Intensification of Thermal Performance of a Heat Exchanger Tube with Knitted Wire Coil Turbulators Installed

Abstract

1. Introduction

2. Experimental Description

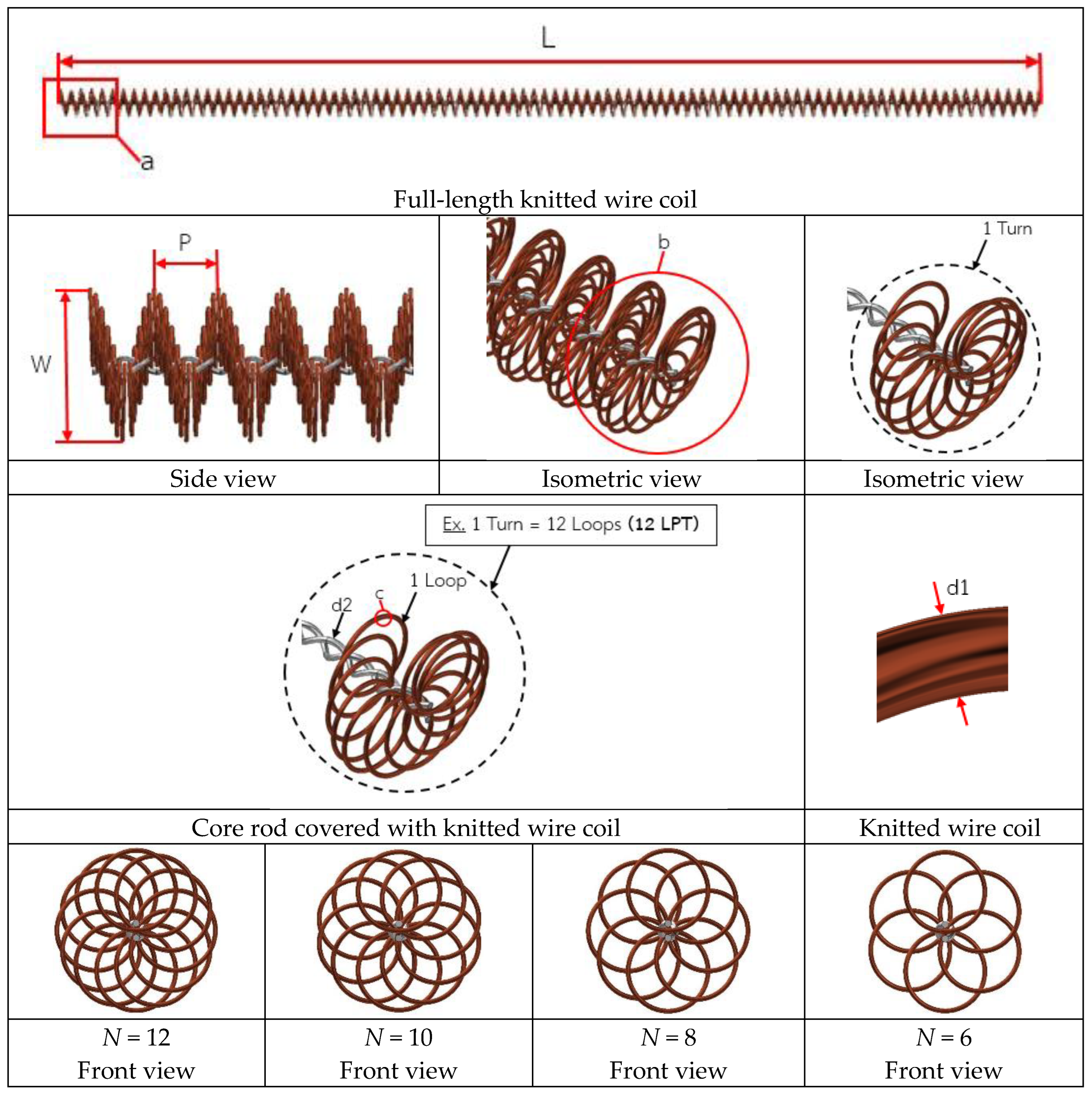

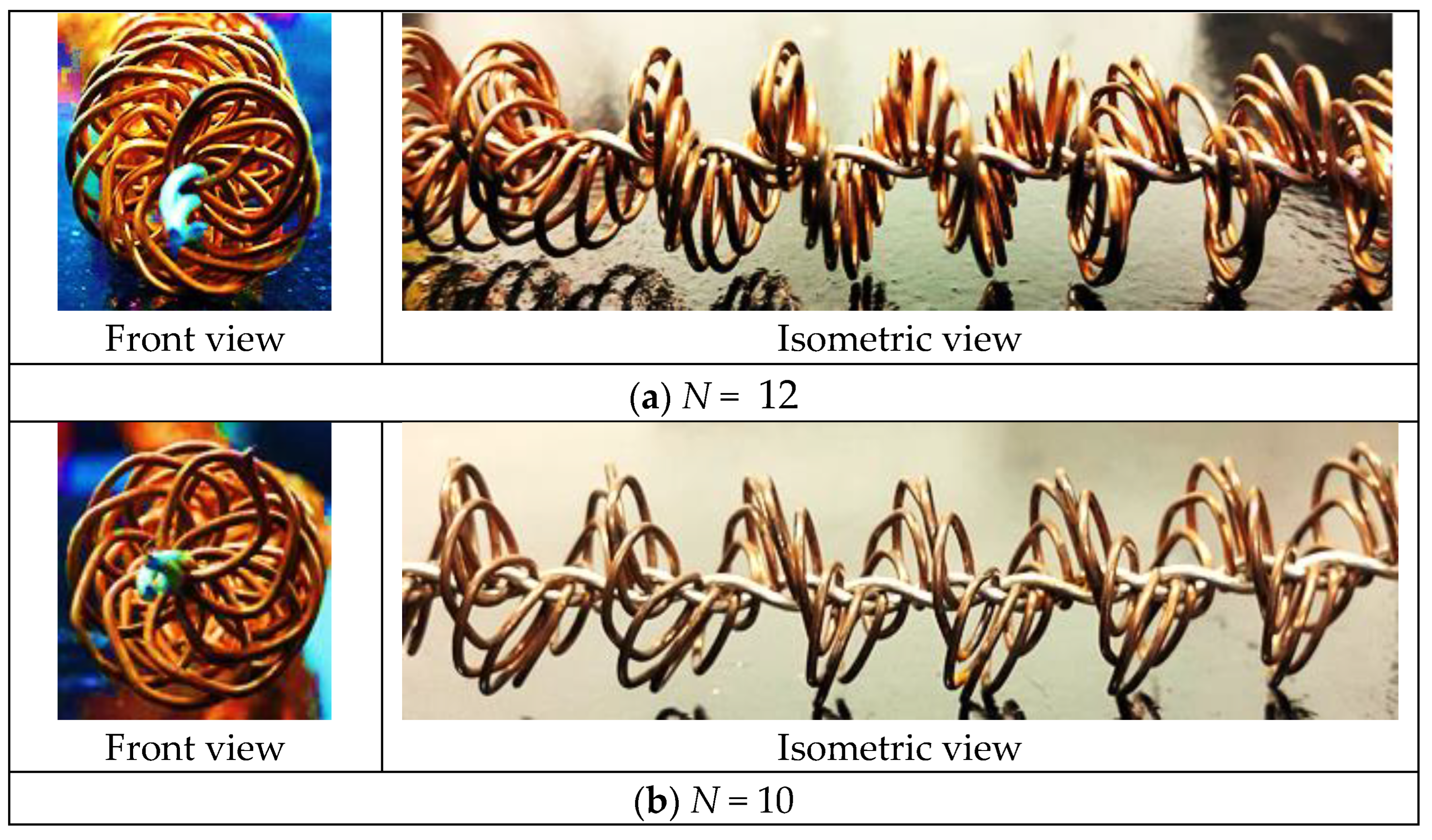

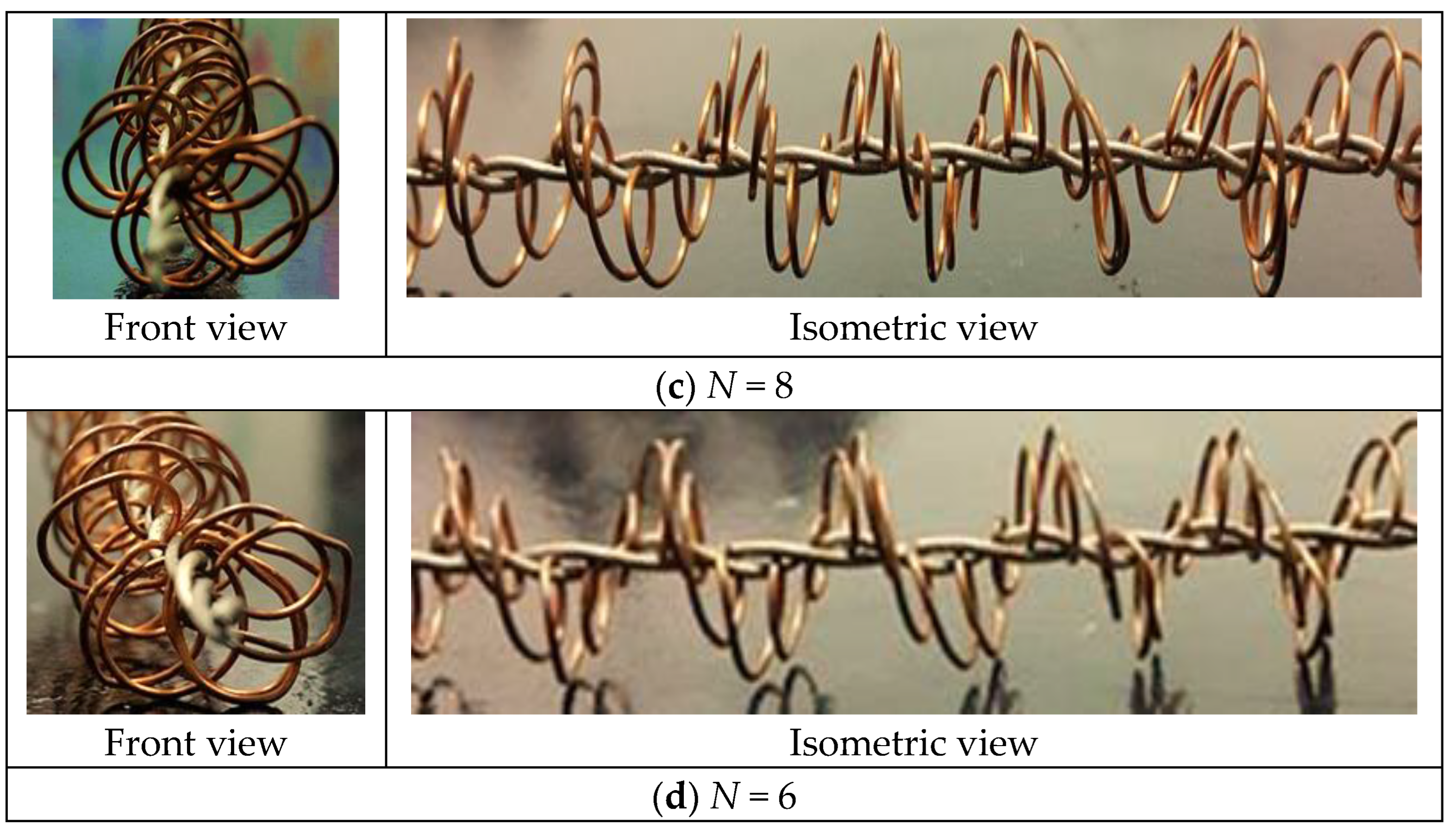

2.1. Knitted Wire Coil Turbulators

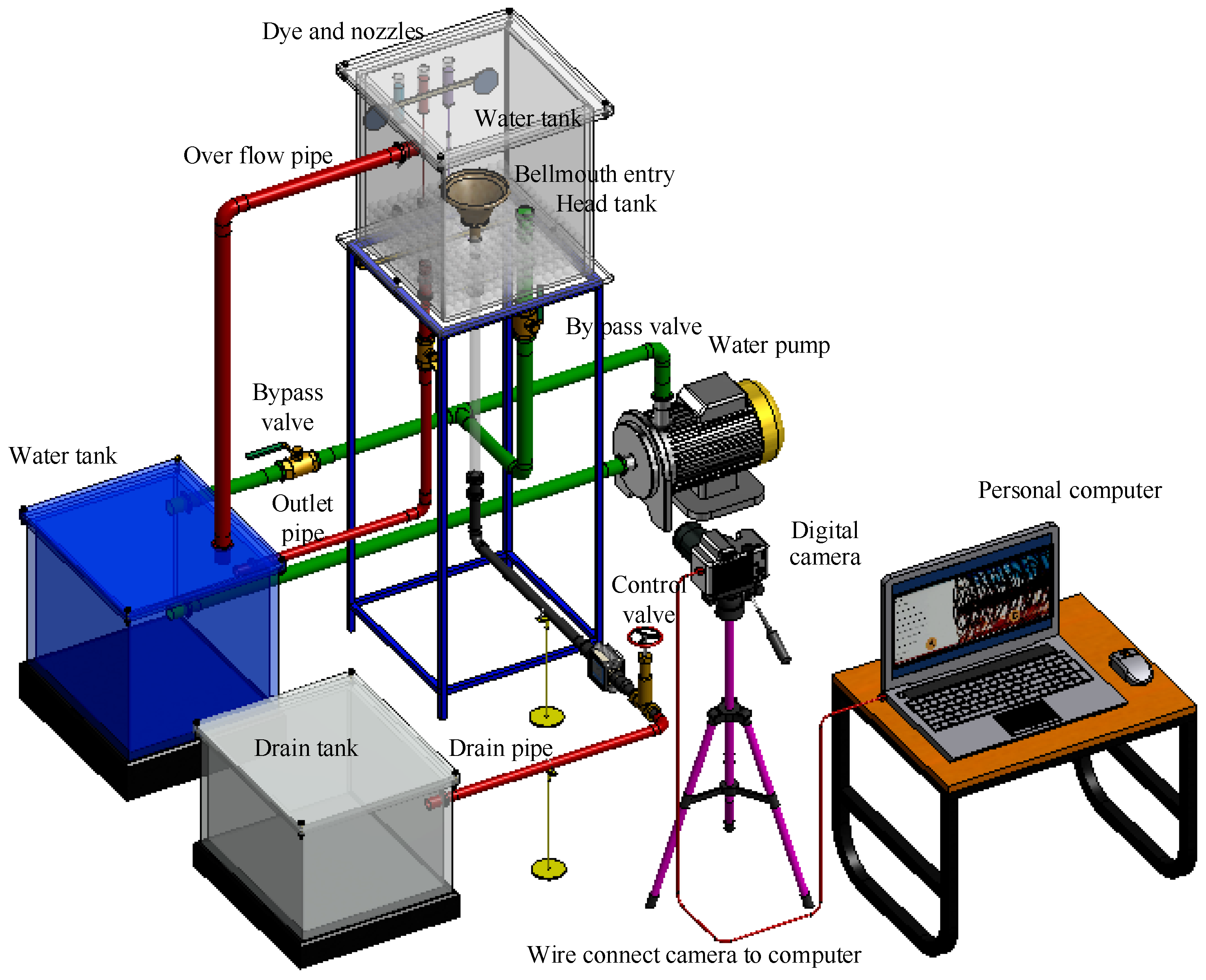

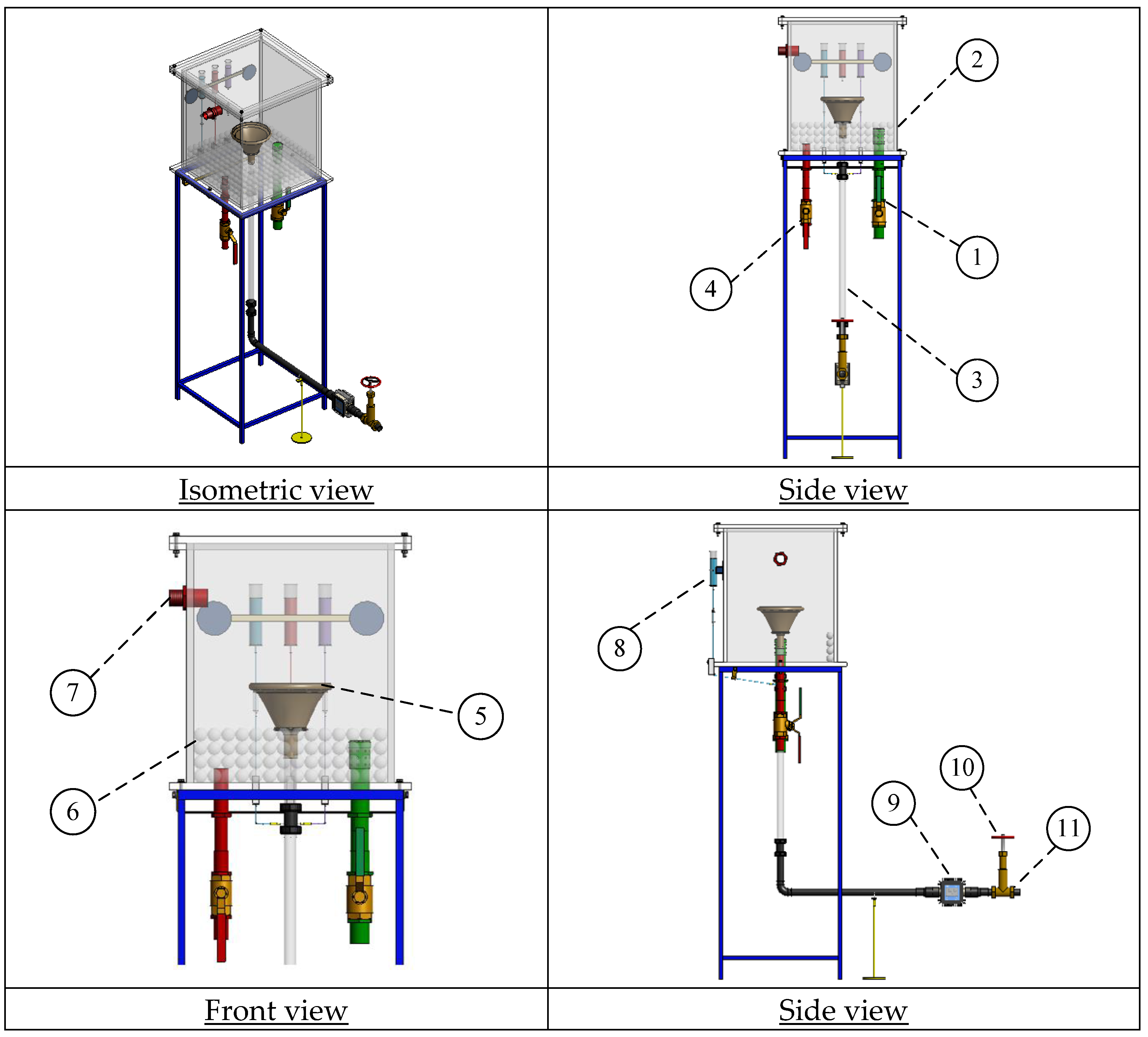

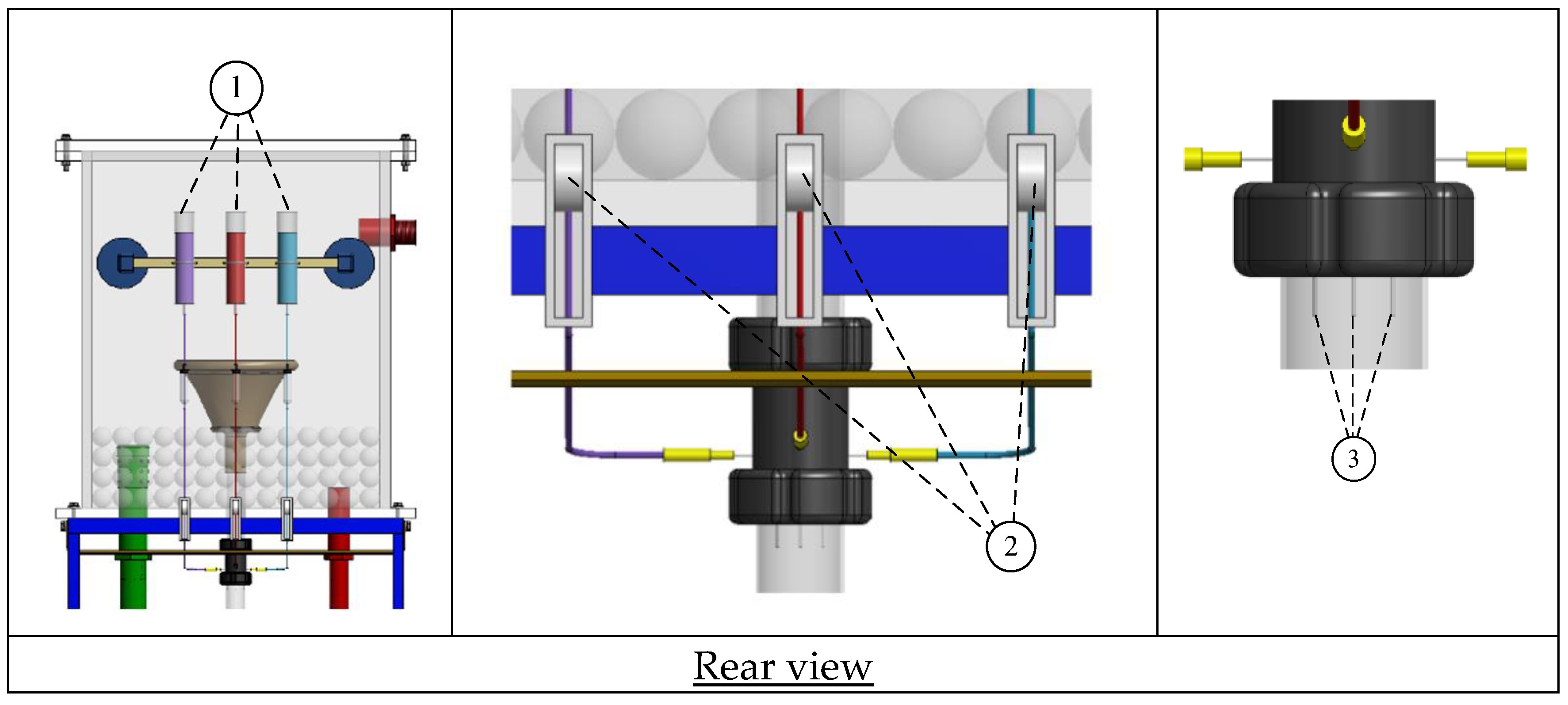

2.2. Flow Visualization Setup

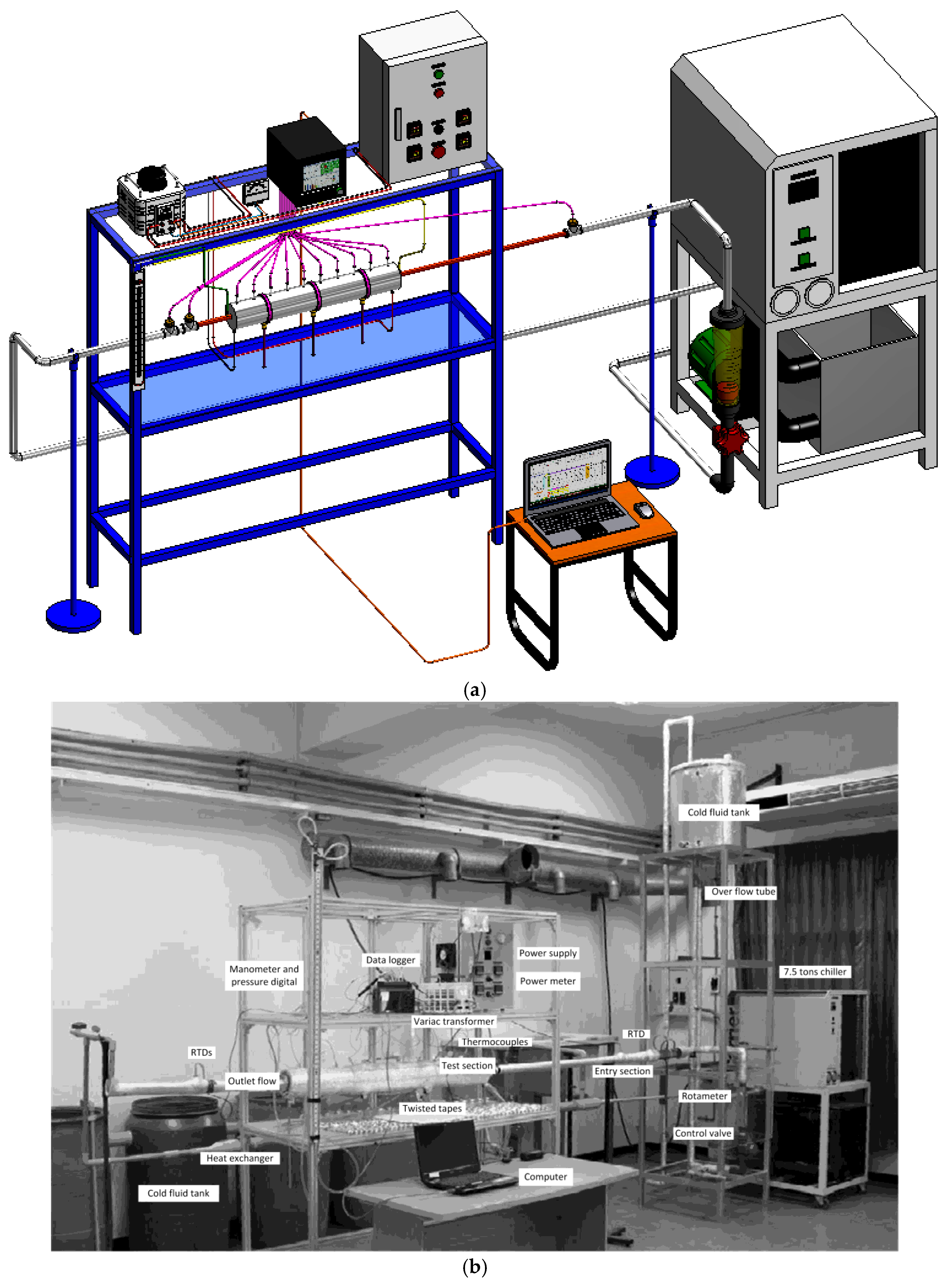

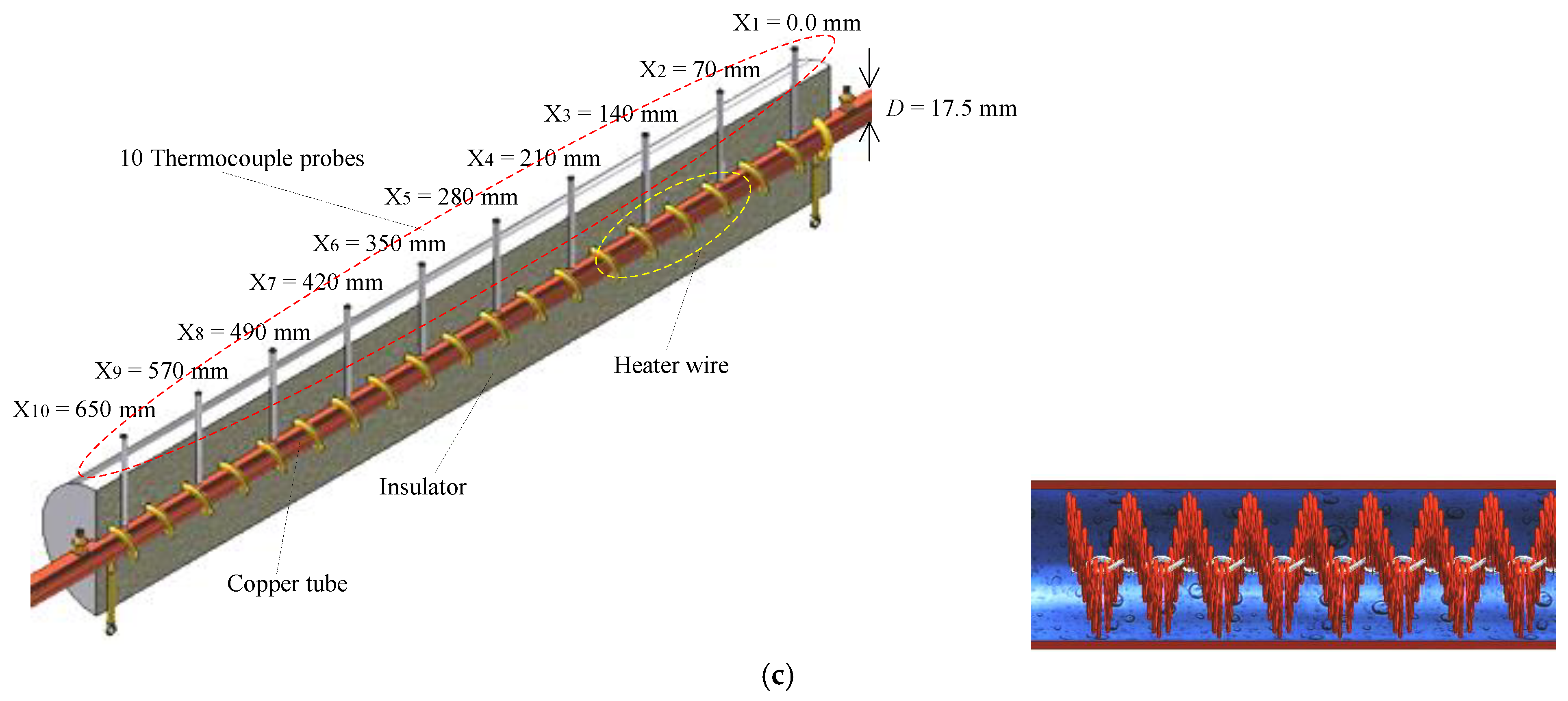

2.3. Experimental Heat Transfer Apparatus

3. Data Reduction

3.1. Heat Transfer Evaluation

3.2. Friction Factor Evaluation

3.3. Thermal Performance Index (TPI) Evaluation

4. Results and Discussion

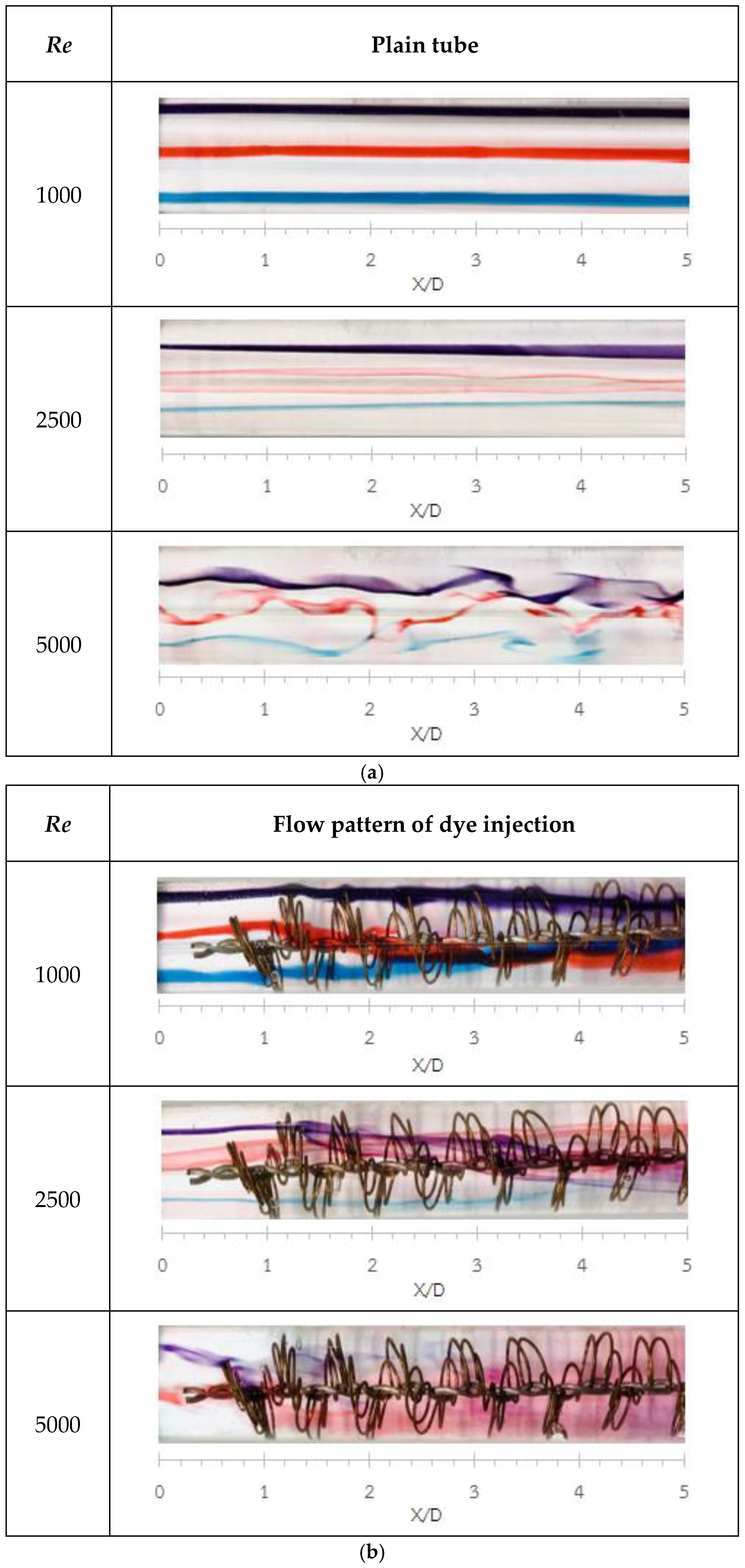

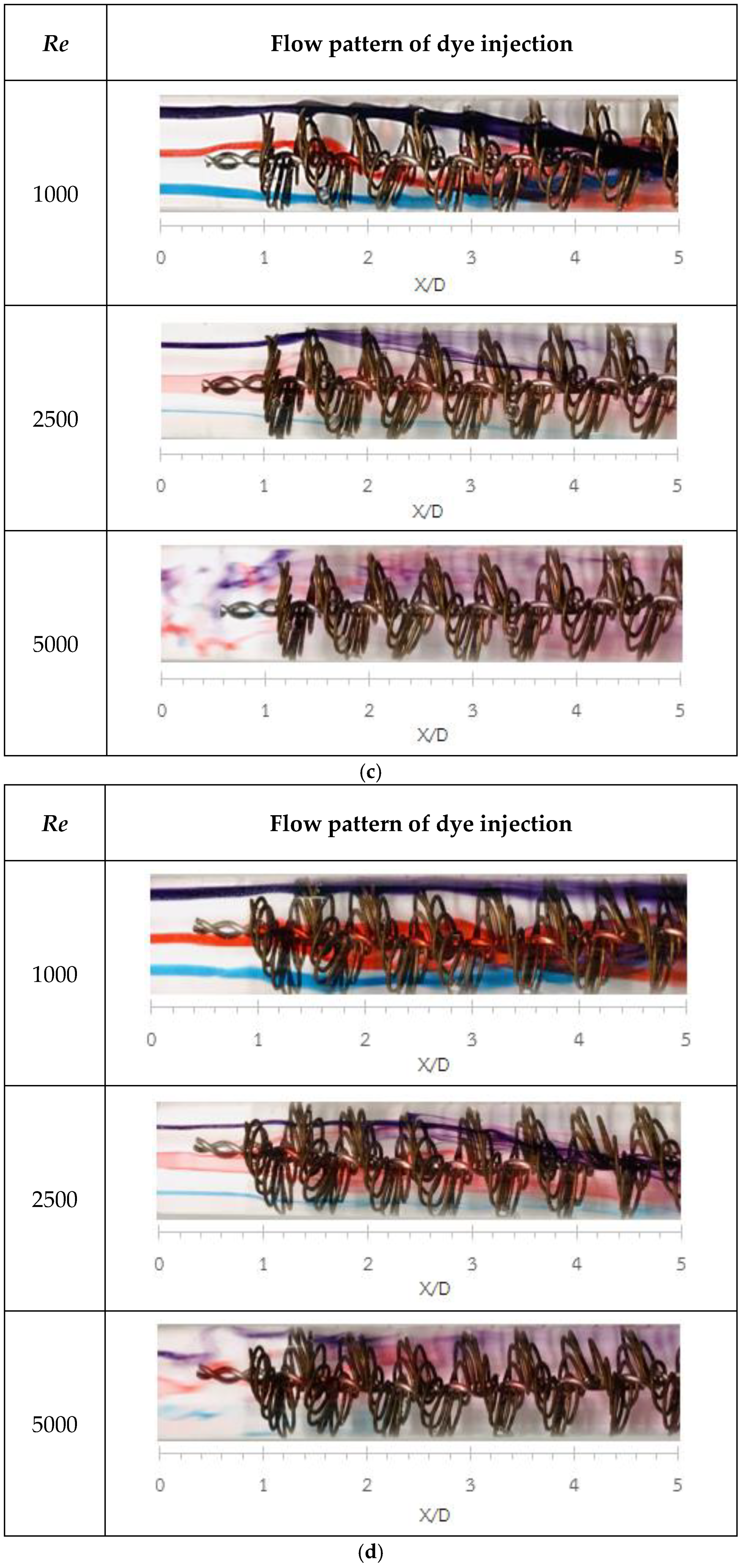

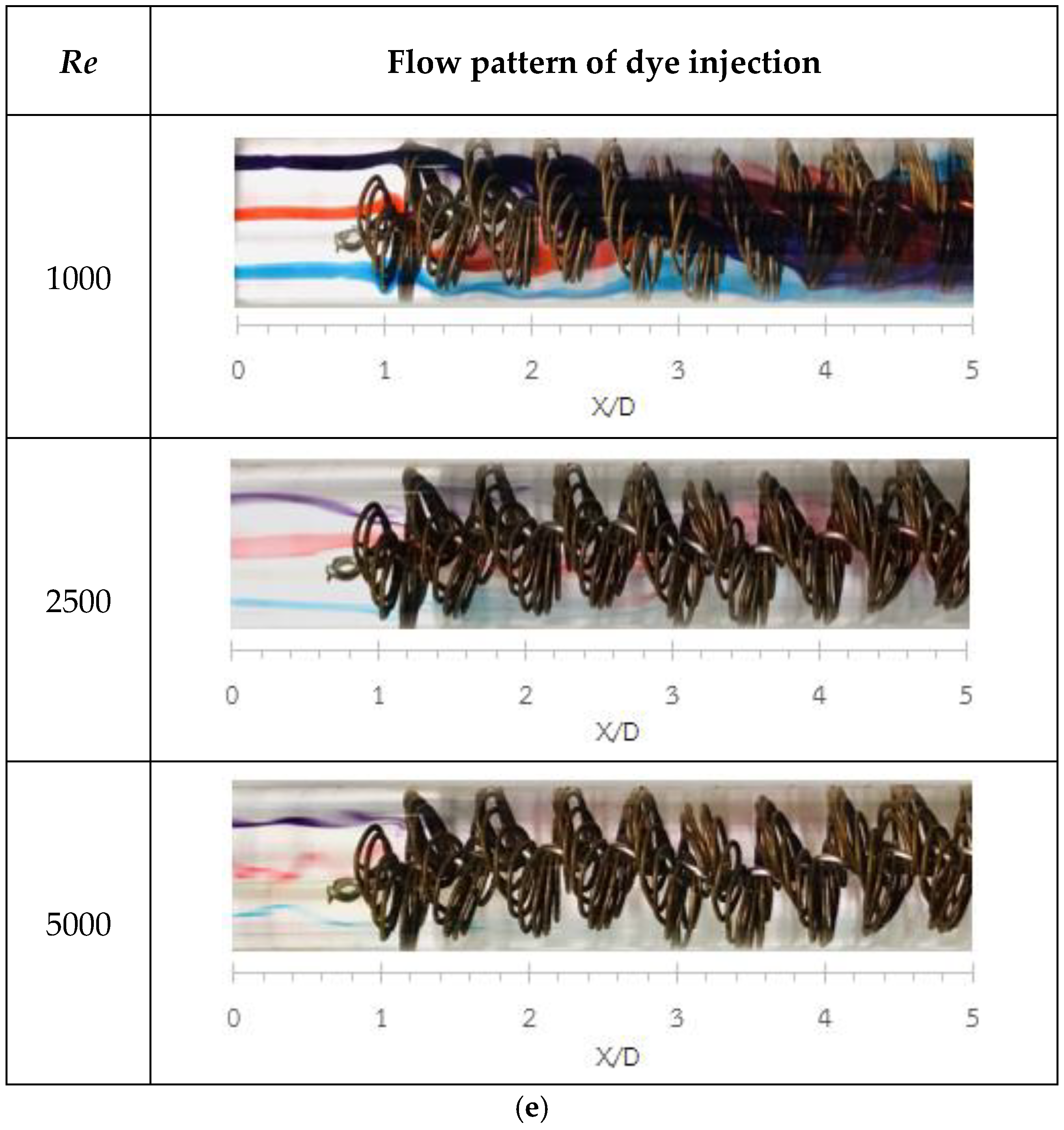

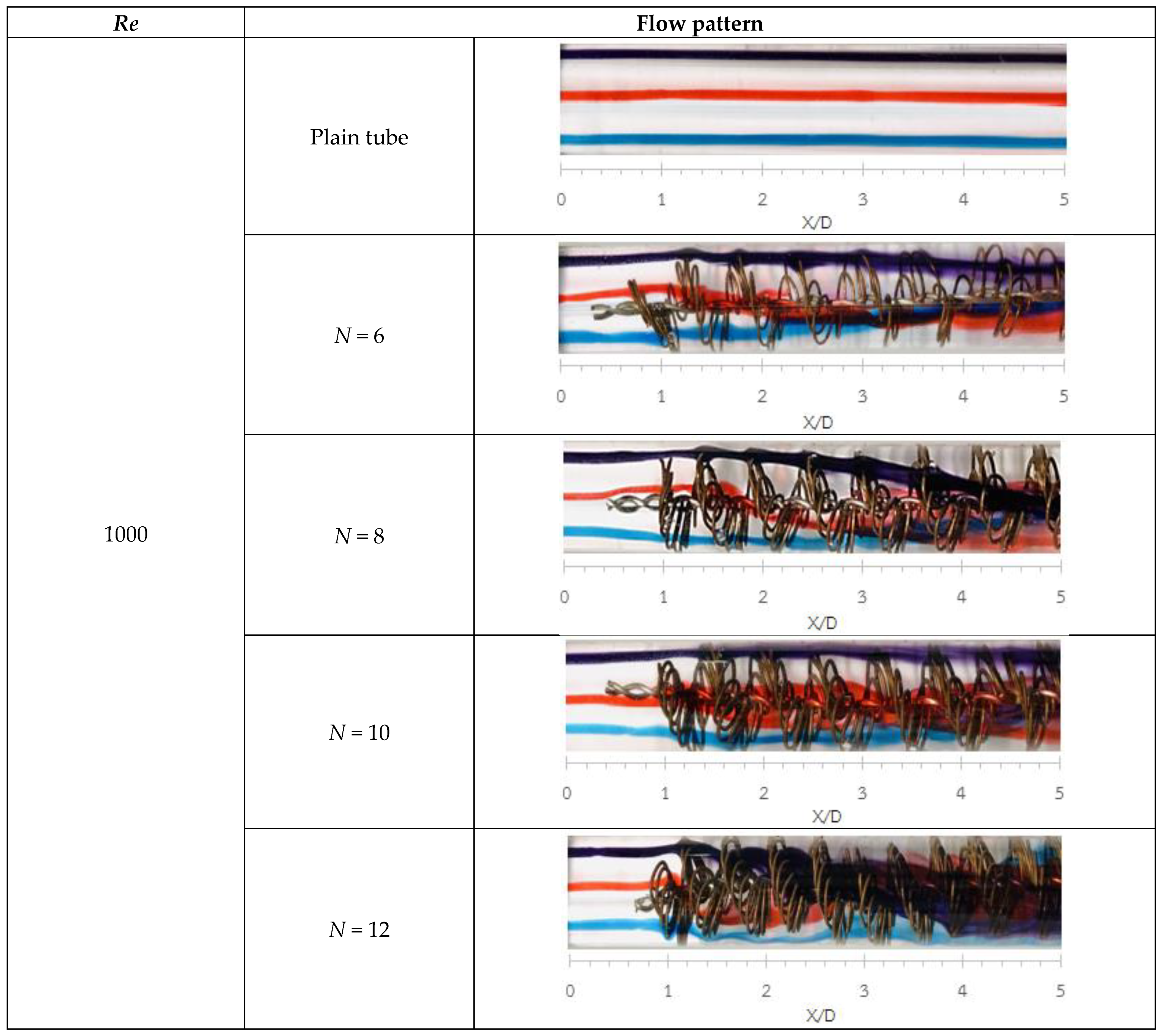

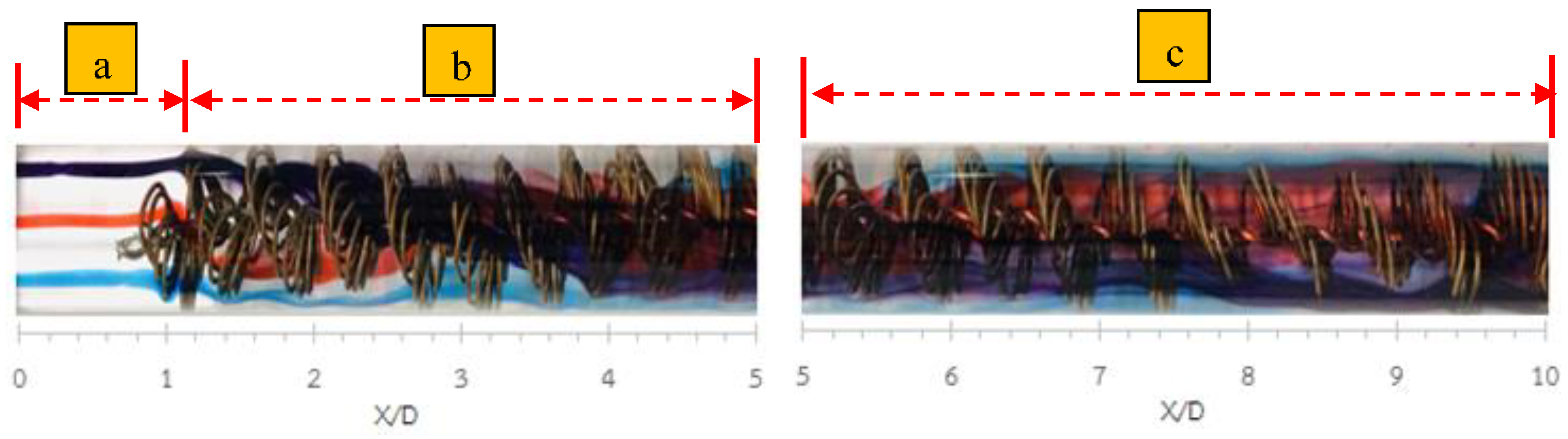

4.1. Flow Visualization Results

4.1.1. The Tube Without Turbulator

4.1.2. The Tube with Knitted Wire Coil Turbulators

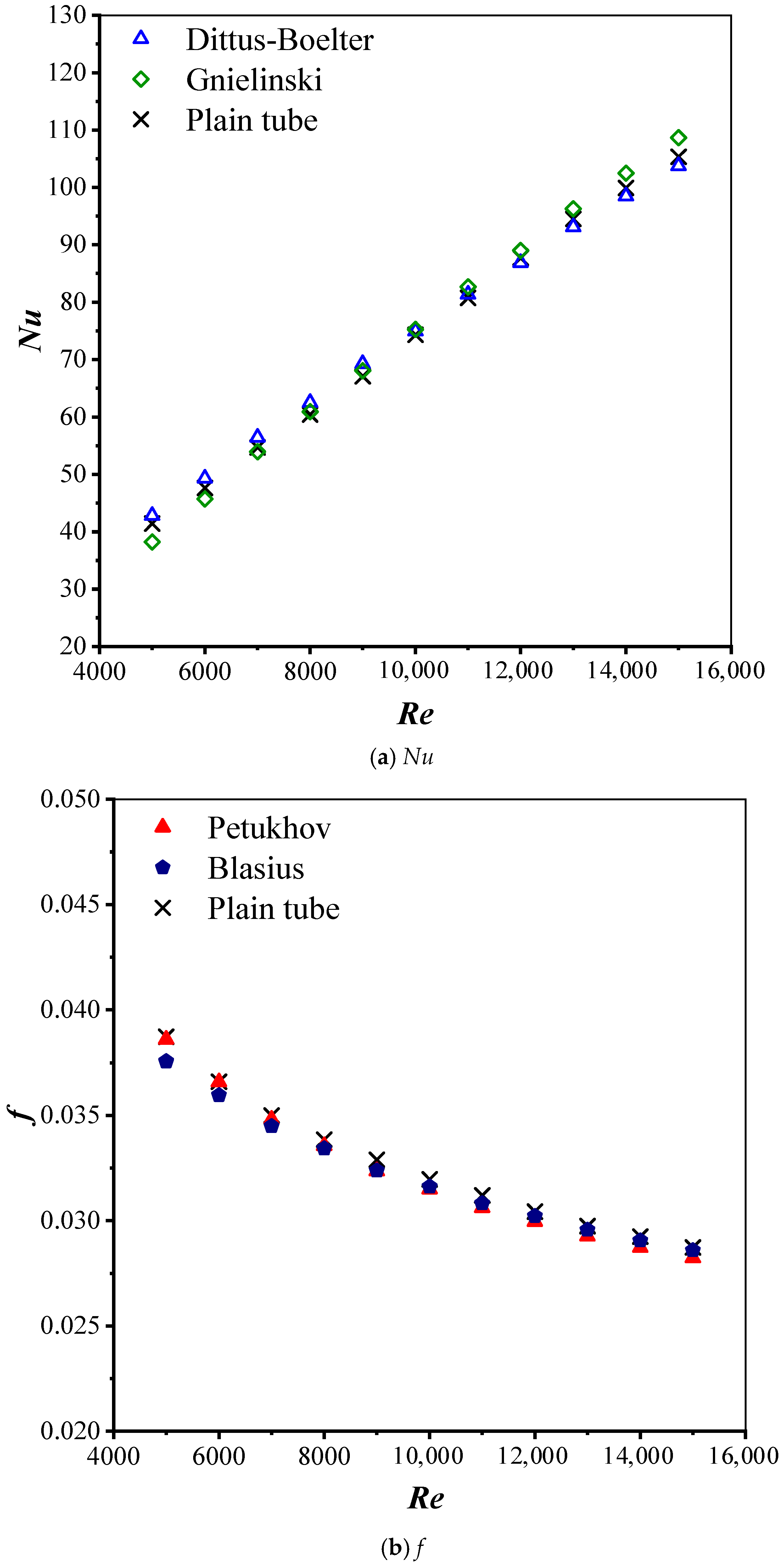

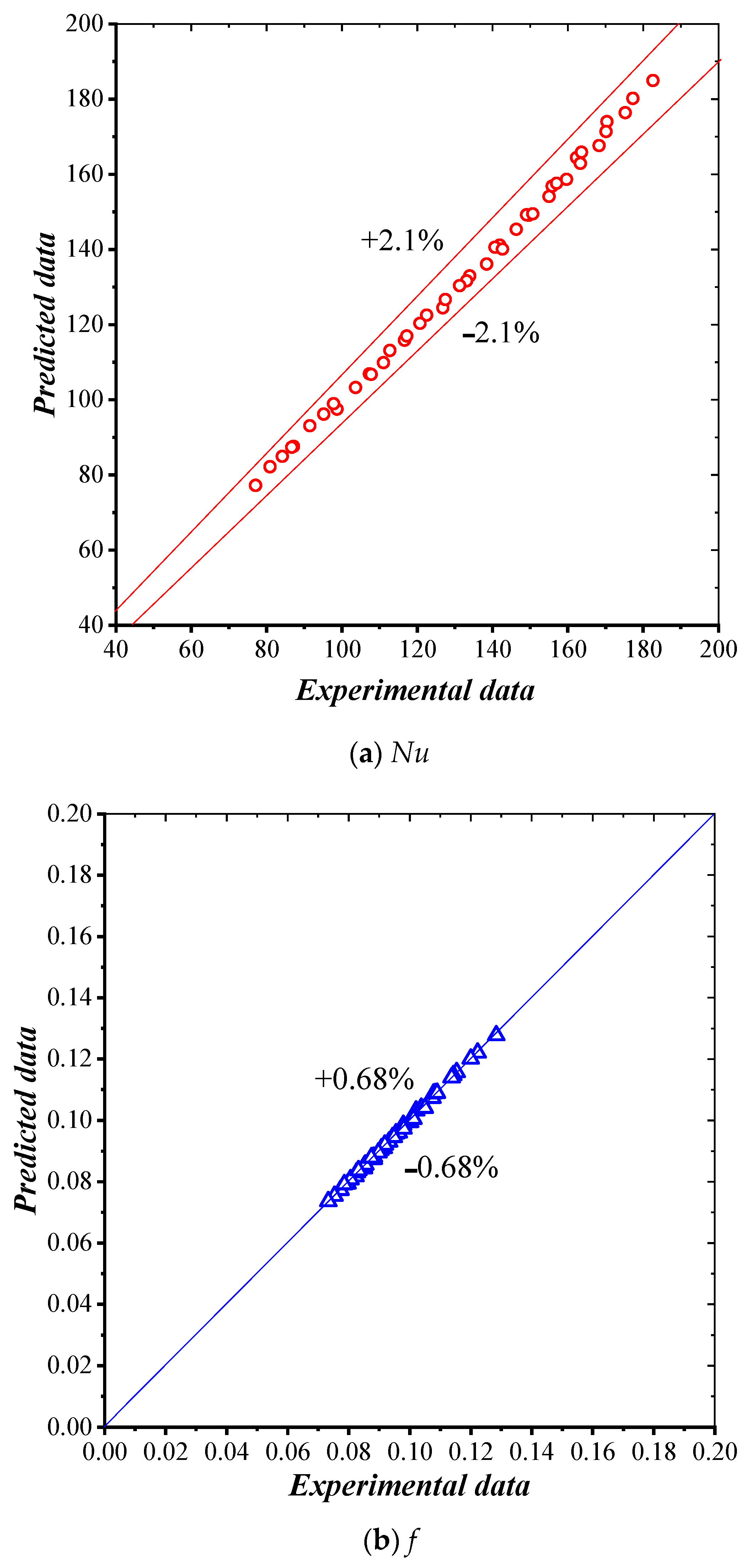

4.2. Validation of a Plain Tube

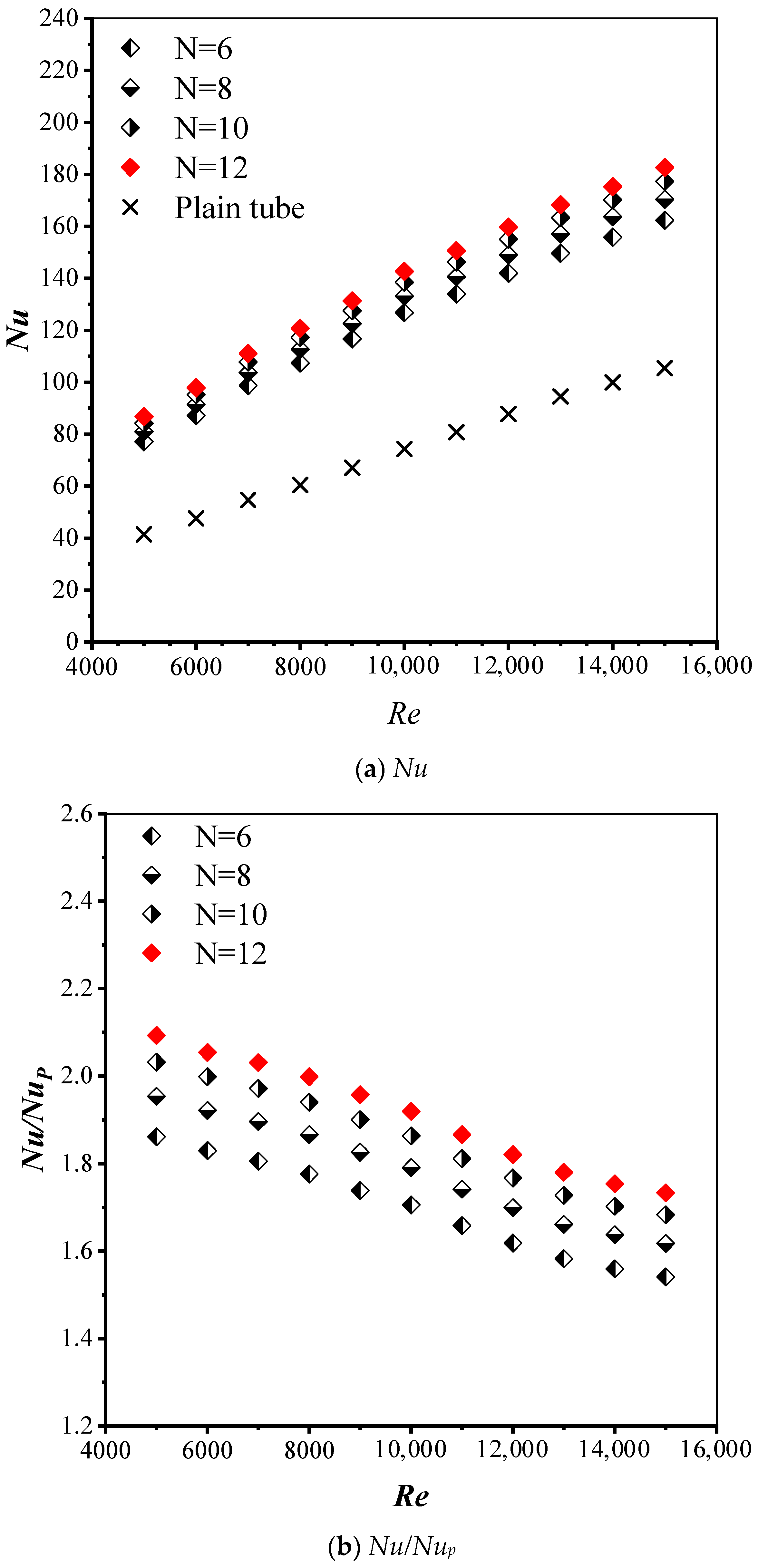

4.3. Heat Transfer Results

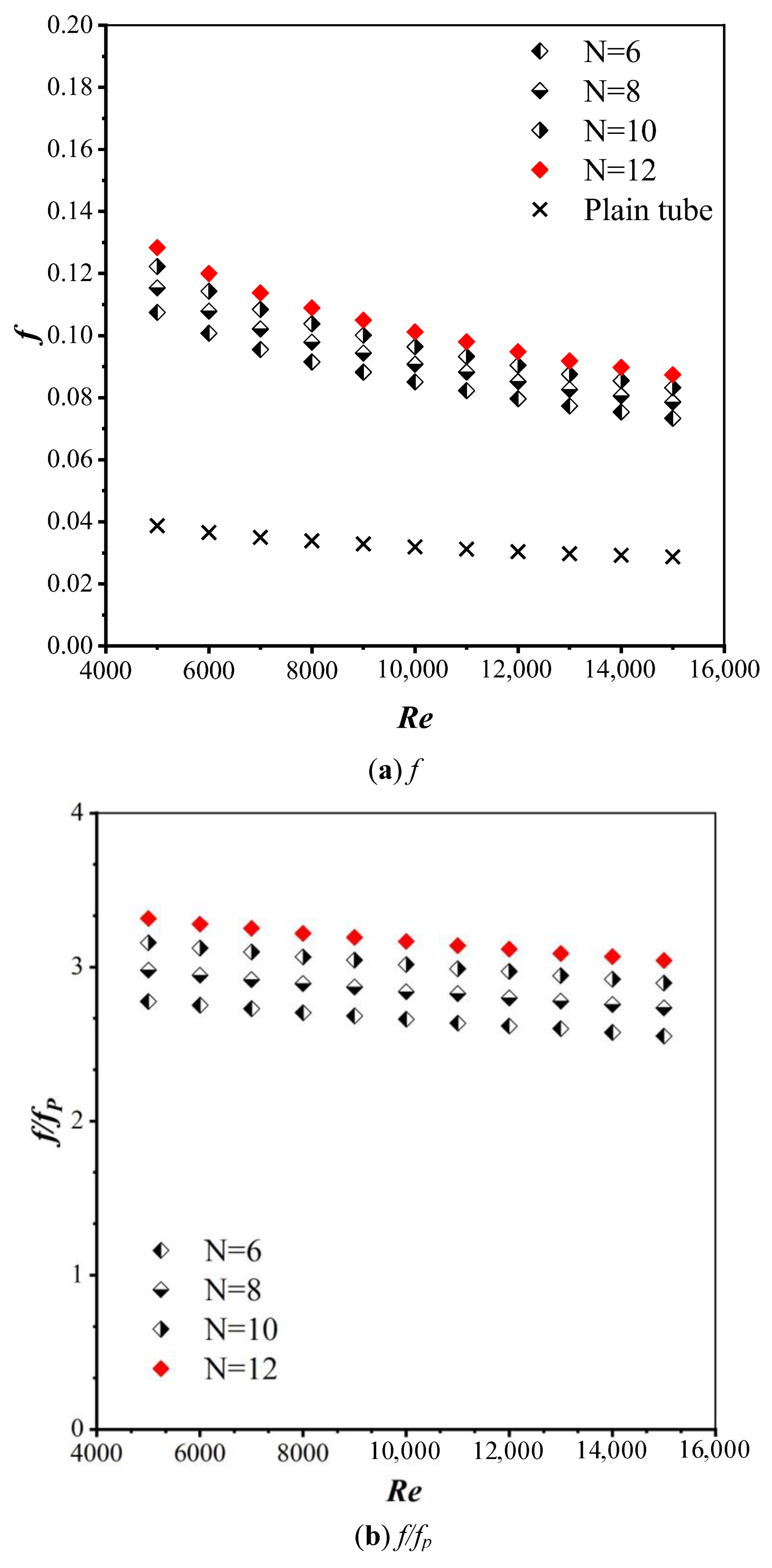

