1. Introduction

Pavement-quality concrete is essential for maintaining safe and efficient transportation infrastructure, with its strength properties being paramount. Pavement-quality concrete (PQC) is essential for maintaining safe and efficient transportation infrastructure, with its strength properties being paramount [

1]. Traditional materials like concrete have exhibited limitations in durability and strength under harsh conditions [

2]. Researchers have turned to nanomaterials such as nano SiO

2, nano TiO

2, nano clay, and nano Al

2O

3 to address these challenges [

3]. Studies have demonstrated the effectiveness of these nanomaterials in enhancing the mechanical properties of pavement-quality concrete [

4,

5,

6].

However, while several studies have explored the application of nanomaterials in concrete, there remains a significant gap in understanding their combined effects, dosage optimization, and real-world performance under prolonged loading conditions [

2]. Previous research has predominantly focused on laboratory-scale investigations, with limited emphasis on how these modifications translate to large-scale pavement applications [

7]. Moreover, fatigue performance and crack-healing mechanisms, which are critical for PQC, have not been extensively reviewed in the context of nanomaterial-enhanced formulations [

8,

9,

10]. This review aims to provide a comprehensive overview of the current state of research on nanomaterials’ impact on the strength aspects of pavement-quality concrete, exploring their types, properties, and potential applications [

11].

Despite significant advancements in nanotechnology, existing studies largely focus on the isolated effects of individual nanomaterials rather than evaluating their synergistic interactions in PQC [

12]. Additionally, limited research has been conducted to validate their long-term durability and large-scale applicability in actual pavement conditions [

13]. When considering the durability of nano-SiO

2-modified concrete, and especially when used in recycled aggregate concrete, further research is needed to understand the long-term effects [

14]. Addressing these gaps, this study systematically analyzes nanomaterials’ influence on PQC properties, identifies key challenges, and emphasizes the need for large-scale field validation to enhance their practical implementation in infrastructure projects [

15]. Furthermore, the effects of nanomaterials, such as graphene oxide, on the abrasion resistance and strength of concrete have been recently studied and can be considered when evaluating concrete performance [

16]. Lastly, research into coal gangue foam concrete modified by nanomaterials shows promising results in physical properties, pore structure, and electromagnetic properties, demonstrating the continuous evolution of nanomaterial applications in concrete [

17].

The paper will also discuss the challenges and limitations of using nanomaterials in concrete and identify areas for future research to maximize their benefits.

1.1. Background of Nanomaterials in Concrete Pavement

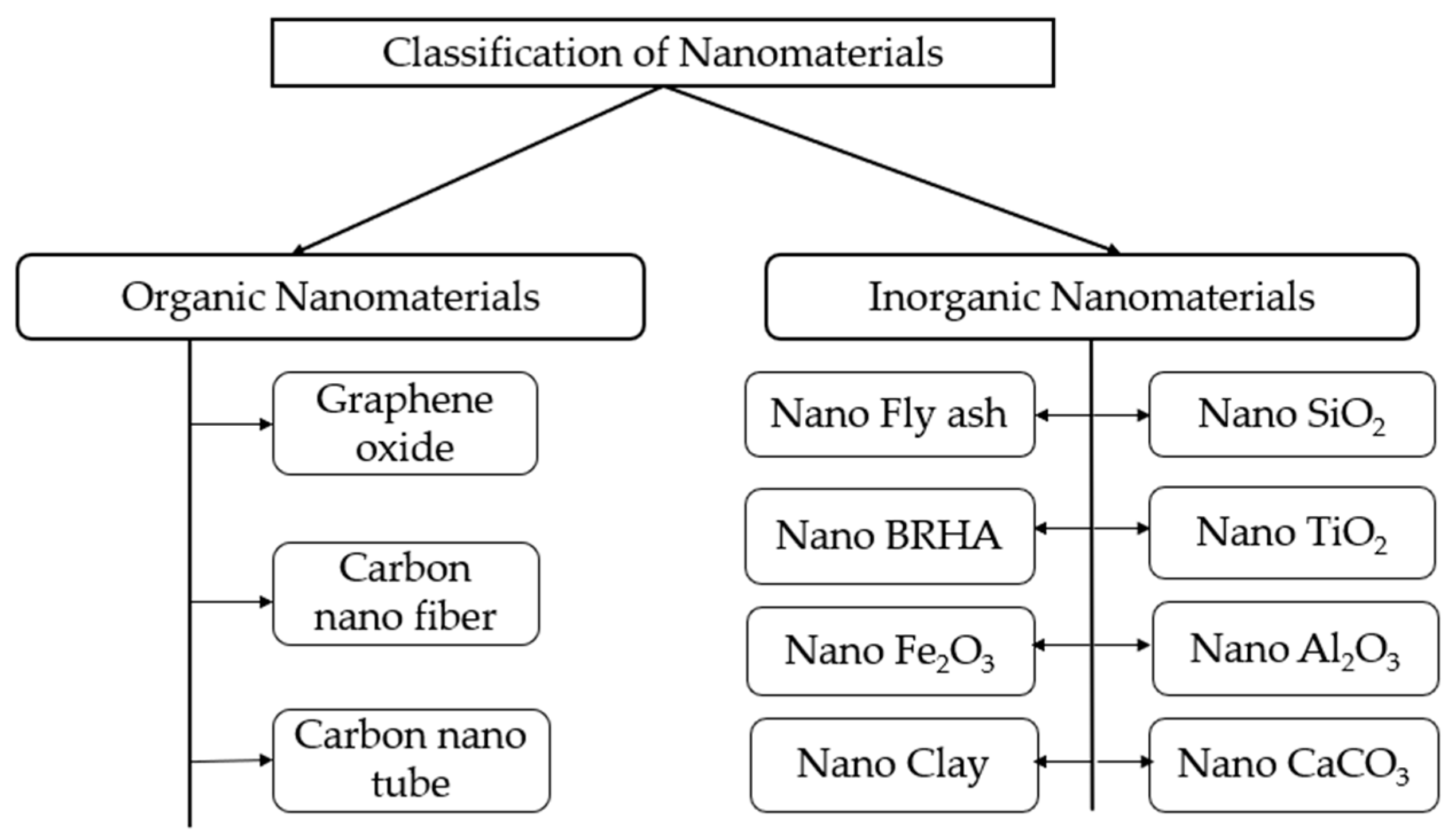

In recent years, the integration of nanoparticles into concrete pavement has emerged from advancements in nanotechnology and materials science. This innovation, dating back to the early 2000s, has sparked extensive exploration by researchers and engineers to leverage nanomaterials’ potential benefits. The primary aim is to enhance concrete’s performance, durability, and sustainability, addressing limitations observed in traditional concrete, such as strength, permeability, and environmental resistance [

2]. Nanomaterials can be categorized into organic and inorganic groups based on their composition and structure. Organic nanomaterials, such as graphene oxide, carbon nanotubes, and carbon nanofibers, are primarily carbon-based. Inorganic nanomaterials are composed of non-carbon elements, including nano SiO

2, nano TiO

2, nano CaCO

3, nano Al

2O

3, nano Fe

2O

3, etc. [

6]. The classification of organic and inorganic nanomaterials is shown in

Figure 1.

1.1.1. Nano SiO2 (Nano Silicon Dioxide)

Nano SiO

2, comprising amorphous silicon dioxide nanoparticles with a size range of 5 to 25 nm, serves as a pozzolanic material in concrete. Its incorporation increases strength, reduces permeability, and improves durability through a pozzolanic reaction with calcium hydroxide during cement hydration [

14,

18,

19].

1.1.2. Nano TiO2 (Nano Titanium Dioxide)

Nano TiO

2, featuring nanoparticles of titanium dioxide ranging from 1 to 15 nm, functions primarily as a photocatalyst in concrete. Its exposure to UV light enables self-cleaning and pollutant-degrading properties, thereby enhancing air quality and aesthetic appeal [

18,

20].

1.1.3. Nano Clay

Nano clay, derived from processed layered silicate minerals, possesses nanoscale particles with a few nanometers thickness and lateral dimensions ranging from 1 to 2 nm. It reinforces concrete, enhancing mechanical properties, reducing crack propagation, and improving durability [

1].

1.1.4. Nano BRHA (Black Rice Husk Ash)

Derived from ground-granulated blast furnace slag, nano BRHA undergoes grinding to achieve nanoscale particle sizes (~66 nm). As a supplementary cementitious material, it enhances concrete properties, including strength, heat of hydration reduction, and workability [

21].

1.1.5. Nano Fe2O3 (Nano Iron Oxide)

Nano Fe

2O

3, comprising iron oxide nanoparticles (1–15 nm), offers magnetic properties and stability. When incorporated appropriately, it acts as a coloring agent and enhances mechanical properties, such as compressive strength and abrasion resistance [

22].

1.1.6. Nano CaCO3 (Nano Calcium Carbonate)

Nano CaCO

3, composed of calcium carbonate nanoparticles (40–50 nm), serves as a filler material in concrete, enhancing mechanical properties, reducing shrinkage, and improving workability [

23].

1.1.7. Nano Al2O3 (Nano Aluminum Oxide)

Nano Al

2O

3, comprising aluminum oxide nanoparticles (8–40 nm), reinforces concrete, enhancing mechanical performance and abrasion resistance and reducing cracking and moisture ingress [

4,

24].

1.1.8. Nano Fly Ash

Nano fly ash, with particle sizes ranging from 1 to 100 nm, exhibits enhanced reactivity and increased surface area compared with conventional fly ash [

24]. It improves concrete workability, strength, and durability, contributing to sustainability and a refined microstructure [

24].

1.1.9. Graphene Oxide (GO)

Graphene Oxide (GO) has unique properties, including high mechanical strength, large surface area, and excellent dispersion in water and other solvents due to its hydrophilic nature. Graphene oxide (GO) is a single layer of carbon atoms arranged in a hexagonal lattice, with each layer approximately 0.08–1 nm thick. The lateral dimensions of GO sheets can range from a few micrometers (µm) to tens of micrometers (µm) [

5,

25].

1.1.10. Carbon Nanofibers (CNFs)

Carbon nanofibers (CNFs) have diameters typically ranging from 150 nm to 200 nm and lengths from 10 μm to 20 μm. CNFs offer high tensile strength and good electrical and thermal conductivity, though generally not as high as CNTs. They also have a high surface area, are beneficial for applications requiring large active surfaces, and have high chemical stability. However, CNFs are less flexible than CNTs due to their larger diameter and less perfect structure [

25].

1.1.11. Carbon Nanotubes (CNTs)

Carbon nanotubes (CNTs) are cylindrical nanostructures with diameters ranging from 0.7 to 3 nanometers (nm) for single-walled carbon nanotubes (SWCNTs) and 2 to 30 nanometers (nm) for multi-walled carbon nanotubes (MWCNTs). The lengths of CNTs can vary from 5 to 15 μm (µm). CNTs exhibit extraordinary tensile strength, surpassing that of steel, and high elasticity. CNTs are chemically stable and have a high aspect ratio, making them ideal for reinforcing materials [

26].

2. Review Methodology

The impact of nanomaterials on the strength and performance of pavement-quality concrete is a significant focus in civil engineering. Incorporating nanotechnology into concrete shows promise for enhancing its performance. The nanomaterials selected for this review, such as nano SiO

2, nano TiO

2, graphene oxide (GO), carbon nanotubes (CNTs), nano CaCO

3, and nano Al

2O

3, were chosen based on their demonstrated effectiveness in enhancing PQC properties. Nano SiO

2 has been widely recognized for improving compressive strength, permeability resistance, and microstructural refinement due to its pozzolanic reaction and micro-filling capability [

13,

14,

27]. Nano TiO

2 enhances abrasion resistance, fatigue performance, and self-cleaning capabilities in concrete pavements, making it particularly beneficial for long-term durability [

20,

28]. Graphene oxide (GO) significantly improves tensile strength, crack resistance, and hydration efficiency due to its large surface area and excellent interfacial bonding with cementitious materials [

16].

Carbon-based nanomaterials such as CNTs and CNFs play a crucial role in crack-bridging and fatigue resistance, extending the pavement’s lifespan under cyclic loading conditions [

29,

30]. Additionally, nano CaCO

3 and nano Al

2O

3 contribute to early strength gain, improved durability, and reduced shrinkage, making them valuable for enhancing PQC performance [

4,

31].

This review aims to summarize existing research, particularly focusing on methodologies. The authors can assess reliability, identify gaps, and suggest future research by analyzing methods. The study follows a content analysis paradigm, integrating qualitative and quantitative approaches. Phases include literature search, methodology examination, identifying gaps, future scope, and conclusion presented in

Figure 2.

2.1. Systematic Review Process

Two international web databases, Scopus and Web of Science (WoS), rated by academics as having a high level of singularity and having the highest data coverage to help form a trustworthy bibliometric investigation, are the subjects of a systematic review of the literature. The search terms “nano AND materials AND concrete AND pavement” are utilized in the Scopus and WoS databases. A total of 298 documents were discovered through the search process, and 215 of them met the inclusion criteria of being published in an engineering journal or conference proceedings in English, being written in English, and being published between 2006 and 2024. Therefore, 55 duplicate papers were eliminated from the remaining 215 documents. Fifty-three articles were chosen from the remaining 160 articles for screening using a two-phase review method (Phase 1: Title and Abstract Screening and Phase 2: In-depth Full-Text Evaluation). Additionally, a few significant publications and standards were added to the screened materials for the literature study. Fifty-eight pieces were ultimately chosen for qualitative, quantitative analysis, and critical debate. An established systematic review approach is shown in

Figure 3.

