Abstract

The printing and dyeing industries generate wastewater containing toxic, hard-to-degrade organic dyes like methylene blue (MB). Recent research focuses on biodegradable, renewable materials such as cellulose-based absorbents to address this issue. This study investigates bacterial cellulose (BC) functionalized with citric acid as a sustainable adsorbent for MB removal. BC, a by-product of kombucha fermentation, is functionalized with citric acid, and its adsorption capacity is analyzed. BC production reaches 3.65 ± 0.16 g L−1 by day 12. Using 0.05 g of functionalized BC (FBC) at pH 7, a maximum adsorption capacity of 13.22 ± 1.27 mg g−1 is achieved for MB at 600 mg L−1 over 60 min. The adsorption mechanism is complex, with both pseudo-first- and pseudo-second-order models fitting well at 20 °C, 40 °C, and 70 °C. The carboxyl groups of citric acid bind to the hydroxyl groups of cellulose fibers via esterification, altering the material’s charge, reactivity, thermal, and crystallinity properties. This functionalization enhances BC’s adsorption capacity, making it a promising material for bioremediation in circular systems.

1. Introduction

Industrial development and population growth have led to widespread environmental pollution, particularly through industrial wastewater. The printing and dyeing industries are significant sources of wastewater containing organic dyes with aromatic structures and azo groups, such as methylene blue (MB), which are highly soluble in water, toxic, and difficult to degrade [1]. Therefore, applying suitable treatment strategies to efficiently remove dyes from wastewater systems before discharge is crucial to avoid adverse effects on ecological balance and human health [2].

Traditional wastewater treatment methods often rely on synthetic adsorbents, which are effective but non-biodegradable, creating further environmental concerns [3]. On the other hand, biological treatments have the potential for removing dyes from textile wastewater; however, due to the inherent resistance of dye compounds to microbial activity, these processes are time-consuming and could result in by-products with higher toxicity [4]. In response to the urgent need for sustainable and efficient solutions, recent research has focused on biodegradable and renewable materials like cellulose-based absorbents [5,6].

Despite being an organic polymer material with film-forming capability, biodegradability, and biocompatibility, cellulose faces challenges such as insolubility in most organic solvents, hygroscopic nature, and difficulty in melting, which hinder its multifunctionality and more efficient application [7]. Conversely, biomass sourced from agricultural products presents environmental challenges and leads to significant economic costs for disposal and regeneration [8]. Bacterial cellulose (BC) offers significant advantages over plant-based cellulose due to its nanometric structure, high water retention capacity, large surface area, purity—which eliminates the need for expensive purification steps—and ease of chemical modification [9,10]. A common drawback of these native materials is their low adsorption capacity; however, chemical modifications have significantly improved their adsorption performance [11]. It has been demonstrated that the adsorption efficiency of BC depends on the activity and accessibility of hydroxyl groups in its structure, and functionalization introduces more active adsorption sites, resulting in a higher adsorption capacity [1,12,13].

In addition, the circular economy promotes the regeneration of components and the use of discarded materials to reduce accumulation and environmental concerns [14]. Accordingly, the biosynthesis of bacterial cellulose, produced as a by-product in kombucha fermentation, or using various residues from agroindustry, food, and forestry has demonstrated potential as an effective approach for making the production process economically sustainable [9].

In this context, shifts in consumer preferences toward healthier diets and active aging have increased the popularity of fermented beverages like kombucha, a carbonated beverage having a low calorie content that is projected to reach an estimated global market of US$5 billion by 2025 [15]. Kombucha is a fermented, acidic beverage with a history spanning thousands of years, traditionally used in East Asia as a remedy for various health problems, with over 200 distinct varieties now available worldwide [16,17]. SCOBY, a cellulose biofilm containing a symbiotic culture of bacteria and yeast, is a by-product of kombucha tea fermentation [14]. These microorganisms, comprising acetic acid bacteria, lactic acid bacteria, and osmophilic yeasts, produce bioactive compounds that confer therapeutic properties, such as antioxidant, antimicrobial, anti-inflammatory, antidiabetic, antihypertensive, cancer prevention, hepatoprotective, and detoxifying effects [15,18]. Unfortunately, coupled with the increasing demand for the fermented beverage due to its health benefits, a higher disposal of SCOBY as a by-product is generated.

Recently, SCOBY, traditionally used to initiate a new batch of kombucha fermentation, has garnered interest for its potential as a raw material in biomaterial preparation and environmental biotechnology [19]. Thus, using beverage industry waste such as SCOBY as a source of BC may offer a sustainable approach to producing an eco-friendly adsorbent. Furthermore, by increasing oxygenated functional groups, such as esters, on the surface of BC, mediated by organic acids, a higher electronegativity and nucleophilicity can enhance the adsorption capacity of cationic pollutants. Other studies utilize generic cellulose functionalized with citric acid [20], but insights into the esterification reaction, its link to material properties, and adsorption mechanism changes while addressing the sustainability aspect remain unexplored. This study aims to explore the potential of using bacterial cellulose functionalized with citric acid as a sustainable adsorbent for the reduction of methylene blue concentration in wastewater.

2. Materials and Methods

2.1. Chemicals

All reagents were of analytical grade and purchased from Merck KGaA (St. Louis, MO, USA) unless indicated otherwise.

2.2. Production and Functionalization of Bacterial Cellulose (BC)

The Hestrin and Schramm medium (HS medium) was composed of (g L−1) glucose 20, bactopeptone (Difco) 5, yeast extract 5, Na2HPO4 2.7, and citric acid 1.15 [21]. To inoculate the medium, 10% v v−1 of commercially purchased kombucha from a local market was added to 40 mL of HS medium (pH 5.0) and autoclaved at 121 °C for 15 min in 70 mL glass bottles. The culture was cultivated statically at 30 °C for 15 days. The synthesized cellulose was filtered through Whatman No. 4 filter paper, purified by boiling in 0.1 M NaOH for 30 min, and washed with distilled water until the product became transparent and the pH was 7.0. The BC was then dried (Memmert, Schwabach, Germany) at 70 °C for 18 h, crushed with a mortar, and stored in plastic sealed bags at 25 °C until use. The BC production was expressed as the dry weight per liter of medium (g L−1) every 24 h for 15 days.

The synthesized BC was functionalized according to Feng et al. [11]. Briefly, 20 g of BC was combined with 200 mL of 0.4 M citric acid and placed in an oven at 60 °C for 2 h. The solids were then subjected to centrifugation at 4000 rpm using a 5810R centrifuge (Eppendorf, Hamburg, Germany) before undergoing esterification at 120 °C for 3 h in the oven. The functionalized product was washed, dried, crushed, and stored until required for experiments.

2.3. Characterization of Bacterial Cellulose

Scanning electron microscopy (SEM) and atomic force microscopy (AFM) were used to investigate the surface morphology of both native and functionalized bacterial cellulose (BC). Before SEM analysis, the samples were sputter-coated with gold for 60 s at a current of 30 mA (Desk V, Denton Vacuum, Moorestown, NJ, USA) and viewed with a JXA-8530FPlus microscope (Jeol, Akishima, Tokyo, Japan) at 15 kV. AFM images, captured with a resolution of 256 × 256 pixels, were produced using a Multimode V atomic force microscope (Veeco, Plainview, NY, USA) in contact mode with silicon tips (Bruker RTESP Cantilever, Karlsruhe, Germany). The results were analyzed using XEI Version 5.2.0 software (Park Systems, Suwon, Republic of Korea).

