Polyformaldehyde Fiber Shotcrete Bending Fracture Test and Finite Element Simulation Research

Abstract

1. Introduction

2. Experiments

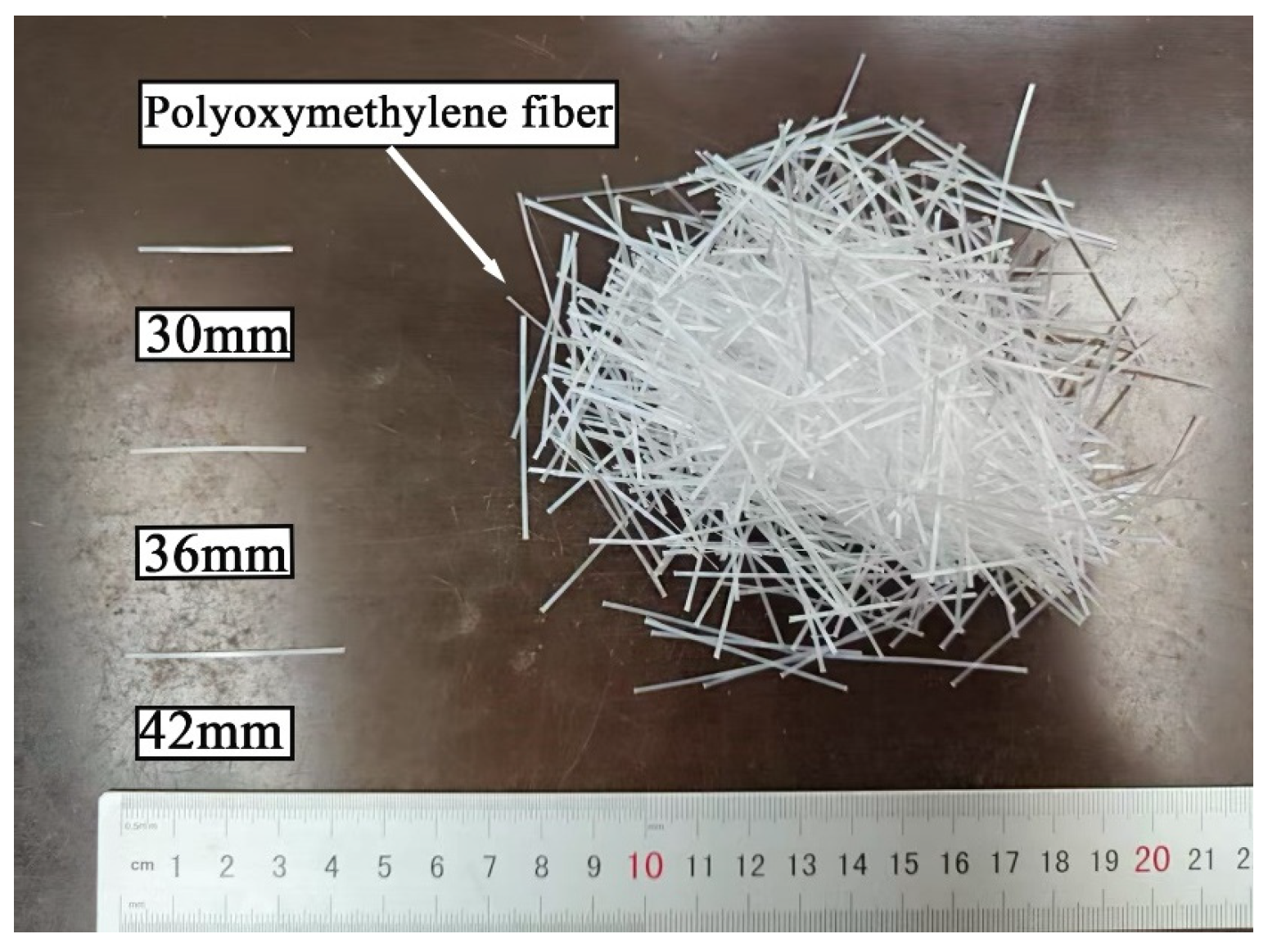

2.1. Materials

2.2. Mix Proportion

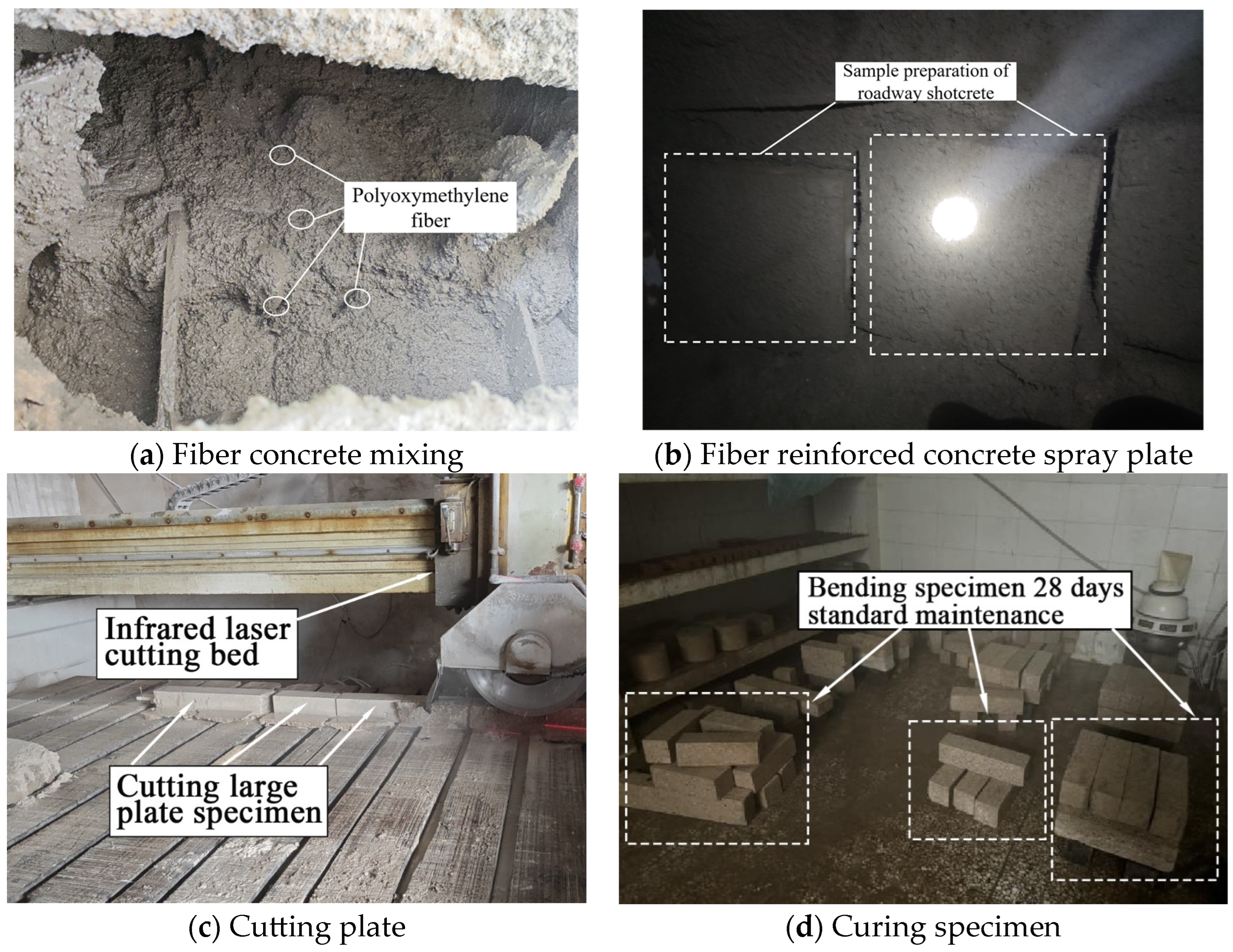

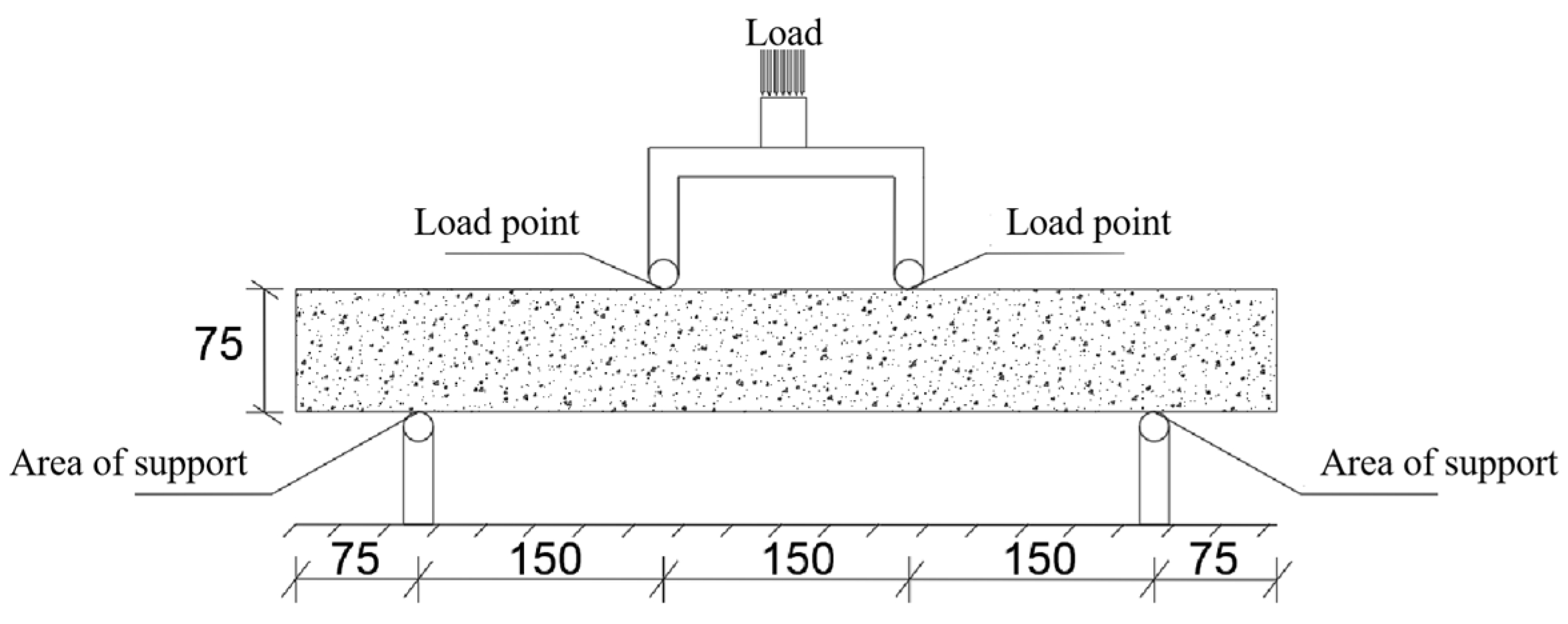

2.3. Experimental Process and Method

2.4. Calculation of Experimental Results

3. Experiment Results and Analyses

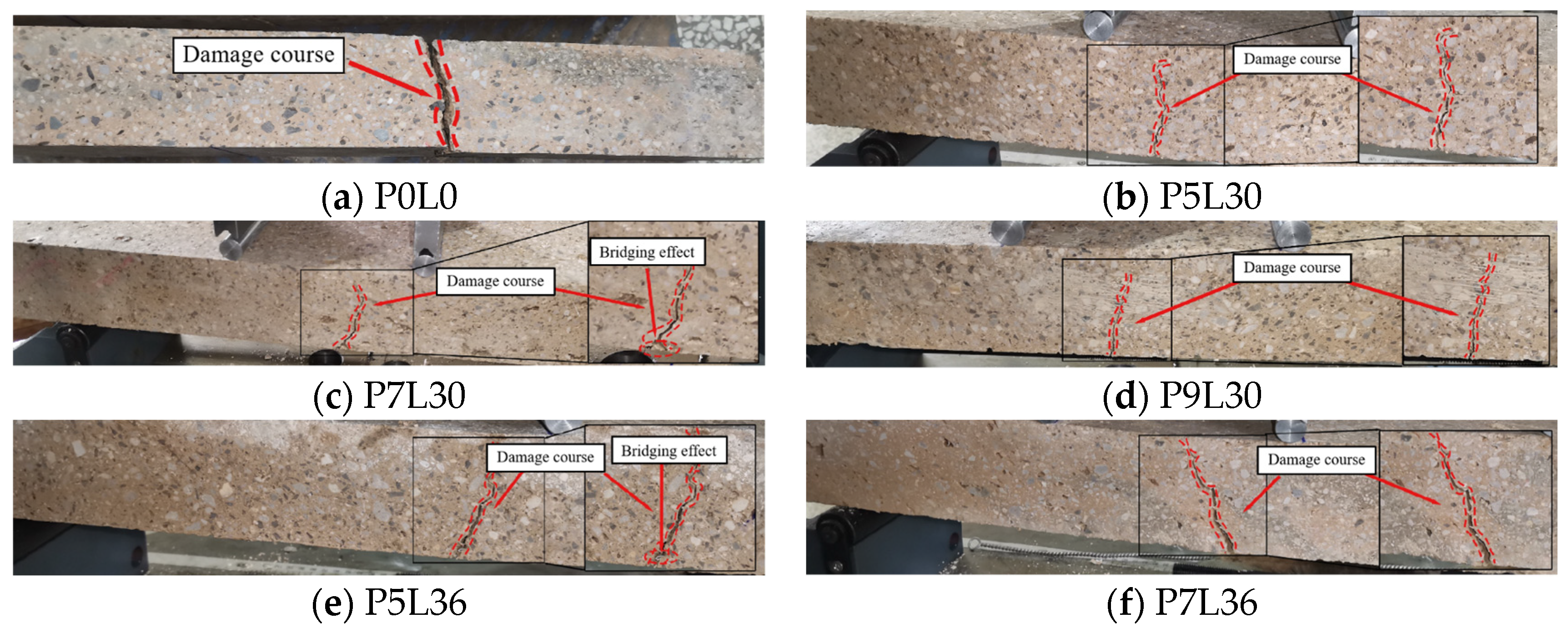

3.1. Failure State Analysis

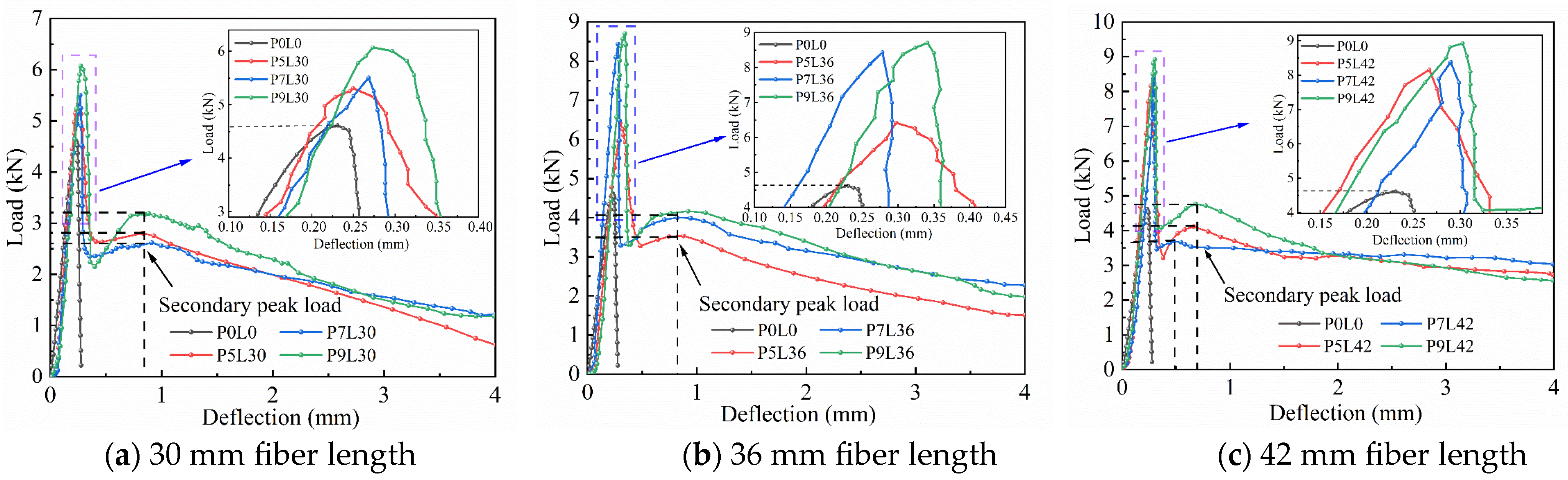

3.2. Load-Deflection Curves

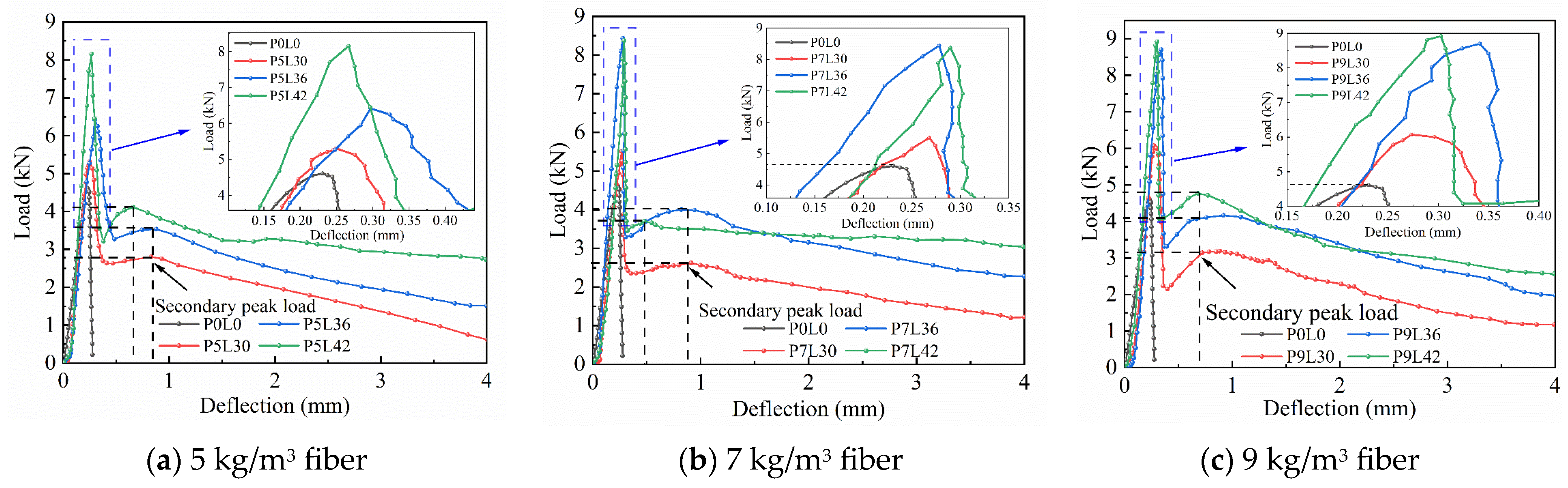

3.3. Analysis of Flexural Strength of Fiber Reinforced Concrete

3.4. Flexural Toughness Analysis of Fiber Reinforced Concrete

4. Numerical Simulation

