Design and Construction of an Engine Oil Viscosity Meter with Electronic Control †

Abstract

1. Introduction

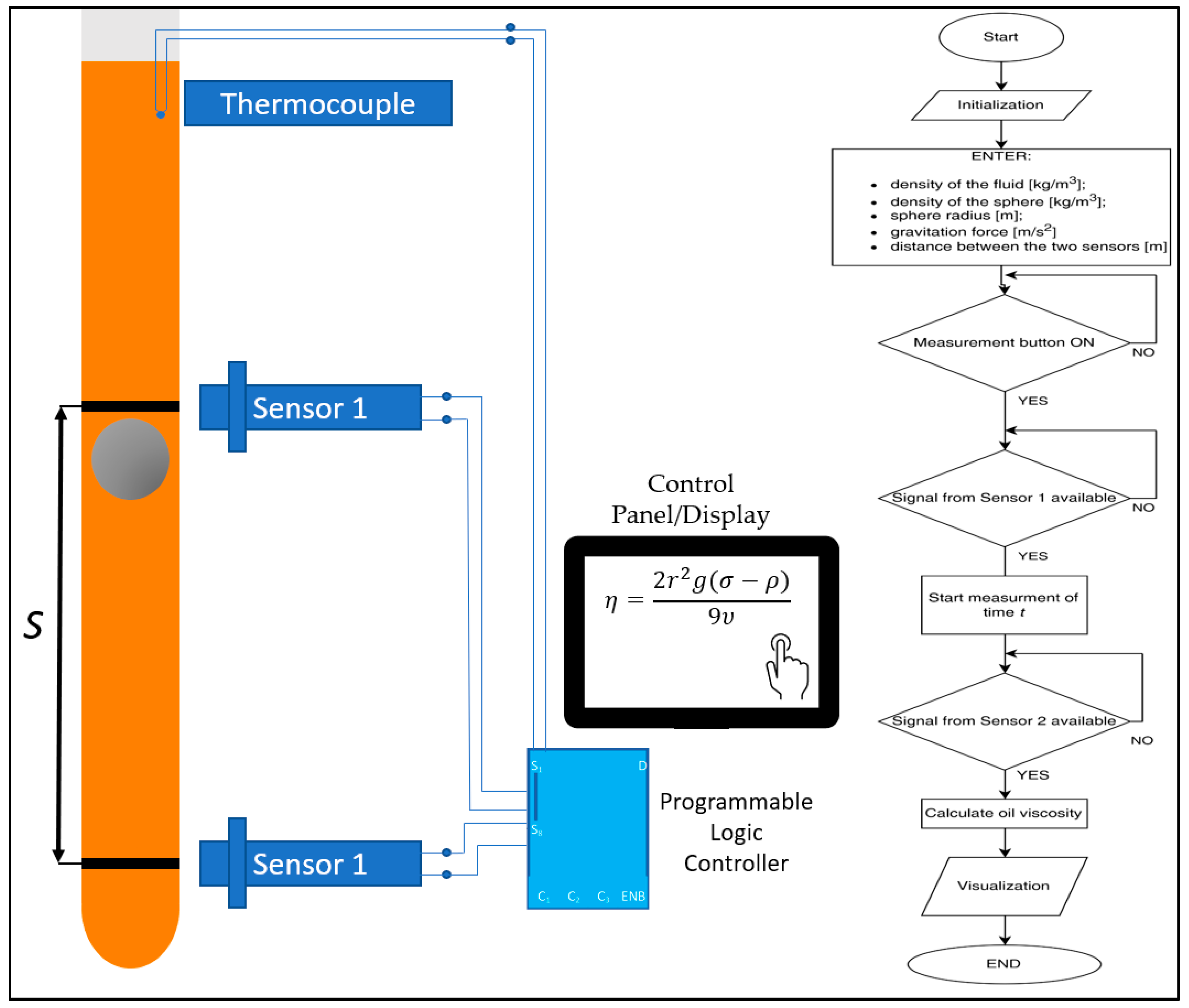

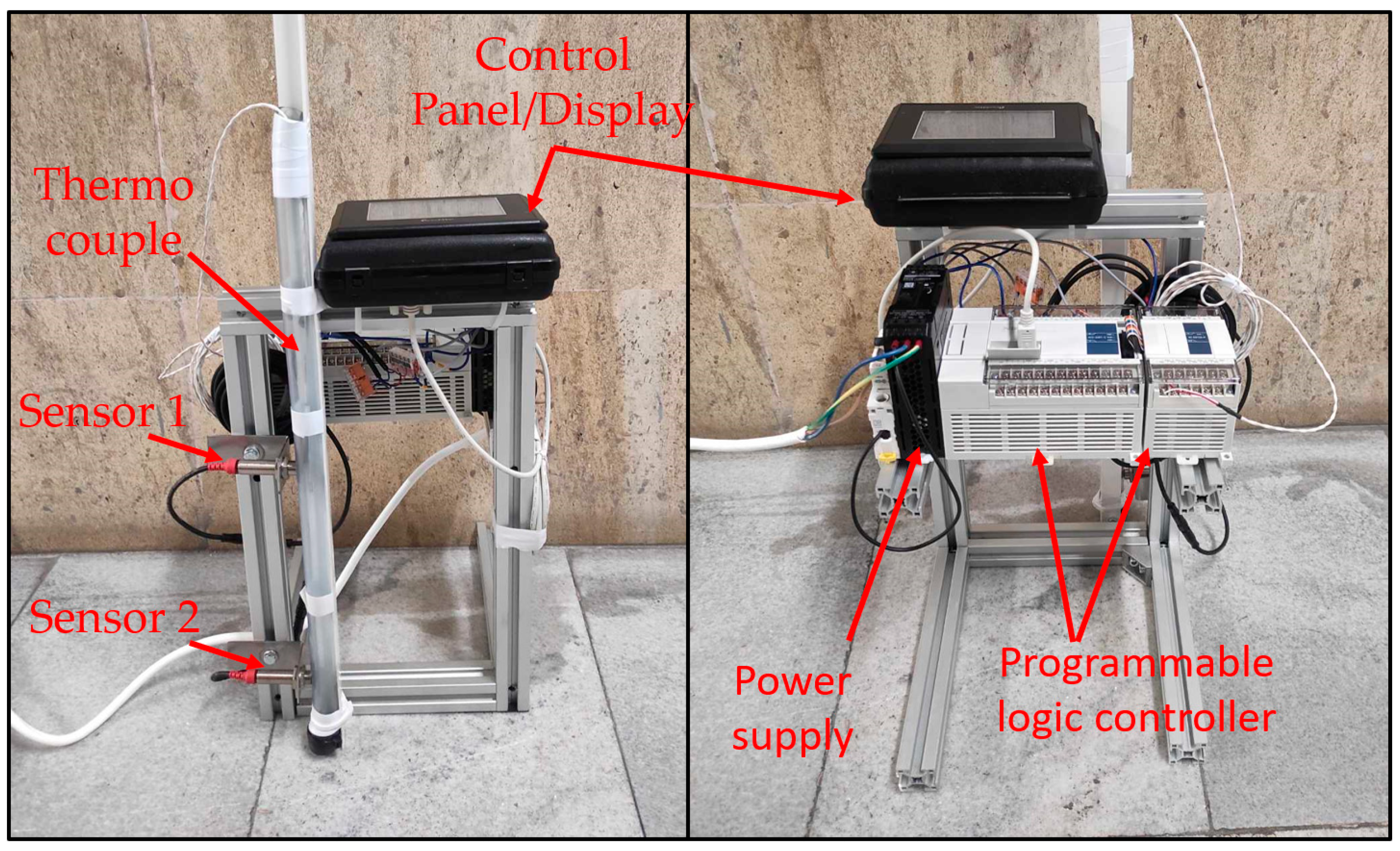

2. Materials and Methods

3. Results and Discussions

- Clear visualization: The vertical layout of the apparatus allows for straightforward adjustments when changing the sphere or the fluid medium. This configuration facilitates rapid reconfiguration in laboratory setups, making it simple to test different oil samples or modify experimental parameters.

- Automated timing: by using sensors to automatically trigger timing events (i.e., starting the timer as the sphere passes sensor 1 and stopping it at sensor 2), the system minimizes human error. This automated approach ensures high repeatability in measurements, which is critical for both research and diagnostic applications.

- User-friendly interface: The intuitive controller interface, combined with a simple measurement button sequence, enables users to easily switch between different oil samples or operational conditions. This feature not only improves usability but also reduces the need for extensive operator training.

