Antioxidant Capacity with Physical Property Variations of Morinda citrifolia L. Juice in Traditional Fermentation †

Abstract

:1. Introduction

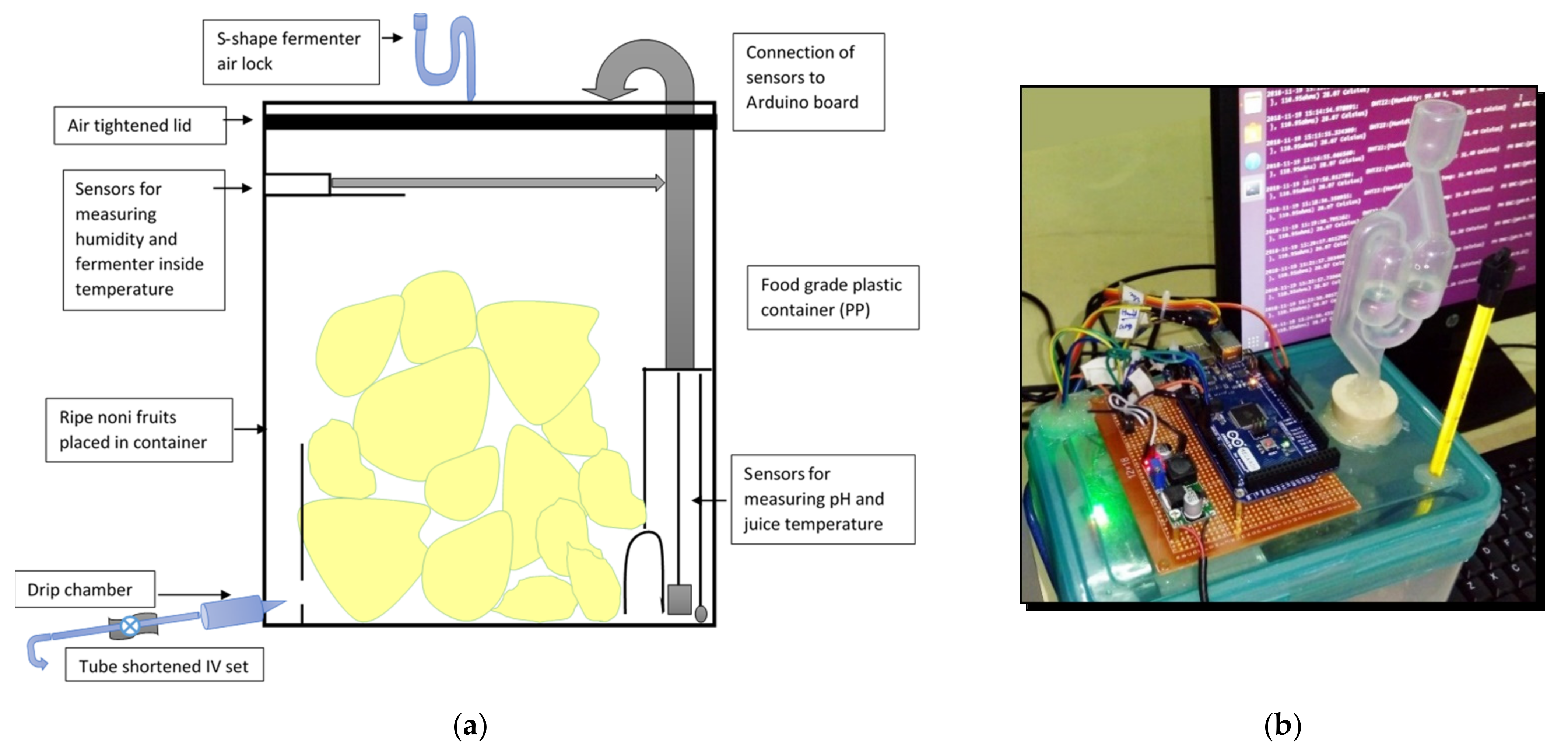

2. Materials and Methods

2.1. Materials

2.2. Preparation of Noni Fruits

2.3. Measurement of Physical Properties with Traditional Fermentation

2.4. Measurement of Antioxidant Capacity by DPPH Assay

2.5. Determination of Correlations of Physical Properties and Antioxidant Capacity of Noni Juice

