Abstract

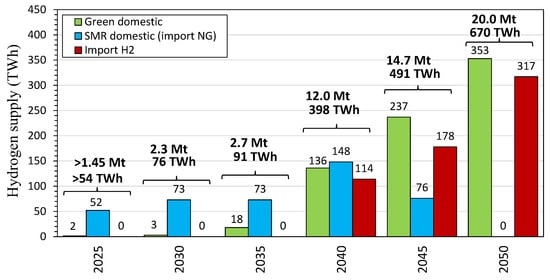

This review presents a critical analysis of Japan’s hydrogen strategy, focusing on the broader context of its decarbonization efforts. Japan aims to achieve carbon neutrality by 2050, with intermediate targets including 3 million tons of hydrogen use by 2030 and 20 million tons by 2050. Unlike countries with abundant domestic renewables, Japan’s approach emphasizes hydrogen imports and advanced storage technologies, driven by limited local renewable capacity. This review not only synthesizes policy and project-level developments but also critically evaluates Japan’s hydrogen roadmap by examining its alignment with global trends, technology maturity, and infrastructure scalability. The review integrates recent policy updates, infrastructure developments, and pilot project results, providing insights into value chain modeling, cost reduction strategies, and demand forecasting. Three policy conclusions emerge. First, Japan’s geography justifies an import-reliant pathway, but it heightens exposure to price, standards, and supply-chain risk; diversification across LH2 and ammonia with robust certification and offtake mechanisms is essential. Second, near-term deployment is most credible in industrial feedstocks (steel, ammonia, methanol) and the maritime sector, while refueling rollout lags materially behind plan and should be recalibrated. Third, cost competitiveness hinges less on electrolyzer CAPEX than on electricity price, liquefaction, transport; policy should prioritize bankable offtake, grid-connected renewables and transmission, and targeted CAPEX support for import terminals, bunkering, and cracking. Japan’s experience offers a pathway in the global hydrogen transition, particularly for countries facing similar geographic and energy limitations. By analyzing both the progress and the limitations of Japan’s hydrogen roadmap, this study contributes to understanding diverse national strategies in the rapidly changing state of implementation of clean energy.

1. Introduction

In recent years, the global economy and energy sector have been increasingly pressured to address vital issues of environmental pollution, energy security, and the need for alternative energy sources [1,2]. This has accelerated the transition away from traditional fossil fuels towards renewable energy options [3,4]. Hydrogen power has emerged as a promising solution for sustainable energy production due to its potential for low emissions and diverse applications across sectors [5,6,7,8].

Hydrogen supports decarbonization by lowering greenhouse gas emissions and enabling flexible energy storage. It can also blend with natural gas for transitional use [9,10]. However, challenges remain, including high production costs, energy losses, complex storage due to low volumetric density (e.g., ~5300 MJ/m3 at 700 bar; ~8500 MJ/m3 as liquid at 20 K) [11]. Additionally, green hydrogen production depends on access to ample renewable energy, which varies by region [12].

Clean hydrogen is projected to supply around 10% of global energy by 2050, driven by demand in heavy industry (e.g., steel, ammonia, methanol) and transport sectors like freight, shipping, and aviation [13,14]. Today, most hydrogen is produced using steam methane reforming (SMR), a fossil-based method that generates significant CO2 emissions; the resulting product is commonly referred to as grey hydrogen [15,16]. The transition toward “green hydrogen” by electrolysis using renewables is accelerating, with “blue hydrogen” (with carbon capture) as a bridge. Other methods include “pink” and “purple” hydrogen from nuclear energy and naturally occurring “white hydrogen” [17,18,19].

In response to growing energy security concerns and global decarbonization goals, Japan has adopted a long-term strategy to develop a clean energy system centered in part on hydrogen. The Basic Hydrogen Strategy, first released in 2017 and updated in 2023, outlines Japan’s roadmap toward carbon neutrality by 2050, including specific targets for hydrogen production, infrastructure development, and sectoral integration [20,21,22,23]. The strategy emphasizes the deployment of green hydrogen (produced via renewable electricity) and blue hydrogen (produced from natural gas with carbon capture and storage), with Japan aiming to use 3 Mt of hydrogen annually by 2030 and 20 Mt by 2050. While Japan was an early adopter of hydrogen planning, it now faces increasing competition from countries such as China and Germany, which have rapidly scaled investment, renewable integration, and domestic manufacturing capabilities. Japan’s approach remains distinct, however, due to its focus on liquefied hydrogen (LH2) logistics and its reliance on international hydrogen partnerships to address domestic renewable limitations.

Japan’s hydrogen roadmap focuses on scaling up infrastructure, including hydrogen production facilities and refueling stations, and predicting a future where hydrogen powers not only the transportation sector but also industry, residential energy, and heavy-duty applications [22,23,24]. Hydrogen power in Japan can lead the way in transitioning towards a low-carbon society, setting a model for hydrogen utilization that balances energy security, environmental responsibility, and economic growth [25,26].

This review provides an in-depth overview of Japan’s hydrogen society, considering logistical strategies and potential for optimization, and a roadmap for Japan’s ambitious hydrogen economy and its implications for the global energy transition.

2. Hydrogen Value Chain

In Japan, efficient liquefaction and mid-term storage are essential for long-distance hydrogen transport. However, large-scale hydrogen liquefaction facilities have not yet been implemented at the scale required to meet expected demand. This is attributed to a variety of technical, technological, and economic challenges inherent in managing hydrogen’s unique characteristics under cryogenic temperatures and high-pressure conditions [27,28].

Optimizing Japan’s hydrogen value chain is vital for making hydrogen a cost-effective energy carrier. The hydrogen supply chain includes several stages [29,30]: production, transformation, transportation, storage, distribution, and end-use applications. Production often occurs through methods such as electrolysis or natural gas reforming. Subsequently, hydrogen is transformed, typically through liquefaction, a process in which it is cooled to extremely low temperatures to facilitate compact storage and long-distance transportation. Specialized cryogenic tanks and vessels transport liquefied hydrogen across regions, while high-pressure or cryogenic tanks are used for storage [31,32]. Finally, Japan’s distribution network delivers hydrogen to key sectors, including transportation (via fuel cells), industrial applications (such as steel and ammonia production), and energy generation [4,33,34].

2.1. Hydrogen Production

In Japan, hydrogen production is evolving with various methods, each with unique costs, resources, and environmental impacts [35,36]. Green hydrogen, produced from renewable sources such as wind, hydro, and solar power, is the cleanest option with zero emissions and is currently prioritized [37]. Conventional methods, such as grey and brown hydrogen from natural gas and coal, are highly polluting, whereas blue hydrogen mitigates emissions through carbon capture. Emerging lower-emission alternatives include pink hydrogen, produced via nuclear power, and white hydrogen, either naturally occurring or biotechnologically generated.

As Japan advances toward its hydrogen economy, the focus is increasingly on clean production methods to support sectors where direct electrification is challenging. Although most hydrogen today is produced through fossil-fuel-based natural gas reforming, a significant shift toward green hydrogen is underway, largely due to the increased use of water electrolysis. This process, which splits water into hydrogen and oxygen without CO2 emissions, is projected to play a central role in future hydrogen production [34,38].

Japan’s hydrogen production goals align with broader global ambitions, as global demand for hydrogen is projected to surge from under 1 million metric tons (Mt) per year to 10 Mt by 2030, potentially reaching 600 Mt worldwide by 2050 [39,40,41]. Achieving these levels may necessitate substantial renewable energy resources, estimated at approximately 200 GW, particularly if electrolysis emerges as the predominant method of hydrogen production. Projected hydrogen production costs vary, with proton exchange membrane (PEM) electrolysis estimated at 1.8 USD/kgH2, alkaline electrolysis at 1.6 USD/kgH2, and SMR with carbon capture and storage at 1.2 USD/kgH2 [42,43]. While these estimates provide useful cost benchmarks, the practical competitiveness of CCS remains subject to regional policy stimulus, infrastructure readiness, and long-term viability. Norway, for instance, has led early CCS initiatives but still faces challenges in achieving widespread commercial scalability [1,15]. This economic and technological landscape demonstrates Japan’s ongoing investments and innovations in achieving a sustainable, hydrogen-based energy future.

2.1.1. Natural Gas Steam Methane Reforming

Natural gas steam methane reforming (SMR) is one of the most widely used methods for producing hydrogen today [44,45]. It involves the extraction of hydrogen from natural gas by using steam at high temperatures. This process is the dominant technology for industrial hydrogen production, but it has significant carbon emissions unless paired with carbon capture and storage (CCS).

In SMR, natural gas (methane) reacts with steam (H2O) at high temperatures (700–1000 °C) in the presence of a catalyst, typically made from nickel. This reaction produces hydrogen and carbon monoxide (CO).

The primary reaction is:

CH4 + H2O → CO + 3H2

The byproduct of this reaction, carbon monoxide, is then further reacted with steam in the water-gas shift reaction to produce additional hydrogen:

CO + H2O → CO2 + H2

The overall process produces hydrogen and CO2, which is the main environmental concern with this method.

