Engineering Parameter Design for CO2 Geological Storage: Research Progress and Case Analyses

Abstract

1. Introduction

2. Basic Overview of Global CCS Project Development

2.1. European and African Regions

2.2. Americas

2.3. Asia-Pacific Region

3. Saline Aquifer Storage Project

3.1. Norway’s Sleipner Project

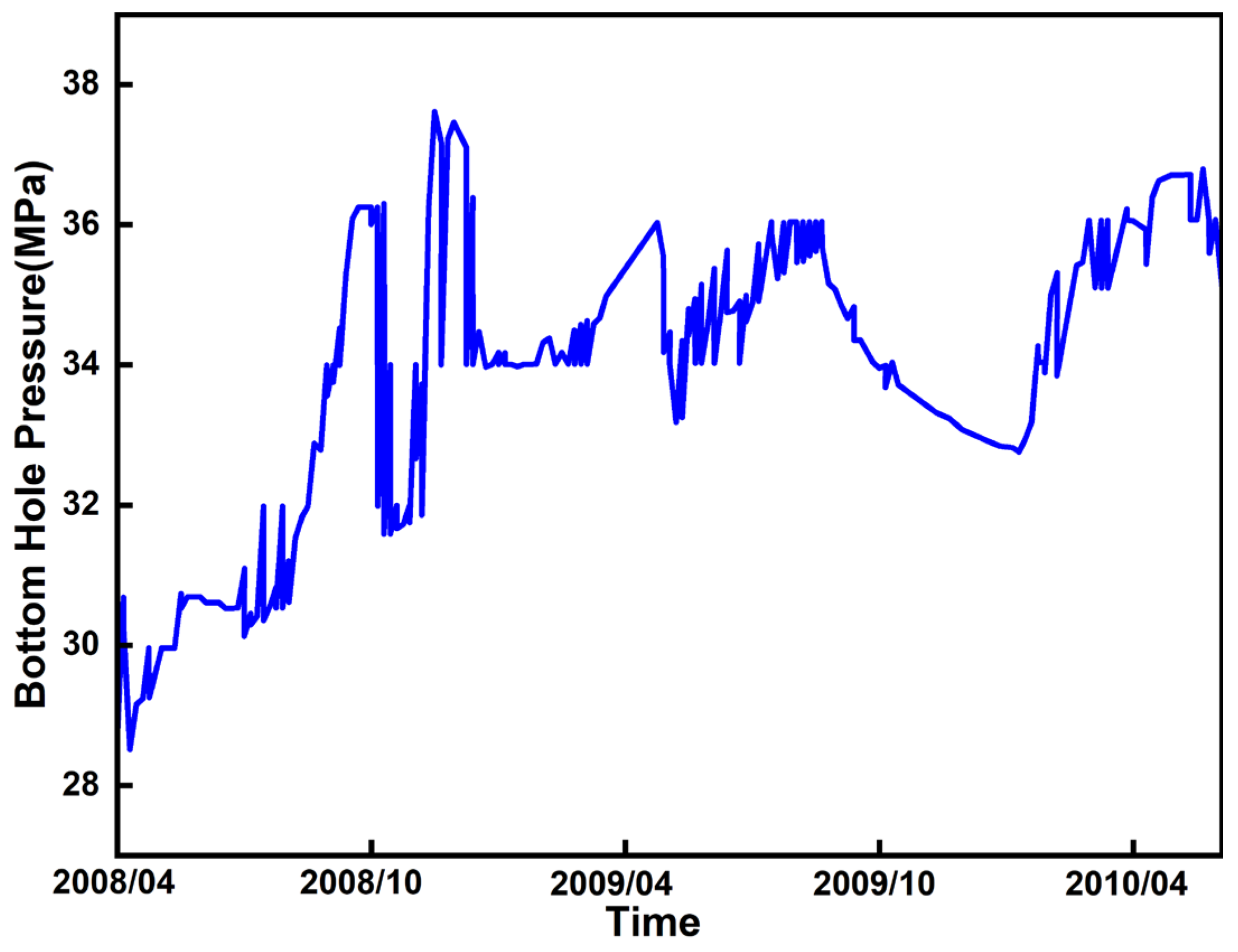

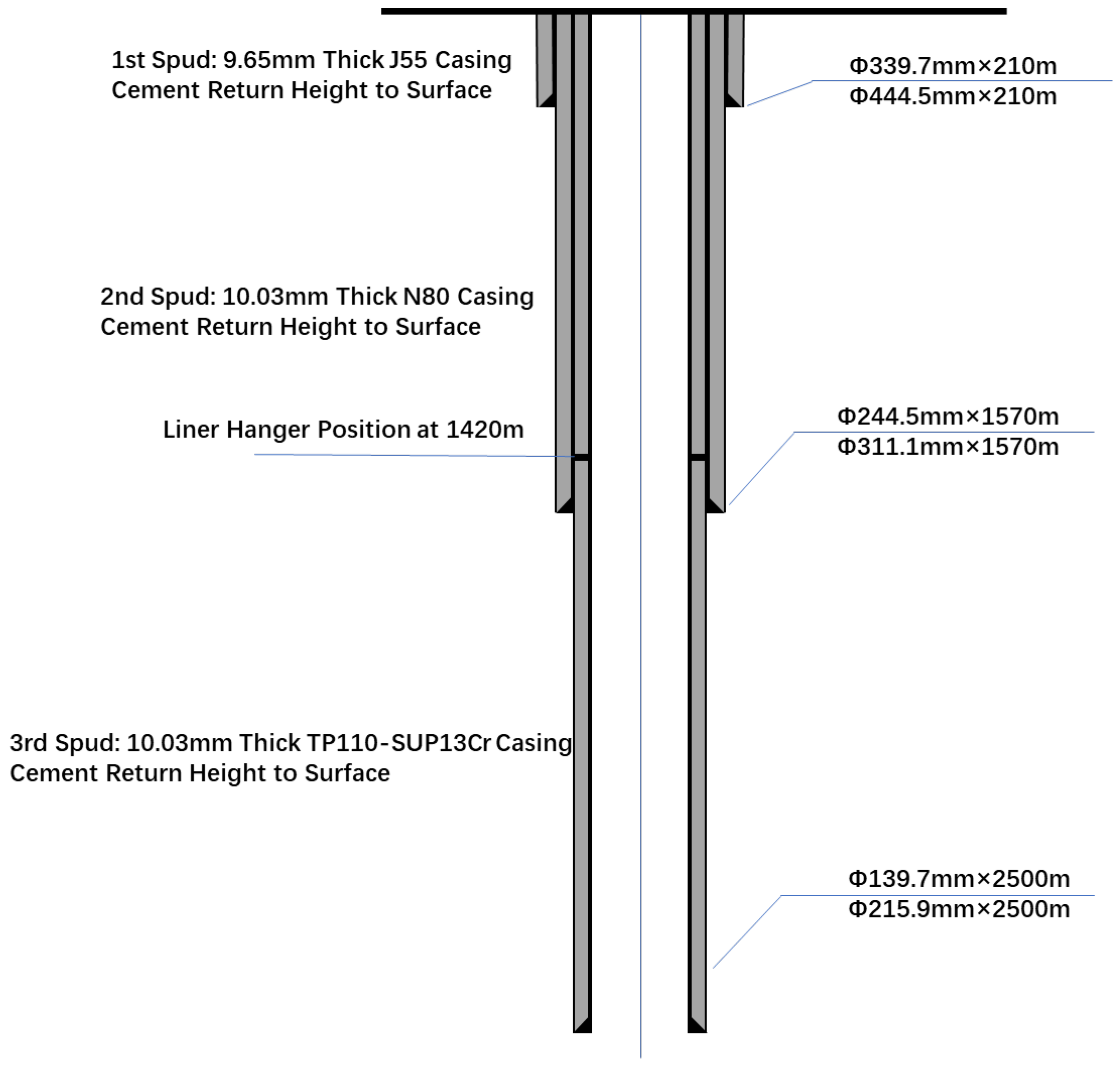

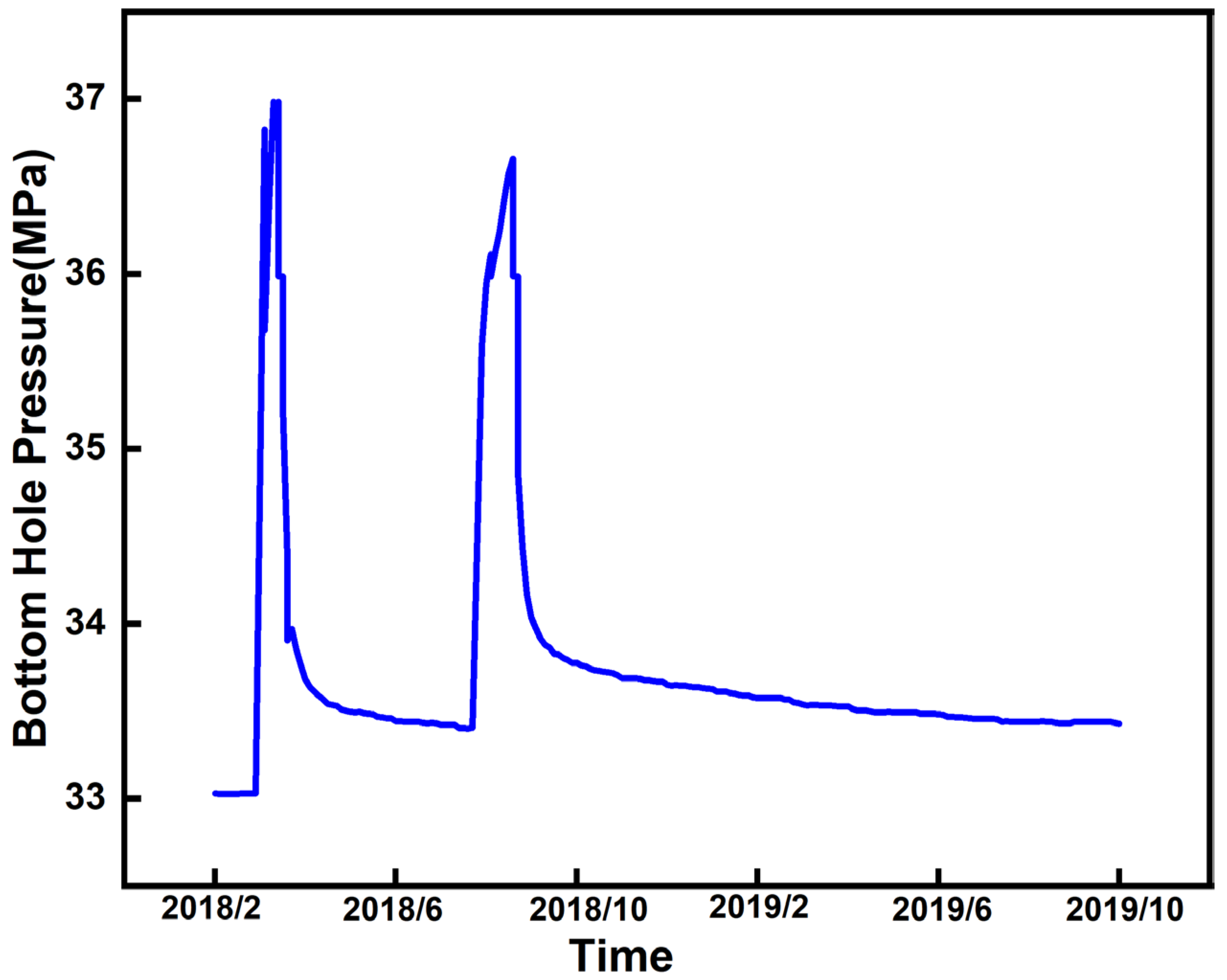

3.2. Norway’s Snøhvit Project

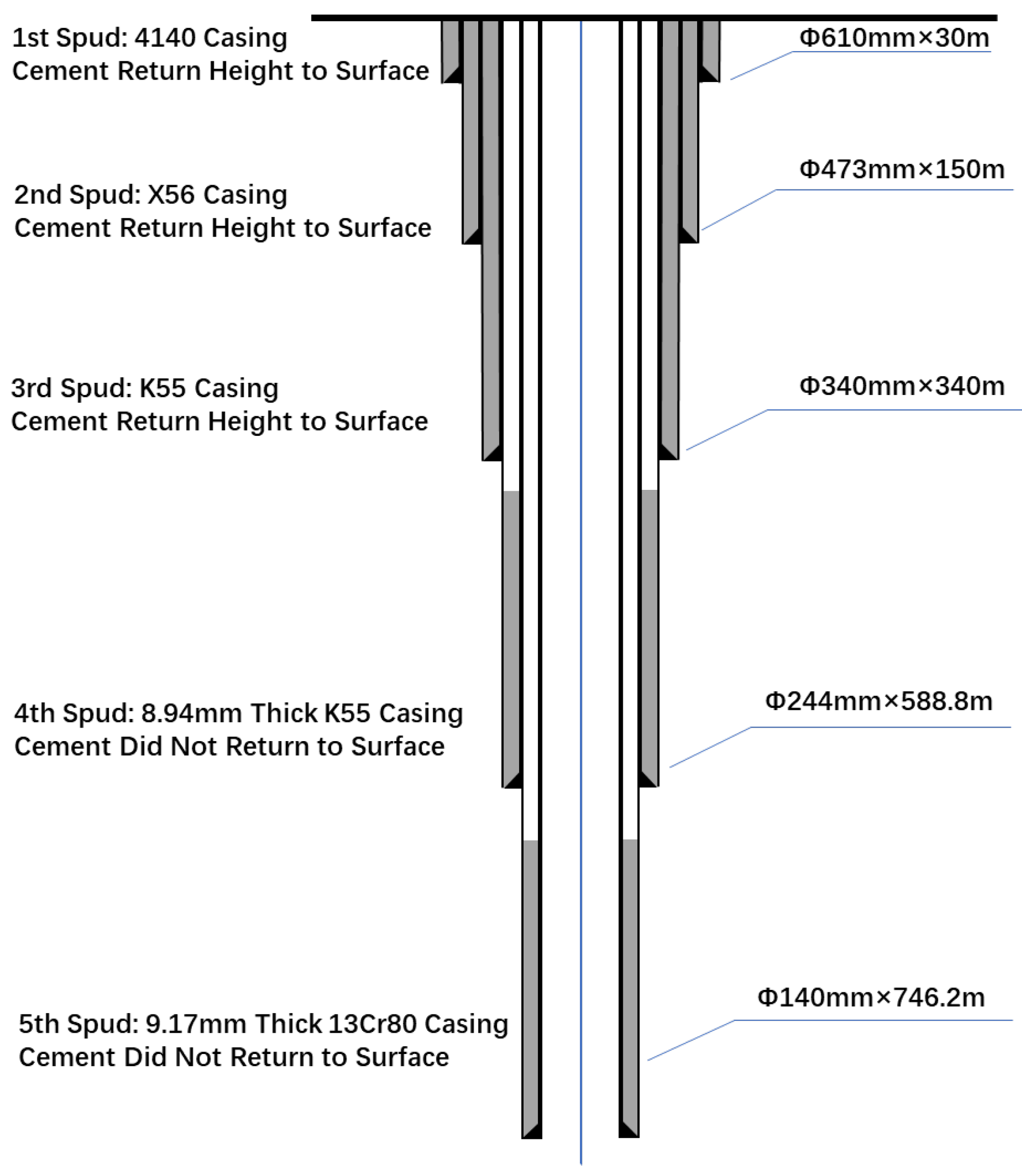

3.3. Germany’s Ketzin Project

3.4. Canada’s Quest Project

3.5. U.S. Decatur Project

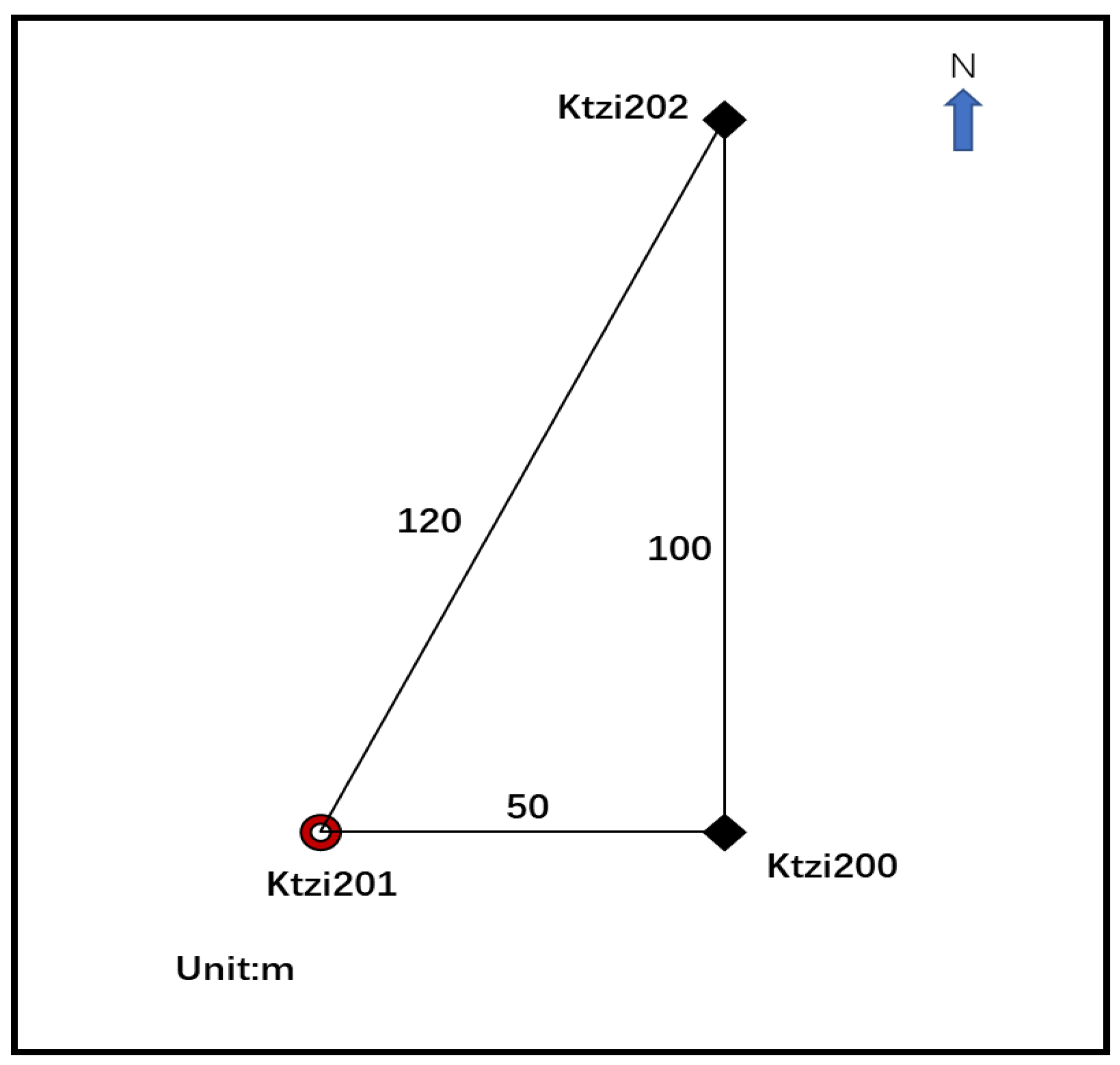

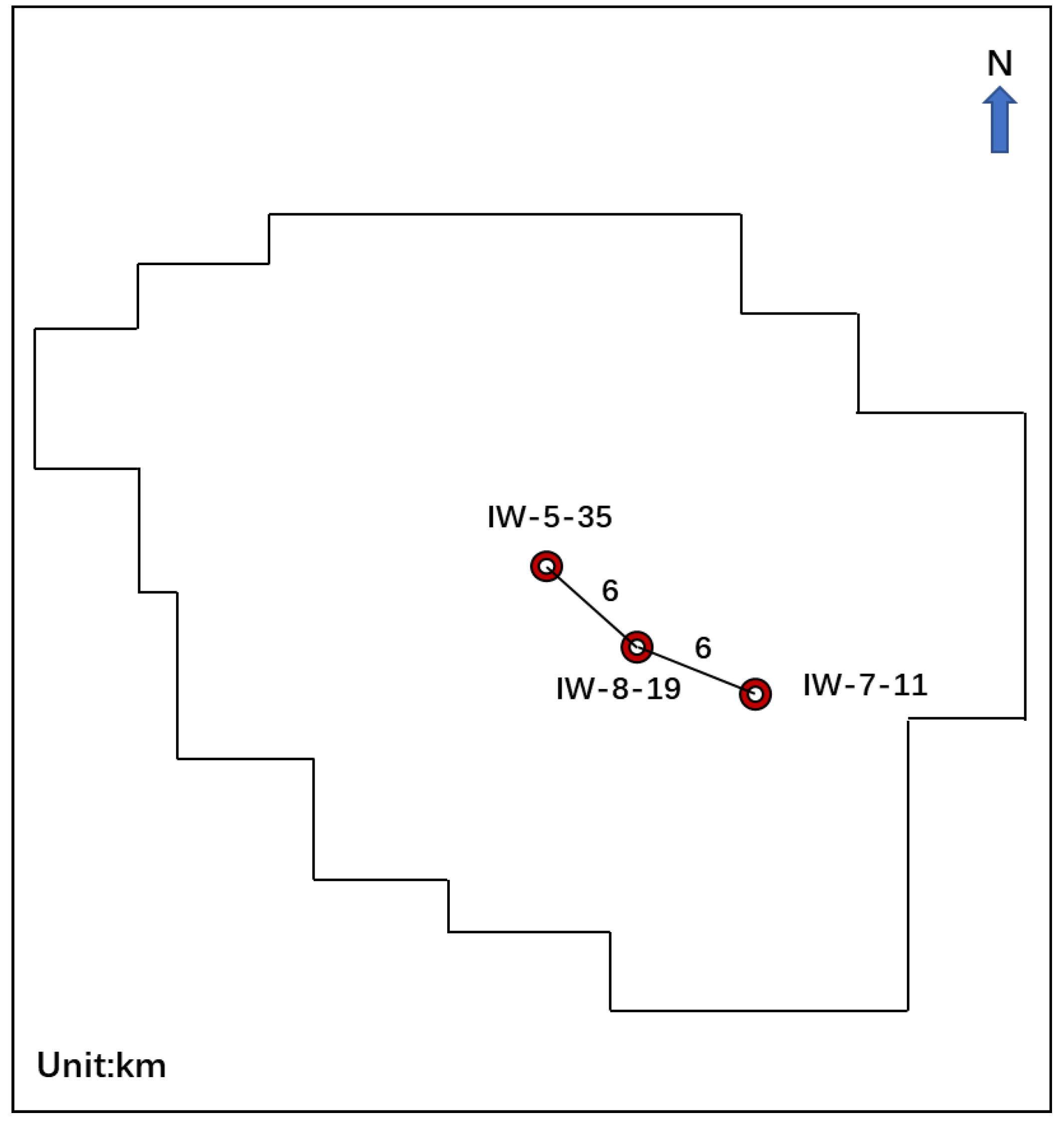

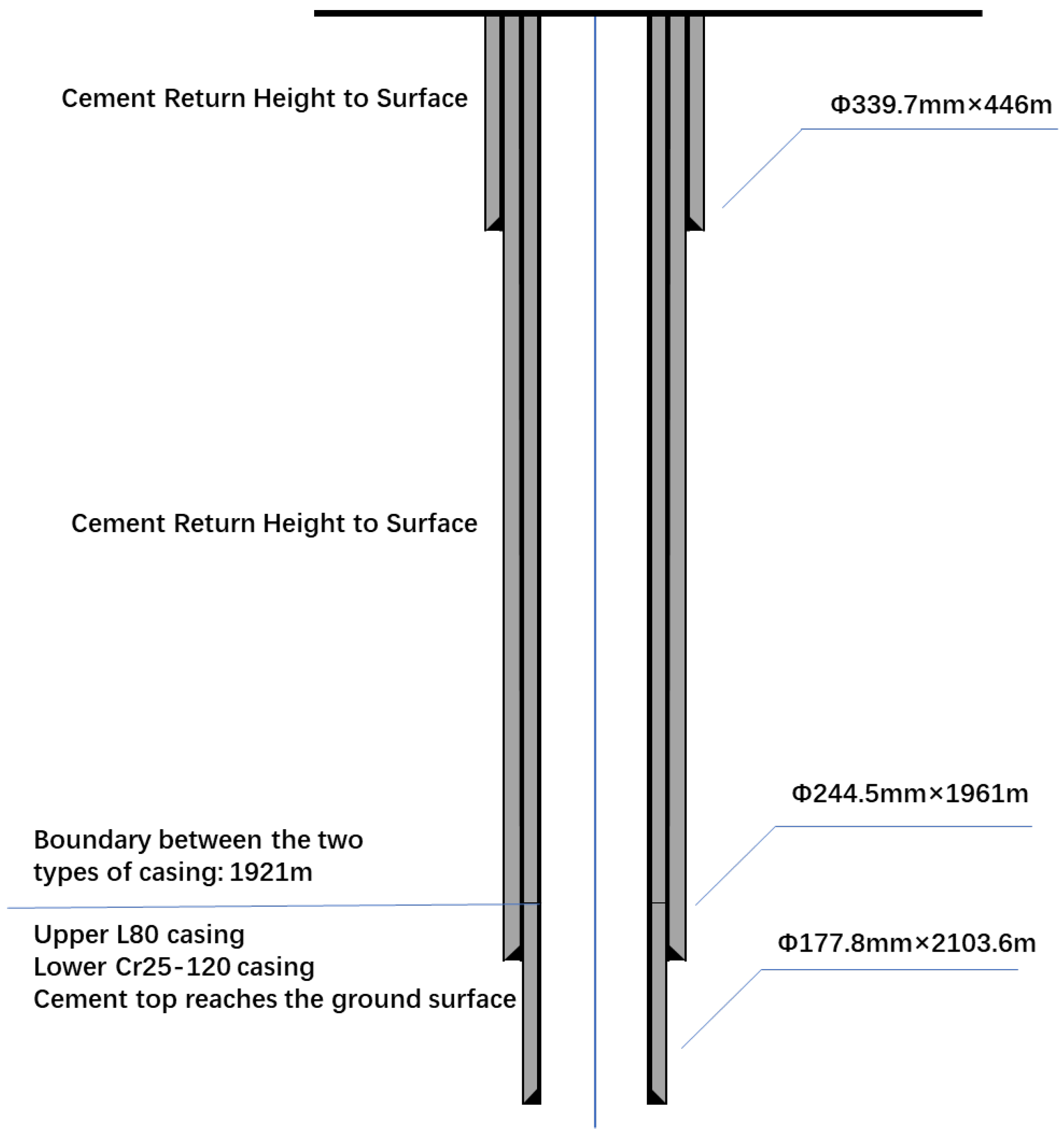

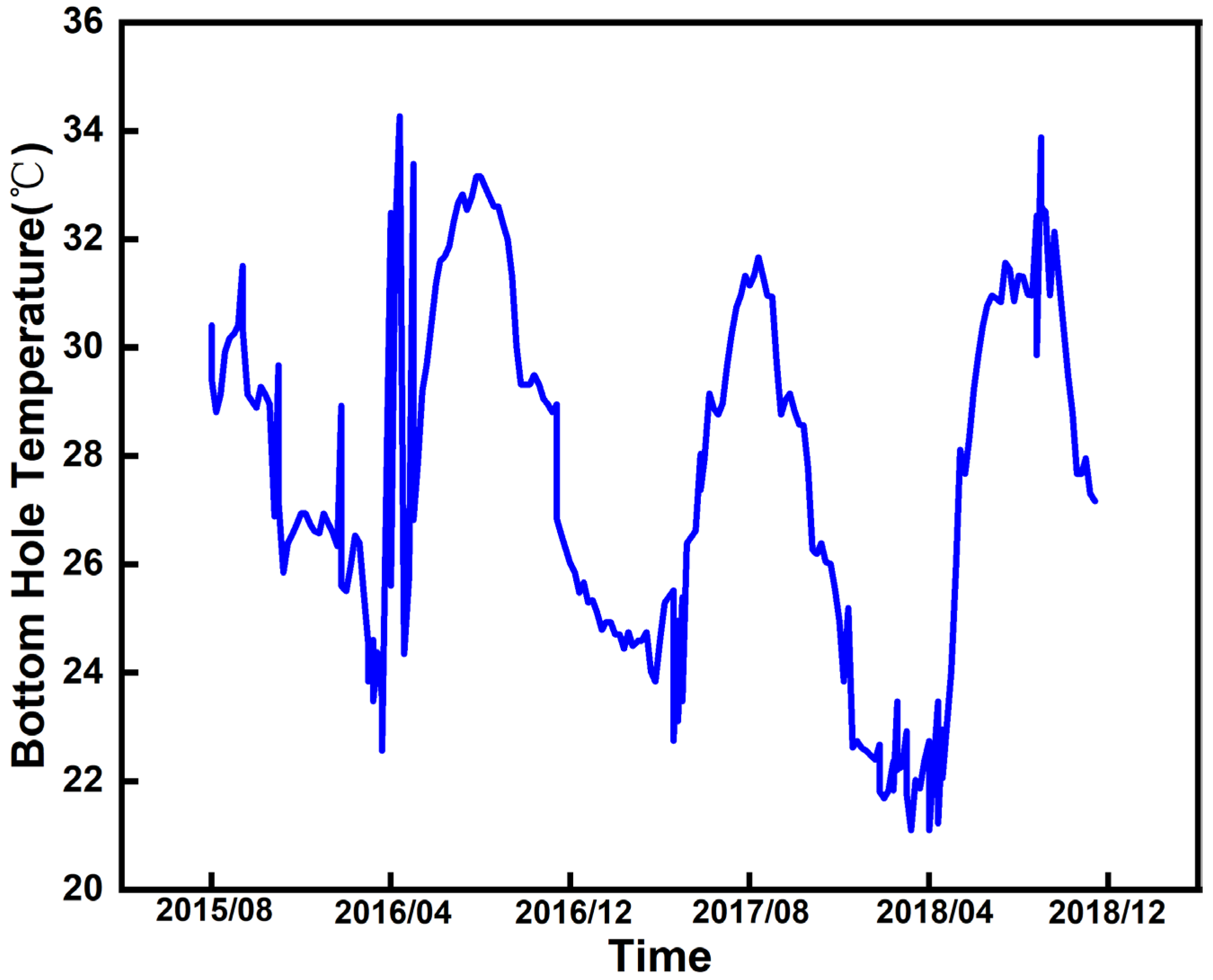

3.6. China’s Shenhua Project

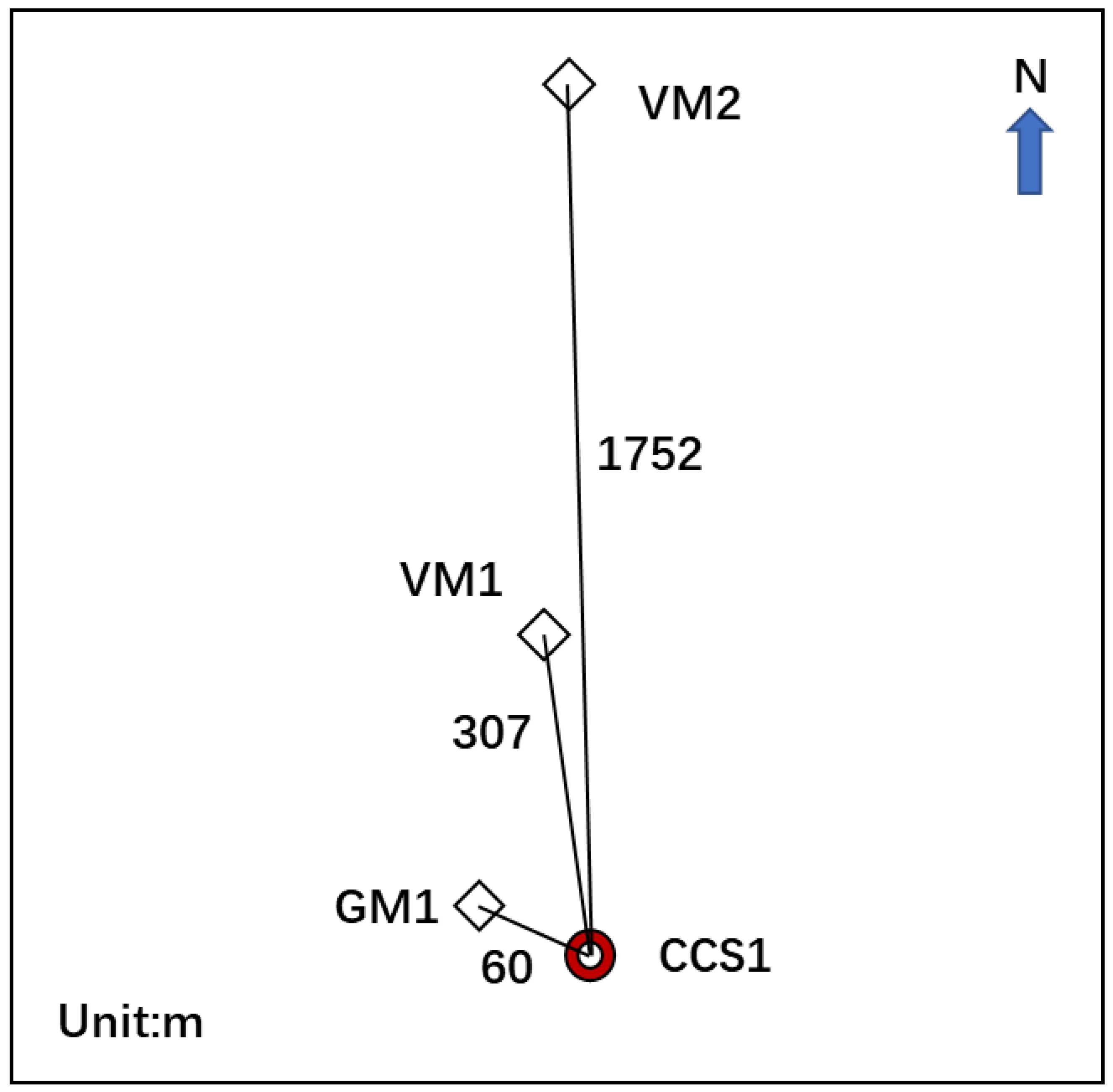

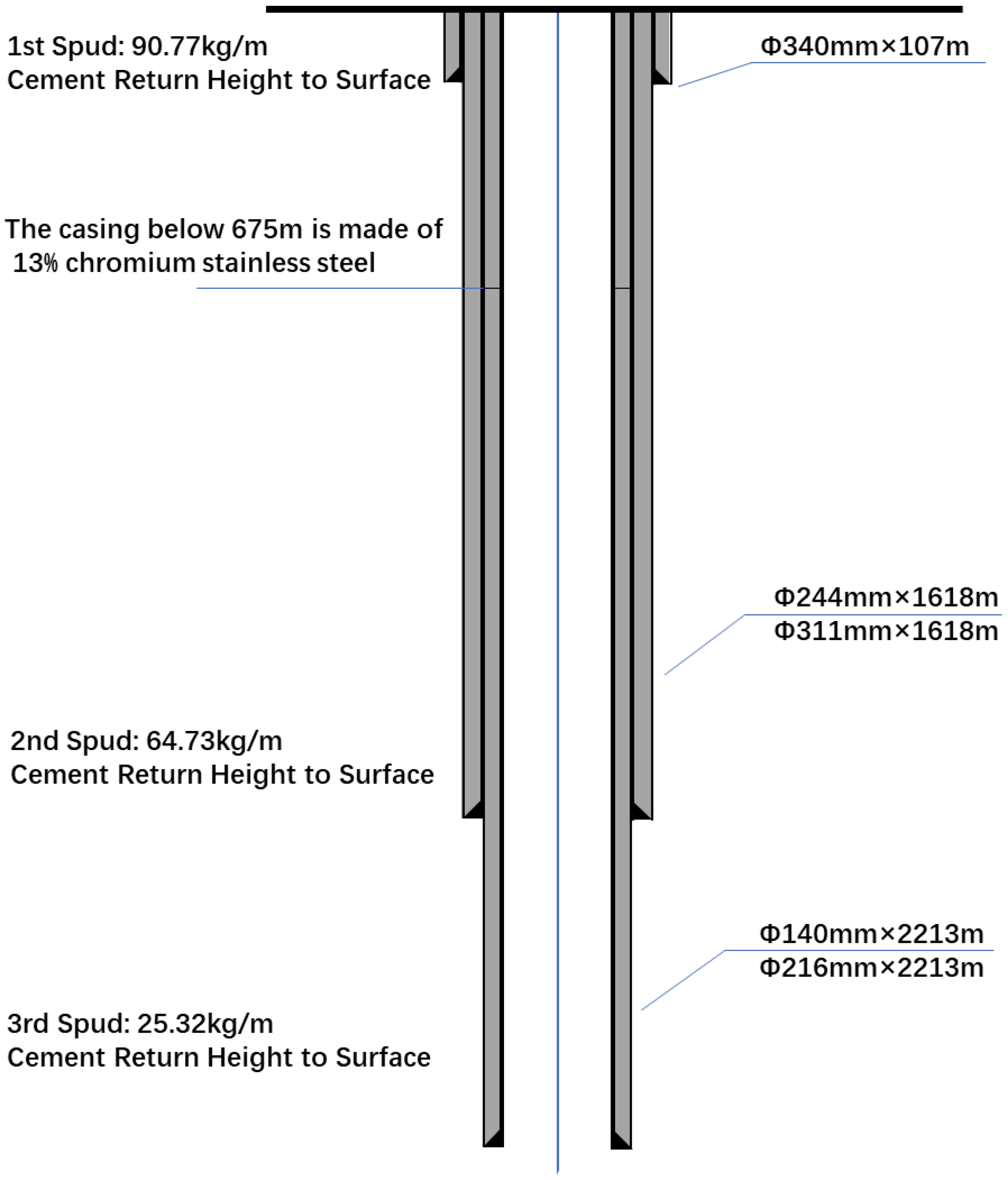

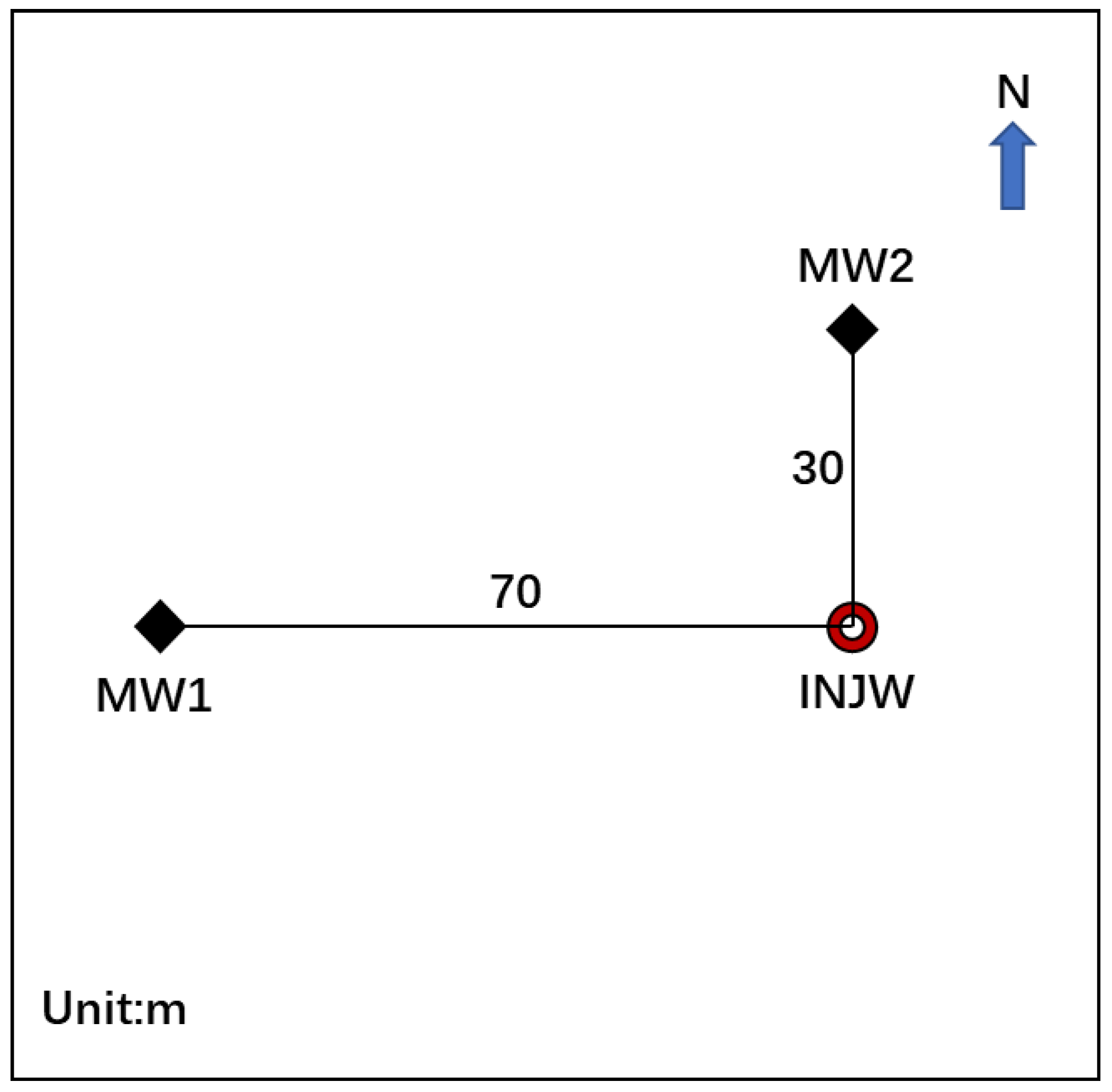

3.7. Japan’s Tomakomai Project

3.8. Australia’s Gorgon Project

3.9. Summary of Saline Aquifer Storage Projects

4. Depleted Oil and Gas Reservoir Storage Project

4.1. Algeria’s in Salah Project

4.2. Brazilian Pre-Salt Project

4.3. Canada’s Weyburn Project

4.4. Canada’s Pembina Project

4.5. Summary of Depleted Oil and Gas Reservoir Storage Projects

5. Basalt Storage Project

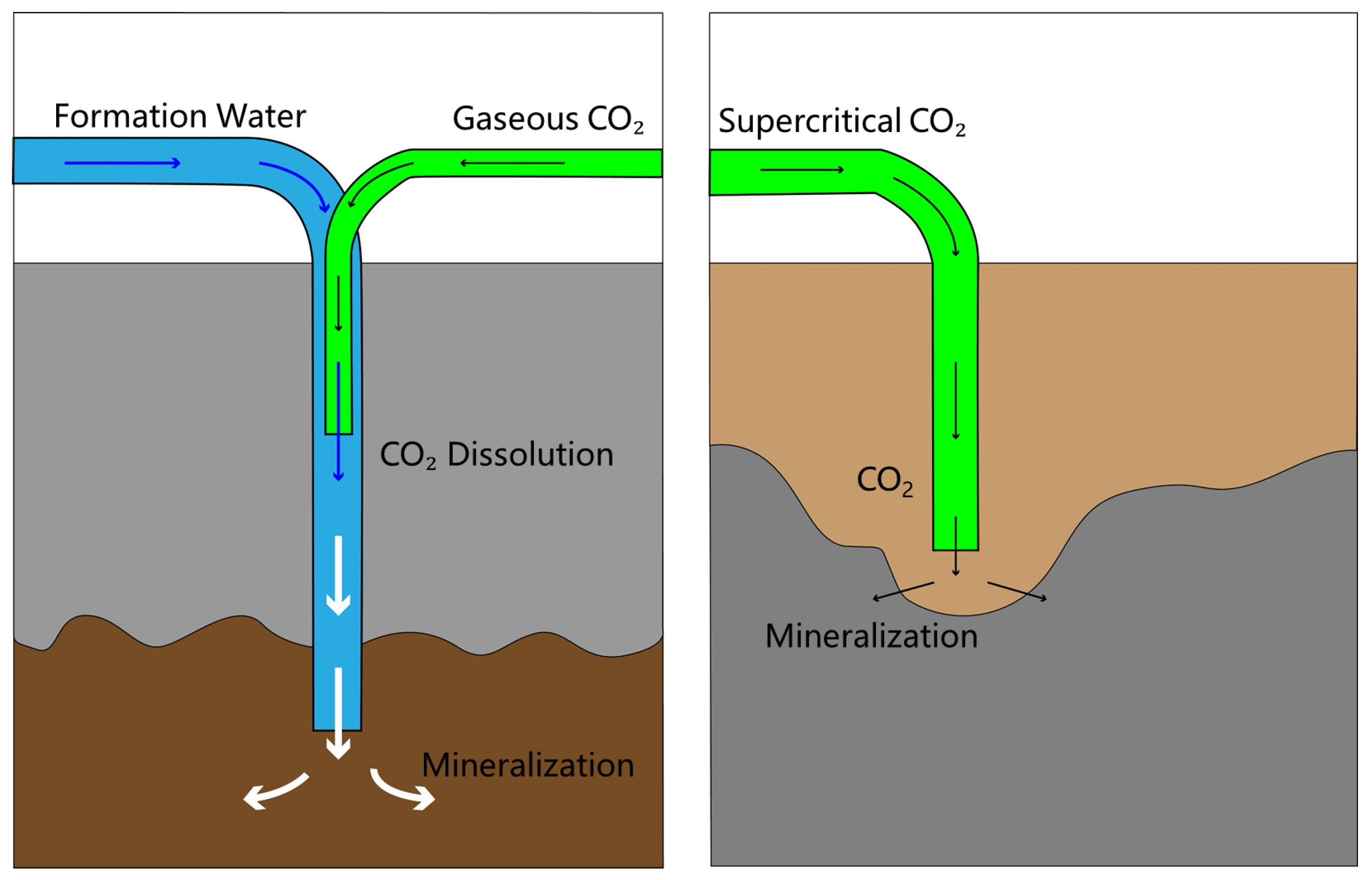

5.1. Iceland’s Carbfix Project

5.2. U.S. Wallula Project

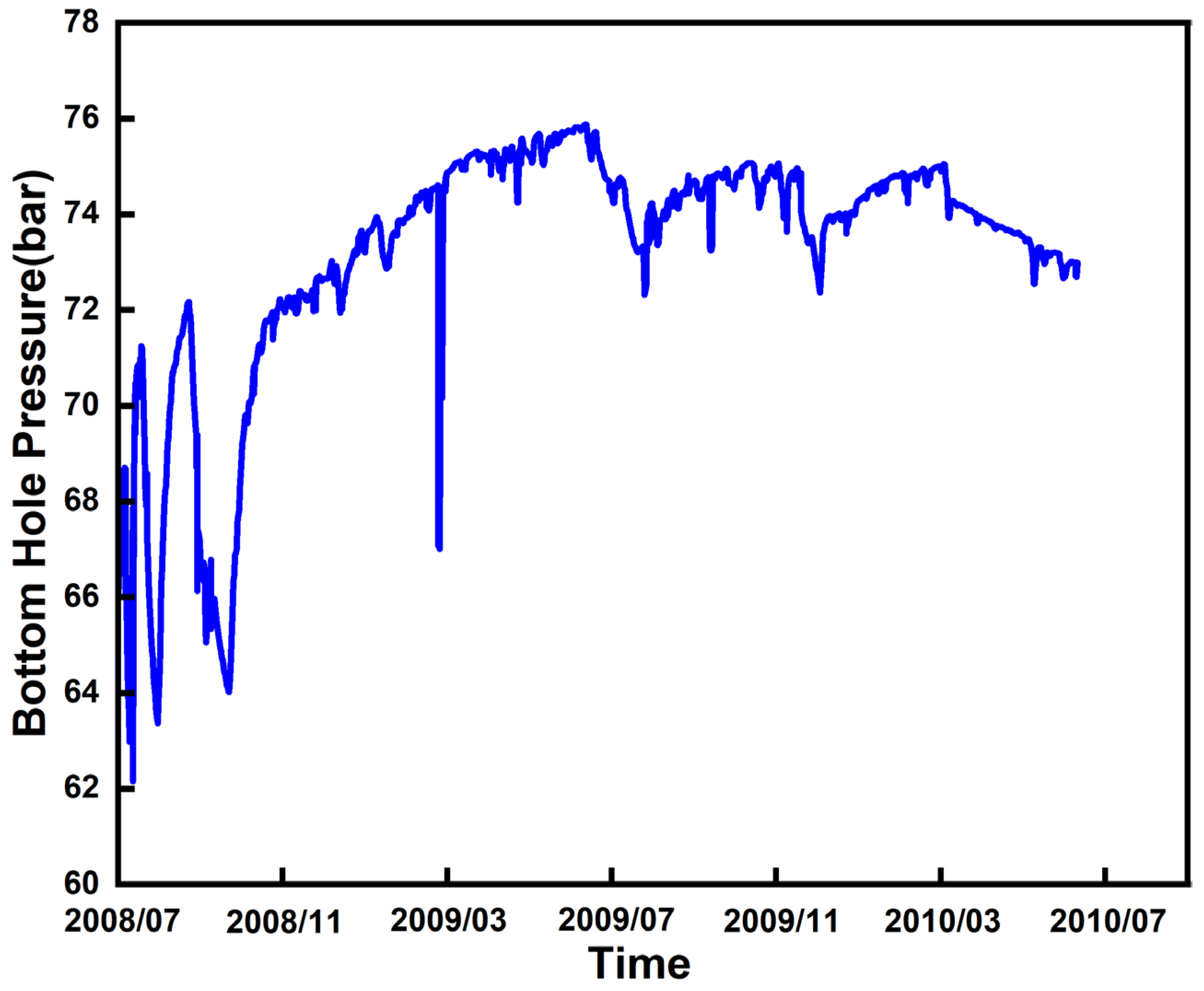

5.3. Japan’s Nagaoka Project

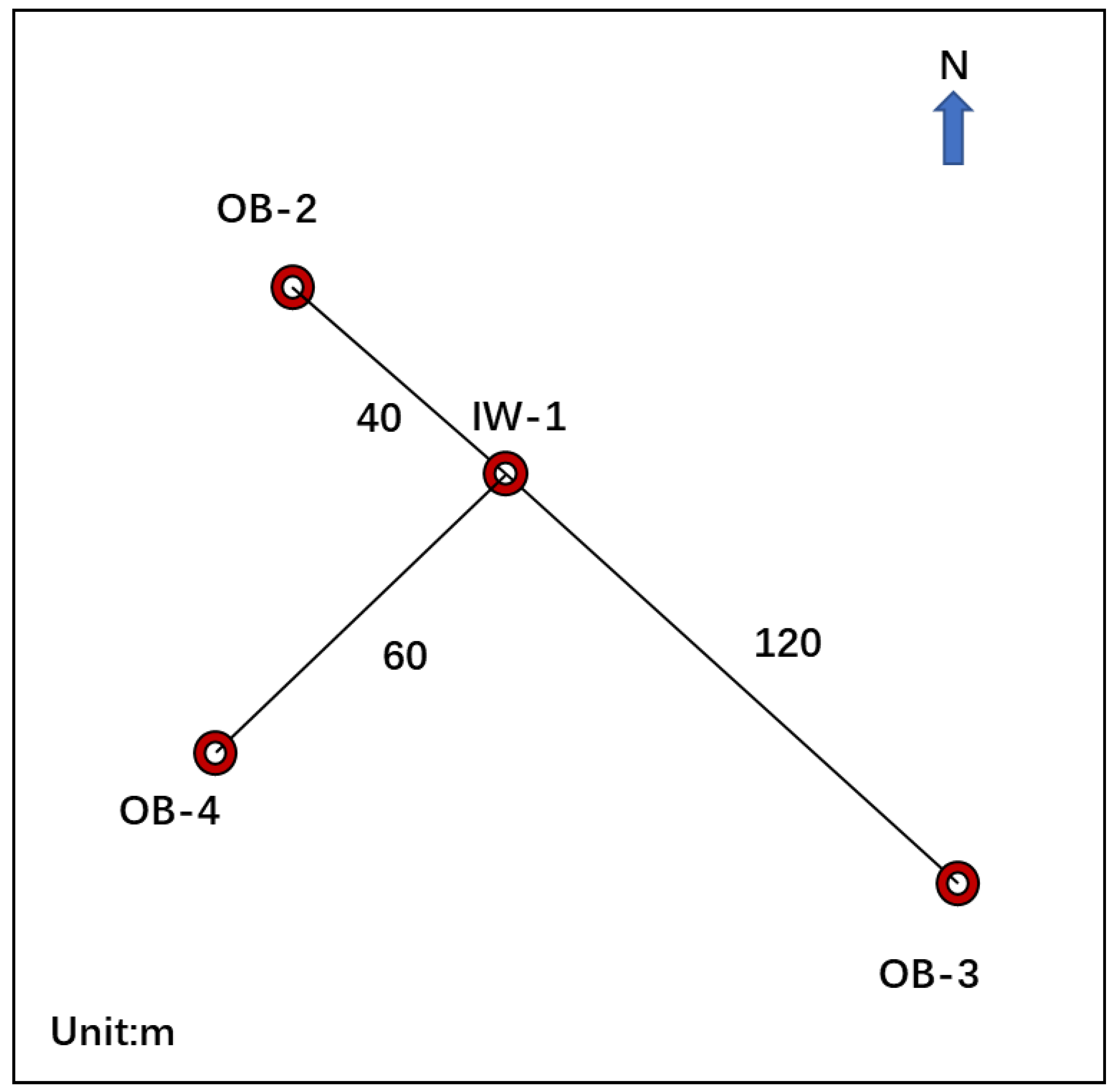

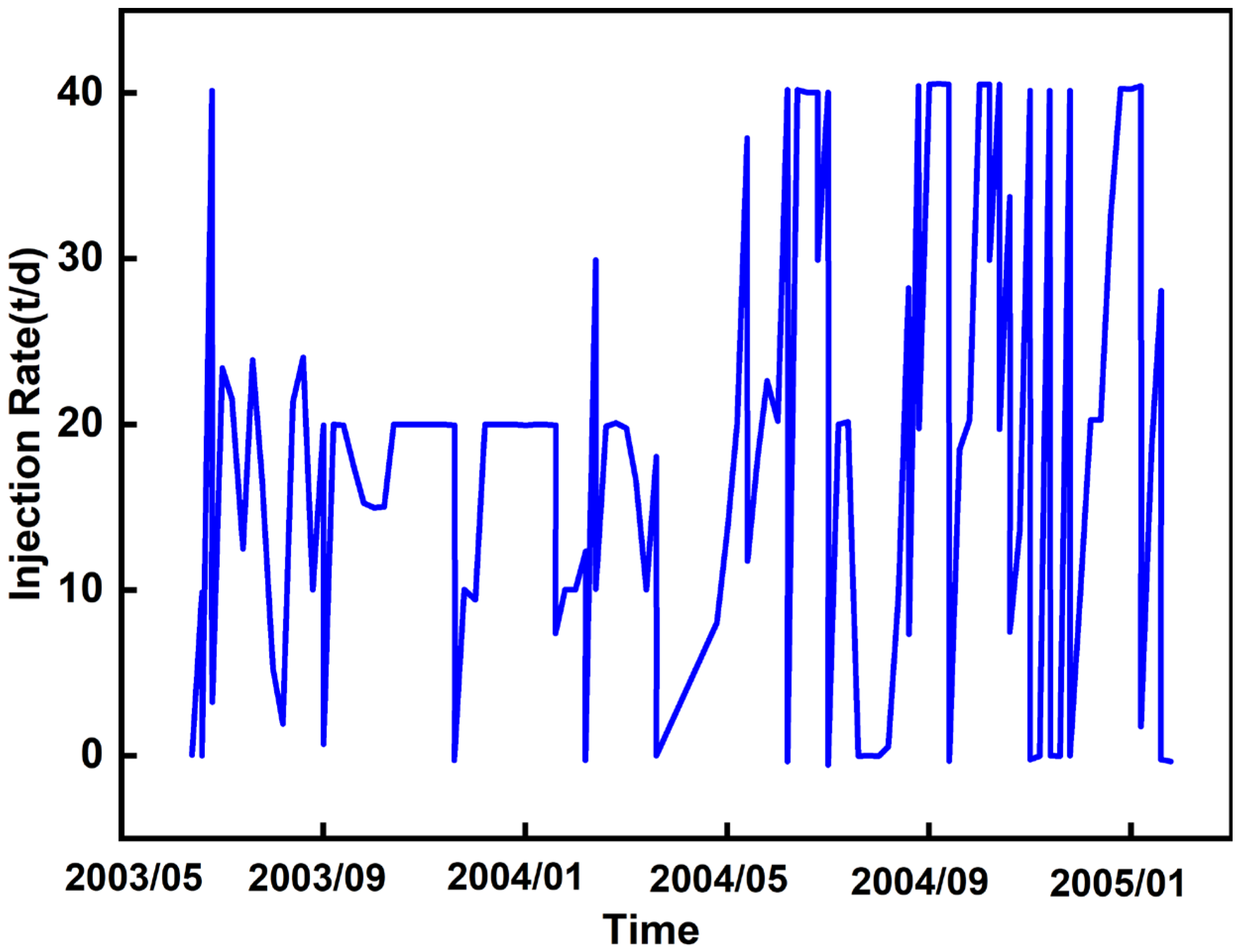

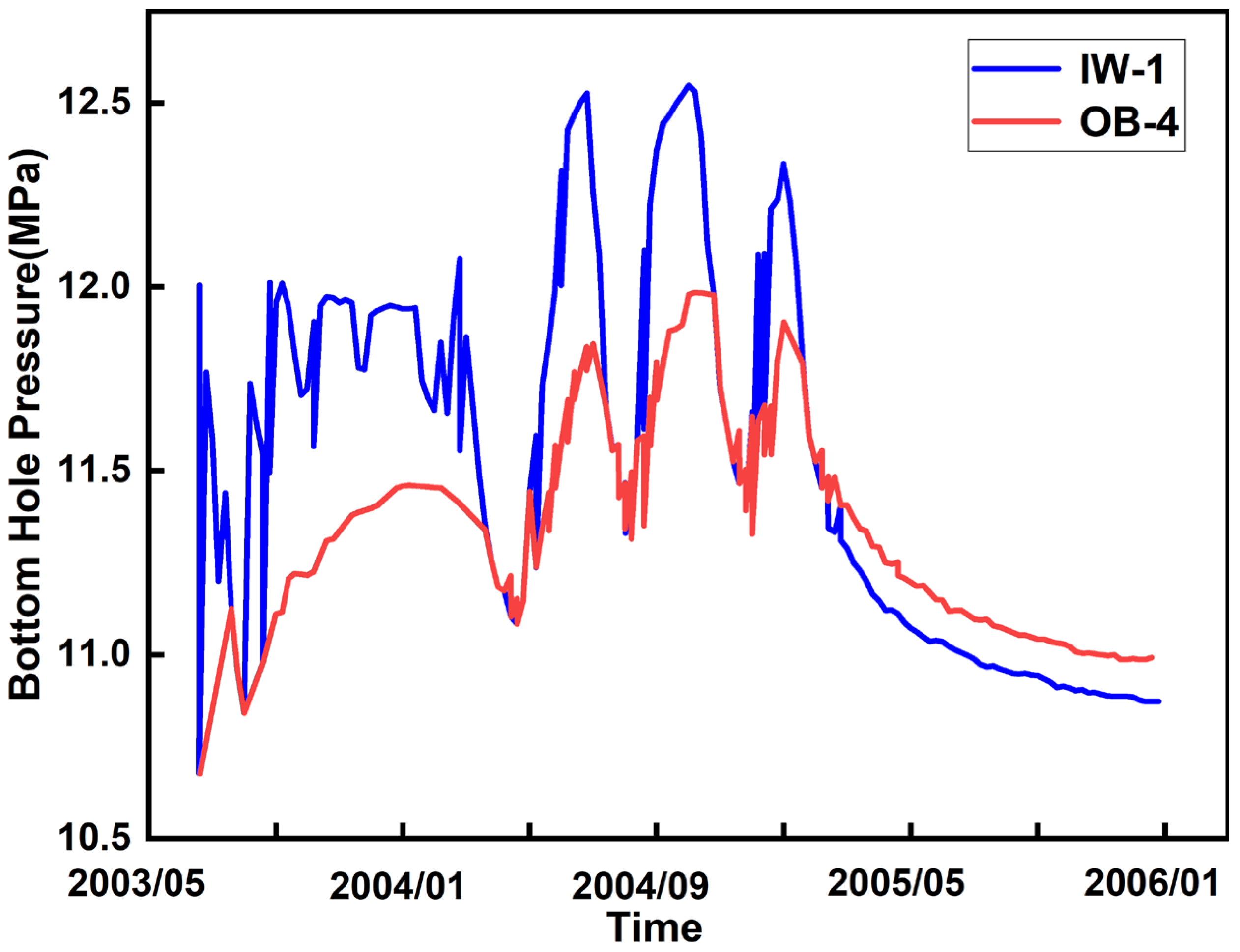

5.4. Summary of Basalt Storage Projects

6. Challenges and Measures for the Engineering and Technological Development of CCS Projects

6.1. Challenges in the Engineering and Technological Development of CCS Projects

6.2. Engineering and Technological Response Measures for CCS Projects

7. Conclusions and Prospects

7.1. Conclusions

7.2. Prospects

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zang, Y.Q.; Gao, Z.J.; Zhong, W. Overview of Research and Application of CO2 Geological Sequestration at Home and Abroad. J. Environ. Eng. Technol. 2012, 2, 503–507. [Google Scholar]