3. Results and Discussion

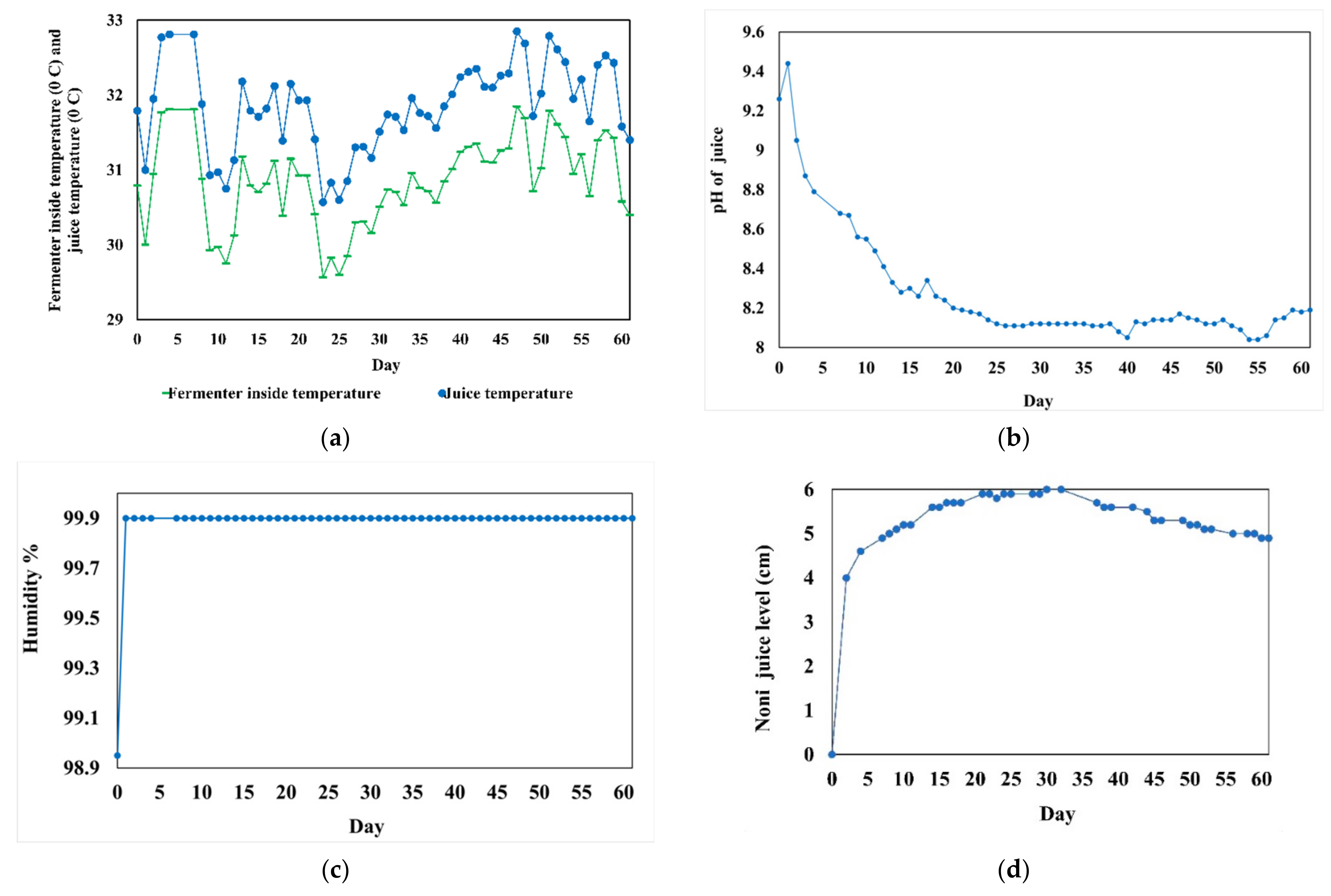

3.1. Temperature Variation

3.2. pH Variation

3.3. Humidity Variation

3.4. Level of Juice Formed

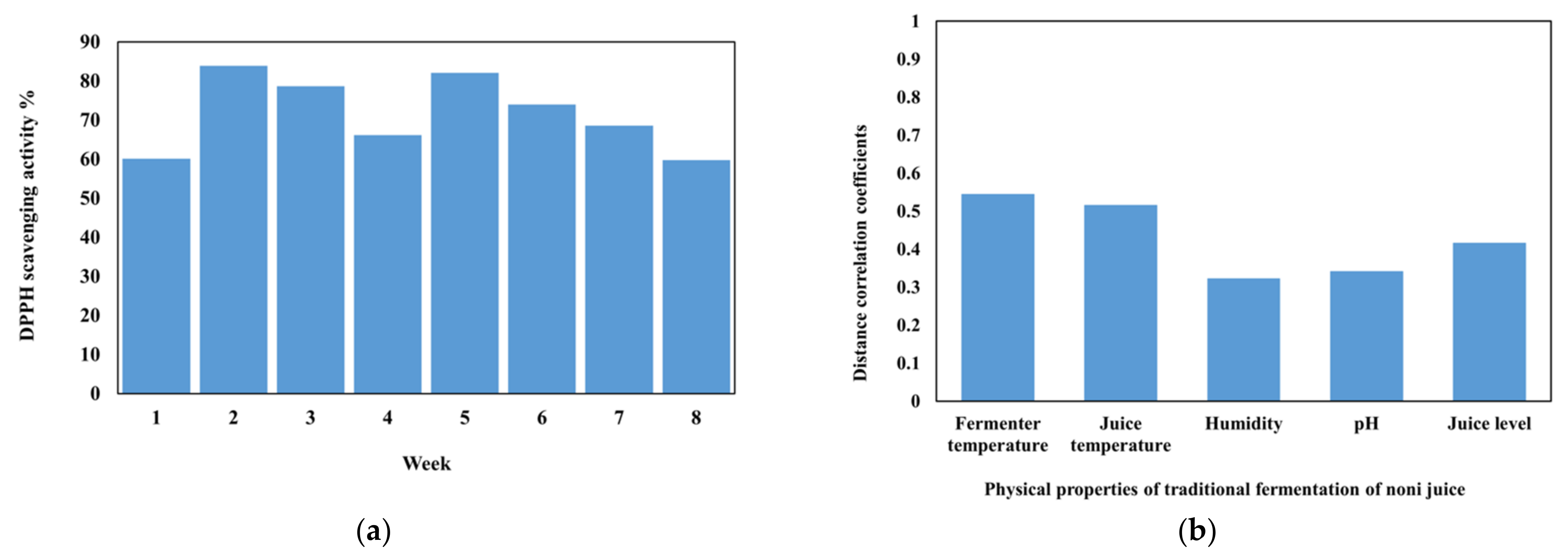

3.5. Antioxidant Capacity Variation

3.6. Correlation of Physical Properties during Traditional Fermentation of Noni Juice with Its Antioxidant Capacity

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Meilawati, L.; Ernawati, T.; Dewi, R.; Megawati, M.; Sukirno, S. Study of Total Phenolic, Total Flavonoid, Scopoletin Contents and Antioxidant Activity of Extract of Ripened Noni Juice. J. Kim. Terap. Indones. 2021, 23, 55–62. [Google Scholar] [CrossRef]

- Krishnaiah, D.; Bono, A.; Sarbatly, R.; Anisuzzaman, S. Antioxidant activity and total phenolic content of an isolated Morinda citrifolia L. methanolic extract from Polyethersulphone (PES) membrane separator. J. King Saud Univ. Eng. Sci. 2015, 27, 63–67. [Google Scholar]