4.4. Friction Factor Results

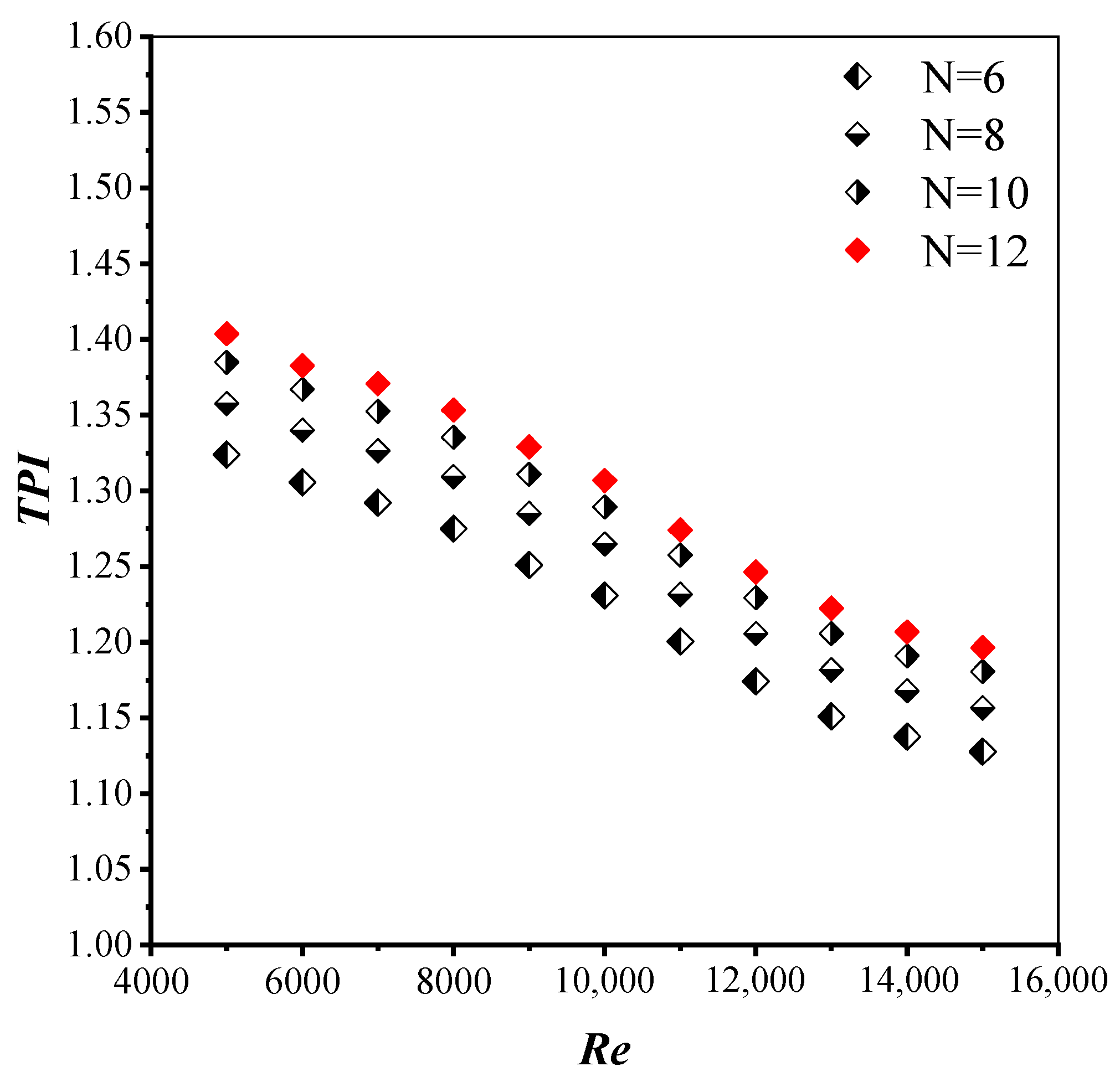

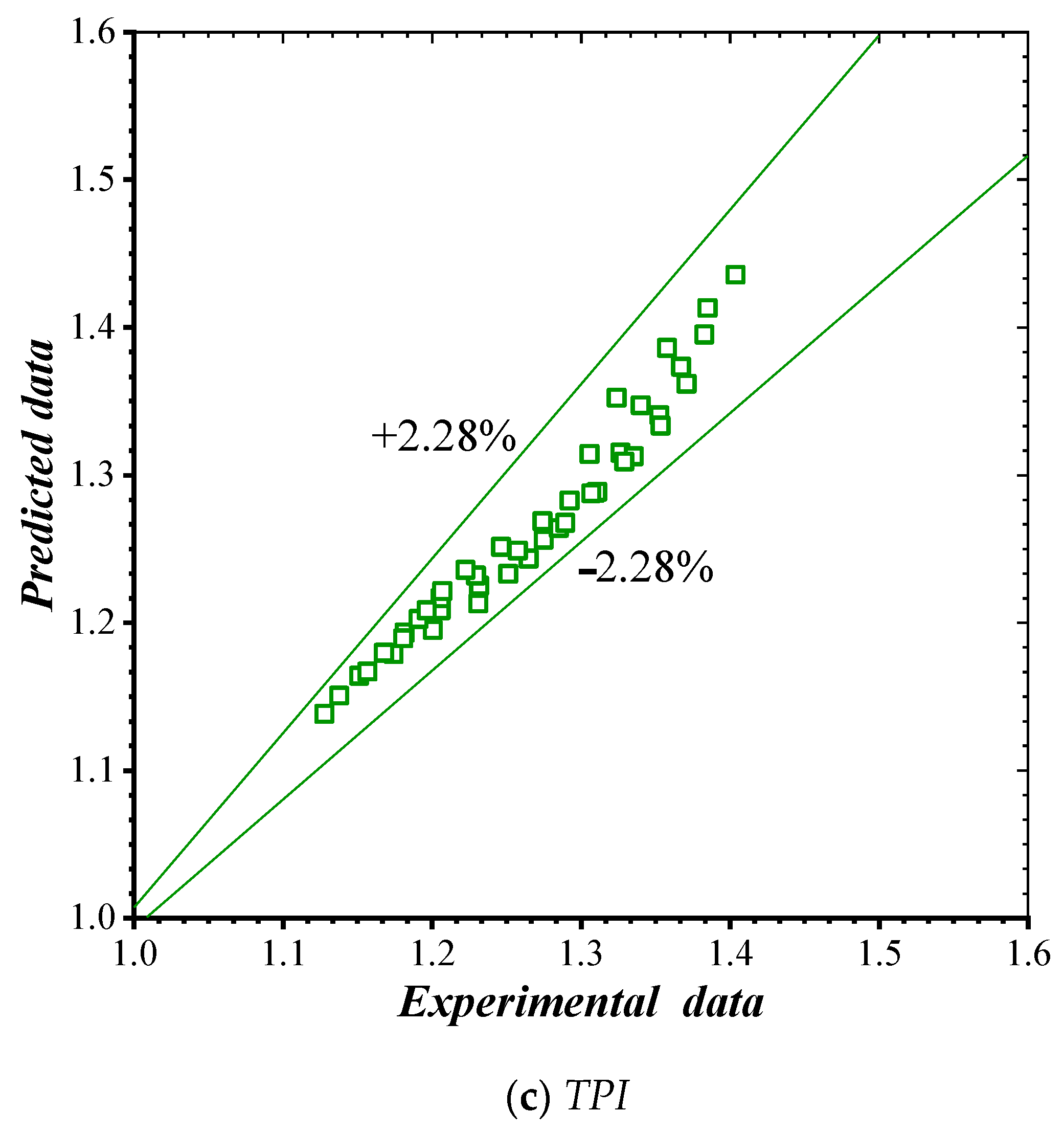

4.5. Thermal Performance Index Results

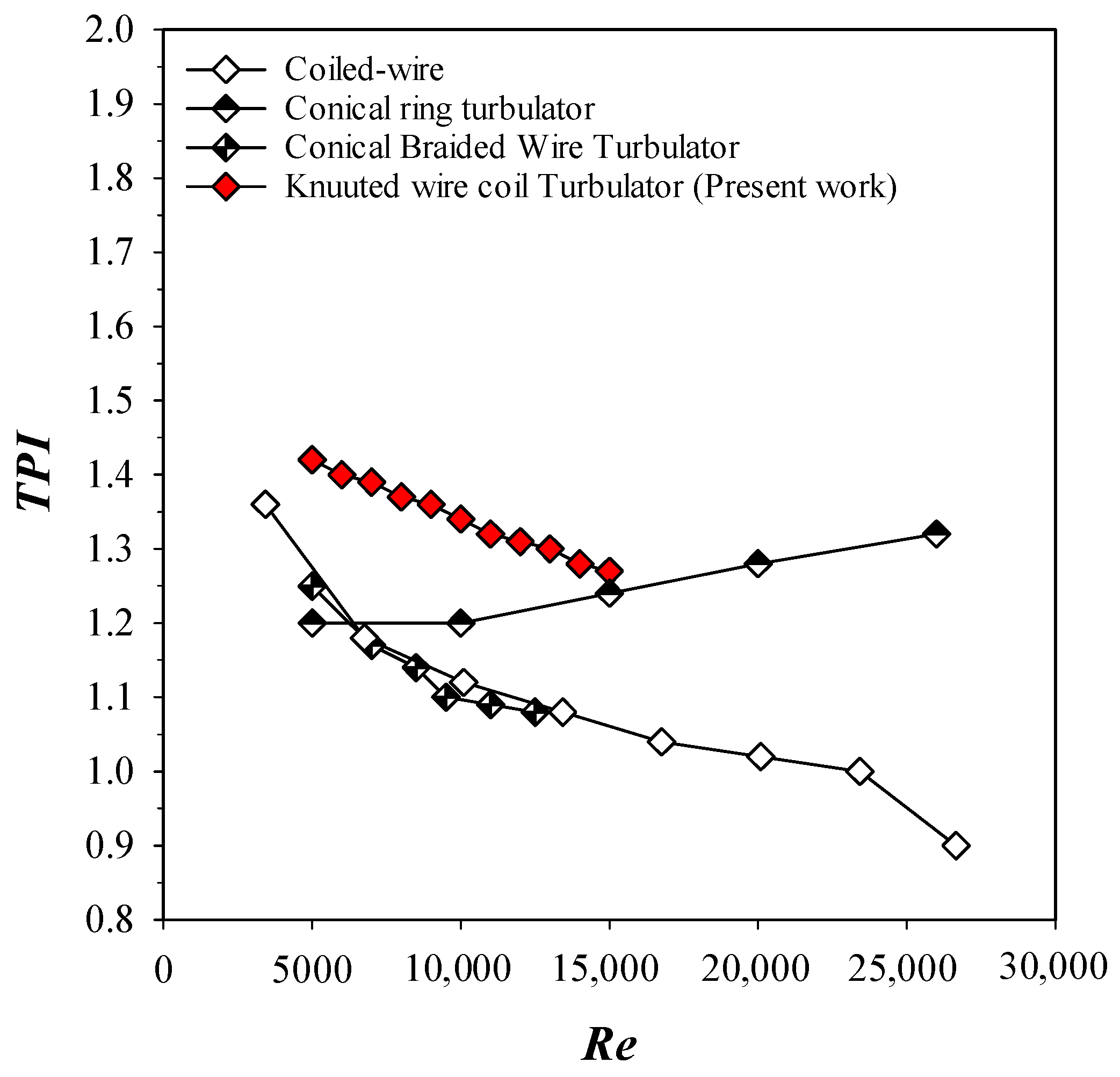

4.6. Comparison with Works

5. Conclusions

- ○

- The use of knitted wire coil turbulators significantly increased the Nusselt number (Nu) and friction factor (f).

- ○

- Increasing the wire loop number density (N) enhanced the heat transfer rate, friction loss, and thermal performance index (TPI).

- ○

- Compared to the case with no turbulator, the use of knitted wire coil turbulators with N = 6, 8, 10, and 12 increased the Nusselt number by 86.1, 95.4, 103.2, and 109.3%, respectively.

- ○

- The friction factors for tubes with knitted wire coil turbulators at N = 6, 8, 10, and 12 were 1.77, 1.97, 2.15, and 2.31 times higher than that of a plain tube, respectively.

- ○

- The maximum TPI values achieved for knitted wire coil turbulators with N = 6, 8, 10, and 12 were 1.32, 1.36, 1.38, and 1.4, respectively, with N = 12 outperforming N = 6, 8, and 10 by approximately 6.23, 3.46, and 1.4%, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| TPI | Thermal performance index |

| A | Test cross-section area, m2 |

| Cp | Specific heat at constant pressure, J/kg K |

| D | Test section diameter, m |