- Luo, D.; Chen, J.W.; Yuan, Y.; Li, Q.; Liang, J.; Zhao, H. Progress of Norway’s Northern Lights project and its implications for offshore CO2 geological storage of China. Mar. Geol. Front. 2025, 41, 48–55. [Google Scholar]

- Bi, F.Q.; Li, F.; Liang, H. Domestic and Foreign Research and Application Progress on CO2-EOR Technology. Value Eng. 2011, 30, 206–207. [Google Scholar]

- Zheng, C.Y.; Cai, Y.N.; Lei, H.W.; Feng, G.H. Simulation of Two-Phase Reactive Flow Characteristics of Natural CO2 Leakage Along Wellbore. Saf. Environ. Eng. 2024, 31, 196–204. [Google Scholar]

- Li, X.G.; Li, K.Y.; Yang, Z.Z.; Zhu, J.G.; Yuan, J.F.; Yi, L.G. Dynamic characteristics of chemical reactions between supercritical CO2 and clay minerals. Fault-Block Oil Gas Fld. 2025, 32, 331–338. [Google Scholar]

- Peng, H.; Yang, J.; Peng, J.; Han, H.; Gou, X.; Jia, Y.; Li, Y.; Kadet, V. Influence of Supercritical CO2 on the Physical Property of Tight Sandstone. Petroleum 2024, 10, 520–526. [Google Scholar] [CrossRef]

- Fan, X.; Li, L.; Gao, X.; Chen, Z.-H. The analysis of COP28 Global Stocktake outcome and global climate governance prospects. Adv. Clim. Change Res. 2024, 20, 253–260. [Google Scholar]

- Michael, K.; Golab, A.; Shulakova, V.; Ennis-King, J.; Allinson, G.; Sharma, S.; Aiken, T. Geological Storage of CO2 in Saline Aquifers—A Review of the Experience from Existing Storage Operations. Int. J. Greenh. Gas Control 2010, 4, 659–667. [Google Scholar] [CrossRef]

- Furre, A.-K.; Eiken, O.; Alnes, H.; Vevatne, J.N.; Kiær, A.F. 20 Years of Monitoring CO2-Injection at Sleipner. Energy Procedia 2017, 114, 3916–3926. [Google Scholar] [CrossRef]

- Eiken, O.; Ringrose, P.; Hermanrud, C.; Nazarian, B.; Torp, T.A.; Høier, L. Lessons Learned from 14 Years of CCS Operations: Sleipner, In Salah and Snøhvit. Energy Procedia 2011, 4, 5541–5548. [Google Scholar] [CrossRef]

- Estublier, A.; Lackner, A.S. Long-Term Simulation of the Snøhvit CO2 Storage. Energy Procedia 2009, 1, 3221–3228. [Google Scholar] [CrossRef]

- Buscheck, T.A.; White, J.A.; Carroll, S.A.; Bielicki, J.M.; Aines, R.D. Managing Geologic CO2 Storage with Pre-Injection Brine Production: A Strategy Evaluated with a Model of CO2 Injection at Snøhvit. Energy Environ. Sci. 2016, 9, 1504–1512. [Google Scholar] [CrossRef]