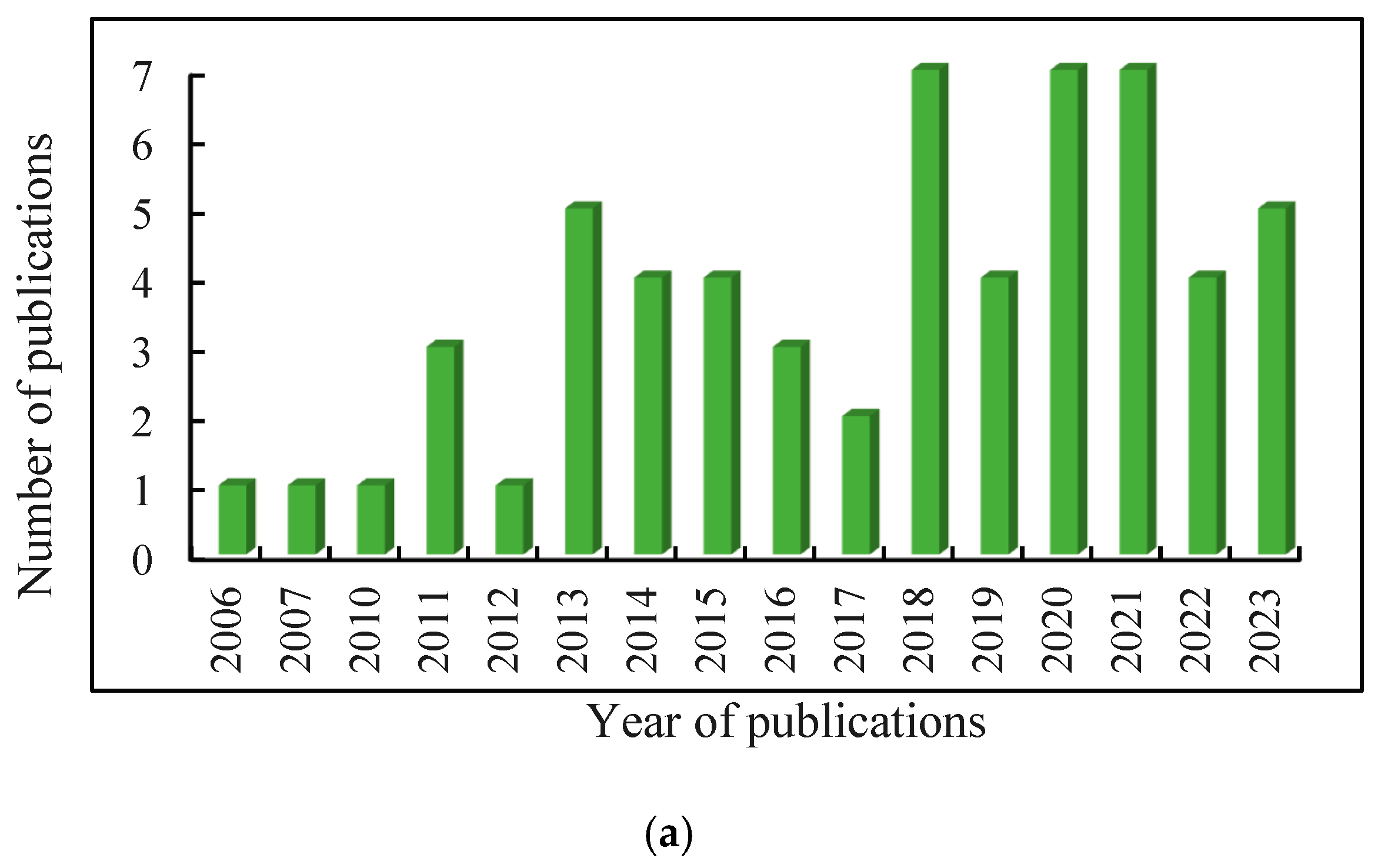

2.2. Distribution of Publication Times and Sources

Figure 4a depicts the publication trend from 2006 to 2023, showing a peak in 2018, 2020, and 2021, indicating a surge in research interest in nanomaterials in concrete pavement. This trend highlights the increasing focus on optimizing the performance of PQC using advanced nanomaterials. Recent studies have particularly explored the influence of nano SiO

2 on permeability and strength improvements [

18,

32], nano TiO

2 on abrasion and fatigue resistance [

28,

33], and graphene oxide on crack resistance and flexural performance [

16,

34].

Additionally, the latest research emphasizes the role of carbon-based nanomaterials in enhancing fatigue performance and crack-bridging mechanisms in PQC [

29]. The increasing number of publications suggests that researchers are shifting towards refining the properties of concrete, pavements using nanomaterials rather than traditional modifications, reinforcing the relevance of this review.

Figure 4b illustrates the global involvement in this research domain, highlighting the international nature of exploration into nanomaterials in concrete pavement.

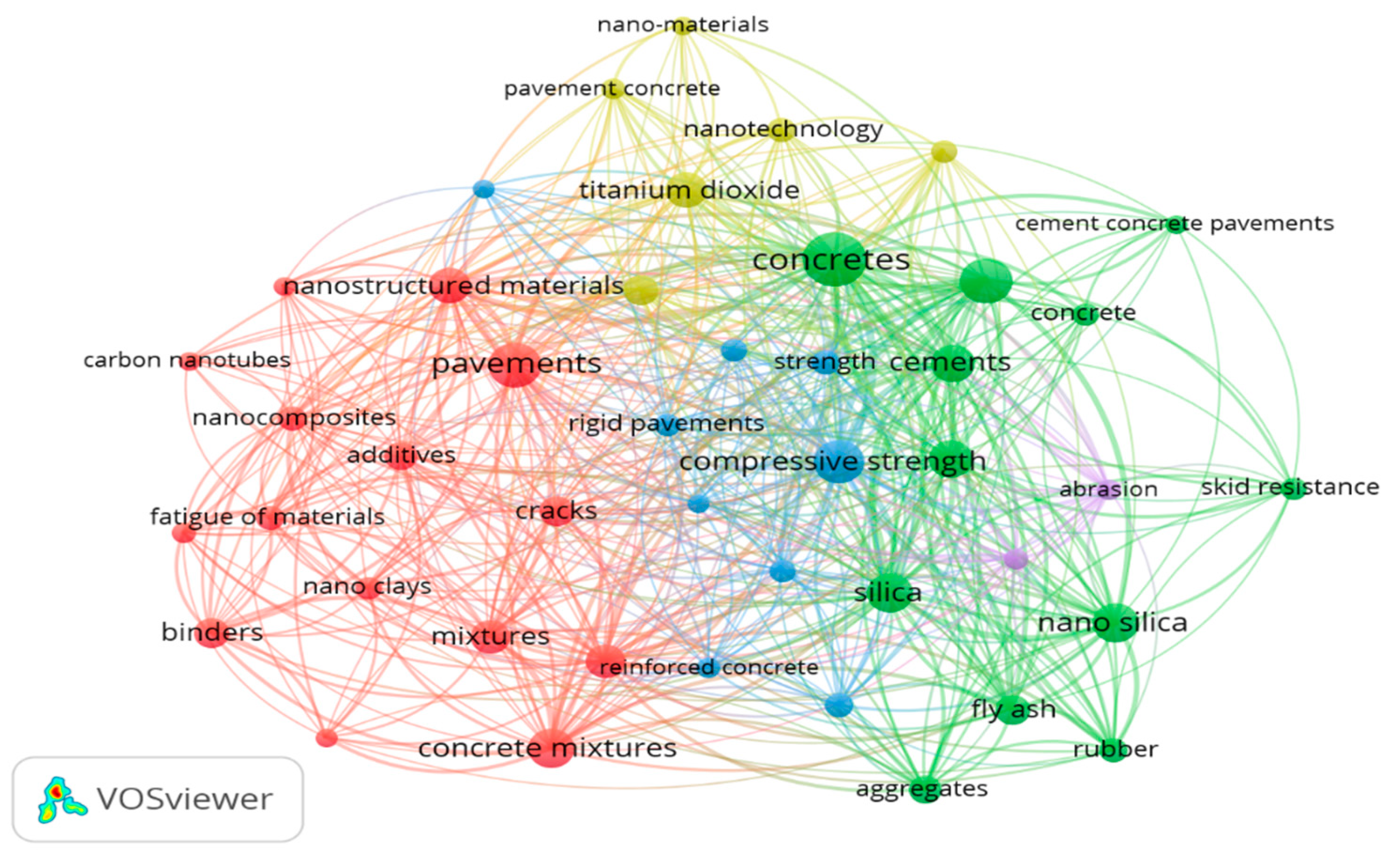

The VOS Viewer software 1.6.19, developed by Nees Jan van Eck and Ludo Waltman at Leiden University is invaluable for bibliographic analysis. In this study, the authors used VOS Viewer version 1.6.19 to perform co-occurrence analysis on selected documents’ keywords, yielding the results shown in

Figure 5. The analysis focused on “All keywords” appearing at least five times, resulting in 44 keywords. The most frequently occurring keywords were “concretes”, “compressive strength”, “nanostructured materials”, and “concrete pavements”. The analysis identified five distinct clusters, each with link strengths surpassing 20. Key terms included “compressive strength”, “nanostructured materials”, “nano-silica”, “durability”, and “cracks”. The strongest co-occurrences were observed between “nano-silica” and “titanium dioxide”, “fatigue”, “flexural strength”, and “pavements”, reinforcing the importance of these materials in PQC applications. The frequent appearance of nano SiO

2 and nano TiO

2 as key terms aligns with findings that these materials significantly improve strength, permeability, and durability [

18,

27,

28]. The association of “fatigue” with carbon-based nanomaterials supports their role in enhancing crack-bridging and long-term performance [

29,

30].

The presence of “cracks” in multiple clusters also suggests that crack-healing nanomaterials such as graphene oxide (GO) and carbon nanotubes (CNTs) are being widely studied for their reinforcement and self-healing properties in pavement concrete [

16,

34]. This keyword analysis validates the selection of materials in this study, as these nanomaterials consistently appear in recent research as critical contributors to PQC performance. These findings underscore the significance of nanomaterials like nano-silica, titanium dioxide, nano clay, and carbon nanotubes in enhancing the strength and longevity of concrete particularly in pavement applications.

3. Review of Literature

The field of nanotechnology has witnessed significant research endeavors in the concrete context. Researchers around the world have explored the potential applications of nanomaterials to enhance the strength and performance of concrete structures. This section concisely reviews the notable work carried out in nanotechnology in concrete.

3.1. Effect of Nanomaterials on Compressive Strength of Concrete

This section presents the behavior of the compressive strength of concrete pavements with various types of nanoparticles, such as nano SiO2, nano TiO2, nano clay, graphene oxide (GO), carbon nanotubes, carbon nanofibers, and nano BRHA.

3.1.1. Impact of Nano SiO2 on Compressive Strength of Concrete

Various researchers conducted experiments to investigate the effect of incorporating 1% nano SiO

2 on the behavior of concrete. Their findings consistently indicate a significant improvement in the compressive strength of concrete, with enhancements ranging from 12.31% to 27% [

5,

6,

7,

13,

20,

35,

36,

37].

Adamu et al. [

13] studied the behavior of 1% nano SiO

2, which was examined in conjunction with different percentages of fly ash. The researchers observed that the compressive strength increased by 42.84% without fly ash and by 52.79% when 50% fly ash was utilized. When nano SiO

2 was combined with fly ash, the pozzolanic reaction between fly ash and the calcium hydroxide was released during hydration, contributing to the formation of additional calcium silicate hydrate (C–S–H) and densifying the cement matrix, thereby significantly enhancing the compressive strength.

Gonzalez et al. [

15] reported on the behavior of nano concrete for rigid pavements, incorporating 1.5% nano SiO

2 in their experiment. They observed a significant increase of 17.81% in the maximum compressive strength compared with conventional concrete.

Zhang [

18] and Zhang et al. [

35] investigated the behavior of concrete by introducing 2% nano SiO

2 based on the weight of cementitious material. Their results demonstrated a notable enhancement in compressive strength, with improvements of 48.88% and 48% compared with conventional concrete, respectively.

Researchers such as Li et al. [

28] and Salemi and Behfarnia [

27] investigated the impact of nano SiO

2 on concrete pavement. Their studies revealed that the inclusion of 3% nano SiO

2 in the concrete mix enhanced the compressive strength by 3.51% and 16.67%, respectively.

Tavakoli et al. [

37] explored the properties of roller-compacted concrete pavement containing various percentages of waste aggregates as a replacement for fine aggregate, along with nano SiO

2. Their findings indicated that incorporating 0.7% nano SiO

2 with 40% ceramic waste, 40% concrete waste, and 40% glass waste led to respective increases of 24.6%, 12.1%, and 19% in compressive strength compared with conventional concrete.

The influence of nanoparticles on the durability of fiber-reinforced concrete pavement by incorporating 5% and 7% nano SiO

2 was evaluated [

27]. They observed significant enhancements in compressive strength, with increases of 30.13% and 23.58%, respectively, compared with the control mix.

Yusak et al. [

38,

39] conducted studies on the behavior of concrete utilizing 10% nano SiO

2, resulting in a consistent increase of 9.08% in compressive strength across both investigations.

Tarangini et al. [

40] conducted a study that yielded significant findings regarding using 3% nano-silica. Their research revealed a substantial 16.03% increase in compressive strength when this nano-silica was incorporated into the material.

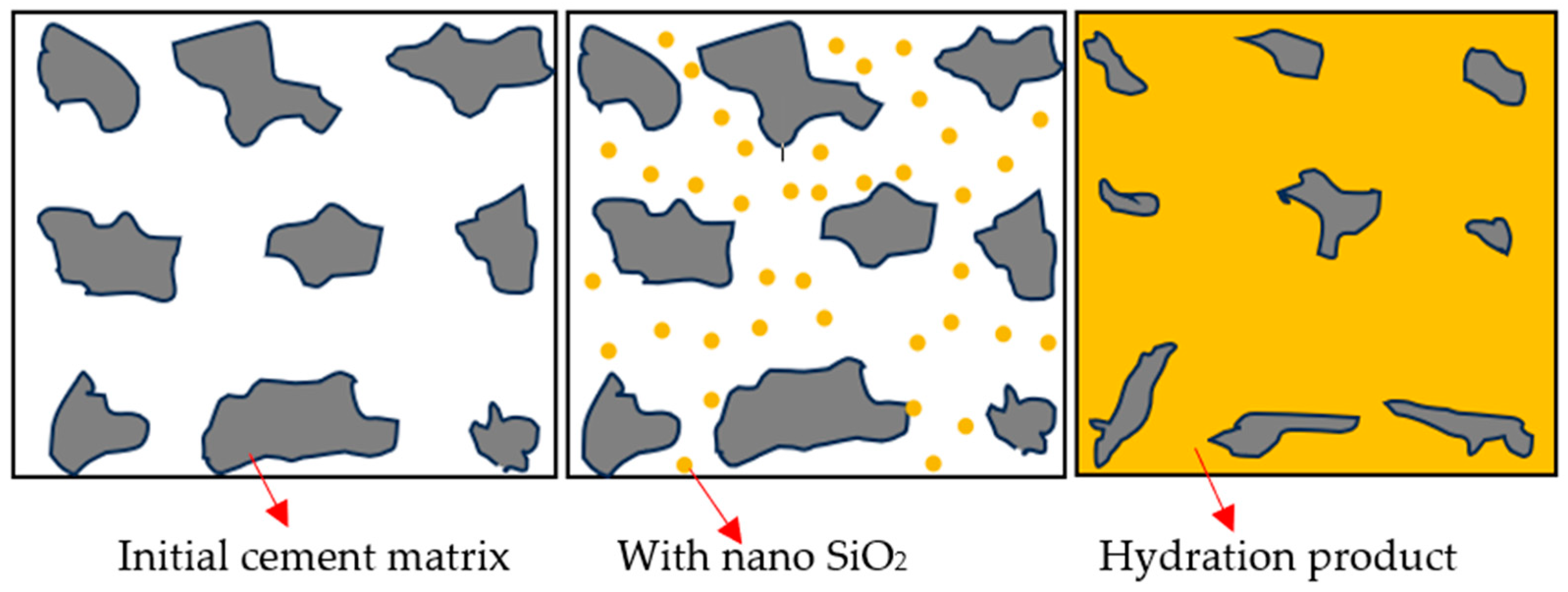

Figure 6 shows the process of cement hydration and the resulting improvement in the pore structure of concrete in the presence of nano SiO

2.

