Bulk Tungsten Fiber-Reinforced Tungsten (Wf/W) Composites Using Yarn-Based Textile Preforms

Abstract

1. Introduction

1.1. Mechanical Properties of Tungsten and Wf/W Composites

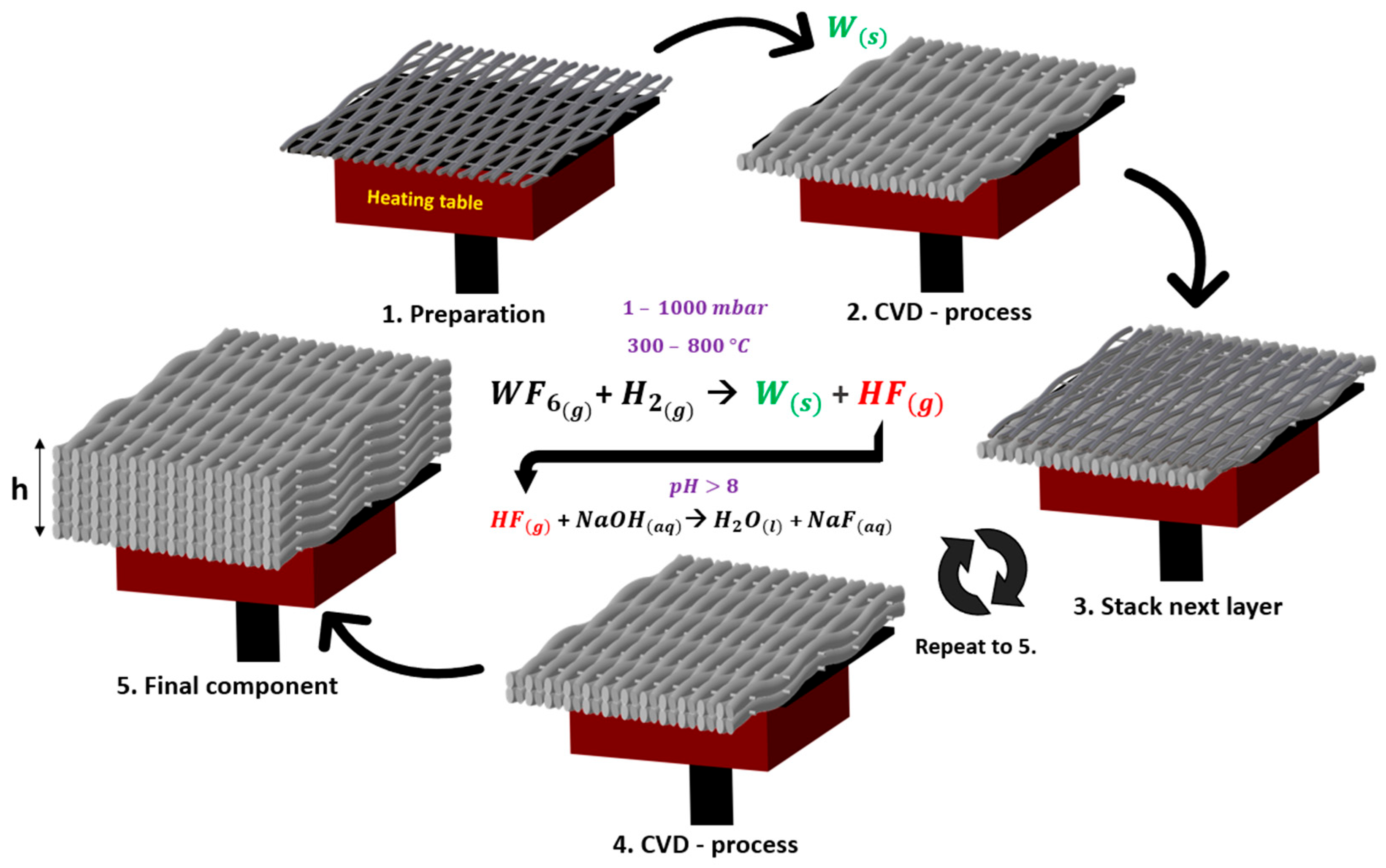

1.2. Production of Wf/W via Chemical Vapor Deposition (CVD)

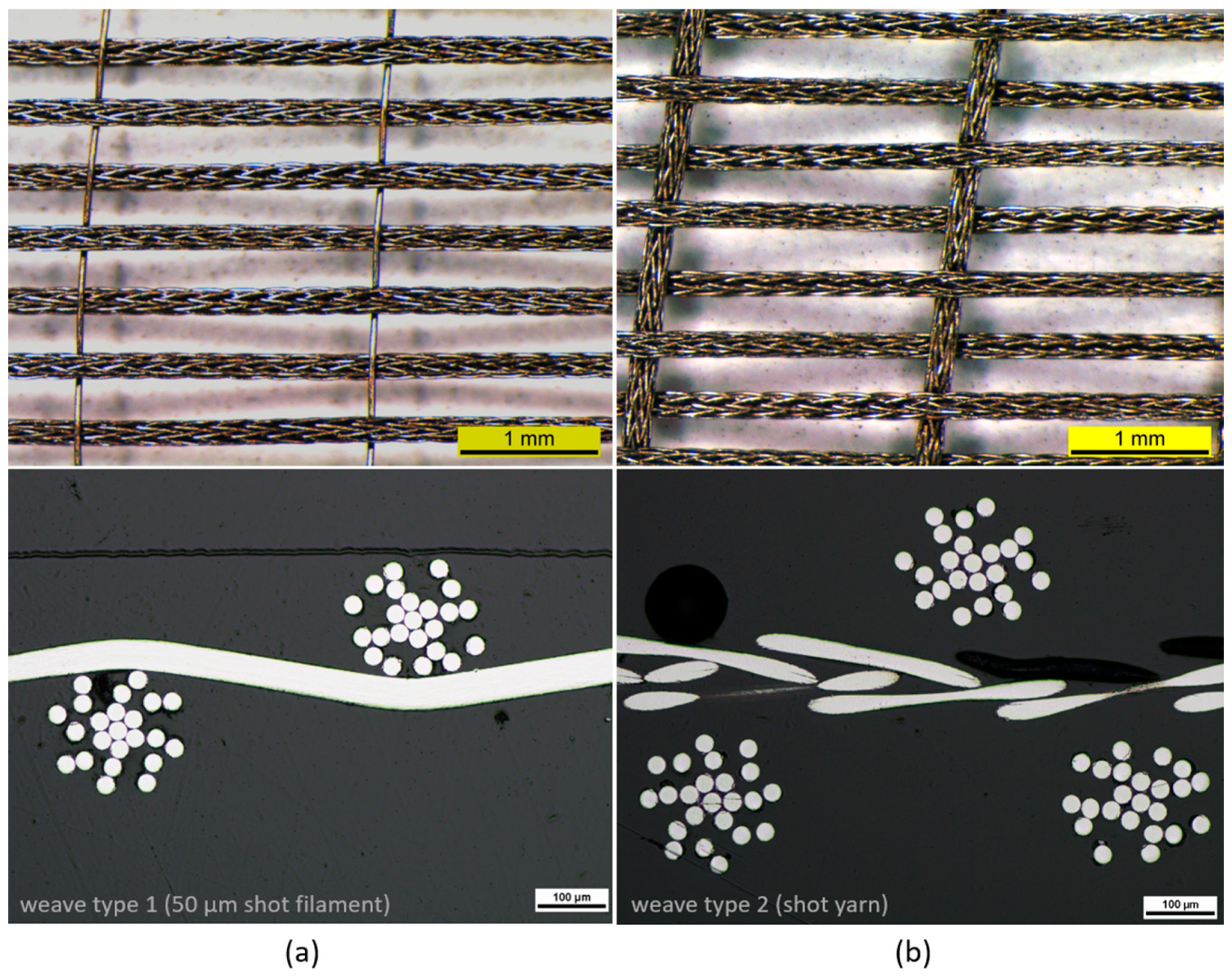

1.3. Development of New Tungsten Preforms