- Aradóttir, E.S.; Sigurdardóttir, H.; Sigfússon, B.; Gunnlaugsson, E. CarbFix: A CCS Pilot Project Imitating and Accelerating Natural CO2 Sequestration. Greenh. Gases Sci. Technol. 2011, 1, 105–118. [Google Scholar] [CrossRef]

- Li, W.L.; Xu, J.J.; Jia, L.X.; Ma, B. Chen, J. Research progress on key technologies of CO2 storage in basalts. Hydrogeol. Eng. Geol. 2022, 49, 164–173. [Google Scholar]

- Ye, H.; Liu, Q.; Bao, Q.; Wang, Z.; Xie, Y.; Michelle, T.; Zhao, W.; Xian, C. Review on In-Situ CO2 Mineralization Sequestration: Mechanistic Understanding and Research Frontiers. Int. J. Coal Sci. Technol. 2025, 12, 15. [Google Scholar] [CrossRef]

- Matter, M.J.; Stute, M.; Snæbjörnsdottir, Ó.S.; Oelkers, H.E.; Gislason, R.S.; Aradottir, S.E.; Sigfusson, B.; Gunnarsson, I.; Sigurdardottir, H.; Gunnlaugsson, E.; et al. Rapid Carbon Mineralization for Permanent Disposal of Anthropogenic Carbon Dioxide Emissions. Science 2016, 352, 1312–1314. [Google Scholar] [CrossRef]

- Martens, S.; Kempka, T.; Liebscher, A.; Luth, S.; Moller, F.; Myrttinen, A.; Norden, B.; Schmidthattenberger, C.; Zimmer, M.; Kuhn, M. Europe’s Longest-Operating On-Shore CO2 Storage Site at Ketzin, Germany: A Progress Report After Three Years of Injection. Environ. Earth Sci. 2012, 67, 323–334. [Google Scholar] [CrossRef]

- Bergmann, P.; Kashubin, A.; Ivandic, M.; Lüth, S.; Juhlin, C. Time-lapse difference static correction using prestack crosscorrelations: 4D seismic image enhancement case from Ketzin. Geophysics 2014, 79(6), B243–B252. [Google Scholar] [CrossRef]

- Zheng, Y.-K.; Wang, C.; Liang, H.-H.; Wang, Y.-B.; Zeng, R.-S. 3D Seismic Forward Modeling from the Multiphysical Inversion at the Ketzin CO2 Storage Site. Appl. Geophys. 2024, 21, 593–605. [Google Scholar] [CrossRef]

- Martens, S.; Liebscher, A.; Möller, F.; Würdemann, H.; Schilling, F.; Kühn, M.; Ketzin Group. Progress Report on the First European On-Shore CO2 Storage Site at Ketzin (Germany)—Second Year of Injection. Energy Procedia 2011, 4, 3246–3253. [Google Scholar] [CrossRef]

- Zhou, Y.B.; Wang, R.; Cheng, C.J.; Dai, Q.Q. Enlightenment of CO2 Geological Storage Demonstration Project in In Salah Oilfield, Algeria. J. Earth Sci. Environ. 2023, 45, 1368–1379. [Google Scholar]

- Rock, L.; McNaughton, C.; Black, A. Assessment of CO2 Levels Prior to Injection Across the Quest Sequestration Lease Area. In Proceedings of the International Conference on Greenhouse Gas Control Technologies, Lausanne, Switzerland, 14–18 November 2016. [Google Scholar]