Ling et al. [

41] investigated the effect of polyvinyl alcohol (PVA) fibers and nano-SiO

2 (NS) on the compressive strength of cementitious composites. The study found that adding 0.6% PVA fiber increased compressive strength to 67.3 MPa without NS and 64.3 MPa with NS, representing an enhancement of 8.03% and 8.07%, respectively, compared with the control mix. This enhancement is due to the crack-bridging ability of PVA fibers, which helps resist crack propagation. However, increasing the fiber content beyond 0.6% caused a decline in strength due to fiber agglomeration and increased porosity. Additionally, the inclusion of 2% NS slightly reduced compressive strength, likely due to particle clustering that interfered with proper hydration.

Golewski [

42] studied the effect of nano SiO

2 and coal fly ash (CFA) on concrete’s mechanical properties. The results showed a significant improvement in compressive strength. The addition of 15% CFA and 5% SiO

2 resulted in a 37.68% increase compared with the control concrete. This improvement is attributed to the role of SiO

2, which helps fill pores and microcracks in the cement matrix, resulting in a denser and stronger material.

Zhang et al. [

43] observed that the incorporation of nano-silica (NS) significantly improved the compressive strength of concrete containing coal fly ash (CFA). With an increase in NS content, the compressive strength first rose, reaching a peak of 52.3 MPa at 3% NS, which was a 15.5% improvement compared with the control concrete. The enhancement in compressive strength is attributed to the pozzolanic reaction between NS and calcium hydroxide (Ca (OH)

2) in the cement matrix, forming additional C–S–H gel and strengthening the concrete structure.

Tu et al. [

17] studied the impact of nano-silica (NS) on the compressive strength and microstructure of coal gangue foam concrete (CGFC). They found that incorporating 3% NS led to a significant increase in compressive strength, with improvements of 43% at 3 days and 40.7% at 7 days compared with the control group. NS accelerated the cement hydration process by consuming Ca (OH)₂, promoting the formation of C–S–H gel, which contributed to enhanced early strength. The addition of NS also improved the microstructure, making the cement slurry denser and reducing the average pore size, thus preventing foam merging and stress concentration. The study explored the effects of nano-calcium carbonate (NC) in combination with NS on CGFC. The results indicated that the addition of NC, particularly in a 1:1 ratio with NS, further enhanced the compressive strength of CGFC, with a 7.75% increase at 3 days compared with the NS-only group. NC contributed to the improvement of the microstructure by converting flocculent C–S–H gel into a more organized network structure, effectively filling harmful pores and reducing the connectivity of the pore network, thereby enhancing the material’s overall stability and strength.

3.1.2. Impact of Nano TiO2 on Compressive Strength of Concrete

Several researchers conducted studies on the impact of nano TiO

2 on concrete pavements. Their findings revealed that incorporating 1% nano TiO

2 into conventional concrete caused a significant increase in compressive strength. The compressive strength showed improvement ranging from 18% to 36.30% [

7,

18,

20,

31,

44].

The researchers Li et al. [

28] and Zhang and Li [

44] further investigated the impact of 3% nano TiO

2 on concrete pavement. Their studies demonstrated that the compressive strength improved by 13% and 12.76%, respectively.

3.1.3. Impact of Nano CaCO3 on Compressive Strength of Concrete

Hasaninasab et al. [

31] explored the effect of nano CaCO

3 on the strength and permeability of roller-compacted concrete pavement (RCCP). They found that 1% CaCO

3 yielded the highest observed compressive strength in the RCCP. The utilization of nano-sized CaCO

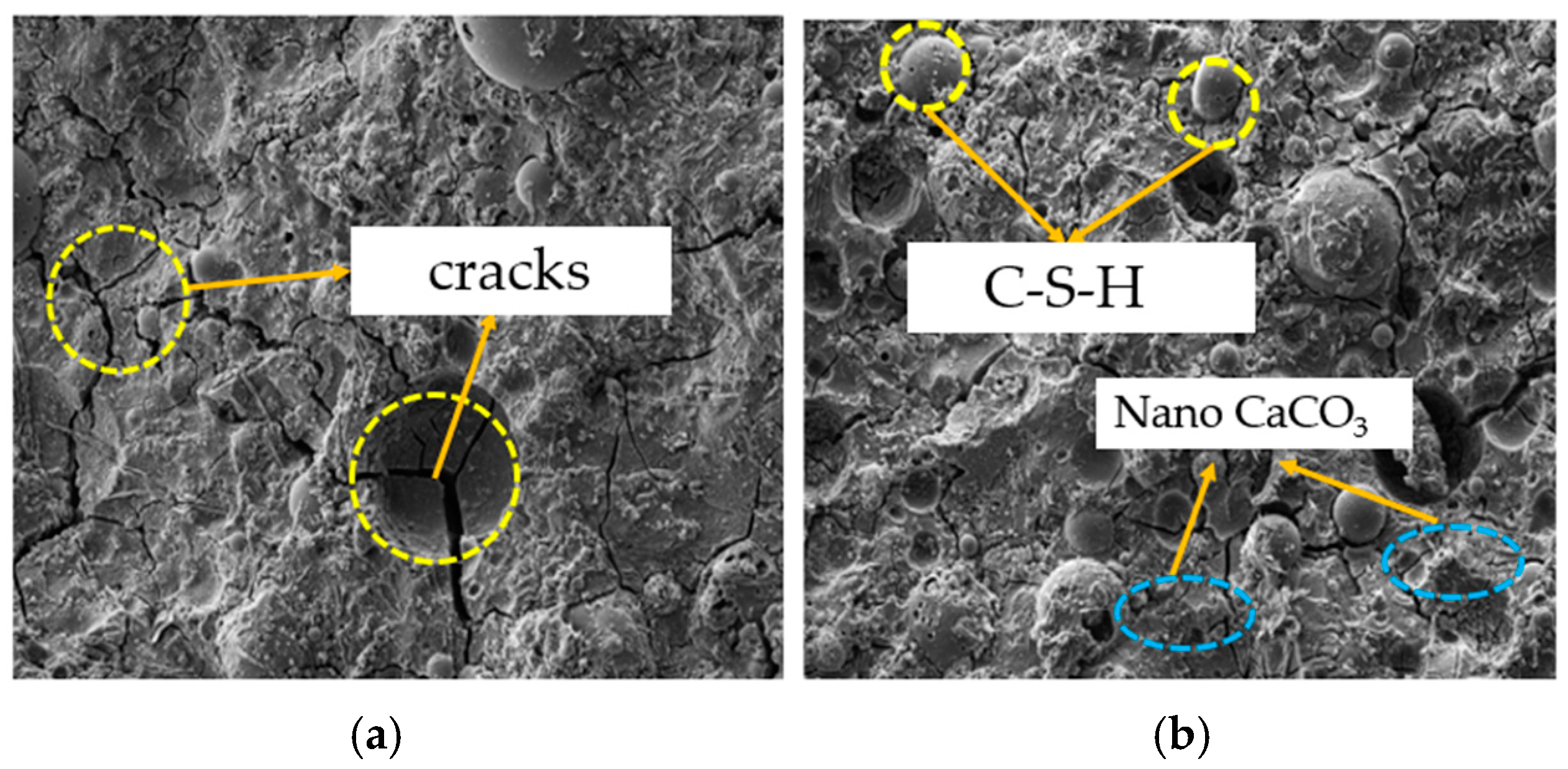

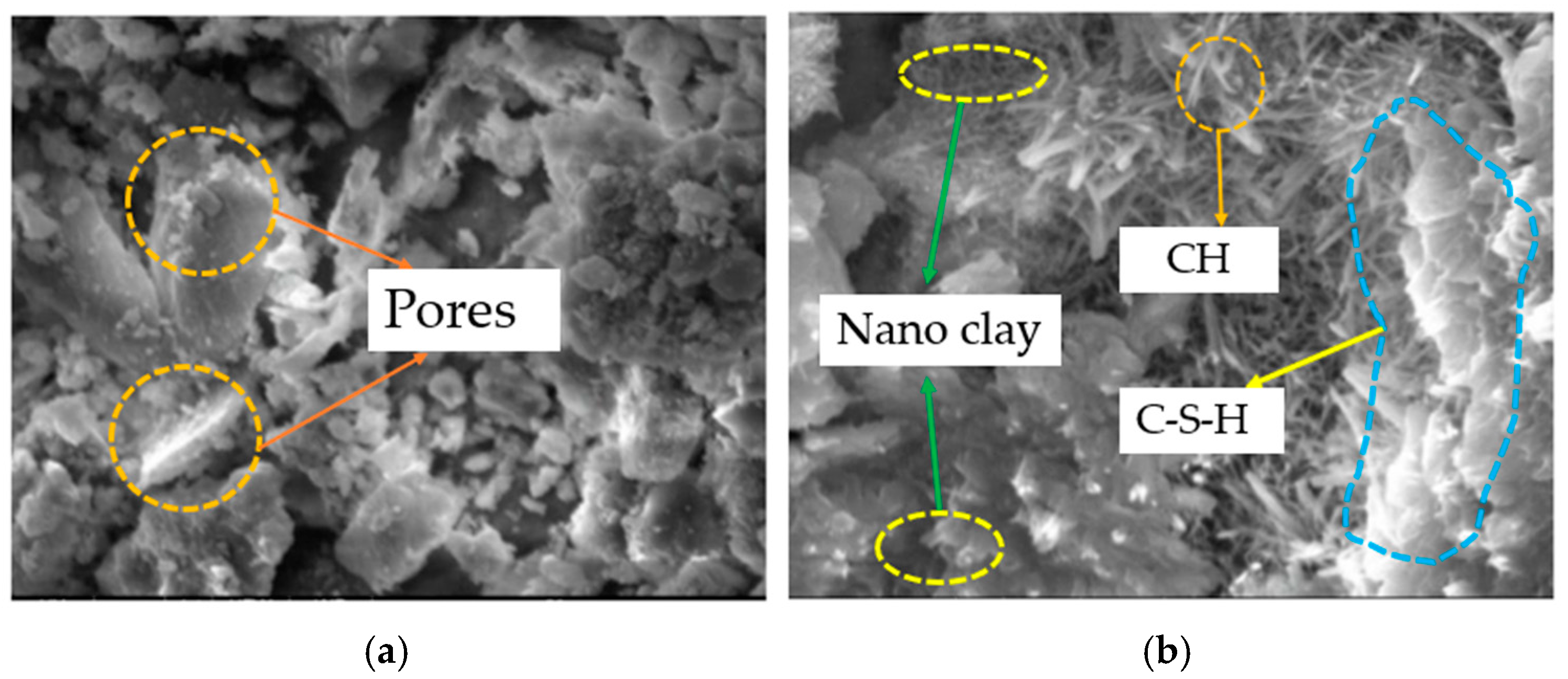

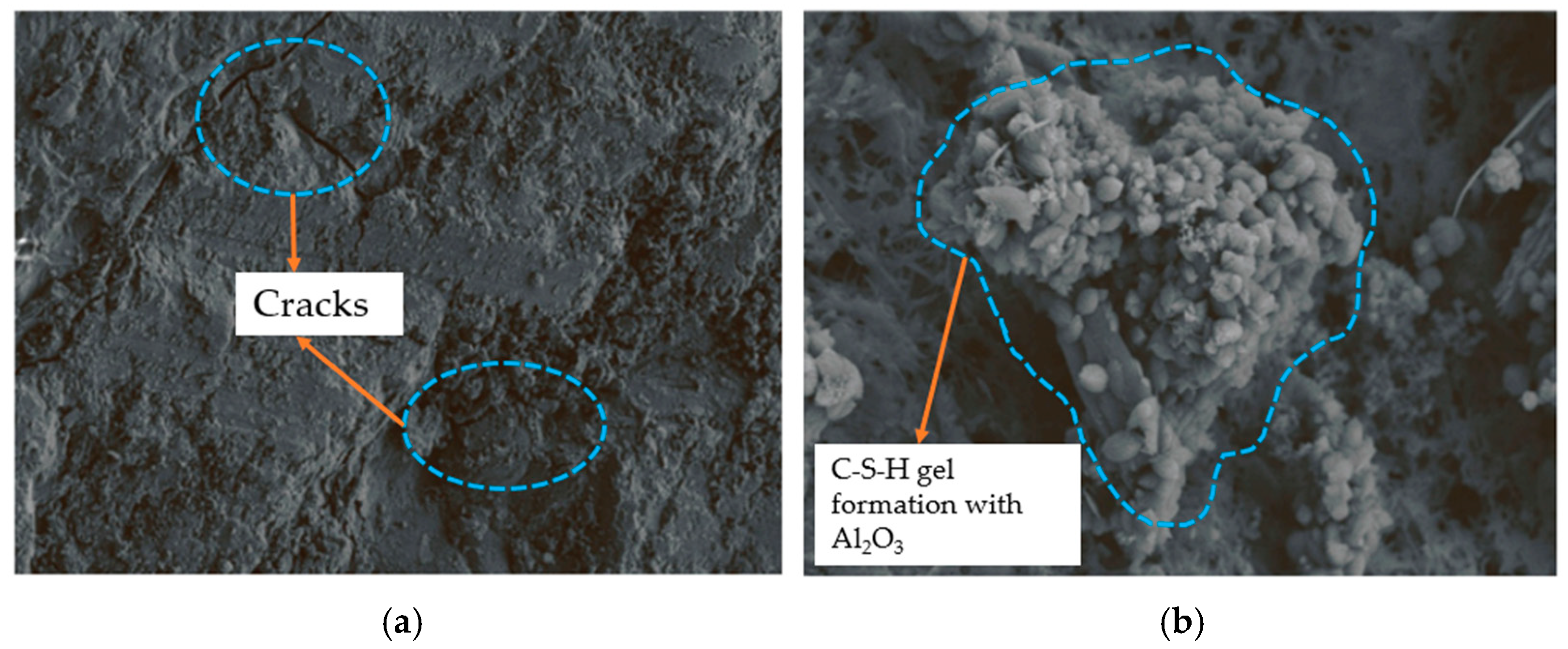

3 particles results in a larger surface area, facilitating improved interaction and bonding with the cementitious matrix. Consequently, this enhanced interaction promotes better interparticle packing and a denser microstructure, increasing the compressive strength of the RCCP. SEM images in

Figure 7 compare concrete samples with and without CaCO

3, demonstrating a more compact and homogeneous microstructure in concrete modified with nanomaterials. This improvement is attributed to the nanoparticles’ pozzolanic reaction and filler function.