The hydrogen is separated from the other gases, typically using techniques like pressure swing adsorption (PSA), leaving behind carbon dioxide (CO2) and any remaining methane. The SMR process is highly efficient at producing hydrogen, with typical yields of about 3 moles of hydrogen per mole of methane.

The reaction is endothermic, meaning significant heat is required to proceed. This heat is typically supplied by burning some of the methane itself, which leads to carbon dioxide emissions during the process. For every ton of hydrogen produced through SMR, about 9–12 tons of CO2 are emitted if no CCS is applied [16,46]. Without CCS, this process results in a high carbon footprint, making it less environmentally friendly compared to methods such as water electrolysis powered by renewable energy (which produces green hydrogen).

CCS is a technology that captures the CO2 produced during the SMR process and stores it underground to prevent it from entering the atmosphere. With CCS, SMR can produce low-carbon hydrogen, which is sometimes referred to as blue hydrogen. The degree of CO2 capture depends on the efficiency of the CCS system but typically ranges from 70% to 90% of the CO2 produced during the SMR process [47]. However, the economic feasibility of CCS remains a challenge due to high capital and operational costs, and large-scale deployment has been limited despite technological maturity. Blue hydrogen is considered a bridge technology that can reduce emissions in the hydrogen sector, although it still depends on fossil fuels (natural gas) for hydrogen production [48].

SMR is the most mature and widely used method for industrial hydrogen production, accounting for approximately 75% of global hydrogen production. The process is well-established, efficient, and relatively cost-effective compared to newer methods like water electrolysis or biological hydrogen production. The natural gas infrastructure (e.g., pipelines and storage) is already in place in many regions, making it easier to use existing infrastructure for hydrogen production via SMR [10]. The natural gas supply chain is already well-developed and global, providing a stable and easily accessible feedstock for hydrogen production [49]. Additionally, hydrogen produced by SMR can support energy storage applications for grid balancing and seasonal storage in integrated energy systems.

SMR will likely remain an important method of hydrogen production in the near to medium term, particularly for blue hydrogen, where CCS can be applied to mitigate carbon emissions. The future of blue hydrogen could involve integrating SMR with renewable energy sources. For example, renewable electricity could be used to power the CO2 capture and compression processes or to offset some of the energy required for SMR, reducing the overall carbon footprint [50]. Although blue hydrogen may contribute to emission reductions in the short term, the long-term objective is likely to focus on the widespread adoption of green hydrogen derived from renewable energy sources, such as water electrolysis powered by solar, wind, or hydropower, which represents the most environmentally sustainable solution.

In Japan, SMR has a significant meaning due to its industrial efficiency and reliance on natural gas as a primary feedstock. Currently, SMR is employed by major hydrogen producers in Japan, including large-scale industrial facilities that support industries like refining, petrochemicals, and ammonia production. Companies such as Linde and Air Liquide, which operate globally, also have a presence in Japan, providing SMR-based hydrogen solutions. The hydrogen produced through SMR in Japan is largely used for industrial applications, but it is also being integrated into the country’s energy transition plans, particularly when paired with CCS to mitigate CO2 emissions [51,52,53].

Japan’s efforts to decarbonize its hydrogen production are also implementing innovation in reforming technologies. For instance, SMR is being supplemented or replaced in some cases by emerging methods like chemical looping or autothermal reforming, both of which aim to improve energy efficiency and reduce emissions. However, SMR remains the dominant technology due to its established infrastructure and cost-effectiveness. Additionally, high-pressure storage technologies, such as Toyota’s Type 4 composite cylinders capable of 700 bar, offer a viable alternative to liquid hydrogen storage, minimizing the need for energy-intensive cryogenic systems.

In Japan, several companies are currently using SMR for hydrogen production as part of efforts to advance hydrogen-based energy systems. INPEX is involved in the Kashiwazaki Blue Hydrogen/Ammonia Project in Niigata Prefecture, which utilizes SMR combined with carbon capture and storage (CCS) to produce blue hydrogen. This project is part of a broader effort to commercialize hydrogen production in Japan by leveraging existing natural gas infrastructure [54,55]. Known as a leader in hydrogen-related technologies, Iwatani uses SMR to produce hydrogen, which is then distributed for industrial uses and refueling stations in Japan [56,57]. ENEOS has projects using SMR to produce hydrogen for mobility and other applications. The company also integrates CCS into its processes to reduce the carbon footprint of hydrogen production [58].

These companies reflect Japan’s strategy to develop blue hydrogen as a transition fuel while scaling up green hydrogen production in the future. Japan’s adoption of SMR aligns with its goal to establish a reliable hydrogen supply chain and contribute to achieving carbon neutrality by 2050 [20,22].

2.1.2. Natural Gas Autothermal Reforming

Natural Gas Autothermal Reforming (ATR) is another method for producing hydrogen from natural gas. It shares some similarities with SMR but has a main difference in how heat is supplied to the process. ATR is a more efficient alternative to SMR in certain applications, particularly in large-scale hydrogen production [44,59].

In ATR, methane (CH4) reacts with oxygen (O2) and steam (H2O) in the presence of a nickel-based catalyst or rhodium/platinum group metal catalysts at high temperatures (typically around 800–1000 °C) [60]. The reaction occurs in a two-step process [60,61]:

- Partial oxidation, where oxygen is introduced into the system to partially oxidize methane. This reaction generates heat:

CH4 + O2 → CO + 2H2

- 2.

- Steam reforming, where the carbon monoxide (CO) produced in the partial oxidation reaction then reacts with steam (H2O) in the water–gas shift reaction to produce additional hydrogen and carbon dioxide:

CO + H2O → CO2 + H2

The combination of these two reactions provides the heat required for the reaction to proceed. The autothermal part of the process refers to the fact that the heat needed for the reaction is generated internally through the partial oxidation of methane.

Unlike SMR, which is endothermic (requiring external heat, usually from burning some of the methane), ATR is exothermic in the partial oxidation step, meaning it generates heat. This leads to a more efficient process with a better energy balance. Hydrogen is typically separated from the other gases using PSA, while CO2 can be captured using CCS technologies if desired, making the process more environmentally friendly [62].

ATR can handle a wider range of feedstock compositions and can tolerate some impurities in the natural gas, which makes it more flexible compared to SMR. It also typically has better performance when processing high-sulfur natural gas [63].

Like SMR, the CO2 generated in ATR can be captured using CCS technologies. This makes the process potentially low-carbon when paired with CCS, producing blue hydrogen.

Without the use of CCS, NG ATR remains a high-carbon process, like SMR. It still produces significant amounts of CO2 (around 9–12 tons per ton of hydrogen produced) unless the CO2 is captured and stored [64]. The integration of CCS with ATR adds costs and complexity to the process. The infrastructure required to capture and store CO2 can be expensive and may limit the widespread adoption of blue hydrogen. The blue hydrogen from ATR with CCS can serve as a transitional technology for industries that are difficult to decarbonize using other methods [65].

In Japan, autothermal reforming (ATR) is being explored as a promising technology for hydrogen production, particularly in conjunction with carbon capture to create low-carbon hydrogen and ammonia. A key example is the Kashiwazaki Clean Hydrogen and Ammonia Project in Niigata Prefecture, where the Japanese energy company INPEX Corporation has partnered with Air Liquide to implement ATR technology. This demonstration project is Japan’s first to integrate ATR with carbon capture, aiming to produce low-carbon hydrogen and ammonia efficiently and cost-effectively [66,67]. The project highlights ATR’s role in Japan’s strategy to decarbonize its energy and industrial sectors while supporting clean energy initiatives.

This effort reflects Japan’s extensive interest in advancing hydrogen technologies. ATR is considered a viable solution for large-scale hydrogen production due to its efficiency and compatibility with existing infrastructure. While still in the demonstration phase, this project could lead to the wider adoption of ATR in Japan’s hydrogen economy.

2.1.3. Coal Gasification

Coal Gasification is a process that converts coal into synthesis gas (syngas), primarily composed of hydrogen (H2), carbon monoxide (CO), and carbon dioxide (CO2). The gasification process involves reacting coal with oxygen and steam at high temperatures (typically 900–1200 °C). Coal gasification can be used to produce hydrogen, but it is a carbon-intensive process unless coupled with CCS [68,69].

Coal is heated in a controlled environment with a combination of oxygen and steam. This produces syngas, which contains mainly H2, CO, and CO2 [70]. The syngas is then processed to separate hydrogen from the other gases. After gasification, hydrogen is typically extracted through a water-gas shift reaction (to convert CO into CO2 and more H2). Hydrogen is then separated and purified, often using PSA technologies.

Coal is widely available and abundant, making it a potential hydrogen source in regions with significant coal reserves. Coal gasification is a mature and well-established technology used to produce syngas for power generation, chemicals, and hydrogen production. CCS can significantly reduce the carbon emissions associated with coal gasification, making it a potential option for low-carbon hydrogen production [71].