2. Comparison of Bulk Wf/W Using Yarn-Based Preforms

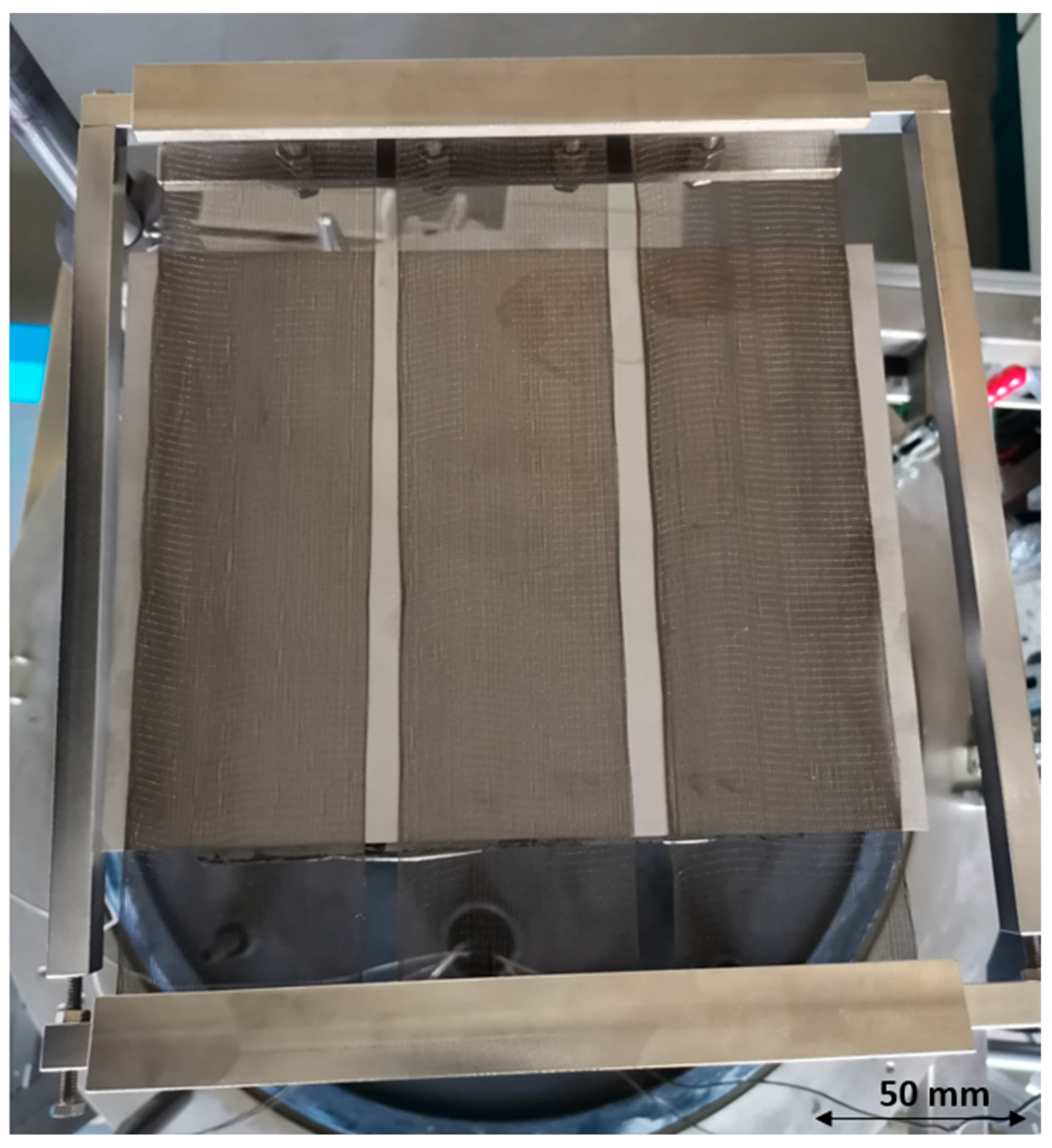

2.1. Production

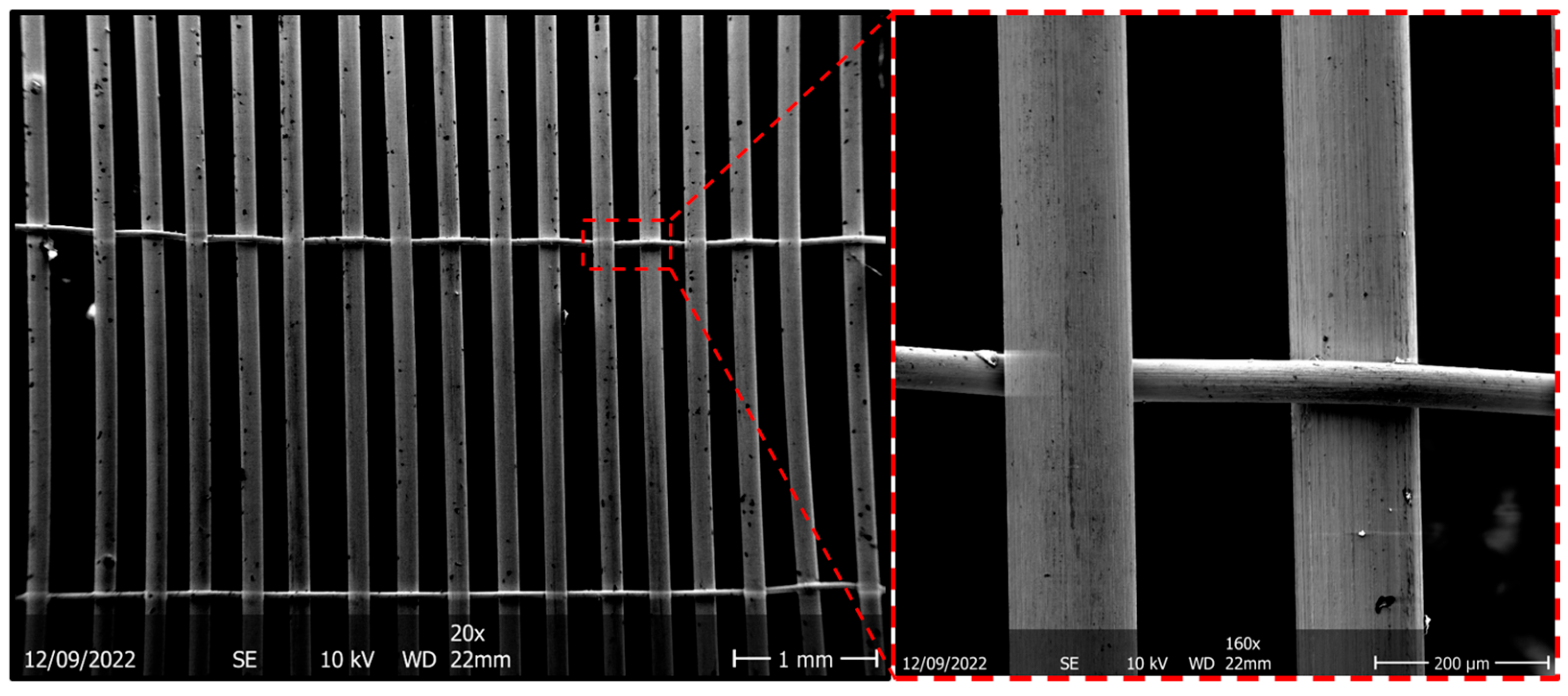

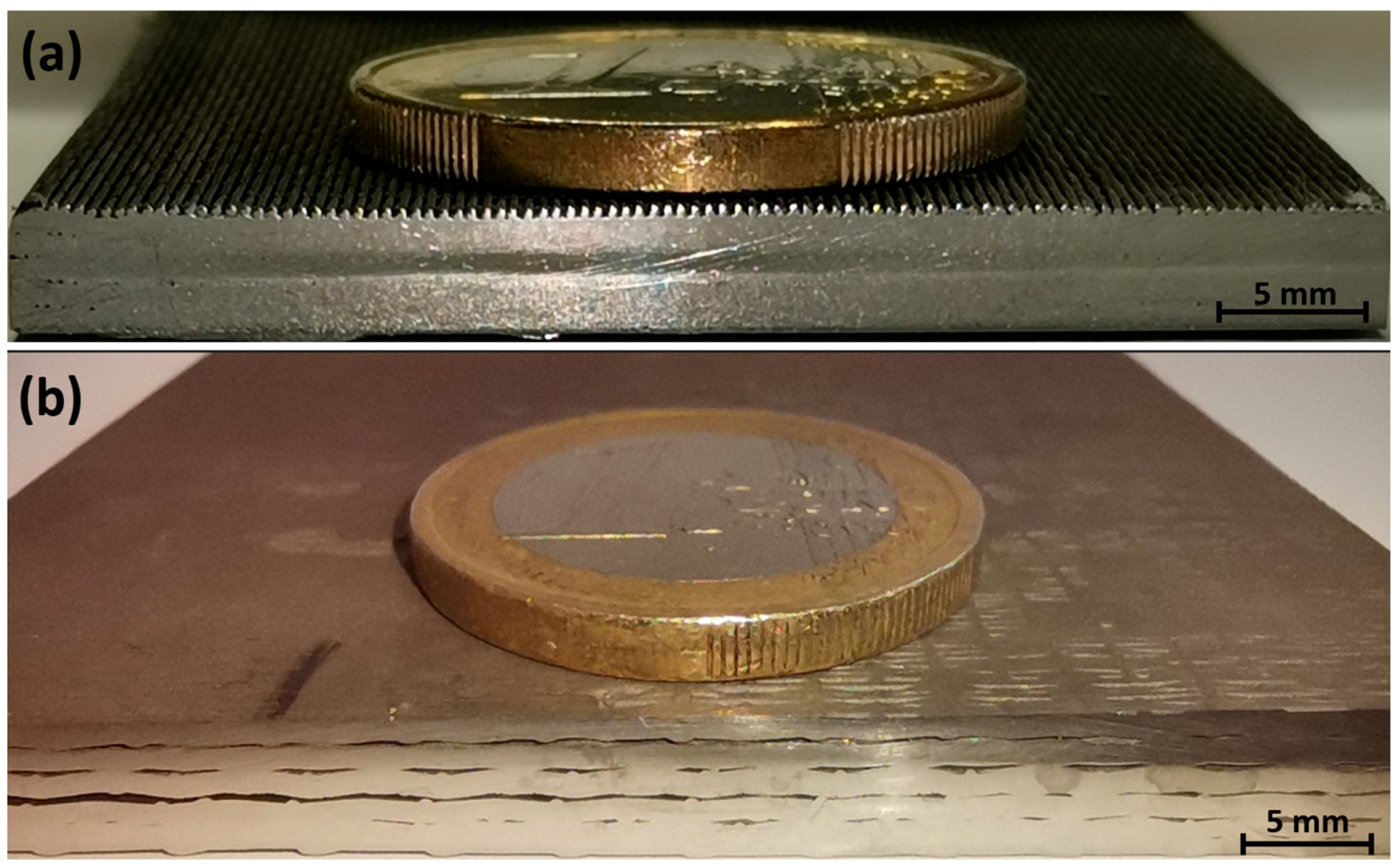

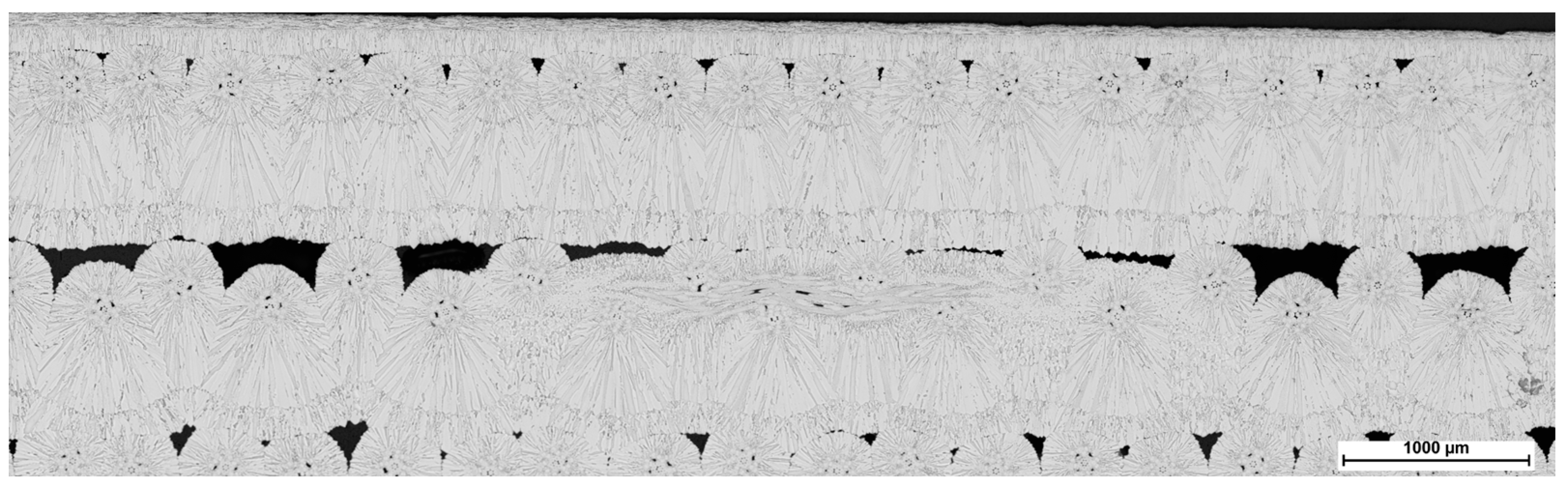

2.2. Optical Analysis, Density and Fiber Volume Fraction

2.3. Mechanical Characterization