Zhang et al. [

46] investigated the effect of nano-CaCO

3 on the compressive strength of concrete incorporating polyvinylalcohol (PVA) fibers and observed a notable improvement when the dosage was maintained at 3%. The compressive strength increased by approximately 12.8% compared with the control mix without nano-CaCO

3. This enhancement is primarily due to the seeding effect of nano-CaCO

3, which accelerates the hydration process by acting as nucleation sites for calcium silicate hydrate (C–S–H) formation. Additionally, the filling effect of nano-CaCO

3 particles helps reduce voids and densify the concrete matrix, leading to increased compressive strength. However, when the dosage was increased to 4%, a reduction in compressive strength was observed, likely due to particle agglomeration and reduced effective bonding between cement particles. This indicates that 3% is the optimal amount of nano-CaCO

3 to achieve maximum compressive strength.

3.1.4. Impact of Nano Al2O3 on Compressive Strength of Concrete

Ahmed and Alkhafaji [

4] examined the effects of nano Al

2O

3 and indicated that adding 1% Al

2O

3 (by weight) provided the best results, with a 9.73% enhancement in compressive strength when compared with standard concrete. The nano Al

2O

3 improved bonding and interparticle interaction within the concrete, which contributed to better load transfer and overall strength.

Salemi and Behfarnia [

27] researched the effect of Al

2O

3 on the fiber-reinforced concrete pavement. The results indicated that the ideal dosage of Al

2O

3, at 2% of the cementitious material’s weight, led to an 11.96% increase in compressive strength relative to the reference mix. The addition of Al

2O

3 nanoparticles in fiber-reinforced concrete pavement improved its durability by enhancing the interfacial bond between the matrix and the fibers. This improved bond resulted in better load transfer and reduced microcracking within the concrete, leading to the observed increase in compressive strength.

3.1.5. Impact of Nano Fe2O3 on Compressive Strength of Concrete

Kumar et al. [

22] studied the effect of nano Fe

2O

3 on high-volume fly ash concrete for pavement construction. The findings showed that adding 0.75% nano iron oxide enhanced the compressive strength when compared with the other control mixes. However, the compressive strength was 28.57% lower than normal concrete.

3.1.6. Impact of Nano Graphene Oxide (GO) on Compressive Strength of Concrete

Fonseka et al. [

16] found that the addition of graphene oxide (GO) significantly enhanced the compressive strength of concrete. Incorporating 0.08% GO into the control mix increased the compressive strength by 21% at 28 days and 19% at 56 days. This improvement was attributed to GO’s ability to create a denser and more cohesive matrix, which reduced micro-cracks and enhanced the overall integrity of the concrete.

Incorporating 0.04% GO by weight into cement paste improved compressive strength by 14% at 28 days. The nucleation sites provided by GO agglomerates accelerated the hydration process and served as seeding material that enhanced the formation of hydration products. This acceleration leads to a refined pore structure, with a more pronounced effect on macropores compared with large and small mesopores. However, concentrations of GO below 0.03% do not contribute positively to compressive strength, indicating the importance of optimal GO content for achieving significant mechanical property enhancements [

47].

Including 0.03% GO resulted in a 38.9% increment in the compressive strength of concrete. This significant enhancement was attributed to the improved microstructure facilitated by GO, which promoted well-distributed hydration products and increased the composite’s load-bearing capacity [

34].

3.1.7. Impact of Carbon Nanotubes (CNTs) on Compressive Strength of Concrete

The compressive strength improved notably with the addition of MWCNTs. Specifically, specimens with 0.03% MWCNTs showed a 4.66% increase at 7 days and a 4.20% increase at 28 days when compared with the control ultra-high-strength concrete (UHSC) sample. The optimal improvement was observed at 0.05% MWCNTs, with a 5.65% increment in the compressive strength of concrete at 7 days and a 4.63% increment at 28 days. This enhancement was attributed to the effective dispersion of MWCNTs, which improved the microstructure and load-bearing capacity of the concrete [

48].

3.1.8. Impact of Carbon Nanofibers (CNFs) on Compressive Strength of Concrete

Wang et al. [

29] explored the impact of CNF content on concrete compressive strength. Their results indicate that incorporating CNFs led to an enhancement in this property. The optimum CNF content for achieving the maximum compressive strength was found to be 0.3%, with a corresponding increase of 9.2% compared with plain concrete.

3.1.9. Impact of Nano Clay on Compressive Strength of Concrete

The research conducted by Ali Shafabakhsh et al. [

1] provides significant insights into enhancing durability in concrete pavement by utilizing nano clay as a modifier. The incorporation of 1% nano clay enhanced the compressive strength, showcasing the potential for nano clay to improve the strength and resilience of the concrete pavements. The study revealed compelling results, as the maximum compressive strength observed in the nano clay-modified concrete pavement was 35% higher compared with the plain concrete (PC), as shown in

Figure 8.

3.1.10. Impact of Nano BRHA on Compressive Strength of Concrete

Ibrahim et al. [

21] and ref. [

50] contributed valuable insights into the effect of nano BRHA and its influence on the compressive strength of concrete. The studies revealed promising results, as the addition of 10% nano BRHA resulted in a rise in compressive strength by 9.08% [

21] and 8.43% [

50] when compared with normal concrete.

3.1.11. Impact of Nano Fly Ash on Compressive Strength of Concrete

In an experimental study conducted by Jabbar et al. [

14], the researchers investigated the behavior of nano fly ash in self-compacting concrete for rigid pavement applications. The study yielded significant findings. Specifically, 5% nano fly ash led to a decrement of 2.24% in compressive strength, while 10% fly ash resulted in a decrease of 3.44% after 28 days. Furthermore, the highest decrement of 8.96% was observed when the concrete contained 15% fly ash. However, the compressive strength increased after 56 days and 90 days. Adding fly ash, especially in higher percentages, affected the particle packing in the concrete mixture. In the short term, this led to a reduction in strength due to changes in the initial microstructure. Over longer curing periods, the concrete underwent further compaction and rearrangement of particles, leading to increased compressive strength.

This section underscores the substantial impact of various nanomaterials on the compressive strength of concrete. Among them, nano SiO2 exhibits the highest enhancement, with improvement ranging up to 48.88%, largely due to improved particle packing, hydration, and reduced porosity. Nano clay and graphene oxide also provide remarkable enhancements of 35% and 38.9%, respectively, while nano TiO2 shows significant improvements, particularly with a 1% dosage, boosting compressive strength by up to 36.30%.

On the other hand, nano CaCO

3 and nano Al

2O

3 contribute to moderate yet notable enhancements in compressive strength, ranging from 9.73% to 30.13%. These improvements are associated with enhanced interparticle bonding and a denser microstructure. Similarly, other materials like nano fly ash initially showed a decrease in strength but demonstrated an increase over extended curing periods. These findings highlight the varied impact of different nanomaterials on concrete’s mechanical properties, with some offering exceptional enhancements and others providing moderate but still valuable improvements.

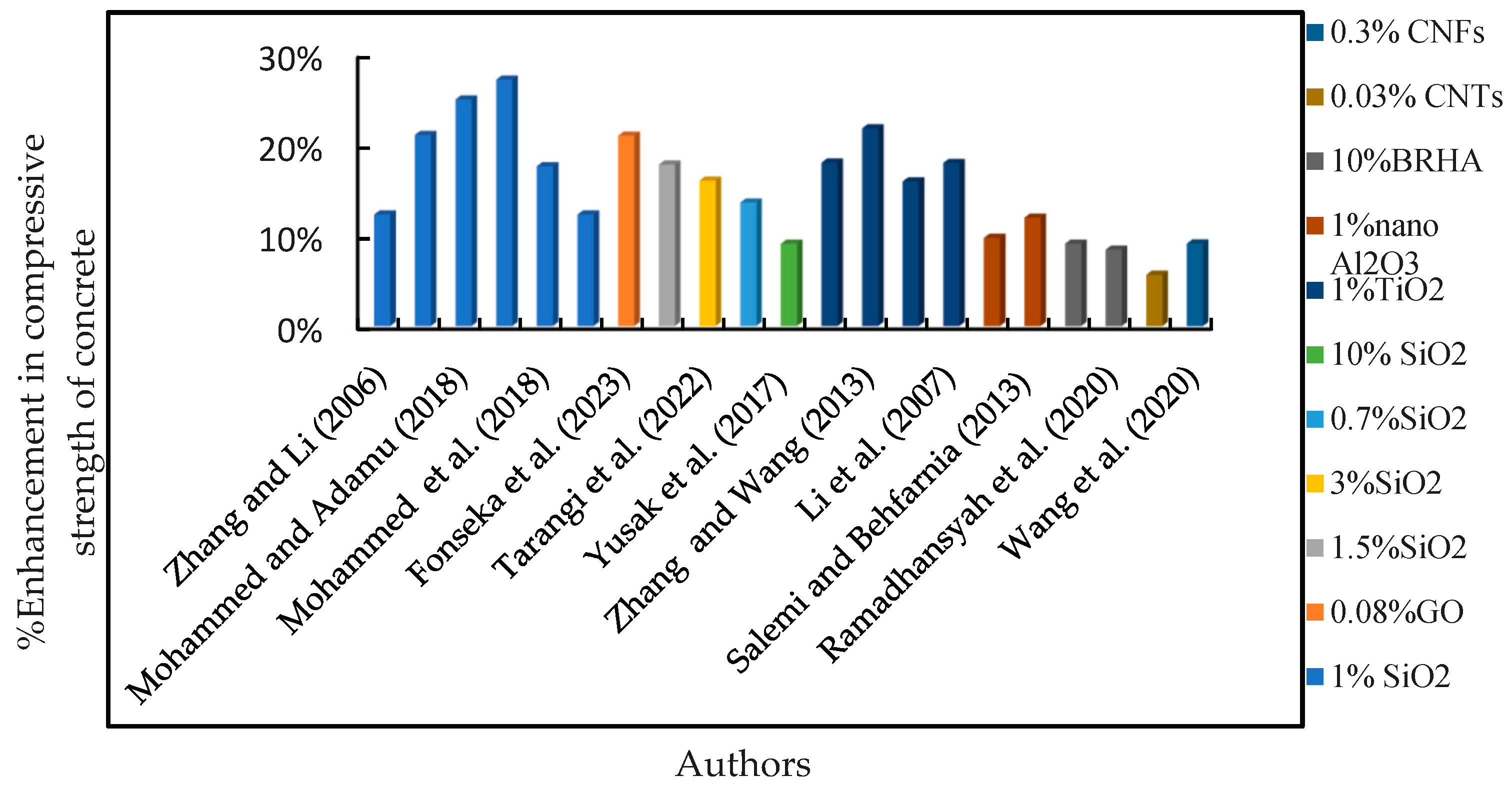

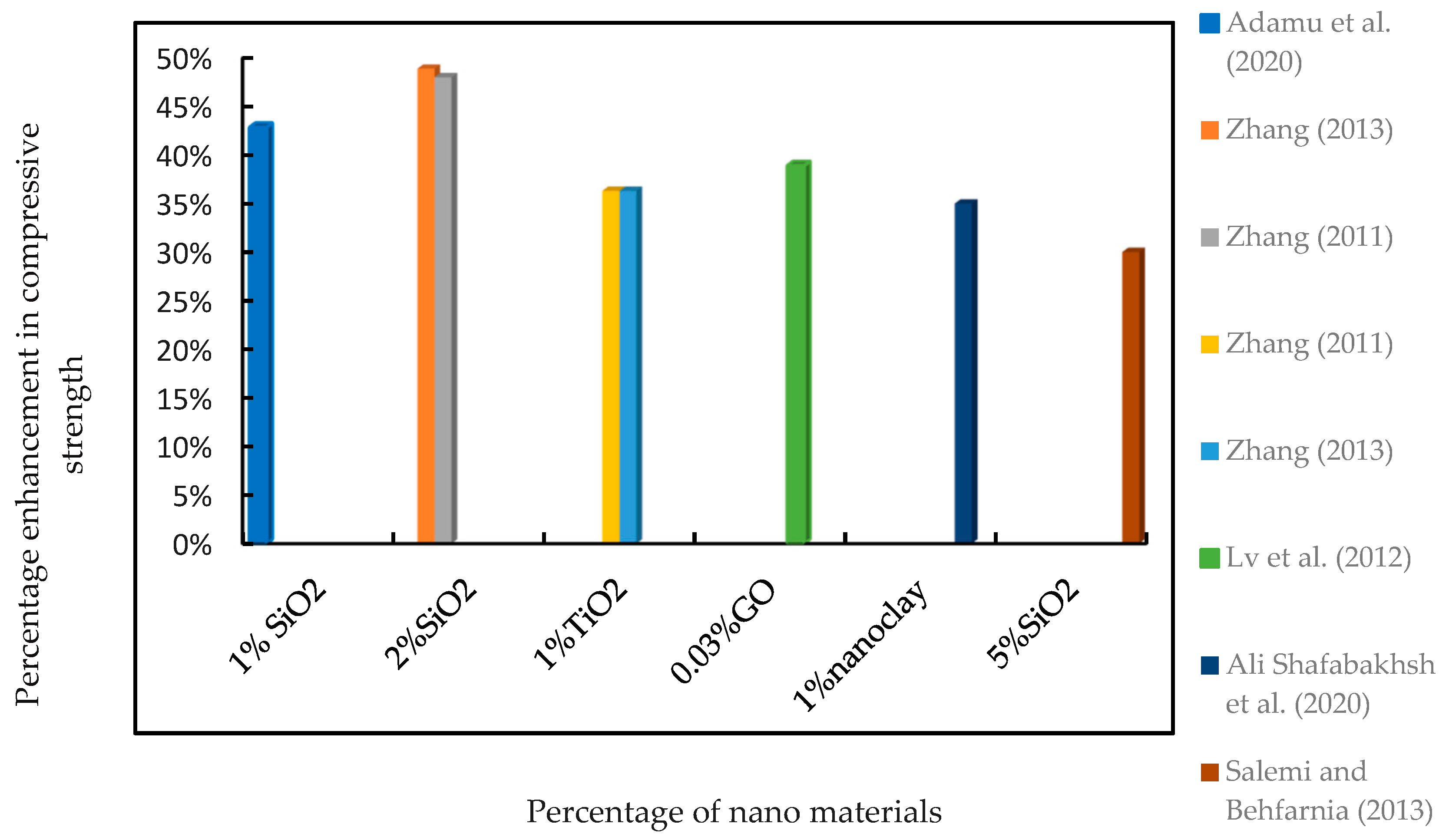

Figure 9 illustrates the improvement in compressive strength of concrete using various nanomaterials at lower concentrations (<30%) by various authors, and

Figure 10 compares the improvement of compressive strength of concrete at higher concentrations (>30%) for different nanomaterials.

3.2. Effect of Nanomaterials on Flexural Strength of Concrete

This section presents the flexural behavior of concrete pavements with various types of nanoparticles, such as nano SiO2, nano TiO2, nano clay, graphene oxide (GO), carbon nanotubes, carbon nanofibers, and nano BRHA.

3.2.1. Impact of Nano SiO2 on Flexural Strength of Concrete

Several researchers have investigated the flexural behavior of concrete by incorporating 1% nano SiO

2, leading to observed enhancements in flexural strength ranging from 4% to 21% [

13,

15,

19,

31,

36,

37,

44,

51].