The conformational characteristics of native and functionalized BC were analyzed. Functional groups were identified using Fourier transform infrared spectroscopy (FTIR), with spectra obtained from 16 scans on a Spectrum 100 infrared spectrometer (PerkinElmer, MA, USA) within the range of 600–4000 cm−1. Differential scanning calorimetry (DSC) was employed to analyze thermal properties using a DSC822e and STARe 15.01 software (Mettler-Toledo, OH, USA) from 10 °C to 350 °C at a heating rate of 10 °C min−1, with indium as the standard and nitrogen as the purge gas. X-ray diffraction (XRD) patterns were captured using a Rigaku-Ultima 4 diffractometer (Rigaku Miniflex, The Woodlands, TX, USA) under CuK radiation (λ = 1.5418 Å) at 45 kV and 40 mA, with a scanning range from 5° to 60° at 2θ. The MDI Jade 5.0 XRD software (Materials Data, Livermore, CA, USA) was utilized for processing the diffraction patterns. The crystallinity index (CrI, Equation (1)), crystalline size (CrS, Equation (2)), and Iβ/Iα index were derived from the X-ray diffraction measurements.

where Imax is the maximum intensity of the lattice diffraction at 2θ, and Iam is the intensity of the baseline for the amorphous part of cellulose at 2θ ≈ 18°.

where K is the shape factor (0.9), λ is the X-ray wavelength (1.54 Å), β is the full width at half maximum height, and θ is the Bragg’s angle.

2.4. Adsorption Experiments

The impact of mass of adsorbent (from 0.05 to 0.3 g L−1), time to reach equilibrium (from 0 to 60 min), and the starting concentration of methylene blue (from 150 to 600 mg L−1) were evaluated using 50 mg of functionalized adsorbent and an adsorbate concentration of 600 mg L−1 at pH 7.0, 25 °C, and a shaking speed of 150 rpm (Thermo shaker MSC-100, Thermo Fisher Scientific, Waltham, MA, USA), except when distinct parameters were indicated. Langmuir, Freundlich, and Sips isotherm models were utilized to fit the equilibrium data. The isolation factor (RL) was determined according to Majamo et al. [22]. The impact of pH (ranging from 2 to 10) on the adsorption process was assessed. Pseudo-first-order, pseudo-second-order, and Elovich models were utilized to study the adsorption kinetics at temperatures of 25 °C, 40 °C, and 70 °C. The concentration of methylene blue (MB) in the liquid phase was quantified with a UV–Vis spectrophotometer (Genesys 10S, Thermo Fisher Scientific) at 668 nm after the solid phase was removed from the sample by centrifugation at 3000 rpm for 10 min. A standard curve of MB concentration versus absorbance was determined using Beer–Lambert’s equation. The adsorption quantity of MB at any moment was derived using Equation (3) [5], as follows:

where Q (mg g−1) is the quantity of MB biosorbed per gram of biosorbent at any time, Ct (mg L−1) is the MB concentration in the liquid phase at any time, C0 (mg g−1) is the initial dye concentration, m is the biosorbent amount (g), and V is the volume of solution (L).

2.5. Statistical Analysis

Each experiment was executed in triplicate, and the results represent the mean ± standard deviation. One-way analysis of variance (ANOVA) and Tukey’s test were used to determine significant differences (p < 0.05) among mean values with Minitab 16.2.4 (State College, PA, USA). The experimental data were analyzed through regression analysis using statistical software to assess the fit of the data with the adjusted R2 (adj R2) or coefficient of determination (r2).

3. Results

3.1. Production and Functionalization of Bacterial Cellulose (BC)

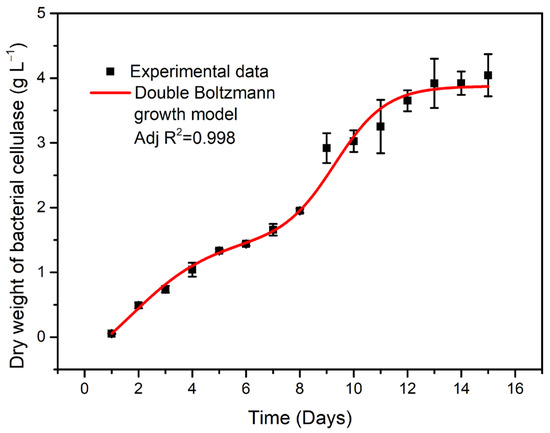

The BC formed during kombucha fermentation is commonly known as SCOBY (symbiotic culture of bacteria and yeast), or “kombucha mushroom”, despite the absence of any actual mushroom in the culture [23]. The production of bacterial cellulose was successfully modeled using the sigmoidal-Boltzmann mathematical approach over 15 days, with an adjusted R2 value of 0.998, as shown in Figure 1. During the first five days, an exponential growth pattern was observed, followed by a slowdown in growth over the next two days. This was followed by another exponential growth phase lasting five days, after which growth slowed again during the final three days. On day 12, BC production reached 3.65 ± 0.16 g L−1, which is consistent with reported fermentation periods ranging from 7 to 15 days. However, the production range varies widely, from 1.5 to 236 g L−1, due to several factors, such as pH, temperature, substrate concentration, and fermentation duration, all of which influence microbial growth rate and cellulose yield [19,23,24,25,26]. Sigmoidal semilogarithmic functions, shaped by Boltzmann equations, are increasingly popular for describing diverse biological processes, such as SCOBY biomass formation [27]. These functions combine the properties of a sigmoid curve with logarithmic transformation, effectively capturing processes that demonstrate rapid initial growth, followed by slowing and eventual stabilization [28,29]. The high-adjusted R2 value suggests that the model accurately represents the underlying patterns and dynamics of BC production over the 15-day period.

Figure 1.

Bacterial cellulose production over 15 days in Hestrin and Schramm (HS) medium, pH 5.0 at 30 °C. Data are shown as mean ± standard deviation (n = 3).

The Hestrin and Schramm (HS) medium is widely recognized for its ability to support optimal BC production, providing favorable conditions for fermentation [23]. SCOBY comprises a complex microbial consortium that includes acetic acid bacteria (Acetobacter, Gluconacetobacter, and Komagataeibacter) and yeast (Saccharomyces and Zygosaccharomyces) that regulate the fermentation process by utilizing sucrose as the carbon source [18,30]. The BC production follows distinct growth phases. The initial rapid growth phase is likely due to the faster division rate of bacteria compared to yeast. The subsequent transition phase could be attributed to the depletion of essential nutrients, the accumulation of inhibitory by-products, or changes in environmental conditions that slow down microbial growth [19,27,31]. The second growth phase might be associated with an adaptive response, where microorganisms utilize different substrates or metabolic pathways to continue growth until nutrient depletion or waste accumulation induces stress [19,23,32]. The purification of BC is commonly achieved using NaOH, which hydrolyzes proteins and cell debris, solubilizes amphiphilic substances, and reduces bacterial load [23]. Citric acid has been used to functionalize cellulosic materials, offering an efficient, economical, and environmentally friendly method that enhances adsorption capacity [6,11]. Kombucha SCOBY and chemical-modified cellulosic materials have been successfully applied in biosorption processes for removing contaminants from aqueous solutions and wastewater [6,19]. However, scaling up BC production in specialized bioreactors and shortening the process of improving fermentation conditions while maintaining cost-efficiency is critical to meeting the growing demand across various industries [23]. Since kombucha production is already underway for beverage purposes, the generation of BC from the residual SCOBY adds additional economic value to the process without significantly affecting production time. This study aligns with sustainability goals, and the potential applications of BC in biosorption make it a valuable and worthwhile process despite the production time.