| f | Friction factor |

| h | Heat transfer coefficient, W/m2 K |

| I | Electrical current, Amps |

| k | Thermal conductivity, W/m K |

| L | Length of the test section, m |

| Mass flow rate of water, kg/s | |

| Nu | Nusselt number |

| ΔP | Pressure drop, Pa |

| Pr | Prandtl number |

| Heat flux, W/m2 | |

| Q | Heat transfer rate, W |

| Qconv | Convective heat transfer, W |

| Qt | Total heat generated under constant wall heat flux, W |

| Qw | Heat absorbed by the water, W |

| Re | Reynolds number |

| T | Temperature, K |

| Average temperature, K | |

| U | Velocity, m/s |

| V | Input voltage, volt |

| Volume metric flow rate, m3/s | |

| Greek symbols | |

| ΔP | Pressure drop, Pa |

| μ | Water dynamic viscosity, Ns/m−2 |

| ρ | Water density, kg/m3 |

| Subscripts | |

| b | Bulk |

| i | Inlet |

| o | Outlet |

| p | Plain tube |

| w | Wall |

References

- Fan, A.; Deng, J.; Guo, J.; Liu, W. A Numerical Study on Thermo-Hydraulic Characteristics of Turbulent Flow in a Circular Tube Fitted with Conical Strip Inserts. Appl. Therm. Eng. 2011, 31, 2819–2828. [Google Scholar] [CrossRef]

- Govindasamy, M.; Ezhumalai, M.; Dhairiyasamy, R.; Varshney, D.; Singh, S.; Gabiriel, D. Comprehensive Investigation into the Thermal Performance of Nanofluid-Enhanced Heat Pipes for Advanced Thermal Management Systems. Eng 2025, 6, 55. [Google Scholar] [CrossRef]