- Immediate feedback: Real-time display of the calculated viscosity on the digital panel allows for rapid assessment of the oil’s properties. This immediate feedback is particularly beneficial in maintenance contexts, where quick decision-making is required.

- Measurement accuracy: The overall accuracy of the developed viscosity meter is highly dependent on the precision of several key input parameters. These include the accurate determination of the fluid’s density, the density and radius of the falling sphere, and the exact measurement of the distance between the two sensors. A deviations in any of these parameters can lead to errors in the calculated viscosity values. Therefore, special attention must be paid to ensuring the reliability and repeatability of all dimensional and material property inputs used in the calculation process.

- Data integration: The integration of the falling-ball method with digital sensor technology provides an effective way to reduce human error and improve overall data reliability. This is essential for applications in which oil degradation needs to be tracked over time.

- Potential for future improvements: Future iterations of the device could incorporate advanced data processing algorithms to further refine the measurement accuracy, especially under transient conditions.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Garcia Tobar, M.; Pinta Pesantez, K.; Jimenez Romero, P.; Contreras Urgiles, R.W. The Impact of Oil Viscosity and Fuel Quality on Internal Combustion Engine Performance and Emissions: An Experimental Approach. Lubricants 2025, 13, 188. [Google Scholar] [CrossRef]

- Abou-Ziyan, H.Z. Heat transfer characteristics of some oils used for engine cooling. Energy Convers. Manag. 2004, 45, 2553–2569. [Google Scholar] [CrossRef]

- Tormos, B.; Ramirez, L.; Johansson, J.; Bjorling, M.; Larsson, R. Fuel consumption and friction benefits of low viscosity engine oils for heavy duty applications. Tribol. Int. 2017, 110, 23–24. [Google Scholar] [CrossRef]

- Hei, D.; Zheng, M.; Liu, C.; Jiang, L.; Zhang, Y.; Zhao, X. Study on the frictional properties of the top ring-liner conjunction for different-viscosity lubricant. Adv. Mech. Eng. 2023, 15. [Google Scholar] [CrossRef]

- Blanco-Rodriguez, J.; Simon-Montero, X.; Cortada-Garcia, M.; Maroto, S.; Portiero, J. Modelling the impact of reducing lubricant viscosity on a conventional passenger car fuel economy and wear protection. Results Eng. 2024, 24, 103159. [Google Scholar] [CrossRef]

- Basu, A.; Berndorfer, A.; Buelna, C.; Campbell, J.; Ismail, K.; Lin, Y.; Rodriguez, L.; Wang, S.S. “Smart sensing” of Oil Degradation and Oil Level Measurements in Gasoline Engines. SAE Int J Fuels Lubr. 2000, 109, 857–863. [Google Scholar] [CrossRef]

- Garcia Tobar, M.; Cabrera Ojeda, O.; Crespo Montaño, F. Impact of Oil Viscosity on Emissions and Fuel Efficiency at High Altitudes: A Response Surface Methodology Analysis. Lubricants 2024, 12, 277. [Google Scholar] [CrossRef]

- Dabir, V.; Ghosh, T.; Prasad, D.; Dutt, N.; Reni, K. Viscosity of Liquids; Springer: Dordrecht, The Netherlands, 2007; ISBN 10-1-4020-5481-5. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mitev, P.; Tashev, A.; Stoyanov, Y. Design and Construction of an Engine Oil Viscosity Meter with Electronic Control. Eng. Proc. 2025, 100, 55. https://doi.org/10.3390/engproc2025100055

Mitev P, Tashev A, Stoyanov Y. Design and Construction of an Engine Oil Viscosity Meter with Electronic Control. Engineering Proceedings. 2025; 100(1):55. https://doi.org/10.3390/engproc2025100055

Chicago/Turabian StyleMitev, Penko, Atanasi Tashev, and Yordan Stoyanov. 2025. "Design and Construction of an Engine Oil Viscosity Meter with Electronic Control" Engineering Proceedings 100, no. 1: 55. https://doi.org/10.3390/engproc2025100055

APA StyleMitev, P., Tashev, A., & Stoyanov, Y. (2025). Design and Construction of an Engine Oil Viscosity Meter with Electronic Control. Engineering Proceedings, 100(1), 55. https://doi.org/10.3390/engproc2025100055