Besides CO2, coal gasification can produce other pollutants such as nitrogen oxides (NOx), sulfur compounds, and particulates, depending on the coal quality and gasification technology. Additionally, the cost of implementing CCS is high, making coal gasification with CCS more expensive than other low-carbon hydrogen production methods, such as water electrolysis. Coal gasification with CCS could be implemented in regions with abundant coal reserves as a transition technology for producing blue hydrogen [72,73].

While coal gasification with CCS offers technological maturity and short-term reliability for hydrogen production, its high emissions (1.2–2.0 kg CO2/kg H2), costs (2.92–5.00 USD/kgH2), and energy security concerns make it an unsustainable option in Japan’s long-term strategy. Coal-based hydrogen risks being phased out as Japan prioritizes cleaner alternatives like electrolysis powered by renewables and explores transitional technologies such as ATR with CCS. Japan’s focus should remain on accelerating green hydrogen solutions while limiting coal gasification to a temporary, localized role in industrial sectors where alternatives are not yet viable [74,75].

2.1.4. Coal/Torrefied Woody Biomass Gasification

Coal/Torrefied Woody Biomass Gasification is a hybrid process that combines coal and torrefied woody biomass as feedstocks for gasification to produce hydrogen and other valuable gases such as carbon monoxide (CO) and carbon dioxide (CO2) [76,77]. The integration of torrefied woody biomass—a processed form of biomass characterized by higher energy density and improved handling properties compared to raw biomass—has the potential to enhance the sustainability of the process relative to conventional coal gasification. However, the overall environmental impact is contingent upon the extent to which carbon capture and storage (CCS) is implemented.

The torrefied woody biomass serves as a partial renewable feedstock, potentially reducing the overall carbon intensity of the process compared to pure coal gasification. Coal and torrefied woody biomass are gasified together in a reactor with a mixture of oxygen and steam at high temperatures (900–1200 °C) [78]. The resulting syngas (synthesis gas) contains mainly hydrogen (H2), carbon monoxide (CO), carbon dioxide (CO2), and trace amounts of other gases such as methane (CH4) and nitrogen (N2). After gasification, hydrogen is separated from the syngas using methods such as pressure swing adsorption, and the remaining gases are often processed further for other uses. Torrefied biomass has a higher energy content than raw biomass, which makes it a more efficient and attractive feedstock when mixed with coal for hydrogen production.

Coal gasification is carbon-intensive, as it involves fossil fuel (coal) as a feedstock. However, using torrefied woody biomass can reduce the overall carbon intensity because biomass is considered carbon-neutral (the CO2 released during combustion or gasification is offset by the CO2 absorbed by the plants during their growth). CCS can be integrated with this process to capture the CO2 generated from both coal and biomass components, which helps reduce the overall carbon footprint. If the torrefied woody biomass proportion is significant in the feedstock, the overall carbon emissions may be lower than pure coal gasification. The biomass portion offsets some of the CO2 produced, but this depends on how much of the feedstock is biomass vs. coal [79]. However, unless CCS is applied, this process still emits significant amounts of CO2, and without the capture of these emissions, the process could be categorized as grey hydrogen.

Biomass sourcing can have land-use implications, particularly if large-scale cultivation of energy crops is involved. The availability of sustainable biomass is a potential limitation, especially if biomass demand competes with food production or biodiversity concerns. The cost of torrefied biomass is typically higher than raw coal, and the economic viability of the process will depend on the relative prices of coal and biomass, as well as the costs of CCS. If biomass prices are high or if the market does not sufficiently reward the low-carbon benefits of this process, it could limit widespread adoption [80,81].

2.1.5. Alkaline Electrolysis

Alkaline Electrolysis (ALK) is a well-established method for producing hydrogen through the electrolysis of water using an alkaline electrolyte (typically potassium hydroxide (KOH) or sodium hydroxide (NaOH) solution) [44,82]. The electrolyte helps improve the conductivity of the solution, allowing for more efficient electron transfer and reducing the voltage required for the process. The electrolyte is a key component because it affects the efficiency, durability, and overall performance of the electrolysis system [83]. It is a mature and reliable technology used to generate hydrogen using a clean and sustainable method, provided that the electricity used is from renewable sources.

In ALK, water (H2O) is split into hydrogen gas (H2) and oxygen gas (O2) by passing an electric current through an alkaline solution [45,84]. The process occurs in an electrolyzer consisting of two electrodes, known as the anode and the cathode.

Anode: the positive electrode where oxygen (O2) is produced:

2H2O → O2 + 4H+ + 4e−

Cathode: the negative electrode where hydrogen (H2) is produced:

4H+ + 4e− → 2H2

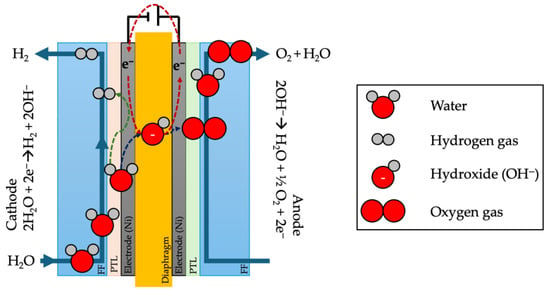

The hydrogen produced at the cathode is then separated and collected, while the oxygen is released at the anode (Figure 1).

Figure 1.

A schematic representation of alkaline electrolysis, in which water is introduced at the cathode, is provided. Upon the application of an electrical potential, hydrogen is evolved at the cathode, while oxygen is evolved at the anode. FF: flow field; PTL: porous transport layer (inspired by [82]).

ALK is one of the most established forms of electrolysis, with decades of proven industrial use, particularly for producing hydrogen in industries such as chlor-alkali production. Alkaline electrolyzers can be scaled to a wide range of sizes, from small-scale installations for localized hydrogen production to large industrial plants capable of producing significant quantities of hydrogen [85].

ALK electrolyzers are generally less expensive than other types of electrolyzers, such as PEM electrolyzers. The materials used in ALK (such as stainless steel and potassium hydroxide) are relatively low-cost compared to the more advanced materials used in other electrolyzers. ALK typically has an electrical efficiency of around 60–70%, although newer advancements in technology are improving its efficiency further [86]. The efficiency depends on factors such as the current density, operating temperature, and electrolyte composition.

In comparison to PEM electrolyzers, alkaline (ALK) systems typically exhibit lower current densities, necessitating larger electrolyzer volumes to achieve equivalent hydrogen production outputs. Consequently, ALK systems may be less compact and exhibit reduced efficiency in certain high-demand applications. Furthermore, ALK electrolyzers are generally larger than other types, such as PEM, and may demonstrate lower efficiency at smaller scales. As a result, they are predominantly deployed in large-scale, centralized installations, rather than in small-scale, decentralized applications.

Alkaline electrolysis is a key near-term solution for Japan’s hydrogen economy, offering a mature, reliable, and zero-emission method of producing green hydrogen. Examples such as the Fukushima Hydrogen Energy Research Field [87] and Hokkaido wind-to-hydrogen projects [88] demonstrate ALK’s project ENEOS [89,90] viability when coupled with renewable energy. However, high electricity costs and infrastructure development remain barriers to scaling. Japan should continue investing in renewable energy, optimizing ALK efficiency, and expanding hydrogen infrastructure to drive down costs and solidify ALK’s role in achieving its carbon-neutrality goals by 2050.

2.1.6. Proton Exchange Membrane Electrolysis

Proton Exchange Membrane Electrolysis is an advanced and highly efficient method for producing hydrogen through the electrolysis of water. It uses a solid polymer membrane as the electrolyte to separate the hydrogen and oxygen produced during the electrolysis process. PEM electrolysis is increasingly recognized as a promising technology for green hydrogen production, particularly when powered by renewable electricity such as from solar or wind sources [91,92].

In PEM electrolysis, water (H2O) is split into hydrogen gas (H2) and oxygen gas (O2) by passing an electric current through catalytic electrodes coated onto a solid proton-conducting membrane [93,94]. Reactions are like (5) and (6).

The protons (H+) evolved at the anode travel through the proton-conducting membrane to the cathode, where they combine with electrons (e−) from the external electrical circuit to produce hydrogen. The oxygen produced at the anode is released as gas.

The solid polymer membrane is a proton-conductive material that separates the hydrogen and oxygen gases. The materials used in PEM electrolysis rely on precious metals such as platinum and iridium as catalysts, which enhance efficiency but contribute to high system costs. Platinum is primarily used at the cathode for hydrogen evolution reactions, while iridium is utilized at the anode for oxygen evolution reactions due to its stability under acidic conditions [95,96]. The process occurs in high-pressure environments (often around 30–80 bar), which makes it suitable for applications where pressurized hydrogen is needed, such as in fuel cells [97,98].

PEM electrolysis is one of the most efficient electrolysis technologies, with efficiencies typically ranging from 65% to 80% depending on the system design and operating conditions. The high efficiency makes it ideal for green hydrogen production when powered by renewable energy. PEM electrolyzers are compact and modular, making them easier to scale and integrate into different applications, from small-scale installations to large industrial plants [99]. Their modular design allows for scalability based on demand. They can also operate at high current densities, which leads to smaller system sizes compared to other electrolysis technologies, making them suitable for distributed generation systems.