Khot and Pol [

5] researched the effect of incorporating 1.5% nano SiO

2 with 0.05% graphene in rigid pavement. The findings revealed a notable improvement in the flexural strength of concrete, with an increment of 44.28%.

Zhang and Wang [

20], Zhang et al. [

51], and Zhang [

52] conducted studies using 2% of nano SiO

2 and found flexural strength improved by 12.28%, 30.77%, and 30.77, respectively.

Tarangini et al. [

40] studied and reported that the incorporation of 3% nano-silica into a material led to a substantial 17.43% increment in the flexural strength of concrete. The remarkable enhancement in flexural strength highlights the potential of nano-silica as a valuable additive, offering the prospect of developing materials with superior resistance to bending and deformation.

Ling et al. [

41] investigated and found that the flexural strength of concrete was improved significantly as PVA fiber content increased, with the maximum gain observed at 1.5% PVA fiber, an increase of 114.4% without nano SiO

2 (NS) and 116.4% with NS. This improvement is attributed to the bridging effect of PVA fibers, which enhanced tensile resistance. Unlike compressive strength, flexural strength benefited more from higher fiber content. However, adding 2% NS did not significantly impact flexural performance, as particle agglomeration limited the positive effects of pozzolanic reaction and filling.

Zhang et al. [

43] studied and reported that the flexural strength of concrete was significantly enhanced with the addition of nano SiO

2 (NS), with a 27.3% increase observed at 3% NS, resulting in a peak value of 8.86 MPa. This improvement was attributed to the enhanced bonding between the cement paste and aggregate facilitated by the NS particles, which improves the concrete’s resistance to bending stresses and enhances overall structural integrity.

The enhancement percentages of flexural strength reported in the above paragraph range from 4% to 44.28%. Among the studies mentioned, the investigation by Khot and Pol [

5] focused on rigid pavement and reported the highest enhancement of 44.28% in flexural strength. Graphene is a two-dimensional nanomaterial known for its exceptional mechanical properties, such as high tensile strength and stiffness. Its incorporation into the concrete mixture enhanced the overall structural performance and contributed to increased flexural strength.

3.2.2. Impact of Nano TiO2 on Flexural Strength of Concrete

Several researchers have studied the behavior of concrete by incorporating 1% nano TiO

2, resulting in a notable improvement in flexural strength ranging from 10% to 40%. Zhang [

18], Zhang and Wang [

20], Zhang and Li [

44], Zhang et al. [

51], Zhang and Yu [

51], Li et al. [

8], and Zhang [

35] reported enhancements of 40.29%, 4.93%, 10.28%, 10%, 10.28%, 40.29%, and 10%, respectively.

In their study, Zhang et al. [

51] studied the properties of concrete pavement with 2% nano TiO

2 and observed a significant enhancement of 24.18% in flexural strength.

Li et al. [

28] and Zhang and Li [

36] explored the effects of 3% nano TiO

2 on concrete pavement and found an increment in flexural strength by 2.5% and 3.04%, respectively.

3.2.3. Impact of Nano CaCO3 on Flexural Strength of Concrete

The flexural strength of the concrete also showed improvement with the addition of nano-CaCO

3, achieving a 10.1% increase at the optimal dosage of 3%. This increase can be attributed to the enhanced bond strength at the interfacial transition zone (ITZ) between the aggregate and cement matrix, resulting from the micro-filling capability of the nanoparticles. The presence of nano-CaCO

3 not only promotes the formation of dense C–S–H gel but also fills microcracks, thereby enhancing the material’s resistance to bending forces. However, increasing the dosage beyond 3% led to a decline in flexural strength, which can be associated with the clustering of nano-CaCO

3 particles that hinder uniform dispersion and affect the concrete’s integrity [

46].

3.2.4. Impact of Nano Clay on Flexural Strength of Concrete

Shafabakhsh et al. [

1] focused on examining the durability of concrete pavement by incorporating 1% nano clay. Their findings revealed a noteworthy enhancement of 9% in the flexural strength of the concrete. Nano clay in the concrete mixture enhanced the overall microstructure of the material. As nano-sized clay particles possessed a large surface area and a high aspect ratio, they promoted better interfacial bonding with the cement matrix. This improved bonding helped distribute the load more effectively, enhancing flexural strength.

3.2.5. Impact of Nano BRHA on Flexural Strength of Concrete

In their respective studies, Ibrahim et al. [

21] and Jaya [

53] investigated the performance of porous concrete pavement incorporating 10% nano BRHA. They found improvement in the flexural strength of concrete by 10.75% and 10.01%, respectively. Incorporating nano BRHA improved interfacial bonding between the cementitious matrix and aggregate particles. The nano-sized particles filled in the voids between the larger particles, resulting in a denser microstructure. This densification enhanced the load transfer efficiency within the concrete, contributing to the observed increase in flexural strength.

3.2.6. Impact of Graphene Oxide (GO) on Flexural Strength of Concrete

Lv et al. [

34] found that adding 0.03% GO to cement composites enhanced the flexural strength of cement composites by 60.7%. GO nanosheets contributed to a more robust composite structure, which reduced brittleness and increased toughness, leading to better flexural performance.

3.2.7. Impact of Carbon Nanotubes (CNTs) on Flexural Strength of Concrete

The flexural strength was enhanced by incorporating MWCNTs (multi-walled carbon nanotubes). 0.03% MWCNTs improved flexural strength by 5.11% at 28 days, while at 0.05% MWCNTs, the improvement reached 7.56%. This enhancement was likely due to the enhanced bonding of the cement matrix with the MWCNTs, which enhanced the toughness and resistance to bending [

25].

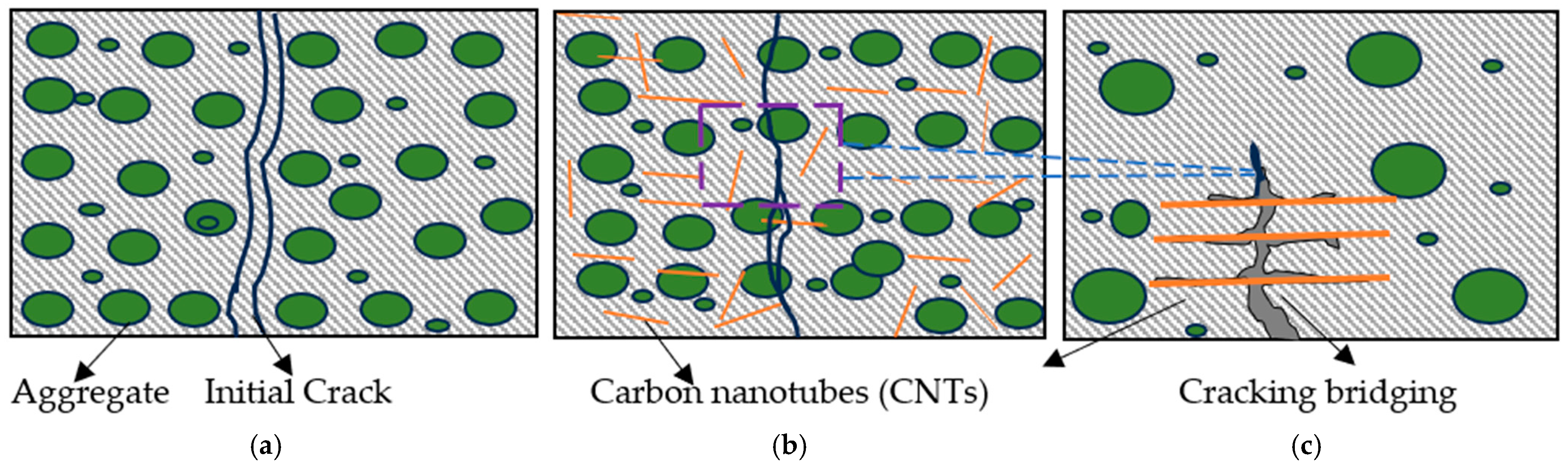

Figure 11a shows an initial crack forming in the concrete matrix,

Figure 11b demonstrates how CNTs, dispersed within the matrix, intersect the crack path, providing reinforcement, and

Figure 11c shows the CNTs bridging the crack, preventing it from propagating further and thereby enhancing the material’s toughness and resistance to fracture.

3.2.8. Impact of Carbon Nanofibers (CNFs) on Flexural Strength of Concrete

According to Wang et al. [

29], the flexural strength of concrete was significantly improved by the addition of CNFs. The optimal CNF content for maximizing flexural strength was 0.3%, with a 13.2% increase compared with plain concrete. Exceeding this CNF content resulted in a decrease in flexural strength.

Liu et al. [

30] explored the effect of incorporating carbon nanofibers (CNFs) at 0.04% (by weight) on the flexural strength of concrete. They found 7.4% and 17.7% higher flexural strength in nanofiber concrete compared with ordinary fiber concrete and plain concrete, respectively. This enhancement in flexural strength indicated that nanofiber-reinforced concrete possesses superior load-bearing capacity and resistance to bending forces.

This section underscores the substantial effect of various nanomaterials on the flexural strength of concrete. Among the various nanomaterials studied, graphene oxide (GO) and nano SiO

2 consistently demonstrated the most significant improvements in flexural strength. The highest enhancement in flexural strength, up to 60.7% with 0.03% graphene oxide (GO), is because of the ability of the graphene oxide (GO) to transfer load and prevent microcrack propagation within the concrete matrix. Additionally, 1.5% nano SiO

2 with 0.05% GO achieves significant improvements through the synergistic effect of SiO

2’s pozzolanic reaction and GO’s structural reinforcement. Nano TiO

2 with 1% and nano BRHA with 10% dosage also showed promising results, with increases ranging from 10% to 40%. Carbon nanomaterials like CNTs and CNFs offered moderate enhancements, typically around 10%. CNTs were effective at 0.05%, while CNFs showed improvements at 0.3% and 0.04%. Overall, the effectiveness of nanomaterials in enhancing flexural strength depends on the type of nanomaterial, dosage, and combination with other materials, etc.

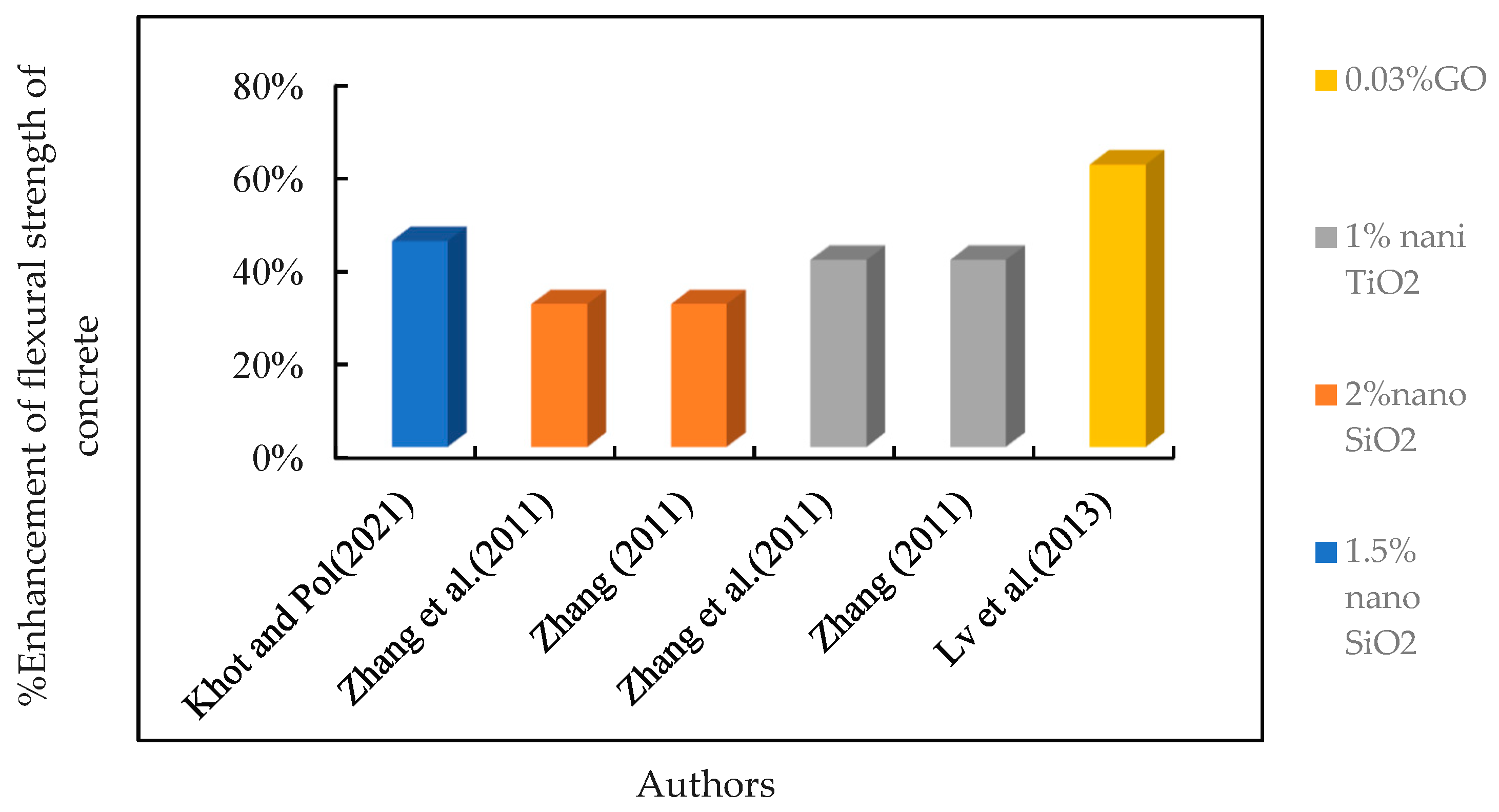

Figure 12 presents the graph that shows the relationship between the enhancement of flexural strength of concrete pavement after 28 days of curing and different percentages of nanomaterials according to various authors.

Figure 12 illustrates the enhancement in the flexural strength of concrete using various nanomaterials at lower concentrations (<30%) by various authors, and

Figure 13 illustrates the enhancement in the flexural strength of concrete using various nanomaterials at higher concentrations (>30%) for different nanomaterials.

3.3. Effect of Nanomaterials on Split Tensile Strength of Concrete

The split tensile strength of pavement-quality concrete depends on the nanoparticle’s type, quantity, and size. Generally, adding nanoparticles to the concrete mixture will improve the split tensile strength of the concrete pavement. This section shows how different percentages of nanomaterials, such as nano SiO2, nano TiO2, graphene oxide (GO), nano clay, nano CaCO3, nano Fe2O3, carbon nanofibers, and nano-BRHA, can improve the split tensile strength of concrete pavement.

