Abstract

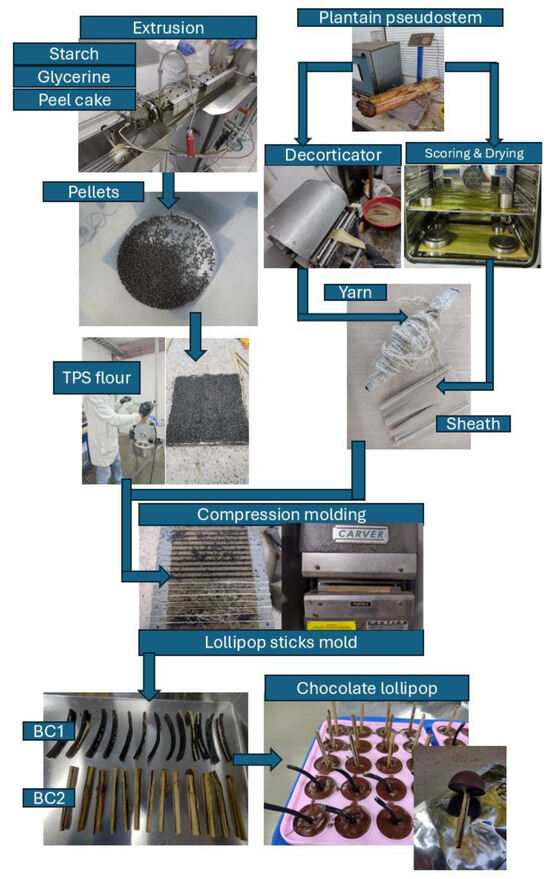

Lollipop sticks were developed with fully biobased materials made of different plantain by-products, using extrusion processing followed by hot compression molding. The thermoplastic matrix was constituted of flour and starch from plantain bunch pulp and plantain peel cake. At the same time, two types of reinforcement were used, one of them being yarn from the lignocellulosic fibers of the pseudostem sheaths to constitute the BC1 lollipop stick and the other directly from the plantain pseudostem treated sheath to establish the BC2 lollipop stick. The biobased lollipop sticks were characterized in the migration test, finding a higher structural stability in lipophilic foods, with chocolate chosen as a confection to undergo physicochemical, structural, mechanical, and dynamic–mechanical characterization when interacting with the two biobased lollipop sticks until post-consumption was reached. The BC2 lollipop stick was characterized by maintaining higher stability in maximum tensile strength (12.62 to 11.76 MPa), higher flexural strength (19.07 to 10.11 MPa), storage modulus (4.97 to 1.65 GPa at 30 °C), and Tan delta (66.90 to 52.64 °C).

1. Introduction

The development and progress of different sectors and/or economic activities in which humanity participates have progressively exceeded the use of polymeric materials derived from petroleum for the production of transformed plastic products, reaching values close to 299 million tons each year [1]; this is partly because they have some relevant advantages over metals and ceramics, with a low melting temperature, high capacity for deformation to the breaking point, low density, electrical resistance, low thermal conductivity, optical clarity, and the possibility of being easily assigned a specific color. Plastics can be used in different sectors, such as packaging and containers, construction, medicine, storage, transportation, and entertainment [2]. The packaging sector has contributed 36% of global plastic production through the processing of polyethylene (HDPE and LDPE), polypropylene (PP), polystyrene (PS), polyvinyl chloride (PVC), polyethylene terephthalate (PET), among other polymers, using different processing techniques such as extrusion and injection molding [2,3,4,5,6], Gholampour and Ozbakkaloglu, 2020 [7], obtaining plastic elements such as bags, trays, containers, and utensils to prolong the conservation and storage of food and non-food products [7,8,9,10,11]. However, at the end of the plastic’s use, continuous population growth has increased the speed of plastic waste release deposited on the surface, landfills, and in water bodies by between 60 and 95% compared to other accumulated materials [3,12,13]. In comparison, its recycling can reach values of less than 5%. The inadequate management of plastic materials has affected water quality (rivers, lakes, seas, and oceans) through the formation and dispersion of macroplastics (diameter or length > 5 mm) and microplastics (diameter < 5 mm) presenting particulate forms and fibers under the influence of oxygen, heat, and ultraviolet rays from the sun [1,3,5,14]. These plastic fibers and particles affect the quality of marine life, generating internal and external entanglements and strangulations in fish and bird organisms through plastic fibers. At the same time, microplastics can cause toxicity through their accumulation in organisms, including humans, whose diet includes food from freshwater (rivers and lakes) and saltwater (seas and oceans) [1]. Asensio-Montesinos et al., 2020 [2] reported the presence of different plastic elements that had originated from the packaging and food sector and been discarded and accumulated along 192 km of the beaches of Cadiz (Spain), quantifying their participation and relating it to the environmental impact generated at a global level. Among the representative elements belonging to these sectors, 5.6% were plastic bags, 5.3% were rigid containers, 1.7% were wrapping film, 1.6% were plastic lids, 1.3% were food utensils (spoons, forks, knives, stirrers, and disposable straws), and 0.9% were lollipop sticks, the latter consisting mainly of PP. Among the alternative materials that could be used to counteract the accumulation of plastic elements in the environment, the use of natural raw materials with the capacity to biodegrade by undergoing a composting process for the production of bioplastics can be considered, including starches and lignocellulosic fibers that can be processed and molded to obtain biobased composite materials (BCM) with mechanical, thermal, and structural properties that can replace conventional plastics. Despite achieving TPS blends with short lignocellulosic fibers up to 40% in a MCB, the mechanical properties are lost as the storage time progresses from the water absorption capacity granted by the TPS matrix exposed to the storage environment; therefore, the alternative of using the sheaths from the pseudostem of a musaceae such as banana has been identified to recover and reinforce the TPS matrix by compression molding with hot plates to preserve the tensile, flexural, and impact properties for a longer storage time [8,15,16,17,18,19].

The objective of this work consisted of taking advantage of different plantain by-products, such as flour and starch from the pulp bunch, the peel cake, yarn made from the long lignocellulosic fibers from the sheaths, and the pseudostem sheaths, for the development of two BCMs, using an extrusion process followed by hot compression molding, to validate their use as lollipop sticks, considering the follow-up of its mechanical, physicochemical, viscoelastic, and structural properties after the consumption of the candy. The procedure proposed for the transformation of the BCM in the present research can be adapted for the development of other plastic elements different from lollipop sticks, including the production of single-use plastic products such as spoons, knives, forks, drink stirrers, sticks for hard ice cream or popsicles, and even for the production of trays.

2. Materials and Methods

2.1. Plantain Pulp Flour and Starch

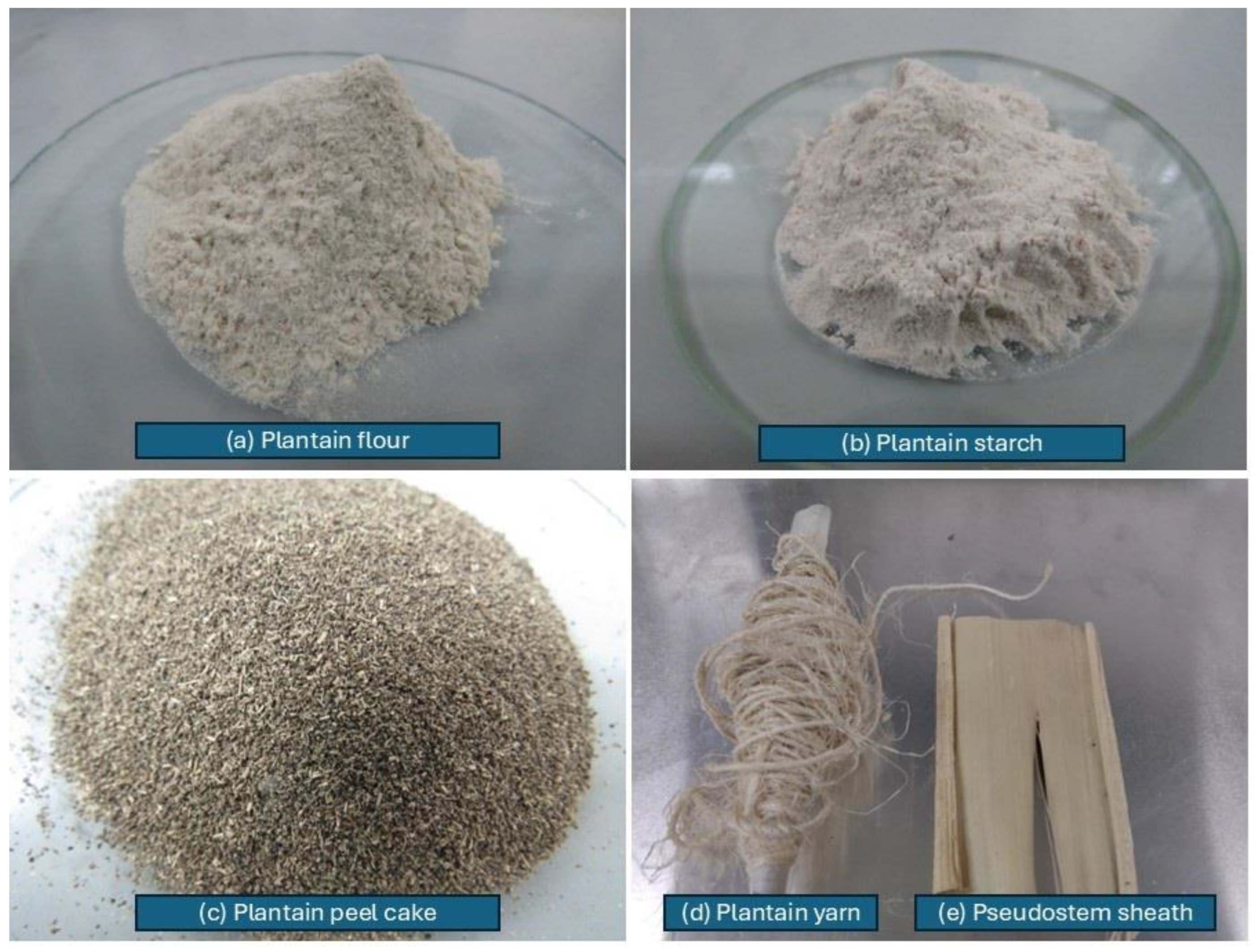

Native flour and starch extracted from the pulp of the plantain bunch variety Dominico hartón from the Asociación de Productores de Finca Tradicional del Norte del Cauca (ASPROFINCA), located in the municipality of Villa Rica (Cauca, Colombia), were used (Figure 1a,b). The flour was obtained via unit operations of peeling, grinding, drying (70 °C for 24 h) (Binder, FD 115, Tuttlingen, Germany), milling (Fritsch, Pulverisette 15, Idar-Oberstein, Germany), and sieving (100 mesh/depth according to Tyler series). Starch extraction was carried out using a 1.2% sodium metabisulfite solution, followed by filtering (separating the slurry and cake), settling of the slurry, drying of the starch paste at 60 °C for 24 h, milling using a blade mill, and sieving using the 100 mesh/deep sieve according to the Tyler series, presenting a particle size of less than 150 µm [20].

Figure 1.

Plantain-based raw materials used for the development of BCMs: (a) plantain flour; (b) plantain starch; (c) plantain peel cake; (d) plantain yarn; (e) pseudostem sheath.

2.2. Plantain Peel Cake (PPC)

This plantain by-product was obtained by extracting starch from the plantain peel by filtration and separating it from the slurry. The resulting PPC was then subjected to drying in a forced convection oven at a temperature of 70 °C for 24 h, followed by grinding through a knife mill, using a sieve with 2 mm openings, and finally, sieving with 100 mesh according to the Tyler series, obtaining a particle size greater than 150 µm [13,21]. The PPC presented a dark green color (Figure 1c), and was used in the bio-based matrix (BM) that constitutes the two BCM lollipop sticks.

2.3. Obtaining Yarn from the Lignocellulosic Fibers of Plantain Pseudostems

A yarn made of the long native fibers from plantain pseudostem native sheaths was used. The sheaths were exposed to a mechanical defibrator, allowing the separation of the long lignocellulosic fibers from the parenchyma and water. Once the lignocellulosic fibers were available, they were dried at a temperature of 50 °C for 12 h, followed by combing to remove tangles from the fibers. The yarn was obtained using a spinning machine that allowed the union of 15 fibers at each end through entanglement and twisting, generating an average diameter of 1465 ± 195 µm [22]. The yarn was used as the first alternative of reinforcement constituted by continuous fibers for the elaboration of the BC1 lollipop sticks (Figure 1d).

2.4. Plantain Pseudostem Treated Sheaths

After a pseudostem was harvested, the native sheaths were removed and separated from the core. Each sheath was adapted by removing the inner epidermis and part of the parenchyma with a knife. The sheaths were dried at 58 °C for 3 h using a forced convection oven [18]. The treated sheaths previously mentioned were used as a second alternative for reinforcement and coating (Figure 1e) of the BC2 lollipop sticks.