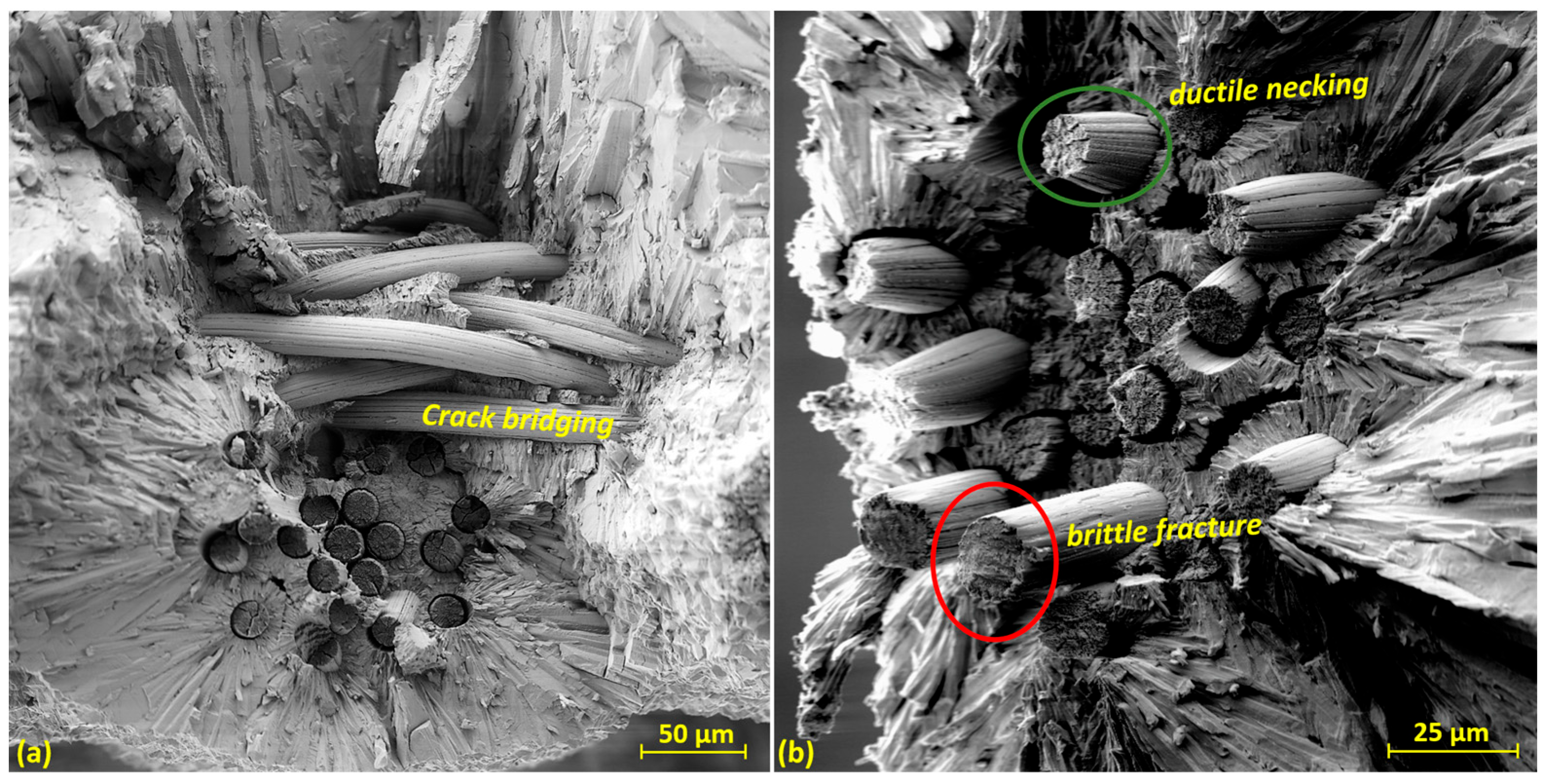

2.3.1. Monotonic Three-Point Bending Tests with KLST-Type Samples

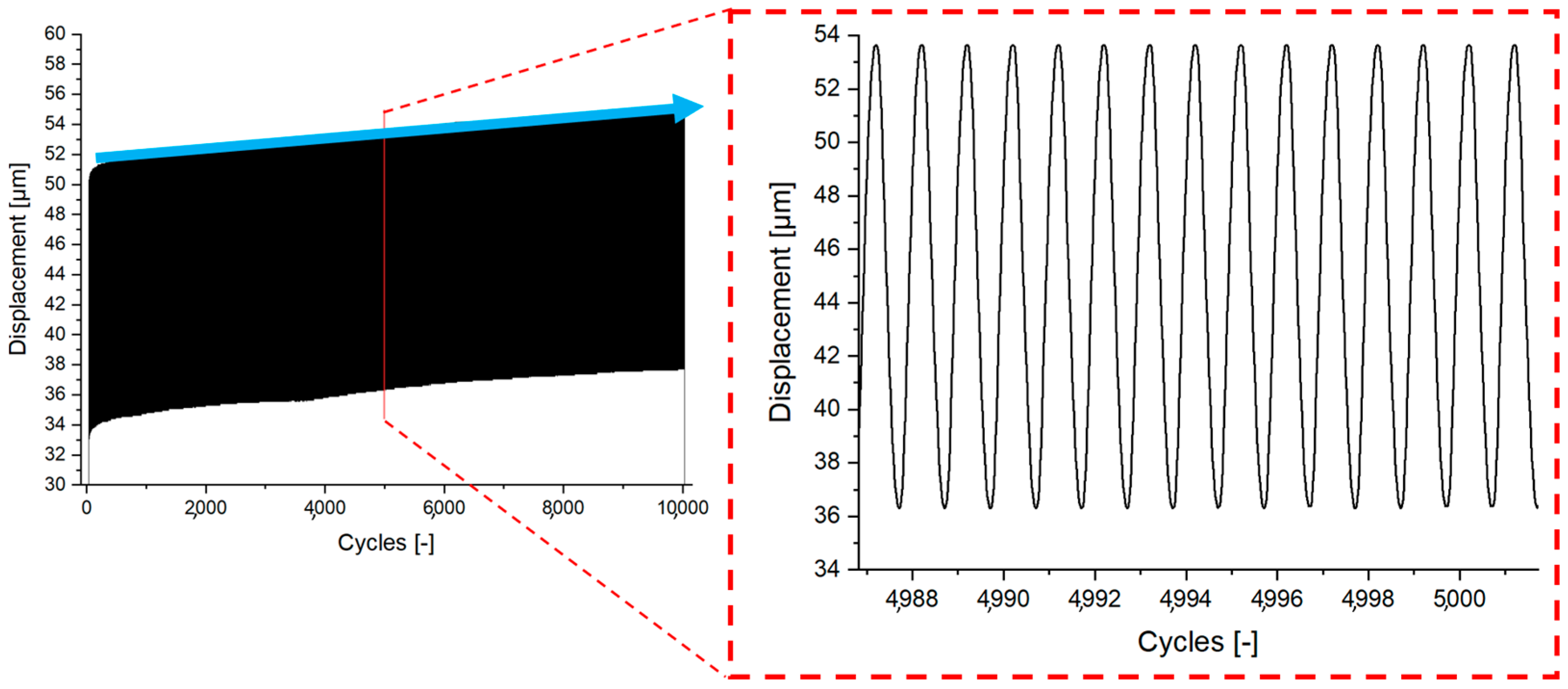

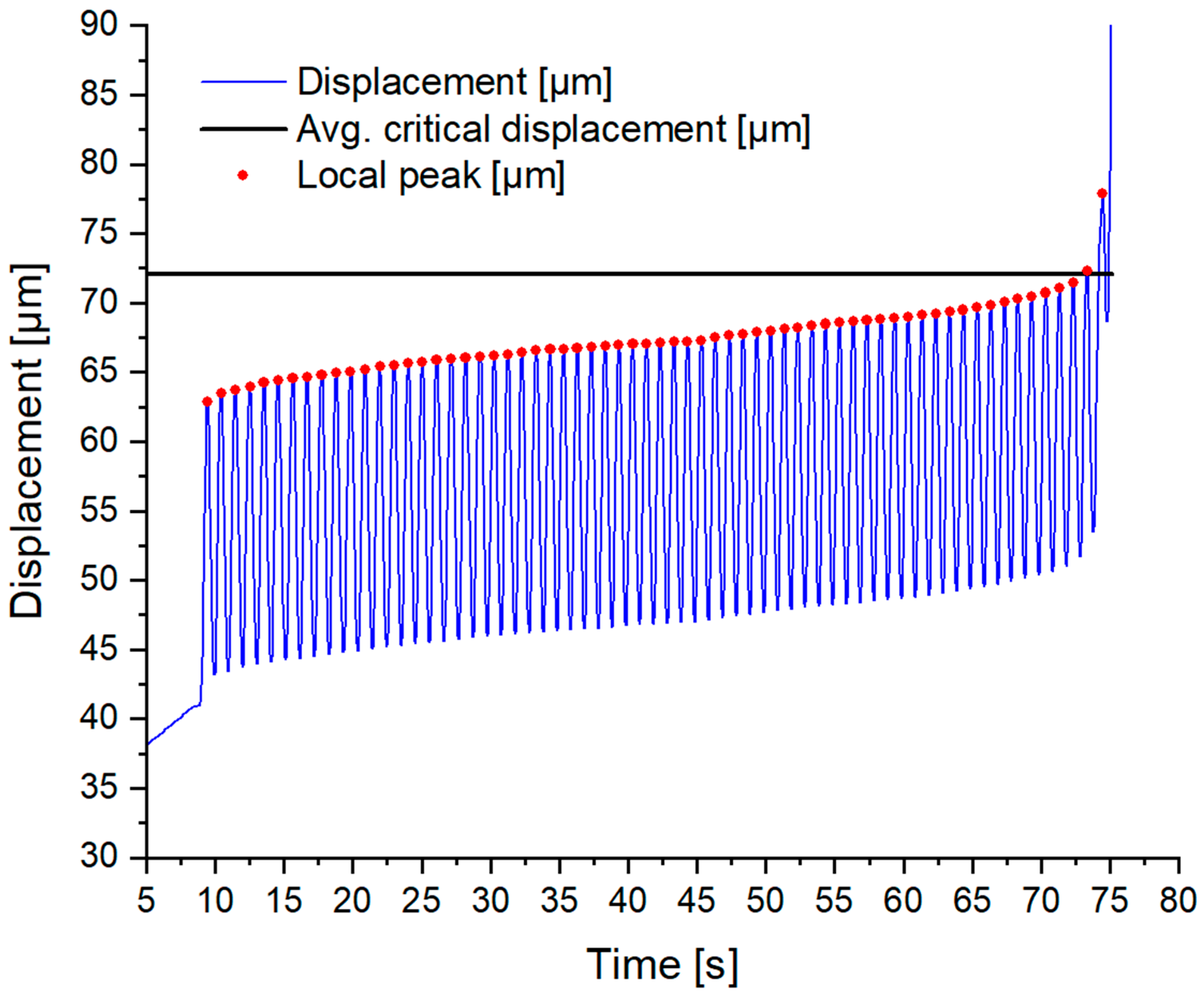

2.3.2. Cyclic Tests with KLST-Type Samples

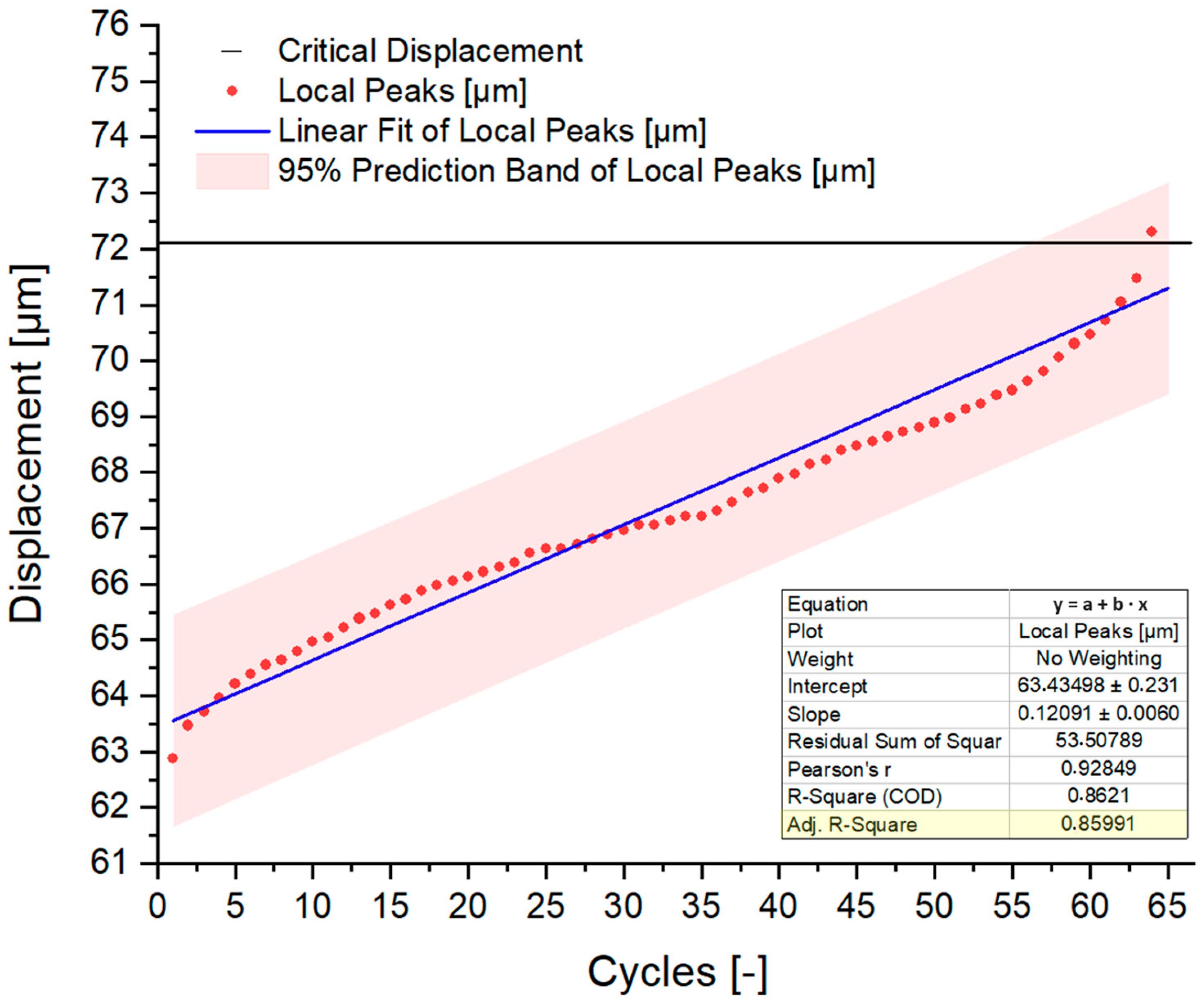

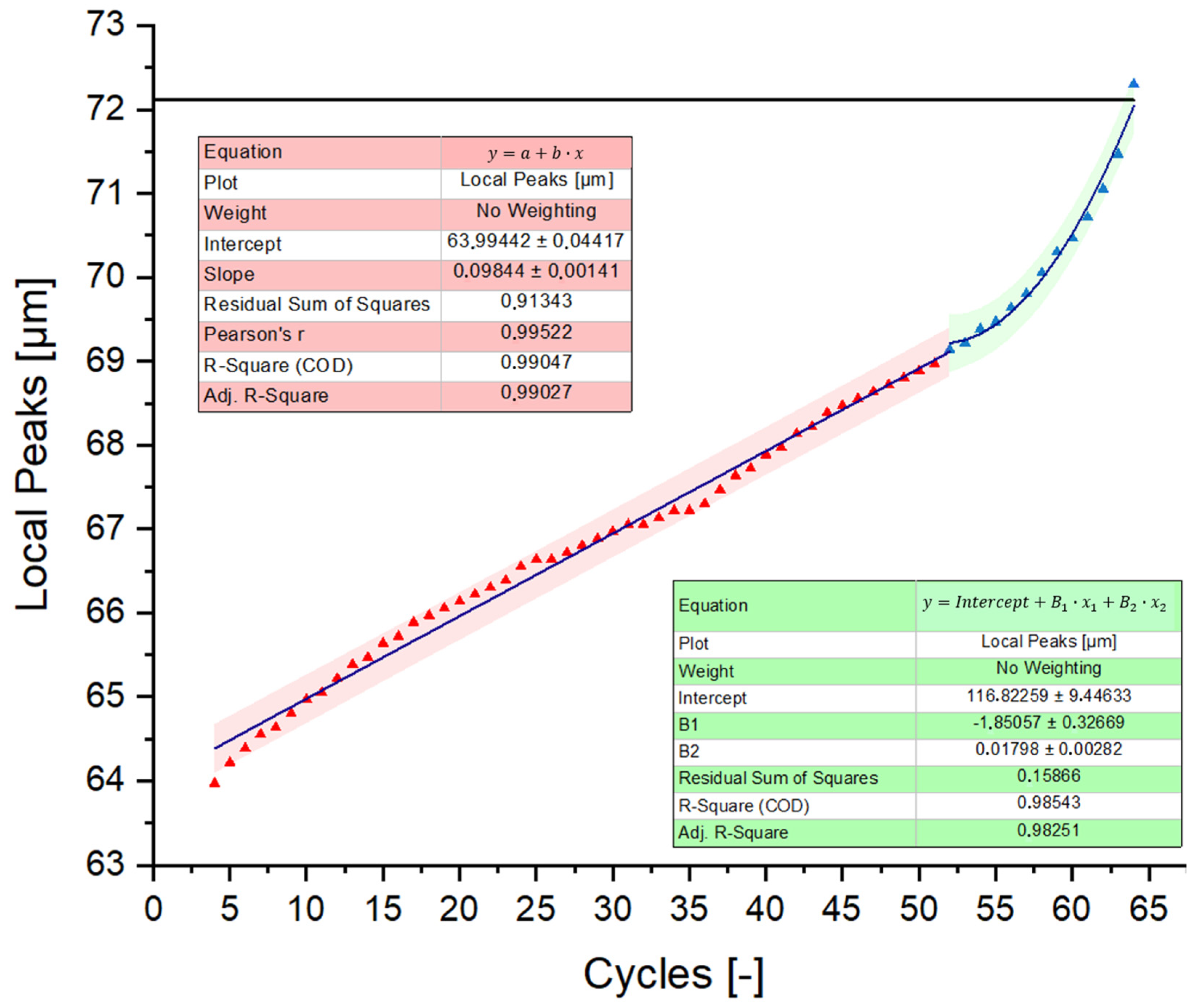

2.3.3. Prediction of the Fatigue Behavior

