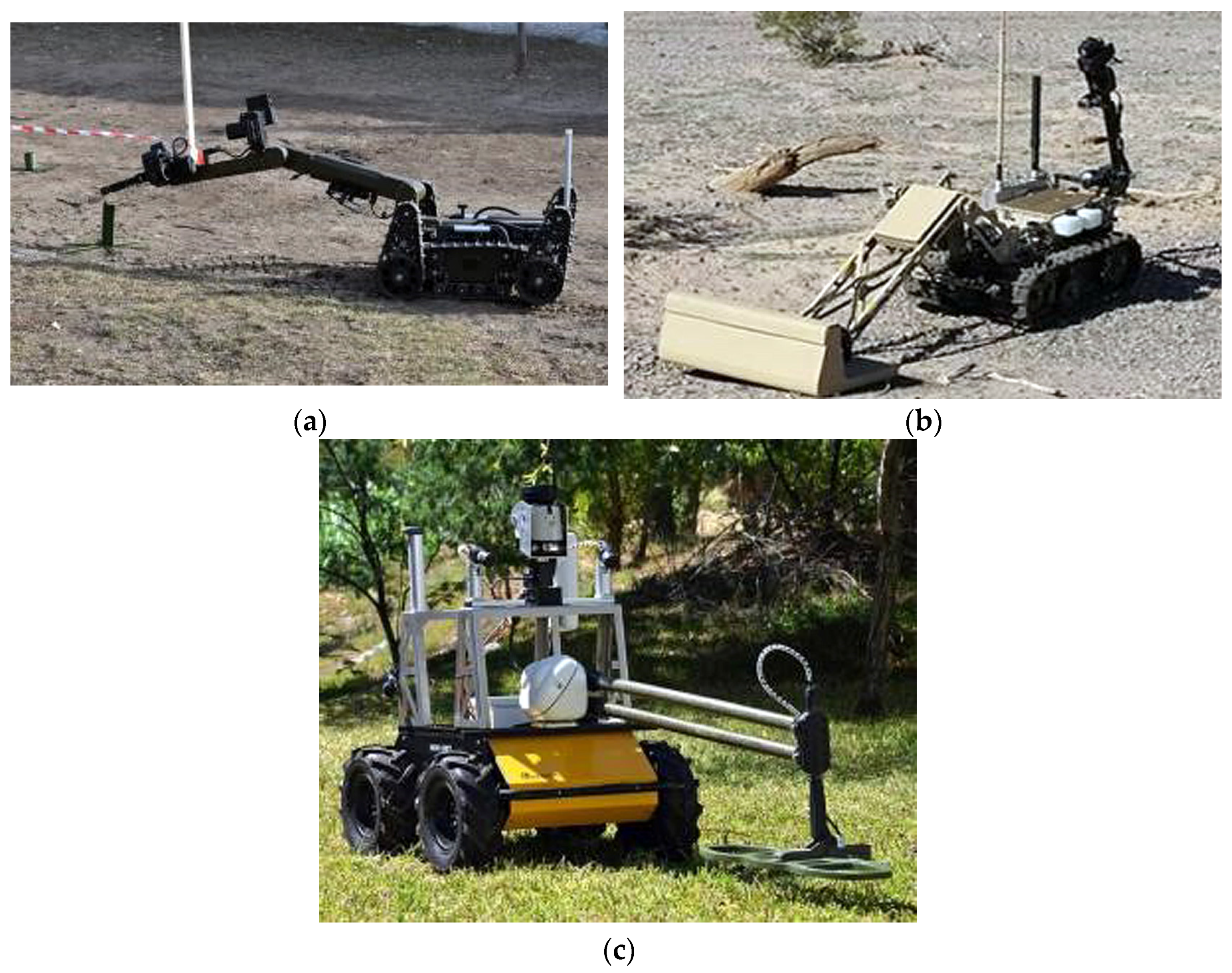

2. Materials and Methods

3. Results and Discussion

- -

- The LiDAR generates a point cloud of the surface;

- -

- The RGB/IR camera extracts texture and thermal features;

- -

- The PI frame records electromagnetic disturbances from metallic inclusions;

- -

- The microwave horn induces a short-term thermal response, enhancing the contrast of non-metallic casings.