- Rock, L.; O’Brien, S.; Tessarolo, S.; Duer, J.; Bacci, V.O.; Hirst, B.; Randell, D.; Helmy, M.; Blackmore, J.; Duong, C.; et al. The Quest CCS Project: 1st Year Review Post Start of Injection. Energy Procedia 2017, 114, 5320–5328. [Google Scholar] [CrossRef]

- The Shell Quest Carbon Capture Project Reaches the Milestone of 5 Million Metric tonnes. Sino-Glob. Energy 2020, 25, 104.

- Couëslan, M.L.; Butsch, R.; Will, R.; Locke, R.A. Integrated Reservoir Monitoring at the Illinois Basin—Decatur Project. Energy Procedia 2014, 63, 2836–2847. [Google Scholar] [CrossRef]

- Streibel, M.; Finley, R.J.; Martens, S.; Greenberg, S.; Möller, F.; Liebscher, A. From Pilot to Demo Scale—Comparing Ketzin Results with the Illinois Basin-Decatur Project. Energy Procedia 2014, 63, 6323–6334. [Google Scholar] [CrossRef]

- McGrail, B.; Spane, F.; Amonette, J.; Thompson, C.; Brown, C. Injection and Monitoring at the Wallula Basalt Pilot Project. Energy Procedia 2014, 63, 2939–2948. [Google Scholar] [CrossRef]

- White, S.K.; Spane, F.A.; Schaef, H.T.; Miller, Q.R.S.; White, M.D.; Horner, J.A.; McGrail, B.P. Quantification of CO2 Mineralization at the Wallula Basalt Pilot Project. Environ. Sci. Technol. 2020, 54(22), 14609–14616. [Google Scholar] [CrossRef]

- Nunes, P.P.J.; Seabra, S.G.; Sousa, D.C.L. A Review of CO2-Injection Projects in the Brazilian Pre-Salt—Storage Capacity and Geomechanical Constraints. Int. J. Greenh. Gas Control 2024, 137, 104232. [Google Scholar] [CrossRef]

- Zhang, Y.; Jackson, C.; Krevor, S. An Estimate of the Amount of Geological CO2 Storage over the Period of 1996–2020. Environ. Sci. Technol. Lett. 2022, 9, 693–698. [Google Scholar] [CrossRef]

- Liu, H.J.; Were, P.; Li, Q.; Gou, Y.; Hou, Z. Worldwide Status of CCUS Technologies and Their Development and Challenges in China. Geofluids 2017, 2017, 6126505. [Google Scholar] [CrossRef]

- Li, Q.; Zhao, N.; Liu, L.C.; Xu, L.F. Environmental Risk Assessment Method for Geologic Carbon Dioxide Storage: Case Study of Australian Gorgon Project. Environ. Eng. 2019, 37, 22–26. [Google Scholar]