3. Conclusions and Outlook

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pitts, R.; Carpentier, S.; Escourbiac, F.; Hirai, T.; Komarov, V.; Lisgo, S.; Kukushkin, A.; Loarte, A.; Merola, M.; Naik, A.S.; et al. A full tungsten divertor for ITER: Physics issues and design status. J. Nucl. Mater. 2013, 438, S48–S56. [Google Scholar] [CrossRef]

- Linsmeier, C.; Rieth, M.; Aktaa, J.; Chikada, T.; Hoffmann, A.; Houben, A.; Kurishita, H.; Jin, X.; Li, M.; Litnovsky, A.; et al. Development of advanced high heat flux and plasma-facing materials. Nucl. Fusion 2017, 57, 092007. [Google Scholar] [CrossRef]

- Philipps, V. Tungsten as material for plasma-facing components in fusion devices. J. Nucl. Mater. 2011, 415, S2–S9. [Google Scholar] [CrossRef]

- Coenen, J.W. Fusion Materials Development at Forschungszentrum Jülich. Adv. Eng. Mater. 2020, 22, 1901376. [Google Scholar] [CrossRef]

- Evans, A.; Zok, F.; Davis, J. The Role of Interfaces in Fiber-Reinforced Brittle Matrix Composites. Compos. Sci. Technol. 1991, 42, 3–24. [Google Scholar] [CrossRef]