2.5. Glycerin

Commercial-grade glycerin was used as a plasticizer, being a polyol of functionality three. Its purity was 99.7%. The plasticizer was supplied by PROQUIM Industrial S.A.S. (Cali, Colombia).

2.6. Additional Materials

For the experiment, 70% real chocolate was used from cocoa beans harvested in the western part of Risaralda department and processed at the Centro de Desarrollo Tecnológico Agroindustrial (CDTA-UTP) located in Pereira, Colombia.

2.7. Development of Biobased Composite Material

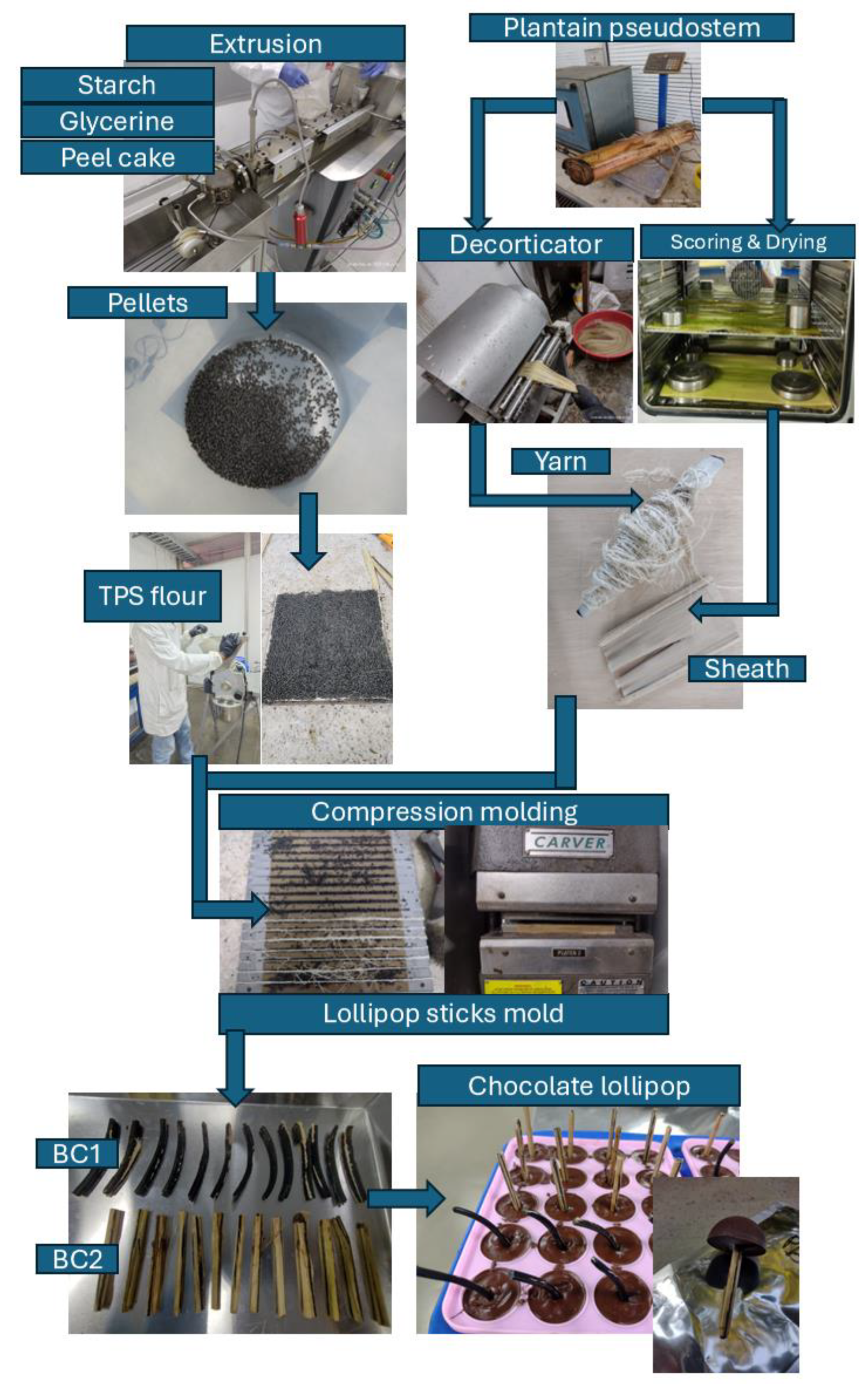

Once the lignocellulosic fiber yarn, the treated sheaths, and the biobased thermoplastic matrix (BM) were available, the BCMs were processed using compression molding, applying the methodology used by Rodríguez-Soto et al., 2019 [18] with modifications related to the use of a 304 stainless steel mold containing 18 cylindrical cavities with a diameter of 4 mm and a length of 14 cm in each plate that constitutes the mold (Figure 2), placing the previously mentioned raw materials for their subsequent melting, compression, and cooling in a compression molding machine (Carver, model 4389, Wabash, IN, USA). Initially, preheating was carried out without applying pressure, using a temperature of 136 °C for 10 min, followed by a compression of 5.5 metric tons for 15 min. Finally, the previous pressure was maintained by stopping the supply of heat to the mold and starting its cooling by recirculating water at room temperature in said system for 15 min and then removing the lollipop sticks from the mold. Following the procedure, two BCMs were obtained, consisting of a thermoplastic matrix reinforced with 7.50% of PPC (BM), including in the first BCM a second reinforcement from a native yarn obtained from the long native fibers of the plantain pseudostem sheaths (BC1) with an average diameter of 4.4 mm and a real density of 1.4 g/cm3. In contrast, the second BCM presented a second reinforcement from the coating of the thermoplastic matrix with a mechanically and thermally treated sheath (BC2) with an average diameter of 5.1 mm and a real density of 1.4 g/cm3. The above treatments were compared with the commercial synthetic lollipop stick (SLS) for the Colombina candy brand, reference “pirulito leche” (Table 1), presenting an average diameter of 3.7 mm, length of 7 cm, and a real density of 0.9 g/cm3.

Figure 2.

Processing of the lollipop sticks and their positioning in the bon bon-type confectionery.

Table 1.

Lollipop sticks raw materials composition.

2.8. Preparation of Confectionery and Incorporation of the Biobased Lollipop Stick

Initially, the chocolate bars were subjected to crushing to reduce their particle size, followed by melting at 50 °C, reserving 1/3 of the melted chocolate in storage while the remaining 2/3 was subjected to cooling using a marble surface until a temperature of 28 °C was reached, before being mixed again with the previously stored 1/3, achieving a temperature of 32 °C; subsequently, the molding of the confections began in a silicone mold, placing each of the lollipop sticks by submerging 2.5 cm of one end in the chocolate (Figure 2), subjecting it to refrigeration for 20 min for the hardening of the confectionery, and finally packing it in high barrier bags [23]. The post-consumption conditions of the lollipop sticks are based on the stage after consumption of the chosen candy. Forty people were chosen at random to consume the candy after 10 days of storage. A specific procedure was not developed for the execution of the activity, since the consumer may have different methods to assimilate the candy, such as biting, melting, or sucking.

2.9. Physicochemical and Structural Characterization

2.9.1. Migration

The migration test was performed using three food simulants (water, 50% ethanol, and hexane) as indicated by the European Commission [24], to determine total migration. The above liquids and solutions were used to simulate the main characteristic components in various foods, such as beverages with a pH above 4.5, emulsions, and foods or confections with high lipid content [25,26,27,28]. The immersion time used for the BCM samples was 10 days at room temperature (25 to 30 °C). Each of the lollipop sticks were immersed to a depth of 2 cm in each of the simulants by using 25 mL of the respective solutions in a Falcon tube. The global migration consisted of removing the BCM sample from the respective simulants, and its surface area was reported. The calculation of the surface in each cylindrical sample was determined by Equation (1), considering r as the ratio and h as the length of the sample. Each simulant was subjected to drying at 40 °C for 72 h, before the mass of the resulting residue was recorded and the migration was determined in µg/dm2 [25].

2.9.2. Contact Angle

As a measure of the degree of hydrophilicity (wettability) or hydrophobicity of the samples, the average contact angle of 10 measurements forming a 5 μL distilled water droplet at a temperature of 25 °C on the surface of the samples was determined using a Drop Tensiometer (TrackerTM H, Teclis, Civrieux-d’Azergues, France), following the sessile drop method [29].

2.9.3. FT-IR Spectrophotometry with ATR

The samples were analyzed using a Fourier Transform Infrared (FT-IR) spectrophotometer (Shimadzu, IRAFFINITY 1S, Kyoto, Japan) coupled to an attenuated total reflectance (ATR) accessory. The test specimens consisted of cylinders with a length of 4 cm. These experiments were performed according to ASTM E1252 [30]. The samples were kept at a relative humidity of 50% and 23 °C; the analysis was performed at 100 scans and in a range between 4000 and 550 cm−1 [31].

2.9.4. Scanning Electron Microscopy (SEM)

Morphological analysis of the samples was performed on a JEOL machine, JSM 6490 LV, Tokyo, Japan. The samples were coated with a layer of palladium gold to provide a conductive surface during the assay. Each lollipop stick’s base and wall surfaces were placed on a carbon ribbon. The images obtained were from the backscattered electron method with an acceleration power of 20 kV and a vacuum of 30 Pa in the microscope chamber, achieving magnifications between 40 and 500× [32].

2.9.5. Mechanical Properties

Tensile Test

Based on ASTM D638 [33] with modifications, the tensile test was performed using a universal testing machine (Tinius Olsen, H50KS, Horsham, PA, USA) to evaluate the BCM’s lollipop sticks. The distance between the grips was set to 40 mm, the grips were moved at a speed of 5 mm/min, a load cell of 500 N was used, and five specimens were evaluated per sample tested. The maximum tensile strength (σmax), the elastic modulus (E), and the deformation at the breaking point (ε) were determined before and after the chocolate lollipop consumption [15,33,34].

Flexural Test

The determination of flexural strength followed the methodology defined by ASTM D790 [35], using a universal testing machine (Tinius Olsen, H50KS, Horsham, PA, USA). The specimens of the thermoplastic materials presented a cylindrical geometry with a length of 75 mm and a diameter of 4 mm. For the measurement of each specimen, it was placed on the supporting pins of the flexural device from the universal machine at 1 cm from the ends; then, a flexural force was applied in the center of the specimen until its fracture or a maximum deflection in bending of 5% was reached. The test speed was 2 mm/min. Five specimens were evaluated per sample tested. Through this test, the maximum flexural strength (σFmax) and the maximum flexural deflection (εF) were determined for each specimen [36,37].

2.9.6. Dynamic–Mechanical Analysis of the Lollipop Stick

Using Dynamo–Mechanical Analysis equipment (Mettler Toledo, DMA/SDTA 861, Columbus, IN, USA), the BCMs were subjected to dynamic analysis by recording the storage modulus (E′), the loss modulus (E″), and the tangent delta (δ) in a temperature range between 30 and 150 °C, employing the flexural test at a frequency of 1 Hz and a heating rate of 10 °C/min [38,39].