- Weijermars, R. Concurrent Challenges in Practical Operations and Modeling of Geological Carbon Dioxide Sequestration: Review of the Gorgon Project and FluidFlower Benchmark Study. Energy Strategy Rev. 2024, 56, 101586. [Google Scholar] [CrossRef]

- Wang, H.M.; Sun, D.W. Actively Exploring the Construction of Coal-Based Low-Carbon Energy Systems by Shenhua Group—Taking the Lead in Implementing the High-Concentration CO2 Capture and Sequestration Demonstration Project. Chin. Pet. Chem. Ind. 2010, 11, 22–24. [Google Scholar]

- Nguyen, M.C.; Zhang, Y.; Li, J.; Li, X.; Bai, B.; Wu, H.; Wei, N.; Stauffer, P.H. A Geostatistical Study in Support of CO2 Storage in Deep Saline Aquifers of the Shenhua CCS Project, Ordos Basin, China. Energy Procedia 2017, 114, 5826–5835. [Google Scholar] [CrossRef]

- Li, X.; Li, Q.; Bai, B.; Wei, N.; Yuan, W. The geomechanics of Shenhua carbon dioxide capture and storage (CCS) demonstration project in Ordos Basin, China. J. Rock Mech. Geotech. Eng. 2016, 8, 948–966. [Google Scholar] [CrossRef]

- Xie, J.; Zhang, K.N.; Hu, L.T. Numerical investigation of geological CO2 storage with multiple injection wells for the Shenhua Ordos CCS project. J. Beijing Norm. Univ. (Nat. Sci. Ed.) 2015, 51, 636–642. [Google Scholar]

- Yi, H.L.; Guo, X.; Jia, J.Y.; Hualei, Y.; Xin, G.; Jinyao, J. Research on CO2 re-injection and storage engineering scenario of EP15-1 oilfield development. Chin. Offshore Oil Gas 2023, 35, 163–169. [Google Scholar]

- Zhou, S.W.; Li, Q.P.; Zhu, J.L.; Zhou, Y.J.; Zhao, C.Z.; He, Y.F. Consideration on CO2 marine storage and exploration of new paths. Nat. Gas Ind. 2024, 44, 1–10. [Google Scholar]

- Yamamoto, H.; Nakajima, T.; Xue, Z. Quantitative interpretation of trapping mechanisms of CO2 at Nagaoka pilot project—A history matching study for 10-year post-injection. In Proceedings of the International Conference on Greenhouse Gas Control Technologies, Lausanne, Switzerland, 14–18 November 2016. [Google Scholar]

- Sawada, Y.; Tanaka, J.; Suzuki, C.; Tanase, D.; Tanaka, Y. Tomakomai CCS Demonstration Project of Japan, CO2 Injection in Progress. Energy Procedia 2018, 154, 3–8. [Google Scholar] [CrossRef]

- Tanaka, Y.; Sawada, Y.; Tanase, D.; Tanaka, J.; Shiomi, S.; Kasukawa, T. Tomakomai CCS Demonstration Project of Japan, CO2 Injection in Process. Energy Procedia 2017, 114, 5836–5846. [Google Scholar] [CrossRef]