- -

- 0.80 for humanitarian mode (to minimize false-positive rates, FPR);

- -

- 0.60 for accelerated military breaching (to maximize throughput).

- -

- Reduced sensitivity of the pulsed-induction channel in wet, clay-rich soils (water content > 25%).

- -

- Increased power consumption of the microwave module during prolonged continuous operation.

- -

- GNSS navigation degradation under dense vegetation.

- -

- Integration of local UWB positioning.

- -

- An adaptive timing algorithm for microwave pulses to reduce average radiation power.

4. Conclusions

- -

- Humanitarian operations (expected TPR ≥ 0.95, FPR ≤ 0.05);

- -

- High-throughput breaching (planned ), thus minimizing the traditional trade-off between localization accuracy and clearance speed.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AI | Artificial Intelligence |

| CFD | Computational Fluid Dynamics |

| EO/IR | Electro-Optical/Infrared |

| EOD | Explosive Ordnance Disposal |

| FPR | False Positive Rate |

| GPR | Ground-Penetrating Radar |

| GNSS | Global Navigation Satellite System |

| IMAS | International Mine Action Standards |

| INS | Inertial Navigation System |

| LiDAR | Light Detection and Ranging |

| MICLIC | Mine Clearing Line Charge |

| PI | Pulsed Induction |

| RGB | Red–Green–Blue (camera channel) |

| RANSAC | Random Sample Consensus |

| SLAM | Simultaneous Localization and Mapping |

| TPR | True Positive Rate |

| UAV | Unmanned Aerial Vehicle |

| UGV | Unmanned Ground Vehicle |

| UWB | Ultra-Wideband |

References

- United Nations Mine Action Service. Annual Report. Available online: https://www.unmas.org (accessed on 3 April 2025).

- Armtrac Ltd. Mine-Clearance Machines. Available online: https://armtrac.net/mine-clearance-equipment-uk/mine-clearance-machines/ (accessed on 3 April 2025).

- First Combat Use of the “Passage-1” Robotic Mine-Clearance Complex Recorded in Donbas. Available online: https://vpk.name/en/616794 (accessed on 3 April 2025).

- Korendiy, V.; Kachur, O.; Boikiv, M.; Novitskyi, Y.; Yaniv, O. Analysis of kinematic characteristics of a mobile caterpillar robot with a SCARA-type manipulator. Transp. Technol. 2023, 4, 56–67. [Google Scholar] [CrossRef]

- Han, L.; Ding, F.; Zhao, L.; Li, P.; Li, C.; Liu, M.; Ren, L.; Li, Y. Design and motion analysis of a coal mine robot with variable wheel diameter. Sci. Rep. 2025, 15, 6497. [Google Scholar] [CrossRef] [PubMed]

- Ma, Z.; Ding, C.; Li, L.; Tian, B. The Design of Decoupled Robotic Arm Based on Chain Transmission. Machines 2024, 12, 410. [Google Scholar] [CrossRef]

- Petrişor, S.M.; Simion, M.; Bârsan, G.; Hancu, O. Humanitarian Demining Serial-Tracked Robot: Design and Dynamic Modeling. Machines 2023, 11, 548. [Google Scholar] [CrossRef]

- Ganesh, Y.; Raju, R.S.; Hegde, R. Surveillance drone for land-mine detection. In Proceedings of the 2015 International Conference on Advanced Computing and Communications (ADCOM), Chennai, India, 18–20 September 2015; pp. 33–38. [Google Scholar] [CrossRef]

- Havisto, J.; Matselyukh, T.; Paavola, M.; Uusitalo, S.; Savolainen, M.; Sobrecueva González, A.; Knobloch, A. Golden AI data acquisition and processing platform for safe, sustainable and cost-efficient mining operations. In Proceedings of the 2021 IEEE International Geoscience and Remote Sensing Symposium IGARSS, Brussels, Belgium, 11–16 July 2021; pp. 5775–5778. [Google Scholar] [CrossRef]