PEM electrolysis produces high-purity hydrogen because the proton-exchange membrane prevents any impurities from mixing with the hydrogen, making it particularly useful for applications that require high-purity hydrogen, such as in fuel cells or semiconductor manufacturing [100].

The materials cost can be a barrier to large-scale adoption, although costs are expected to decrease with advancements in technology and economies of scale [101]. Research is ongoing to find more cost-effective, durable catalysts that can reduce reliance on precious metals.

It should be noted that PEM electrolyzers are being deployed in the Tohoku region to produce green hydrogen from local solar and wind power, supporting industrial clusters and hydrogen refueling stations [102].

Japan is actively expanding its hydrogen infrastructure to support fuel cell vehicles (FCVs) and promote a hydrogen-based society. As of April 2024, the Kanto region, covering Tokyo, leads with 47 hydrogen refueling stations, contributing to a nationwide total of 161 stations. The Japanese government aims to increase this number to 1000 by 2030 to facilitate the adoption of FCVs [103,104].

Kawasaki Heavy Industries is at the forefront of Japan’s hydrogen initiatives through its “Kawasaki Hydrogen Road” project [105]. This comprehensive plan includes the development of technologies for hydrogen production, liquefaction, transportation, storage, and utilization. A notable achievement is the construction of the world’s first liquefied hydrogen carrier, the Suiso Frontier, designed to transport large volumes of hydrogen, thereby establishing a global hydrogen supply chain.

2.1.7. Anion Exchange Membrane Electrolysis

Anion Exchange Membrane Electrolysis (AEM) is the newest and most promising electrolysis technology for producing hydrogen from water. It uses an AEM instead of the PEM to separate hydrogen and oxygen during the electrolysis process. AEM electrolysis is considered to offer several advantages over traditional methods, such as ALK and PEM, but also comes with its own set of challenges [106].

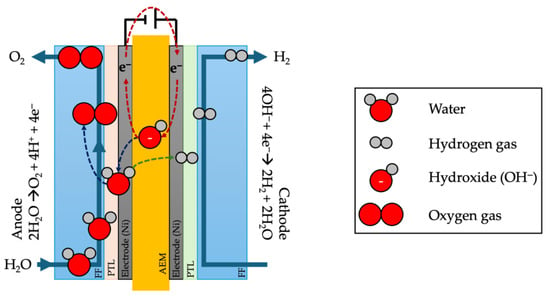

Like other types of water electrolysis, AEM electrolysis splits water (H2O) into hydrogen gas (H2) and oxygen gas (O2) (Figure 2). The primary difference is that AEM electrolysis uses an anion-conducting membrane instead of a proton-conducting membrane like in PEM [107]. The process consists of two half-reactions:

Figure 2.

A schematic illustrating anion exchange membrane electrolysis, in which water is supplied to the anode, is presented. Upon the application of an electrical potential, oxygen is evolved at the anode, while hydrogen is evolved at the cathode. FF: flow field; PTL: porous transport layer (inspired by [108]).

Anode (positive electrode):

2H2O → O2 + 4H+ + 4e−

Cathode (negative electrode):

4OH− + 4e− → 2H2 + 2H2O

The main component of AEM electrolysis is the anion exchange membrane, which allows for the transfer of hydroxide ions (OH−) between the cathode and anode while preventing the mixing of hydrogen and oxygen. It is typically made from a polymer-based material that can conduct anions. AEMs are generally cheaper and more abundant than the proton exchange membranes used in PEM electrolysis, making them a potential solution for reducing the cost of hydrogen production.

One of the important advantages of AEM electrolysis over PEM electrolysis is the lower cost of the ion-exchange membrane and the electrode materials. AEMs do not require precious metal catalysts (platinum or iridium), which are needed in PEM systems. Instead, AEM electrolyzers can use more abundant and cheaper materials, such as nickel or iron, for the electrodes [109].

AEM electrolysis typically offers higher efficiency than ALK, as it can operate at higher current densities and has a more compact design compared to alkaline systems [110]. The current density of AEM electrolysis is comparable to PEM, making it suitable for higher efficiency and faster response times than ALK, especially when integrating with intermittent renewable energy sources (wind, solar). Since AEM electrolysis does not require precious metal catalysts and operates with alkaline electrolytes, the system design is simpler and more cost-effective compared to PEM electrolysis. The lower costs make it a more attractive option for large-scale hydrogen production.

AEM electrolysis can operate at higher pressures, which is beneficial for directly producing pressurized hydrogen for storage or use in fuel cells, thereby excluding the need for additional compression equipment. AEM electrolysis uses alkaline electrolytes (such as potassium hydroxide (KOH) or sodium hydroxide (NaOH)) [111]. This can contribute to longer operational lifetimes and reduced maintenance costs.

Japan is actively advancing AEM electrolysis technology to produce green hydrogen efficiently and cost-effectively. In July 2023, Tokyo Gas introduced Japan’s first AEM water electrolyzer at its Senju Hydrogen Station. This facility utilizes renewable electricity to produce hydrogen, supporting Tokyo Gas’s goal of achieving carbon neutrality by 2050 [112]. Researchers from Waseda University and the University of Yamanashi have developed a new polyphenylene-based AEM with robust hydrophobic components, enhancing durability and ion conductivity. This advancement is crucial for improving the performance and longevity of AEM water electrolyzers [113,114]. A comprehensive project led by the Japan Science and Technology Agency (JST) Project focuses on developing innovative water electrolysis systems, including AEM types, aiming for low-cost, high-efficiency, and durable solutions [115].

2.1.8. Solid Oxide Electrolysis

Solid Oxide Electrolysis (SOEC) is an advanced and highly efficient method for producing hydrogen through the electrolysis of water. Unlike traditional electrolysis methods such as alkaline electrolysis or proton exchange membrane electrolysis, SOEC operates at high temperatures (typically 700 °C to 1000 °C) and uses a solid oxide electrolyte to split water into hydrogen and oxygen [116].

In SOEC, water (H2O) is split into hydrogen gas (H2) and oxygen gas (O2) by passing electricity through a solid oxide electrolyte at high temperatures. This method is based on high-temperature electrolysis (HTE), where the heat plays a significant role in driving the electrochemical reactions and enhancing the efficiency of the process [117,118]. The main components and reactions of the SOEC system are [119]:

Anode:

2O2− → O2 + 4e−

Cathode:

H2O + 2e− → H2 + O2−

The oxygen is released at the anode, and hydrogen is produced at the cathode. The solid oxide electrolyte conducts oxide ions (O2−) between the electrodes, allowing the reactions to take place.

The electrolyte used in SOEC is typically a ceramic material, such as yttria-stabilized zirconia (YSZ), that conducts oxide ions (O2−) at high temperatures. The electrolyte is a key component that differentiates SOEC from other electrolysis technologies, as it operates at higher temperatures, unlike PEM and alkaline electrolysis, which are based on liquid or solid polymer electrolytes. The high operating temperatures of SOEC reduce the amount of electrical energy required to split water, as thermal energy from the heat source can contribute to the electrolysis process, improving overall efficiency [120].

SOEC is one of the most efficient electrolysis methods, with efficiencies of up to 85% or higher, depending on the system design and operating conditions [119,121]. This is because the high operating temperatures reduce the electrical energy required to split water by using thermal energy, which enhances the overall energy efficiency. The efficiency of SOEC can be significantly improved by integrating it with high-temperature processes such as industrial waste heat or nuclear power, making it a promising option for large-scale hydrogen production. The ability to operate at high temperatures and pressures makes it suitable for integration with existing industrial infrastructures, such as steelmaking or refining industries.

SOEC systems tend to have higher capital costs compared to other electrolysis technologies. The high temperature and the materials required to withstand those temperatures (such as ceramic electrolytes and high-temperature resistant components) add to the complexity and expense of SOEC systems. The high operating temperatures of SOEC systems present challenges related to material degradation [122,123]. The materials used for the electrolyte and electrodes (typically ceramics and nickel-based alloys) must withstand both thermal stresses and the corrosive environment created during electrolysis. The lifetime of these materials can be a limiting factor [124].

Japan is actively advancing SOEC technology to produce green hydrogen efficiently. In July 2023, DENSO launched a pilot program at its Hirose Plant utilizing an SOEC device developed in-house. This system produces green hydrogen through high-temperature steam electrolysis, aiming to enhance the sustainability of DENSO’s manufacturing operations and contribute to its goal of carbon neutrality by 2035 [125,126]. In April 2024, MHI commenced the operation of a 400 kW SOEC test module at its Takasago Hydrogen Park in Hyogo Prefecture. Based on solid oxide fuel cell technology, this system seeks to achieve an overall efficiency of 90% (Higher Heating Value) and is a significant step toward high-efficiency hydrogen production [127]. Toshiba is developing an SOEC system as part of its efforts to establish a hydrogen society. Their research focuses on enhancing the efficiency and durability of SOEC technology to facilitate large-scale hydrogen production [128].

