Abstract

Fertilizers with nitrogen (N), phosphate (P), and potassium (K) were formulated using a custom-made rotary pan granulator. The granules were characterized by analysis of their composition, specific surface and porosity (Brunauer–Emmett–Teller, BET analysis), Scanning Electron Microscopy (SEM), and X-ray diffraction (XRD). Using the rotary pan granulator led to the formation of the intended NPK fertilizer granules. The most used for soil treatment, the 2–4 mm diameter granules, were separated, and the granules with smaller or higher dimensions were re-introduced to the process.

1. Introduction

Mineral fertilizers are used worldwide to ensure food security [,]. However, the intense use of fertilizers may affect soil quality, soil productivity, and global health. Improvements related to fertilizer application and formulation are needed to avoid such situations. One direction is to formulate combinations of mineral fertilizers that include nitrogen (N), phosphate (P), and potassium (K) and to coat the resulting combinations with various (bio)organic products [,,], leading to slow-release formulations. The formulations of mineral fertilizers include different ratios between N (expressed as total nitrogen), P (expressed as P2O5), and K (expressed as K2O). These ratios are related to the cultivated plants, soil type, and soil nutrient content [].

The granulation process is the first step in producing the slow-release, coated fertilizer. The granulation process can be performed using several methods, the most used being a rotating pan granulator [,] or a fluidized bed granulator [,,]. The rotating pan granulator is easier to use and more accessible to design for custom needs. It is also used for the second step in the production of slow-release fertilizer formulations, i.e., coating [,].

In this study, we developed a custom-made, easy-to-use rotary pan granulator, and we tested it for formulating an NPK 1:1:1-type fertilizer at a laboratory scale. The granulator parameters, production capacity, and the physicochemical properties of the NPK fertilizer, such as morphology, pore size, and crystallinity, were determined. The granulator was efficient, producing more than 73% granules from 3 to 4 mm in one of the tested treatments.

2. Materials and Methods

2.1. Materials

The chosen formulation for this experiment was NPK 111, the numbers representing the mass ratio of nitrogen, phosphorus (as P2O5), and potassium (as K2O). The raw materials used for granulation were urea (Merck, Rahway, NJ, USA), mono-ammonium phosphate (MAP, Merck, Rahway, NJ, USA), potassium sulfate (K2SO4, Sigma-Aldrich, St Louis, MO, USA), potassium chloride (KCl, Sigma–Aldrich, St Louis, MO, USA), and kaolin (Brenntag SE, Essen, Germany).

In Table 1, the theoretical macroelement content of the chosen NPK formulation is presented.

Table 1.

Theoretical macroelement content of the NPK 111 fertilizers.

Ligand composition = 150 g NPK 111 for granulation in 500 mL distilled water + 5% food-grade glycerol solution.

The ligand used was 5% food-grade glycerol solution, final concentration.

2.2. Granulation Process of the NPK Fertilizer

The raw materials were ground to obtain particles smaller than 200 microns. Such dimensions are needed for powder homogenization, an optimal final composition, and the formation of non-friable granules with good mechanical resistance. The grinding was carried out in a dry system using a ZM 200 centrifugal mill (Retsch, Verder, Haan, Germany). The milling conditions were 250 g batch size, 8000 rpm rotor speed, 5 min batch milling time, and a sieve mesh size of 0.25 mm.

The milled raw materials were mixed as 1000 g batches in a longitudinal oscillating mixer (Dry Powder Rotator, Glas-Col, Terre Haute, IN, USA) with variable amplitudes for 3 h. The mixing material was placed in a 3 L cylindrical vessel and fixed on the device. Periodically, after 30 min, the cylindrical vessel was manually mixed by rotating it for 5 min, resuming the oscillating mixing afterward.

The granulation was performed using the custom-made granulator, which will be presented in detail in the Results and Discussion section. Spraying was performed in a discontinuous way, manually, using a pulverization device standardized nozzle that had a diameter of ϕ = 0.25 mm. The fertilizer granules were dried at room temperature for 24 h.

A system composed of 2 stainless steel sieves, a collecting vessel, and a lid was used to fractionate the granules and to select the optimal dimension size of the fertilizer granules (2–4 mm) after the granulation process. The dimensions of the sieve were 2 mm in diameter for the lower sieve and 4 mm for the top sieve. The fertilizer granules from every batch were sieved individually.