- Gunes, S.; Ozceyhan, V.; Buyukalaca, O. The Experimental Investigation of Heat Transfer and Pressure Drop in a Tube with Coiled Wire Inserts Placed Separately from The Tube Wall. Appl. Therm. Eng. 2010, 30, 1719–1725. [Google Scholar] [CrossRef]

- Karakaya, H.; Durmus, A. Heat Transfer and Exergy Loss in Conical Spring Turbulators. Int. J. Heat Mass Transf. 2013, 60, 756–762. [Google Scholar] [CrossRef]

- San, J.Y.; Huang, W.C.; Chen, C.A. Experimental Investigation on Heat Transfer and Fluid Friction Correlations for Circular Tubes with Coiled-Wire Inserts. Int. Commun. Heat Mass. Transf. 2015, 6, 8–14. [Google Scholar] [CrossRef]

- Keklikcioglu, O.; Ozceyhan, V. Experimental Investigation on Heat Transfer Enhancement in a Circular Tube with Equilateral Triangle Cross Sectioned Coiled-Wire Inserts. Appl. Therm. Eng. 2018, 131, 686–695. [Google Scholar] [CrossRef]

- Nanan, K.; Yongsiri, K.; Wongcharee, K.; Thianpong, C.; Eiamsa-ard, S. Heat Transfer Enhancement by Helically Twisted Tapes Inducing Co- and Counter-Swirl Flows. Int. Commun. Heat Mass. Transf. 2013, 46, 67–73. [Google Scholar] [CrossRef]