2.1.9. Other Methods

Japan is actively exploring diverse hydrogen production technologies to meet its carbon neutrality goals. Methane pyrolysis offers an innovative route to turquoise hydrogen production, decomposing methane into hydrogen and solid carbon at high temperatures (1000–1300 °C). This process eliminates direct CO2 emissions, producing a usable solid carbon byproduct and aligning with Japan’s focus on low-emission solutions. However, the technology’s maturity (technology readiness level (TRL) 3–8) requires further R&D to achieve scalable and economic competitiveness [129].

Japan is also prioritizing biomass-based hydrogen production, using abundant local resources such as agricultural residues and forestry byproducts [130,131]. Biomass steam reforming and biomass pyrolysis produce hydrogen alongside byproducts: bio-oil, syngas, and char. These methods can deliver green hydrogen with a net-zero carbon impact when coupled with carbon capture and sustainable sourcing. Emerging methods such as biomass hydrothermal liquefaction and photo-fermentation provide additional flexibility in utilizing wet biomass and sunlight-driven processes, supporting Japan’s renewable energy strategy [132]. However, it should be noted that scaling up hydrogen production from biomass in Japan faces challenges related to limited domestic biomass availability, high logistics costs, and competition with other bioenergy applications.

2.1.10. Analysis of Hydrogen Production Methods in the Context of Japan’s Hydrogen Strategy

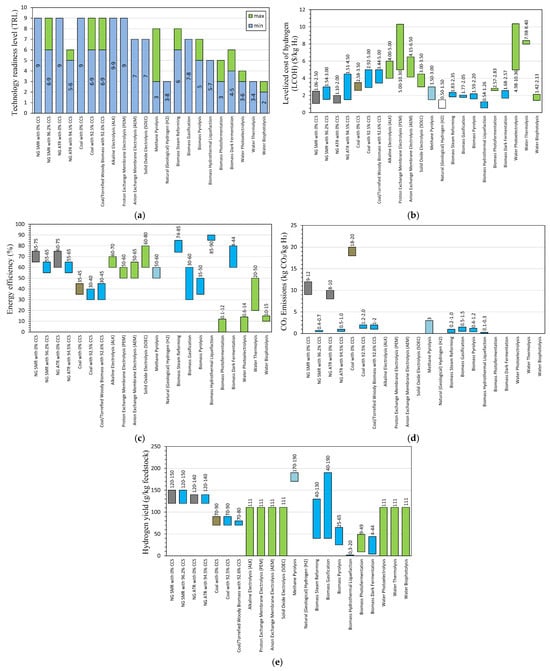

While SMR without CCS has low production costs, its high emissions (9–12 kg CO2/kg H2) conflict with Japan’s low-carbon goals. SMR with CCS offers a balance between cost and emissions reduction, with emissions as low as 0.4–0.7 kg CO2/kg H2 (Figure 3). This option is more favorable but is not fully aligned with carbon neutrality.

Figure 3.

Overview of hydrogen production methods, including technological readiness level (a), cost of hydrogen (b), energy efficiency (c), CO2 emissions (d), hydrogen yield (e). Values are based on the literature listed in Section 2.1. Colors for (b–e) correspond to the type of hydrogen.

ATR has similar costs to SMR and slightly lower CO2 emissions. With CCS, it becomes a more viable low-carbon option. Japan’s hydrogen strategy may leverage ATR with CCS as a bridge technology, but further advancements in CCS technology will be needed to reduce costs and improve feasibility.

Even with CCS, coal-based hydrogen production remains high in emissions and is costly. Due to Japan’s reliance on imported coal, this method poses energy security risks and is less favorable in the long term.

Electrolysis aligns well with Japan’s strategy due to zero CO2 emissions when powered by renewables. Alkaline and PEM electrolysis are more mature technologies (TRL 9), while SOEC and AEM are emerging (TRL 7) with higher efficiency potential. Despite high production costs, Japan is focusing on scaling electrolysis, coupled with its growing renewable energy sector.

Biomass pathways align with Japan’s strategy as they leverage biogenic CO2 emissions, which are considered carbon neutral. These methods support Japan’s goal to diversify hydrogen production sources, especially in rural areas with biomass availability. Biomass steam reforming and gasification have relatively mature TRLs and offer lower Levelized cost of hydrogen (LCOH), making them attractive for local, decentralized hydrogen production.

Analyzing the goals of Japan’s strategy, it can be highlighted that Japan is relying on blue hydrogen (e.g., NG SMR or ATR with CCS) as a bridge technology due to its relatively low cost and reduced emissions compared to grey hydrogen (Table 1). This approach enables the scaling of hydrogen use in industries and transportation without the significant investments of fully transitioning to green hydrogen. Table 1 presents an analysis and evaluation alignment with Japan’s strategy:

Table 1.

Prospects of the hydrogen production methods and Japan’s Hydrogen Strategy.

- Low level—minimal relevance to goals, lacks scalability or compatibility with strategy;

- Medium level—partial relevance, potential for niche or regional applications with further development; and,

- High level—fully aligned with goals, supports scalability, decarbonization, and infrastructure.

At the same time, Japan’s long-term goal emphasizes green hydrogen production through various electrolysis methods powered by renewables. However, high LCOH (4–10 USD/kgH2) is a significant barrier. Government subsidies and investments in renewable infrastructure are part of the strategy to bring these costs down over time.

On the other side, technologies such as SOEC are promising due to higher efficiencies, although they are currently less mature. Japan’s strategy includes funding R&D for such innovations to make green hydrogen economically viable.

Biomass-based hydrogen production methods provide a renewable option that utilizes domestic resources. While these processes emit biogenic CO2, they may serve as a viable part of the mix due to their carbon-neutral status when using sustainable biomass. In addition, approaches such as natural geological hydrogen and methane pyrolysis also show promise and minimize emissions, but they still have low TRL.

Due to this, we can say that Japan’s hydrogen strategy is based on a balanced, phased approach:

- Short-term: Focus on blue hydrogen production (e.g., NG SMR/ATR with CCS) to scale hydrogen usage with lower emissions.

- Medium-term: Invest in lowering the costs of green hydrogen via electrolysis and advancing technologies such as SOEC and AEM.

- Long-term: Shift towards renewable-powered green hydrogen to achieve a fully sustainable hydrogen economy.

At the same time, it should be noted that, based on estimates for 2023–2025, hydrogen production costs in Japan remain relatively high compared to global benchmarks. Green hydrogen produced via PEM or alkaline electrolysis ranges between 3.0 and 10.3 USD/kgH2, largely influenced by electricity prices and project scale. In contrast, blue hydrogen produced by SMR with CCS is estimated at 1.2–2.3 USD/kgH2. These costs are higher than those in countries such as Australia, where green hydrogen costs can be within 1.5–3.5 USD/kgH2.

The success of Japan’s strategy depends on reducing the cost of green hydrogen production, improving efficiency, and creating a resilient supply chain that integrates domestic and international resources.

2.1.11. Environmental Lifecycle Assessment of Hydrogen Production

To comprehensively evaluate the sustainability of Japan’s hydrogen strategy, it is essential to consider the environmental lifecycle impacts of various hydrogen production routes. Lifecycle assessment (LCA) provides insights into total greenhouse gas emissions, resource use, and environmental impacts from production to end-use. For instance, gray hydrogen produced by SMR without carbon capture results in lifecycle emissions of approximately 9–12 kgCO2/kgH2, while blue hydrogen can reduce this to 1–3 kgCO2/kgH2 and lower, depending on capture efficiency. Green hydrogen, derived from electrolysis using renewable electricity, has the lowest emissions footprint, but it depends on the electricity mix and the efficiency of electrolyzers. Incorporating LCA into hydrogen policy development is crucial to ensure climate goals.

2.2. Hydrogen Transportation

Transporting hydrogen efficiently and safely is essential to Japan’s strategy for establishing a hydrogen economy. Given hydrogen’s low energy density and challenges in long-distance transport, Japan is investing in multiple methods for hydrogen transportation.

2.2.1. Compressed Hydrogen Gas

One of the main methods for transporting and distributing hydrogen is transporting it as a compressed gas in high-pressure cylinders (typically 350–700 bar). It is mainly suited for short- and medium-distance use. Today, the Japanese industry uses compressed hydrogen for local distribution, especially for fueling hydrogen stations in urban areas. For example, today, there are about 160 stations in operation and development [103,104]. However, compressed gas is not ideal for long-distance transport due to the limited capacity of cylinders and the cost of high-pressure compression.

2.2.2. Liquid Hydrogen (LH2)

Hydrogen can be liquefied by cooling it to −253 °C, which increases energy density and makes it suitable for long-distance shipping, though the process is energy-intensive.

It should be noted that Japan has pioneered the use of liquid hydrogen tankers, with the Suiso Frontier, the world’s first liquefied hydrogen carrier, transporting hydrogen from Australia to Japan [133]. This method is central to Japan’s strategy for importing hydrogen from overseas. As Japan lacks domestic hydrogen production resources, liquid hydrogen transport is vital to its plan to import hydrogen from countries such as Australia, where hydrogen can be produced using local resources and renewable energy.