3.2. Characteristics of Adsorbent

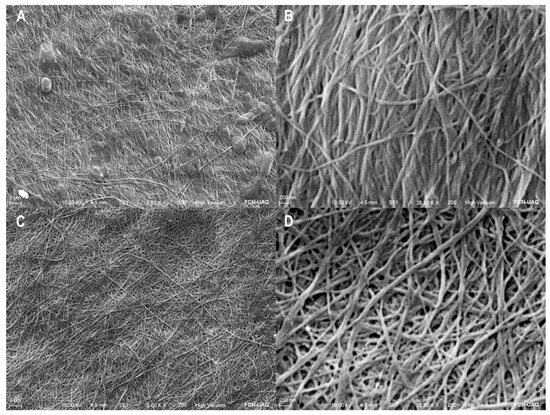

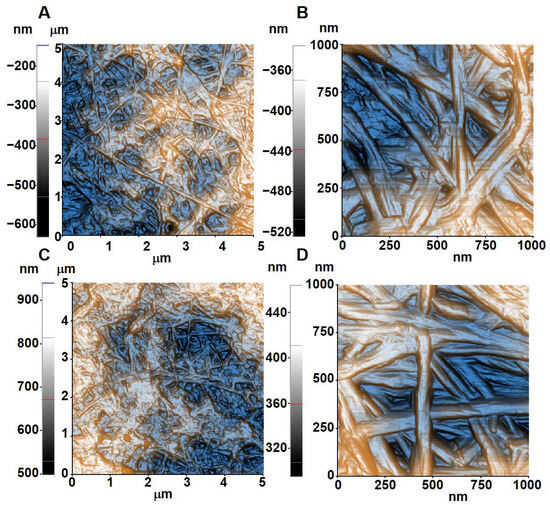

The native and functionalized BC samples’ surface morphologies were characterized using SEM (Figure 2) and AFM (Figure 3). Both samples exhibit a rough surface with a fibril-like structure, but the native BC shows a dense and compact matrix (Figure 2A,B and Figure 3A,B), in contrast to the looser, three-dimensional, and porous nature of functionalized BC (Figure 2C,D and Figure 3C,D). From the AFM micrographs, the mean radius of fibrils accounted for 81.03 ± 13.51 nm for both samples. The morphology and fiber dimensions of the cellulose agree with previous observations [10,13]. The quadratic mean roughness (Rq) increased from 42.75 nm to 50.71 nm after BC was functionalized, while the surface height distribution (Kurtosis, Rku) decreased from 3.35 to 2.70. After the adsorption process using the FBC, the Rq and Rku further increased to 60.89 nm and 3.1, respectively. The higher roughness observed in SEM and calculated from AFM could be attributed to the removal of residual extracellular polymeric substances that agglutinated the fibrils of native BC, along with cells eliminated by the citric acid functionalization process, which included two heating stages (2 h at 60 °C and 3 h at 120 °C) followed by NaHCO3 and deionized water washes. This led to a looser, three-dimensional, and porous microstructure in FBC, offering a greater surface area for molecule adsorption compared to native BC. Moreover, the presence of molecules attached to the surface of FBC fibrils resulted in sharper peaks and deeper valleys (Rku > 3, leptokurtic distribution) in surface height, which is likely related to a monolayer adsorption model.

Figure 2.

SEM images of the native (A,B) and functionalized (C,D) BC samples at magnifications of 5000× (A,C) and 25,000× (B,D).

Figure 3.

Three-dimensional-rendered images from AFM analysis of the native (A,B) and functionalized BC (C,D) samples at sizes of 5 × 5 µm (A,C) and 1 × 1 µm (B,D).

Despite BC sharing a chemical structure similar to plant cellulose, comprising β-1,4-glycosidic linked glucose units, BC fibers exhibit exceptional purity and form a dense, interconnected network [23]. Synthesized BC consists of two types of microfibrils: a highly ordered structure known as cellulose I and a less ordered structure known as cellulose II [6]. Citric acid, a small molecule, can chemically bind to the surface of cellulose fibers through esterification between the carboxyl groups of citric acid and the hydroxyl groups of cellulose, modifying the charge or reactivity of the fibers [11] seemingly without altering their superficial morphology.

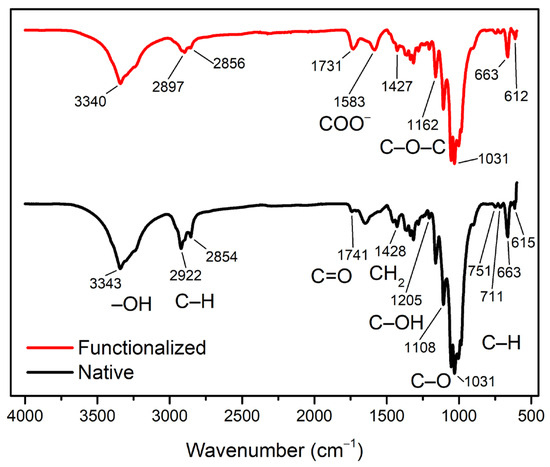

By comparing the FTIR spectra across the 4000 cm−1 to 600 cm−1 range for both native and citric acid-functionalized BC, chemical changes resulting from the treatment can be identified (Figure 4). Most of the prominent peaks in the FTIR spectra did not change or shift significantly, corresponding to the structure of cellulose. The signal at 3343 cm−1 corresponds to –OH groups, while the region around 2922 cm−1 and 2854 cm−1 is associated with C–H stretching vibrations [11,33]. The peak at 1741–1731 cm−1 is attributed to the stretching vibration of C=O from the carboxyl group in BC [13,33]. The presence of an absorption band at 1731 cm−1 in FBC, which is absent in microcrystalline cellulose [20], can be explained by the formation of ester bonds or the presence of carboxylic acid groups, both commonly observed in esterification reactions [34]. The weak band in 1741 cm−1 in BC may be attributed to intermolecular interactions or the presence of absorbed impurities, such as lipids, proteins, or residual acids derived from bacterial metabolism, associated with the cellulose matrix [23]. Bands around 1428 cm−1 correspond to CH2 scissoring and OH bending vibrations [1]. Peaks at 1108 cm−1 and 1031 cm−1 are linked to the C–O–C and C–O stretching vibrations within the pyranose ring skeleton of cellulose molecules [2]. The signals at 663 cm−1 and 615 cm−1 are attributed to the out-of-plane bending vibrations of O–H groups, indicating hydrogen bonding in the cellulose I form and skeletal vibrations involving C–H and C–O–C bonds, respectively [33,35].

Figure 4.

FTIR spectra of the native and functionalized BC samples.

Treating BC with citric acid introduces new functional groups, such as carboxyl groups and esters, into the cellulose structure. The signal at 1583 cm−1 and 1234 cm−1 corresponds to the asymmetric stretching of carboxylate groups (COO−) and C−O stretching vibrations in esters, indicating the presence of carboxyl groups and ester bonds formed between citric acid and the hydroxyl groups of cellulose [34,36]. The disappearance of signals at 751 cm−1 and 711 cm−1 may result from structural changes in cellulose Iα and Iβ due to citric acid functionalization, which alters the original vibrational characteristics of cellulose [22,26,33,34,35]. BC structures exhibit crystalline regions (Iα) with highly ordered, parallel cellulose strands and amorphous regions (Iβ) composed of randomly oriented fibers [23,33]. The changes observed in the FTIR spectrum confirm that BC was successfully functionalized with citric acid, resulting in the introduction of carboxyl groups and the formation of ester bonds, likely cross-linking cellulose molecules. This is reflected in the appearance of new signals and the disappearance of others corresponding to the native structure of cellulose. Additionally, BC primarily consists of cellulose I, characterized by a crystalline, parallel chain arrangement, as evidenced by the FTIR bands at 663 cm−1 and 615 cm−1 that are associated with their hydrogen bonding network and skeletal vibrations. The disappearance of bands at 751 cm−1 and 711 cm−1 after citric acid functionalization indicates structural disruption, suggesting partial conversion of cellulose I to cellulose II or the creation of amorphous regions. Furthermore, the transition from cellulose I to cellulose II or the formation of amorphous regions during functionalization can also be evidenced by changes in the 1100 cm−1 to 900 cm−1 region, where peaks related to C–O–C stretching in the pyranose ring can shift, indicating changes in the crystallinity or disorder of the cellulose structure. These changes in the FTIR spectra are consistent with findings from several studies that demonstrate the influence of chemical treatments, such as esterification, on the crystallinity and amorphousness of cellulose [22,26,33,34,35]. This chemical modification of BC with citric acid, an environmentally friendly, abundant, and easily produced substance, enhances the cellulose’s oxygen-containing functional groups, increasing its electronegativity and nucleophilicity. This modification potentially improves its adsorption capacity for cationic pollutants, such as MB [2,11].