2.3. Physicochemical Characterization of the NPK Granules

The morphology of the NPK beads in section and on the surface was assessed using a TM4000Plus Tabletop Scanning Electron Microscope (Hitachi, Chiyoda City, Tokyo, Japan) at 15 kV in standard vacuum conditions (as specified in the TM4000Plus software, version 2023 vacuum settings). The micrographs were obtained using a BSE (backscattered electrons) detector at multiple magnifications.

X-ray diffraction measurements were carried out with a Rigaku Smartlab diffractometer (Applied Rigaku Technologies, Inc., Cedar Park, TX, USA) using a Cu Kα radiation (λ = 1.54 Å). In this experiment, the accelerating voltage of the generator radiation was set at 45 kV and the emission current at 200 mA. The diffractogram was recorded in parallel beam geometry over 2θ = 5° to 90° continuously at a scan rate of 4°/min. Prior to analysis, the granules were ground in an agate mortar. The diffraction maxima were identified based on the sheets from the ICDD (International Center for Diffraction Data). Also, the crystallinity index was calculated as the ratio between the total area of the diffraction maxima of the crystalline phases and the total area of the diffractograms after eliminating the background.

BET analyses were conducted by isothermic sorption measurements at 77 K, using a NOVA 2200e-Quantachrome Analyzer porosimeter (Quantachrome Corporation, Boynton Beach, FL, USA). Before measurements, the NPK sample was degassed at 120 °C in a vacuum for 6 h. The textural parameters that were evaluated were the specific surface (determined from the standard BET equation (Brunauer–Emmett–Teller)), the total pore volume (estimated from the adsorbed volume at a relative pressure p/p0 close to unity), and the pore size distribution and mesopore volume (obtained from the isothermal desorption branch by applying the Barrett–Joyner–Halenda (BJH) model). The obtained results were processed using the NovaWin software, version 11.03.

3. Results and Discussion

The custom-made rotating pan granulator used for the fertilizer granulation is presented in Figure 1. The dimensional and functional characteristics of the rotating pan granulator are as follows: fabrication material—stainless steel AISI 304; motor: 200 W power, 12V c.c. electric voltage; rotating pan diameter Dn = 20 cm; rotating pan height H = 8 cm; α tilt angle to the horizontal axis = 35–55 degrees (from 5 to 5 degrees); turation interval of the pan granulator = 0–120 rpm.

Figure 1.

Custom-made rotating pan granulator developed in this study and used for granulation experiments.

After laboratory trials, the optimal parameters for the granulation of NPK fertilizers were determined as follows: rotating pan tilting angle α = 40–45°; rotating pan turation = 20–25 rpm; rotating direction: anticlockwise; mass ratio binder/NPK = 1/4–1/5; granulating time (for one batch) = 60–150 min.

Approximately 3 kg of NPK 111 fertilizer was formulated using the parameters presented in Table 2.

Table 2.

NPK fertilizers’ composition.

The results of the granulation experiments are presented in Table 3 below. The average granulation time for a batch of 200 g was approx. 100 min, the maximum granulator capacity being approx. 400 g/batch. The ratio of raw material/ligand mass seems to be the most important for increasing the proportion of NPK granules with a 2–4 mm diameter, the other parameters having less influence.

Table 3.

The granulometric analysis of NPK 1:1:1 fertilizers.

A sample of NPK 111 obtained with the parameters of the experimental treatment 9 from Table 3 is presented in Figure 2.

Figure 2.

NPK 111 granules.

The shape of the NPK granules was more or less spherical, which was expected to happen when using the rotating pan granulator and is comparable with other types of fertilizer granules obtained using the same method [,]. The NPK granules were sieved in order to separate the granules with a 2–4 mm diameter from the rest. The sieving process led to three fractions: (1) the granules with a diameter smaller than 2 mm that remained in the collecting vessel were dried, ground, and reused for the next granulation batch; (2) the granules with a 2–4 mm diameter were weighed and deposited; (3) the granules with a diameter over 4 mm, collected on the top sieve, were dried and ground to be reused for the next granulation batch. The proportion of granules with a 2–4 mm was higher than 73% in the experimental treatment 9 from Table 3.

The chemical composition of the NPK 1:1:1 is presented in Table 4.

Table 4.

Chemical composition of NPK 1:1:1.

