Strain Localisation and Fracture of Nuclear Reactor Core Materials

Abstract

1. Introduction

2. Unirradiated Material

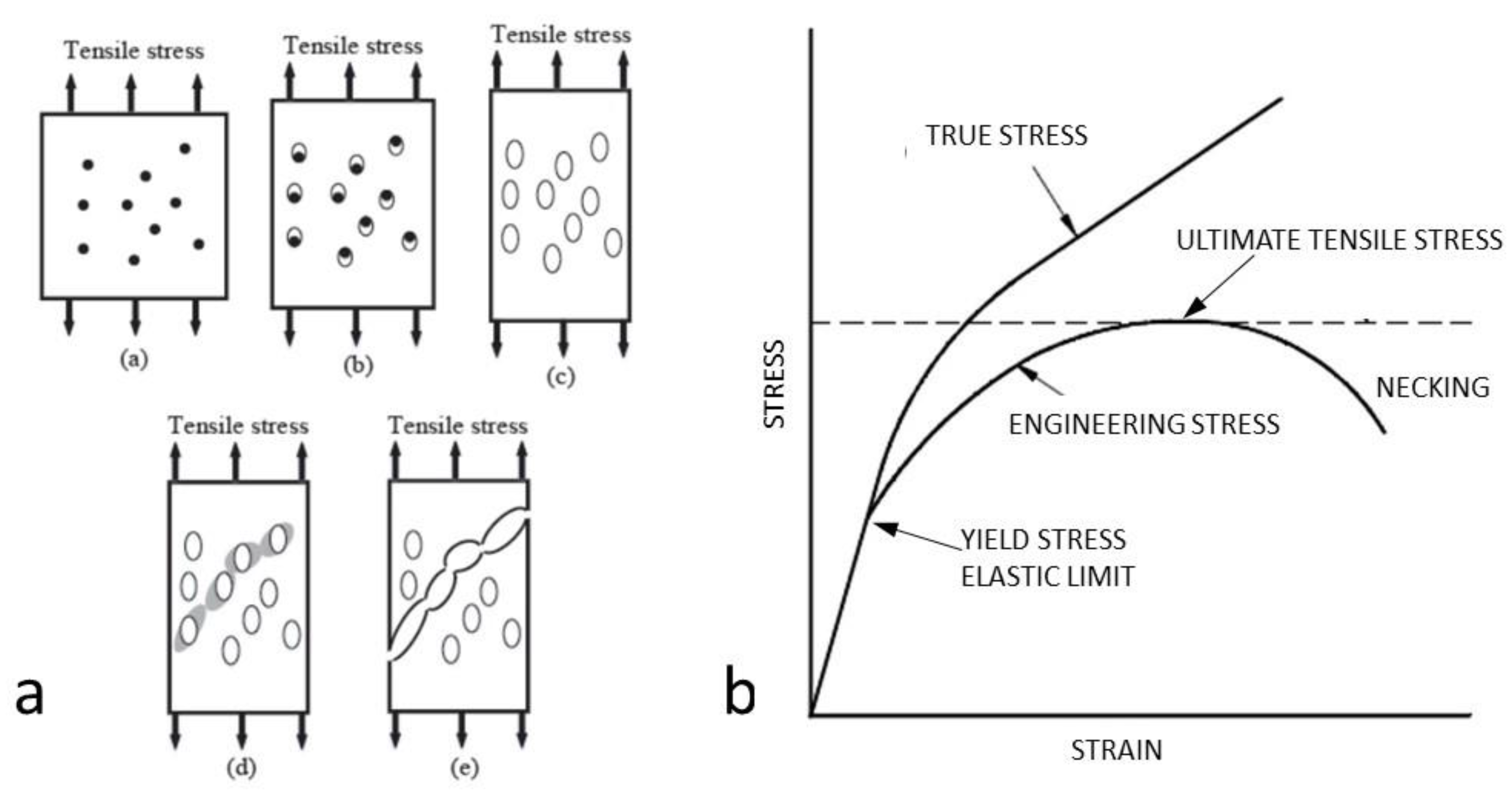

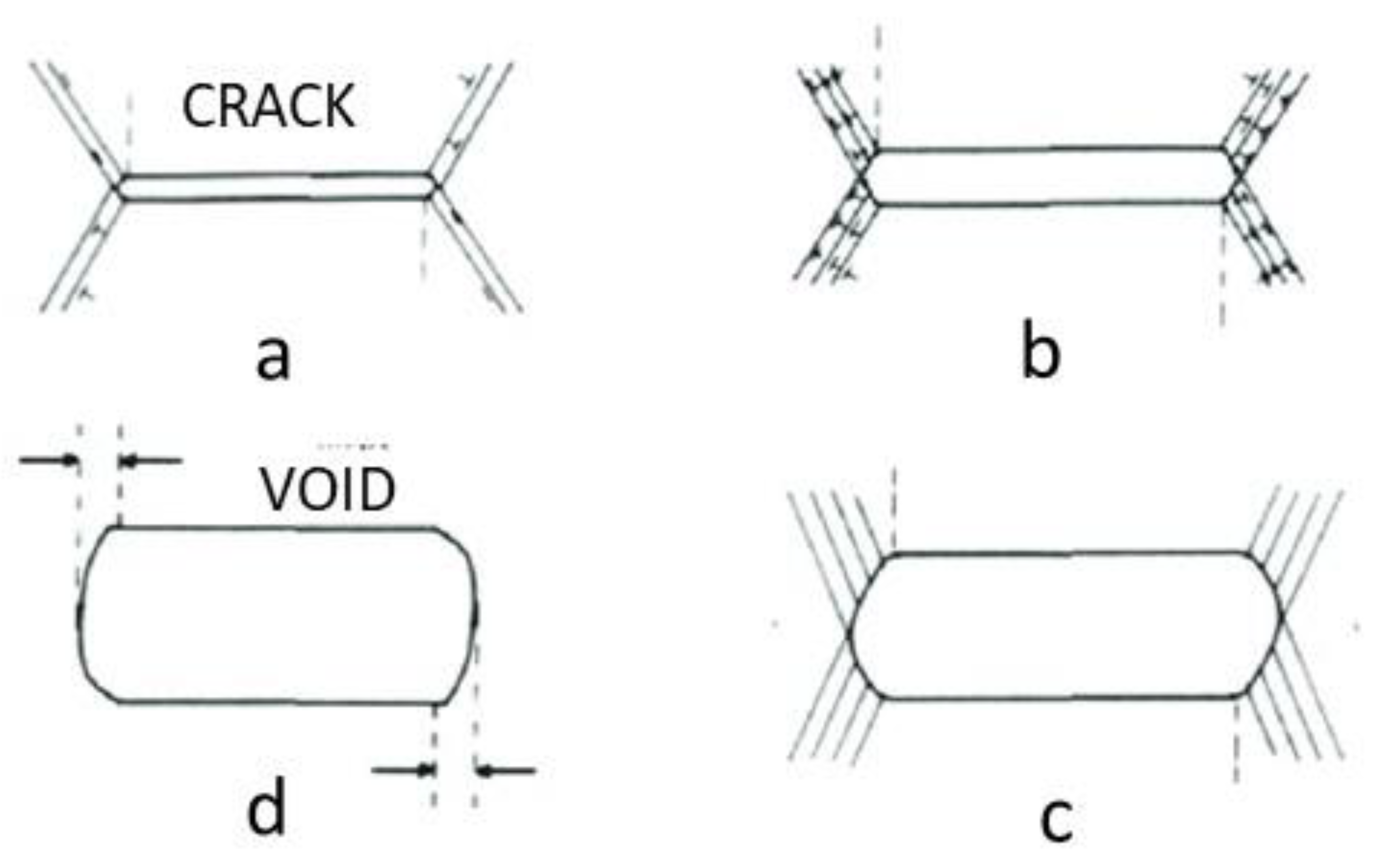

2.1. Ductile Deformation and Fracture

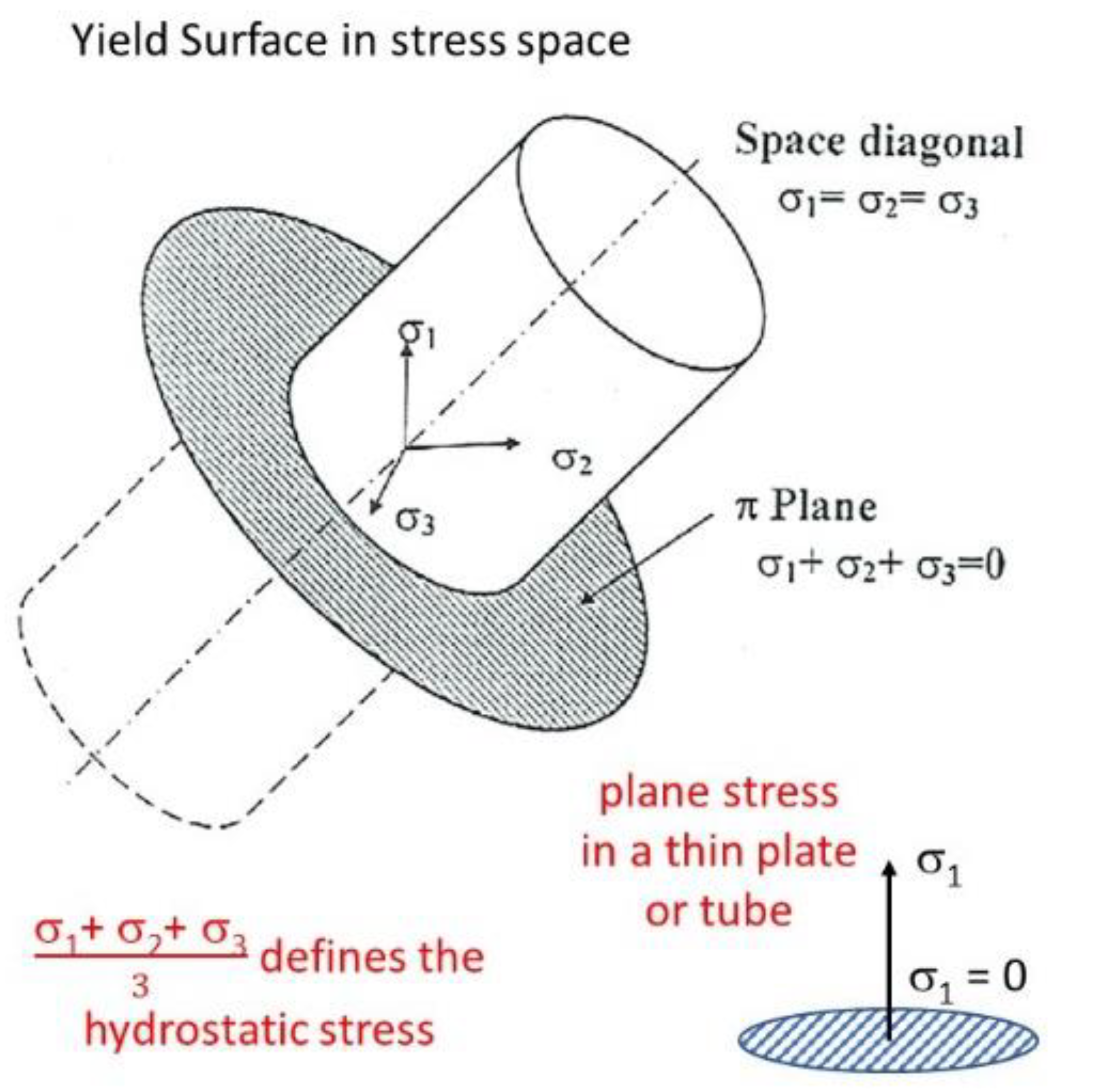

2.2. Yield Criteria and Creep

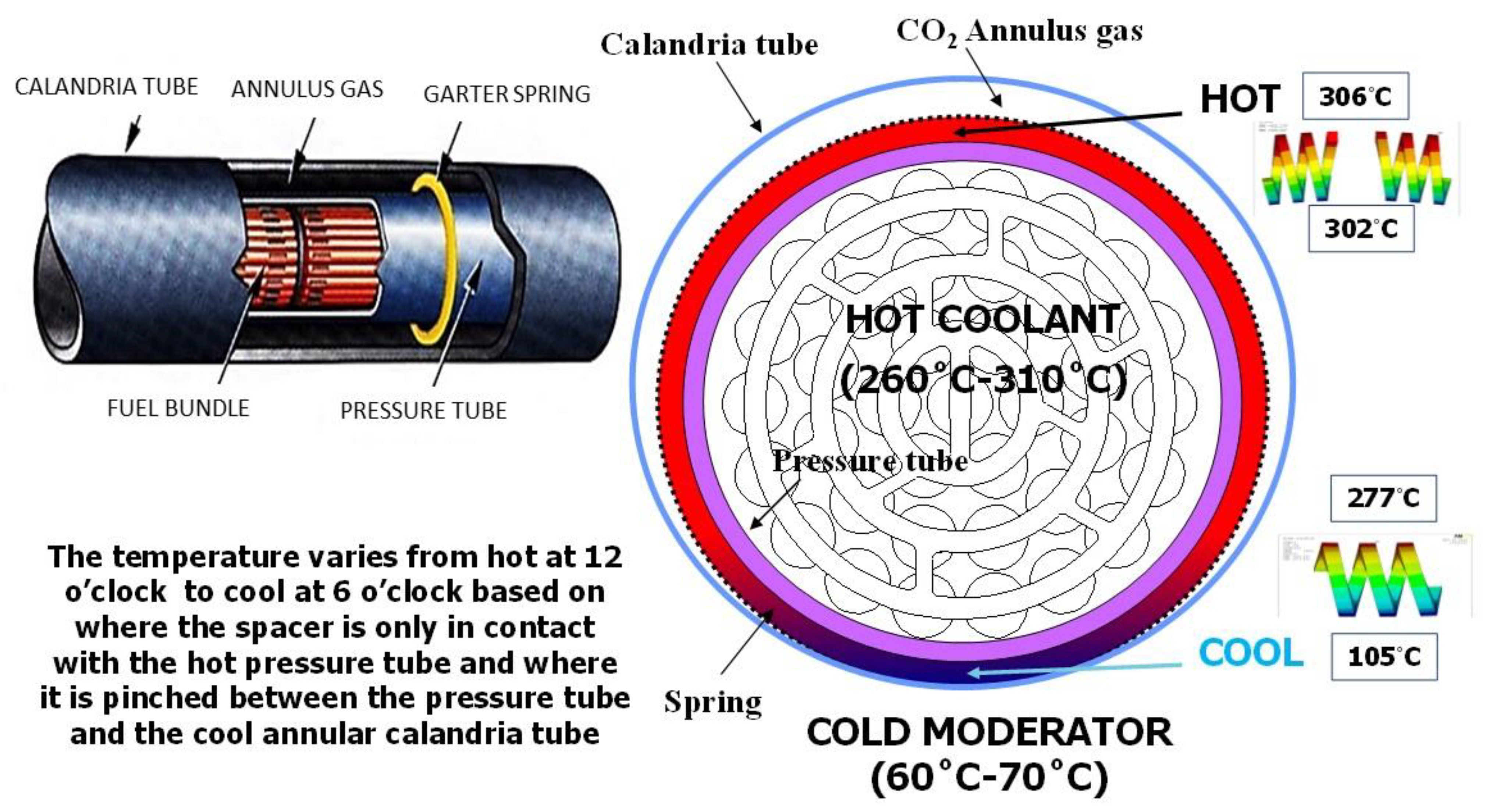

2.3. Texture-Induced Flow Localisation—Calandria Tube Failure

3. Irradiated Material

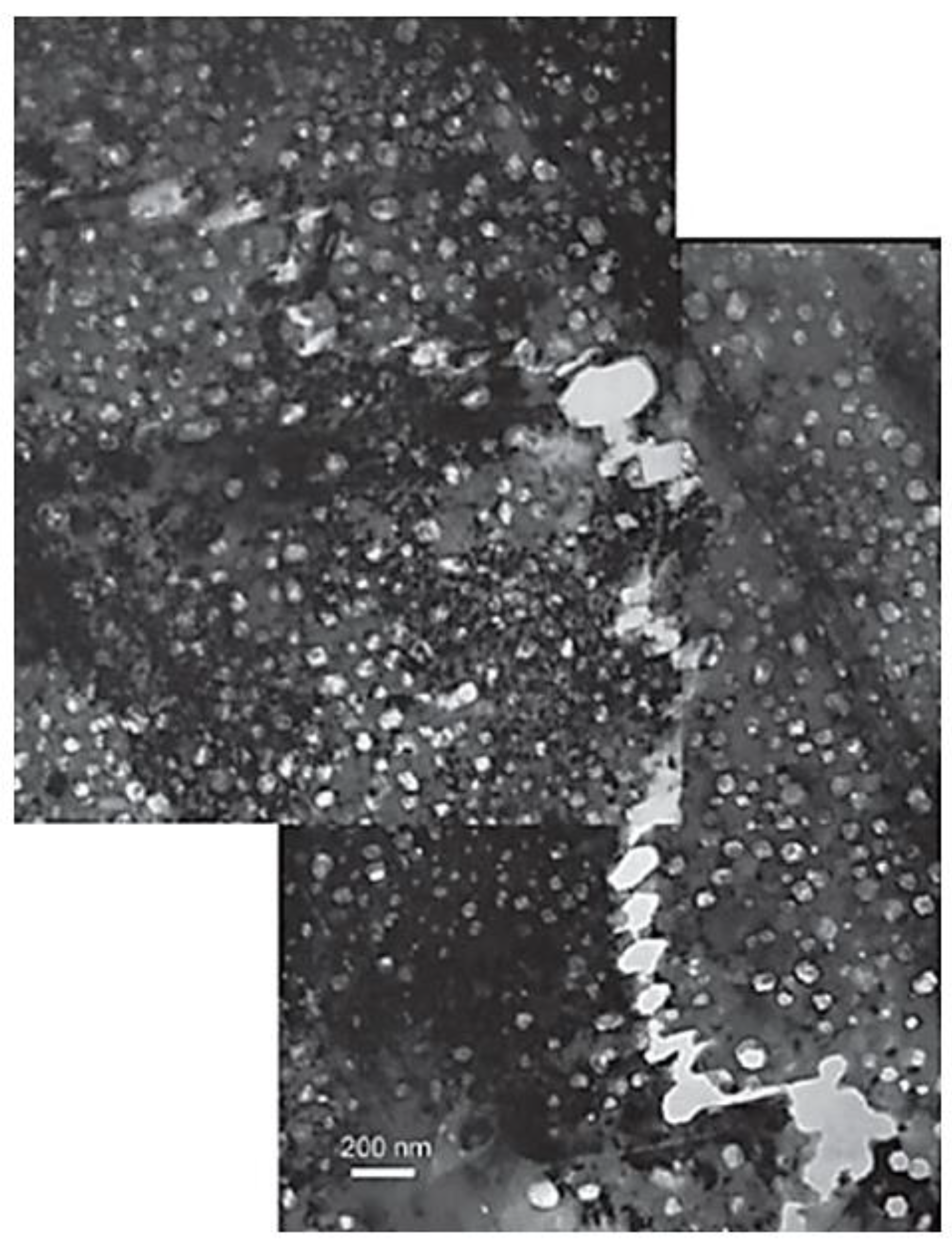

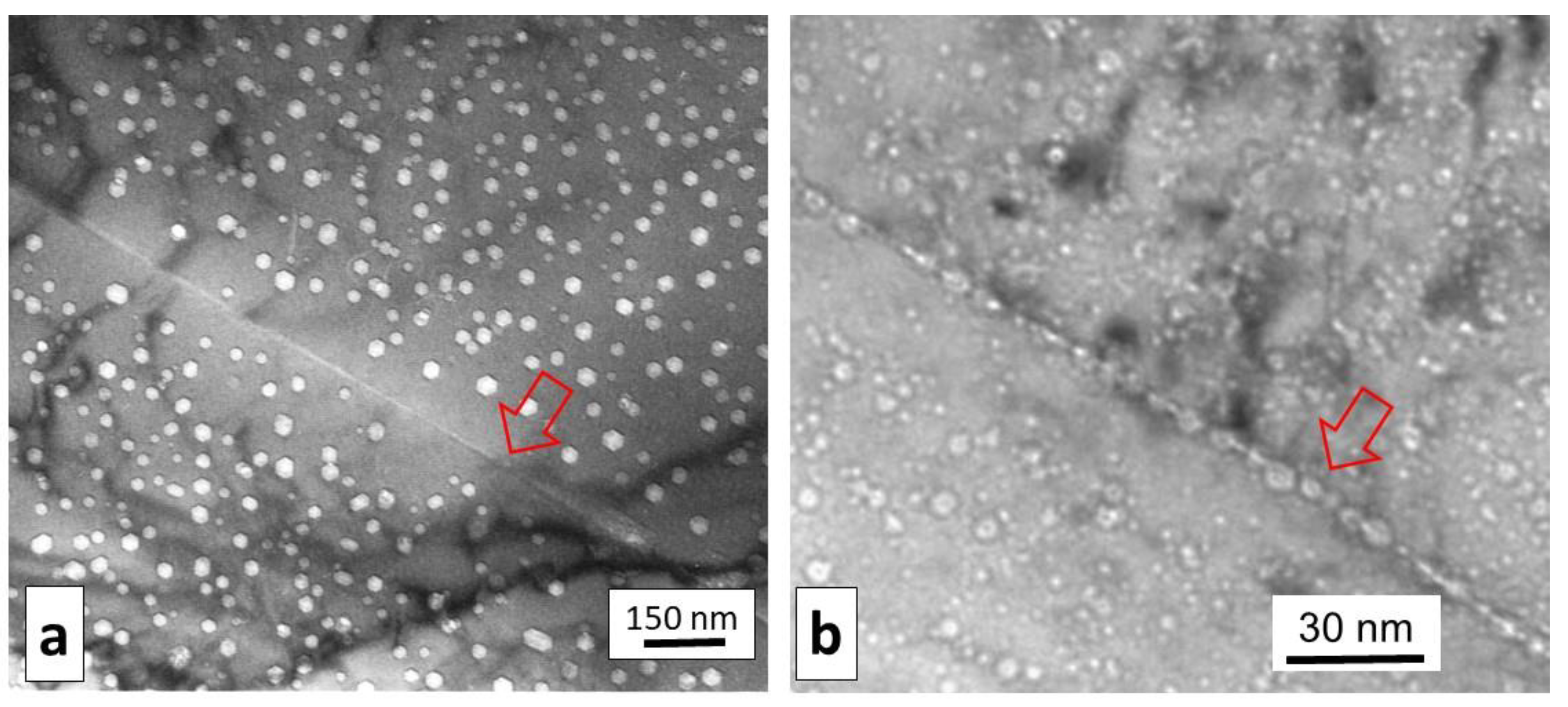

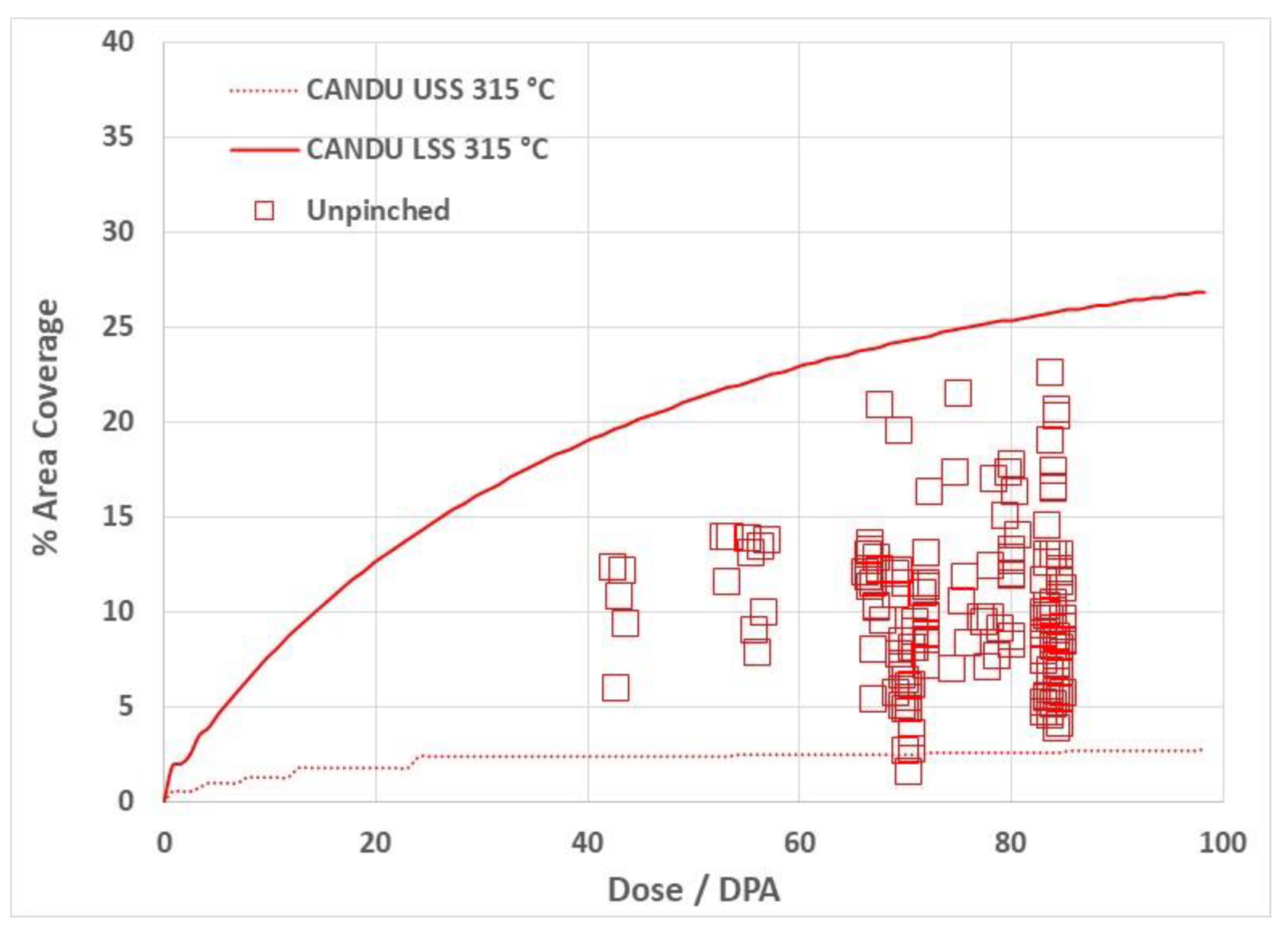

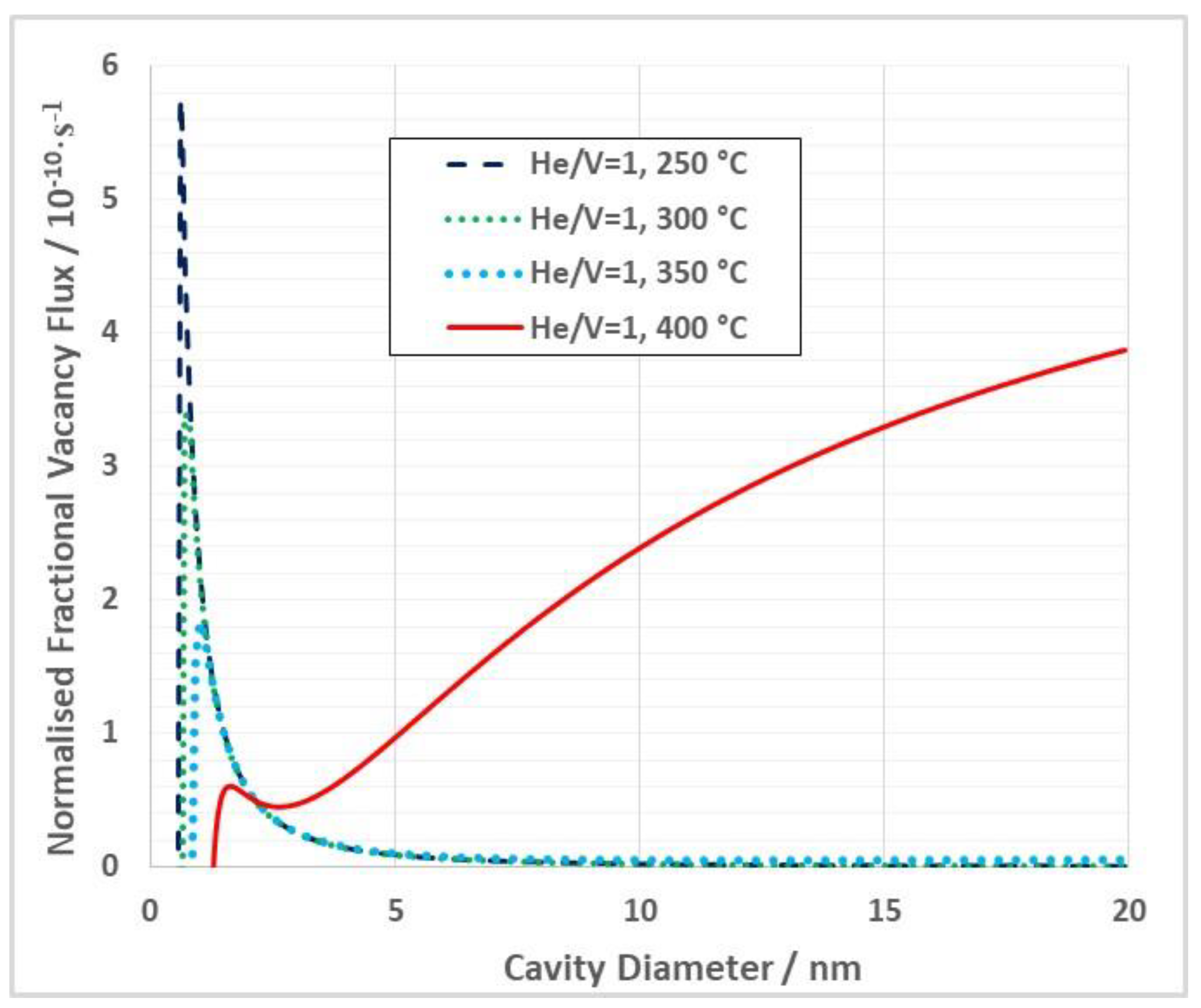