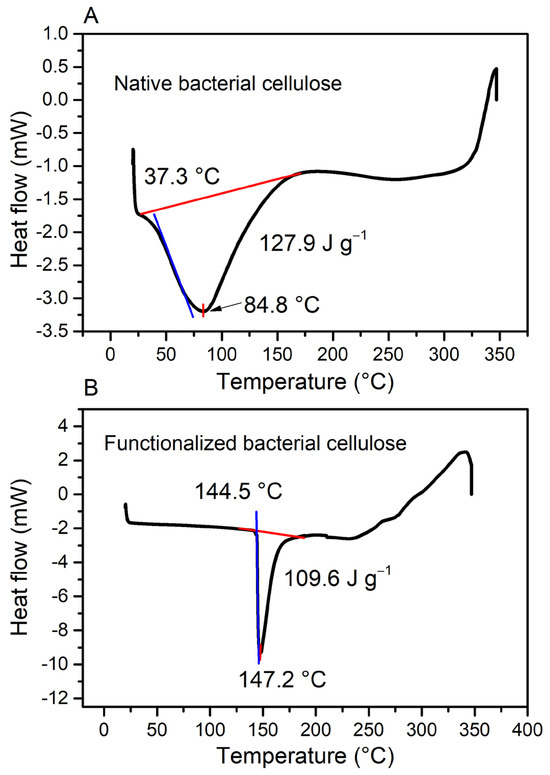

The DSC analysis of native and functionalized BC is presented in Figure 5A,B. A single prominent depressed peak was observed in both samples. In native BC, the glass transition phase occurred at 37.3 °C, along with a broad endothermic peak at 84.4 °C, with a heat capacity of 127.9 J g−1. In contrast, functionalized BC exhibited a glass transition observed at 144.5 °C, along with a narrower endothermic peak at 147.2 °C, with a heat capacity of 109.6 J g−1. Above 200 °C, additional thermal events related to degradation were observed for both samples. Thermal properties, such as degradation temperature and glass transition temperature, change when cellulose is exposed to temperature variation during production or processing, providing insights into its purity and composition [23], as observed before functionalization with citric acid. In amorphous or partially crystalline materials like BC, the glass transition manifests as a shift in the curve’s slope, suggesting alterations in the mobility of polymer chains. In native BC, the hydrogen bond interactions between cellulose chains create an organized, crystalline structure [37], explaining the broad endothermic peak with a slope change at a lower temperature than in functionalized BC. The endothermic peak signifies heat absorption during the partial disorganization of the crystalline structure, associated with water loss and the melting of amorphous cellulose regions [1,37]. The observed thermal behavior aligns with the structural changes in BC caused by citric acid functionalization, as confirmed by the FTIR analysis. This process increases the material’s thermal stability due to cross-linking between cellulose chains. In functionalized cellulose, citric acid disrupts the hydrogen bond network, reducing the mobility of cellulose chains by increasing the degree of cross-linking and creating a more rigid structure [11,37]. This leads to a narrower endothermic peak at higher temperatures than in the native sample. At temperatures above 200 °C, both samples degrade into COx and H2O due to combustion [1,2,38].

Figure 5.

DSC analysis of the native (A) and functionalized (B) BC samples.

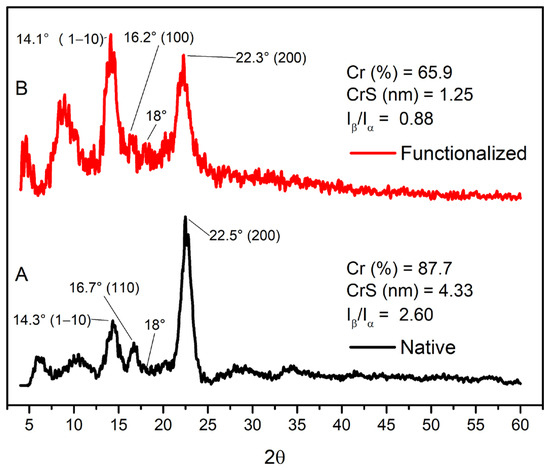

Figure 6 illustrates the X-ray diffractograms for native and functionalized BC. The XRD patterns of BC exhibit characteristic peaks at 2θ = 22.5°, 14.3°, and 16.7°, corresponding to the (200), (1–10), and (110) crystallographic planes and interplanar distances of the cellulose Iα and Iβ phases [26,38,39,40], which shifted slightly after functionalization with citric acid. The calculated crystallinity index (CrI), crystallite size (CrS), and Iβ/Iα index for native BC were 1.3-, 3.5-, and 3-fold larger than those for functionalized BC, respectively. These properties are consistent with previously reported values for BC [19,25,40].

Figure 6.

X-ray diffraction patterns of the native and functionalized BC samples.

As suggested by the FTIR and DSC analyses, the reduction in the hydrogen bonding caused by the cross-linking through ester bonds formed by citric acid could explain the decline in BC crystallinity [22,23]. Cellulose I can transform into the more thermodynamically stable cellulose II during thermal and chemical processes, rearranging the carbohydrate chains from parallel to anti-parallel configurations, which reduces crystallinity [6]. BC contains a single unit cell formed by two cellobiose units (dimers of two anhydrous D-glucose linked by b-1-4 bonds) arranged parallel to one another in a planar orientation when dried [19]. Esterification with citric acid likely disrupts this unit cell arrangement, leading to smaller crystallite sizes. Cellulose I in BC has a crystalline structure with two allomorphs, Iα and Iβ, which are structurally similar but differ in crystallite arrangement. Iα shows a triclinic arrangement, while Iβ displays a monolithic arrangement [6,19,26]. The differences in crystallinity index and crystallite size before and after functionalization may also be linked to a reduction in the ratio of Iβ to Iα crystallite arrangements. FTIR, DSC, and XRD analyses were used to confirm the successful modification of bacterial cellulose and its impact on structural and thermal properties. This work, therefore, provides a comprehensive analysis of the esterification reaction mechanism between citric acid and the hydroxyl groups of bacterial cellulose, further linking these reactions to significant changes in the material’s charge, reactivity, crystallinity, and thermal stability. However, future studies could include other important parameters for assessing functionalization, such as the degree of substitution for the glucose unit, surface area, pore size, adsorption type isotherm, and the reusability/recovery of the adsorbent, to complete the characterization of the biomaterial.