3.3.1. Impact of Nano SiO2 on Split Tensile Strength of Concrete

Mohammed and Adamu [

7] reported an enhancement of 21.4% by using 1% nano SiO

2 and 30% crumb rubber to partially replace fine aggregate, while Zhang et al. [

51] observed a substantial improvement of 33.33% by using 1% nano SiO

2.

Furthermore, Khot and Pol [

5] studied the impact of adding 1.5% nano SiO

2 along with 0.05% graphene on the rigid pavement. Their findings showed an impressive increase of 42.29% in the split tensile strength of the concrete, as the combination of graphene and nano SiO

2 helped in achieving more uniform dispersion in the cement matrix, which reduced the agglomeration and improved the microstructure.

The study by Zhang [

35] and Zhang et al. [

51] focused on the properties of pavement concrete with the incorporation of 2% nano SiO

2. Both studies revealed notable enhancements in split tensile strength, with 52.50% and 52.80% improvements, respectively. This enhancement was attributed to the high reactivity and fineness of nano SiO

2, which contributed to a more refined and homogenous structure. Nano SiO

2 particles filled the micro-pores within the cement matrix and promoted the formation of additional calcium silicate hydrate (C–S–H), which led to stronger interfacial bonding of cement paste with the aggregates. This resulted in improved tensile properties and greater resistance to cracking under tensile stresses.

Tavakoli et al. [

37] investigated the properties of concrete pavement incorporating waste aggregate and nano SiO

2. They found that using 0.7% nano SiO

2 with 40% ceramic waste and 40% waste glass fiber resulted in an 18% and 12.76% improvement in split tensile strength, respectively. However, when 40% waste concrete was used with 0.7% nano SiO

2, the split tensile strength was found to be similar to the control mix.

In a laboratory investigation on nano-silica in concrete pavement conducted by Tarangini et al. [

40], a significant and impressive 29.32% increment in split tensile strength was observed when 3% nano-silica was added to the concrete mixture. Nano SiO

2 possesses unique properties that allow it to fill the gaps and voids within the concrete matrix at a nanoscale level. This results in improved interlocking and bonding of particles, thereby increasing the overall cohesion and tensile strength of the concrete.

Golewski [

42] studied the effect of nano-silica (nS) and coal fly ash (CFA) on concrete’s mechanical properties. The results showed a significant improvement in splitting tensile strength. With the addition of 15% CFA and 5% nS, the splitting tensile strength increased by 36.21%. The enhanced tensile properties are due to the synergistic effect of nS and CFA, which together improve the microstructure and bonding in the matrix, making the concrete more resistant to cracking under tensile stress.

Zhang et al. [

43] reported that the splitting tensile strength of concrete also improved with the addition of nano SiO

2 (NS). The highest increase in tensile strength (19%) was observed at 2% NS, with a peak value of 4.51 MPa. This improvement can be linked to the refining of the concrete’s pore structure due to the presence of NS particles, which reduces crack propagation and enhances the material’s ability to withstand tensile forces.

3.3.2. Impact of Nano TiO2 on Split Tensile Strength of Concrete

Zhang [

35] and Zhang et al. [

51] conducted studies on the properties of pavement concrete incorporating 1% nano TiO

2. Both studies observed a significant enhancement in the split tensile strength of concrete, of 32.73% and 32.73%, respectively. Nano TiO

2 particles acted as nucleation sites during the cement hydration process. This promoted the formation of calcium silicate hydrate (C–S–H) gel, which enhanced the densification and cohesion of the concrete matrix. A denser matrix with improved cohesion contributed to the increased split tensile strength of concrete.

3.3.3. Impact of Nano Fe2O3 on Split Tensile Strength of Concrete

Kumar et al. [

22] studied the impact of Fe

2O

3 on concrete pavement. They found that incorporating 0.75% nano iron oxide alone did not significantly improve the split tensile strength of concrete. However, when high-volume fly ash concrete (HVFAC) was used in combination with 0.75% nano Fe

2O

3, the split tensile strength exhibited a noticeable enhancement of 7.14%. The incorporation of HVFAC contributes to the overall reduction in the ratio of the water-to-cementitious material, resulting in improved hydration and densification of the cementitious matrix. This, in turn, leads to increased strength and enhanced performance.

3.3.4. Impact of Nano Clay on Split Tensile Strength of Concrete

Ali Shafabakhsh et al. [

1] focused on examining the durability of concrete pavement through the incorporation of 1% nano clay. The result showed a significant enhancement of 34% in the split tensile strength of concrete. Nano clay in concrete pavement positively impacted the split tensile strength due to improved interfacial bonding, densification of the matrix, and reduced porosity.

3.3.5. Impact of Nano BRHA on Split Tensile Strength of Concrete

Ibrahim et al. [

10] studied the performance of porous concrete pavement by incorporating 10% nano BRHA and found that the split tensile strength of concrete improved by 8.26%. Nano BRHA enhanced the interfacial bonding between the aggregate particles and cementitious materials, which improved the load transfer and the distribution of stresses within the concrete. This improved interfacial bonding contributes to the observed increase in split tensile strength.

3.3.6. Impact of Nano CaCO3 on Split Tensile Strength of Concrete

Hasaninasab et al. [

31] studied the impact of incorporating 0.5% and 1% nano CaCO

3 on the concrete mix and observed an improvement of 4.91% and 13.11%, respectively, in the split tensile strength of concrete.

3.3.7. Impact of Nano Fly Ash on Split Tensile Strength of Concrete

Jabbar et al. [

24] examined the behavior of self-compacting concrete incorporating nano fly ash for rigid pavement applications. They found when 5% fly ash was used in the concrete, a significant increase of 9.73% in split tensile strength was observed. Similarly, with 10% fly ash, the results demonstrated an 11.04% increment in split tensile strength. Additionally, utilizing 15% fly ash led to a noteworthy increase of 9.73% in split tensile strength.

3.3.8. Impact of Nano Graphene Oxide (GO) on Split Tensile Strength of Concrete

Incorporating graphene oxide (GO) into cement composites showed substantial benefits in enhancing mechanical properties and durability. Specifically, the addition of 1.5% GO increased tensile strength by 48% due to the uniform dispersion of GO flakes and strong interfacial bonding within the cement matrix. The use of advanced characterization techniques, such as FE-SEM, confirmed the effective distribution of GO and the robust interaction with the cement matrix, and the XRD analysis revealed that GO promoted the growth of calcium silicate hydrate gels, which was pivotal in improving the composite’s microstructure, reducing permeability, and consequently enhancing its durability [

54].

In their study, Lv et al. [

34] explored that the presence of 0.03% GO increased the tensile strength of cement composites by 78.6% compared with those without GO. This improvement was due to the ability of GO to refine the microstructure by regulating the formation of hydration crystals, which enhanced tensile performance.

3.3.9. Impact of Carbon Nanofibers (CNFs) on Split Tensile Strength of Concrete

The research conducted by Wang et al. [

29] demonstrated a substantial enhancement in the splitting tensile strength of concrete through the incorporation of CNFs. The most significant improvement of 17.5% was achieved at a CNF content of 0.3%. These findings underscore the effectiveness of CNFs in improving the tensile properties of concrete. While higher CNF contents also led to increases in splitting tensile strength, the optimum value for this property was determined to be 0.3%.

Liu et al. [

30] examined the impact of 0.04% carbon nanofibers (CNFs) on the split tensile strength of concrete. They found that the split tensile strength of nanofiber-reinforced concrete was improved by approximately 9.8% over ordinary fiber concrete and 16.7% over plain concrete. These improvements indicate that nanofiber concrete can resist tensile stresses and crack formation, enhancing the material’s overall durability and structural integrity.

This review highlights the effect of various nanomaterials on the split tensile strength of concrete, with a focus on identifying those that provide the most significant improvements. The highest enhancement was observed with 1.5% graphene oxide (GO), which increased tensile strength by 48% due to its uniform dispersion and strong interfacial bonding within the cement matrix. Additionally, 0.03% GO further increased tensile strength by 78.6%, attributed to the capability of graphene oxide to improve the microstructure and enhance hydration crystal formation. Moderate enhancements were also noted with other nanomaterials, such as carbon nanofibers (CNFs) and nano clay. CNFs, particularly at a 0.3% dosage, improved split tensile strength by 17.5%, with smaller improvements at other dosages. Nano clay at 1% resulted in a 34% increase, owing to better interfacial bonding and matrix densification. Other materials like nano Fe₂O₃ combined with high-volume fly ash concrete (HVFAC) and nano BRHA showed smaller but notable improvements in tensile strength, emphasizing the importance of material selection and dosage in optimizing concrete performance.

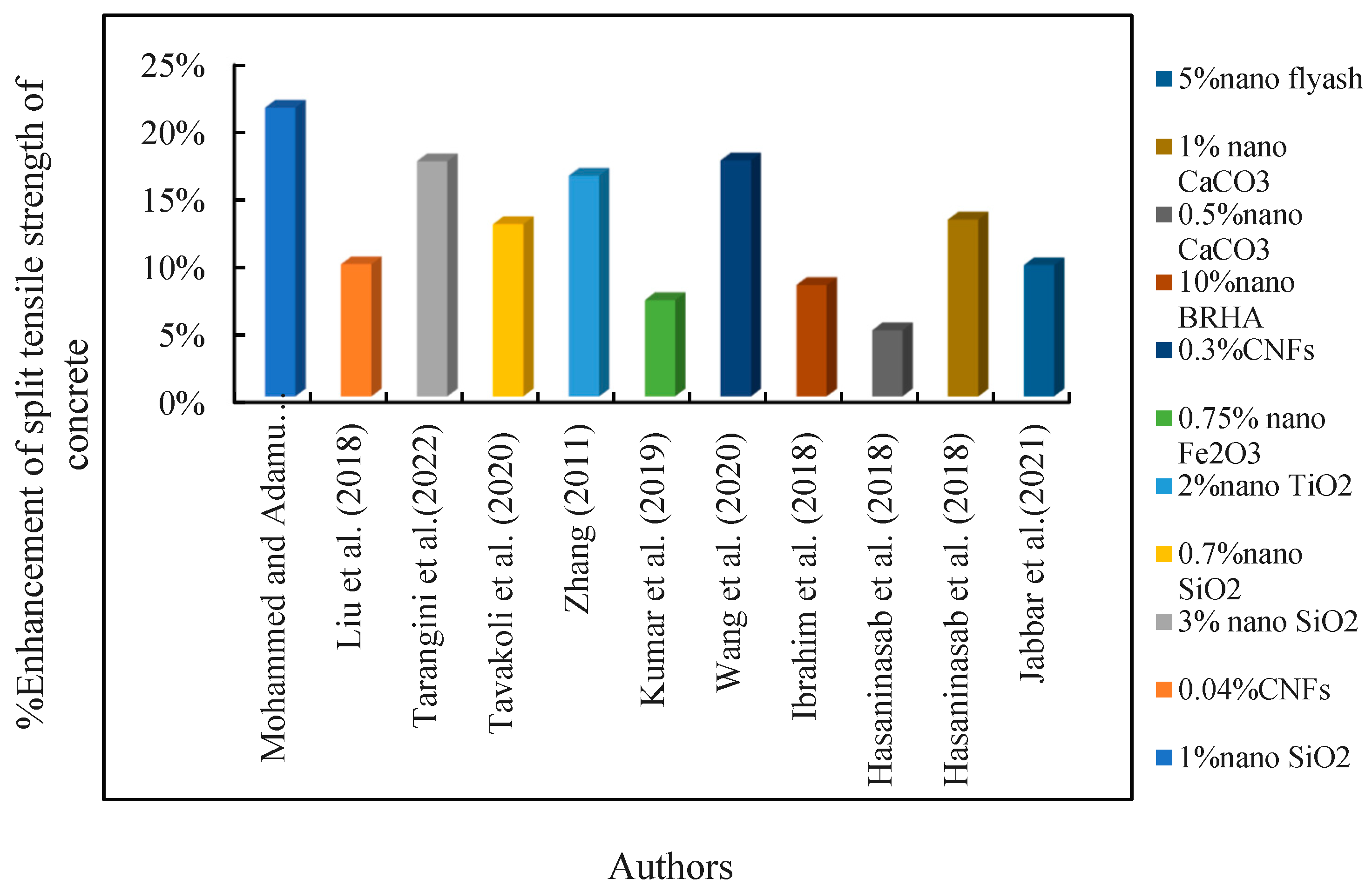

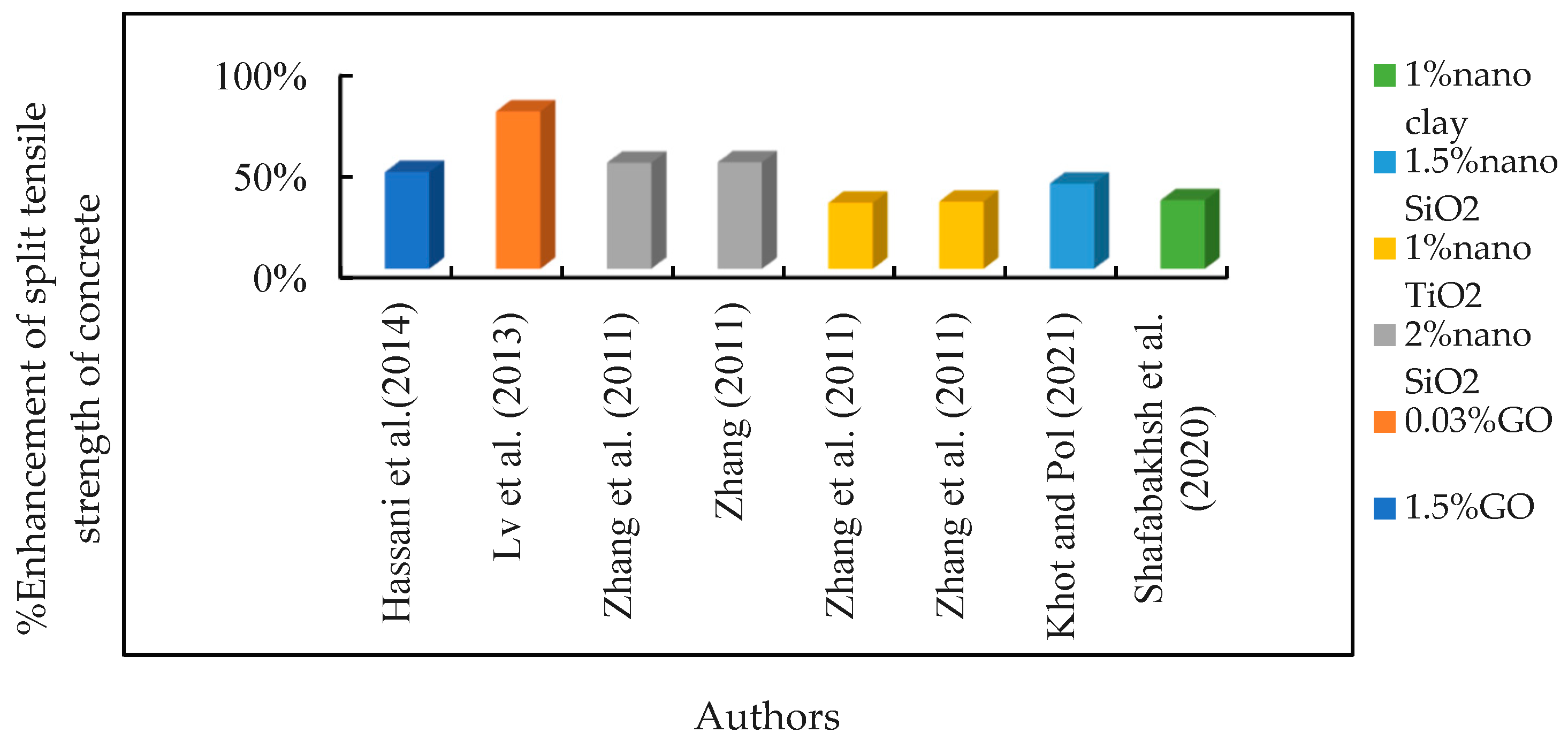

Figure 14 illustrates the improvement of the split tensile strength of concrete using various nanomaterials at lower concentrations (<30%) by various authors, and

Figure 15 compares the improvement of the split tensile strength of concrete using various nanomaterials at higher concentrations (>30%) for different nanomaterials.