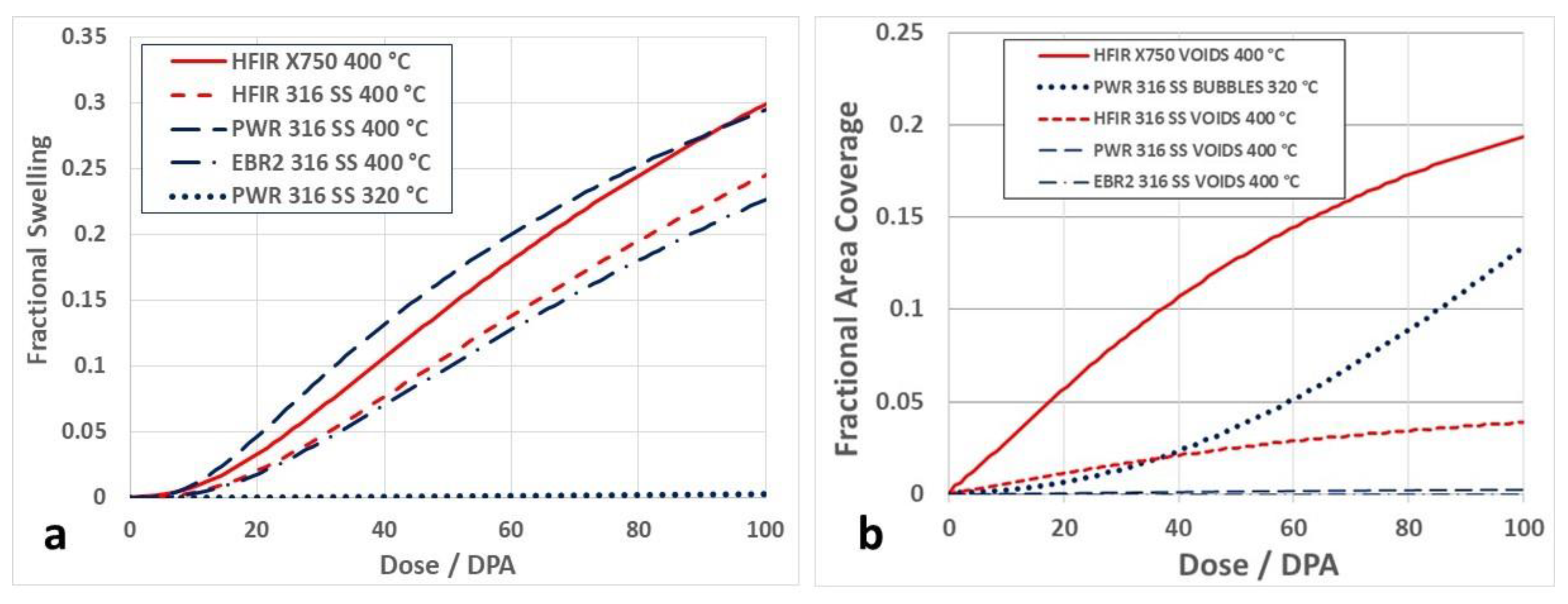

3.1. Swelling-Induced Embrittlement

3.2. Channeling-Induced Embrittlement

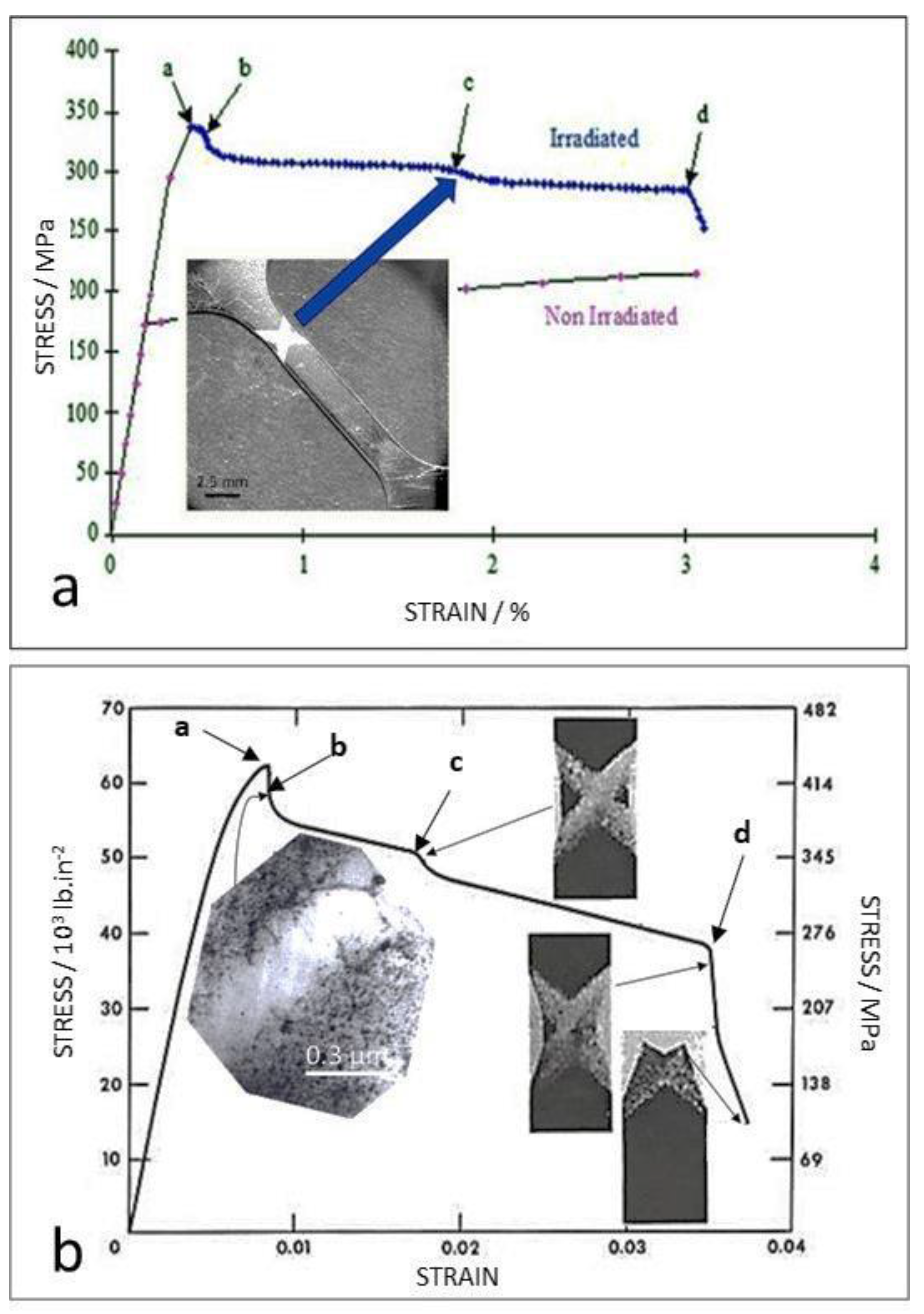

3.2.1. Zirconium Alloys

3.2.2. Austenitic Stainless Steels and Nickel Alloys

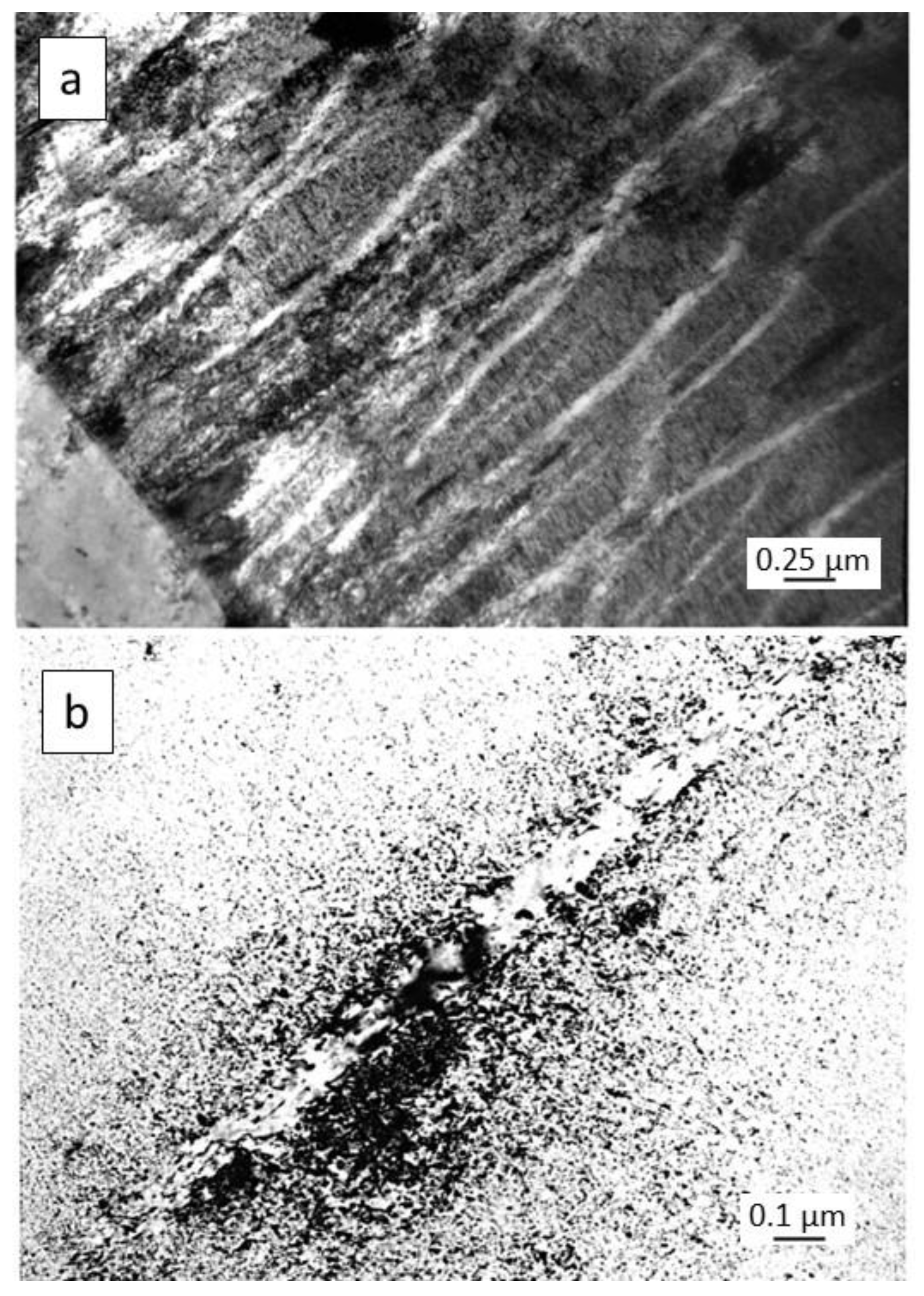

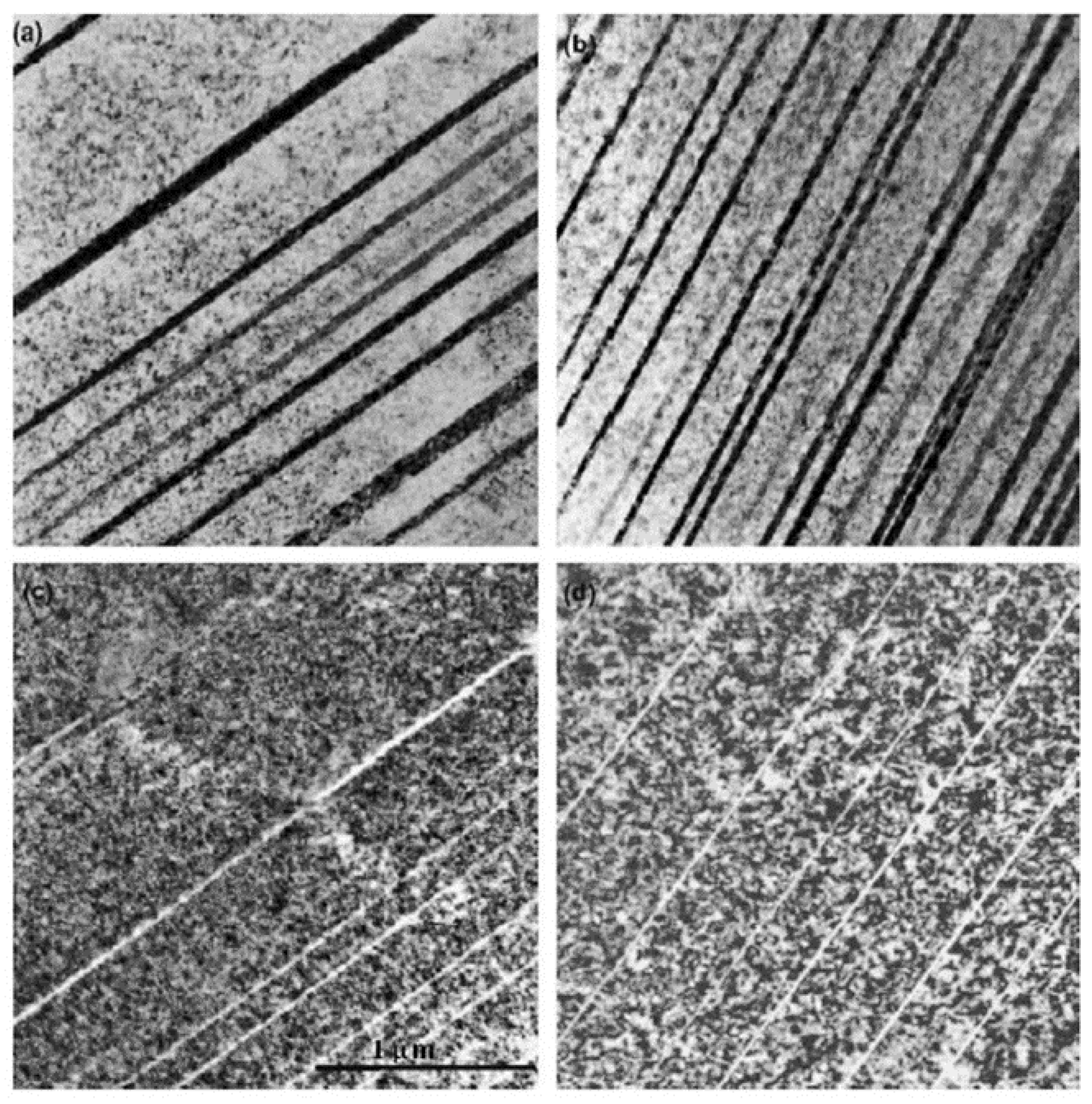

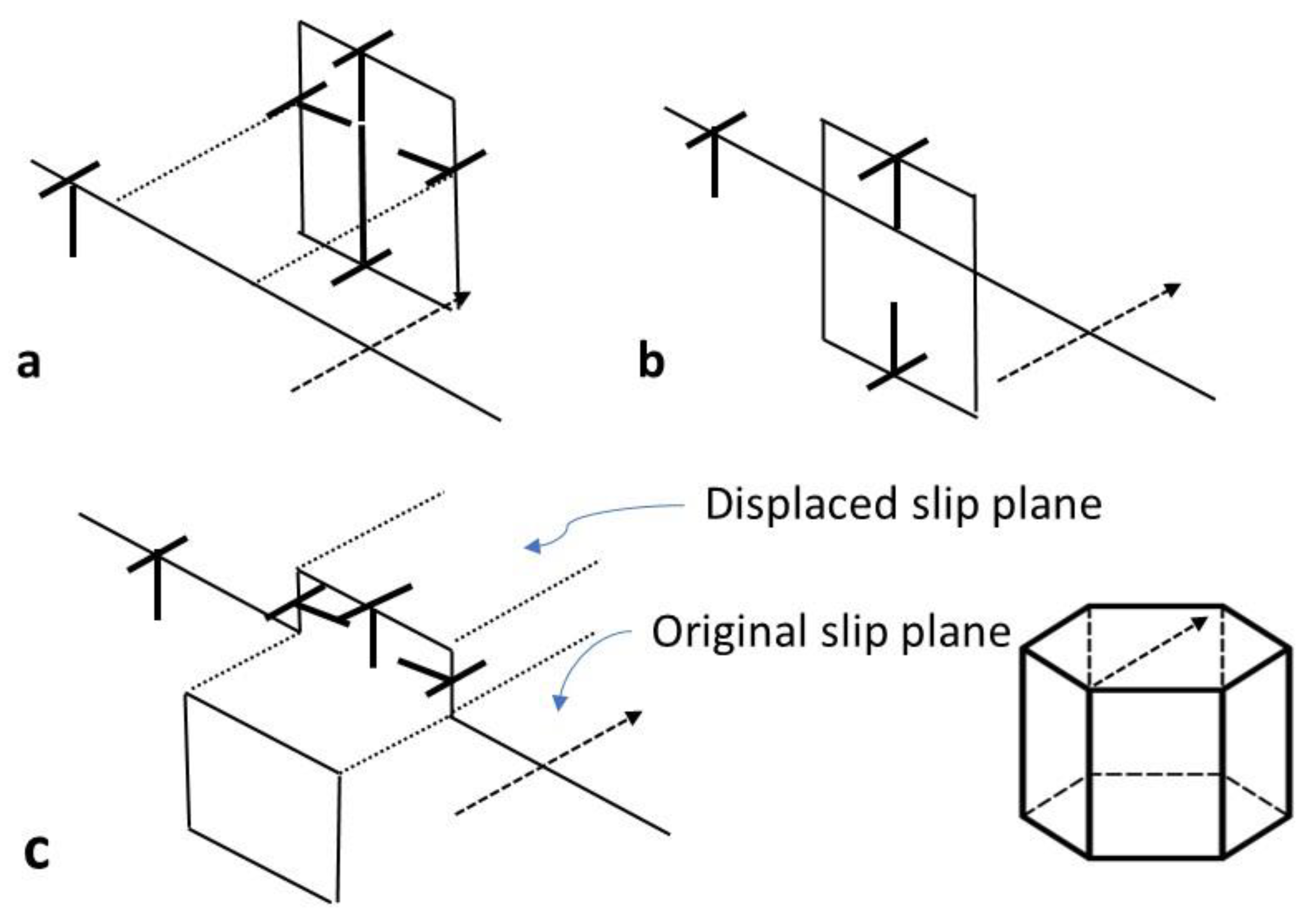

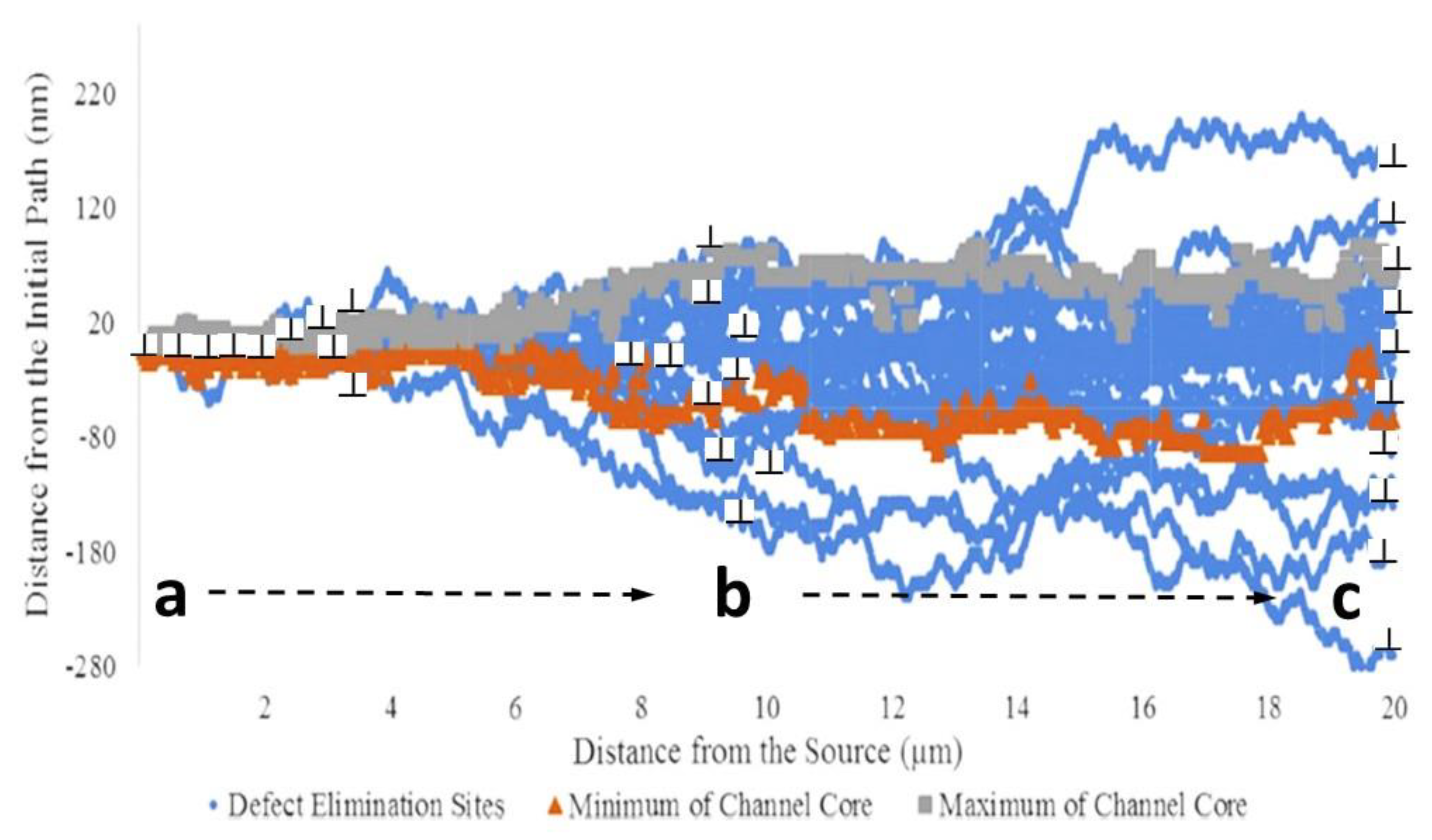

3.2.3. Channeling Mechanism

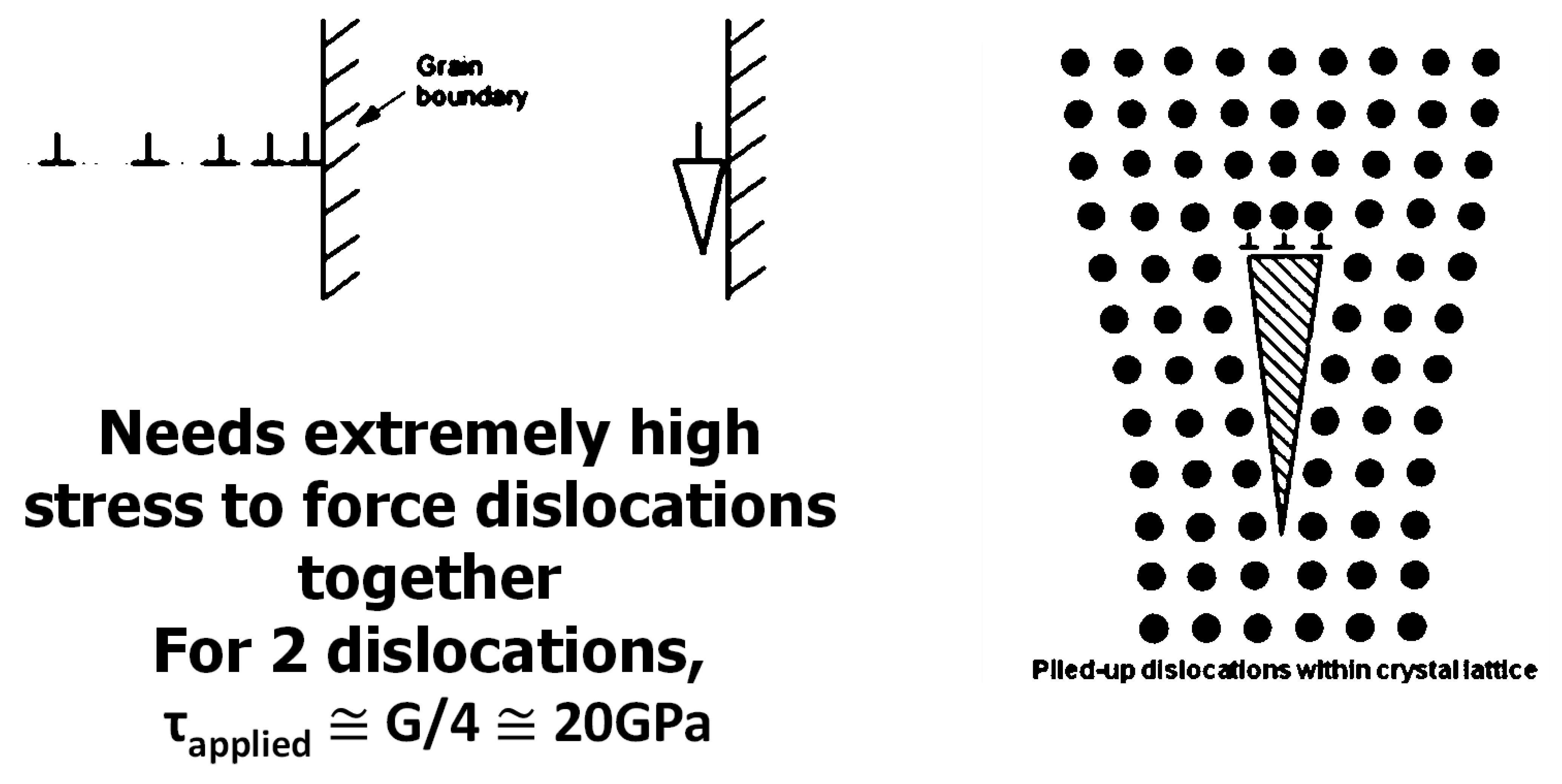

3.2.4. Stroh Cracks

3.2.5. Cracking

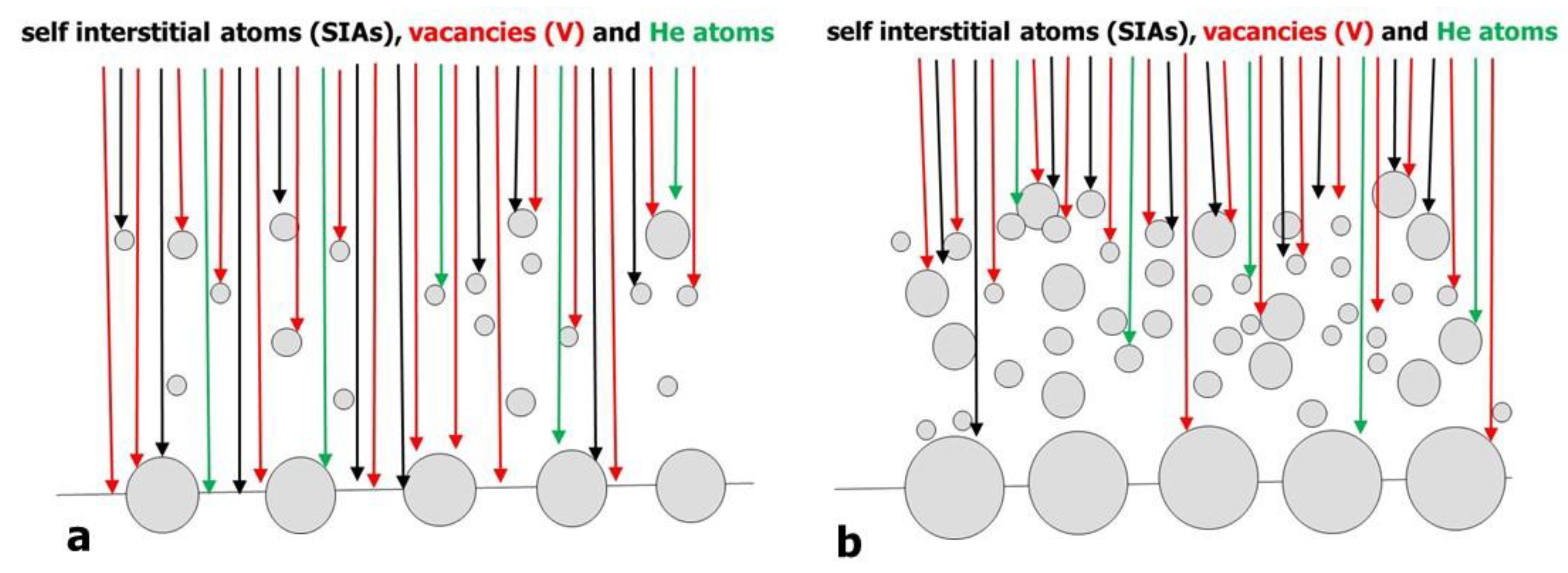

4. Helium Embrittlement

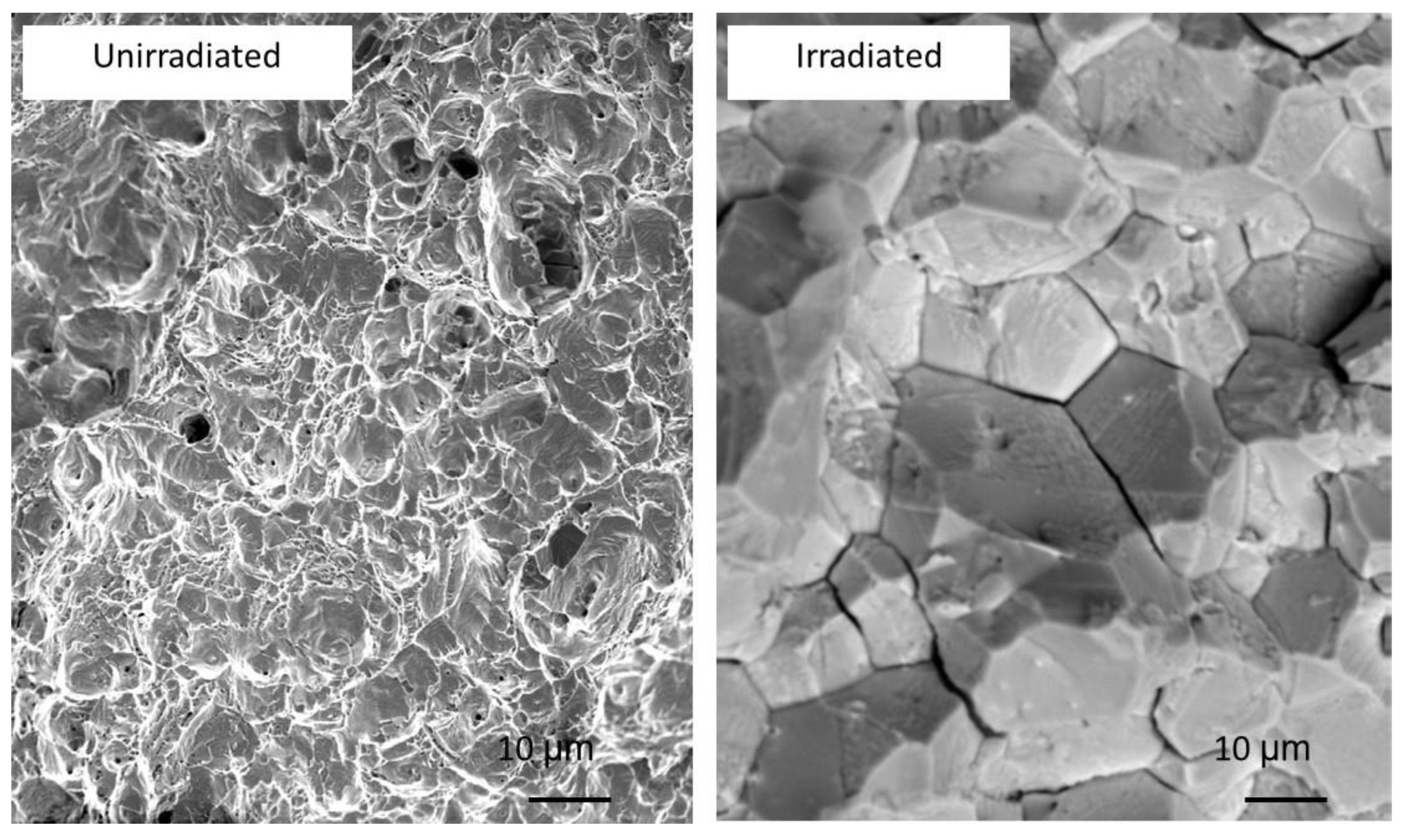