3.3. Adsorption Process

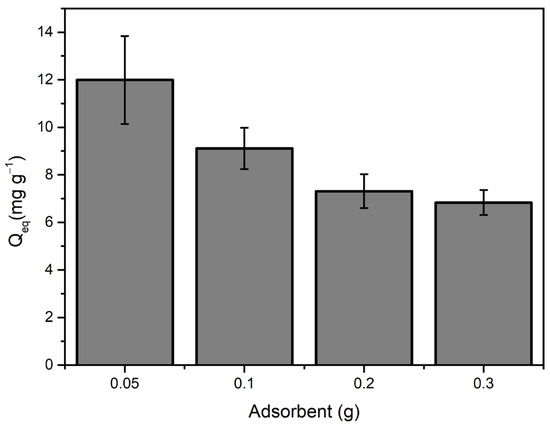

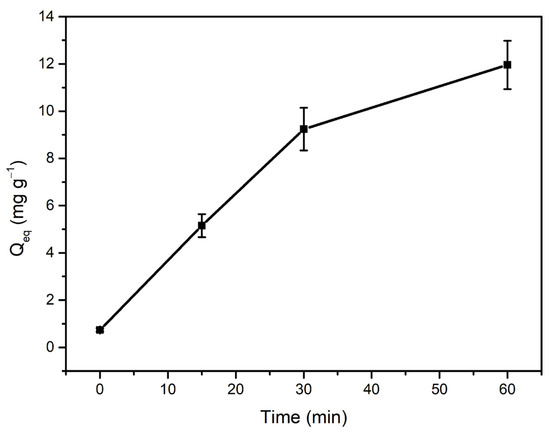

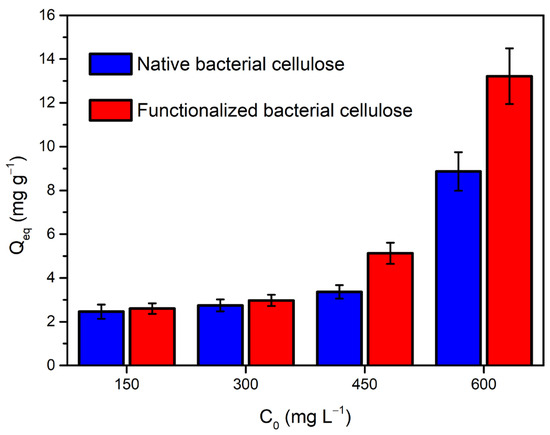

Removing dyes from wastewater is commonly achieved through the adsorption process, and developing sustainable adsorbents with high dye adsorption capacity is crucial. In this study, functionalized bacterial cellulose (FBC) was employed for the removal of MB from aqueous solutions as an adsorbent. Figure 7, Figure 8 and Figure 9 demonstrate the influence of adsorbent dosage, equilibrium time, and the initial MB concentration on the adsorption capacity of BC. The highest observed MB adsorption capacity was 11.99 ± 1.85 mg g−1 using 0.05 g of FBC (Figure 7). However, increasing the adsorbent mass by 2-, 4-, and 6-fold reduced the adsorption capacity by 76%, 61%, and 57%, respectively. This decrease in adsorption with increasing adsorbent dosage is likely due to a reduction in the ratio of available surface adsorption sites relative to the dye molecules [36], as well as overlapping adsorbent particles, which increases the diffusion path length [41]. The behavior of the adsorption capacity of FBC over 60 min is shown in Figure 8. A gradual increase in adsorption capacity during this period, with a 1.8-fold increase from the 15 min to 30 min contact period. However, the increase from 30 min to 60 min was only 1.3-fold, suggesting that a stationary phase or equilibrium was reached. Extended contact time enhances the likelihood of dye molecules binding to available adsorption sites on the adsorbent, and the time required to achieve equilibrium depends on the maximum adsorption capacity [34].

Figure 7.

Impacts of adsorbent dosage from 0.05 to 0.3 g L−1 on adsorption capacity using 50 mg of functionalized adsorbent and an initial adsorbate concentration of 600 mg L−1 at pH 7.0, 25 °C, and 150 rpm. Data are shown as mean ± standard deviation (n = 3).

Figure 8.

Time to reach equilibrium from 0 to 60 min on adsorption capacity using 50 mg of functionalized adsorbent and an initial adsorbate concentration of 600 mg L−1 at pH 7.0, 25 °C, and 150 rpm. Data are shown as mean ± standard deviation (n = 3).

Figure 9.

Initial concentration of methylene blue from 150 to 600 mg L−1 on adsorption capacity using 50 mg of functionalized adsorbent and an initial adsorbate concentration of 600 mg L−1 at pH 7.0, 25 °C, and 150 rpm. Data are shown as mean ± standard deviation (n = 3).

The impact of the starting MB concentration (150, 300, 450, and 600 mg L−1) on the adsorption capacity of both native BC and FBC was also investigated using 0.05 g of adsorbent and 60 min of contact time (Figure 9). The adsorption process was significantly affected (p < 0.05) by the initial dye concentration and the adsorbent’s functionalization. The highest achieved adsorption capacity was 13.22 ± 1.27 mg g−1 at 600 mg L−1 with FBC, which is 1.5 times higher than with native BC. In contrast, lower adsorption capacities were observed with decreasing initial dye concentrations for FBC, with reductions of 20%, 22%, and 39% for 150, 300, and 450 mg L−1, respectively. A similar trend was recorded for native BC, with reductions of 28%, 31%, and 38%, respectively. At lower adsorbate concentrations, such as 150 mg L−1 and 300 mg L−1, the hydroxyl groups present in both native and functionalized bacterial cellulose can participate in hydrogen bonding and physical adsorption, which are sufficient to accommodate the adsorbate. Thus, the functionalization with citric acid may not significantly improve the sorption performance because the adsorption sites on BC are not fully utilized at these concentrations. The sorption capacity difference becomes more evident at higher concentrations, such as 450 mg L−1 and 600 mg L−1, where FBC provides more available or reactive sites due to the introduction of carboxyl groups. The increase in adsorption capacity with higher initial MB concentrations is likely due to a greater concentration gradient, leading to more frequent molecular collisions and more molecules interacting with active adsorption sites [1,38]. Similar adsorption capacities in the range of 28−49 mg g−1 have been reported being used for minimally processed bacterial cellulose materials, such as bacterial cellulose-based aerogels for cationic dyes [38] and kombucha SCOBY for heavy metals [19]. On the other hand, bacterial cellulose composites involving complex modification processes have demonstrated higher adsorption capacities. For example, a three-dimensional porous bacterial cellulose/graphene oxide composite hydrogel showed an adsorption capacity of 224.5 mg g−1 for Pb(II) [13], activated carbon derived from bacterial cellulose produced through phosphoric acid activation at a carbonization temperature of 500 °C achieved an adsorption capacity of 505.8 mg g−1 [39], and bacterial cellulose/attapulgite magnetic composites exhibited an adsorption capacity of 243.2 mg g−1 for Congo red [42]. Thus, there is an opportunity to balance the adsorption performance of materials with the extent and complexity of the preparation procedure. In this study, the use of a simple functionalization process offers significant environmental benefits by reducing waste and creating a value-added product.

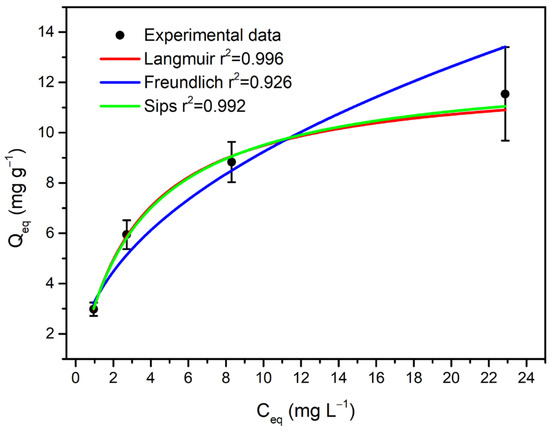

To describe the mechanisms of interaction between the adsorbate and the adsorbent, the adsorption data were analyzed using the Langmuir, Freundlich, and Sips isotherm models (Figure 10). The results indicated that the experimental data fitted the Langmuir and Sips models better than the Freundlich model, as shown by the correlation coefficient (r2 > 0.99). The Langmuir model is typically effective for predicting adsorption at low adsorbate concentrations [39]. The Sips or Langmuir–Freundlich model combines elements of both Langmuir and Freundlich models, overcoming the limitations of the Freundlich model; at low adsorbate concentrations, the Sips model behaves like the Freundlich isotherm, while at higher concentrations, it resembles the Langmuir model [5].

Figure 10.

Equilibrium adsorption data of MB on functionalized BC analyzed by the Langmuir (red), Freundlich (blue), and Sips (green) isotherms. Data represent the mean ± standard deviation (n = 3).

The maximum adsorption capacities (Qo) of 12.33 ± 0.48 mg g−1 and 12.76 ± 1.67 mg g−1, as determined from the Langmuir and Sips equations, respectively, align with the experimental value of 13.22 ± 1.27 mg g−1. The dimensionless constant isolation factor of the Langmuir isotherm indicates that the adsorption system was favorable [36], with a distribution coefficient below unity. This suggests that a citric acid-functionalized cellulose surface consists of homogenous adsorption sites where MB molecules are adsorbed onto localized sites, forming a monomolecular layer, with no interaction between the adsorbate molecules, which is consistent with both the Langmuir [41,43] and Sips models [5]. At low MB concentrations, the system behaves more like the Freundlich model, while at higher concentrations, saturation behavior is characteristic of the Langmuir or Sips models. The fit with the Sips model also suggests that the surface may present different types of adsorption sites with varying affinities for MB, which aligns with the random functionalization of the cellulose. This is also related to the looser three-dimensional and porous microstructure observed in AFM analysis.