- Mao, Y.; Coenen, J.; Riesch, J.; Sistla, S.; Almanstötter, J.; Jasper, B.; Terra, A.; Höschen, T.; Gietl, H.; Linsmeier, C.; et al. Influence of the interface strength on the mechanical properties of discontinuous tungsten fiber-reinforced tungsten composites produced by field assisted sintering technology. Compos. Part A Appl. Sci. Manuf. 2018, 107, 342–353. [Google Scholar] [CrossRef]

- Shu, R.; Mao, Y.; Coenen, J.W.; Terra, A.; Liu, C.; Schönen, S.; Riesch, J.; Linsmeier, C.; Broeckmann, C. Interface and mechanical properties of the single-layer long fiber reinforced Wf/W composites fabricated via field assisted sintering technology. Mater. Sci. Eng. A 2022, 857, 144098. [Google Scholar] [CrossRef]

- Gandhi, C.; Ashby, M. Fracture-Mechanism Maps for Materials Which Cleave—Fcc, Bcc and Hcp Metals and Ceramics. Acta Metall. Mater. 1979, 27, 1565–1602. [Google Scholar] [CrossRef]

- Gietl, H.; Olbrich, S.; Riesch, J.; Holzner, G.; Höschen, T.; Coenen, J.; Neu, R. Estimation of the fracture toughness of tungsten fibre-reinforced tungsten composites. Eng. Fract. Mech. 2020, 232, 107011. [Google Scholar] [CrossRef]

- Mao, Y.; Coenen, J.W.; Riesch, J.; Sistla, S.K.; Almanstötter, J.; Reiser, J.; Terra, A.; Chen, C.; Wu, Y.; Raumann, L.; et al. Fracture behavior of random distributed short tungsten fiber-reinforced tungsten composites. Nucl. Fusion 2019, 59, 086034. [Google Scholar] [CrossRef]

- Zinkle, S.; Ghoniem, N. Operating temperature windows for fusion reactor structural materials. Fusion Eng. Des. 2000, 51–52, 55–71. [Google Scholar] [CrossRef]

- Zhang, L.; Jiang, Y.; Fang, Q.; Zhang, T.; Wang, X.; Liu, C. Toughness and microstructure of tungsten fibre net-reinforced tungsten composite produced by spark plasma sintering. Mater. Sci. Eng. A 2016, 659, 29–36. [Google Scholar] [CrossRef]

- Zhang, L.; Jiang, Y.; Fang, Q.; Xie, Z.; Miao, S.; Zeng, L.; Zhang, T.; Wang, X.; Liu, C. Microstructure and mechanical properties of tungsten composite reinforced by fibre network. Front. Mater. Sci. 2017, 11, 190–196. [Google Scholar] [CrossRef]

- Zhang, L.; Jiang, Y.; Fang, Q.; Liu, R.; Xie, Z.; Zhang, T.; Wang, X.; Liu, C. Comparative Investigation of Tungsten Fibre Nets Reinforced Tungsten Composite Fabricated by Three Different Methods. Metals 2017, 7, 249. [Google Scholar] [CrossRef]

- Mao, Y.; Coenen, J.W.; Riesch, J.; Sistla, S.; Chen, C.; Wu, Y.; Raumann, L.; Neu, R.; Linsmeier, C.; Broeckmann, C. Spark Plasma Sintering Produced W-Fiber-Reinforced Tungsten Composites. In Spark Plasma Sintering of Materials: Advances in Processing and Applications; Springer Nature: Cham, Switzerland, 2019; pp. 239–261. [Google Scholar] [CrossRef]

- Treitz, M. Development of Production Routines for Fibre Reinforced Metal Matrix Composites. Master’s Thesis, University of Applied Sciences Munich, Munich, Germany, 2019. [Google Scholar]

- Schwalenberg, D.; Coenen, J.W.; Riesch, J.; Hoeschen, T.; Mao, Y.; Lau, A.; Gietl, H.; Raumann, L.; Huber, P.; Linsmeier, C.; et al. Large-Scale Tungsten Fibre-Reinforced Tungsten and Its Mechanical Properties. J. Nucl. Eng. 2022, 3, 306–320. [Google Scholar] [CrossRef]

- Zhao, S.X.; Liu, F.; Qin, S.G.; Song, J.P.; Luo, G.N. Preliminary Results of W Fiber Reinforced W (Wf/W) Composites Fabricated with Powder Metallurgy. Fusion Sci. Technol. 2013, 64, 225–229. [Google Scholar] [CrossRef]

- Riesch, J.; Höschen, T.; Linsmeier, C.; Wurster, S.; You, J.-H. Enhanced toughness and stable crack propagation in a novel tungsten fibre-reinforced tungsten composite produced by chemical vapour infiltration. Phys. Scr. 2014, T159, 014031. [Google Scholar] [CrossRef]

- Riesch, J.; Han, Y.; Almanstötter, J.; Coenen, J.W.; Höschen, T.; Jasper, B.; Zhao, P.; Linsmeier, C.; Neu, R. Development of tungsten fibre-reinforced tungsten composites towards their use in DEMO—Potassium doped tungsten wire. Phys. Scr. 2016, T167, 014006. [Google Scholar] [CrossRef]

- Mao, Y.; Coenen, J.; Sistla, S.; Liu, C.; Terra, A.; Tan, X.; Riesch, J.; Hoeschen, T.; Wu, Y.; Broeckmann, C.; et al. Design of tungsten fiber-reinforced tungsten composites with porous matrix. Mater. Sci. Eng. A 2021, 817, 141361. [Google Scholar] [CrossRef]

- Mao, Y.; Coenen, J.W.; Sistla, S.; Tan, X.; Riesch, J.; Raumann, L.; Schwalenberg, D.; Höschen, T.; Chen, C.; Wu, Y.; et al. Development of tungsten fiber-reinforced tungsten with a porous matrix. Phys. Scr. 2020, T171, 014030. [Google Scholar] [CrossRef]

- Terentyev, D.; Riesch, J.; Lebediev, S.; Bakaeva, A.; Coenen, J. Mechanical properties of as-fabricated and 2300 °C annealed tungsten wire tested up to 600 °C. Int. J. Refract. Met. Hard Mater. 2017, 66, 127–134. [Google Scholar] [CrossRef]

- Zhao, P.; Riesch, J.; Höschen, T.; Almanstötter, J.; Balden, M.; Coenen, J.; Himml, R.; Pantleon, W.; von Toussaint, U.; Neu, R. Microstructure, mechanical behaviour and fracture of pure tungsten wire after different heat treatments. Int. J. Refract. Met. Hard Mater. 2017, 68, 29–40. [Google Scholar] [CrossRef]

- Coenen, J.W.; Antusch, S.; Aumann, M.; Biel, W.; Du, J.; Engels, J.; Heuer, S.; Houben, A.; Hoeschen, T.; Jasper, B.; et al. Materials for DEMO and reactor applications—Boundary conditions and new concepts. Phys. Scr. 2015, T167, 014002. [Google Scholar] [CrossRef]