3. Results and Discussions

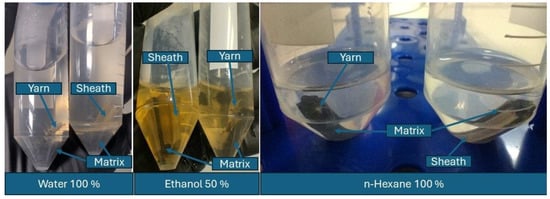

3.1. Global Migration

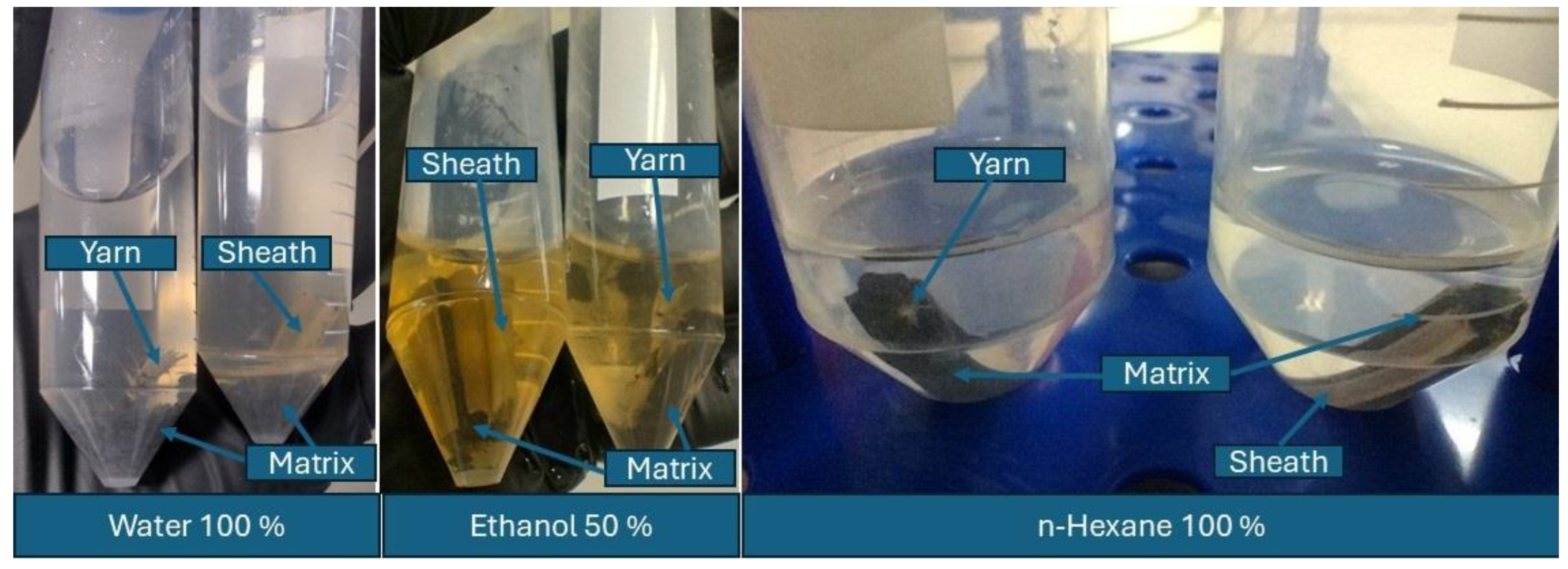

Using the three food simulants made it possible to identify the behaviors of the lollipop sticks exposed to foods that provide different environments: hydrophilic, emulsions, and lipophilic. When using water as a hydrophilic food simulant, the two types of biobased stick disintegrated 15 min after immersion, with the respective reinforcement and the biobased matrix becoming separated. In contrast, in the cases of 50% ethanol solution and hexane, the lollipop sticks maintained their cylindrical geometry for their global migration study. However, for the lollipop sticks exposed to the 50% ethanol solution for 10 days, the respective reinforcements were detached without disintegrating the respective matrices (Figure 3). In the case of SLS, when exposed to water, no structural alteration occurred, and no migration of its components in the hydrophilic medium was recorded (Table 2), which is a similar result to that reported by [40].

Figure 3.

Migration of biobased sticks in food simulants.

Table 2.

Global migration of synthetic and biobased plantain sticks.

Considering the amount of components that migrated into the food simulant solutions, greater diffusion (mass transport) was evidenced in the 50% ethanol solution, relating to the contact of the lollipop sticks with food emulsions such as dairy products and being higher in BC1 when exposing the thermoplastic matrix directly with the simulant, while the sheath present in BC2 restricted the migration of hydrophilic components (Table 2). Tsochatzis et al., 2023 [26] identified the migration of glycerin and maltose from a pea thermoplastic starch (TPS) when exposed to a food simulant consisting of 50% ethanol, probably due to the diffusion of the plasticizer with maltose from the plantain thermoplastic matrix, contributing to an amber coloration in the resulting media of the BC1 and BC2 lollipop sticks. Chongcharoenyanon and Sane, 2021 [25] when using 50% ethanol at 20 °C for 10 days as a food simulant in mixtures of polylactic acid (PLA) and cassava TPS, reported a migration between 150 and 180 µg/dm2, which is lower than the two BC1 and BC2 lollipop sticks, since these mixtures contained 60% PLA. Similarly, the previous authors mentioned that as the concentration of TPS increases in the mixture of the final material, greater migrations of the components that constitute it are generated since it has a hydrophilic character. On the other hand, migration was increased by changing the study conditions in the PLA and cassava TPS mixtures for 2 h and applying a temperature of 70 °C, reaching values between 225 and 300 µg/dm2. According to the above, the lollipop sticks have a considerable migration of glycerin and maltose from the high concentration of TPS and starches in the lignocellulosic reinforcements, where their values were higher than those given by the SLS. When using a highly lipophilic environment (hexane), results were lower than 93 µg/dm2, possibly related to the migration of components from the reinforcements, and were higher in the BC2 lollipop stick since it presented the highest participation of reinforcement (Table 2). It is probable that the hexane removed lipids coming from the cell membranes that constitute the sheaths and the yarn of the pseudostem due to the affinity between hexane and lipids [41,42,43]. However, Solá-Pérez et al., 2018 [44] reported the extraction of other minority components by evaluating three lignocellulosic residues (wheat straw, maguey bagasse, and sugarcane), finding the presence of terpenes, ketones, fatty acids, and steroids. In this case, the biobased lollipop sticks presented a lower migration concerning SLS because the latter has an apolar character, similar to the exposure medium [40].

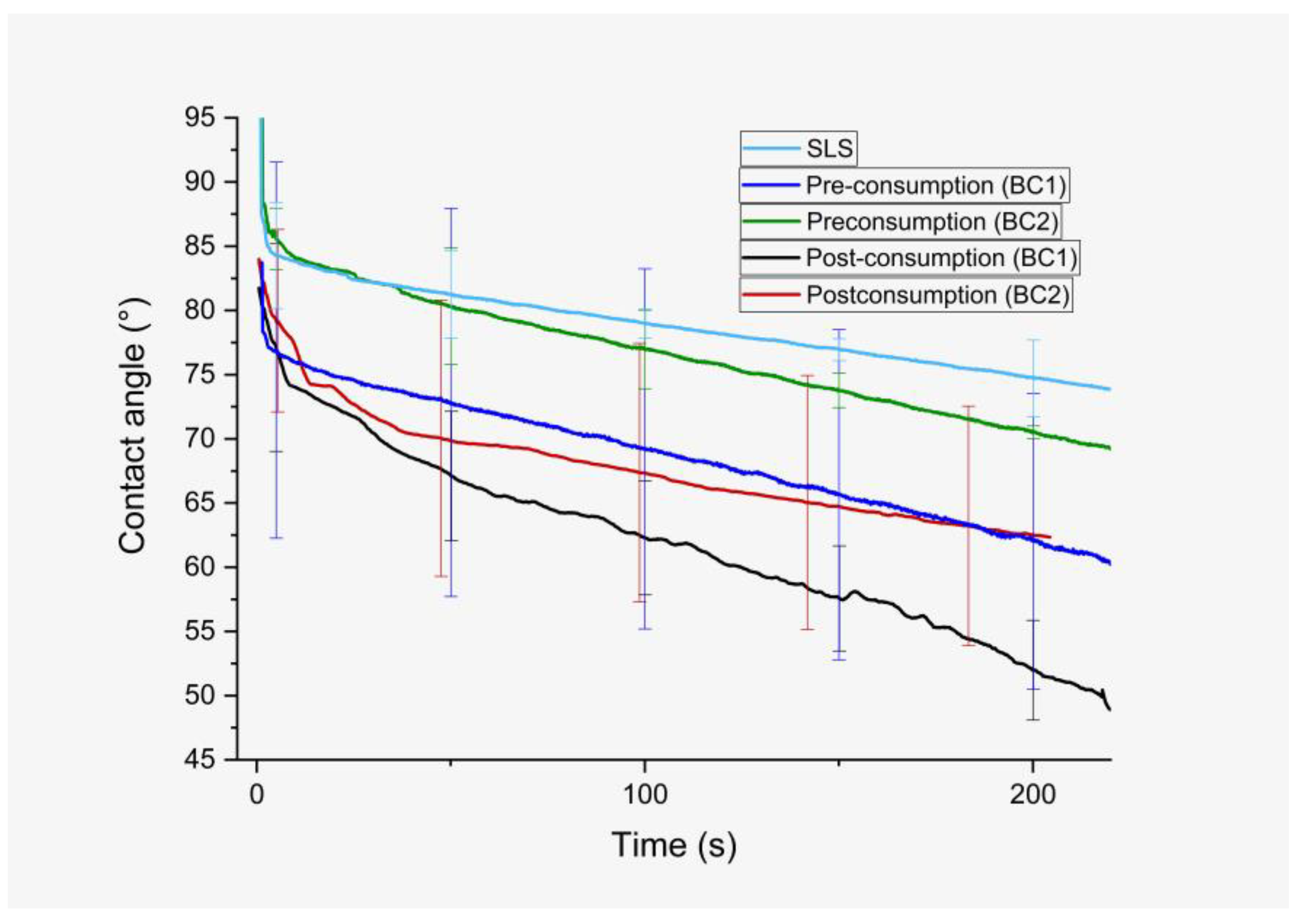

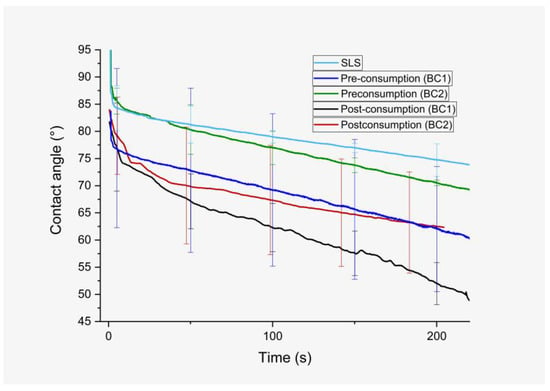

3.2. Contact Angle

The use of the sheath as a coating on the BC2 lollipop stick gave a contact angle value close to that identified in the SLS despite having a higher degree of water absorption according to the slope behavior (Table 3 and Figure 4); this was because the lignocellulosic fibers that constitute the sheaths have less affinity for water than starch does [45,46]. The presence of residual chocolate on the lollipop stick surfaces after consumption of the bonbon-type confectionery did not generate an increase in the contact angle despite having a hydrophobic or lipophilic character due to its high lipid content and presenting a contact angle between 92.3 and 94.0° [47]. The reduction of the contact angle values in the two types of lollipops stick to values close to 74° in the post-consumption was due to the wetting of the sheath through contact with the consumer’s saliva, affecting the barrier identified in the pre-consumption of the chocolate candy through the hydration of the starch and the remaining pectin in its structure [15,22]. However, the presence of the sheath in the BC2 lollipop stick restricted the characteristic velocity in the absorption of the water droplet by the TPS surface compared to the BC1 lollipop stick [48], generating a lower negative slope. Regarding the BC2 lollipop stick, its slope was similar during the pre-consumption and post-consumption study, relating to a higher stability in its hydrophilic degree due to lignocellulosic fibers in the sheath.

Table 3.

Contact angle of synthetic and biobased plantain lollipop sticks.

Figure 4.

Contact angle curves of synthetic and biobased plantain lollipop sticks.