- Akhavan-Behabadi, M.A.; Kumar, R.; Salimpour, M.R.; Azimi, R. Pressure Drop and Heat Transfer Augmentation Due to Coiled Wire Inserts During Laminar Flow of Oil Inside a Horizontal Tube. Int. J. Therm. Sci. 2010, 49, 373–379. [Google Scholar] [CrossRef]

- Ozceyhan, V.; Gunes, S.; Buyukalaca, O.; Altuntop, N. Heat Transfer Enhancement in a Tube Using Circular Cross Sectional Rings Separated From Wall. Appl. Therm. Eng. 2006, 83, 280–298. [Google Scholar] [CrossRef]

- Gunes, S.; Ozceyhan, V.; Buyukalaca, O. Heat Transfer Enhancement in a Tube with Equilateral Triangle Cross Sectioned Coiled Wire Inserts. Exp. Therm. Fluid Sci. 2010, 34, 684–691. [Google Scholar] [CrossRef]

- Hong, Y.; Du, J.; Wang, S.; Huang, S.M.; Ye, W.B. Heat Transfer and Fluid Flow Behaviors in aTube with Modified Wire Coils. Int. J. Heat Mass Transf. 2018, 124, 1347–1360. [Google Scholar] [CrossRef]

- Eiamsa-ard, S.; Koolnapadol, N.; Promvonge, P. Heat Transfer Behavior in a Square Duct with Tandem Wire Coil Element Insert. Chin. J. Chem. Eng. 2012, 20, 863–869. [Google Scholar] [CrossRef]

- Abdul Hamid, K.; Azmi, W.H.; Mamat, R.; Sharma, K.V. Heat Transfer Performance of Tio2–Sio2 Nanofluids in a Tube with Wire Coil Inserts. Appl. Therm. Eng. 2019, 152, 275–286. [Google Scholar] [CrossRef]

- Dyga, R.; Płaczek, M. Efficiency of Heat Transfer in Heat Exchangers with Wire Mesh Packing. Int. J. Heat Mass Transf. 2010, 53, 5499–5508. [Google Scholar] [CrossRef]