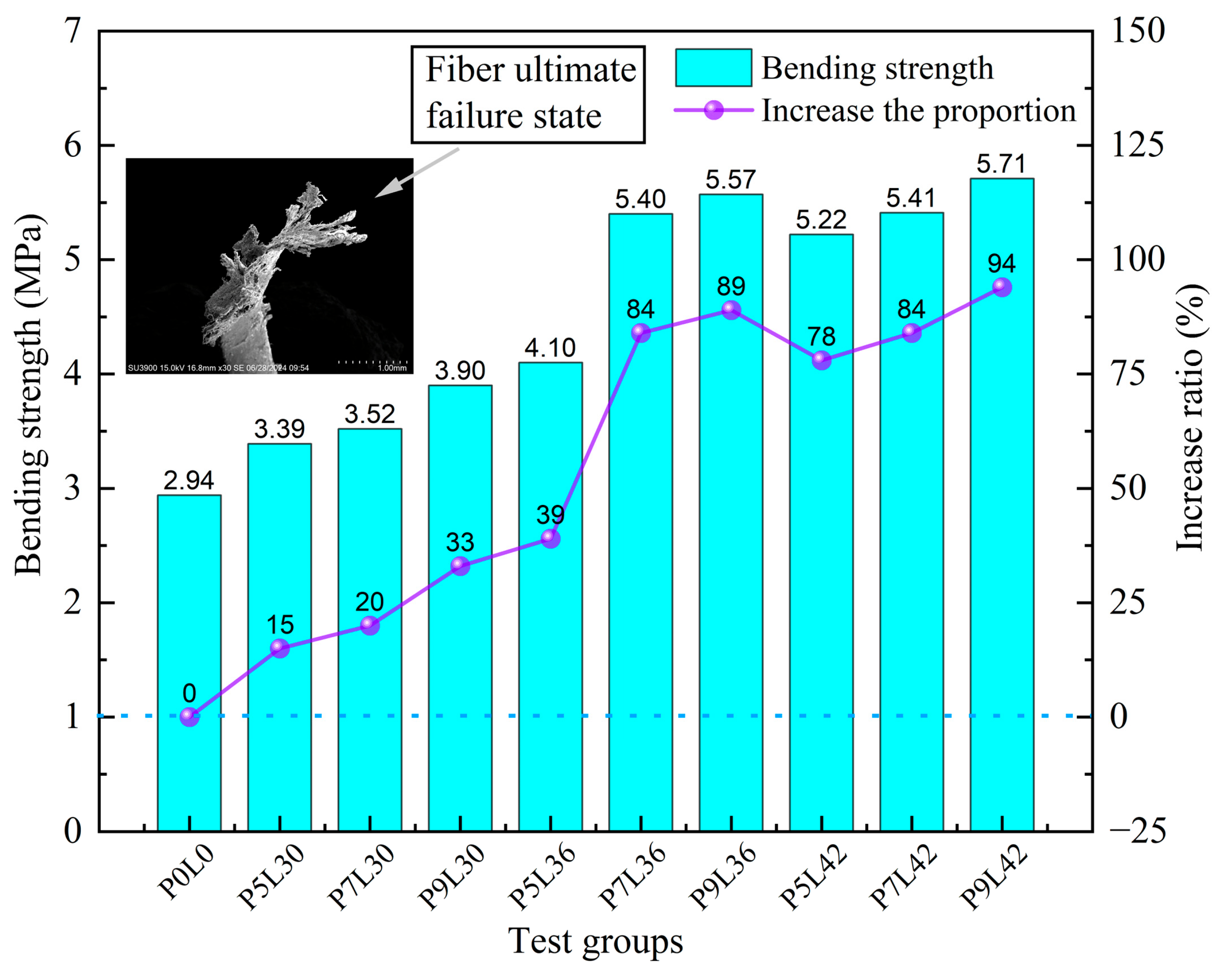

4.1. Physical Model of Polyformaldehyde Fiber Concrete

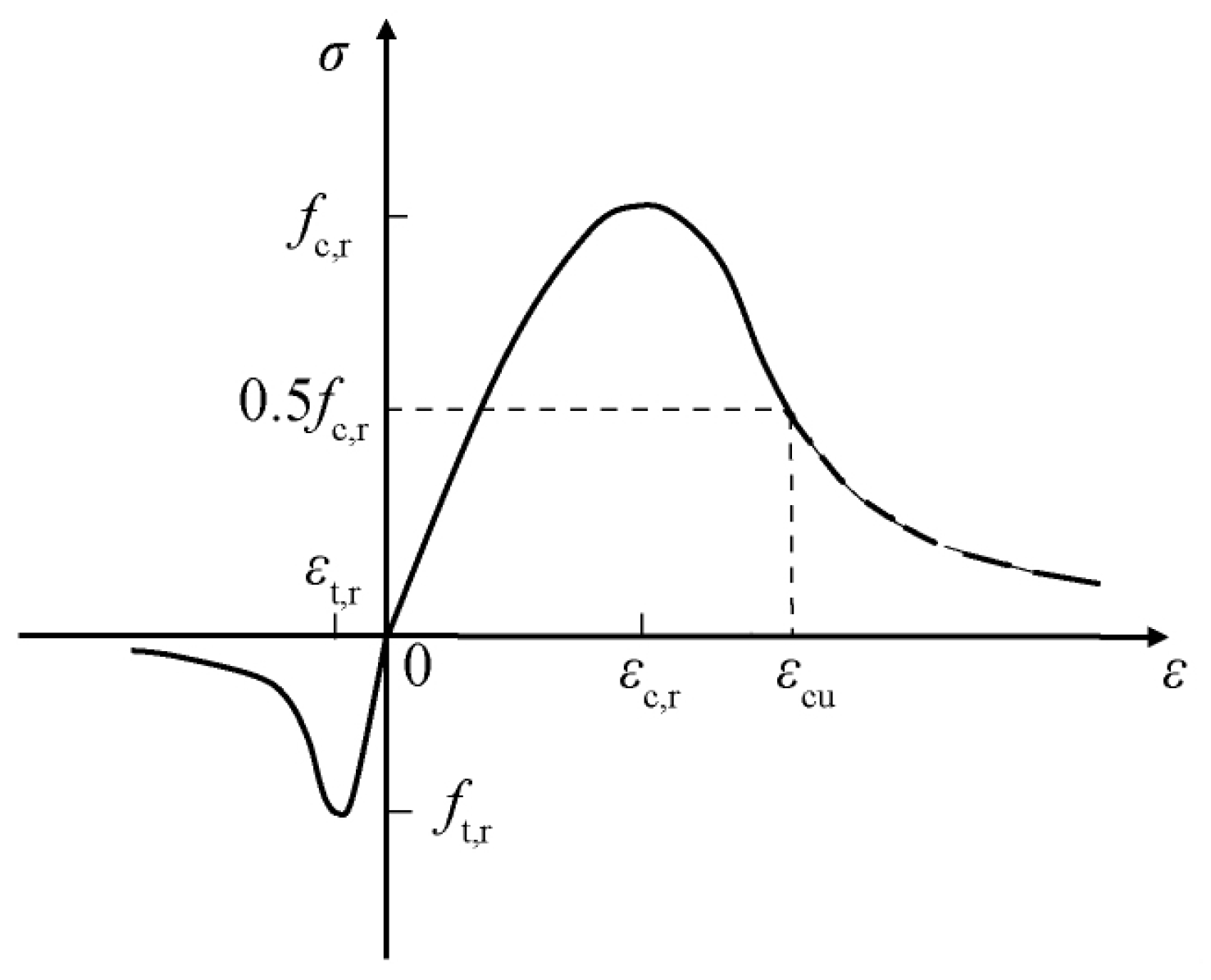

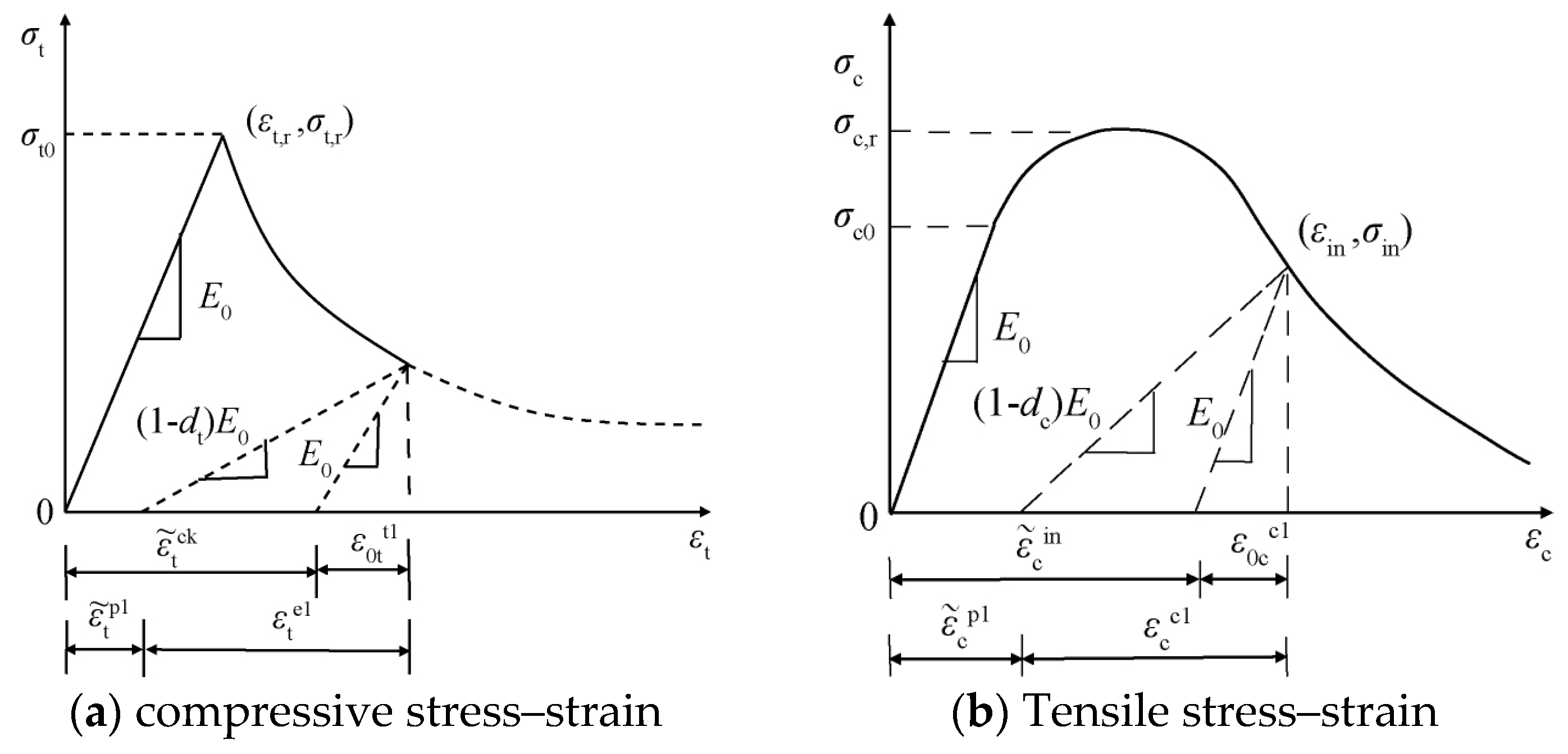

4.2. Material Plastic Damage Constitutive

4.3. Model Parameter

4.4. Simulation Results

4.4.1. Failure State and Analysis

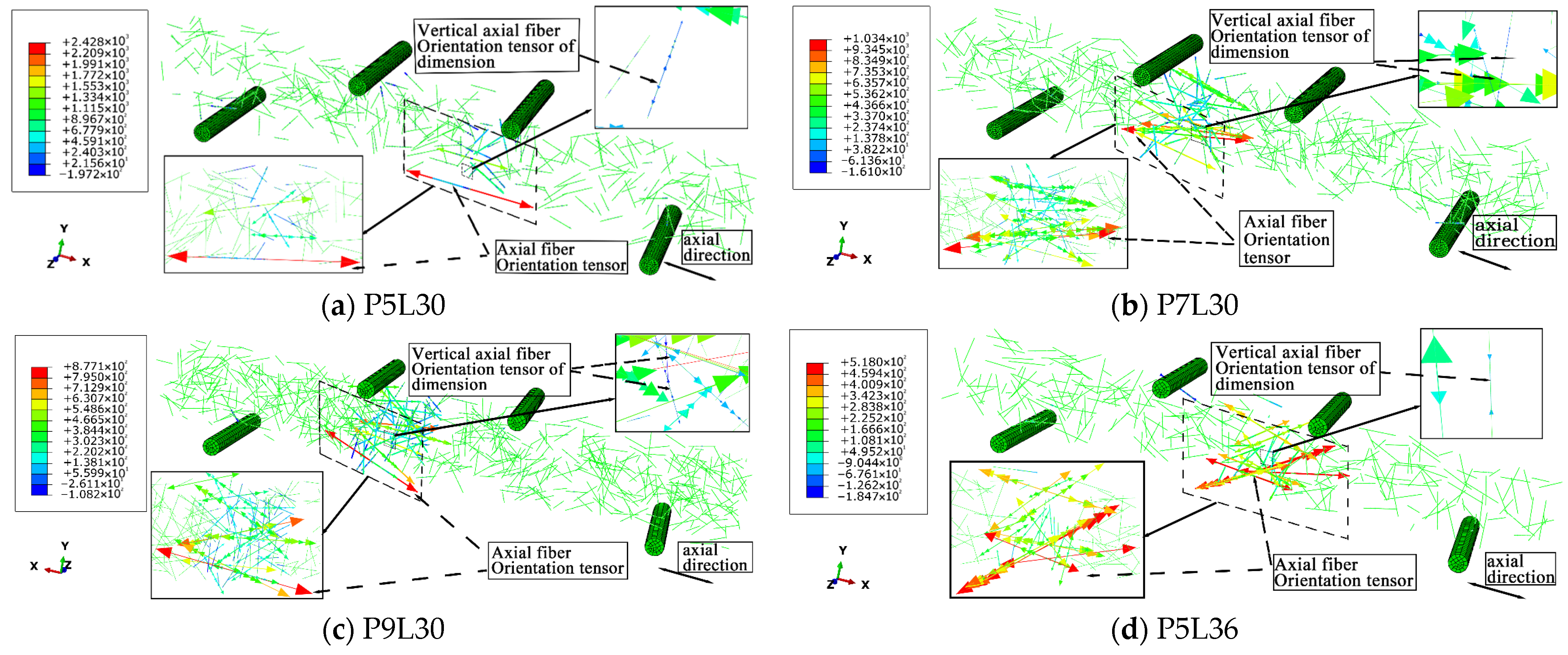

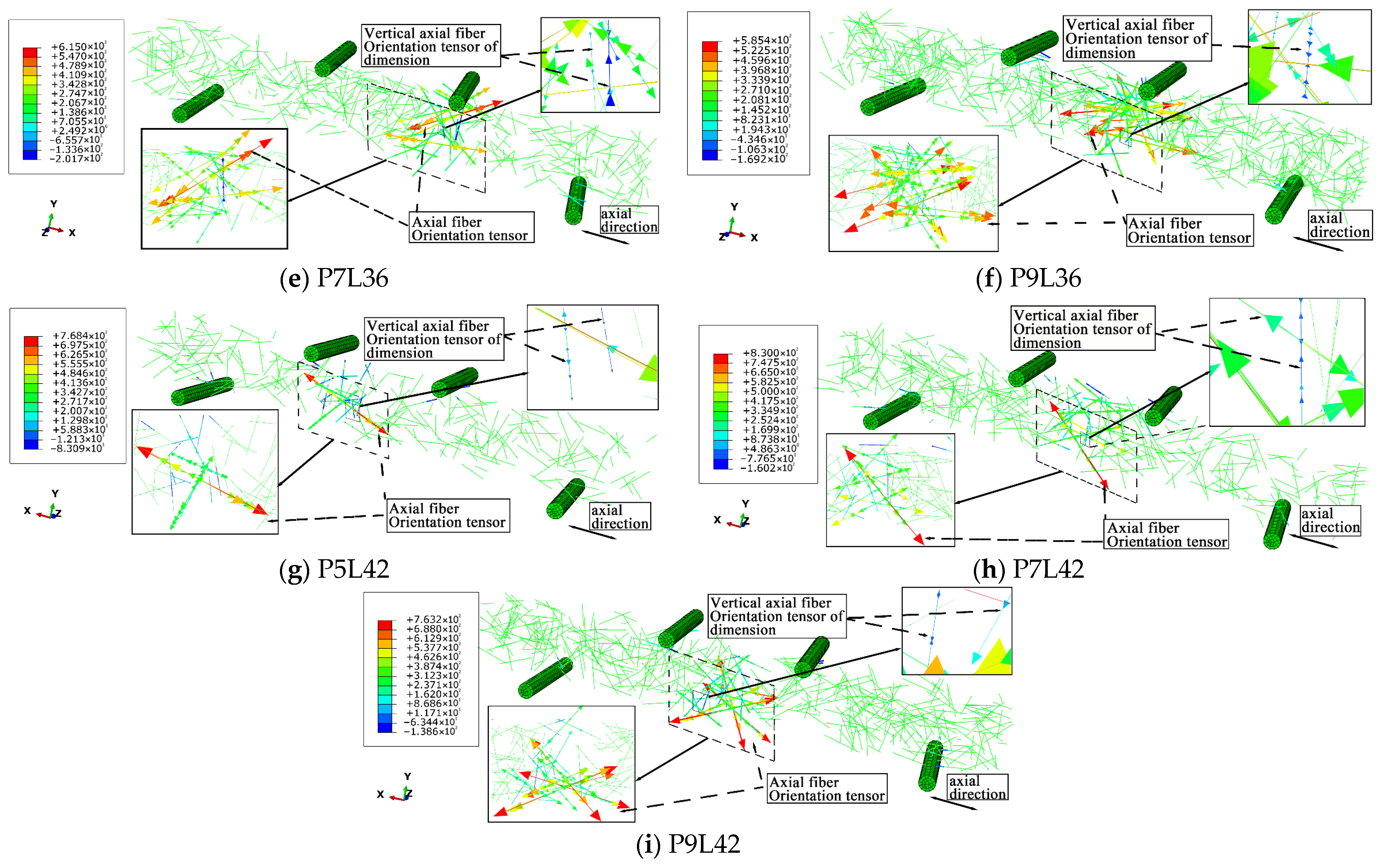

4.4.2. Analysis of Fiber Reinforcement Mechanism

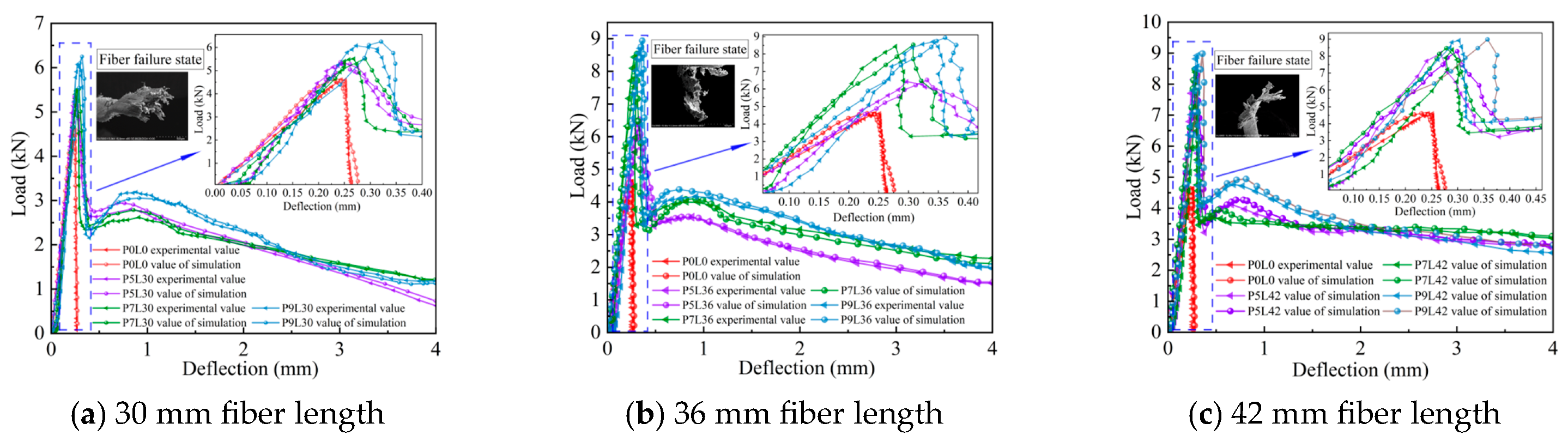

4.4.3. Load-Deflection Curve

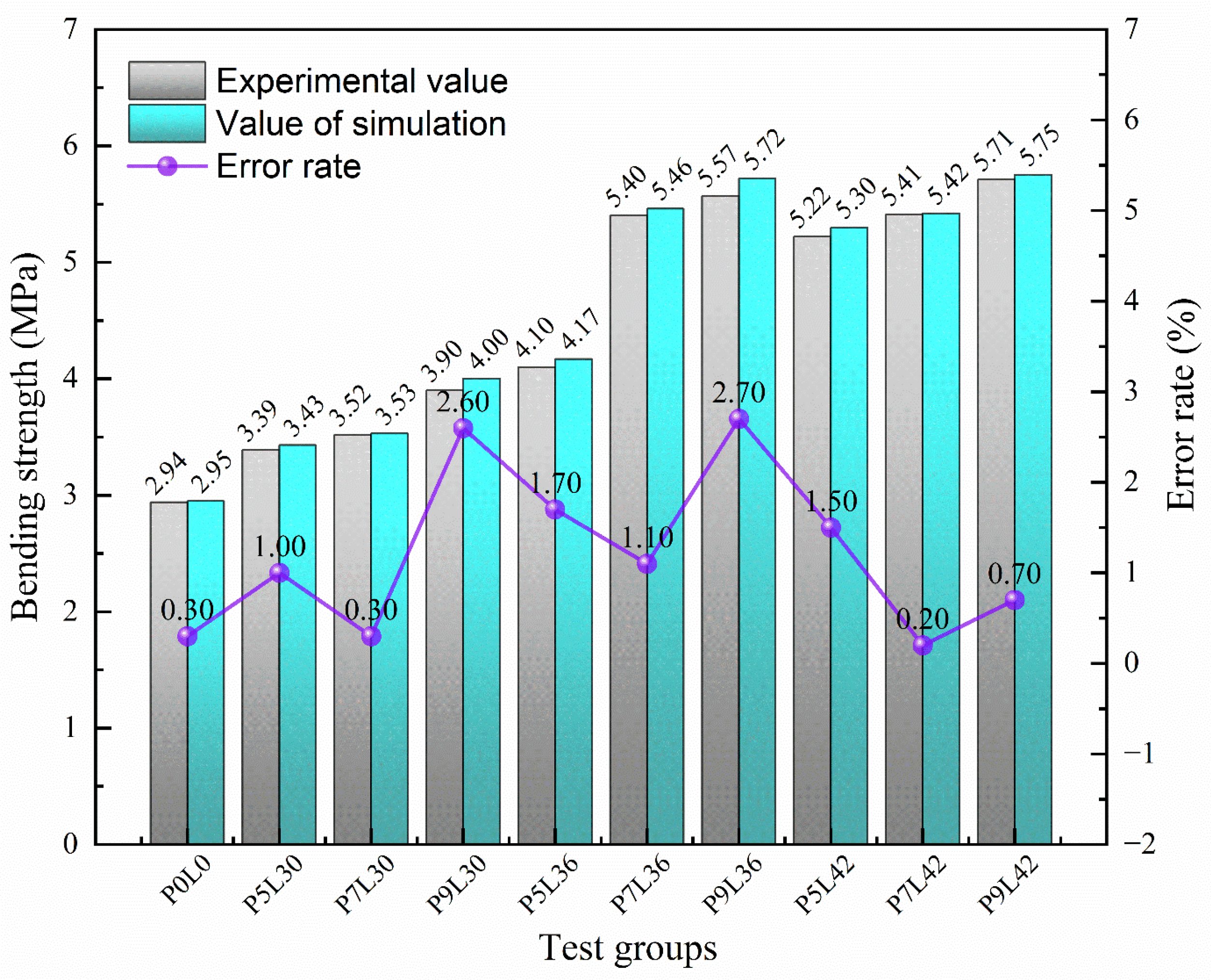

4.4.4. Bending Strength Analysis

5. Conclusions

- (1)

- In the four-point bending test, the SC specimens quickly developed cracks in the middle during loading, which continued to expand and eventually fractured into two