3.4. Impact of Nanomaterials on the Permeability of Concrete

Permeability in concrete refers to its ability to allow the passage of fluids, typically liquids like water or gases, through its pores and capillaries. It is a critical property in construction and civil engineering since excessive levels can result in numerous problems, such as diminished durability, corrosion of reinforcements, and heightened susceptibility to freeze–thaw cycles. This section discusses the influence of nanomaterials, such as nano-silica, nano clay, nano CaCO3, and carbon nanomaterials, on the permeability and water absorption of concrete pavement.

3.4.1. Impact of Nano SiO2 on the Permeability of Concrete

In a study conducted by Abbas and Abbas [

32], the investigation focused on water penetration depth in concrete mixes. They found that the lowest water penetration depth was achieved when using 3% nano-silica in combination with 0% lightweight aggregates (LWA). In this scenario, the water penetration depth was measured at an impressive 11.5 mm. This outcome starkly contrasted with the control mix, where the water penetration depth was notably higher at 15 mm. These findings underscore the efficiency of incorporating nano SiO

2, particularly in the absence of lightweight aggregates, as it reduced the permeability by 30.43% and enhanced its resistance to water penetration.

The addition of nano-silica at a concentration of 2% can reduce water absorption by up to 58% [

55]. This is attributed to the ability of nano-silica to fill the micro-pores within the cement matrix, thereby reducing the overall porosity and enhancing the density of the concrete. They also found that nano SiO

2 at a low concentration of 0.3% can reduce chloride migration by 28.7%. This improvement is linked to the densification of the cement matrix and the refinement of pore structure as nano-silica reacts with calcium hydroxide through a pozzolanic reaction.

Salemi and Behfarnia [

27] examined the impact of nanoparticles on the durability of fiber-reinforced concrete pavement. Notably, they discovered a substantial reduction in permeability when 7% nano-silica was incorporated into the concrete mixture. Specifically, the permeability was reduced by an impressive 31.91% compared with the control group. This significant decrease in permeability was identified as the optimal percentage for achieving enhanced durability in fiber-reinforced concrete pavement.

Sun et al. [

56] conducted a study to investigate the permeability of cement concrete pavement when nano SiO

2 was used as an admixture. The initial findings indicated that the introduction of fly ash as an admixture slightly reduced the permeability of the cement concrete. However, the inclusion of nano SiO

2 had a more significant and variable outcome on permeability. Notably, the permeability of the concrete with 2% nano SiO

2 was reduced by a significant 45.2%. Following closely, the permeability of concrete with 3% nano SiO

2 was also reduced by 37%.

Kumar et al. [

22] investigated the impact of nano SiO

2 on the strength and durability of concrete pavement. Their research revealed that the addition of 2% nano SiO

2 to High-Volume Fly Ash Concrete (HVFAC) containing 55% fly ash proved to be highly suitable for use as pavement-quality concrete. Notably, HVFAC with 2% nano-silica demonstrated significant improvements in permeability compared with normal concrete (NC), with a remarkable 115% 66.67% increase in permeability coefficient levels (from 6.00 × 10

−8 to 1.00 × 10

−7 cm/s). These findings underscore the potential of nano SiO

2 as a valuable addition to enhance the performance and durability of concrete in pavement construction.

In their study, Wang et al. [

57] examined the effect of nano SiO

2 on the permeability of cement-based composites. They found that PVAF-RCC (polyvinyl alcohol fiber-reinforced cementitious composites incorporating 1.5% nano-SiO

2 exhibited superior anti-permeability properties, achieving 150% performance compared with composites containing only PVA (polyvinyl alcohol) fibers. Furthermore, the same composition showed enhanced resistance to chloride salt erosion, reaching 103.6% of the resistance level of composites with only PVA (polyvinyl alcohol) fibers.

3.4.2. Impact of Nano TiO2 on the Permeability of Concrete

In a study by Ma et al. [

33], it was found that incorporating nano TiO

2 into concrete significantly enhances its durability properties. Specifically, when the nano TiO

2 content is increased to 3% at 28 days, a marked reduction of 65% in water absorption indicates a substantial advancement in the resistance of concrete to water ingress. Additionally, the water absorption coefficient experiences a decline of over 40%, further highlighting the improved performance. The study also reveals a significant decrease in the water-vapor permeability coefficient, with a reduction of 43.9% compared with mortars without nano TiO

2. These results highlight the potential of nano TiO

2 to significantly enhance the impermeability and durability of concrete materials.

3.4.3. Impact of Nano BRHA on the Permeability of Concrete

Hainin et al. [

58] examined the porosity and permeability properties of nano Black Rice Husk Ash (BRHA) in porous concrete pavement. The research involved replacing varying percentages of BRHA in the concrete mix. The result showed a significant increment in the permeability coefficient across all specimens, indicating a notable change in permeability properties. Remarkably, it was determined that the optimal replacement percentage for nano BRHA was 40%, resulting in a substantial 250% increase in the permeability coefficient.

3.4.4. Impact of Nano CaCO3 on the Permeability of Concrete

Adding nano calcium carbonate (nano CaCO

3) to cement concrete significantly improves its permeability characteristics. Specifically, Shaikh and Supit [

59] found that adding 1% nano CaCO

3 reduced the chloride permeability by around 12% at 28 days and by 8% at 90 days. However, the effectiveness of nano-CaCO

3 was diminished when fly ash was included in the concrete mix. The study also compared the performance of nano-CaCO

3 with nano-silica (nS) and concluded that nano-silica was more effective in reducing chloride permeability in cementitious materials. Additionally, the incorporation of nano-CaCO

3 in HVFA concretes further improved the permeability properties, demonstrating its potential to enhance the durability of concrete structures.

Incorporating nano calcium carbonate (nano CaCO

3) into concrete significantly improves its microstructure by refining the pores and increasing overall density. Khotbehsara et al. [

45] observed that the addition of 3% nano CaCO

3 resulted in a substantial 65–70% reduction in water absorption. However, increasing the nano CaCO

3 content beyond 3% led to a notable rise in water absorption capacity. This enhanced performance is attributed to nano CaCO

3’s ability to modify the hydration reactions, resulting in cementitious compounds with smaller crystal sizes, which in turn improve the overall durability and performance of the concrete.

3.4.5. Impact of Carbon Nanotubes (CNTs) on the Permeability of Concrete

Carbon nanotubes (CNTs) also show promise in reducing water absorption. Studies have indicated that using 0.08% of CNTs can achieve a reduction of 35.8% in water absorption [

55]. This improvement is mainly attributed to the high aspect ratio and large surface area of CNTs, which aid in bridging cracks and filling voids within the concrete. They also found that carbon nanotubes, when used in concentrations ranging from 0.05% to 0.1%, decrease the chloride diffusion coefficient by 12%. This reduction is attributed to the ability of CNTs to form a more interconnected and impermeable network within the concrete.

3.4.6. Impact of Graphene Oxide (GO) on the Permeability of Concrete

Graphene oxide (GO) is another nanomaterial that has been explored for its impact on water absorption. Incorporating 0.8% of GO has been shown to decrease water absorption by 46%. The layered structure of GO, along with its functional groups, contributes to improved hydration processes and reduced pore connectivity in the concrete. They also found that using 0.03% of GO could reduce the chloride penetration depth by 51.73%. The high surface area and functional groups of GO facilitate better dispersion within the cement matrix, thereby blocking the pathways for chloride ions [

55].

3.4.7. Impact of Carbon Nanofibers (CNFs) on the Permeability of Concrete

Incorporating carbon nanofibers (CNFs) into concrete significantly reduces its permeability. At a 0.3% CNF volume fraction, the water seepage height and relative permeability coefficient decreased by 39.1% compared with plain concrete (PC). Even at higher volume fractions of 0.4% and 0.5%, the permeability remains reduced by 37.5% and 32.8%, respectively. This indicates that while the optimal reduction is achieved at 0.3%, higher concentrations still provide substantial benefits in lowering the permeability of concrete [

57].

This review highlights the impact of various nanomaterials on the permeability and water absorption properties of concrete, emphasizing those that provide the most significant improvements. The highest reduction in permeability was observed with 3% nano-calcium carbonate (nano-CaCO

3), which reduced water absorption by 65–70% due to its capacity to refine pore structure and enhance the density of the cement matrix. Additionally, nano TiO

2 at 3% significantly reduced water absorption by 65% and decreased the water-vapor permeability coefficient by 43.9%, showcasing its effectiveness in improving concrete durability. Moderate enhancements were achieved with other nanomaterials like nano SiO

2, carbon nanotubes, and graphene oxide. GO at 0.8% reduced water absorption by 46% and decreased chloride penetration depth by 51.73% due to its layered structure and functional groups that improve hydration and reduce pore connectivity. CNTs at 0.08% achieved a 35.8% reduction in water absorption by forming an interconnected, impermeable network within the concrete. Nano SiO

2 also demonstrated significant improvements, with reductions in permeability of up to 45.2% when used at a 2% dosage, primarily due to its capability to fill the micro pores and improve the density of the cement matrix. These findings underscore the potential of these nanomaterials to improve concrete’s durability and resistance to environmental factors.

Figure 16 shows the reduction in the permeability of concrete by using different percentages of nanomaterials, according to several authors.

3.5. Impact of Nanomaterials on Abrasion Resistance of Concrete

Using nanomaterials in concrete can improve abrasion resistance as the nanoparticles are smaller in size and have larger surface areas that can improve the adhesion and cohesion of the concrete. In addition, the use of nanoparticles can reduce porosity and permeability, which can improve abrasion resistance. Finally, nanoparticles can improve the abrasion resistance of concrete by providing additional protection against its surface’s mechanical wear and tear. This section shows the improvement of the abrasion resistance of concrete by using different percentages of nanomaterials such as nano SiO2, nano TiO2, nano Al2O3, etc.

3.5.1. Impact of Nano SiO2 on Abrasion Resistance of Concrete

Li et al. [

47] studied the abrasion resistance of concrete containing nano SiO

2 for pavement applications. Their findings revealed that adding 1% nano SiO

2 increased the surface index by an impressive 157%, while 3% nano SiO

2 resulted in a 100.8% increase. Similarly, the side index showed enhancements of 139.4% and 89% with 1% and 3% nano SiO

2, respectively, based on the weight of the cementitious material.

In the study of Adamu et al. [

19], nano SiO

2 proved effective in improving the roughness indices of high-volume fly ash roller-compacted concrete pavement (RCCP). The optimum results were found by incorporating 1%, 2%, and 3% nano SiO

2 along with the combination of 20% crumb rubber and 50% high-volume fly ash (HVFA) contributed to the roughness index. increases of approximately 10.53%, 7.02%, and 5.26%, respectively, under wet conditions compared with scenarios without nano SiO

2. Similarly, under dry conditions, enhancements of about 8.77%, 12.28%, and 5.26% were observed with 1%, 2%, and 3% nano SiO

2, respectively.

Khot and Pol [

5] studied rigid pavement using nano concrete and discovered that incorporating 1.5% nano SiO

2 with 0.05% graphene significantly increased abrasion resistance by 26.5%.

Gonzalez et al. [

15] examined the influence of various nano SiO

2 concentrations on the weight characteristics of concrete for rigid pavement construction. The study revealed differing weight outcomes based on the nano SiO

2 content and the finishing used. In concrete with broom finishing, weight reductions of approximately 9.84% and 16.39% were observed with 1% and 1.5% nano SiO

2, respectively. Conversely, concrete without nano SiO

2 experienced a weight loss of roughly 60.66%. In contrast, concrete with smooth finishing showed minimal changes in weight, with a slight reduction of approximately 7.14% noted with 1% nano SiO

2. Moreover, weight remained relatively stable with 2% nano SiO

2. Without nano SiO

2, a substantial weight loss of approximately 71.43% was observed.

In another study by Tavakoli et al. [

37] on concrete pavement containing waste aggregate and nano SiO

2, 0.7% nano SiO

2 improved the abrasion resistance of concrete pavement by 38.63%. When combined with 40% ceramic or 40% glass waste, the abrasion resistance improved by 40.9% and 40.15%, respectively. Moreover, the skid resistance of the concrete pavement increased by 3% with 40% concrete waste and 0.7% nano SiO

2 and by 6% with 40% glass waste and 0.7% nano SiO

2. However, using 0% waste material with 0.7% nano SiO

2 and 40% ceramic waste with 0.7% nano SiO

2 decreased skid resistance by 9% and 3%, respectively.

3.5.2. Impact of Nano Al2O3 on Abrasion Resistance of Concrete

Ahmed and Alkhafaji [

4] studied the effect of nano Al

2O

3 on concrete pavements and revealed that the incorporation of 1% nano Al

2O

3 resulted in a substantial decrease in weight loss by 78% and wear depth by 77% when compared with conventional concrete. The significant enhancement in wear resistance was attributed to the unique properties of nano Al

2O

3. The addition of nano Al

2O

3 particles promoted better interfacial bonding and dispersion within the concrete matrix, leading to improved load transfer and resistance against wear. These particles acted as strengthening agents, creating a denser, more durable microstructure.

Figure 17 shows the SEM image of the comparison between the concrete sample without nano Al

2O

3 and the sample with 1% Al

2O

3, and it shows how the microstructure is improved by using nano Al

2O

3.

3.5.3. Impact of Nano TiO2 on Abrasion Resistance of Concrete

Li et al. [

28] studied the effect of nano TiO

2 on the abrasion resistance of concrete pavement. Their findings revealed significant enhancements in the surface index, with an increase of 180.7% by adding 1% nano TiO

2 and 147.7% by adding 3% nano TiO

2. Similarly, the side index demonstrated improvements of 173.3% and 140.2% when incorporating 1% and 3% nano TiO

2, respectively, based on the weight of the cementitious material.