- Xing, F.; Xie, J.; Xu, J. Modulated Heat Transfer Tube with Mesh Cylinder Inserted. Int. Commun. Heat Mass. Transf. 2014, 56, 15–24. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, G.; Luo, X.; Li, H.; Ma, J. An Experimental Investigation on Fluid Flow and Heat Transfer Characteristics of Sintered Woven Wire Mesh Structures. Appl. Therm. Eng. 2015, 80, 118–126. [Google Scholar] [CrossRef]

- Kurian, R.; Balaji, C.; Venkateshan, S.P. Experimental Investigation of Near Compact Wire Mesh Heat Exchangers. Appl. Therm. Eng. 2016, 108, 1158–1167. [Google Scholar] [CrossRef]

- Fu, Y.; Wen, J.; Zhang, C. An Experimental Investigation on Heat Transfer Enhancement of Sprayed Wire-Mesh Heat Exchangers. Int. Commun. Heat Mass. Transf. 2017, 112, 699–708. [Google Scholar] [CrossRef]

- Kotresha, B.; Gnanasekaran, N. Determination of Interfacial Heat Transfer Coefficient for The Flow Assisted Mixed Convection Through Brass Wire Mesh. Int. J. Therm. Sci. 2019, 138, 98–108. [Google Scholar] [CrossRef]

- Sayed, M.A.; ELdein Hussin, A.M.T.A.; Mahmoud, N.A.; Aboelsoud, W. Performance Evaluation of Wire Mesh Heat Exchangers. Appl. Therm. Eng. 2020, 169, 114891. [Google Scholar] [CrossRef]