4.1. Intergranular Fracture

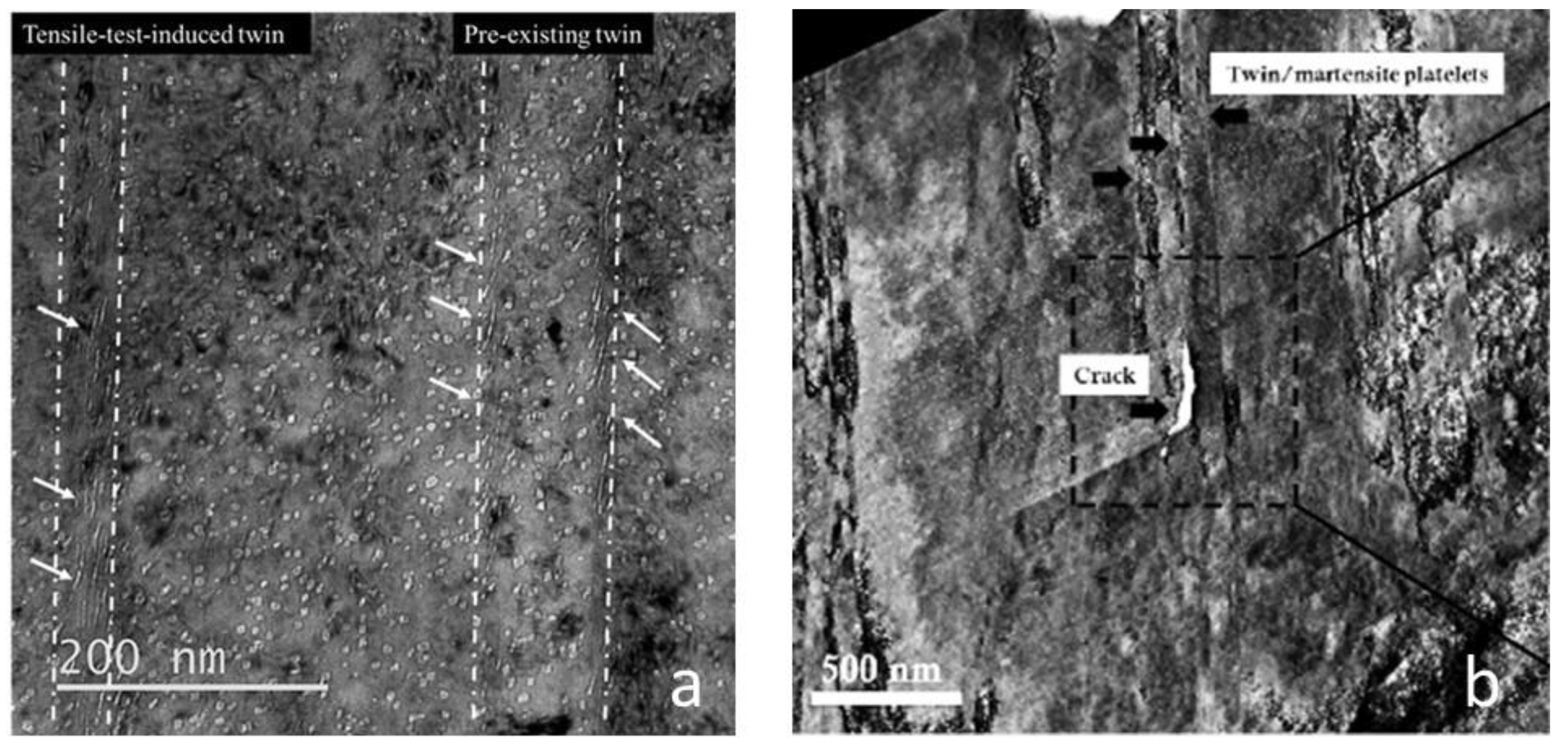

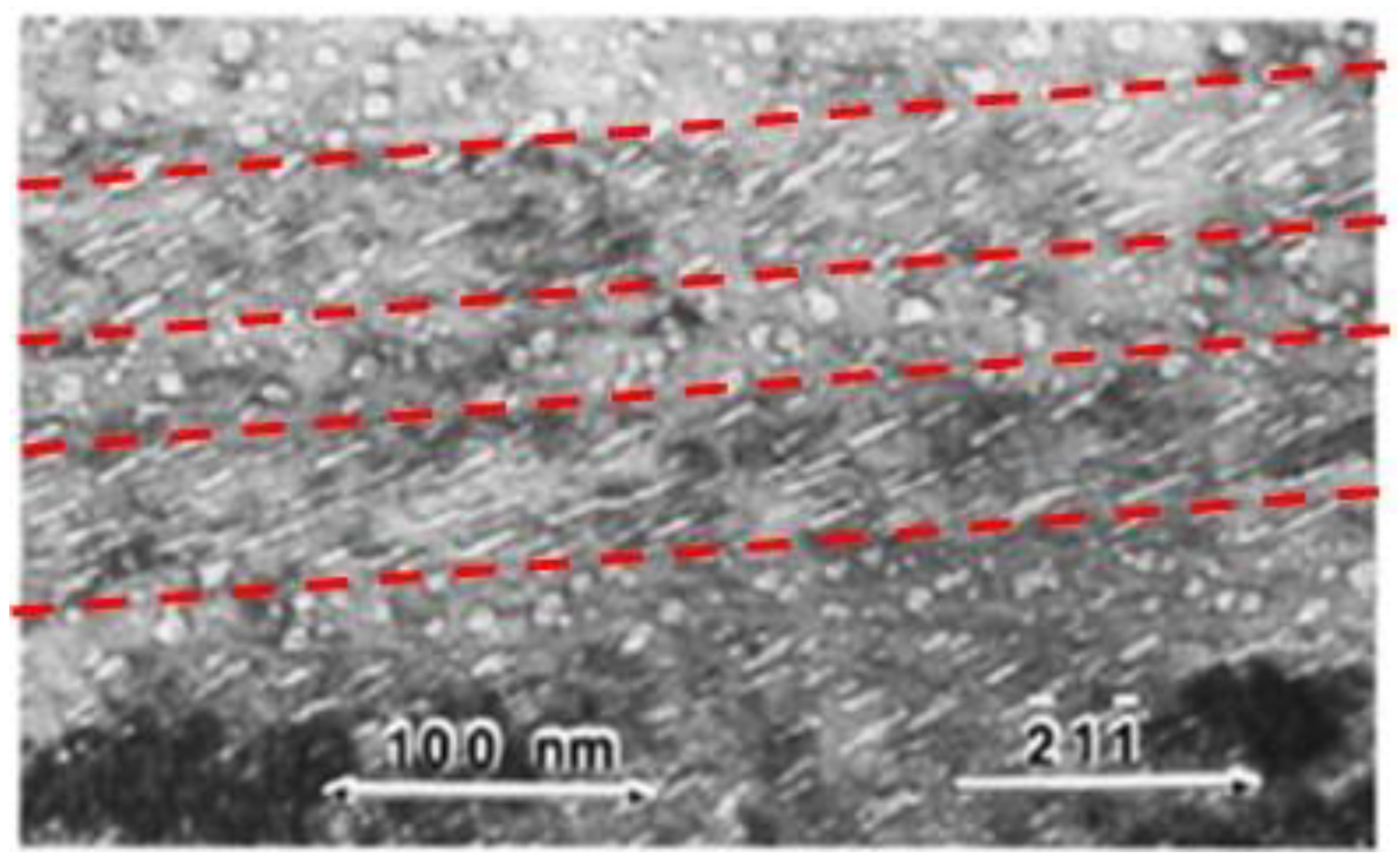

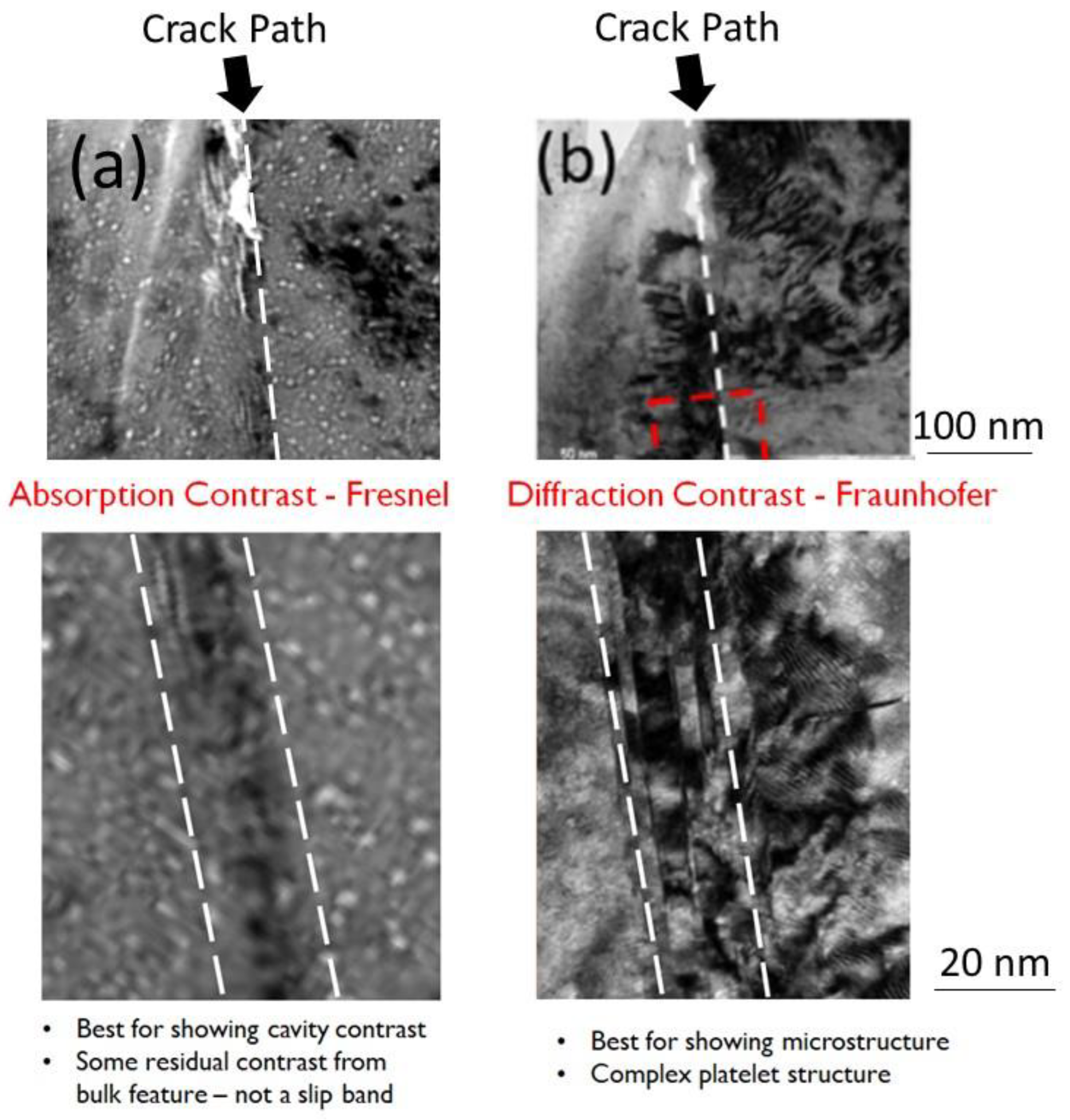

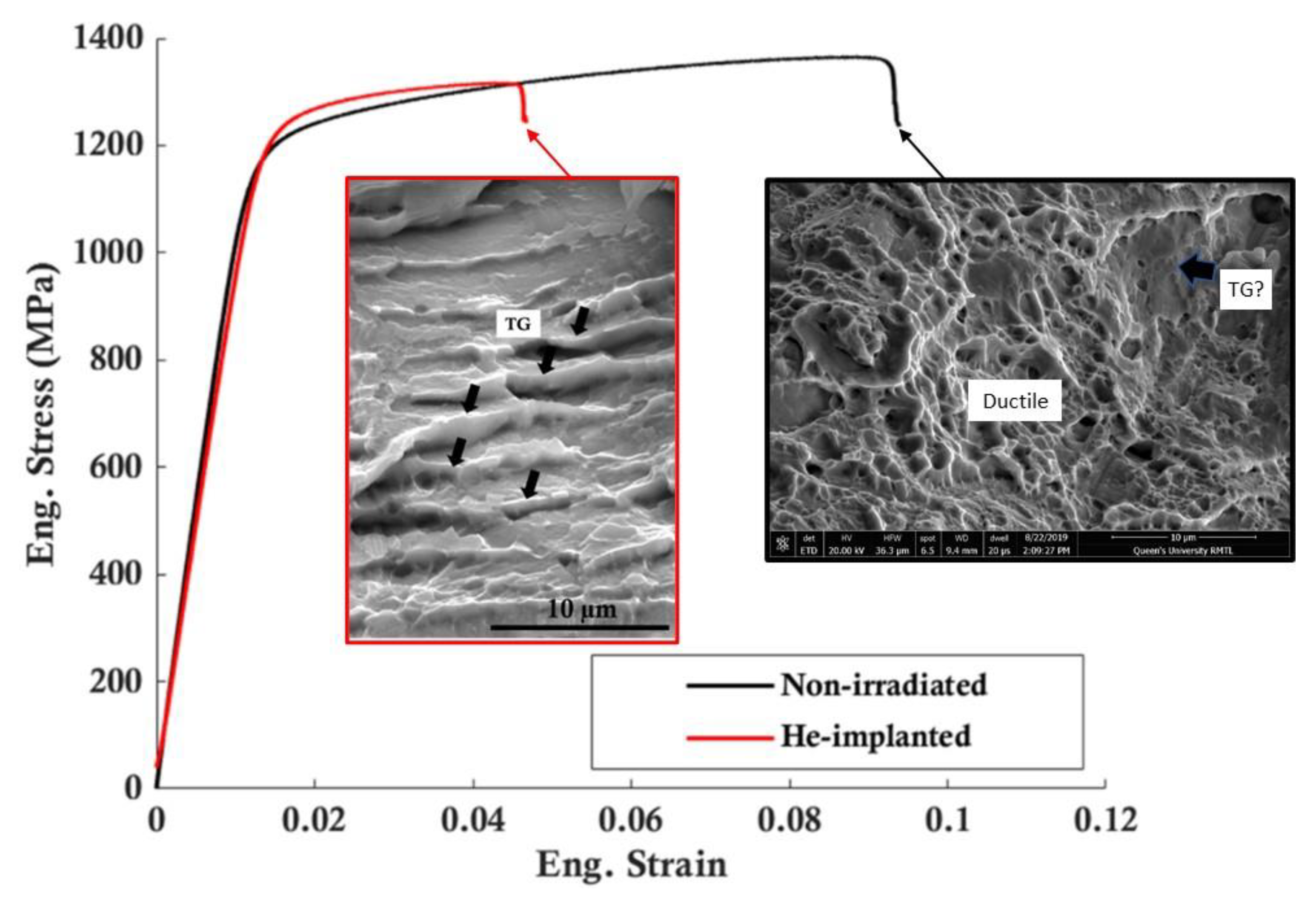

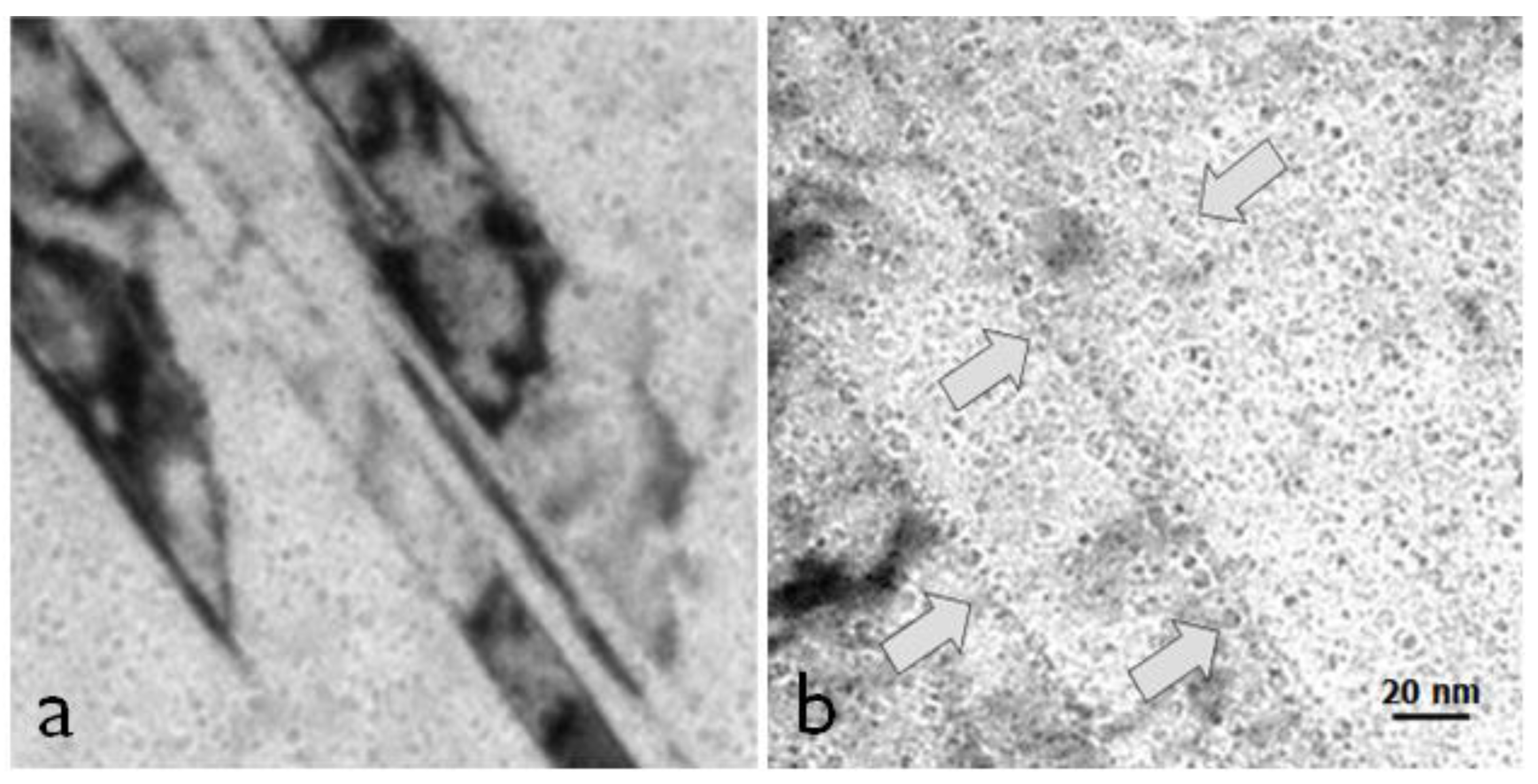

4.2. Transgranular Fracture

5. Conclusions

- He bubble segregation at grain boundaries is, in many cases, responsible for intergranular fracture during post-irradiation mechanical testing of neutron-irradiated materials.

- It is highly likely that He bubble segregation at twin/ε-martensite platelet interfaces, coupled with the fact that platelets themselves constitute inhomogeneities in the matrix, is responsible for transgranular fracture in neutron-irradiated Inconel X-750.