- Martinsen, M.; Dahlquist, E.; Lönnermark, A.; Säker, Ö. Decision tree for enhancing maintenance activities with drones in the mining business. In Proceedings of the 61st SIMS Conference on Simulation and Modelling SIMS 2020, Virtual Conference, 22–24 September 2020; pp. 272–280. [Google Scholar] [CrossRef]

- Mukherjee, S.J.; Bell, R.S.; Barkhouse, W.; Adavani, S.S.; Lelièvre, P.; Farquharson, C. High-resolution imaging of subsurface infrastructure using deep-learning artificial intelligence on drone magnetometry. Lead. Edge 2022, 41, 462–469. [Google Scholar] [CrossRef]

- Tiwari, V. IoT-based land-mine detection robot. Int. J. Res. Appl. Sci. Eng. Technol. 2021, 9, 276–284. [Google Scholar] [CrossRef]

- Żur, P. Combination of a DC Motor Controller and Telemetry System to Optimize Energy Consumption. Sensors 2023, 23, 6923. [Google Scholar] [CrossRef] [PubMed]

- Al-Furati, I.S.; Ayoob, S.M.; Qadir, R.R.; Al-Maliki, Z.A. A military-application robot that works as a mine-and-gas detector. PriMera Sci. Eng. 2024, 5, 39–54. [Google Scholar] [CrossRef]

- Nandakumar, K.; Kesavan, R.; Niyasudeen, N.; Surendra Prasad, M.; Vaseem Akram, Y. Military-based land-mine detection robotic vehicle. Int. J. Res. Granthaalayah 2023, 11, 1–8. [Google Scholar] [CrossRef]

- Colon, E.; Alexandre, P.; Weemaels, J.; Doroftei, I. Development of a high-mobility wheeled robot for humanitarian mine clearance. In Proceedings of the Robotic and Semi-Robotic Ground Vehicle Technology, Orlando, FL, USA, 12 August 1998; pp. 59–66. [Google Scholar] [CrossRef]

- Nurgizat, Y.; Uzbekbayev, A.; Alipbayev, K.; Sergazin, G.; Zhetenbayev, N. Improved Accuracy through Optimised Projectile Flight Control. In Proceedings of the 2024 5th International Conference on Communications, Information, Electronic and Energy Systems (CIEES), Veliko Tarnovo, Bulgaria, 20–22 November 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 1–5. [Google Scholar]

- Uran-6 Mine-Clearing Robot. Available online: https://www.army-technology.com/projects/uran-6-mine-clearing-robot/ (accessed on 12 March 2025).

- Multifunctional Robotic System MV-4. Available online: https://dok-ing.hr/ (accessed on 23 February 2025).

- Engineering Capability for RCVs. Available online: https://www.pearson-eng.com/capability/engineering-capability-for-rcvs/ (accessed on 25 February 2025).

- General Dynamics Land Systems. S-MET: Squad Multipurpose Equipment Transport. Available online: https://www.gdls.com/gdls-smet22/ (accessed on 25 February 2025).

- Geneva International Centre for Humanitarian Demining. Demining Robot DMR-364. Available online: https://www.gichd.org/publications-resources/equipment-catalogue/demining-robot-dmr-364/ (accessed on 24 April 2025).

- Keller, J. Army Set to Open Competition to Develop Autonomous Mine Detection System (AMDS). Military & Aerospace Electronics. Available online: https://www.militaryaerospace.com/computers/article/16720172/army-set-to-open-competition-to-develop-autonomous-mine-detection-system-amds (accessed on 24 April 2025).

- Clearpath Robotics. Coimbra Autonomous Demining Husky UGV. Available online: https://clearpathrobotics.com/coimbra-autonomous-demining-husky/ (accessed on 24 April 2025).