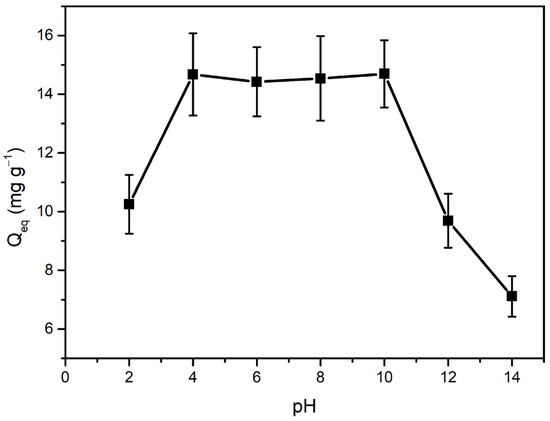

The effect of pH on the adsorption of MB dye using FBC is shown in Figure 11. A wide bell-shaped curve was observed for the pH range of 2 to 14, with the maximum adsorption capacity of approximately 14.6 mg g−1 occurring between pH 4 and 10. Adsorption capacity decreased by 30% to 52% at pH levels of 2, 12, and 14. The pH level influences the ionization of functional groups on both the adsorbent surface and the MB dye molecules [34]. As the surface charge density of the adsorbent becomes more negatively charged and the surface charge density of the dye molecules more positively charged, electrostatic attraction is strengthened, enhancing the adsorption process [37].

Figure 11.

Influence of pH on MB dye adsorption using 50 mg of FBC and an adsorbate concentration of 600 mg L−1 at 25 °C for 60 min of contact time and a shaking speed of 150 rpm. Data are expressed as mean ± standard deviation (n = 3).

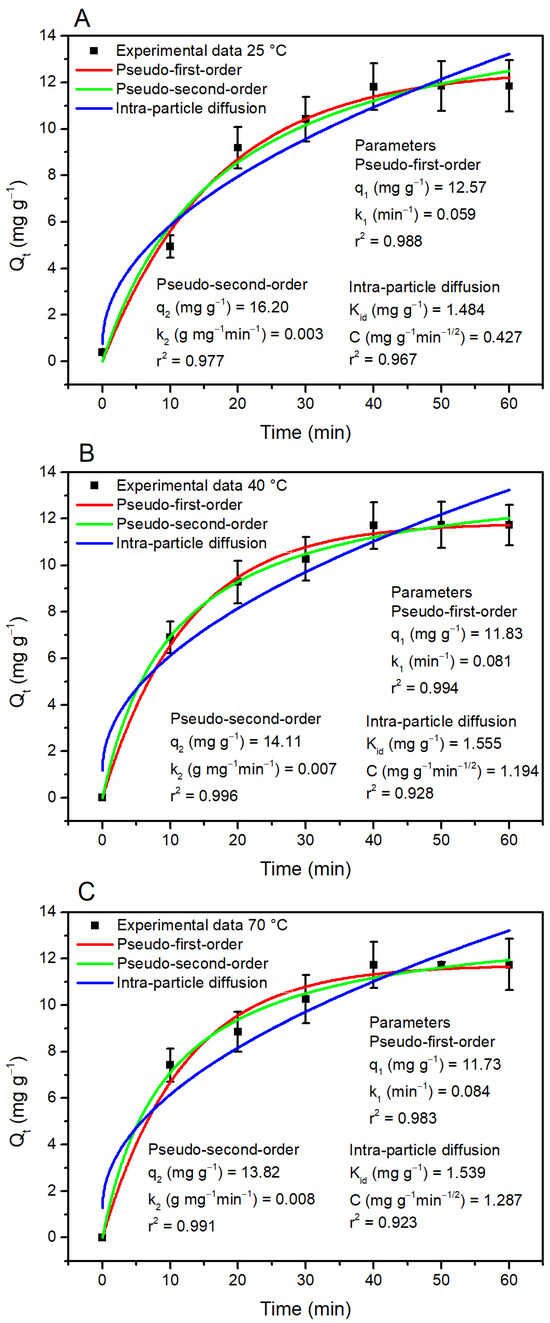

The dynamics of MB sorption (600 mg L−1, pH 7) were examined using the pseudo-first-order, pseudo-second-order, and intra-particle diffusion non-linear kinetic models as a function of contact time, with 50 mg of FBC at 25 °C, 40 °C, and 70 °C (Figure 12). MB adsorption kinetics demonstrate a rapid onset that lasts roughly 10 min, after which the adsorption rate decreases and gradually approaches equilibrium at 60 min. The first stage likely corresponds to the movement of MB molecules from the liquid phase to the exposed surface of the FBC. The second stage involves slower diffusion of dye molecules, and the final stage represents equilibrium attainment [43].

Figure 12.

Kinetic models and parameters for MB sorption (600 mg L−1, pH 7.0) were analyzed using pseudo-first-order (red), pseudo-second-order (green), and intra-particle diffusion (blue) models, with 50 mg of FBC at 25 °C (A), 40 °C (B), and 70 °C (C) as a function of contact time. Data are expressed as mean ± standard deviation (n = 3).

The results showed that temperature influences adsorption kinetics: at lower temperatures (25 °C), the data fit a pseudo-first-order kinetic model (r2 = 0.988), while at higher temperatures (70 °C), they fit a pseudo-second-order kinetic model (r2 = 0.991), with both models fitting at the intermediate temperature. The equilibrium adsorption capacities (Qeq) of MB, ranging from 11.81 mg g−1 to 14.69 mg g−1, agreed well with the experimentally determined values of q1 = 11.73 mg g−1, q2 = 14.11 mg g−1, and q2 = 13.82 mg g−1 for 25 °C, 40 °C, and 70 °C, respectively. The reaction constants k1 = 0.084 min−1, k2 = 0.007 g mg−1 min−1, and k2 = 0.008 g mg−1 min−1 were determined for the adsorption process at the respective temperatures. Similar adsorption kinetic parameters for organic dyes have been reported using different cellulose-based adsorbents, such as cellulose nanocrystals hydrogels [41], activated carbon from walnut shells [36], bacterial cellulose-based aerogels [38], and nanocellulose-graphene oxide aerogels [2]. However, higher adsorption capacities have been reported using adsorbents such as carboxymethyl cellulose–graphene oxide composites [43], corncob cellulose-based hydrogels [22], amide-functionalized cellulose [44], cellulose nanocrystals/carboxymethyl cellulose/zeolite membranes [34], and activated carbon from bacterial cellulose [39]. It is foreseen that chemical modification affects the adsorption capacity of cellulose-based materials. The adsorption mechanism of MB onto FBC appears complex, as indicated by the similar correlation coefficients for both the pseudo-first-order and pseudo-second-order models at the tested temperatures, along with the fit to the combined Sips isotherm.

Adsorption kinetics explains the time-dependent migration of adsorbates from a solution onto an adsorbent, providing key parameters for developing and optimizing the adsorption process, particularly through pseudo-first-order and pseudo-second-order models [22,44]. According to the pseudo-first-order model for FBC, the adsorption rate is governed by both the dye concentration in solution and the availability of active sites on the adsorbent surface. This implies that adsorption may be controlled by diffusion in the liquid phase or by the initial interaction between the dye molecules and the adsorbent’s active sites [12]. On the other hand, the pseudo-second-order model indicates that the rate-determining step in the adsorption process involves both physical and chemical interactions, such as electrostatic interactions, which may be attributed to the hydroxyl (–OH) and ether (–O–) groups in the FBC, interacting with the positively charged nitrogen atoms and lone electron pairs in the MB molecule [38]. Furthermore, the structural changes resulting after functionalizing the bacterial cellulose align with the complex isotherm and kinetic models fitted to the FBC adsorption process. This study demonstrates a complex interplay of pseudo-first-order and pseudo-second-order models at multiple temperatures, providing a nuanced understanding of the kinetics. In addition, it emphasizes the performance of functionalized bacterial cellulose under challenging conditions typical of real-world wastewater.

4. Conclusions

The production of BC followed a sigmoidal growth pattern. The functionalization of BC with citric acid induced structural changes that enhanced its adsorption capacity. The amount of MB adsorbed on FBC increased over time until equilibrium was reached, driven by electrostatic forces between the dye and the hydroxyl and carboxyl functional groups present on the adsorbent. The adsorption of MB from water using functionalized BC was influenced by parameters including the mass of the adsorbate, duration of contact, initial dye concentration, and pH. There is a growing interest in establishing regional and local circular systems where BC can be efficiently utilized, benefiting the communities where it is produced. BC is gaining attention as a versatile material with applications in different fields, such as bioremediation, where it can be effectively used in circular systems. Interdisciplinary efforts should focus on scaling up laboratory BC production to commercial levels, embracing its practical utility. This work underscores the potential of FBC as a bioremediation material within circular systems, linking the production and application of the material to sustainable practices and waste valorization.