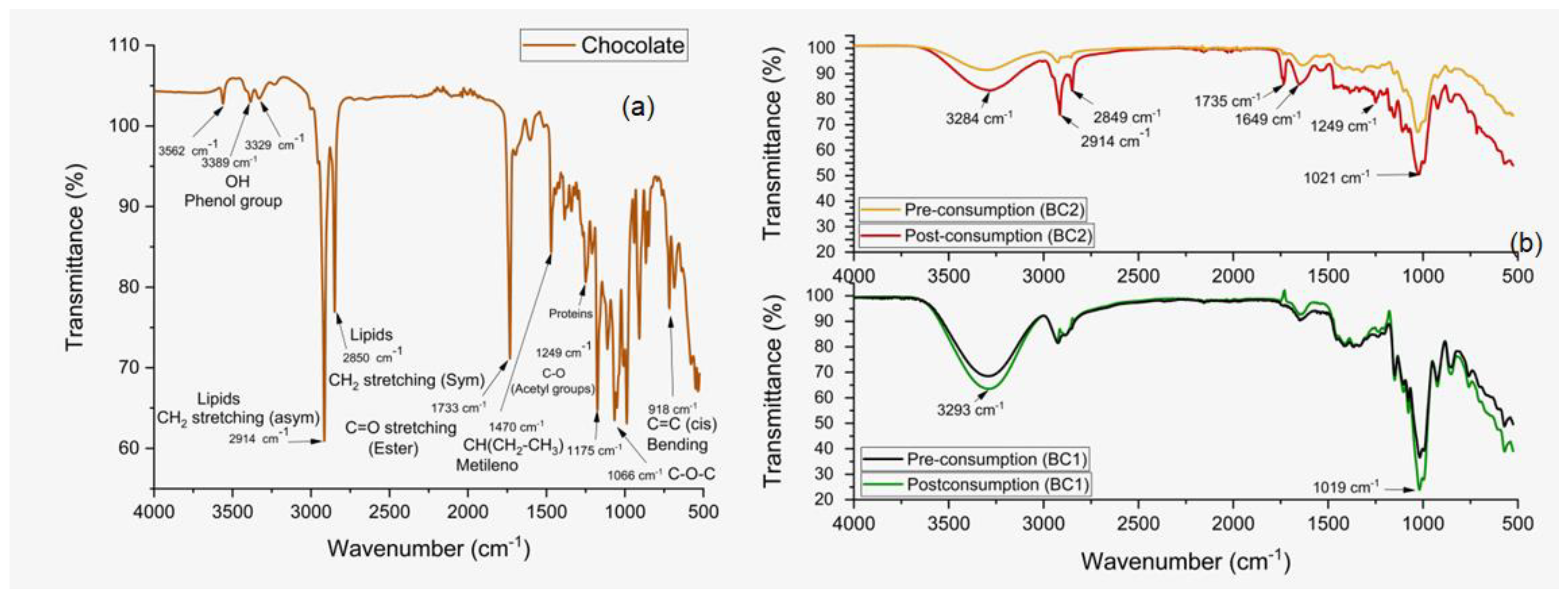

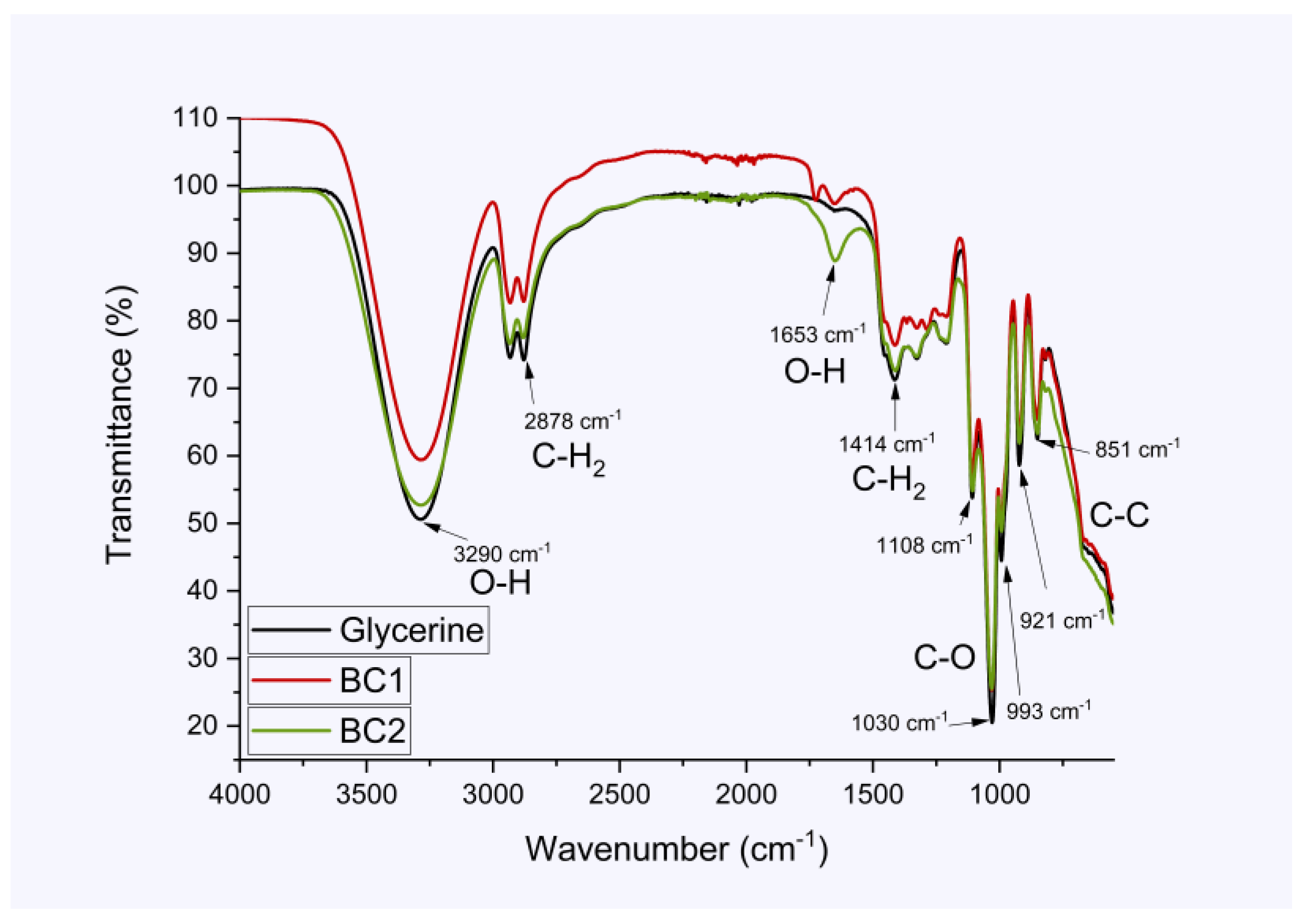

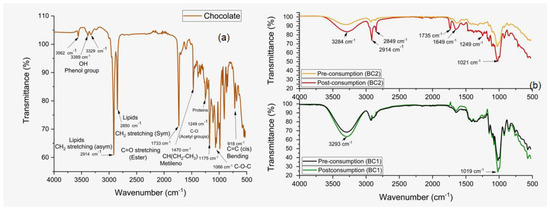

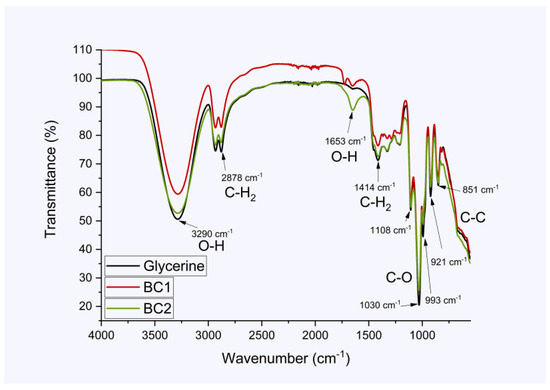

3.3. Fourier Transform Infrared Spectroscopy (FT-IR-ATR)

Regarding the identified and characteristic signals in chocolate (Figure 5a), the presence of phenols (3562 to 3329 cm−1), lipids (2914, 2850 and 1733 cm−1), protein (1249 cm−1), and sugar (1066 cm−1) was reported [49,50,51,52,53], with differences identified in the lollipop sticks after consumption of the bonbon-type confectionery. In the case of the BC1 lollipop stick, an increase in the intensity of the stretching band belonging to the hydroxyl group (3293 cm−1) was recorded (Figure 5b), relating to an increase in water absorption [54] from the consumer’s saliva even though the strain signal of the O-H bonds (1647cm−1) did not manifest an increase in its intensity post-consumption. Another signal that increased in intensity corresponded to the carbohydrate fingerprint (1019 cm−1) [55], which was due to the adhesion of the sugar from the chocolate on the surface of the lollipop stick [56]. With the BC2 lollipop stick (Figure 5b), greater additional changes were identified concerning what was manifested in the BC1 lollipop stick, with three characteristic signals of lipids (2914, 2849, and 1735 cm−1) and a signal of the protein (1249 cm−1) from the chocolate identified, explaining the greater capacity in the surface adhesion of the chocolate on the sheath with respect to the surface of the TPS-based matrix. It is also relevant to mention that the representative peak of the strain in the O-H bonds belonging to the BC2 lollipop stick presented a higher intensity post-consumption, confirming the water retention when the lollipop stick was exposed to the consumer’s saliva for a short time. Another analysis that was performed using the present analytical technique was related to the components that diffused in 50% ethanol in the global migration test, which identified similar signals to the glycerin and the resulting migration of the two lollipop sticks as reported by Arofai et al., 2024 [57], finding the band of hydroxyl groups at 3290 cm−1, and symmetric and asymmetric stretching of CH2 bonds at 2878 and 1414 cm−1, respectively; C-O bonds were found at 1108, 1030, and 993 cm−1, identifying the presence of secondary and primary alcohols (Figure 6). Meanwhile, the strain signals at 921 and 851 cm−1 represent C-C and C-C-O bonds and aggregates of glycerol hydroxyl groups. Among the impurities in the migration resulting from the two lollipop sticks, absorbed moisture was identified from a strain peak at 1653 cm−1.

Figure 5.

Spectrograms (a) of chocolate and (b) biobased plantain sticks.

Figure 6.

Spectrograms of glycerol and the resulting migrants from BC1 and BC2 lollipop sticks.