- Channeling is often poorly identified and can (in many cases) be attributed to twins or twin/ε-martensite platelets.

- Strain localisation (necking) is associated with micro-void formation and coalescence at cracks in unirradiated materials. The voids are formed at high stresses and strains because of cracking at inhomogeneities such as precipitates/inclusions.

- Strain localisation in low-dose neutron or ion-irradiated materials (Zr or austenitic alloys) containing prismatic dislocation loops is the result of gliding dislocations sweeping up the loops and creating channels of softer material. The loops are swept up in a channel that may or may not be parallel with the slip plane. This type of dislocation channeling has not been proven in high dose neutron-irradiated material containing a high density of cavities.

- Strain localisation leading to fracture during post-irradiation testing of high-dose neutron- or ion-irradiated austenitic steels and Ni alloys containing He bubbles is at grain boundaries, precipitates and twin/ε-martensite interfaces. The cracking and ultimate failure are mostly intergranular in nature but can also be transgranular when the material contains many large twin/ε-martensite platelets.

- There is little evidence for in-plane pileup sufficient to create a Stroh-type crack in neutron irradiated engineering alloys. The conditions for in-plane pileup must be considered hypothetical. Crystal distortions result from the accumulation of dislocations of the same sign in a localised volume of material. Dislocations will tend to align in polygonised walls to minimise their elastic interaction energies creating a plastic tilt or twist in the crystal that may be mis-interpreted as being the result of an elastic stress/strain.