The NPK composition was close to the theoretical composition presented in Table 1. The leftover raw materials during the granulation process probably caused a slight decrease. What remained was reused for the next batch of NPK 1:1:1 fertilizer.

BET tests were conducted to determine the pore sizes and are presented in Table 5.

Table 5.

Pore diameter of NPK 1:1:1 granules.

The pore size and the specific surface were similar to those determined in other studies on NPK fertilizers [].

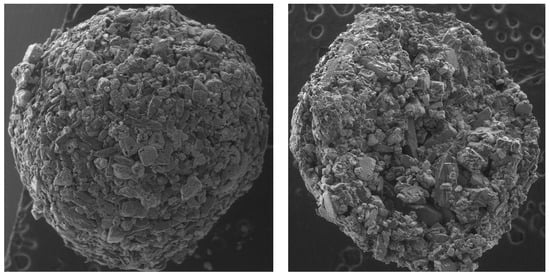

The results of the SEM analysis are presented in Figure 3. SEM images reveal a compact granule with a rough surface suitable for further coating application.

Figure 3.

SEM analysis on the surface (left) and section (right) of a 1/1/1 NPK granule.

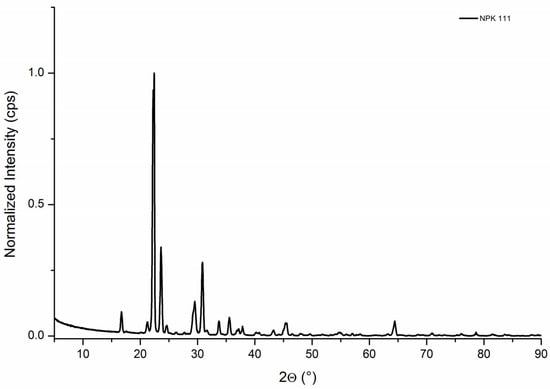

From the XRD measurements (Figure 4), the specific diffraction peaks of biphosphammite (NH4)(H2PO4) were identified, with the most intense diffraction peaks at the 2θ angles: 16.70°, 23.71° and 29.21° (ICDD 01-089-7401). The diffraction peaks for urea (ICDD 02-064-1170) are identified with intense diffraction peaks at the 2θ angles: 22.25°, 24.61° and 29.32°. The peaks from K2SO4 in the form of arcanite have maxima of intense diffraction at the 2θ angles: 30.77°, 29.75° and 30.96° (ICDD 00-005-0613).

Figure 4.

The X-ray diffraction (XRD) of the NPK 1:1:1 granules.

The crystallinity degree of the NPK 1:1:1 granules was established to be greater than 99%. The XRD analysis confirmed the stability of the used raw material during the granulation process.

4. Conclusions

The granulation experiments using the custom-made rotating pan granulator went as expected. The ligand that was used (composition: 150 g NPK 111 for granulation in 500 mL distilled water + 5% food-grade glycerol solution) gave good results, as seen in Table 3 presented above.

The analyses performed showed that the NPK 111 granules are compact and their composition is close to the theoretical one. The SEM analysis showed compact granules. The granules with a diameter greater than 2–4 mm were reused in the granulation process to prevent wasting raw materials. The rotating pan granulator was easy to manipulate and will be used further for these formulations and tested for film coating capacity.

Author Contributions

Conceptualization, C.N., F.O. and L.M.; methodology, C.N., V.A.F. and L.M.; validation, D.C.-A. and F.O.; formal analysis, D.C.-A. and R.T.; investigation, V.A.F., C.N., D.C.-A., M.G., L.M.; L.C. and G.V.; resources, F.O.; data curation, V.A.F. and C.N.; writing—original draft, V.A.F.; writing—review and editing, D.C.-A. and F.O.; visualization, D.C.-A.; supervision, F.O.; project administration, F.O.; funding acquisition, F.O. and R.T. All authors have read and agreed to the published version of the manuscript.

Funding

The work of this paper was supported by Cohesion Funds of the European Union: POC-A1-A1.2.3-G-2015-P_40_352-SECVENT. Sequential processes to close the bioeconomy side stream and innovative bioproducts resulted from these, contract 81/2016, SMIS 105684, subsidiary project no.1397/2019, with SC Chemark Rom Srl as co-founder.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data are presented in this article.

Acknowledgments

The XRD diffractometer was acquired within the POS-CCE “Agri-Flux” project, nr. 645/18.03.2014, SMIS-CSNR 48695. The scanning electron microscope was purchased with funds from the project 15PFE Next-Bexcel.