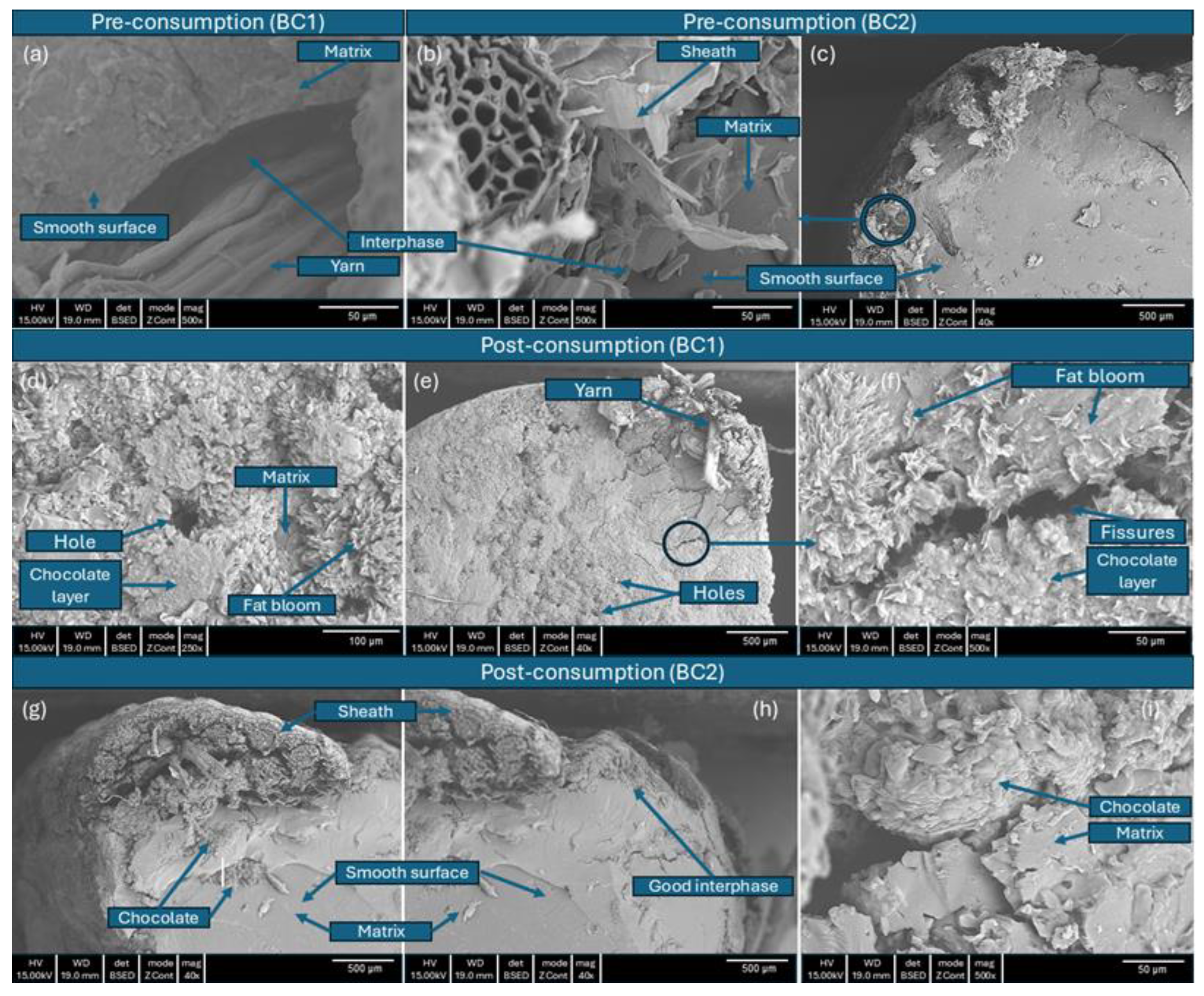

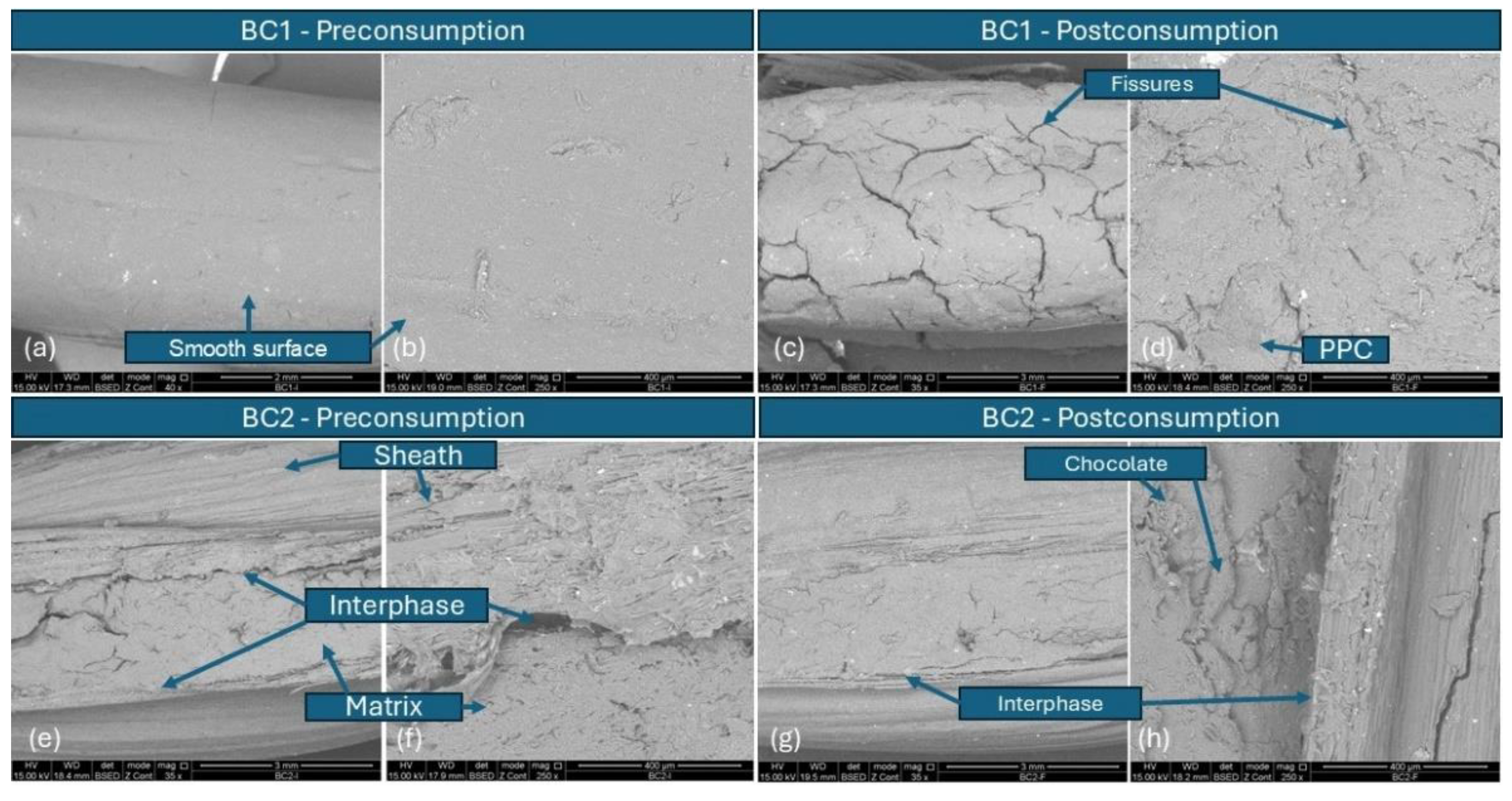

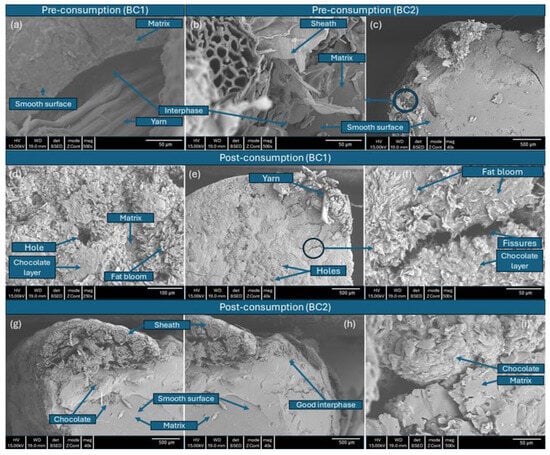

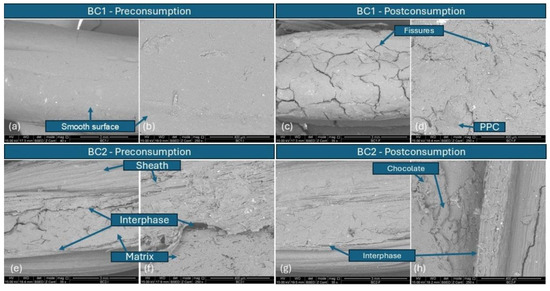

3.4. Scanning Electron Microscopy (SEM)

We carried out topographical analysis of the two types of lollipop sticks, pre-consumption and post-consumption, as specified in the areas that came into contact with the chocolate, considering the base and the walls of the cylindrical geometry of the lollipop stick. In the pre-consumer chocolate, soft and smooth surfaces of the matrix composing the two sticks were identified, being characteristic of gelatinization of most of the plantain starch granules [58], each lollipop stick being differentiated by the quality of the interfacial area between the respective reinforcements with the matrix, identifying gaps between the matrix and the yarn in the BC1 lollipop stick (Figure 7a). In contrast, the sheath and the matrix did not generate the spacings characteristic of a weak interface (Figure 7b,c). In the case of the wall surfaces of the BC1 lollipop stick, its smooth aspect with low presence of cracks was highlighted (Figure 8a,b), differing from the BC2 stick; its matrix and interfacial area present cracks from the cut generated to remove the burr after processing by hot compression molding (Figure 8c,d).

Figure 7.

SEM micrographs of the bases of biobased plantain lollipop sticks: (a) BC1 pre-consumer; (b,c) BC2 pre-consumer; (d–f) BC1 post-consumer; (g–i) BC2 post-consumer.

Figure 8.

SEM micrographs of the walls of biobased plantain lollipop sticks: (a,b) BC1 pre-consumer; (c,d) BC1 post-consumer; (e,f) BC2 pre-consumer; (g,h) BC2 post-consumer.

Post-consumption of the confectionery, the presence of remaining chocolate on the base and walls of the two types of lollipop stick was verified, highlighting the higher retention on the surfaces corresponding to the walls of the BC2 lollipop stick, specifically on the sheath, due to a possible higher apolar affinity between the chocolate and the sheath than what was exposed in the BC1 lollipop stick, between the chocolate and the thermoplastic matrix based on plantain starch, considering that Mendes et al., 2021 [59] reported an adequate affinity between chocolate and its derivatives by mixing them with cassava TPS to obtain biobased materials. However, this behavior was not maintained in the bases of the sticks since a higher presence of chocolate was evidenced in the BC1 than in the BC2 lollipop stick. In Figure 7d–f, the formation of chocolate sheets was identified in two structural states (fresh and fat bloom), generating a coating on the surface of the lollipop sticks. In the fresh state, an irregularly shaped mass with rounded particles and folds was visualized, representing the ingredients that make up the chocolate, such as cocoa solids, fat (triglycerides), and sugar. Another structural characteristic of chocolate is the formation of porosities generated for storing fat in the liquid state [23,60,61,62,63,64]. In the case of tempering, use of ingredients, inadequate storage conditions, or an advanced aging time in chocolate, the βVI structure can be manifested, which generates a blade-like bloom due to the migration of the fat that constitutes the chocolate, moving from its interior to the surface [23,61,62]. In the case of the surfaces belonging to the walls of the BC1 lollipop stick, they presented a high concentration of cracks related to surface erosion from the contact of saliva with the mechanical shear action since the matrix has a greater hydrophilic character than the BC2 lollipop stick, as detected in the global migration test (Figure 8e,f). In the case of the BC2 lollipop stick, the chocolate confection was evident, and the interface between the sheath and the matrix was weakened by the generation of larger spacings (Figure 8g,h). Another differentiating characteristic of the BC2 lollipop stick was a possible increase in the sheath’s volume post-consumption (Figure 7g–i), which was due to the contribution of moisture from the mouth of the chocolate consumer, where the FTIR-ATR identified an increase in absorbed water, considering that the confectionery has a lipophilic nature [47].

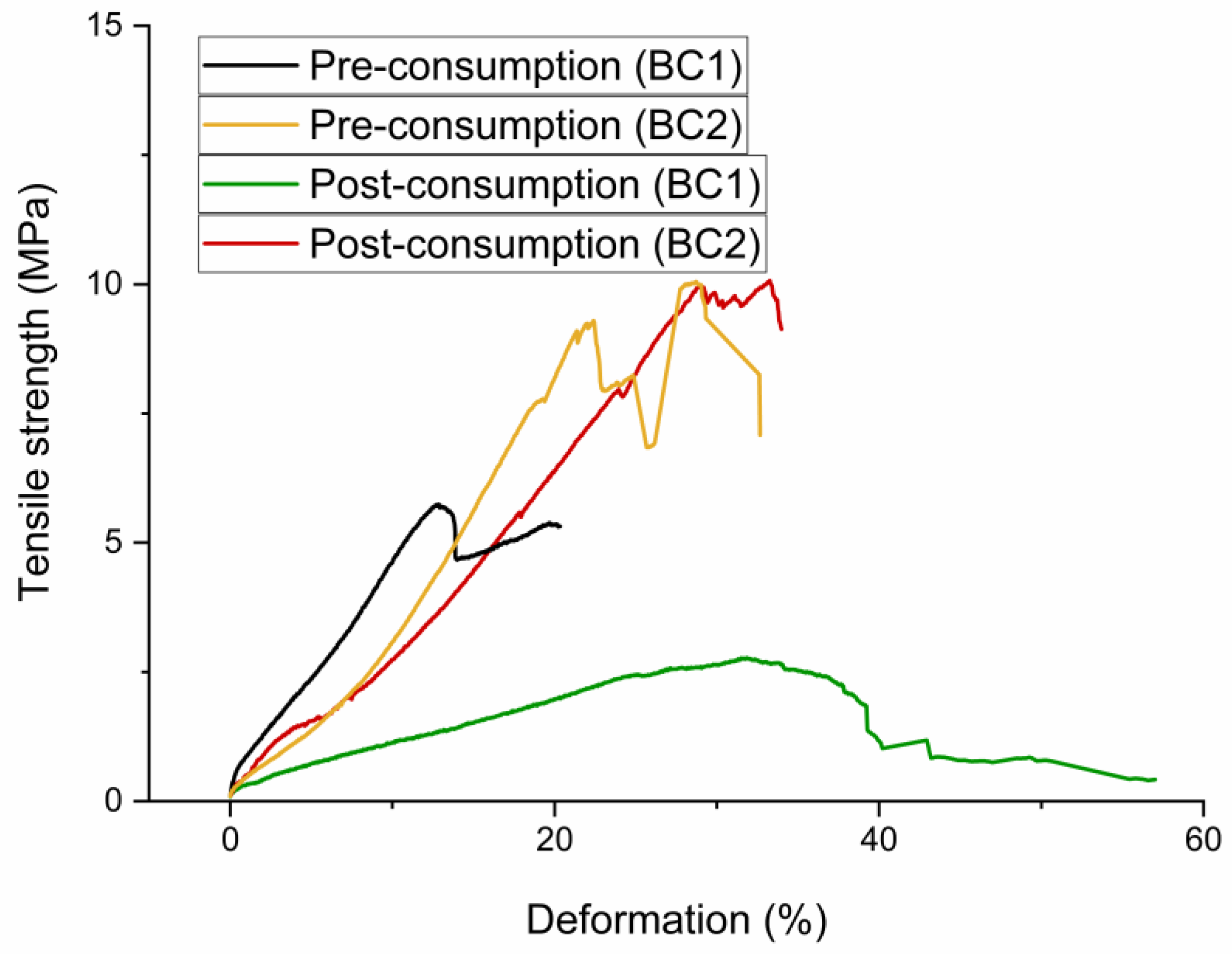

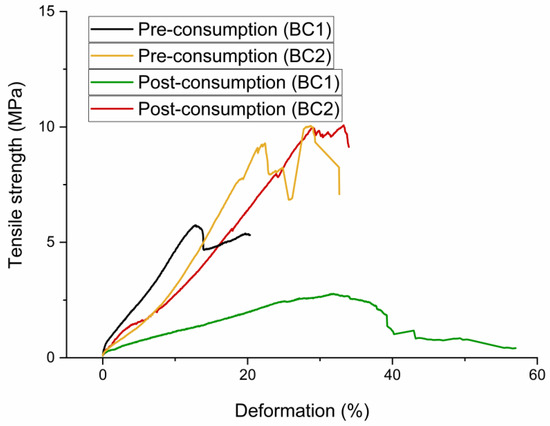

3.5. Tensile Test

The SLS presented a higher σmax concerning the BC1 and BC2 lollipop sticks from its composition (Table 4 and Figure 9) since PP constitutes the SLS, generating values between 20 and 27 MPa [65,66]. In the case of biobased sticks, the use of the sheath contributed to a higher σmax than that granted by the yarn, considering the presence of the highest amount of reinforcement (37%), employing long fibers with unidirectional orientation in the sheaths that constitute the BC2 lollipop stick and the lignocellulosic fibers it contains, possessing σmax values between 232.40 and 489.54 MPa [22,67]. Post-consumption, a reduction of 55.72% in the σmax of the BC1 lollipop stick was generated, while, when using the sheath as reinforcement in the BC2 lollipop stick, a loss of 6.81% was presented. Despite the exposure of the two types of BCM to chocolate at a temperature close to 32 °C for molding and cooling, followed by storage for 10 days and subsequent consumption, and being moistened with some mechanical exposure during handling and consumption of the confection, the function of the sheath restricted the passage of moisture during chocolate consumption, avoiding the rapid speed in the loss of mechanical properties from the wetting of the thermoplastic matrix [15] which was manifested in the BC1 lollipop stick, since the free spaces between the reinforcement and the matrix evidenced through SEM images increased the capacity for water absorption and affected its mechanical behavior [68]. Similarly, the wetting generated in the biobased lollipop sticks from chocolate consumption promoted changes in the E and the ε, reducing the structural stiffness and increasing strain by retaining higher moisture content. Despite the reduction of the σmax and E of the BC2 lollipop stick post-consumption, its σmax retained a competitive value when compared to that reported by [69], obtaining a value of 8.16 MPa in a BCM constituted by flour from plantain peel, plasticized with 50% glycerin, and reinforced with 6.54% of fibers from plantain pseudostem. In comparison, the E was higher, with a value of 281 MPa. In the case of Cheng, 2019 [70], a σmax of 12.15 MPa and an E of 506 MPa were reported when using a corn TPS reinforced with 23.44% of lignocellulosic fibers and 5.13% of calcium carbonate (CaCO3). When compared with those obtained by Rodriguez-Soto et al., 2019 [18], the σmax and E were higher with the use of a BCM formed by a bilayer sheet using cassava acetylated thermoplastic starch (first layer) and a sheath from the plantain pseudostem by hot compression molding, obtaining values of 50 MPa and 2.7 GPa, respectively.