Supplementary Materials

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Griffiths, M. Effect of Neutron Irradiation on the Mechanical Properties, Swelling and Creep of Austenitic Stainless Steels. Materials 2021, 14, 2622. [Google Scholar] [CrossRef]

- Byun, T.S.; Hashimoto, N.; Farrell, K.; Lee, E.H. Characteristics of microscopic strain localization in irradiated 316 stainless steels and pure vanadium. J. Nucl. Mater. 2006, 349, 251–264. [Google Scholar] [CrossRef]

- English, C.; Hyde, J. Radiation Damage of Reactor Pressure Vessel Steel. In Comprehensive Nuclear Materials; Konings, R., Stoller, R., Eds.; Elsevier: Oxford, UK, 2012; Volume 3, Chapter 3; pp. 169–196. [Google Scholar]

- Banabic, D.; Kami, A. Applications of the Gurson’s model in sheet metal forming. In Proceedings of the MATEC Web of Conferences, ICNFT, 5th International Conference on New Forming Technology (ICNFT 2018), Bremen, Germany, 18 September 2018; Volume 190, p. 01002. [Google Scholar] [CrossRef]

- Von Mises, R. Mechanik der festen Körper im Plastisch-Deformablen Zustand. In Nachrichten von der Gesellschaft der Wissenschaften zu Göttingen, Mathematisch-Physikalische Klasse; EuDML: Grenoble, France, 1913; Volume 1, pp. 582–592. [Google Scholar]

- Hamza, B.A.; Radhi, A.R.; Al-Madhlom, Q. Effect of (B/D) ratio on ultimate load capacity for horizontally curved box steel beam under out of plane concentrated load. Eng. Sci. Technol. 2019, 22, 533–537. [Google Scholar] [CrossRef]

- Hill, R. The Mathematical Theory of Plasticity; Oxford Classic Texts in Physical Sciences; Clarendon Press: Oxford, UK, 1998. [Google Scholar]

- Nye, J.F. Physical Properties of Crystals. Their Representation by Tensors and Matrices; Oxford University press: Oxford, UK, 1957; p. 157. ISBN 9780198511656. [Google Scholar]

- Adamson, R.B.; Coleman, C.E.; Griffiths, M. Irradiation creep and growth of zirconium alloys: A critical review. J. Nucl. Mater. 2019, 521, 167–244. [Google Scholar]

- Hutchinson, J.W. Bounds and self-consistent estimates for creep of polycrystalline materials. Proc. R. Soc. London Ser. A Math. Phys. Sci. 1976, 348, 101–127. [Google Scholar]

- Grossbeck, M.L.; Ehrlich, K.; Wassilew, C. An assessment of tensile, irradiation creep, creep rupture, and fatigue behavior in austenitic stainless steels with emphasis on spectral effects. J. Nucl. Mater. 1990, 74, 264–281. [Google Scholar] [CrossRef]

- Coleman, C.E. The Metallurgy of Zirconium; International Atomic Energy Agency (IAEA) IAEA: Vienna, Austria, 2022; Volume 3. [Google Scholar]

- Field, G.J.; Shanahan, M.W. The Failure of the Pressure Tube in Fuel Channel N06 of 390 Bruce NGS-A Unite 2 in March 1986. In Proceedings of the CNS 8th Annual Conference, Ottawa, ON, Canada, 16–17 June 1987; pp. 390–396. [Google Scholar]

- Ells, C.E.; Coleman, C.E.; Fidleris, V.; Ho, E.T.C.; Causey, A.R. The Behaviour of the Candu Calandria Tubes. In Proceedings of the CNS 8th Annual Conference, Ottawa, ON, Canada, 16–17 June 1987; pp. 382–389. [Google Scholar]

- Cogez, L.; Li, W.; Woo, O.T. Mechanical Properties of Zircaloy-2 Neutron Irradiated to High Fluence. CNL Nucl. Rev. 2017, 6, 221–230. [Google Scholar] [CrossRef]

- Kearns, J.J. Thermal Expansion and Preferred Orientation in Zircaloy; WAPD-TM-472; Technical Report from Bettis Atomic Power Lab.: Pittsburgh, PA, USA, 1965. [Google Scholar]

- Christodoulou, N.; Levi, M.R.; Turner, P.A.; Ho ET, C.; Chow, C.K. Anisotropy of yielding in a Zr-2.5Nb pressure tube material. Metall. Mater. Trans. A 2000, 31, 409–420. [Google Scholar] [CrossRef]

- Scattergood, D.O.; Bacon, D.J. The Strengthening Effect of Voids. Acta Metall. 1982, 30, 1665–1677. [Google Scholar] [CrossRef]

- Garner, F.A. Radiation-Induced Damage in Austenitic Structural Steels Used in Nuclear Reactors. In Comprehensive Nuclear Materials; Konings, R., Stoller, R., Eds.; Elsevier: Oxford, UK, 2020; Volume 3, Chapter 2; pp. 57–168. [Google Scholar]

- Neustroev, V.S.; Garner, F.A. Severe embrittlement of neutron irradiated austenitic steels arising from high void swelling. J. Nucl. Mater. 2009, 386–388, 157–160. [Google Scholar] [CrossRef]

- Porollo, S.I.; Vorobjev, A.N.; Konobeev, Y.V.; Dvoriashin, A.M.; Krigan, V.M.; Budylkin, N.I.; Mironova, E.G.; Garner, F.A. Swelling and void-induced embrittlement of austenitic stainless steel irradiated to 73–82 dpa at 335–365 °C. J. Nucl. Mater. 1998, 258–263, 1613–1617. [Google Scholar] [CrossRef]

- Kozlov, A.V.; Portnykh, I.A.; Bryushkova, S.V.; Kinev, E.A. Effect of vacancy porosity on the strength characteristics of austenitic steel. Fiz. Met. Metalloved. 2003, 95, 87–97. [Google Scholar]

- Porollo, S.I.; Shulepin, S.V.; Konobeev Yu, V.; Garner, F.A. Influence of silicon on swelling and microstructure in Russian austenitic stainless steel EI-847 irradiated to high neutron doses. J. Nucl. Mater. 2008, 378, 17–24. [Google Scholar] [CrossRef]

- Fregonese, M.; Régnard, C.; Rouillon, L.; Magnin, T.; Lefebvre, F.; Lemaignan, C. Failure Mechanisms of Irradiated Zr Alloys Related to PCI: Activated Slip Systems, Localized Strains, and Iodine-Induced Stress Corrosion Cracking; Zirconium in the Nuclear Industry: Twelfth Int’l Symposium; ASTM STP 1354; Sabol, G.P., Moan, G.D., Eds.; American Society for Testing and Materials: West Conshohocken, PA, USA, 2000; pp. 377–398. [Google Scholar]

- Bement, A.L.; Tobin, J.C.; Hoagland, R.G. Effects of Neutron Irradiation on the Flow and Fracture Behaviour of Zircaloy-2, Flow and Fracture; ASTM STP 380; ASTM: West Conshohocken, PA, USA, 1965; pp. 364–383. [Google Scholar]

- Higashiguchi, Y.; Kayano, H. Effect of fast-neutron irradiation on twinning deformation of zirconium. J. Nucl. Sci. Technol. 1978, 15, 263–271. [Google Scholar] [CrossRef]

- Byun, T.S.; Lee, E.H.; Hunn, J.D. Plastic deformation in 316LN stainless steel–characterization of deformation microstructures. J. Nucl. Mater. 2003, 321, 29–39. [Google Scholar] [CrossRef]

- Byun, T.S.; Hashimoto, N.; Farrell, K. Deformation mode maps for tensile deformation of neutron-irradiated structural alloys. J. Nucl. Mater. 2006, 351, 303–315. [Google Scholar] [CrossRef]

- Fournier, L.; Savoie, M.; Delafosse, D. Influence of localized deformation on A-286 austenitic stainless steel stress corrosion cracking in PWR primary water. J. Nucl. Mater. 2007, 366, 187–197. [Google Scholar] [CrossRef]

- Gussev, M.N.; Field, K.G.; Busby, J.T. Deformation localization and dislocation channel dynamics in neutron-irradiated austenitic stainless steels. J. Nucl. Mater. 2015, 460, 139–152. [Google Scholar] [CrossRef]

- Busby, J.T.; Hash, M.C.; Was, G.S. The relationship between hardness and yield stress inirradiated austenitic and ferritic steels. J. Nucl. Mater. 2015, 336, 267–278. [Google Scholar] [CrossRef]

- Foreman, A.J.E.; Sharp, J.V. A mechanism for the sweeping-up of loops by glide dislocations during deformation. Philos. Mag. 1969, 19, 931–937. [Google Scholar] [CrossRef]

- Carpenter, G.J.C. Dislocation Channeling by Prism Slip in HCO Metals. Scr. Metall. 1976, 10, 411–413. [Google Scholar] [CrossRef]

- Diaz De La Rubia, T.; Zbib, H.M.; Khraishi, T.A.; Wirth, B.D.; Victoria, M. Multiscale Modelling of Plastic Flow Localization in Irradiated Materials. Nature 2000, 406, 871–874. [Google Scholar] [CrossRef] [PubMed]

- Voskoboinikov, R.E.; Osetsky, Y.N.; Bacon, D.J. Interaction of of ⅓<1120> (0001) edge dislocation with point defect clusters created in displacement cascades in α-zirconium. Mater. Sci. Eng. A 2005, 400, 49–53. [Google Scholar]

- Terentyev, D.; Malerba, L.; Bacon, D.; Osetsky, Y.N. The effect of temperature and strain rate on the interaction between an edge dislocation and an interstitial dislocation loop in α-iron. J. Phys. Condens. Matter 2007, 19, 456211. [Google Scholar] [CrossRef]

- Onimus, F.; Dupuy, L.; Pompiou, F. In situ TEM observation of interactions between gliding dislocations and prismatic loops in Zr-ion irradiated zirconium alloys. J. Nucl. Mater. 2012, 57, 77–85. [Google Scholar] [CrossRef]

- Serra, A.; Bacon, D.J. Atomic-level computer simulation of the interaction between ⅓<1120> {1100} dislocations and ⅓<1120> interstitial loops in α-zirconium. Model. Simul. Mater. Sci. Eng. 2013, 21, 045007. [Google Scholar] [CrossRef]

- Doyle, P.J.; Benensky, K.M.; Zinkle, S.J. Modeling of dislocation channel width evolution in irradiated metals. J. Nucl. Mater. 2018, 499, 47–64. [Google Scholar] [CrossRef]

- Andresen, P.L.; Was, G.S. Irradiation Assisted Stress Corrosion Cracking. In Comprehensive Nuclear Materials, 2nd ed.; Rudy, J.M., Konings, R.E., Stoller, Y., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; Volume 5, pp. 190–217. [Google Scholar]

- Nye, J.F. Some geometrical relations in dislocated crystals. Acta Metallurgica. 1953, 1, 153–162. [Google Scholar] [CrossRef]

- Stroh, A.N. The formation of cracks as a result of plastic flow. Proc. R. Soc. Lond. Ser. A. Math. Phys. Sci. 1954, 223A, 404–414. [Google Scholar] [CrossRef]

- Cottrell, A.H.; Bilby, B.A. Dislocation theory of yielding and strain ageing of iron. Proc. R. Soc. Lond. A Math. Phys. Sci. 1949, 62, 49–62. [Google Scholar] [CrossRef]

- Eshelby, J.D.; Frank, F.C.; Nabarro, F.R.N. The equilibrium of linear arrays of dislocations. Philos. Mag. 1951, 42, 351–364. [Google Scholar] [CrossRef]

- Voskoboinikov, R.E.; Chapman, S.J.; Ockendon, J.R.; Allwright, D.J. Continuum and discrete models of dislocation pile-ups. I. Pile-up at a lock. J. Mech. Phys. Solids 2007, 55, 2007–2025. [Google Scholar] [CrossRef]

- Voyiadjis, G.Z.; Yaghoobi, M. (Eds.) Chapter 1-Introduction: Size Effects in Materials; Size Effects in Plasticity; Academic Press: Cambridge, MA, USA, 2019; pp. 1–79. [Google Scholar]

- Monnet, G.; Pouchon, M.A. Determination of the critical resolved shear stress and the friction stress in austenitic stainless steels by compression of pillars extracted from single grains. Mater. Lett. 2013, 98, 128–130. [Google Scholar] [CrossRef]

- Robertson, I.; Bond, G.; Lee, T.; Shih, D.; Birnbaum, H. Dynamic Studies of Deformation and Fracture at Grain Boundaries. J. De Phys. Colloq. 1988, 49, C5-677–C5-680. [Google Scholar] [CrossRef]

- Onchi, T.; Dohi, K.; Soneda, N.; Cowan, J.R.; Scowen, R.J.; Castano, M.L. Fractographic and microstructural characterization of irradiated 304 stainless steel intergranularly fractured in inert gas. J. Nucl. Mater. 2003, 320, 194–208. [Google Scholar] [CrossRef]

- Jiao, Z.; Busby, J.T.; Was, G.S. Deformation microstructure of proton-irradiated stainless steels. J. Nucl. Mater. 2007, 361, 218–227. [Google Scholar] [CrossRef]

- Jiao, Z.; Was, G.S. Impact of localized deformation on IASCC in austenitic stainless steels. J. Nucl. Mater. 2011, 408, 246–256. [Google Scholar] [CrossRef]

- Field, K.G.; Gussev, M.N.; Busby, J.T. Microstructural characterization of deformation localization at small strains in a neutron-irradiated 304 stainless steel. J. Nucl. Mater. 2014, 452, 500–508. [Google Scholar] [CrossRef]

- Johnson, D.C.; Kuhr, B.; Farkas, D.; Was, G.S. Quantitative analysis of localized stresses in irradiated stainless steels using high resolution electron backscatter diffraction and molecular dynamics modeling. Scr. Mater. 2016, 116, 87–90. [Google Scholar] [CrossRef]

- Villacampa, I.; Chen, J.C.; Spätig, P.; Seifert, H.P.; Duval, F. Helium effects on irradiation assisted stress corrosion cracking susceptibility of 316L austenitic stainless steel. Int. J. Corros. Process. Corros. Control. Issue 8 Corros. Nucl. Mater. 2017, 52, 2010–2019. [Google Scholar]

- Was, G.S. Localized Deformation as a Primary Cause of Irradiation Assisted Stress Corrosion Cracking. DOE/ID/14703, Technical Report TRN: US0902123, United States. 2009. Available online: https://www.osti.gov/servlets/purl/950834 (accessed on 10 March 2023). [CrossRef]

- Sharp, J.V. Correlation between cleared channels and surface slip steps in neutron irradiated copper crystals. Radiat. Eff. 1972, 14, 71–75. [Google Scholar] [CrossRef]

- Stephenson, K.J.; Was, G.S. The role of dislocation channeling in IASCC initiation of neutron irradiated stainless steel. J. Nucl. Mater. 2016, 481, 214–225. [Google Scholar] [CrossRef]

- McMurtrey, M.D.; Was, G.S.; Cui, B.; Robertson, I.; Smith, L.; Farkas, D. Strain localization at dislocation channel–grain boundary intersections in irradiated stainless steel. Int. J. Plast. 2014, 56, 219–231. [Google Scholar] [CrossRef]

- Gussev, M.N.; Field, K.G.; Busby, J.T.; Leonard, K.J.; Byun, T.S.; Stephenson, K.J.; Was, G.S. Localized Deformation in Irradiated Austenitic Steels. Available online: https://www.energy.gov/sites/default/files/2015/10/f27/Gussev_Localized%20deformation%20and%20IASCC.pdf (accessed on 21 March 2023).