2.2.3. Ammonia as a Hydrogen Carrier

Ammonia (NH3) can store hydrogen in a stable, easily liquefiable form (liquid at −33 °C) and can be transported in conventional chemical tankers. Ammonia can then be “cracked” to release hydrogen or used directly in fuel cells and combustion.

Japan considers ammonia to be a promising hydrogen carrier for international shipping due to its existing infrastructure for ammonia transport and storage, with lower storage costs and fewer safety challenges compared to liquefied hydrogen.

2.2.4. Liquid Organic Hydrogen Carriers (LOHCs)

LOHCs are organic compounds (such as methylcyclohexane) that can chemically bind hydrogen, allowing it to be transported at ambient temperatures and pressures. Hydrogen is extracted through a catalytic process at the destination.

Nowadays, Japan is testing LOHC technology, especially because of the flexibility it offers in hydrogen storage and transportation. Japanese company Chiyoda Corporation is involved in LOHC projects for secure, long-distance transport. In this case, LOHCs could simplify hydrogen logistics by utilizing existing fuel distribution infrastructure and avoiding the extreme temperatures or pressures required by other methods.

2.2.5. Hydrogen Pipelines

Pipelines are a widely used method of transporting hydrogen and offer a continuous and direct way to transport hydrogen over short to medium distances. However, modifying natural gas pipelines or building hydrogen pipelines requires significant investment and technical adjustments. Hydrogen pipelines are being considered for local distribution around industrial hubs and ports, but are not yet widespread. Japan will consider pipeline networks in high-demand regions as its domestic hydrogen market grows.

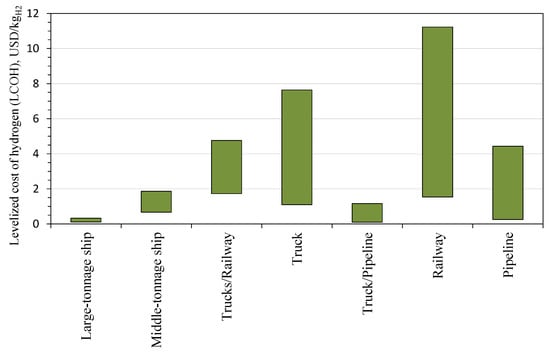

2.2.6. Alignment with Japan’s Hydrogen Goals

In analyzing hydrogen transportation methods in the context of Japan’s hydrogen strategy, cost considerations, and specific infrastructure options, in Table 2 and Table 3 and Figure 4, we can see that Japan’s hydrogen strategy is heavily focused on cost-effective, large-scale hydrogen import due to limited domestic production capabilities [134,135]. Given geographic constraints, Japan’s system will be anchored by large- and mid-tonnage maritime carriers for long-haul supply (primarily from Australia and the Middle East), which offer the lowest unit costs at scale but require portside cryogenic capability and boil-off management for liquid hydrogen [136]. Domestically, pipelines are the most efficient backbone where feasible on the main islands, while truck/rail combinations provide flexible delivery to hydrogen refueling stations and industrial hubs despite higher per-kg costs—truck-only routes should be limited to short hauls or pilots. For maritime carriers, ammonia and LOHCs avoid extreme cryogenic conditions but introduce cracking/dehydrogenation penalties. At the same time, ammonia is especially attractive given the established shipping infrastructure and energy density. Taken together, this two-level chain (ocean carriers—pipelines/trucks) aligns with Japan’s geography and minimizes delivered cost.

Table 2.

The main performance of the hydrogen transportation methods [28,30,137,138].

Table 3.

Relevance of the transportation hydrogen ways to Japan’s Hydrogen Strategy.

Figure 4.

The levelized cost of hydrogen via different modes of transportation.

2.3. Hydrogen Storage

There are a lot of efficient methods for storing hydrogen, which can be divided into two main parts: physical storage and material-based or chemical storage. In the hydrogen strategy, methods can be chosen depending on the direction of the use of hydrogen and the scale of the distribution [27,28,30].

2.3.1. Compressed Gaseous Hydrogen (CGH2)

Compressed Gaseous Hydrogen (CGH2) is one of the most widely used and mature hydrogen storage methods. It involves compressing hydrogen gas to high pressures (typically 350 to 700 bar) for storage in specially designed tanks [139,140]. This form of storage is common in hydrogen refueling stations, industrial sites, and mobile hydrogen applications, such as fuel cell vehicles (FCVs). In such a method, hydrogen gas is compressed using industrial compressors to pressures of 350 bar (for industrial use) or 700 bar (for mobility and FCVs). The CGH2 is stored in cylindrical or spherical high-pressure tanks made from advanced materials such as carbon fiber composites or metal alloys to withstand extreme pressures [141,142]. However, high-pressure tanks can cost between 500 and 1000 USD/kgH2 of storage capacity, influenced by material selection (steel vs. composite materials) [143,144].

Hydrogen refueling stations across Japan, such as those in Tokyo and Osaka, primarily use CGH2 technology. Compared to LH2 or advanced storage methods, CGH2 infrastructure requires less capital investment and is ideal for short to medium distances and urban refueling networks due to the fast-refueling times (3–5 min for FCVs) [145].

However, this approach has challenges, such as hydrogen in gaseous form having low volumetric energy density and requiring large, high-pressure tanks to store meaningful quantities of hydrogen. Also, tube trailers used to transport CGH2 can carry limited amounts of hydrogen, making long-distance transport inefficient. Distributed storage systems in urban areas or industrial clusters could use CGH2 to supply local refueling stations or small-scale industrial applications in medium-scale decentralized storage. Osaka Hydrogen Industrial Cluster is part of the Kansai Hydrogen Consortium, which uses CGH2 storage to supply hydrogen to local industries, fuel cell buses, and forklifts in industrial zones. Medium-scale CGH2 tanks installed at industrial facilities and refueling stations sourced from regional production sites provide a decentralized hydrogen supply tailored to industrial and urban energy needs [146,147].

In addition, hydrogen’s flammability and diffusion rate require reliable safety protocols, including sensors, venting systems, and double-walled tanks.

Today’s Japan’s hydrogen stations primarily utilize CGH2 to fuel FCVs such as the Toyota Mirai [148,149,150] and in industrial hubs. Multiple hydrogen stations across Tokyo provide CGH2 refueling at 700 bar, supporting Japan’s fuel cell vehicle fleet expansion [103]. Fukushima’s facility produces and stores CGH2, which is distributed to local refueling stations and industrial applications [151,152]. Kawasaki City utilizes CGH2 storage for local hydrogen applications, including fueling hydrogen buses and commercial vehicles [153].

2.3.2. Liquid Hydrogen Storage

LH2 is produced by cooling gaseous hydrogen to −253 °C at atmospheric pressure, significantly increasing its energy density and allowing for more efficient transport and storage compared to compressed gaseous hydrogen (CGH2) [68,154].

LH2 is stored in double-walled, vacuum-insulated cryogenic tanks that minimize heat transfer and reduce boil-off losses (evaporation of hydrogen during storage). It can be transported via specialized liquid hydrogen tankers or cryogenic containers to distribution points, where it is either used directly or converted back to gas for industrial and mobility applications [155].

It should be noted that efficiency is 60–70% due to the liquefaction being energy-intensive, consuming 30–40% of the hydrogen’s energy content during the process. In addition, continuous evaporation results in 0.3–1.0% daily losses during storage and up to 5–10% during transport for long voyages [156]. Cryogenic tanks cost 1000–1500 USD/kgH2 of hydrogen capacity, higher than CGH2 tanks [157]. At the same time, LH2 technology has been in use for decades, particularly in the space industry (rocket fuel), and is now being adapted for large-scale energy applications [158].

However, such a way of hydrogen storage needs LH2 infrastructure (liquefaction plants, cryogenic tankers, and specialized terminals) and requires significant capital investment. On the other hand, handling cryogenic hydrogen at −253 °C poses technical and safety challenges, as leaks or tank failures can lead to embrittlement or frostbite hazards [159,160].

Japan’s hydrogen import projects, such as the partnership with Australia’s Hydrogen Energy Supply Chain (HESC), heavily rely on LH2 for transporting hydrogen produced from brown coal and renewables [161]. The development of the Suiso Frontier, the world’s first liquefied hydrogen tanker, is a significant milestone in Japan’s hydrogen import infrastructure, demonstrating the feasibility of large-scale LH2 transport [29,162].

There is an example of the LH2 infrastructure and large-scale storage is Kobe LH2 Terminal. Japan’s first liquefied hydrogen receiving terminal is in Kobe, where LH2 from Australia is offloaded and distributed to local hydrogen refueling stations and industrial users [136]. This facility serves as a blueprint for future hydrogen import terminals. An industry company such as Iwatani operates several LH2-based hydrogen refueling stations across Japan, supporting the country’s fuel cell vehicle rollout and operating small-scale and short-term LH2 storage [163].

2.3.3. Cryo-Compressed Hydrogen

Cryo-compressed hydrogen (CcH2) is an advanced hydrogen storage method that combines cryogenic cooling (to temperatures near −253 °C) with compression (typically 200–350 bar) [164,165]. This hybrid approach increases hydrogen density beyond what is achievable by CGH2 or LH2 alone, providing greater storage capacity with fewer boil-off losses. Japan is actively exploring this technology to address its hydrogen import and domestic distribution needs, but widespread adoption remains limited due to technological complexity, high costs, and infrastructure challenges (Table 4).