Table 4.

Tensile and flexural properties of synthetic and biobased plantain lollipop sticks.

Figure 9.

Tensile test curves for all sticks pre-consumption.

3.6. Flexural Test

In this type of mechanical action, SLS maintained a higher σFmax from its PP-based composition, while the biobased lollipop sticks presented a reduction of the σFmax by 40.85% in the BC1 lollipop stick post-consumption. In comparison, the value for the BC2 lollipop stick was 46.98%; the decrease, concerning the properties obtained previously, in tensile stresses is more notable. In the case of the BC1 lollipop stick, the acquired moisture contributed to the plasticization of the biobased matrix that composes it, while in the case of the BC2 lollipop stick, the absorption of moisture possibly caused a reduction in stiffness initially generated by the starch and pectin present in the interior of the sheath, leaving only the lignocellulosic fibers exposed as possible reinforcement. On the other hand, the lignocellulosic fibers did not contribute to the generation of σFmax from the softening of the parenchyma belonging to the sheath when wetted. They possibly contributed to the weakening of the interfacial area between the sheath and the matrix, preventing the transmission of the flexural stress towards the lignocellulosic fibers of the sheath from the beginning of chocolate consumption, since Müssig, 2010 [71] reported that lignocellulosic fibers in a pure state do not contribute to the σFmax. When comparing the results pre-consumption and post-consumption of chocolate candy, higher σFmax values were reported when using PP blends with banana pseudostem fibers with a participation of 30% as reinforcement, with values between 65 and 68 MPa [67].

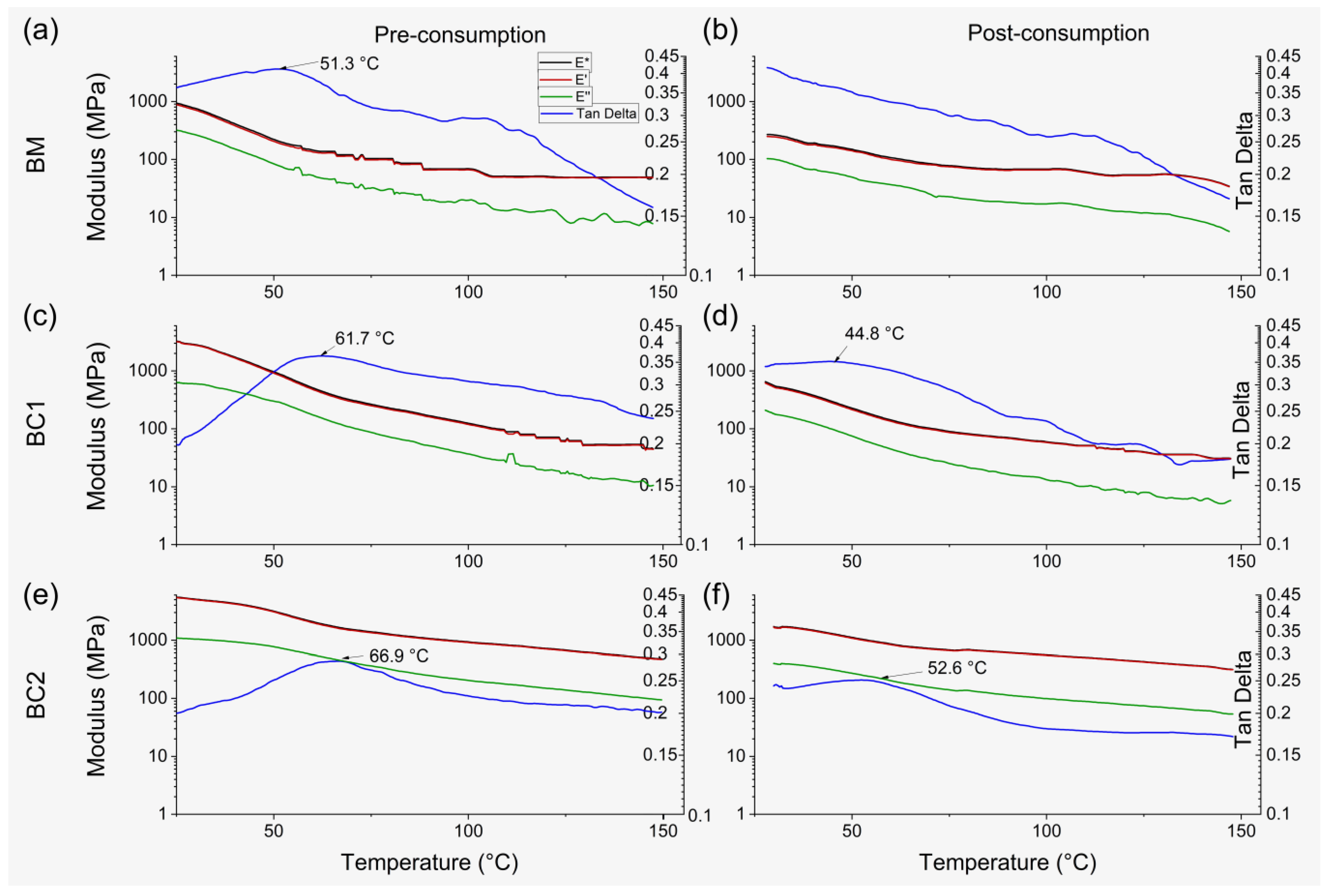

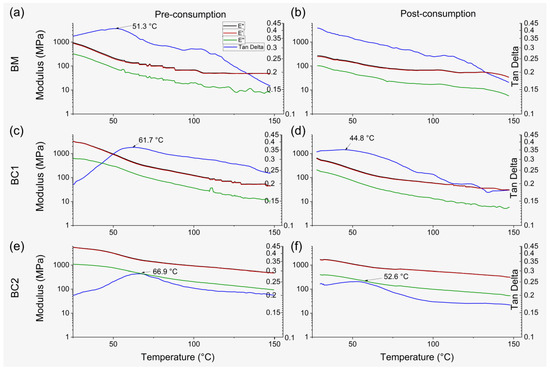

3.7. Dynamic Mechanical Analysis (DMA)

Regarding the analysis of the moduli in a temperature interval between 30 and 150 °C (Table 5), a reduction in their values was evidenced as the temperature increased, which is a characteristic behavior of a semicrystalline thermoplastic polymer, since the lollipop sticks presented a tendency of the complex (E*) and storage (E′) moduli to 0 when exposed to higher temperature values; likewise, the intensity of the tangent delta reached values lower than 1 [22,72]. In the case of the loss modulus (E″), a lower manifestation was identified throughout the study temperature range, related to stiffness in the lollipop sticks. Bashir, 2021 [73] mentioned that E″ is associated with the internal friction generated with the movement of segments of the polymeric chains, indicating the greater macromolecular restriction in the BC2 lollipop sticks. In the E′ at 30 °C, a contribution of reinforcement of the thermoplastic matrix was identified by incorporating the yarn and sheaths in the BC1 and BC2 lollipop sticks, increasing from 0.70 to 2.75 and 4.97 GPa, respectively, generating a higher stiffness and restriction in the macromolecular mobility of the thermoplastic matrix. From the increase of E′ in BC1 and BC2, an interfacial region was generated between the lignocellulosic reinforcement (yarn and sheath) and the matrix, formed by two nano-layers. The first nano-layer that surrounds or tops the surface of the lignocellulosic reinforcement with a thickness between 0.1 and 2.0 nm contains polymeric chains of the matrix that possess a high restriction in their mobility due to their strong fixation with the surface of the lignocellulosic reinforcement, depending on the physical and chemical affinity of the matrix and the reinforcement, the volume fraction, particle size, and dispersion quality of the reinforcement. In comparison, the second nano-layer can present a greater thickness (2.5 to 9.0 nm), containing polymeric chains with a slight anchorage with the lignocellulosic reinforcement [73]. The above behavior was identified in BCMs consisting of polyhydroxy butyrate valerate (PHBV) reinforced with recycled cellulose fibers in two concentrations (15 and 40%), generating an E′ at 30 °C of 1.8 and 2.9 GPa, respectively [74]. Similarly, the higher contribution of the reinforcement presented in the BC2 lollipop stick is related to the higher value of E′, the higher temperature of the Tan delta, and the lower intensity in its signal, relating to a greater interaction between the matrix and the reinforcement used [73]. Post-consumption of the chocolate candy, a reduction in the viscoelastic properties was generated in the biobased lollipop sticks from the contact of saliva and friction with the internal tissues of the mouth and teeth of the consumer, weakening the interfacial region of the BCM; however, BC2 maintained an E′ higher than 1.5 GPa, due to the moisture barrier provided by the sheath. As the temperature increased, it was noticed that the lignocellulosic reinforcements maintained a higher E′ than the thermoplastic matrix, especially in the BC2 lollipop stick (Table 5 and Figure 8), and also higher than that manifested in a composite material constituted by PP reinforced by banana pseudostem fibers between 20 to 30%, which generated an E′ close to 2.25 GPa at a temperature of 50 °C [75], lower than that shown by the BC2 lollipop stick (Table 5 and Figure 10), while in other investigations using TPS as matrix, reinforced with cellulose nanofibers and sisal fibers in native and alkalinized states between 0.5 and 10%, the E′ at 50 °C did not exceed 1.9 GPa [76,77,78]. At the same evaluation temperature and when comparing the E′ of the BC2 lollipop stick, it is worth noting a BCM made of matrices such as polyhydroxybutyrate (PHB) and PHBV reinforced with recycled cellulose, native flax fiber, and silanized between 15 and 50%, achieving maximum values of 2.84 GPa [79]. According to the above, the BC2 lollipop stick has an elastic behavior that stands out over other BCMs developed in other investigations. As for the Tan delta, which corresponds to the existence of the glass transition temperature (Tg) [73,80], as the amount of reinforcement in the lollipop stick increased, it was located at a higher temperature, relating to a more significant restriction in macromolecular mobility [81,82], maintaining the superiority in the BC2 lollipop stick; and, after the confectionery had been consumed, a reduction in its value was generated, contributing to an increase in macromolecular mobility because of the moisture received by the consumer. The Tan delta may also depend on the type of reinforcement used in the BCM, giving a greater molecular restriction when using fibers with a higher aspect ratio in a TPS matrix, reporting a Tan delta of macrofibers between 10.0 and 12.6 °C. At the same time, when using cellulose nanofibers, its value can be found between 80.5 and 87.5 °C, the latter being responsible for increasing the restriction in the molecular movement of the starch chains [76,77,78,83]. Another behavior that should be mentioned is the absence of Tan delta registration in the BM post-consumption, relating to a possible reduction of Tg below 30 °C, and relating to the highest saliva plastification in comparison with BC1 and BC2.

Table 5.

Dynamic–mechanical properties of biobased plantain lollipop sticks. Storage modulus (E′).

Figure 10.

Dynamic–mechanical behavior of biobased plantain lollipop sticks pre-consumption and post-consumption: (a,b) BM; (c,d) BC1; (e,f) BC2. Complexe modulus (E*); Storage modulus (E′); Loss modulus (E″).

4. Conclusions

From the use of plantain by-products for the development of lollipop sticks for bonbon-type confectionery, it was identified that the lipophilic character provided by the chocolate is adequate due to the lower migration generated from the lollipop stick to the confectionery, since other simulants generated migrations higher than 2369.50 µg/dm2 in emulsions and the disintegration of the lollipop sticks in a short time in hydrophilic foods. After consumption of the chocolate confectionery, a reduction in contact angle and retention of confectionery in biobased lollipop sticks was evidenced from SEM and FT-IR-ATR, as well as reductions in σmax, E, σFmax, E*, E′ and Tan delta. However, the use of the sheaths as reinforcement and coating of the thermoplastic matrix present in the BC2 lollipop stick contributed to generating lower losses in the properties, presenting a potential as a possible alternative to the conventional lollipop sticks used in chocolate confections since it generated a loss of 6.81% in the σmax, maintained the σFmax above 10 MPa, maintained an E′ (30 °C) of 1.65 GPa, and a Tan Delta (Tg) of 52.64 °C, all of which are properties related to the stiffness of the lollipop stick post-consumption of the confectionery. In the case of the BC1 lollipop stick, the loss of properties was mainly based on the direct exposure of the thermoplastic matrix to the application environment and direct contact with moisture. Based on the limitations identified in the BC2 lollipop stick and its use in emulsions, alcoholic beverages, and hydrophilic foods, further study is required in one of the three alternatives to mitigate the effects that water can cause in the structure and properties of the lollipop stick, using starch modification, hydrophobization of the surfaces by plasma treatment, or coating with an apolar resin.