- Ringrose, P.; Sæther, Ø. CO2 injection operations: Insights from Sleipner and Snøhvit. In Proceedings of the Carbon Capture Utilisation and Storage Conference—Virtual Event, Aberdeen, UK, 26 October 2020. [Google Scholar]

- Zhou, Y.B.; Wang, R.; He, Y.F.; Zhao, S.X.; Zhou, Y.L.; Zhang, Y. Analysis and comparison of typical cases of CO2 geological storage in saline aquifer. Pet. Geol. Recovery Effic. 2023, 30, 162–167. [Google Scholar]

- Liu, G.Y.; Zhi, S.J.; Liu, X.; Chai, C.; Wang, C.; Yu, X.R.; Hu, Q.H.; Rao, S.D. Research progress on internal corrosion of supercritical/dense-phase CO2 pipelines for CCUS. Oil Gas Storage Transp. 2024, 43, 510–523. [Google Scholar]

- Zheng, X.P. Offshore Capture and Reinjection Technology for Associated CO2 in Offshore Natural Gas Fields. In Proceedings of the 2007 Annual Conference on Ocean Engineering, Aberdeen, UK, 24–27 June 2007. [Google Scholar]

- Li, C.; Zhang, K.N.; Xu, Y.Q.; He, Q.C. Analysis of Impacts of Variation in Injection Rate on the Potential of Proposed Reservoir for CO2 Geological Sequestration. Shanghai Land Resour. 2011, 32, 24–27. [Google Scholar]

- Department of Economic and Social Affairs United Nations. Energy Statistics Yearbook 2014; United Nations Publication: New Your, NY, USA, 2017; pp. 18–27. [Google Scholar]

- Shi, J.-Q.; Imrie, C.; Sinayuc, C.; Durucan, S.; Korre, A.; Eiken, O. Snøhvit CO2 Storage Project: Assessment of CO2 Injection Performance Through History Matching of the Injection Well Pressure Over a 32-months Period. Energy Procedia 2013, 37, 3267–3274. [Google Scholar] [CrossRef]

- Hansen, O.; Gilding, D.; Nazarian, B.; Bård, O.; Ringrose, P.; Kristoffersen, J.-B.; Eiken, O.; Hansen, H. Snøhvit: The history of injecting and storing 1 Mt CO2 in the fluvial Tubåen Fm. Energy Procedia 2013, 37, 3565–3573. [Google Scholar] [CrossRef]

- Rahman, M.J. Compaction, Rock Properties Evaluation, Rock Physics Diagnostics, AVO Modeling and Seismic Inversion in the 3N/8WHT Field, SW Barents Sea. Master’s Thesis, University of Oslo, Oslo, Norway, 6 June 2012. [Google Scholar]

- Maldal, T.; Tappel, I. CO2 underground storage for Snøhvit gas field development. Energy 2004, 29, 1403–1411. [Google Scholar] [CrossRef]

- Ringrose, S.P. The CCS hub in Norway: Some insights from 22 years of saline aquifer storage. Energy Procedia 2018, 146, 166–172. [Google Scholar] [CrossRef]

- Bergmann, P.; Ivandic, M.; Norden, B.; Rücker, C.; Kiessling, D.; Lüth, S.; Schmidt-Hattenberger, C.; Juhlin, C. Combination of seismic reflection and constrained resistivity inversion with an application to 4D imaging of the CO2 storage site, Ketzin, Germany. Geophysics 2014, 79, B37–B50. [Google Scholar] [CrossRef]

- Zemke, K.; Liebscher, A.; Möller, F. Monitoring of well integrity by magnetic imaging defectoscopy (MID) at the Ketzin pilot site, Germany. In Proceedings of the EGU General Assembly Conference, Vienna, Austria, 23–28 April 2017. [Google Scholar]

- Carey, J.W.; Wigand, M.; Chipera, S.J.; WoldeGabriel, G.; Pawar, R.; Lichtner, P.C.; Wehner, S.C.; Raines, M.A.; Guthrie, G.D. Analysis and performance of oil well cement with 30 years of CO2 exposure from the SACROC Unit, West Texas, USA. Int. J. Greenh. Gas Control 2007, 1, 75–85. [Google Scholar] [CrossRef]

- Shone, B.E. Corrosion in the petrochemical industry. Br. Corros. J. 2013, 30, 190. [Google Scholar] [CrossRef]

- Gawel, K.; Todorovic, J.; Liebscher, A.; Wiese, B.; Opedal, N. Study of materials retrieved from a Ketzin CO2 monitoring well. In Proceedings of the International Conference on Greenhouse Gas Control Technologies, Lausanne, Switzerland, 14–18 November 2016. [Google Scholar]

- Martens, S.; Liebscher, A.; Möller, F.; Henninges, J.; Kempka, T.; Lüth, S.; Norden, B.; Prevedel, B.; Szizybalski, A.; Zimmer, M.; et al. CO2 Storage at the Ketzin Pilot Site, Germany: Fourth Year of Injection, Monitoring, Modelling and Verification. Energy Procedia 2013, 37, 6434–6443. [Google Scholar] [CrossRef]

- Bergmann, P.; Diersch, M.; Götz, J.; Ivandic, M.; Ivanova, A.; Juhlin, C.; Kummerow, J.; Liebscher, A.; Lüth, S.; Meekes, S.; et al. Review on geophysical monitoring of CO2 injection at Ketzin, Germany. J. Pet. Sci. Eng. 2016, 139, 112–136. [Google Scholar] [CrossRef]

- Eunseon, J.; Bernd, W.; Peter, P.; Fischer, S.; Schmind-Hattenberger, C. Geochemical modeling of CO2 injection and gypsum precipitation at the Ketzin CO2 storage site. Environ. Earth Sci. 2022, 81, 286. [Google Scholar] [CrossRef]

- Liebscher, A.; Möller, F.; Bannach, A.; Köhler, S.; Wiebach, J.; Schmidt-Hattenberger, C.; Weiner, M.; Pretschner, C.; Ebert, K.; Zemke, J. Injection operation and operational pressure–temperature monitoring at the CO2 storage pilot site Ketzin, Germany—Design, results, recommendations. Int. J. Greenh. Gas Control 2013, 15, 163–173. [Google Scholar] [CrossRef]

- Martens, S.; Möller, F.; Streibel, M.; Liebscher, A.; The Ketzin Group. Completion of Five Years of Safe CO2 Injection and Transition to the Post-closure Phase at the Ketzin Pilot Site. Energy Procedia 2014, 59, 190–197. [Google Scholar] [CrossRef]

- Nial, S.; Paul, B.; Adegbenro, O.; van Essen, G.; Guo, R.; Reynolds, M.A.; Friesen, L.; Cano, M.C.; O’Brien, S. Quest CCS facility: Halite damage and injectivity remediation in CO2 injection wells. Int. J. Greenh. Gas Control 2022, 119, 103718. [Google Scholar]

- Lee, S.-Y.; Swager, L.; Pekot, L.; Piercey, M.; Will, R.; Zaluski, W. Study of operational dynamic data in Aquistore project. Int. J. Greenh. Gas Control. 2018, 76, 62–77. [Google Scholar] [CrossRef]

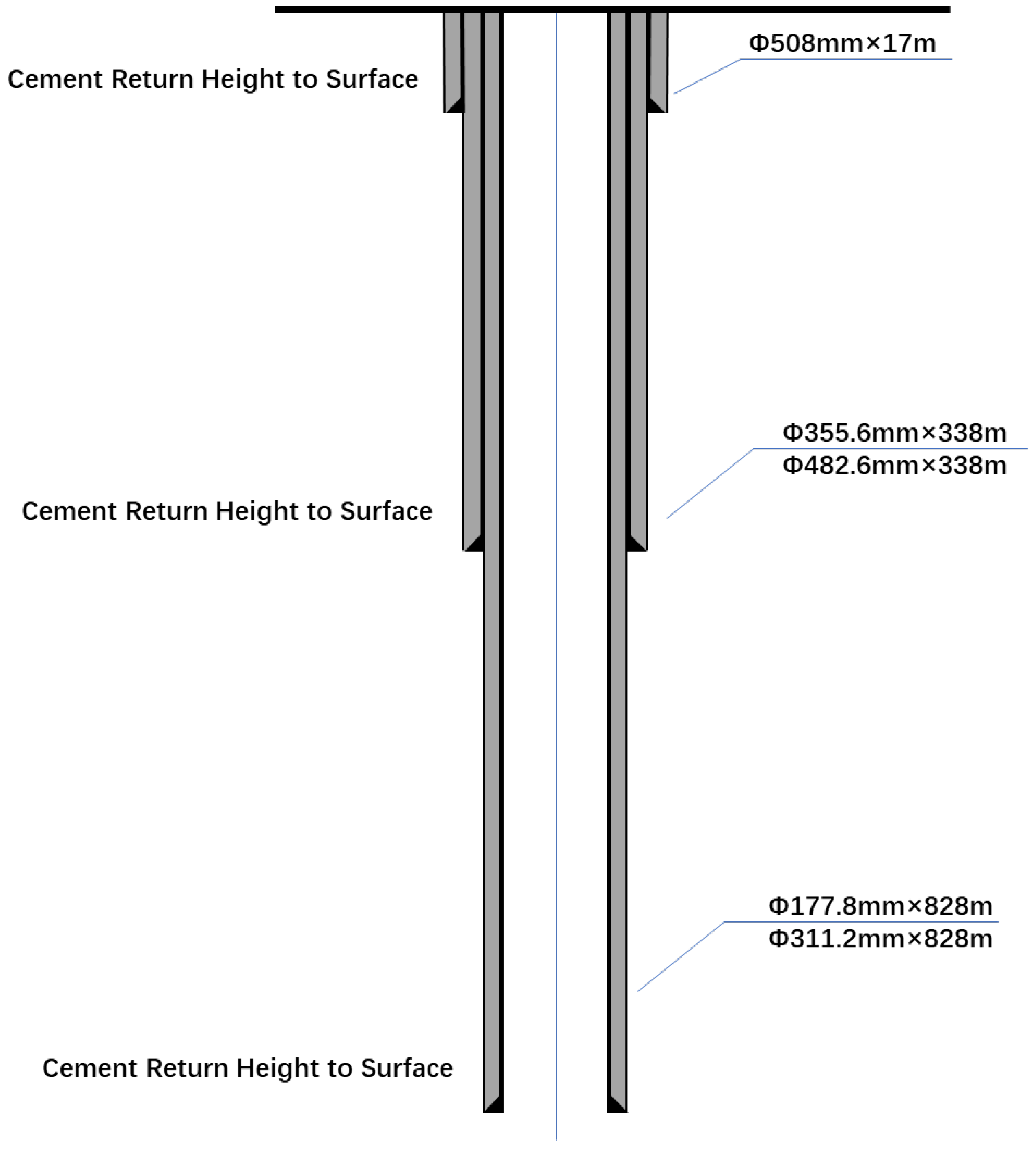

- Shell Canada Limited. Quest Carbon Capture and Storage Project: Directive 65: Application for a CO2 Acid Gas Storage Scheme; Shell Canada Limited: Calgary, AB, Canada, 2010. [Google Scholar]

- Tawiah, P.; Duer, J.; Bryant, S.L.; Larter, S.; O’Brien, S.; Dong, M. CO2 injectivity behaviour under non-isothermal conditions—Field observations and assessments from the Quest CCS operation. Int. J. Greenh. Gas Control 2020, 92, 102843. [Google Scholar] [CrossRef]

- Shell Canada Limited. Quest Carbon Capture and Storage Project 2023 Annual Status Report; AER Approval Number: 11837C; Shell Canada Limited: Calgary, AL, Canada, 2024. [Google Scholar]

- Nordbotten, J.M.; Celia, M.A.; Bachu, S. Injection and Storage of CO2 in Deep Saline Aquifers: Analytical Solution for CO2 Plume Evolution During Injection. Transp. Porous Media 2005, 58, 339–360. [Google Scholar] [CrossRef]

- Peng, D.Y.; Robinson, D.B. New Two-Constant Equation of State. Ind. Eng. Chem. Fundam. 1976, 15, 3069–3078. [Google Scholar] [CrossRef]

- Li, H.; Yan, J. Impacts of equations of state (EOS) and impurities on the volume calculation of CO2 mixtures in the applications of CO2 capture and storage (CCS) processes. Appl. Energy 2009, 86, 2760–2770. [Google Scholar] [CrossRef]

- Bauer, A.R.; Carney, M.; Finley, J.R. Overview of microseismic response to CO2 injection into the Mt. Simon saline reservoir at the Illinois Basin-Decatur Project. Int. J. Greenh. Gas Control 2016, 54, 378–388. [Google Scholar] [CrossRef]

- Finley, R.J.; Frailey, S.M.; Leetaru, H.E.; Senel, O.; Couëslan, M.L.; Scott, M. Early Operational Experience at a One-million Tonne CCS Demonstration Project, Decatur, Illinois, USA. In Proceedings of the International Conference on Greenhouse Gas Control Technologies, Austin, TX, USA, 5–9 October 2014. [Google Scholar]

- Ii, R.L.; Larssen, D.; Salden, W.; Patterson, C.; Kirksey, J.; Iranmanesh, A.; Wimmer, B.; Krapac, I. Preinjection Reservoir Fluid Characterization at a CCS Demonstration Site: Illinois Basin—Decatur Project, USA. Energy Procedia 2013, 37, 6424–6433. [Google Scholar] [CrossRef]

- URS Corporation; Malone Service Corporation. Injection Well WDW-138 2009 Mechanical Integrity Test & Bottomhole Pressure Survey Report; Sandia Project No. 1168-URS-09; Sandia Technologies, LLC.: Houston, TX, USA, 2009. [Google Scholar]

- Finley, J.R.; Frailey, M.S.; Leetaru, E.H.; Senel, O.; Couëslan, M.L.; Scott, M. Early Operational Experience at a One-million Tonne CCS Demonstration Project, Decatur, Illinois, USA. Energy Procedia 2013, 37, 6149–6155. [Google Scholar] [CrossRef]

- Greenberg, S.E.; Bauer, R.; Will, R.; Ii, R.L.; Carney, M.; Leetaru, H.; Medler, J. Geologic Carbon Storage at a One Million Tonne Demonstration Project: Lessons Learned from the Illinois Basin–Decatur Project. Energy Procedia 2017, 114, 5529–5539. [Google Scholar] [CrossRef]

- Gan, M.; Nguyen, M.C.; Zhang, L.; Wei, N.; Li, J.; Lei, H.; Wang, Y.; Li, X.; Stauffer, P.H. Impact of reservoir parameters and wellbore permeability uncertainties on CO2 and brine leakage potential at the Shenhua CO2 Storage Site, China. Int. J. Greenh. Gas Control 2021, 111, 103443. [Google Scholar] [CrossRef]