- Nanan, K.; Pimsarn, M.; Jedsadaratanachai, W.; Eiamsa-ard, S. Heat Transfer Augmentation Through the Use of Wire-Rod Bundles Under Constant Wall Heat Flux Condition. Int. Commun. Heat Mass. Transf. 2013, 48, 133–140. [Google Scholar] [CrossRef]

- Naphon, P.; Suchana, T. Heat Transfer Enhancement and Pressure Drop of the Horizontal Concentric Tube with Twisted Wires Brush Inserts. Int. Commun. Heat Mass. Transf. 2011, 38, 236–241. [Google Scholar] [CrossRef]

- Bhuiya, M.M.K.; Chowdhury, M.S.U.; Islam, M.; Ahamed, J.U.; Khan, M.J.H.; Sarker, M.R.I.; Saha, M. Heat Transfer Performance Evaluation for Turbulent Flow Through a Tube with Twisted Wire Brush Inserts. Int. Commun. Heat Mass. Transf. 2012, 39, 1505–1512. [Google Scholar] [CrossRef]

- Yu, C.; Zhang, H.; Wang, Y.; Zeng, M.; Gao, B. Numerical Study on Turbulent Heat Transfer Performance of Twisted Oval Tube with Different Cross Sectioned Wire Coil. Case Stud. Therm. Eng. 2020, 22, 100759. [Google Scholar] [CrossRef]

- Dang, W.; Wang, L.B. Convective Heat Transfer Enhancement Mechanisms in Circular Tube Inserted with a Type of Twined Coil. Int. Commun. Heat Mass. Transf. 2021, 169, 120960. [Google Scholar] [CrossRef]

- Keklikcioglu, O.; Ozceyhan, V. Heat Transfer Augmentation in a Tube with Conical Wire Coils Using a Mixture of Ethylene Glycol/Water as a Fluid. Int. J. Therm. Sci. 2022, 171, 107204. [Google Scholar] [CrossRef]