segments, showing typical brittle failure. The specimens mixed with fibers showed significant differences: in the low-dosage group (P5L30/36/42), the cracks were thin and short at the maximum load, the fiber bridging effect was weak, and the crack expansion was disordered; in the medium-dosage group (P7L30/36/42), the crack length increased, the fibers were partially exposed and showed a linear expansion trend, and the bridging effect was enhanced; in the high-dosage group (P9L30/36/42), the crack width was the largest but the distribution was concentrated, more fibers were exposed and formed a continuous bridging network, and the cracks expanded regularly along a straight line. By inhibiting the crack width and guiding the expansion path, the fibers effectively improve the brittle fracture mode of SC, resulting in a more complete failure morphology, and the toughening effect is significantly enhanced with the increase in dosage.

- (2)

- After adding fibers, the load-deflection curves of PFS show similar trends, the failure mode changes from brittle fracture to ductile failure, the post-peak softening segment is significantly extended, and the residual load-bearing capacity is improved. Under the same dosage, the 42 mm long fibers are conducive to stress transfer due to their dense distribution, resulting in the most significant improvement in bending load and the largest peak load. Under the same length, the 9 kg/m3 fibers form a bridging ductile damage zone through the cross-linked network due to their large volume quantity, resulting in the largest peak load. The order of significant improvement in flexural strength of each group of PFS is: P9L42 > P9L36 > P7L42 > P7L36 > P5L42 > P5L36 > P9L30 > P7L30 > P5L30 > P0L0. Compared with the plain concrete group, the flexural strength of the fiber groups increased by 0.45–2.77 MPa, with an increase ratio of 10–100%. Among them, the P9L42 group has the highest flexural strength of PFS, which is 5.71 MPa, with an increase ratio of 94%. That is, the fiber ratio of 42 mm in length and 9 kg/m3 in dosage has the best improvement effect on SC.

- (3)

- The numerical simulation analysis shows that the plastic damage failure and load-deflection curves of each group of concrete specimens are in good agreement with the experimental