- Raumann, L.; Coenen, J.W.; Riesch, J.; Mao, Y.; Gietl, H.; Höschen, T.; Linsmeier, C.; Guillon, O. Modeling and validation of chemical vapor deposition of tungsten for tungsten fiber reinforced tungsten composites. Surf. Coat. Technol. 2019, 381, 124745. [Google Scholar] [CrossRef]

- Gietl, H.; Riesch, J.; Coenen, J.; Höschen, T.; Neu, R. Production of tungsten-fibre reinforced tungsten composites by a novel continuous chemical vapour deposition process. Fusion Eng. Des. 2019, 146, 1426–1430. [Google Scholar] [CrossRef]

- Raumann, L.; Coenen, J.; Riesch, J.; Mao, Y.; Schwalenberg, D.; Wegener, T.; Gietl, H.; Hoschen, T.; Linsmeier, C.; Guillon, O. Modeling and experimental validation of a W-f/W-fabrication by chemical vapor deposition and infiltration. Nucl. Mater. Energy 2021, 28, 101048. [Google Scholar] [CrossRef]

- Raumann, L.; Coenen, J.; Riesch, J.; Mao, Y.; Schwalenberg, D.; Gietl, H.; Linsmeier, C.; Guillon, O. Improving the W Coating Uniformity by a COMSOL Model-Based CVD Parameter Study for Denser W-f/W Composites. Metals 2021, 11, 1089. [Google Scholar] [CrossRef]

- You, J.; Visca, E.; Bachmann, C.; Barrett, T.; Crescenzi, F.; Fursdon, M.; Greuner, H.; Guilhem, D.; Languille, P.; Li, M.; et al. European DEMO divertor target: Operational requirements and material-design interface. Nucl. Mater. Energy 2016, 9, 171–176. [Google Scholar] [CrossRef]

- Mao, Y.; Engels, J.; Houben, A.; Rasinski, M.; Steffens, J.; Terra, A.; Linsmeier, C.; Coenen, J. The influence of annealing on yttrium oxide thin film deposited by reactive magnetron sputtering: Process and microstructure. Nucl. Mater. Energy 2017, 10, 1–8. [Google Scholar] [CrossRef]

- Garrison, L.; Katoh, Y.; Snead, L.; Byun, T.; Reiser, J.; Rieth, M. Irradiation effects in tungsten-copper laminate composite. J. Nucl. Mater. 2016, 481, 134–146. [Google Scholar] [CrossRef]

- Coenen, J.; Berger, M.; Demkowicz, M.; Matveev, D.; Manhard, A.; Neu, R.; Riesch, J.; Unterberg, B.; Wirtz, M.; Linsmeier, C. Plasma-wall interaction of advanced materials. Nucl. Mater. Energy 2017, 12, 307–312. [Google Scholar] [CrossRef]

- Palaniyappan, S.; Trautmann, M.; Mao, Y.; Riesch, J.; Gowda, P.; Rudolph, N.; Coenen, J.W.; Neu, R.; Wagner, G. Yttria-Coated Tungsten Fibers for Use in Tungsten Fiber-Reinforced Composites: A Comparative Study on PVD vs. CVD Routes. Coatings 2021, 11, 1128. [Google Scholar] [CrossRef]

- Gietl, H.; von Muller, A.; Coenen, J.; Decius, M.; Ewert, D.; Hoschen, T.; Huber, P.; Milwich, M.; Riesch, J.; Neu, R. Textile pre-forms for tungsten fibre-reinforced composites. J. Compos. Mater. 2018, 52, 3875–3884. [Google Scholar] [CrossRef]

- Coenen, J.W.; Huber, P.; Lau, A.; Raumann, L.; Schwalenberg, D.; Mao, Y.; Riesch, J.; Terra, A.; Linsmeier, C.; Neu, R. Tungsten fiber reinforced tungsten (Wf/W) using yarn based textile preforms. Phys. Scr. 2021, 96, 124063. [Google Scholar] [CrossRef]

- Coenen, J.; Treitz, M.; Gietl, H.; Huber, P.; Hoeschen, T.; Raumann, L.; Schwalenberg, D.; Mao, Y.; Riesch, J.; Terra, A.; et al. The use of tungsten yarns in the production for W-f/W. Phys. Scr. 2020, T171, 014061. [Google Scholar] [CrossRef]

- Hertzberg, R.; Vinci, R.; Hertzberg, J. Deformation and Fracture Mechanics of Engineering Materials, 6th ed.; Wiley: Hoboken, NJ, USA, 2020. [Google Scholar]

- Meyers, M.; Chawla, K. Mechanical Behavior of Materials, 2nd ed.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2009. [Google Scholar]

| Aspect | Type 1 | Type 2 |

|---|---|---|

| Weft material | Yarn R.B. 16 + 7 | Yarn R.B. 16 + 7 |

| Warp material | 50 µm filament | Yarn R.B. 16 + 7 |

| Avg. relative density | 97.14% | 96.59% |

| Fiber volume fraction | 14–17% | 7–10% |

| Processing Multilayer | very good | macroscopic gaps |

| Avg. max. load (KLST-type samples) | 299.74 N | 243.96 N |

| 10,000 cycles between 50–90% of rel. max. load | Sample intact—prediction possible | Sample intact—prediction not possible |

| Reproducibility | Very good | OK |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lau, A.; Coenen, J.W.; Schwalenberg, D.; Mao, Y.; Höschen, T.; Riesch, J.; Raumann, L.; Treitz, M.; Gietl, H.; Terra, A.; et al. Bulk Tungsten Fiber-Reinforced Tungsten (Wf/W) Composites Using Yarn-Based Textile Preforms. J. Nucl. Eng. 2023, 4, 375-390. https://doi.org/10.3390/jne4020027

Lau A, Coenen JW, Schwalenberg D, Mao Y, Höschen T, Riesch J, Raumann L, Treitz M, Gietl H, Terra A, et al. Bulk Tungsten Fiber-Reinforced Tungsten (Wf/W) Composites Using Yarn-Based Textile Preforms. Journal of Nuclear Engineering. 2023; 4(2):375-390. https://doi.org/10.3390/jne4020027

Chicago/Turabian StyleLau, Alexander, Jan Willem Coenen, Daniel Schwalenberg, Yiran Mao, Till Höschen, Johann Riesch, Leonard Raumann, Michael Treitz, Hanns Gietl, Alexis Terra, and et al. 2023. "Bulk Tungsten Fiber-Reinforced Tungsten (Wf/W) Composites Using Yarn-Based Textile Preforms" Journal of Nuclear Engineering 4, no. 2: 375-390. https://doi.org/10.3390/jne4020027

APA StyleLau, A., Coenen, J. W., Schwalenberg, D., Mao, Y., Höschen, T., Riesch, J., Raumann, L., Treitz, M., Gietl, H., Terra, A., Göhts, B., Linsmeier, C., Theis-Bröhl, K., & Gonzalez-Julian, J. (2023). Bulk Tungsten Fiber-Reinforced Tungsten (Wf/W) Composites Using Yarn-Based Textile Preforms. Journal of Nuclear Engineering, 4(2), 375-390. https://doi.org/10.3390/jne4020027