- Chompookham, T.; Chingtuaythong, W.; Chokphoemphun, S. Influence of a Novel Serrated Wire Coil Insert on Thermal Characteristics and Air Flow Behavior in a Tubular Heat Exchanger. Int. J. Therm. Sci. 2022, 171, 107184. [Google Scholar] [CrossRef]

- Subirana, A.M.; Solano, J.P.; Herrero-Martín, R.; García, A.; Pérez-García, J. Mixed Convection Phenomena in Tubes with Wire Coil Inserts. TSEP 2023, 42, 101839. [Google Scholar]

- Hashemian, M.; Jafarmadar, S.; Ayed, H.; Wae-hayee, M. Thermal-Hydrodynamic and Exergetic Study of Two-Phase Flow in Helically Coiled Pipe with Helical Wire Insert. Case Stud. Therm. Eng. 2022, 30, 101718. [Google Scholar] [CrossRef]

- Hong, Y.; Du, J.; Wang, S.; Ye, W.B.; Huang, S.M. Turbulent Thermal-Hydraulic and Thermodynamic Characteristics in a Traverse Corrugated Tube Fitted with Twin and Triple Wire Coils. Int. J. Heat Mass Transf. 2019, 130, 483–495. [Google Scholar] [CrossRef]

- Webb, R.L.; Kim, N.H. Principles of Enhanced Heat Transfer, 2nd ed.; Taylor & Francis: New York, NY, USA, 2005; p. 785. [Google Scholar]

- Kline, S.J.; McClintock, F.A. Describing Uncertainties in Single Sample Experiments. Mech. Eng. 1953, 75, 3–8. [Google Scholar]

- Bergman, T.L.; Lavine, A.S.; Incropera, F.P.; Dewitt, P.D. Fundamentals of Heat and Mass Transfer, 7th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2011. [Google Scholar]

- Wang, H.; Al-amir, Q.R.; Jasim, D.J.; Ayed, H.; Mouldi, A.; Deifalla, A.; Mahariq, I. Enhancing the Heat Transfer Efficiency of an Engine Heat Exchanger Through the Utilization of an Innovative Conical Braided Wire Turbulator. Case Stud. Therm. Eng. 2024, 61, 104873. [Google Scholar] [CrossRef]

- Rinik, R.A.; Bhuiyan, A.A.; Karim, M.R. Enhancement of Heat Transfer Using Elliptical Twisted Inner Pipe with Convergent Conical Ring Turbulator for Turbulent Flow in Double Pipe Heat Exchanger. Int. J. Therm. Sci. 2025, 210, 109558. [Google Scholar] [CrossRef]

| Authors | Summary of Experimental Circular Tube Thermal Performance Index (TPI) |

|---|---|

| Fan et al. [1] | Numerical study of a circular tube with conical strip inserts for turbulent flow (Re = 12,000–42,000). Larger slant angles and smaller pitches improved heat transfer but increased resistance, with slant angle having a stronger influence. |

| Gunes et al. [3] | Coiled wire inserts (Re = 4105–26,400). Results showed Nu/Nup = 2.38–3.03, f/fp = 7.13–8.22, and TPI ≈ 1.51. Optimal performance occurred at P/D = 1.0, s = 1.0 mm, Re ≈ 4220, giving ~50% higher efficiency than the smooth tube. Decreasing the pitch ratio and wall gap enhanced both Nusselt number and friction factor |

| Karakaya and Durmus [4] | Conical spring turbulators (CST) at angles of 30°, 45°, and 60° (Re = 10,000–34,000). The inserts enhanced heat transfer and increased pressure drop compared to a smooth tube. Optimal conditions were found at moderate spring angles, where Thermal performance index and exergy efficiency were improved. Conical-shaped springs with a 30° cone angle exhibited the highest heat transfer enhancement. |

| Keklikcioglu and Ozceyhan [6] | Triangular coiled-wire inserts placed 1 mm from the wall (Re = 2851–27,732). The best configuration (e/D = 0.0892, P/D = 1.0) achieved Nu/Nup = 2.12–3.41, f/fp = 4.2–8.8, and TPI ≈ 1.68, showing ~18% higher enhancement than earlier wire designs. The optimal configuration (e/D = 0.089, P/D = 1.0) achieved up to 1.68 times higher thermal performance than a smooth tube. |

| Nanan et al. [7] | Helically twisted tape inserts inducing co- and counter-swirl flows (Re = 6000–20,000). Results showed Nu/Nup = 2.82–3.29, f/fp = 33.2–36.7, and TPI ≈ 1.29. Counter-swirl tapes gave higher heat transfer but lower overall efficiency, while co-swirl tapes provided better thermal performance index at larger pitch ratios. Helically twisted tapes inducing co-swirl flows achieved higher thermal performance factors than counter-swirl tapes, while reducing pitch ratios increased Nusselt number and friction factor but lowered thermal performance. |

| Akhavan-Behabadi et al. [8] | Double-pipe heat exchanger with coiled wire inserts during oil heating (Re based on oil flow). Wire diameters of 2.0 and 3.5 mm with pitches of 12–69 mm were tested. The inserts significantly increased the heat transfer coefficient and friction factor compared to a smooth tube. Empirical correlations for Nu/Nup and f/fp were developed, predicting results within ±20%, with optimal performance at smaller pitch and larger wire diameter. Wire coil inserts with smaller wire diameters demonstrated superior thermal performance, particularly at low Reynolds numbers, while variations in coil pitch had only a minor influence on heat transfer enhancement. |

| Gunes et al. [10] | Triangular coiled-wire inserts placed 1 mm from the wall (Re = 3500–27,000). Results showed Nu/Nup = 2.12–3.41 and f/fp = 4.2–8.8. The best performance occurred at a/D = 0.0892, P/D = 1, Re ≈ 3858, with ~36.5% overall enhancement, especially effective at low Reynolds numbers for compact heat exchanger design. Increasing wire thickness and decreasing pitch ratio improved heat transfer, with the highest overall enhancement efficiency of 36.5% achieved at a/D = 0.0892 and P/D = 1.0 for a Reynolds number of 3858 |

| Hong et al. [11] | Wire coil (WC) inserts of uniform, varying pitch, and gradually varying width (Re = 6000–20,000). Heat transfer was enhanced with Nu/Nup = 1.46–2.49 and friction factor increased to f/fp = 8.36–18.62. The highest TPI ≈ 1.14 was achieved for uniform pitch WCs at p/d = 1.034, while varying pitch and width provided no further efficiency improvement despite higher Nu. |

| Nanan et al. [21] | Wire-rod bundle turbulators (Re = 6000–20,000). Results showed Nu/Nup = 1.04–1.69 and f/fp = 2.56–4.53, depending on rod number and pitch ratio. The TPI ≈ 1.02 was achieved at high rod numbers with low pitch ratios, indicating minor efficiency gains but consistent enhancement trends. Increasing the number of wires and reducing the pitch ratio improved the Nusselt number and thermal performance. |

| Naphon and Suchana [22] | Concentric tube heat exchanger with twisted wire brush inserts (Re = 6000–20,000). Increasing brush density (100–300 wires/cm) enhanced heat transfer but also caused significant pressure loss. Compared to the plain tube, heat transfer rose markedly (Nu/Nup > 1) while friction increased substantially, with no optimal TPI beyond unity due to high flow resistance. Increasing the density of full-length twisted wires enhanced heat transfer and Nusselt number, with the 300-wire insert giving the best results. |

| Bhuiya et al. [23] | Twisted wire brush inserts (Re = 7200–50,200). Heat transfer and friction were significantly enhanced, with Nu/Nup ≈ 2.15 and f/fp ≈ 2.0 over the plain tube. The TPI ≈ 1.85 was obtained at higher wire densities, confirming strong thermo-hydraulic improvement under constant blower power. |

| Chompookham et al. [27] | Serrated wire coil (SWC) inserts combining coiled wire and V-shaped ribs (Re = 5114–14,752). Heat transfer increased with decreasing pitch and larger coil diameter, giving Nu/Nup = 1.75–2.46 and f/fp = 3.31–8.16. The maximum TPI ≈ 1.41 was achieved at DC = 47.9 mm, PC = 10 mm, Re = 5114, confirming SWC as a more effective turbulator than conventional coils. Smaller pitch lengths and larger coil diameters improved heat transfer enhancement. |

| Hashemian et al. [29] | Helically coiled tubes with helical wire inserts under single-phase (water) and two-phase (air–water) flow. Water flow rates of 2–8 L/min and air flow rates of 1.0–5.0 L/min were tested (VF = 0.11–0.714). Results showed enhanced heat transfer but increased pressure drop, with exergy efficiency reduced by up to 87% when inserts were used in single-phase flow. Optimal use was suggested for two-phase flow with turbulator where heat transfer improvement outweighs friction losses. For single-phase flow, exergy efficiency is higher without a turbulator. |

| Hong et al. [30] | Traverse corrugated tubes (TCTs) with twin and triple wire coil (WC) inserts (Re = 6000–18,000). Heat transfer rose with coil number and reduced spacing, giving Nu/Nup = 1.74–2.61 and f/fp = 4.57–21.34. The maximum TPI ≈ 1.09 was found for twin WCs at S/D = 18.1, while the TCT alone reached TPI ≈ 1.26. Entropy analysis showed reduced Bejan number, with the lowest augmented entropy generation at triple WCs, S/D = 0.0, Re ≈ 6428. Heat transfer improved with more coils and smaller spacing, though the best overall performance occurred with twin WCs at the largest spacing |

| List | Value | Unit |

|---|---|---|

| Cross-sectional diameter (D) | 17.5 | mm |

| Length of knitted wire coil (L) | 650 | mm |

| Pitch of knitted wire coil (P) | 6.8 | mm |

| Pitch ratio (P/D) | 0.9 | - |

| Diameter of wire (d1) | 0.7 | mm |

| Diameter of core rod (d2) | 1.0 | mm |

| Number of loops per pitch (N) | 6, 8, 10, and 12 | - |

| List | Value | Unit |

|---|---|---|

| Test section length | 650 | mm |

| Overall test section length | 1700 | mm |

| Entry length | 700 | mm |

| Exit length | 350 | mm |

| Inner diameter of test tube (Di) | 17.5 | mm |

| Thickness of test tube (δ) | 1.0 | mm |

| Material | Copper | |

| Variable | Uncertainties (%) |

|---|---|

| Air flow velocity, U | ±2.98 |

| Air viscosity, µ | ±0.07 |

| Pressure, P | ±4.1 |

| Ammeter, I | ±2.2 |

| Air temperature, T | ±0.14 |

| Thermal conductivity, k | ±0.37 |

| Voltmeter, V | ±0.97 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wongcharee, K.; Shoon Wai, T.; Maruyama, N.; Hirota, M.; Chuwattanakul, V.; Promthaisong, P.; Eiamsa-ard, S. Intensification of Thermal Performance of a Heat Exchanger Tube with Knitted Wire Coil Turbulators Installed. Eng 2025, 6, 337. https://doi.org/10.3390/eng6120337

Wongcharee K, Shoon Wai T, Maruyama N, Hirota M, Chuwattanakul V, Promthaisong P, Eiamsa-ard S. Intensification of Thermal Performance of a Heat Exchanger Tube with Knitted Wire Coil Turbulators Installed. Eng. 2025; 6(12):337. https://doi.org/10.3390/eng6120337

Chicago/Turabian StyleWongcharee, K., T. Shoon Wai, N. Maruyama, M. Hirota, V. Chuwattanakul, P. Promthaisong, and S. Eiamsa-ard. 2025. "Intensification of Thermal Performance of a Heat Exchanger Tube with Knitted Wire Coil Turbulators Installed" Eng 6, no. 12: 337. https://doi.org/10.3390/eng6120337

APA StyleWongcharee, K., Shoon Wai, T., Maruyama, N., Hirota, M., Chuwattanakul, V., Promthaisong, P., & Eiamsa-ard, S. (2025). Intensification of Thermal Performance of a Heat Exchanger Tube with Knitted Wire Coil Turbulators Installed. Eng, 6(12), 337. https://doi.org/10.3390/eng6120337