Table 4.

General methods of hydrogen storage.

CcH2 requires double-walled, vacuum-insulated pressure vessels designed to withstand both high pressures and low temperatures [166]. These tanks reduce boil-off rates, allowing for longer storage times [167,168]. In this case, approximately 25–35% of the hydrogen’s energy is consumed during the liquefaction and compression stages. Production and storage costs are 4–7 USD/kgH2 of hydrogen, while cryo-compressed tanks are more expensive than standard CGH2 or LH2 tanks, with costs ranging from 1200 to 2000 USD/kgH2 of hydrogen capacity [169,170]. CcH2 achieves up to 80 kg/m3, which makes it ideal for long-range hydrogen vehicles and space-constrained applications [171,172].

Japan’s automotive leaders, such as Toyota and Honda, are investigating CcH2 as a next-generation storage method for hydrogen fuel cell trucks and trains. Toyota is exploring CcH2 for heavy-duty hydrogen trucks and buses, aiming to extend driving ranges and reduce refueling frequency through higher hydrogen storage densities [173,174,175]. The Japan Aerospace Exploration Agency (JAXA) is researching CcH2 technologies for potential use in space applications and fueling hydrogen-powered rockets [176,177].

2.3.4. Material-Based (Chemical) Storage: Adsorption

Adsorption-based hydrogen storage utilizes porous materials, such as activated carbon, metal–organic frameworks (MOFs), zeolites, and carbon nanotubes, to store hydrogen on the surface of the material. This method allows for low-pressure hydrogen storage at relatively low temperatures (typically 77 K or −196 °C, near liquid nitrogen temperatures) [178,179]. Adsorption is considered a safe, compact, and potentially scalable hydrogen storage method, though it remains experimental mainly and is limited in capacity and efficiency (Table 4).

According to the process and technology of adsorption, hydrogen gas is introduced into high-surface-area materials, which adhere to the surface of the porous material at low pressures and temperatures. This process is reversible, allowing hydrogen to be released when needed by increasing the temperature or reducing the pressure. Activated carbon, MOFs, zeolites, and carbon nanotubes are the most common materials explored for adsorption due to their high porosity and large internal surface area [179].

Adsorption-based storage systems use insulated vessels to maintain low temperatures, with hydrogen distributed and stored in compact storage units. It should be noted that desorption or hydrogen release requires energy input to raise temperatures or reduce pressure, further contributing to energy losses [180,181].

On the one hand, adsorption allows for hydrogen storage at low pressures (10–100 bar), enhancing safety compared to high-pressure CGH2 storage (350–700 bar). Adsorption materials offer higher volumetric storage efficiency at low pressures, allowing for compact hydrogen tanks in vehicles and industrial applications [182,183].

Also, it should be highlighted that the low-pressure nature of adsorption storage reduces the risk of leaks, explosions, or embrittlement, making it safer for use in urban environments or sensitive areas. Adsorption technology is being explored for hydrogen-powered drones, portable energy systems, and small hydrogen vehicles, where safety and size constraints are paramount [184,185]. On the other hand, despite advancements, adsorption materials store less hydrogen by weight (typically 1–3% of their mass) compared to LH2 or CGH2, limiting the feasibility of large-scale storage or transport. Also, repeated adsorption–desorption cycles can lead to material degradation over time, reducing the storage system’s lifespan and efficiency.

At present, Japan is investing in the development of adsorption technology through initiatives at academic institutions and private enterprises, though it remains in the experimental phase. Adsorption is being explored for specialized applications, including portable hydrogen storage for drones, backup generators, and hydrogen-powered forklifts. Considering Japan’s emphasis on safety and disaster resilience, the low-pressure, compact characteristics of adsorption align with hydrogen storage strategies designed for urban areas or small-scale hydrogen hubs.

Kyushu University is leading research into MOFs and activated carbon for hydrogen adsorption [186,187,188]. The university is exploring materials capable of achieving higher hydrogen densities at lower pressures. Toyota is evaluating adsorption-based storage as part of its effort to develop next-generation hydrogen fuel cell vehicles with safer and more compact hydrogen storage systems [189,190].

2.3.5. Material-Based (Chemical) Storage: Absorption

Absorption-based hydrogen storage utilizes metal hydrides and chemical materials that chemically bond with hydrogen, forming stable compounds capable of dense hydrogen storage. This method offers safe, compact, and reversible storage, making it attractive for stationary industrial applications or mobile systems requiring stable hydrogen containment [191,192]. Hydrogen stored in this form can be released by applying heat, which breaks the chemical bonds, freeing the hydrogen gas, although slow kinetics present challenges for large-scale applications [193].

In the absorption process, hydrogen gas reacts with metal or chemical compounds (metal hydrides), forming a solid or semi-solid hydride. This is a reversible reaction that allows hydrogen to be released when heat is applied. Hydrogen is released by heating the hydride material, typically requiring 200–400 °C. This process can be slower than other storage methods, limiting real-time hydrogen availability [191,194]. Storage materials include elemental hydrides (magnesium hydride), complex metal hydrides (sodium alanate, borohydrides), and interstitial hydrides (palladium alloys) [194,195].

The need for high-temperature heating during desorption reduces overall system efficiency, and the energy efficiency of the absorption method is 60–80%. Energy losses occur during both hydrogen absorption and release, requiring external heat sources [196,197]. High costs (8–30 USD/kgH2) are driven by the need for rare metals, heating systems, and material degradation over time [192].

It should be noted that hydrides provide stable hydrogen storage, reducing the risk of leaks or explosions compared to compressed or cryogenic storage. An important advantage of absorption technology is its ability to store hydrogen at low pressures (<10 bar), enhancing safety for applications in urban areas or environmentally sensitive settings [198].

On the other hand, slow hydrogen uptake and release in metal hydrides can take hours, limiting the practicality of absorption systems for applications requiring rapid refueling or high energy demand. Over time, hydride materials degrade, reducing hydrogen capacity and requiring regeneration or replacement [199]. There are different types of hydride storage [187,200,201,202]:

- Elemental hydrides (e.g., MgH2, TiH2)—stable, dense storage but heavy, with slow kinetics.

- Complex metal hydrides (e.g., sodium alanate, borohydrides) have higher capacity and are lighter than elemental hydrides, but are expensive to produce and difficult to scale.

- Interstitial hydrides (e.g., palladium alloys)—hydrogen is stored within metal lattices, allowing low-pressure hydrogen uptake.

Today, Japan continues to research and develop absorption technologies, primarily for industrial uses rather than mass hydrogen transport or storage. Kyoto University leads metal hydride development projects, focusing on magnesium and complex hydrides for stationary hydrogen storage and fuel cell backup systems [203]. Tohoku University is researching sodium alanate and borohydride materials to improve hydrogen capacity and reduce absorption/desorption temperatures [204,205]. Hitachi Zosen is developing metal hydride storage systems for use in industrial decarbonization projects, providing compact, dense hydrogen storage solutions [206].

2.3.6. Scale Hydrogen Storage

The analysis of hydrogen storage technologies across scales reveals a need for diversified strategies to meet different storage requirements (Table 5). Table 5 shows hydrogen storage methods by scale and provides insights into each technology’s suitability, challenges, and real-world applications. Small-scale solutions require advancements in materials and efficiency, medium- and large-scale storage faces cost and safety challenges, and very large-scale storage depends on geological options that may not be available in every region [207,208,209,210].

Table 5.

Main trends and scales of hydrogen storage methods [211,212].

2.3.7. Alternative Solutions and Trends

Based on the information provided, it was analyzed that Japan’s hydrogen storage strategy focuses on large-scale storage solutions and their alignment with the country’s overall hydrogen strategy:

Salt caverns. With capacities around, for example, 300,000 m3, salt caverns provide an estimated 122 GWh of energy (based on the lower heating value) [213,214,215]. Although onshore storage facilities incur higher construction costs, estimated at 8.75 USD/kgH2, and offshore facilities are even more expensive due to infrastructure challenges, they provide significant storage capacity, with hydrogen storage costs ranging from 0.66 to 1.75 EUR/kgH2 [216,217]. However, the efficiency of round-trip hydrogen storage is only about 40%, meaning Japan would need to consider ways to boost this efficiency.

Depleted gas fields. These fields offer an economical storage option with a much lower cost of ~1.07 USD/kgH2, with a 45–55% damper gas requirement to maintain pressure [218,219]. Delivery pressures of 50–100 bar make these fields suitable for large-scale, long-term storage. Given the relatively lower infrastructure costs, depleted gas fields may offer a feasible option for Japan, particularly if paired with renewable sources to support large-scale energy storage. However, both large storage options face a low round-trip efficiency (~40%), which could result in significant energy losses.

Compressed gas vessels are suitable for buffering hydrogen, with a usable density of about 1.2 kg H2/m3 [137,140]. Though compact, they might serve as short-term or emergency storage rather than a primary option for Japan’s large-scale needs.