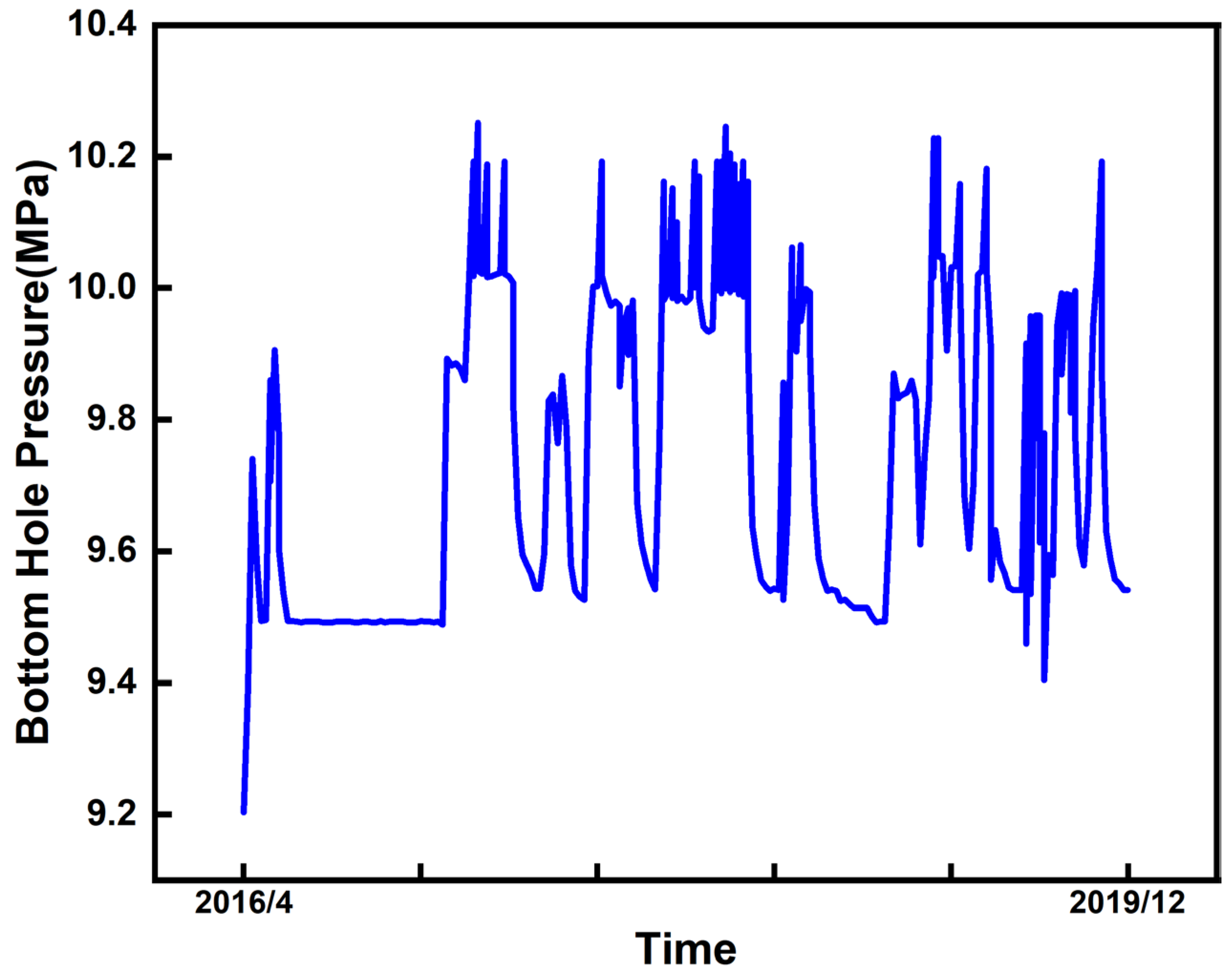

- Cai, Y.; Lei, H.; Li, X.; Feng, G.; Cui, Y.; Bai, B.; Zheng, C. Phase transition and fluid backflow during the non-injection period in the Ordos CCS project, China. J. Clean. Prod. 2022, 349, 131493. [Google Scholar] [CrossRef]

- Zhang, K.; Xie, J.; Li, C.; Hu, L.; Wu, X.; Wang, Y. A full chain CCS demonstration project in northeast Ordos Basin, China: Operational experience and challenges. Int. J. Greenh. Gas Control 2016, 50, 218–230. [Google Scholar] [CrossRef]

- Wu, X.Z. Carbon Dioxide Capture and Geological Storage: The First Massive Exploration in China; Science Press: Beijing, China, 2013. [Google Scholar]

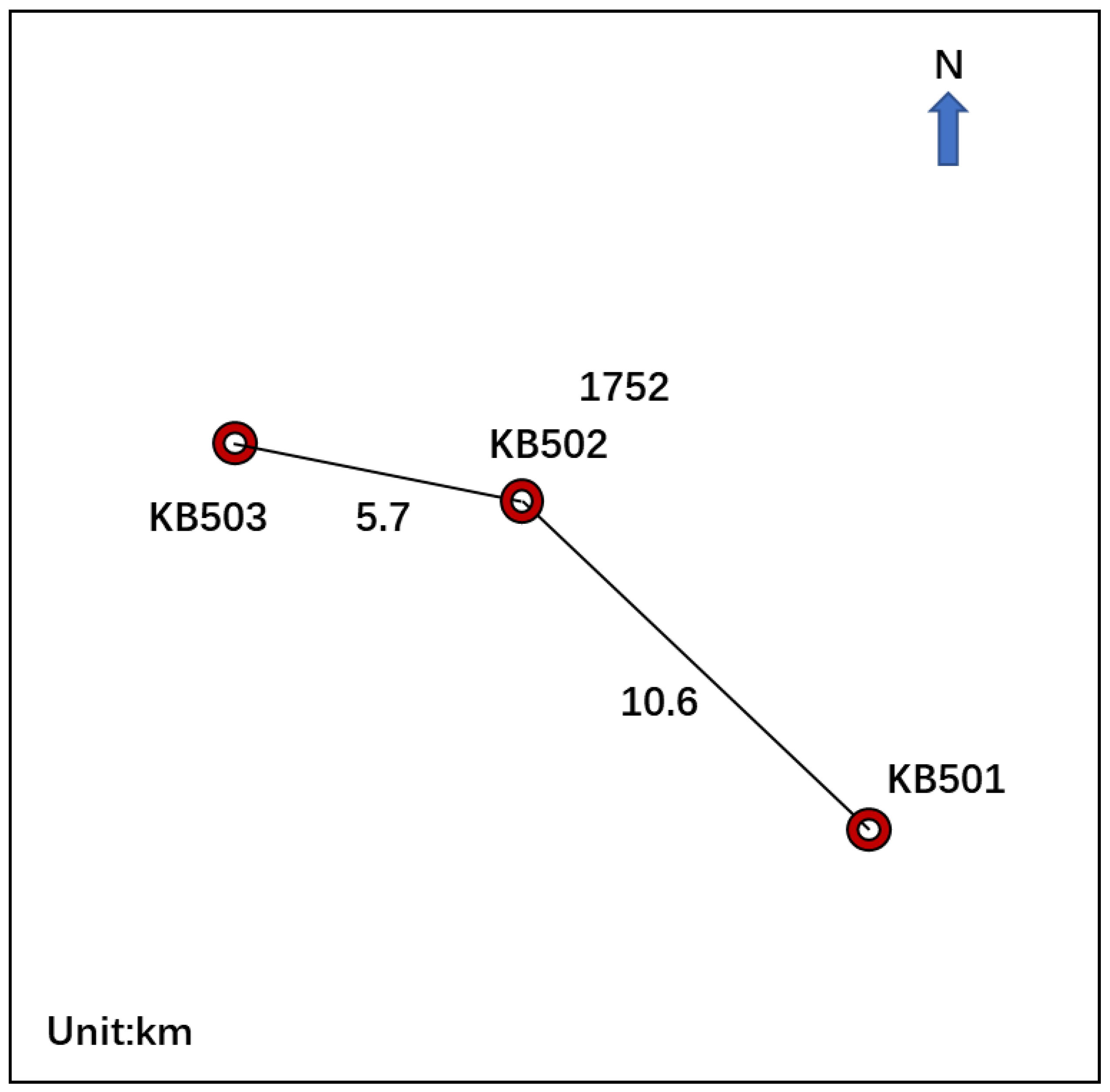

- Xu, X.Y.; Li, Q.; Tan, Y.S.; Liu, G.; Li, X.Y. Analysis of Monitoring Technologies of Offshore CO2 Geological Storage in Japan’s Tomakomai and Its Enlightenment. Geol. J. Chin. Univ. 2023, 29, 13–24. [Google Scholar]

- Japan CCS Co., Ltd. JCCS Tomakomai Monitoring Site. Available online: http://www.jccs-tomakomai-monitoring.com/JCCS/wp-content/uploads/2024/07/202407_ENG.pdf (accessed on 22 November 2019).

- Trupp, M.; Frontczak, J.; Torkington, J. The Gorgon CO2 Injection Project—2012 Update. Energy Procedia 2013, 37, 6237–6247. [Google Scholar] [CrossRef]

- Chevron Australia Pty Ltd. Gorgon Gas Development Revised and Expanded Proposal: Public Environmental Review (EPBC Referral 2008/478, Assessment No. 1727); Chevron Australia Pty Ltd.: Perth, Australia, 2008; ISBN 978-610-67076-8-2. [Google Scholar]

- Wang, Z.J.; Tang, X.; Jing, T.Y.; You, M.X.; Zhang, J.C.; Li, Z.; Zhou, J. Site Selection Strategy for An Annual Million-Ton Scale CO2 Geological Storage in China. Geoscience 2022, 36, 1414–1431. [Google Scholar]

- Li, Q.; Li, Y.Z.; Xu, X.Y.; Li, X.C.; Liu, G.Z.; Yu, H.; Tan, Y.S. Current Status and Recommendations of Offshore CO2 Geological Storage Monitoring. Geol. J. Chin. Univ. 2023, 29, 1–12. [Google Scholar]

- Mathieson, A.; Midgely, J.; Wright, I.; Saoula, N.; Ringrose, P. In Salah CO2 Storage JIP: CO2 sequestration monitoring and verification technologies applied at Krechba, Algeria. Energy Procedia 2011, 4, 3596–3603. [Google Scholar] [CrossRef]

- Verdon, P.J.; Kendall, J.-M.; Stork, L.A.; Chadwick, R.A.; White, D.j.; Bissell, R.C. Comparison of geomechanical deformation induced by megatonne-scale CO2 storage at Sleipner, Weyburn, and In Salah. Proc. Natl. Acad. Sci. USA 2013, 110, E2762–E2771. [Google Scholar] [CrossRef]

- Rutqvist, J.; Vasco, W.D.; Myer, L. Coupled reservoir-geomechanical analysis of CO2 injection and ground deformations at In Salah, Algeria. Int. J. Greenh. Gas Control 2009, 4, 225–230. [Google Scholar] [CrossRef]

- Oye, V.; Aker, E.; Daley, T.M.; Kühn, D.; Bohloli, B.; Korneev, V. Microseismic Monitoring and Interpretation of Injection Data from the in Salah CO2 Storage Site (Krechba), Algeria. Energy Procedia 2013, 37, 4191–4198. [Google Scholar] [CrossRef]

- Smith, J.; Durucan, S.; Korre, A.; Shi, J.-Q. A Methodology to Assess Increased Storage Capacity Provided by Fracture Networks at CO2 Storage Sites: Application to in Salah Storage Site. Energy Procedia 2013, 37, 3711–3718. [Google Scholar] [CrossRef][Green Version]

- De Sant´Anna Pizarro, J.O.; Branco, C.C. Challenges in Implementing an EOR Project in the Pre-Salt Province in Deep Offshore Brasil. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia 2012, Muscat, Oman, 16–18 April 2012. [Google Scholar]

- Godoi, J.M.A.; Matai, P.H.L.D. Enhanced oil recovery with carbon dioxide geosequestration: First steps at Pre-salt in Brazil. J. Pet. Explor. Prod. 2021, 11, 1429–1441. [Google Scholar] [CrossRef]

- Kiyingi, W.; Xiong, R.; Jin, Y.; Guo, J. Geological Carbon Dioxide Storage and Subsurface Rock Mechanics—Geomechanical Risks, Modelling Practices, and Risk Mitigation Strategies. Simul. Model. Pract. Theory 2025, 144, 103195. [Google Scholar] [CrossRef]

- Yuan, J.M.; Peng, C.Z.; Liu, J. Establishment of the Relationship Between CO2 Flooding Performance and Past Water Flooding Performance in Weyburn Oilfield. Foreign Oilfield Eng. 2009, 25, 19–22. [Google Scholar]

- Snæbjörnsdóttir, Ó.S.; Gislason, R.S.; Galeczka, M.I.; Oelkers, H.R. Reaction path modelling of in-situ mineralisation of CO2 at the CarbFix site at Hellisheidi, SW—Iceland. Geochim. Cosmochim. Acta 2018, 220, 348–366. [Google Scholar] [CrossRef]

- International Energy Agency Greenhouse Gas R&D Programme. Quantification Techniques for CO2 Leakage; Report 2012/02; IEA Environmental Projects Ltd.: Cheltenham, UK, 2012. [Google Scholar]

- Riding, J.B.; Rochelle, C.A. Subsurface characterization and geological monitoring of the CO2 injection operation at Weyburn, Saskatchewan, Canada. Geol. Soc. Lond. Spec. Publ. 2009, 313, 227–256. [Google Scholar] [CrossRef]

- Yu, H.T.; Zhang, G.; Yan, X. Research Progress on Mechanism of Near-Fault Reactivation Induced by CO2 Geological Storage. J. Huaqiao Univ. (Nat. Sci.) 2024, 45, 136–149. [Google Scholar]

- Whitecap Resources Inc. Corporate Presentation: Capital Discipline Driving Sustainable Growth; Whitecap Resources Inc.: 2024-11; White Resources Inc.: Calgary, AB, Canada, 2014. [Google Scholar]

- Zhai, K.Q.; Na, J.; Liu, S.Y. Exploring the Effects of Four Important Factors on Oil–CO2 Interfacial Properties and Miscibility in Nanopores. RSC Adv. 2017, 7, 54164–54177. [Google Scholar] [CrossRef]

- Lawton, D.; Alshuhail, A.; Coueslan, M.; Chabot, L. Pembina Cardium CO2 Monitoring Project, Alberta, Canada: Timelapse Seismic Analysis—Lessons Learned. Energy Procedia 2009, 1, 2235–2242. [Google Scholar] [CrossRef][Green Version]

- Wiseman, A.C.S. Geologic Framework, Reservoir Characterization and Production Analyses of the Cardium Formation: Unconventionally Developed North West Pembina Field, Alberta, Canada. Master’s Thesis, University of Calgary, Calgary, AB, Canada, April 2014. [Google Scholar]

- Bosch, N. Acid Gas Injection—A Decade of Operating History in Western Canada. In Proceedings of the Canadian Gas Processors and Suppliers Association (CGPSA) Conference, Calgary, AB, Canada, 16–17 April 2002. [Google Scholar]