Author Contributions

Conceptualization, A.A.-R.; Data curation, K.M.-M., M.E.-G., and S.E.F.-C.; Formal analysis, A.A.-R. and O.Y.B.-G.; Investigation, J.A.R.M.; Methodology, K.M.-M., O.Y.B.-G., H.P., and E.R.-d.L.; Project administration, A.A.-R.; Resources, A.A.-R., S.E.F.-C., J.C.-G., M.A.R.-L., and J.A.R.M.; Supervision, M.A.R.-L. and J.A.R.M.; Validation, J.C.-G.; Visualization, H.P. and E.R.-d.L.; Writing—original draft, A.A.-R.; Writing—review and editing, A.A.-R. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the “National Council for the Humanities, Science, and Technology” (CONAHCYT) with SNII grant number 222109 and by the Autonomous University of Querétaro SIIP-2025.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article; further inquiries can be directed to the corresponding authors.

Acknowledgments

Aldo Amaro-Reyes and José Alberto Rodríguez Morales are corresponding authors.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Omer, A.M.; Sadik, W.A.; Abbas, R.; Tamer, T.M.; Abd-Ellatif, M.M.; Mohy-Eldin, M.S. Novel Amino-Ethyl Carboxymethyl Cellulose Crosslinked Ampholyte Hydrogel Development for Methyl Orange Removal from Waste Water. Sci. Rep. 2024, 14, 14701. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, V.T.; Ha, L.Q.; Nguyen, T.D.L.; Ly, P.H.; Nguyen, D.M.; Hoang, D. Nanocellulose and Graphene Oxide Aerogels for Adsorption and Removal Methylene Blue from an Aqueous Environment. ACS Omega 2022, 7, 1003–1013. [Google Scholar] [CrossRef] [PubMed]

- Omidian, H.; Akhzarmehr, A.; Chowdhury, S.D. Advancements in Cellulose-Based Superabsorbent Hydrogels: Sustainable Solutions across Industries. Gels 2024, 10, 174. [Google Scholar] [CrossRef] [PubMed]

- Barka, N.; Ouzaouit, K.; Abdennouri, M.; El Makhfouk, M. Dried Prickly Pear Cactus (Opuntia ficus indica) Cladodes as a Low-Cost and Eco-Friendly Biosorbent for Dyes Removal from Aqueous Solutions. J. Taiwan Inst. Chem. Eng. 2013, 44, 52–60. [Google Scholar] [CrossRef]

- Meili, L.; Lins, P.V.S.; Costa, M.T.; Almeida, R.L.; Abud, A.K.S.; Soletti, J.I.; Dotto, G.L.; Tanabe, E.H.; Sellaoui, L.; Carvalho, S.H.V.; et al. Adsorption of Methylene Blue on Agroindustrial Wastes: Experimental Investigation and Phenomenological Modelling. Prog. Biophys. Mol. Biol. 2019, 141, 60–71. [Google Scholar] [CrossRef]

- Grzybek, P.; Dudek, G.; van der Bruggen, B. Cellulose-Based Films and Membranes: A Comprehensive Review on Preparation and Applications. Chem. Eng. J. 2024, 495, 153500. [Google Scholar] [CrossRef]

- Dang, X.; Li, N.; Yu, Z.; Ji, X.; Yang, M.; Wang, X. Advances in the Preparation and Application of Cellulose-Based Antimicrobial Materials: A Review. Carbohydr. Polym. 2024, 342, 122385. [Google Scholar] [CrossRef]

- Candra, A.; Ahmed, Y.W.; Kitaw, S.L.; Anley, B.E.; Chen, K.-J.; Tsai, H.-C. A Green Method for Fabrication of a Biocompatible Gold-Decorated-Bacterial Cellulose Nanocomposite in Spent Coffee Grounds Kombucha: A Sustainable Approach for Augmented Wound Healing. J. Drug Deliv. Sci. Technol. 2024, 94, 105477. [Google Scholar] [CrossRef]

- Quijano, L.; Rodrigues, R.; Fischer, D.; Tovar-Castro, J.D.; Payne, A.; Navone, L.; Hu, Y.; Yan, H.; Pinmanee, P.; Poon, E.; et al. Bacterial Cellulose Cookbook: A Systematic Review on Sustainable and Cost-Effective Substrates. J. Bioresour. Bioprod. 2024, 9, 379–409. [Google Scholar] [CrossRef]

- Wang, J.; Li, C.; Tang, Y. Constructing Bacterial Cellulose and Its Composites: Regulating Treatments towards Applications. Cellulose 2024, 31, 7793–7817. [Google Scholar] [CrossRef]

- Feng, Y.; Liu, Y.; Xue, L.; Sun, H.; Guo, Z.; Zhang, Y.; Yang, L. Carboxylic Acid Functionalized Sesame Straw: A Sustainable Cost-Effective Bioadsorbent with Superior Dye Adsorption Capacity. Bioresour. Technol. 2017, 238, 675–683. [Google Scholar] [CrossRef]

- Villabona-Ortíz, Á.; Figueroa-Lopez, K.J.; Ortega-Toro, R. Kinetics and Adsorption Equilibrium in the Removal of Azo-Anionic Dyes by Modified Cellulose. Sustainability 2022, 14, 3640. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, J.; Zhang, Z.; Li, P.; He, C.; Zhong, M. Pb(II) Adsorption Properties of a Three-Dimensional Porous Bacterial Cellulose/Graphene Oxide Composite Hydrogel Subjected to Ultrasonic Treatment. Materials 2024, 17, 3053. [Google Scholar] [CrossRef] [PubMed]

- Agüero, Á.; Corral Perianes, E.; Abarca de las Muelas, S.S.; Lascano, D.; de la Fuente García-Soto, M.d.M.; Peltzer, M.A.; Balart, R.; Arrieta, M.P. Plasticized Mechanical Recycled PLA Films Reinforced with Microbial Cellulose Particles Obtained from Kombucha Fermented in Yerba Mate Waste. Polymers 2023, 15, 285. [Google Scholar] [CrossRef]

- De Melo, L.M.; Soares, M.G.; Bevilaqua, G.C.; Schmidt, V.C.R.; de Lima, M. Historical Overview and Current Perspectives on Kombucha and SCOBY: A Literature Review and Bibliometrics. Food Biosci. 2024, 59, 104081. [Google Scholar] [CrossRef]

- Antolak, H.; Piechota, D.; Kucharska, A. Kombucha Tea—A Double Power of Bioactive Compounds from Tea and Symbiotic Culture of Bacteria and Yeasts (SCOBY). Antioxidants 2021, 10, 1541. [Google Scholar] [CrossRef]

- Esatbeyoglu, T.; Sarikaya Aydin, S.; Gültekin Subasi, B.; Erskine, E.; Gök, R.; Ibrahim, S.A.; Yilmaz, B.; Özogul, F.; Capanoglu, E. Additional Advances Related to the Health Benefits Associated with Kombucha Consumption. Crit. Rev. Food Sci. Nutr. 2024, 64, 6102–6119. [Google Scholar] [CrossRef]

- Prajapati, K.; Prajapati, J.; Patel, D.; Patel, R.; Varshnei, A.; Saraf, M.; Goswami, D. Multidisciplinary Advances in Kombucha Fermentation, Health Efficacy, and Market Evolution. Arch. Microbiol. 2024, 206, 366. [Google Scholar] [CrossRef]

- Laavanya, D.; Shirkole, S.; Balasubramanian, P. Current Challenges, Applications and Future Perspectives of SCOBY Cellulose of Kombucha Fermentation. J. Clean. Prod. 2021, 295, 126454. [Google Scholar] [CrossRef]

- Olivito, F.; Algieri, V.; Jiritano, A.; Tallarida, M.A.; Tursi, A.; Costanzo, P.; Maiuolo, L.; De Nino, A. Cellulose Citrate: A Convenient and Reusable Bio-Adsorbent for Effective Removal of Methylene Blue Dye from Artificially Contaminated Water. RSC Adv. 2021, 11, 34309–34318. [Google Scholar] [CrossRef]