Metal hydrides. AB2-type metal hydrides, which have a hydrogen density of up to 13.9 kg H2/m3, exhibit fast absorption/desorption kinetics. This makes them a viable buffer storage option for industrial applications where hydrogen demand is variable [220].

Underwater storage. Underwater storage offers a relatively low-cost (1.50 USD/kgH2) option at depths of 500 m, where pressures reach 50 bar [12,221]. Fixed-walled storage solutions using materials like HDPE provide a secure, isobaric environment for hydrogen storage. This type of storage might suit Japan’s island geography, allowing hydrogen to be stored offshore at reduced land usage.

2.4. Hydrogen Distribution and Infrastructure, Key Ports for Hydrogen Importation

Japan is rapidly developing its hydrogen economy, and several of its seaports are being positioned as future hubs for hydrogen importation. These ports are either upgrading their infrastructure or are already involved in various hydrogen-related projects to support the country’s push toward a clean energy transition. Table 6 is an overview of the main ports in Japan that could be important in hydrogen imports [133,136,222,223,224,225].

Table 6.

Japanese seaports and potential for hydrogen imports.

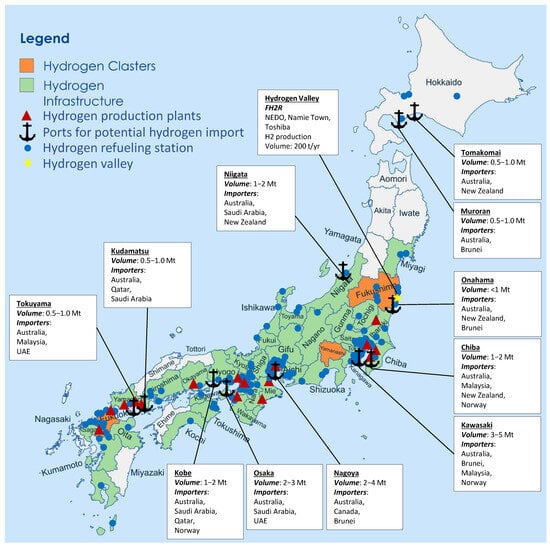

These ports (Figure 5), both large and smaller, are crucial for developing a comprehensive hydrogen import infrastructure across Japan. Larger ports like Kawasaki, Chiba, and Osaka will likely handle significant hydrogen import volumes due to their strategic locations and proximity to major industrial zones. Meanwhile, regional ports such as Niigata, Onahama, Tokuyama, and Kudamatsu will complement the larger ports by providing localized distribution networks for hydrogen to various industrial sectors. The Fukushima Hydrogen Supply Chain project, with Onahama as a main port, highlights the importance of several of these ports in receiving hydrogen from international sources, particularly from Australia, and ensuring that Japan can scale its hydrogen economy. Ports like Tomakomai and Muroran are also poised to become integral players, particularly for hydrogen production and transport from nearby hydrogen-rich regions.

Figure 5.

Japan’s domestic hydrogen geographic landscape, including hydrogen clusters, infrastructure, production plants, potential import ports, and refilling stations.

Ports Kawasaki, Nagoya, and Osaka have the potential to import 2–5 Mt/year by 2030, making them central to Japan’s hydrogen economy. Smaller regional ports such as Muroran, Tomakomai, and Kudamatsu are expected to handle 0.5–1.0 Mt/year, with volumes increasing as demand for hydrogen grows. Japan’s hydrogen import network is expected to involve a diverse mix of ports handling various forms of hydrogen, with LH2 and ammonia.

Kawasaki, Osaka, and Nagoya are pivotal for both green and blue hydrogen, with blue hydrogen expected to dominate in industrial centers such as Nagoya and Tokuyama, while green hydrogen derived from renewable sources is more likely to be found in Muroran, Tomakomai, and Onahama. The predominant forms of hydrogen anticipated at these ports are liquid hydrogen (LH2) and ammonia. LH2 is a key focus for Kawasaki, Kobe, and Nagoya, while ammonia is widely anticipated at ports such as Chiba, Niigata, and Tokuyama, serving as a hydrogen carrier. By 2030, the total volume of hydrogen imports at these ports could range from 0.5 Mt/year at smaller ports like Muroran and Kudamatsu to 3–5 Mt/year at larger, more central ports such as Kawasaki, Nagoya, and Osaka.

Figure 5 shows the location of major hydrogen production plants in Japan, which are primarily located in the major urban and industrial areas of Kanto and Kansai. Industry, academia, and government are collaborating to create hydrogen clusters (also known as hydrogen valleys, hubs, or ecosystems). These clusters are hydrogen value chain demonstrations and pilot projects that cut across sector applications [151,226]. Each cluster leverages its unique comparative advantages and has set out local hydrogen strategies. Fukuoka is the “hydrogen hub of Japan” designated by METI, Fukushima is focused on becoming a renewable energy leader, considering the Fukushima disaster, and Yamanashi is focused on energy storage and becoming a ‘fuel cell valley’, considering its solar resources. Each cluster comprises universities, local government, industry stakeholders, and public research institutions. Further, Japan’s 2021 Strategic Energy Plan outlines a policy plan to transition service stations to “comprehensive energy hubs” to supply energy to electric and fuel cell electric vehicles and “local community infrastructure” to provide services to meet local needs.

Fukuoka:

- As the METI-designated “hydrogen hub of Japan”, Fukuoka has been supporting the development of a sustainable society based on hydrogen energy since 2004 and holds the largest hydrogen conference in Japan, the Fukuoka Strategy Conference for Hydrogen Energy.

- The stakeholders active in the Fukuoka cluster projects: Kyushu University, Kyushi Electric Power Co., Taiyo Nippon Sanso Co., Kyuky Co., Iwatani Co., Nippon Steel Co., JXTG Nippon Oil & Energy, Saibu Gas Energy Co., Sumimoto Metal, Yawate Steel Works, Mitsubishi Kakoki Kaisha Ltd., and Toyota, Tsusho Corp.

- Initiatives include the Hy-Life Project, Fukuoka FCV Club, Q-PIT: Kyushu University Platform of Inter/Transdisciplinary Energy Research, and the Fukuoka Strategy Conference for Hydrogen Energy (~800 members across industry, university, administrative, and research organizations).

- Key demonstration projects include the “Hydrogen Highway”, Kyushu Station, “Fukuoka Hydrogen Town” (Itoshima City), “Hydrogen Town” Kitakyushu City, and Hydrogen production from sewage sludge.

- R&D infrastructure capabilities include Kyushu University (several laboratories on campus, including the world’s largest hydrogen research facility), the Hydrogen Energy Test and Research Centre (HyTReC), and the Centre for Research Activities and Development of Large-scale Pressure Vessel Equipment (CRADLE).

Fukushima:

- As an emerging global center for renewable energy research, Fukushima has been hosting AIST activities in hydrogen energy carriers, as well as hydrogen and heat utilization systems.

- Fukushima hosts a major hydrogen project called the Fukushima Hydrogen Energy Research Field (FH2R) [227], comprising a hydrogen production facility using solar power and electrolysis, transport and storage of compressed hydrogen, and utilization in gas networks and for electricity generation and grid balancing.

- Stakeholders in this cluster include AIST’s Fukushima Renewable Energy Institute (FREA), Toshiba ESS, Tohoku Electric Power Co., and Iwatani Corporation.

Yamanashi:

- Positioning itself as a “Fuel Cell Valley” and national center for storage and fuel cell development, Yamanashi hosts several demonstration projects within its Komekurayama Facilities. This facility includes the Electric Power Storage Technology Research Site (solar power station) and a power-to-gas demonstration.

- Stakeholders contributing to projects in the Yamanashi area include Iwate University, Shinshu University, Tohoku University, AIST, Yamanashi University, TEPCO, Kobe Steel Ltd., Panasonic, Toray Research Centre Inc, Takaoka Toko, HySUT, Miura, Hitz Hitachi Zosen, Japan Steel Works Ltd., Tanaka Kinkinzoku Kogyo KK, Kaneka Corp., and Nissan Arc Ltd.

- R&D infrastructure in the area includes the Clean Energy Research Center, the Hydrogen and Fuel Cell Technical Support Center, the Fuel Cell Nanomaterials Center, and the Hydrogen Technical Center (HySUT).

The Japanese automakers Toyota and Honda launched their fuel cell vehicles (FCVs), MIRAI and Clarity, in 2014 and 2016, respectively, with initial sales prices of around 7 million JPY (approximately 52,000 USD as of 2023) [228,229,230]. A typical HRS has a supply capacity of 300 Nm3/h. The roadmap targets the establishment of 200 HRSs by 2025 and 900 HRSs by 2030.

In addition to passenger vehicles, the use of fuel-cell technology is expanding into other mobility sectors, including fuel-cell buses and fuel-cell loaders. The deployment of fuel cell buses is expected to reach around 100 units by 2025, with a target of 1200 units by 2030. Similarly, the number of fuel cell loaders is projected to grow, with an estimated 500 units expected by 2025 and 10,000 units by 2030 [226].