- Wang, S.X.; Carroll, J.J.; Tang, L. A wellbore flow model and phase state distribution of acid gas injection. Nat. Gas Ind. 2010, 30, 95–100+137. [Google Scholar]

- Sato, K.; Mito, S.; Horie, T.; Ohkuma, H.; Saito, H.; Watanabe, J.; Yoshimura, T. Monitoring and simulation studies for assessing macro- and meso-scale migration of CO2 sequestered in an onshore aquifer: Experiences from the Nagaoka pilot site, Japan. Int. J. Greenh. Gas Control 2011, 5, 125–137. [Google Scholar] [CrossRef]

- Zambrano, N.G. Design, Deployment, Performance and Assessment of Downhole and Near Surface Monitoring Technology for Geological CO2 Storage. Ph.D. Dissertation, University of Alberta, Edmonton, AB, Canada, June 2012. [Google Scholar]

- Alfredsson, H.A.; Hardarson, B.S.; Franzson, H.; Gislason, S.R. CO2 sequestration in basaltic rock at the Hellisheidi site in SW Iceland: Stratigraphy and chemical composition of the rocks at the injection site. Mineral. Mag. 2008, 72, 1–5. [Google Scholar] [CrossRef]

- Snæbjörnsdóttir, Ó.S.; Sigfússon, B.; Marieni, C.; Goldberg, D.; Gislason, R.S.; Oelkers, H.E. Carbon dioxide storage through mineral carbonation. Nat. Rev. Earth Environ. 2020, 1, 90–102. [Google Scholar] [CrossRef]

- Zhou, D.; Xia, C.Y.; Li, P.C. CO2 mineral storage in basalt (I): Technology and application conditions. J. Environ. Eng. 2024, 18, 2708–2718. [Google Scholar]

- Oelkers, E.H.; Gíslason, S.R. Carbon Capture and Storage: From Global Cycles to Global Solutions. Geochem. Perspect. 2023, 12, 179–180. [Google Scholar] [CrossRef]

- Holdsworth, C.; John, C.; Snæbjörnsdóttir, S.; Johnson, G.; Sigfússon, B.; Leslie, R.; Haszeldine, R.; Gilfillan, S. Reconstructing the temperature and origin of CO2 mineralisation in CarbFix calcite using clumped, carbon and oxygen isotopes. Appl. Geochem. 2024, 162, 105925. [Google Scholar] [CrossRef]

- Sigfusson, B.; Gislason, S.R.; Matter, J.M.; Stute, M.; Gunnlaugsson, E.; Gunnarsson, I.; Aradottir, E.S.; Sigurdardottir, H.; Mesfin, K.; Alfredsson, H.A.; et al. Solving the carbon-dioxide buoyancy challenge: The design and field testing of a dissolved CO2 injection system. Int. J. Greenh. Gas Control 2015, 37, 213–219. [Google Scholar] [CrossRef]

- Śliwiński, M.G.; Kitajima, K.; Kozdon, R.; Spicuzza, M.J.; Denny, A.; Valley, J.W. In situ δ13C and δ18O microanalysis by SIMS: A method for characterizing the carbonate components of natural and engineered CO2 reservoirs. Int. J. Greenh. Gas Control 2017, 57, 116–133. [Google Scholar] [CrossRef]

- McGrail, B.; Schaef, H.; Spane, F.; Horner, J.; Owen, A.; Cliff, J.; Qafoku, O.; Thompson, C.; Sullivan, E. Wallula Basalt Pilot Demonstration Project: Post-injection Results and Conclusions. Energy Procedia 2017, 114, 5783–5790. [Google Scholar] [CrossRef]

- McGrail, B.P.; Sullivan, E.C.; Thorne, F.O.; Johnson, C.S.; Robinson, S.P.; Kearn, C.; Drexler, S.P.; Haxel, G.; Ginnold, F.B. Topical Report-Preliminary Hydrogeologic Characterization Results from the Wallula Basalt Pilot Study; Cooperative Agreement DE-FC26-08NT43687; Sandia Project No. PNWD-4129; Battelle Pacific Northwest Division: Richland, WA, USA, 2009–2012. [Google Scholar]

- McGrail, B.; Spane, F.; Sullivan, E.; Bacon, D.; Hund, G. The Wallula basalt sequestration pilot project. Energy Procedia 2011, 4, 5653–5660. [Google Scholar] [CrossRef]

- Zakharova, V.N.; Goldberg, S.D.; Sullivan, C.E.; Herron, M.M.; Grau, A.J. Petrophysical and geochemical properties of Columbia River flood basalt: Implications for carbon sequestration. Geochem. Geophys. Geosyst. 2012, 13, 11. [Google Scholar] [CrossRef]

- Ito, T.; Nakajima, T.; Chiyonobu, S.; Xue, Z. Petrophysical properties and their relation to injected CO2 behavior in a reservoir at the Nagaoka pilot site, Japan. Energy Procedia 2014, 63, 2855–2860. [Google Scholar] [CrossRef]

- Mito, S.; Xue, Z. Post-Injection monitoring of stored CO2 at the Nagaoka pilot site: 5 years time-lapse well logging results. Energy Procedia 2011, 4, 3284–3289. [Google Scholar] [CrossRef]

- Mito, S.; Xue, Z.; Ohsumi, T. Case study of geochemical reactions at the Nagaoka CO2 injection site, Japan. Int. J. Greenh. Gas Control 2008, 2, 309–318. [Google Scholar] [CrossRef]

- Saito, H.; Nobuoka, D.; Azuma, H.; Xue, Z.; Tanase, D. Time-lapse crosswell seismic tomography for monitoring injected CO2 in an onshore aquifer, Nagaoka, Japan. Explor. Geophys. 2006, 37, 30–36. [Google Scholar] [CrossRef]

- Zhou, B.; Lun, Z.M.; Zhang, J.; Tang, Y.Q.; Qi, Y.B.; Xiao, P.F.; Yin, X. Research status of self-sealing mechanisms of caprocks and fractures during CO2 geological storage. Pet. Explor. Geol. 2025, 47, 1177–1184. [Google Scholar]

- Ma, Z.P.; Wang, Y.B.; Zhang, T.; Liu, Y.; Liang, K.Q.; Shen, Z.Z.; Yang, K. Case analysis and suggestions on CO2 leakage monitoring pointdeployment method in CCUS project. China Min. Mag. 2025, 34, 141–148. [Google Scholar]

- Zhang, M.; Yu, B.; Shi, B.C.; Zhu, Q.; Liu, K. Optimization and evaluation of corrosion inhibitor for P110S steel in H2S/CO2 coexistence system. Chem. Pet. Eng. 2025, 54, 106–114. [Google Scholar]

- Guo, S.K.; Li, J.; Lian, W.; Cao, W. Research Progress and Development Suggestions on Wellbore Integrity for CCUS Geological Storage. Pet. Drill. Technol. 2025, 53, 144–154. [Google Scholar]

- Chen, Q.; Fan, J.C.; Zhang, L.B.; Yang, Y.P.; Zhou, Q. Multi-Physical Field Phase Changes After Supercritical CO2 Leakage in Wellbore. Pet. Mach. 2025, 53, 59–67. [Google Scholar]

- Liu, B.; Huang, T.T. Numerical Simulation Study on the Mechanical Integrity of Caprock in CO2 Geological Sequestration. J. Petrochem. Univ. 2025, 38, 33–41. [Google Scholar]

- Deng, C.G.; Sun, X.L.; Liu, K.Y.; An, S.Y.; Yuan, G.G.; Wang, Y.X. Mechanisms underlying the impacts of reservoir pore structures on near-well salt precipitation in CO2 geological storage. Coal Geol. Explor. 2025, 53, 128–140. [Google Scholar]

- Feng, F.P.; You, G.Y.; Zhang, X.C.; Wang, J.Q.; Wang, Q.D.; Cao, J.; Han, X. Corrosion Rate and Service Life Prediction of CO2 Injection Well String. Hot Work. Technol. 2025, 54, 113–118. [Google Scholar]

- Chen, X.M.; Qian, Y.H.; Chen, Z.Z.; Chen, Z.F. Exploration and application of 3D CO2 storage leakage monitoring technology: A case study of Zhangjiaduo oilfield in Subei Basin. Reserv. Eval. Dev. 2025, 15, 508–514. [Google Scholar]

- Lian, W.; Wang, N.H.; Li, J.; Li, Q.X. Research Progress on CO2 Geological Storage Leakage Mechanism and Wellbore Integrity. J. South China Norm. Univ. (Nat. Sci. Ed.) 2024, 56, 1–15. [Google Scholar]

- Lian, W.; Liu, H.; Li, J.; Wu, Y. Site and Formation Selection for CO2 Geological Sequestration: Research Progress and Case Analyses. Appl. Sci. 2025, 15, 11402. [Google Scholar] [CrossRef]

| Project Name | Carbon Source | Sequestration Quantity | Injection Start Time | Injection End Time |

|---|---|---|---|---|

| Norway Sleipner | Natural Gas Extraction | Over 20 million metric tonnes | 1996 | To date |

| Norway Snøhvit | Natural Gas Extraction | Planned 23 million metric tonnes | 2008 | To date |

| Iceland Carbfix | Geothermal Power Plant | Over 100,000 metric tonnes | 2012 | To date |

| Germany Ketzin | Nearby Power Plant | 67,000 metric tonnes | 2008.06 | 2013.08 |

| Algeria In Salah | Natural Gas Extraction | 4 million metric tonnes | 2004.04 | 2011 |

| Canada Quest | Oil Sands Bitumen Extraction | Over 7 million metric tonnes | 2015.08 | To date |

| United States Decatur | Ethanol Plant Capture | 925,300 metric tonnes | 2011.11 | 2014.09 |

| United States Wallula | Paper Mill Capture | 1000 metric tonnes | 2013.07 | 2013.8 |

| Brazil Pre-Salt | Oilfield-Associated Gas | Over 40 million metric tonnes | 2006 | To date |

| Australia Gorgon | Natural Gas Extraction | Estimated 129 million metric tonnes | 2016 | To date |

| China Shenhua | Shenhua Coal Liquefaction Plant | 200,000 metric tonnes | 2011.05 | 2014.06 |

| China Enping 15-1 | Offshore Oilfield Associated | Estimated 1.46 million metric tonnes | 2023.06 | To date |

| Japan Nagaoka | Ammonia Production By-product | 10,400 metric tonnes | 2003.07 | 2005.01 |

| Japan Tomakomai | Hydrogen Production | 300,000 metric tonnes | 2016 | 2019 |

| Canada Weyburn | Coal gasification by-products | Estimated to exceed 30 million metric tonnes | 2000 | To date |

| Canada Pembina | Industrial capture | 66,000 metric tonnes | 2005 | 2008 |

| Project | Number of Injection Wells | Number of Monitoring Wells | Wellhead Temperature (°C) | Wellhead Pressure (MPa) | Bottomhole Temperature (°C) | Bottomhole Pressure (MPa) | Injection Rate (t/d) | Characteristics |

|---|---|---|---|---|---|---|---|---|

| Sleipner | 1 | N/A | 25 | 6.2–6.5 | 48 | Pressure increase of less than 0.5 MPa | 2700 | CO2 enters the reservoir as dense-phase flow |

| Snøhvit | 1 | N/A | 4 | 7.8–17.4 | 95 | 28.5–39 | 2000 | The reservoir is isolated from other formations, and the pressure rises rapidly, approaching the fracture pressure |

| Ketzin | 1 | 4 | 42 | 6.5 | 31–35 | 7.2–7.6 | 83 | The burial depth is less than 800 m, which does not meet the supercritical conditions for CO2 |

| Carbfix | 1 | 1 | N/A | Slightly higher than 2.5 MPa | N/A | N/A | Stage 1: 6.05 Stage 2: 0.864–4.32 | CO2 dissolves in water before entering the formation |

| In Salah | 3 | 5 | 25–55 | 14–18 | 48 | 29 | N/A | The volume of injected CO2 and the volume of produced gas cannot be balanced, leading to an increase in formation pressure |

| Shenhua | 1 | 2 | −13.9 ~ 23.7 | 4.2–8.4 | N/A | N/A | 274 | N/A |

| Tomakomai | 2 | 3 | N/A | Maximum: 23 MPa | Shallow layer: 35.9 °C Deep layer: 87.5 °C | Shallow Layer: 10 | Shallow Layer: 595 Deep Layer: 2.7 | N/A |

| Nagaoka | 1 | 3 | 32–36 | 6.6–7.4 | 45–49 | 11.9–12.6 | 20–40 | N/A |

| Gorgon | 9 | 2 | 54 | N/A | 107 | 26.2 | 10,900 | In CO2 injection projects, challenges such as sand production, pressure management failure, and premature condensation of CO2 into water can significantly impact operational safety and efficiency |

| Quest | 3 | 3 | 7–26 | 6.3 | 22–48 | 22.3 | 2880 | Reservoir temperature and properties significantly affect the physical behavior of CO2, leading to a negative correlation between the CO2 injection rate and the injection temperature. |

| Decatur | 1 | 3 | 35 | 9.3 | 27–42 | 12.93 | 1000 | N/A |

| Wallula | 1 | 2 | N/A | N/A | N/A | N/A | 40 | Injected CO2 mainly accumulates at the top of the reservoir |

| Pre-Salt (Lula) | 3 | N/A | N/A | N/A | N/A | N/A | N/A | Water–Gas Alternating Injection |

| Weyburn | 17 CO2 injection wells and 110 WAG wells | 60 groundwater monitoring wells and 4 shallow monitoring wells | N/A | 10–11 | Decrease by 7 °C | Increase by 8 MPa | 5500 | The combination of horizontal wells and vertical injection wells, combined with water-alternating-gas (WAG) injection, optimizes the injection-production performance. |

| Pembina | 2 | 1 | 37 | 7.7 | 98 | 26.9 | 35–100 | Due to poor reservoir connectivity, the water-alternating-gas (WAG) mode is adopted to enhance sweep efficiency. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Lian, W.; Li, J.; Wu, Y. Engineering Parameter Design for CO2 Geological Storage: Research Progress and Case Analyses. Eng 2025, 6, 329. https://doi.org/10.3390/eng6110329

Liu H, Lian W, Li J, Wu Y. Engineering Parameter Design for CO2 Geological Storage: Research Progress and Case Analyses. Eng. 2025; 6(11):329. https://doi.org/10.3390/eng6110329

Chicago/Turabian StyleLiu, Hangyu, Wei Lian, Jun Li, and Yanxian Wu. 2025. "Engineering Parameter Design for CO2 Geological Storage: Research Progress and Case Analyses" Eng 6, no. 11: 329. https://doi.org/10.3390/eng6110329

APA StyleLiu, H., Lian, W., Li, J., & Wu, Y. (2025). Engineering Parameter Design for CO2 Geological Storage: Research Progress and Case Analyses. Eng, 6(11), 329. https://doi.org/10.3390/eng6110329