- Hestrin, S.; Schramm, M. Synthesis of Cellulose by Acetobacter xylinum. II. Preparation of Freeze-Dried Cells Capable of Polymerizing Glucose to Cellulose. Biochem. J. 1954, 58, 345–352. [Google Scholar] [CrossRef] [PubMed]

- Majamo, S.L.; Amibo, T.A.; Mekonnen, D.T. Expermental Investigation on Adsorption of Methylene Blue Dye from Waste Water Using Corncob Cellulose-Based Hydrogel. Sci. Rep. 2024, 14, 4540. [Google Scholar] [CrossRef] [PubMed]

- Girard, V.D.; Chaussé, J.; Vermette, P. Bacterial Cellulose: A Comprehensive Review. J. Appl. Polym. Sci. 2024, 141, e55163. [Google Scholar] [CrossRef]

- Mohammadkazemi, F.; Azin, M.; Ashori, A. Production of Bacterial Cellulose Using Different Carbon Sources and Culture Media. Carbohydr. Polym. 2015, 117, 518–523. [Google Scholar] [CrossRef]

- Singhsa, P.; Narain, R.; Manuspiya, H. Physical Structure Variations of Bacterial Cellulose Produced by Different Komagataeibacter xylinus Strains and Carbon Sources in Static and Agitated Conditions. Cellulose 2018, 25, 1571–1581. [Google Scholar] [CrossRef]

- Yang, L.; Zhu, X.; Chen, Y.; Jun, W. Enhanced Bacterial Cellulose Production in Gluconacetobacter xylinus by Overexpression of Two Genes (BscC and BcsD) and a Modified Static Culture. Int. J. Biol. Macromol. 2024, 260, 129552. [Google Scholar] [CrossRef]

- Chong, A.Q.; Chin, N.L.; Talib, R.A.; Basha, R.K. Modelling PH Dynamics, SCOBY Biomass Formation, and Acetic Acid Production of Kombucha Fermentation Using Black, Green, and Oolong Teas. Processes 2024, 12, 1301. [Google Scholar] [CrossRef]

- Sevcik, C. Caveat on the Boltzmann Distribution Function Use in Biology. Prog. Biophys. Mol. Biol. 2017, 127, 33–42. [Google Scholar] [CrossRef]

- El Aferni, A.; Guettari, M.; Tajouri, T. Mathematical Model of Boltzmann’s Sigmoidal Equation Applicable to the Spreading of the Coronavirus (Covid-19) Waves. Environ. Sci. Pollut. Res. 2021, 28, 40400–40408. [Google Scholar] [CrossRef]

- Aung, T.; Kim, M.J. A Comprehensive Review on Kombucha Biofilms: A Promising Candidate for Sustainable Food Product Development. Trends Food Sci. Technol. 2024, 144, 104325. [Google Scholar] [CrossRef]

- Tarhan Kuzu, K.; Aykut, G.; Tek, S.; Yatmaz, E.; Germec, M.; Yavuz, I.; Turhan, I. Production and Characterization of Kombucha Tea from Different Sources of Tea and Its Kinetic Modeling. Processes 2023, 11, 2100. [Google Scholar] [CrossRef]

- Upadhyay, A.; Upadhyay, A.; Sarangi, P.K.; Chawade, A.; Pareek, N.; Tripathi, D.; Vivekanand, V. Machine Learning Approach for Microbial Growth Kinetics Analysis of Acetic Acid-Producing Bacteria Isolated from Organic Waste. Biochem. Eng. J. 2024, 202, 109164. [Google Scholar] [CrossRef]

- Makarem, M.; Lee, C.M.; Kafle, K.; Huang, S.; Chae, I.; Yang, H.; Kubicki, J.D.; Kim, S.H. Probing Cellulose Structures with Vibrational Spectroscopy; Springer: Dordrecht, The Netherlands, 2019; Volume 26, ISBN 1057001821. [Google Scholar]

- Ibrahim, M.A.; Salama, A.; Zahran, F.; Abdelfattah, M.S.; Alsalme, A.; Bechelany, M.; Barhoum, A. Fabrication of Cellulose Nanocrystals/Carboxymethyl Cellulose/Zeolite Membranes for Methylene Blue Dye Removal: Understanding Factors, Adsorption Kinetics, and Thermodynamic Isotherms. Front. Chem. 2024, 12, 1330810. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.S.; Han, Y.H.; Ye, Y.X.; Shi, X.X.; Xiang, P.; Chen, D.L.; Li, M. Physicochemical Characterization of High-Quality Bacterial Cellulose Produced by Komagataeibacter Sp. Strain W1 and Identification of the Associated Genes in Bacterial Cellulose Production. RSC Adv. 2017, 7, 45145–45155. [Google Scholar] [CrossRef]

- Hajialigol, S.; Masoum, S. Optimization of Biosorption Potential of Nano Biomass Derived from Walnut Shell for the Removal of Malachite Green from Liquids Solution: Experimental Design Approaches. J. Mol. Liq. 2019, 286, 110904. [Google Scholar] [CrossRef]

- Poornachandhra, C.; Jayabalakrishnan, R.M.; Prasanthrajan, M.; Balasubramanian, G.; Lakshmanan, A.; Selvakumar, S.; John, J.E. Cellulose-Based Hydrogel for Adsorptive Removal of Cationic Dyes from Aqueous Solution: Isotherms and Kinetics. RSC Adv. 2023, 13, 4757–4774. [Google Scholar] [CrossRef]

- Le, H.V.; Dao, N.T.; Bui, H.T.; Kim Le, P.T.; Le, K.A.; Tuong Tran, A.T.; Nguyen, K.D.; Mai Nguyen, H.H.; Ho, P.H. Bacterial Cellulose Aerogels Derived from Pineapple Peel Waste for the Adsorption of Dyes. ACS Omega 2023, 8, 33412–33425. [Google Scholar] [CrossRef]

- Khamkeaw, A.; Jongsomjit, B.; Robison, J.; Phisalaphong, M. Activated Carbon from Bacterial Cellulose as an Effective Adsorbent for Removing Dye from Aqueous Solution. Sep. Sci. Technol. 2019, 54, 2180–2193. [Google Scholar] [CrossRef]

- Quiñones-Cerna, C.; Rodríguez-Soto, J.C.; Barraza-Jáuregui, G.; Huanes-Carranza, J.; Cruz-Monzón, J.A.; Ugarte-López, W.; Hurtado-Butrón, F.; Samanamud-Moreno, F.; Haro-Carranza, D.; Valdivieso-Moreno, S.; et al. Bioconversion of Agroindustrial Asparagus Waste into Bacterial Cellulose by Komagataeibacter rhaeticus. Sustainability 2024, 16, 736. [Google Scholar] [CrossRef]

- Abdelaziz, R.M.; El-Maghraby, A.; Sadik, W.A.A.; El-Demerdash, A.G.M.; Fadl, E.A. Biodegradable Cellulose Nanocrystals Hydrogels for Removal of Acid Red 8 Dye from Aqueous Solutions. Sci. Rep. 2022, 12, 6424. [Google Scholar] [CrossRef]

- Chen, X.; Cui, J.; Xu, X.; Sun, B.; Zhang, L.; Dong, W.; Chen, C.; Sun, D. Bacterial Cellulose/Attapulgite Magnetic Composites as an Efficient Adsorbent for Heavy Metal Ions and Dye Treatment. Carbohydr. Polym. 2020, 229, 115512. [Google Scholar] [CrossRef] [PubMed]

- Mohamed, E.N.; Abd-Elhamid, A.I.; El-Bardan, A.A.; Soliman, H.M.A.; Mohy-Eldin, M.S. Development of Carboxymethyl Cellulose-Graphene Oxide Biobased Composite for the Removal of Methylene Blue Cationic Dye Model Contaminate from Wastewater. Sci. Rep. 2023, 13, 14265. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Chen, T.W.; Yang, Y.L.; Bai, Z.C.; Xia, L.R.; Wang, M.; Lv, X.L.; Li, L. Removal of Heavy Metal Ions and Anionic Dyes from Aqueous Solutions Using Amide-Functionalized Cellulose-Based Adsorbents. Carbohydr. Polym. 2020, 230, 115619. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).