- Robertson, I.M.; Cui, B.; He, M.R. Dislocation Grain Boundary interactions in Irradiated Metals. Mech. Mater. Eng. Fac. Publ. 2016, p. 152. Available online: http://digitalcommons.unl.edu/mechengfacpub/152 (accessed on 21 March 2023).

- Garner, F.A.; Simonen, E.P.; Oliver, B.M.; Greenwood, L.R.; Grossbeck, M.L.; Wolfer, W.G.; Scott, P.M. Retention of hydrogen in fcc metals irradiated at temperatures leading to high densities of bubbles or voids. J. Nucl. Mater. 2006, 356, 122–135. [Google Scholar] [CrossRef]

- Mills, W.J.; Lebo, M.R.; Kearns, J.J. Hydrogen embrittlement, grain boundary segregation, and stress corrosion cracking of alloy X-750 in low-and high-temperature water. Metall. Mater. Trans. A 1999, 30, 1579–1596. [Google Scholar] [CrossRef]

- Bhattacharya, A.; Zinkle, S.J. Cavity Swelling in Irradiated Materials. In Comprehensive Nuclear Materials, 2nd ed.; Konings, R.J.M., Stoller, R.E., Eds.; Elsevier: Oxford, UK, 2020; Chapter 12; Volume 1, pp. 406–455. [Google Scholar]

- Griffiths, M. Ni-based Alloys for Reactor Internals and Steam Generator Applications. In Chapter 9 in: Structural Alloys for Nuclear Energy Applications; Zinkle, S., Odette, R., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; ISBN 9780123970466. [Google Scholar]

- Griffiths, M.; Boothby, R. Radiation Effects in Nickel-Based Alloys, 2nd ed.; Konings, R.J.M., Stoller, R.E., Eds.; Elsevier: Oxford, UK, 2020; Volume 3, pp. 334–337. [Google Scholar]

- Fujimoto, K.; Yonezawa, T.; Wachi, E.; Yamaguchi, Y.; Nakano, M.; Shogan, R.P.; Massoud, J.P.; Mager, T.R. Effect of the accelerated irradiation and hydrogen/helium gas on IASCC characteristics for highly irradiated austenitic stainless steels. In Proceedings of the 12th International Conference on Environmental Degradation of Materials in Nuclear Power System-Water Reactors, Warrendale, PA, USA, 14–18 August 2005; p. 299. [Google Scholar]

- Edwards, D.J.; Simonen, E.P.; Bruemmer, S.M.; Efsing, P. Microstructural evolution in neutron-irradiated stainless steels: Comparison of lwr and fast-reactor irradiations. In Proceedings of the 12th International Conference on Environmental Degradation of Materials in Nuclear Power System-Water Reactors, Salt Lake City, UT, USA, 14–18 August 2005; p. 419. [Google Scholar]

- Fukuya, K.; Nishioka, H.; Fujii, K.; Kamaya, M.; Miura, T.; Orimaru, T. Fracture behavior of austenitic stainless steels irradiated in PWR. J. Nucl. Mater. 2008, 378, 211–219. [Google Scholar] [CrossRef]

- Edwards, D.J.; Garner, F.A.; Bruemmer, S.M.; Efsing, P. Nano-cavities observed in a 316 SS PWR flux thimble tube irradiated to 33 and 70 dpa. J. Nucl. Mater. 2009, 384, 249–255. [Google Scholar] [CrossRef]

- Griffiths, M. The Effect of Irradiation on Ni-containing Components in CANDU Reactor Cores: A Review. Nucl. Rev. 2014, 2, 1–16. [Google Scholar]

- Griffiths, M.; Bickel, G.A.; Donohue, S.A.; Feenstra, P.; Judge, C.D.; Poff, D.; Walters, L.; Greenwood, L.R.; Garner, F.A. Degradation of Ni-alloy Components in CANDU Reactor Cores. In 16th International Conference on Environmental Degradation of Materials in Nuclear Power Systems–Water Reactors, Asheville, CA, USA, 11–15 August 2016; NACE International: Houston, TX, USA, 2016; pp. 1008–1030. [Google Scholar]

- Xu, S.X.; Griffiths, M.; Scarth, D.A.; Graham, D. Microstructure-based Polycrystalline Finite Element Modeling of Inconel X-750 Irradiated in a CANDU Reactor. Eng. Fract. Mech. 2022, 276A, 108814. [Google Scholar] [CrossRef]

- Howard, C.; Bhakhri, V.; Dixon, C.; Rajakumar, H.; Mayhew, C.; Judge, C.D. Coupling multi-scale mechanical testing techniques reveals the existence of a trans-granular channel fracture deformation mechanism in high dose Inconel X-750. J. Nucl. Mater. 2019, 517, 17–34. [Google Scholar] [CrossRef]

- Griffiths, M.; Ramos-Nervii, J.; Greenwood, L.R. A Rate Theory Model of Radiation-Induced Swelling in an Austenitic Stainless Steel. J. Nucl. Eng. 2021, 2, 484–515. [Google Scholar] [CrossRef]

- Griffiths, M.; Xu, S.; Ramos Nervi, J.E. Swelling and He-Embrittlement of Austenitic Stainless Steels and Ni-Alloys in Nuclear Reactors. Metals 2022, 12, 1692. [Google Scholar] [CrossRef]

- Judge, C.D.; Griffiths, M.; Walters, L.; Wright, M.; Bickel, G.A.; Woo, O.T.; Stewart, M.; Douglas, S.R.; Garner, F. Embrittlement of Nickel Alloys in a CANDU Reactor Environment. In Effects of Radiation on Nuclear Materials; Yamamoto, T., Ed.; ASTM International: Anaheim, CA, USA, 2012; Volume 25, pp. 161–175. [Google Scholar]

- Zhang, H.K.; Yao, Z.; Morin, G.; Griffiths, M. TEM Characterisation of Neutron Irradiated CANDU Spacer Material, Inconel X-750. J. Nucl. Mater. 2014, 451, 88–96. [Google Scholar] [CrossRef]

- Judge, C.D.; Gauquelin, N.; Walters, L.; Wright, M.; Cole, J.I.; Madden, J.; Botton, G.A.; Griffiths, M. Inter-Granular Fracture in Irradiated Inconel X-750 Containing Very High Concentrations of Helium and Hydrogen. J. Nucl. Mater. 2015, 457, 165–172. [Google Scholar] [CrossRef]

- Judge, C.D.; Rajakumar, H.; Korinek, A.; Botton, G.; Cole, J.; Madden, J.W.; Jackson, J.H.; Freyer, P.D.; Giannuzzi, A.L.; Griffiths, M. High Resolution Transmission Electron Microscopy of Irradiation Damage in Inconel X-750. In The Minerals, Metals & Materials Series, Proceedings of the 18th International Conference on Environmental Degradation of Materials in Nuclear Power Systems–Water Reactors, Oregon, Portland, 13–17 August 2017; Springer: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Shaihh, M.A. Void denudation and grain boundary migration in ion-irradiated nickel. J. Nucl. Mater. 1992, 187, 303–306. [Google Scholar] [CrossRef]

- Demkowicz, M.J. A threshold density of helium bubbles induces a ductile-to-brittle transition at a grain boundary in nickel. J. Nucl. Mater. 2020, 533, 152118. [Google Scholar] [CrossRef]

- Zhu, H.; Qin, M.; Wei, T.; Davis, J.; Ionescu, M. Atomic-Scale Study of He Ion Irradiation-Induced Clustering in σ-Zirconium. Available online: https://ssrn.com/abstract=4184622 (accessed on 10 March 2023).

- Judge, C.D. The Effects of Irradiation on Inconel X-750. Ph.D. Thesis, McMaster University, Hamilton, ON, Canada, 2015. Available online: https://macsphere.mcmaster.ca/handle/11375/18091 (accessed on 9 September 2022).

- Rowcliffe, A.F.; Mansur, L.K.; Hoelzer, D.T.; Nanstad, R.K. Perspectives on Radiation Effects in Nickel-Base Alloys for Applications in Advanced Reactors. J. Nucl. Mater. 2009, 392, 341–352. [Google Scholar] [CrossRef]

- James, M.R.; Maloy, S.A.; Gac, F.D.; Sommer, W.F.; Chen, J.; Ullmaier, H. The mechanical Properties of an Alloy 718 Window after Irradiation in a Spallation Environment. J. Nucl. Mater. 2001, 296, 139–144. [Google Scholar] [CrossRef]

- Braski, D.N. The effect of neutron irradiation on vanadium alloys. J. Nucl. Mater. 1986, 141–143, 1125–1131. [Google Scholar] [CrossRef]

- Fish, R.; Straalsund, J.; Hunter, C.; Holmes, J. Swelling and Tensile Property Evaluations of High-Fluence EBR-II Thimbles, Effects of Radiation on Substructure and Mechanical Properties of Metals and Alloys; ASTM International: West Conshohocken, PA, USA, 1973. [Google Scholar]

- Hamilton, M.L.; Huang, F.H.; Yang, W.J.; Garner, F.A. Mechanical properties and fracture behavior of 20% cold-worked 316 stainless steel irradiated to very high neutron exposures. In Influence of Radiation on Material Properties: 13th International Symposium (Part II); ASTM International: West Conshohocken, PA, USA, 1987. [Google Scholar]

- Huang, F.H. Comparison of fracture behavior for low-swelling ferritic and austenitic alloys irradiated in the Fast Flux Test Facility (FFTF) to 180 DPA. Eng. Fract. Mech. 1992, 43, 733–748. [Google Scholar] [CrossRef]

- Garner, F.A. Irradiation Performance of Cladding and Structural Steels in Liquid Metal Reactors, Materials Science and Technology. In A Comprehensive Treatment; VCH Publishers: Weinheim, Germany, 1994; Volume 10A, Chapter 6; pp. 483–514. [Google Scholar]

- Hojná, A. Overview of Intergranular Fracture of Neutron Irradiated Austenitic Stainless Steels. Metals 2017, 7, 392. [Google Scholar] [CrossRef]

- Horton, L.; Ohr, S.M.; Jesser, W.A. TEM Observations of Crack Tip-Cavity Interactions. J. Nucl. Mater. 1981, 104, 865–870. [Google Scholar] [CrossRef]

- Wang, Q.; Judge, C.D.; Howard, C.; Mattucci, M.; Rajakumar, H.; Hoendermis, S.; Dixon, C.; Daymond, M.; Bickel, G. Investigation on the deformation mechanisms and size-dependent hardening effect of He bubbles in 84 dpa neutron irradiated Inconel X-750 micro-tensile specimens. Nucl. Mater. Energy 2021, 28, 101025. [Google Scholar] [CrossRef]

- Changizian, P.; Yao, Z.; Long, F.; Topping, M.; Xu, S.X.; Daymond, M.R.; Griffiths, M. Mechanical behavior of recrystallized and precipitation-hardened Inconel X-750 before and after helium-implantation. Mater. Charact. 2023, 199, 112810. [Google Scholar] [CrossRef]

- Changizian, P.; Yao, Z.; Xu, S.X.; Daymond, M.R.; Griffiths, M. Mechanical behavior of recrystallized and precipitation-hardened Inconel X-750 before and after helium-implantation and proton irradiation. In Materials Characterisation; Submitted for publication; Elsevier: Amsterdam, The Netherlands, 2023. [Google Scholar]

- Griffiths, M. Microstructural Effects on Irradiation Creep of Reactor Core Materials. Materials 2023, 16, 2287. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Griffiths, M. Strain Localisation and Fracture of Nuclear Reactor Core Materials. J. Nucl. Eng. 2023, 4, 338-374. https://doi.org/10.3390/jne4020026

Griffiths M. Strain Localisation and Fracture of Nuclear Reactor Core Materials. Journal of Nuclear Engineering. 2023; 4(2):338-374. https://doi.org/10.3390/jne4020026

Chicago/Turabian StyleGriffiths, Malcolm. 2023. "Strain Localisation and Fracture of Nuclear Reactor Core Materials" Journal of Nuclear Engineering 4, no. 2: 338-374. https://doi.org/10.3390/jne4020026

APA StyleGriffiths, M. (2023). Strain Localisation and Fracture of Nuclear Reactor Core Materials. Journal of Nuclear Engineering, 4(2), 338-374. https://doi.org/10.3390/jne4020026