3.5.4. Impact of Graphene Oxide (GO) on Abrasion Resistance of Concrete

Fonseka et al. [

16] found that incorporating graphene oxide (GO) into concrete significantly enhanced its abrasion resistance and refined its microstructure. Adding 0.08% GO by weight of cement increased abrasion resistance by over 23% at 28 days and 20% at 56 days compared with the control mix. This improvement in abrasion resistance was strongly correlated with increased compressive strength. The enhancement was attributed to the capability of graphene oxide to create a denser and more cohesive matrix, making the concrete more resistant to wear. Additionally, the incorporation of 0.08% GO led to the most significant refinement of the concrete’s microstructure, resulting in a denser and more durable concrete matrix.

Figure 18 shows the SEM image of concrete without graphene oxide (GO) and concrete with the presence of graphene oxide (GO).

This review emphasizes the impacts of different nanomaterials on the abrasion resistance of concrete, emphasizing those that provided more than 100% improvement. The most significant enhancements were observed by incorporating 1% nano TiO2, which increased the surface index by 180.7% and the side index by 173.3%. Similarly, 1% nano SiO2 also demonstrated a remarkable increase in surface and side indices by 157% and 139.4%, respectively. These substantial improvements are attributed to the ability of nanomaterials to refine the microstructure, improve interfacial bonding, and create a denser, more cohesive matrix within the concrete. Nano Al2O3 and GO also provided notable enhancements on the abrasion resistance, attributed to better dispersion and load transfer within the concrete matrix.

3.6. Effect of Nanomaterial on Fatigue Performance of Concrete

Fatigue failure in concrete occurs due to gradual weakening from repeated loading, leading to eventual fracture. It is characterized by the accumulation of small cracks over time. Factors affecting fatigue life include concrete quality, load magnitude, frequency, and environmental conditions. Stress–strain fatigue models like the S–N curve approach predict concrete fatigue behavior. Adding nanomaterials like nano SiO2, nano TiO2, and carbon nanomaterials can enhance fatigue resistance, analyzed using the S–N curve model.

3.6.1. Impact of Nano SiO2 on Fatigue Performance of Concrete

In Adamu et al. [

19], the effects of crumb rubber and nano SiO

2 on roller-compacted concrete (RCC) pavement fatigue properties were investigated. Two fatigue equations, single logarithmic

and double logarithmic

were employed to determine optimal ratios. The S–N curve assessed fatigue, with coefficients x and y determining curve shape, where 0.55 < S < 0.85 indicated equation choice. Results showed M20C1N (20% crumb rubber, 1% nano SiO

2) had superior fatigue performance with higher x (0.3987) and y (0.095) coefficients, implying extended fatigue life. Conversely, M0C0N (0% crumb rubber, 0% nano SiO

2) exhibited poorer fatigue behavior with lower x (0.1016) and y (0.046) coefficients, representing shorter fatigue life. Additionally, high-volume fly ash (HVFA) reduced RCC pavement fatigue life.

Figure 19 illustrates the S–N curve for different mixes.

3.6.2. Impact of Carbon Nanofibers (CNFs) on Fatigue Performance of Concrete

Liu et al. [

30] investigated the influence of mineral nanofibers on the durability of road cement concrete. Their study revealed a significant enhancement in bending fatigue life for nanofiber-reinforced concrete compared with conventional concrete. This improvement was particularly pronounced under lower bending fatigue stress (<0.80) conditions, typical of real-world applications. Notably, nanofiber-reinforced concrete exhibited a 15% and 50% longer bending fatigue life compared with ordinary fiber-reinforced and plain concrete, respectively. These results suggest that nanofiber-reinforced concrete offers superior durability and extended service life for road infrastructure.

3.6.3. Impact of Nano TiO2 on Fatigue Performance of Concrete

Li et al. [

19] investigated the effects of nano TiO

2 in concrete on its flexural fatigue performance. They utilized single logarithmic (

S =

α −

βlogN) and double logarithmic (

logS =

logα −

βlogN) fatigue equations to evaluate different concrete specimens. The fatigue lives followed a double-parameter Weibull distribution, with concrete containing 1% nano TiO

2 displaying the maximum flexural fatigue performance. The enhancement in regression parameter α was greatest for this concrete, while the enhancement in β was the smallest. Increasing stress levels were found to increase concrete pavement fatigue life. At the stress level of 0.85, the fatigue life improved by 475%, and at the 0.70 stress level, the fatigue life improved by 267%. Moreover, the fatigue life of nano-modified concrete with 1% nano TiO

2 surpassed the concrete with 1% nano SiO

2, 3% nano TiO

2, and the combination of nano TiO

2 with pp fiber, with conventional concrete exhibiting the lowest fatigue life.

3.6.4. Impact of Graphene Oxide (GO) on the Fatigue Performance of Concrete

Cho and Nam [

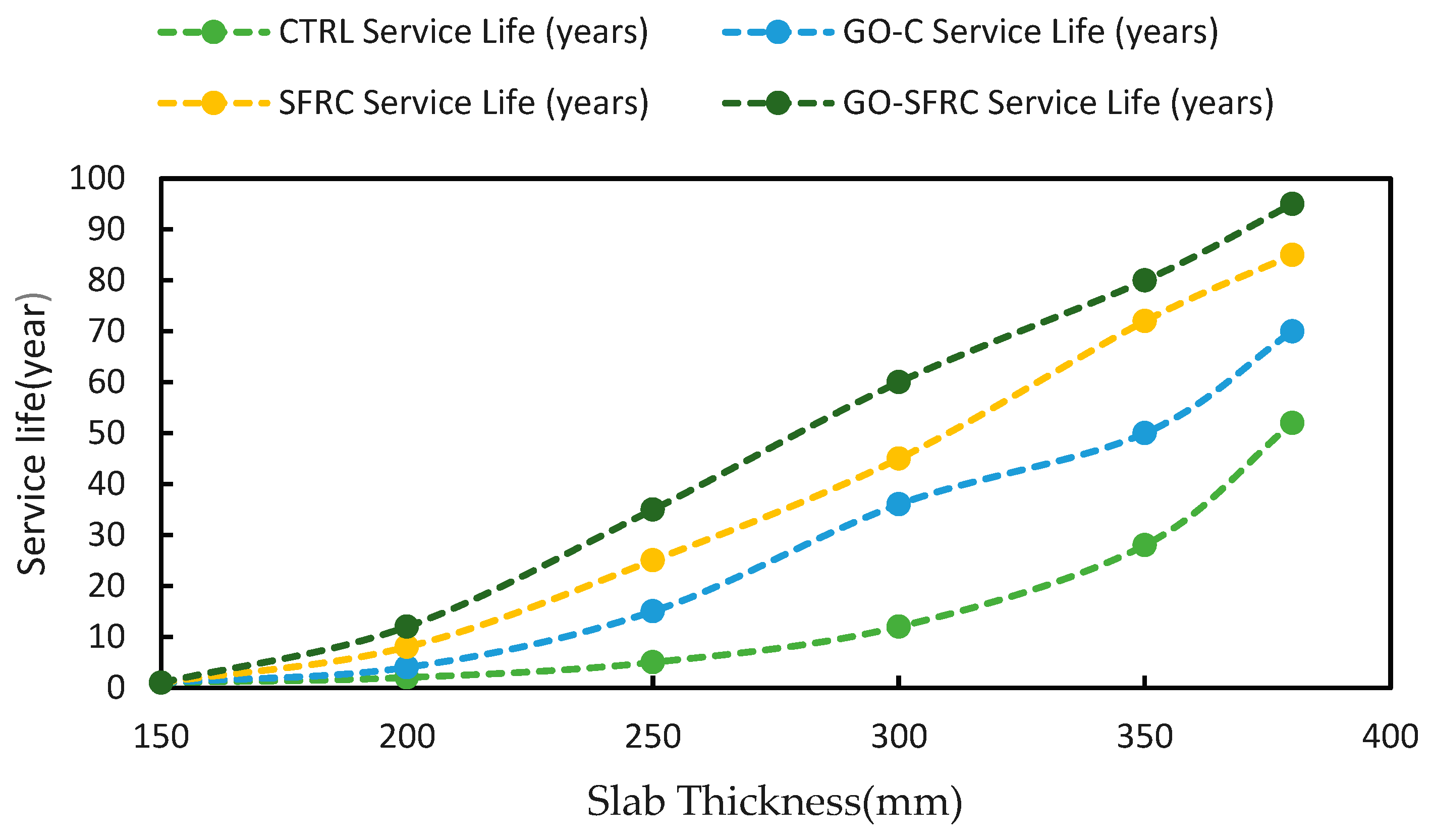

10] used 0.1% graphene oxide in the form of nanoflakes (GONF) and explored the fatigue performance of conventional concrete and steel fiber-reinforced concrete (SFRC). GONF reduced the stress ratio in concrete slabs, enhancing durability under cyclic loading conditions. Finite element analysis (FEA) shows that while steel fibers increase maximum principal stresses by 7–12%, GONF and SFs together reduce stress ratios, improving fatigue performance. Additionally, they found that 0.1% GONF reduced the slab thickness by 12.6–14.6%, and the pavement service life extended up to 25–50 years, offering potential cost savings and material efficiency.

Figure 20 compares the service life of concrete slabs with different treatments and thicknesses. Untreated concrete (CTRL) has the shortest service life, while graphene oxide-treated (GO-C) and steel fiber-reinforced (SFRC) concretes show improved longevity. The combination of graphene oxide and steel fiber (GO-SFRC) results in the longest service life, particularly in thicker concrete slabs.

This review examines the fatigue life of concrete by using various nanomaterials, highlighting significant enhancements. The most substantial improvements are observed in concrete containing 1% nano TiO2, which increased theoretical fatigue life by 475% at a stress level of 0.85 and by 267% at 0.70. Additionally, the flexural fatigue performance of concrete with 1% nano TiO2 surpassed that of concrete with 1% nano SiO2, 3% nano TiO2, and the combination of nano TiO2 with polypropylene fibers. Moderate improvements were seen with 20% crumb rubber and 1% nano SiO2 in roller-compacted concrete (RCC) and with 0.1% graphene oxide nanoflakes (GONF) in normal and steel fiber-reinforced concrete. These materials enhanced fatigue life by refining microstructures and improving load transfer, leading to extended durability and service life under cyclic loading conditions.

3.7. Impact of Nanomaterials on Crack-Healing Performance of Concrete

The integration of nanomaterials into concrete has paved the way for significant advancements in its mechanical properties and durability, which are essential for extending the service life and performance of concrete structures. Among these nanomaterials, nano SiO2, carbon nanotubes (CNTs), carbon nanofibers (CNFs), and nano TiO2 have significant potential in enhancing the mechanical properties and self-healing capabilities of concrete and other cementitious composites.

3.7.1. Impact of Nano SiO2 on the Crack-Healing Performance of Concrete

Evangelia and Maria [

9] examined the crack healing performance of concrete incorporating 1.5% nano SiO

2 at 7, 14, and 28 days. After 7 days, the nano-SiO

2-modified specimens exhibited faster healing than the reference samples, particularly for cracks smaller than 100 µm. By 28 days, nearly 100% crack closure was achieved for these smaller cracks. The enhanced healing was due to the accelerated hydration in the presence of nano SiO

2, which further promoted the formation of healing compounds, improving the autogenic healing capacity of the concrete.

Ling et al. [

41] investigated the influence of nano-silica (NS) on the fracture performance of cementitious composites, contrasting mixes with and without 2% NS addition. The study revealed that irrespective of NS presence, increasing PVA fiber content up to 1.2% led to enhanced ductility and toughness compared with the control mix (0% PVA fiber). This enhancement can be attributed to fibers’ well-documented crack-bridging effect, which impedes crack propagation by transferring stress across crack interfaces. However, 2% NS resulted in a slight reduction in peak load for all mixes, indicating a minor decrease in overall strength compared with composites without NS. Despite this, the general trend of improved fracture performance with increasing PVA fiber content was maintained in the NS-modified composites. The reduction in peak load with NS addition could be due to the excessive NS content, which may lead to the expansion of the silicate polymer and a relatively loose internal structure.

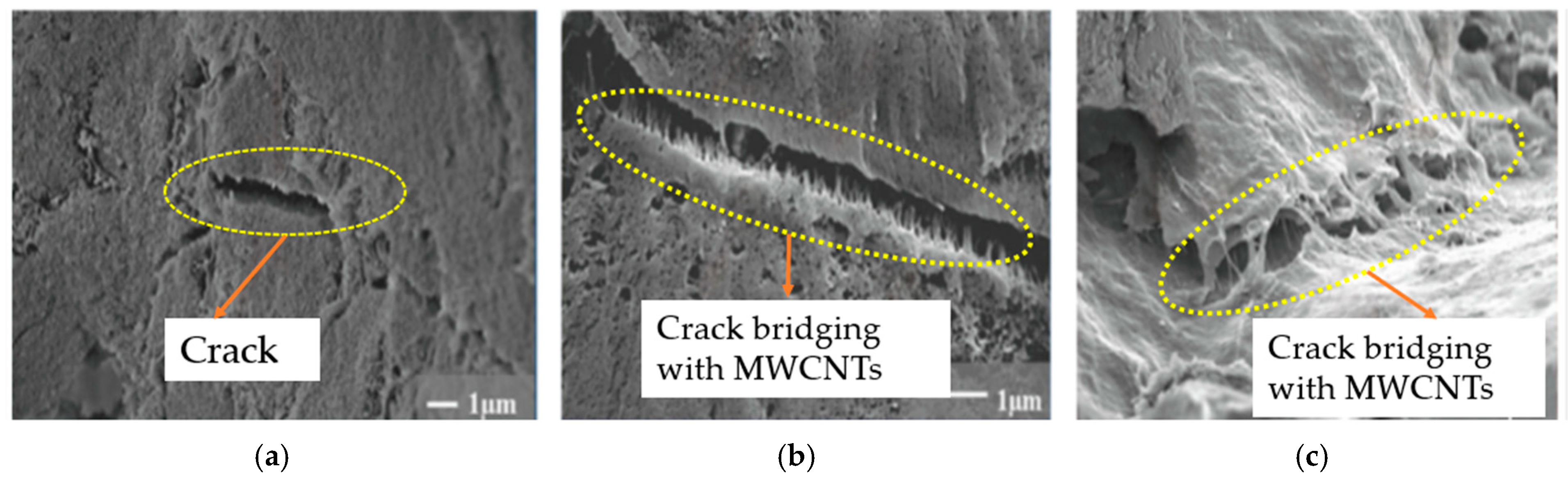

3.7.2. Impact of Carbon Nanotubes (CNTs) on the Crack-Healing Performance of Concrete

Carbon nanotubes (CNTs), particularly nickel-coated CNTs (Ni-CNTs), have shown substantial promise in improving the mechanical performance of reactive powder concrete (RPC). Dong et al. [