Author Contributions

Conceptualization, J.P.C.-N., J.H.M.-H., and J.F.S.-D.; methodology, J.P.C.-N., L.G.O.-A., Y.C.Z.-D., J.H.M.-H., and R.O.Z.-G.; formal analysis, J.P.C.-N., L.G.O.-A., and Y.C.Z.-D.; investigation, J.P.C.-N., L.G.O.-A., Y.C.Z.-D., J.H.M.-H., J.A.S.-J., E.P.-P., and R.O.Z.-G.; writing—original draft preparation, J.P.C.-N., L.G.O.-A., Y.C.Z.-D., J.H.M.-H., J.A.S.-J., E.P.-P., R.O.Z.-G., and J.F.S.-D.; writing—review and editing, J.P.C.-N., J.H.M.-H., and J.F.S.-D.; project administration, J.H.M.-H. All authors have read and agreed to the published version of the manuscript.

Funding

This research has been funded by Vicerrectoría de Investigaciones de la Universidad del Valle through the Convocatoria Interna 123-2020 (C.I. 21127), Convocatoria de apoyo a estudiantes de Doctorado 149-2023 (C.I. 21243) and for MinCiencias; research project 63587 (contract 185-2019).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

The authors acknowledge the Centro de Desarrollo Tecnológico Agroindustrial (CDTA-UTP) of the Universidad Tecnológica de Pereira, who allowed the development of laboratory practices and the use of chemical reagents and supplies.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Eerkes-Medrano, D.; Thompson, R.C.; Aldridge, D.C. Microplastics in freshwater systems: A review of the emerging threats, identification of knowledge gaps and prioritisation of research needs. Water Res. 2015, 75, 63–82. [Google Scholar] [CrossRef] [PubMed]

- Asensio-Montesinos, F.; Oliva Ramírez, M.; González-Leal, J.M.; Carrizo, D.; Anfuso, G. Characterization of plastic beach litter by Raman spectroscopy in South-western Spain. Sci. Total Environ. 2020, 744, 140890. [Google Scholar] [CrossRef]

- Moore, C.J. Synthetic polymers in the marine environment: A rapidly increasing, long-term threat. Environ. Res. 2008, 108, 131–139. [Google Scholar] [CrossRef] [PubMed]

- Mousania, Z.; Angulo, A.V.; Poon, J.P.H.; Atkinson, J.D. Quantifying the environmental impact of transportation for plastic film packaging end-of-life: Landfill, incineration, physical recycling, or chemical recycling. Resour. Conserv. Recycl. 2024, 207, 107681. [Google Scholar] [CrossRef]

- Neves, D.; Sobral, P.; Ferreira, J.L.; Pereira, T. Ingestion of microplastics by commercial fish off the Portuguese coast. Mar. Pollut. Bull. 2015, 101, 119–126. [Google Scholar] [CrossRef]

- Ragaert, K.; Delva, L.; Van Geem, K. Mechanical and chemical recycling of solid plastic waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef] [PubMed]

- Gholampour, A.; Ozbakkaloglu, T. A Review of Natural Fiber Composites: Properties, Modification and Processing Techniques, Characterization, Applications. J. Mater. Sci. 2020, 55, 829–892. [Google Scholar] [CrossRef]

- Asgher, M.; Qamar, S.A.; Bilal, M.; Iqbal, H.M.N. Bio-based active food packaging materials: Sustainable alternative to conventional petrochemical-based packaging materials. Food Res. Int. 2020, 137, 109625. [Google Scholar] [CrossRef]

- Chang, B.P.; Misra, M. Studies on durability of sustainable biobased composites: A review. RSC Adv. 2020, 10, 17955–17999. [Google Scholar] [CrossRef]

- Wagner, T.P. Reducing single-use plastic shopping bags in the USA. Waste Manag. 2017, 70, 3–12. [Google Scholar] [CrossRef]

- Lightfoot, S.J.; Grant, T.; Boyden, A.; McAlister, S. Single-Use Synthetic Plastic and Natural Fibre Anaesthetic Drug Trays: A Comparative Life Cycle Assessment of Environmental Impacts. Br. J. Anaesth. 2024, 133, 1465–1477. [Google Scholar] [CrossRef]

- Consoli, P.; Costa, V.; Sciutteri, V.; Malara, D.; Pedà, C.; Figurella, F.; Campbell, I.; Deery, E.; Romeo, T.; Andaloro, F. Synthetic polymers: A global threat to aquatic benthic environments. J. Hazard. Mater. 2024, 474, 134848. [Google Scholar] [CrossRef] [PubMed]

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics recycling: Challenges and opportunities. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2115–2126. [Google Scholar] [CrossRef] [PubMed]

- Goel, V.; Luthra, P.; Kapur, G.S.; Ramakumar, S.S.V. Biodegradable/Bio-plastics: Myths and Realities. J. Polym. Environ. 2021, 29, 3079–3104. [Google Scholar] [CrossRef]

- Holguín-Posso, A.M.; Macías-Silva, J.C.; Castañeda-Niño, J.P.; Mina-Hernandez, J.H.; Fajardo Cabrera de Lima, L.D.P. Characterization and Implementation of Cocoa Pod Husk as a Reinforcing Agent to Obtain Thermoplastic Starches and Bio-Based Composite Materials. Polymers 2024, 16, 1608. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Natural fibers, biopolymers, and biocomposites. In Natural Fibers, Biopolymers, and Biocomposites; CRC Press: Boca Raton, FL, USA; Taylor & Francis Group: Boca Raton, FL, USA, 2005. [Google Scholar]

- Mo, X.; Qi, X.; Zhong, Y.; Li, R.; Mo, C. Preparation and Properties of Tapioca Starch-Banana Fiber Composites Modified with Magnesium Hydroxide. Adv. Mat. Res. 2011, 194–196, 1707–1710. [Google Scholar] [CrossRef]

- Rodríguez-Soto, K.; Piñeros-Castro, N.; Ortega-Toro, R. Laminated Composites Reinforced with Chemically Modified Sheets-Stalk of Musa Cavendish. Rev. Mex. Ing. Quim. 2019, 18, 749–758. [Google Scholar] [CrossRef]

- Migneault, S.; Koubaa, A.; Erchiqui, F.; Chaala, A.; Englund, K.; Wolcott, M.P. Effects of Processing Method and Fiber Size on the Structure and Properties of Wood-Plastic Composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 80–85. [Google Scholar] [CrossRef]

- De La Torre-Gutierrez, L.; Torruco-Uco, J.G.; Castellanos-Ruelas, A.; Chel-Guerrero, L.A.; Betancur-Ancona, D. Isolation and structure investigations of square banana (Musa balbisiana) starch. Starch/Staerke 2007, 59, 326–333. [Google Scholar] [CrossRef]

- Ferreira-Villadiego, J.; García-Echeverri, J.; Vidal, M.V.; Pasqualino, J.; Meza-Castellar, P.; Lambis-Miranda, H.A. Chemical modification and characterization of starch derived from plantain (Musa paradisiaca) peel waste, as a source of biodegradable material. Chem. Eng. Trans. 2018, 65, 763–768. [Google Scholar]

- Castañeda-Niño, J.P.; Mina-Hernandez, J.H.; Solanilla-Duque, J.F. Potential of Plantain Pseudostems (Musa AAB Simmonds) for Developing Biobased Composite Materials. Polymers 2024, 16, 1357. [Google Scholar] [CrossRef]

- Sato, S.; Hondoh, H.; Ueno, S. Fat Bloom Caused by Partial De-Oiling on Chocolate Surfaces after High-Temperature Exposure. J. Am. Oil Chem. Soc. 2021, 98, 269–280. [Google Scholar] [CrossRef]

- European Commission. Comission Regulation (EU) No 10/2011 on Plastic Materials and Articles Intended to Come into Contact with Food; European Commission: Brussels, Belgium, 2011. [Google Scholar]

- Chongcharoenyanon, B.; Sane, A. Effect of overall migration on tensile properties of biobased plastics containing polylactic acid, thermoplastic starch and zeolite. Agric. Nat. Resour. 2021, 55, 611–617. [Google Scholar]

- Tsochatzis, E.D.; Vidal, N.P.; Bai, W.; Diamantidou, D.; Theodoridis, G.; Martinez, M.M. Untargeted screening and in silico toxicity assessment of semi- and non-volatile compounds migrating from polysaccharide-based food contact materials. Food Chem. 2023, 425, 136499. [Google Scholar] [CrossRef]

- Vera, P.; Canellas, E.; Nerín, C. Migration of odorous compounds from adhesives used in market samples of food packaging materials by chromatography olfactometry and mass spectrometry (GC-O-MS). Food Chem. 2014, 145, 237–244. [Google Scholar] [CrossRef]

- Zhou, R.; Geng, J.; Jiang, J.; Lin, L.; Zhang, J.; Yang, Y.; Wang, X.; Niu, Y.; Shao, B. Occurrence and migration of organophosphite and organophosphate esters into food simulants from single-use food packaging in China. Environ. Pollut. 2023, 330, 121782. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Wei, X.; Du, Y.; Wang, D. Effect of water-soluble polymers on the performance of dust-suppression foams: Wettability, surface viscosity and stability. Colloids Surf. A Physicochem. Eng. Asp. 2019, 568, 92–98. [Google Scholar] [CrossRef]

- American Society for Testing and Materials (ASTM). In Standard Practice for General Techniques for Obtaining Infrared Spectra for Qualitative Analysis (E1252); ASTM International: West Conshohocken, PA, USA, 2021; pp. 1–13. [CrossRef]

- Lipsa, R.; Tudorachi, N.; Darie-Nita, R.N.; Oprică, L.; Vasile, C.; Chiriac, A. Biodegradation of poly(lactic acid) and some of its based systems with Trichoderma viride. Int. J. Biol. Macromol. 2016, 88, 515–526. [Google Scholar] [CrossRef]

- Dorigato, A.; Fredi, G.; Pegoretti, A. Thermo-mechanical behavior of novel wood laminae-thermoplastic starch biodegradable composites with thermal energy storage/release capability. Front. Mater. 2019, 6, 76. [Google Scholar] [CrossRef]

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM: West Conshohocken, PA, USA, 2014.

- Mina-Hernandez, J.H. Effect of the incorporation of polycaprolactone (PCL) on the retrogradation of binary blends with cassava thermoplastic starch (TPS). Polymers 2021, 13, 38. [Google Scholar] [CrossRef]

- ASTM D790-17; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM: West Conshohocken, PA, USA, 2017.