- Schenone, V.; Estatico, C.; Gragnani, G.L.; Pastorino, M.; Randazzo, A.; Fedeli, A. Microwave-Based Subsurface Characterization through a Combined Finite Element and Variable Exponent Spaces Technique. Sensors 2023, 23, 167. [Google Scholar] [CrossRef] [PubMed]

| System | Mass (t) | End-Effector | Clearance Throughput | Control/Standoff (m) | Advantages | Limitations |

|---|---|---|---|---|---|---|

| Uran-6 | 6.0 | rotary flail, chain rake | 2000 m2 h−1 | remote, ≤1000 | Proven in urban clearance; interchangeable tools | High weight; limited detection precision |

| MV-4 | 6.1 | chain flail | 1400–1800 m2 h−1 | remote, ≤1500 | Compact size; maneuverable in tight terrain | Vulnerable to steep slopes and buried threats |

| MW240 | 6.6–10 | interchangeable flail/plough | 3000 m2 h−1 (depth ≤ 0.25 m) | remote/autonomous, ≤1000 | High throughput; autonomous operation | Large logistical footprint; low selectivity |

| S-MET | 1.9 | barbed-wire cutter, tow hitch | —(up to 450 kg payload) | remote/semi-autonomous, ≤1000 | High modularity; multipurpose use | No built-in detection/neutralization tools |

| EMAV | 3.1 | MICLIC linear charge (100 m lane) | ≈100 m × 5–8 m per shot | remote/semi-autonomous, ≤1000 | Fast breaching; hybrid drive; stealth mode | One-time use per lane; explosive risk |

| System | Sensing Principle | Platform/Propulsion | Autonomy Level | Key Capabilities |

|---|---|---|---|---|

| COMRADE [13] | PI metal detector + multi-UGV sensor fusion | 4-wheel Explorer | Full swarm autonomy | Coverage density ≈ 95% at 0.25 m/s |

| Deminer Robot [22] | Metal detector + camera + SLAM | Tracked micro-UGV | Full autonomy | Generates GIS-compatible mine maps; avoids detonation (mass < 15 kg) |

| Wirelessly Controlled Mines Detection Robot [23] | Metal detector + IR rangefinder + wireless camera | 4-wheel chassis, RF link | Remote control | Comm. range ≈ 150 m; built-in obstacle avoidance |

| SBIR Husky [24] | GPS/INS + UWB + laser odometry | 6 × 6 UGV, diesel-electric | Semi-autonomous | Positioning accuracy ± 0.05 m; search rate > 1 ha/h |

| Mine-spotting drones [21] | ML-based EO/IR imagery processing | UAV (rotary-wing/quadcopter) | Semi-autonomous missions | Coverage ≈ 10 ha/h; classifies mine type and burial depth |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nurgizat, Y.; Sultan, A.; Zhetenbayev, N.; Ayazbay, A.-A.; Uzbekbayev, A.; Sergazin, G.; Alipbayev, K. Comparative Analysis of Modern Robotic Demining Complexes and Development of an Automated Mission Planning Algorithm. Eng. Proc. 2025, 104, 63. https://doi.org/10.3390/engproc2025104063

Nurgizat Y, Sultan A, Zhetenbayev N, Ayazbay A-A, Uzbekbayev A, Sergazin G, Alipbayev K. Comparative Analysis of Modern Robotic Demining Complexes and Development of an Automated Mission Planning Algorithm. Engineering Proceedings. 2025; 104(1):63. https://doi.org/10.3390/engproc2025104063

Chicago/Turabian StyleNurgizat, Yerkebulan, Aidos Sultan, Nursultan Zhetenbayev, Abu-Alim Ayazbay, Arman Uzbekbayev, Gani Sergazin, and Kuanysh Alipbayev. 2025. "Comparative Analysis of Modern Robotic Demining Complexes and Development of an Automated Mission Planning Algorithm" Engineering Proceedings 104, no. 1: 63. https://doi.org/10.3390/engproc2025104063

APA StyleNurgizat, Y., Sultan, A., Zhetenbayev, N., Ayazbay, A.-A., Uzbekbayev, A., Sergazin, G., & Alipbayev, K. (2025). Comparative Analysis of Modern Robotic Demining Complexes and Development of an Automated Mission Planning Algorithm. Engineering Proceedings, 104(1), 63. https://doi.org/10.3390/engproc2025104063