Conflicts of Interest

The authors declare no conflict of interest. The co-funders had no role in the design of the study; the collection, analysis, or interpretation of data; the writing of the manuscript; or the decision to publish the results.

References

- Yu, X.; Li, H.; Doluschitz, R. Towards Sustainable Management of Mineral Fertilizers in China: An Integrative Analysis and Review. Sustainability 2020, 12, 7028. [Google Scholar] [CrossRef]

- Chen, J.; Lü, S.; Zhang, Z.; Zhao, X.; Li, X.; Ning, P.; Liu, M. Environmentally friendly fertilizers: A review of materials used and their effects on the environment. Sci. Total Environ. 2018, 613–614, 829–839. [Google Scholar] [CrossRef] [PubMed]

- Bronick, C.J.; Lal, J. Soil structure and management: A review. Geoderma 2005, 124, 3–22. [Google Scholar] [CrossRef]

- Kamran, M.; Huang, L.; Nie, J.; Geng, M.; Lu, Y.; Liao, Y.; Zhou, F.; Yonghao, X. Effect of reduced mineral fertilization (NPK) combined with green manure on aggregate stability and soil organic carbon fractions in a fluvo-aquic paddy soil. Soil Tillage Res. 2021, 211, 105005. [Google Scholar] [CrossRef]

- Przemysław, B.; Hlisnikovský, L.; Eva, K. Yield, content and nutrient uptake by winter wheat and spring barley in response to applications of digestate, cattle slurry and NPK mineral fertilizers. Arch. Agron. Soil Sci. 2020, 66, 1481–1496. [Google Scholar] [CrossRef]

- Mikula, K.; Izydorczyk, G.; Skrzypczak, D.; Mironiuk, M.; Moustakas, K.; Witek-Krowiak, A.; Chojnacka, K. Controlled release micronutrient fertilizers for precision agriculture—A review. Sci. Total Environ. 2020, 712, 136365. [Google Scholar] [CrossRef] [PubMed]

- Chai, X.; Chen, L.; Xue, B.; Liu, E. Granulation of ammonium chloride fertilizer and agglomeration mechanism. Powder Technol. 2017, 319, 148–153. [Google Scholar] [CrossRef]

- Xue, B.C.; Hao, Q.; Liu, T.; Liu, E.B. Effect of process parameters and agglomeration mechanisms on NPK compound fertiliser. Powder Technol. 2013, 247, 8–13. [Google Scholar] [CrossRef]

- Sharma, L.; Brigaityte, O.; Kenneth, H.; Rasa, S.; Virginijus, S.; Sviklas, A.M.; Baltrusaitis, J. Carnallite-Derived Solid Waste as Potassium (K) and Magnesium (Mg) Source in Granulated Compound NPK Fertilizers. ACS Sustain. Chem. Eng. 2018, 6, 9427–9433. [Google Scholar] [CrossRef]

- Bertín, D.; Cotabarren, I.V.; Piña, J.; Bucalá, J. The effect of binder concentration in fluidized-bed granulation: Transition between wet and melt granulation. Chem. Eng. Res. Des. 2018, 132, 162–169. [Google Scholar] [CrossRef]

- Merkus, H.G.; Meesters, G.M. (Eds.) Production, Handling and Characterization of Particulate Materials; Springer International Publishing: Cham, Switzerland, 2016; pp. 107–136. [Google Scholar]

- Hanifah, W.; Suryo, P.C.W.P. Slow Release NPK Fertilizer Preparation from Natural Resources. In Symposium of Materials Science and Chemistry; Scientific.Net: Baech, Switzerland, 2019; Volume 4, pp. 43–48. [Google Scholar]

- Dimkpa, C.J.; Fugice, J.; Singh, U.; Lewis, T.L. Development of fertilizers for enhanced nitrogen use efficiency—Trends and perspectives. Sci. Total Environ. 2020, 731, 139113. [Google Scholar] [CrossRef] [PubMed]

- Finalis, E.R.; Djangkung, S.M.S.; Noor, I.; Suratno, H.; Rosyadi, E.; Saputra, H.; Noda, R. Development of carbon based NPK slow release fertilizer using biochar from oil palm empty fruits bunch. Indones. J. Energy 2020, 3, 19–24. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).