- Heckadka, S.S.; Kini, M.V.; Ballambat, R.P.; Beloor, S.S.; Udupi, S.R.; Kini, U.A. Flexural Strength Analysis of Starch Based Biodegradable Composite Using Areca Frond Fibre Reinforcement. Int. J. Manuf. Eng. 2014, 2014, 769012. [Google Scholar] [CrossRef]

- Muñoz-Velez, M.F.; Hidalgo-Salazar, M.A.; Mina-Hernandez, J.H. Effect of content and surface modification of fique fibers on the properties of a low-density polyethylene (LDPE)-Al/fique composite. Polymers 2018, 10, 1050. [Google Scholar] [CrossRef] [PubMed]

- Andrzejewski, J.; Markowski, M.; Barczewski, M. The Use of Nanoscale Montmorillonite (MMT) as Reinforcement for Polylactide Acid (PLA) Prepared by Fused Deposition Modeling (FDM)—Comparative Study with Biocarbon and Talc Fillers. Materials 2022, 15, 5205. [Google Scholar] [CrossRef]

- Huda, M.S.; Drzal, L.T.; Misra, M.; Mohanty, A.K.; Williams, K.; Mielewski, D.F. A study on biocomposites from recycled newspaper fiber and poly(lactic acid). Ind. Eng. Chem. Res. 2005, 44, 5593–5601. [Google Scholar] [CrossRef]

- Velásquez, E.; López-de-Dicastillo, C.; Patiño Vidal, C.; Copello, G.; Pérez, C.J.; Guarda, A.; José Galotto, M. Upgrading properties and circularity of the recycled flexible polypropylene by developing composites with an optimal combination of a fumed silica and maleated polypropylene copolymer: Influence of the addition of copolymer, type of fumed silica and the silica/copolymer ratio on packaging properties. Polym. Test. 2024, 138, 108556. [Google Scholar]

- Chen, W.; Wang, H.; Lan, W.; Zhang, A.; Liu, C. Fabrication of sugarcane bagasse ester-based porous nanofiber membrane by electrospinning for efficient oil-water separation. Ind. Crops Prod. 2022, 187, 115480. [Google Scholar] [CrossRef]

- Karatay, S.E.; Demiray, E.; Dönmez, G. Usage potential of apple and carrot pomaces as raw materials for newly isolated yeast lipid-based biodiesel production. Biomass Convers. Biorefinery 2022, 12, 4773–4783. [Google Scholar] [CrossRef]

- Meile, K.; Dobele, G.; Iljina, N.; Zhurinsh, A.; Jurkjane, V. Lignocellulose pyrolysis by-products as an underestimated source of chemicals: Separation and characterisation. Biomass Convers. Biorefinery 2023, 13, 5709–5720. [Google Scholar] [CrossRef]

- Solá-Pérez, J.E.; Saldarriaga-Noreña, H.; Murillo-Tovar, M.; Ronderos-Lara, G.; López-Martínez, V.G. Chemical Characterization of N-Hexane Extract Obtained from Lignocellulose Residual Contained in Agroindustrial Wastes. J. Agric. Chem. Environ. 2018, 7, 94–104. [Google Scholar] [CrossRef][Green Version]

- Pandiselvam, R.; Harikrishnan, M.P.; Khanashyam, A.C.; Basil, M.; Anirudh, M.; Manikantan, M.R.; Kothakota, A. Development and characterization of gelatinized starch doped microcellulose paper from tender coconut (Cocos nucifera L) husk. Process Saf. Environ. Prot. 2024, 184, 615–623. [Google Scholar] [CrossRef]

- Stepczyńska, M.; Rytlewski, P.; Moraczewski, K.; Pawłowska, A.; Karasiewicz, T. Novel Biocomposite of Starch and Flax Fiber Modified with Tannic Acid with Biocidal Properties. Polymers 2024, 16, 1108. [Google Scholar] [CrossRef]

- Nastaj, M.; Sołowiej, B.G.; Stasiak, D.M.; Mleko, S.; Terpiłowski, K.; Łyszczek, R.J.; Tomasevic, I.B.; Tomczyńska-Mleko, M. Development and physicochemical properties of reformulated, high-protein, untempered sugar-free dark chocolates with addition of whey protein isolate and erythritol. Int. Dairy J. 2022, 134, 105450. [Google Scholar] [CrossRef]

- Averous, L.; Moro, L.; Dole, P.; Fringant, C. Properties of thermoplastic blends: Starch-polycaprolactone. Polymer 2000, 41, 4157–4167. [Google Scholar] [CrossRef]

- Batista, N.N.; de Andrade, D.P.; Ramos, C.L.; Dias, D.R.; Schwan, R.F. Antioxidant capacity of cocoa beans and chocolate assessed by FTIR. Food Res. Int. 2016, 90, 313–319. [Google Scholar] [CrossRef]

- Cerit, İ.; Demirkol, O.; Avcı, A.; Arkan, B.S. Phenolic content and oxidative stability of chocolates produced with roasted and unroasted cocoa beans. Food Sci. Technol. Int. 2024, 30, 450–461. [Google Scholar] [CrossRef]

- Che Man, Y.B.; Syahariza, Z.A.; Mirghani, M.E.S.; Jinap, S.; Bakar, J. Analysis of potential lard adulteration in chocolate and chocolate products using Fourier transform infrared spectroscopy. Food Chem. 2005, 90, 815–819. [Google Scholar] [CrossRef]

- Deus, V.L.; Resende, L.M.; Bispo, E.S.; Franca, A.S.; Gloria, M.B.A. FTIR and PLS-regression in the evaluation of bioactive amines, total phenolic compounds and antioxidant potential of dark chocolates. Food Chem. 2021, 357, 129754. [Google Scholar] [CrossRef]

- Quispe-Chambilla, L.; Pumacahua-Ramos, A.; Choque-Quispe, D.; Curro-Pérez, F.; Carrión-Sánchez, H.M.; Peralta-Guevara, D.E.; Masco-Arriola, M.L.; Palomino-Rincón, H.; Ligarda-Samanez, C.A. Rheological and Functional Properties of Dark Chocolate with Partial Substitution of Peanuts and Sacha Inchi. Foods 2022, 11, 1142. [Google Scholar] [CrossRef]

- Gáspár, M.; Benko, Z.; Dogossy, G.; Réczey, K.; Czigány, T. Reducing water absorption in compostable starch-based plastics. Polym. Degrad. Stab. 2005, 90, 563–569. [Google Scholar] [CrossRef]

- Bodirlau, R.; Teaca, C.A.; Spiridon, I. Influence of natural fillers on the properties of starch-based biocomposite films. Compos. Part B Eng. 2013, 44, 575–583. [Google Scholar] [CrossRef]

- Villanueva, E.; Glorio-Paulet, P.; Giusti, M.M.; Sigurdson, G.T.; Yao, S.; Rodríguez-Saona, L.E. Screening for pesticide residues in cocoa (Theobroma cacao L.) by portable infrared spectroscopy. Talanta 2023, 257, 124386. [Google Scholar] [CrossRef]

- Arofai, T.; Gunawan, S.; Purwanto, M. Separation and Purification Residual Salt from Glycerine Pitch from Waste of Refined Glycerine Production. BIO Web Conf. 2024, 98, 06008. [Google Scholar] [CrossRef]

- Gutiérrez, T.J.; Suniaga, J.; Monsalve, A.; García, N.L. Influence of beet flour on the relationship surface-properties of edible and intelligent films made from native and modified plantain flour. Food Hydrocoll. 2016, 54, 234–244. [Google Scholar] [CrossRef]

- Mendes, J.F.; Norcino, L.B.; Martins, H.H.; Manrich, A.; Otoni, C.G.; Carvalho, E.E.N.; Piccolli, R.H.; Oliveira, J.E.; Pinheiro, A.C.M.; Mattoso, L.H.C. Development of quaternary nanocomposites made up of cassava starch, cocoa butter, lemongrass essential oil nanoemulsion, and brewery spent grain fibers. J. Food Sci. 2021, 86, 1979–1996. [Google Scholar] [CrossRef]

- Do, T.A.L.; Vieira, J.; Hargreaves, J.M.; Mitchell, J.R.; Wolf, B. Structural characteristics of cocoa particles and their effect on the viscosity of reduced fat chocolate. LWT 2011, 44, 1207–1211. [Google Scholar] [CrossRef]

- James, B.J.; Smith, B.G. Surface structure and composition of fresh and bloomed chocolate analysed using X-ray photoelectron spectroscopy, cryo-scanning electron microscopy and environmental scanning electron microscopy. LWT 2009, 42, 929–937. [Google Scholar] [CrossRef]

- Jin, J.; Jin, Q.; Wang, X.; Akoh, C.C. Improving heat and fat bloom stabilities of “dark chocolates” by addition of mango kernel fat-based chocolate fats. J. Food Eng. 2019, 246, 33–41. [Google Scholar] [CrossRef]

- Kinta, Y.; Hatta, T. Composition, structure, and color of fat bloom due to the partial liquefaction of fat in dark chocolate. J. Am. Oil Chem. Soc. 2007, 84, 107–115. [Google Scholar] [CrossRef]

- Wang, F.; Liu, Y.; Shan, L.; Jin, Q.; Wang, X.; Li, L. Blooming in cocoa butter substitutes based compound chocolate: Investigations on composition, morphology and melting behavior. J. Am. Oil Chem. Soc. 2010, 87, 1137–1143. [Google Scholar] [CrossRef]

- Achilias, D.S.; Roupakias, C.; Megalokonomos, P.; Lappas, A.A.; Antonakou, V. Chemical recycling of plastic wastes made from polyethylene (LDPE and HDPE) and polypropylene (PP). J. Hazard. Mater. 2007, 149, 536–542. [Google Scholar] [CrossRef]

- Wongpajan, R.; Mathurosemontri, S.; Takematsu, R.; Xu, H.Y.; Uawongsuwan, P.; Thumsorn, S.; Hamada, H. Interfacial Shear Strength of Glass Fiber Reinforced Polymer Composites by the Modified Rule of Mixture and Kelly-Tyson Model. Energy Procedia 2016, 89, 328–334. [Google Scholar] [CrossRef]

- Adeniyi, A.G.; Ighalo, J.O.; Onifade, D.V. Banana and plantain fiber-reinforced polymer composites. J. Polym. Eng. 2019, 39, 597–611. [Google Scholar] [CrossRef]

- Yee-Chang, S.; Ismail, H.; Ahsan, Q. MAH on kenaf-filled composites. BioResources 2012, 7. [Google Scholar]

- Venegas, R.; Torres, A.; Rueda, A.M.; Morales, M.A.; Arias, M.J.; Porras, A. Development and Characterization of Plantain (Musa paradisiaca) Flour-Based Biopolymer Films Reinforced with Plantain Fibers. Polymers 2022, 14, 748. [Google Scholar] [CrossRef] [PubMed]

- Cheng, W. Preparation and properties of lignocellulosic fiber/CaCO3/thermoplastic starch composites. Carbohydr. Polym. 2019, 211, 204–208. [Google Scholar] [CrossRef]

- Müssig, J. Industrial Applications of Natural Fibres: Structure, Properties and Technical Applications; John Wiley & Sons: Hoboken, NJ, USA, 2010; ISBN 9780470660324. [Google Scholar]

- Sepe, M. Dynamic Mechanical Analysis for Plastic Engineering; Plastic Design Library; PDL Handbook Series; Elsevier Science: Amsterdam, The Netherlands, 1998. [Google Scholar]

- Bashir, M.A. Use of Dynamic Mechanical Analysis (DMA) for Characterizing Interfacial Interactions in Filled Polymers. Solids 2021, 2, 108–120. [Google Scholar] [CrossRef]

- Bhardwaj, R.; Mohanty, A.K.; Drzal, L.T.; Pourboghrat, F.; Misra, M. Renewable resource-based green composites from recycled cellulose fiber and poly(3-hydroxybutyrate-co-3-hydroxyvalerate) bioplastic. Biomacromolecules 2006, 7, 2044–2051. [Google Scholar] [CrossRef]

- Biswal, M.; Mohanty, S.; Nayak, S.K. Mechanical, thermal and dynamic-mechanical behavior of banana fiber reinforced polypropylene nanocomposites. Polym. Compos. 2011, 32, 1190–1201. [Google Scholar] [CrossRef]

- Babaee, M.; Jonoobi, M.; Hamzeh, Y.; Ashori, A. Biodegradability and mechanical properties of reinforced starch nanocomposites using cellulose nanofibers. Carbohydr. Polym. 2015, 132, 1–8. [Google Scholar] [CrossRef]

- De Freitas, R.R.M.; Do Carmo, K.P.; De Souza Rodrigues, J.; De Lima, V.H.; Osmari da Silva, J.; Botaro, V.R. Influence of alkaline treatment on sisal fibre applied as reinforcement agent in composites of corn starch and cellulose acetate matrices. Plast. Rubber Compos. 2021, 50, 9–17. [Google Scholar] [CrossRef]

- Ghanbari, A.; Tabarsa, T.; Ashori, A.; Shakeri, A.; Mashkour, M. Preparation and characterization of thermoplastic starch and cellulose nanofibers as green nanocomposites: Extrusion processing. Int. J. Biol. Macromol. 2018, 112, 442–447. [Google Scholar] [CrossRef]

- Shanks, R.A.; Hodzic, A.; Wong, S. Thermoplastic biopolyester natural fiber composites. J. Appl. Polym. Sci. 2003, 91, 2114–2121. [Google Scholar] [CrossRef]

- Nomadolo, N.; Mtibe, A.; Ofosu, O.; Mekoa, C.; Letwaba, J.; Muniyasamy, S. The Effect of Mechanical Recycling on the Thermal, Mechanical, and Chemical Properties of Poly (Butylene Adipate-Co-Terephthalate) (PBAT), Poly (Butylene Succinate) (PBS), Poly (Lactic Acid) (PLA), PBAT-PBS Blend and PBAT-TPS Biocomposite. J. Polym. Environ. 2024, 32, 2644–2659. [Google Scholar] [CrossRef]

- Lila, M.K.; Shukla, K.; Komal, U.K.; Singh, I. Accelerated thermal ageing behaviour of bagasse fibers reinforced Poly (Lactic Acid) based biocomposites. Compos. Part B Eng. 2019, 156, 121–127. [Google Scholar] [CrossRef]

- Ramamoorthy, S.K.; Åkesson, D.; Rajan, R.; Periyasamy, A.P.; Skrifvars, M. Mechanical performance of biofibers and their corresponding composites. Mech. Phys. Test. Biocomposites Fibre-Reinf. Compos. Hybrid. Compos. 2019, 259–292. [Google Scholar]

- Castañeda-Niño, J.P.; Mina-Hernandez, J.H.; Valadez-Gonzalez, A. Potential uses of musaceae wastes: Case of application in the development of bio-based composites. Polymers 2021, 13, 1844. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).