- Yang, J.; Paulino, R.; Janke-Stedronsky, S.; Abawi, F. Free-radical-scavenging activity and total phenols of noni (Morinda citrifolia L.) juice and powder in processing and storage. Food Chem. 2007, 102, 302–308. [Google Scholar] [CrossRef]

- Yang, J.; Gadi, R.; Paulino, R.; Thomson, T. Total phenolics, ascorbic acid, and antioxidant capacity of noni (Morinda citrifolia L.) juice and powder as affected by illumination during storage. Food Chem. 2010, 122, 627–632. [Google Scholar] [CrossRef]

- Sirilun, S.; Sivamaruthi, B.S.; Kesika, P.; Makhamrueang, N.; Chaiyasut, K.; Peerajan, S.; Chaiyasut, C. Development and evaluation of Mustard green pickled liquid as starter for Morinda citrifolia Linn. Fermentation. Int. Food Res. J. 2017, 24, 2170–2176. [Google Scholar]

- Sina, H.; Dramane, G.; Tchekounou, P.; Assogba, M.; Chabi-Sika, K.; Boya, B.; Socohou, A.; Adjanohoun, A.; Baba-Moussa, L. Phytochemical composition and in vitro biological activities of Morinda citrifolia fruit juice. Saudi J. Biol. Sci. 2021, 28, 1331–1335. [Google Scholar] [CrossRef] [PubMed]

- Brand-Williams, W.; Cuvelier, M.; Berset, C. Use of a free radical method to evaluate antioxidant activity. LWT-Food Sci. Technol. 1995, 28, 25–30. [Google Scholar] [CrossRef]

- Samarasiri, M.; Chandrasiri, T.; Wijesinghe, D.; Gunawardena, S. Antioxidant Capacity and Total Phenolic Content Variations against Morinda citrifolia L. Fruit Juice Production Methods. Int. J. Food Eng. 2019, 5, 293–299. [Google Scholar] [CrossRef]

- Székely, G.; Rizzo, M.; Bakirov, N. Measuring and testing dependence by correlation of distances. Ann. Stat. 2007, 35, 2769–2794. [Google Scholar] [CrossRef]

- Konsue, N.; Yimthiang, S.; Kwanhian, W. Effect of fermentation conditions of noni (Morinda citrifolia L.) juice on glutathione content and lipid oxidation in vero cells. Int. Food Res. J. 2018, 25, 1534–1540. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Samarasiri, M.H.; Chandrasiri, T.A.; Wijesinghe, D.B.; Gunawardena, S.P. Antioxidant Capacity with Physical Property Variations of Morinda citrifolia L. Juice in Traditional Fermentation. Chem. Proc. 2022, 10, 17. https://doi.org/10.3390/IOCAG2022-12177

Samarasiri MH, Chandrasiri TA, Wijesinghe DB, Gunawardena SP. Antioxidant Capacity with Physical Property Variations of Morinda citrifolia L. Juice in Traditional Fermentation. Chemistry Proceedings. 2022; 10(1):17. https://doi.org/10.3390/IOCAG2022-12177

Chicago/Turabian StyleSamarasiri, Malsha H., Thushitha A. Chandrasiri, Diunuge B. Wijesinghe, and Sanja P. Gunawardena. 2022. "Antioxidant Capacity with Physical Property Variations of Morinda citrifolia L. Juice in Traditional Fermentation" Chemistry Proceedings 10, no. 1: 17. https://doi.org/10.3390/IOCAG2022-12177

APA StyleSamarasiri, M. H., Chandrasiri, T. A., Wijesinghe, D. B., & Gunawardena, S. P. (2022). Antioxidant Capacity with Physical Property Variations of Morinda citrifolia L. Juice in Traditional Fermentation. Chemistry Proceedings, 10(1), 17. https://doi.org/10.3390/IOCAG2022-12177