conditions, and the fiber stress cloud diagrams all reflect that the internal fiber laws of the concrete are basically consistent. Among them, the fiber orientation tensor distribution cloud diagram reflects that, when the fiber arrangement direction is consistent with the axial direction of the specimen, the contribution rate to the flexural strength of the specimen is higher. The maximum/minimum stress values of the fiber orientation tensor in the P9L42 group are 763 MPa/−138 MPa, with an obvious fluctuation range.

- (4)

- To study the flexural performance of PFS specimens, this study adopted a method combining physical tests and numerical simulations. Based on the test data, a finite element model was established using the plastic damage (CDP) model. The simulation results are in good agreement with the test results, with a maximum error of only 2.7%, verifying the accuracy of the model. Moreover, the model was used to expand the fiber orientation tensor analysis, and the effects of fiber length and dosage were systematically studied, thus obtaining the optimal length and dosage ratio of POM fibers and the flexural strength parameters of PFS. The results show that, compared with SC, the PFS material mixed with POM fibers can significantly improve the flexural performance, which is more conducive to meeting the stability requirements of the roadway surrounding rock support. This study provides a scientific basis for the application of PFS in mine roadway surrounding rock support.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xie, H.; Zhang, R.; Zhang, Z.; Gao, M.; Li, C.; He, Z.; Li, C.; Liu, T. Deep Earth Science and Deep Earth Engineering Technology Exploration and Thinking. J. Coal 2023, 48, 3959–3978. [Google Scholar]

- Manchao, H.; Heping, X.; Suping, P.; Yaodong, J. Study on rock mechanics in deep mining. J. Rock Mech. Eng. 2005, 24, 2803–2813. [Google Scholar]

- Wu, A.; Sun, W.; Han, B.; Hong-Jiang, W.; Shao-Yong, W.; Gong-Cheng, L. Effect of temperature on wet shotcrete support strength in cold mining area and its engineering application. J. Min. Saf. Eng. 2015, 32, 697–705. [Google Scholar]

- Wang, Q.; Jiang, Z.; Jiang, B.; Kang, H.; Zhang, C. physical simulation test on dynamic impact and energy absorption control of deep roadway. Accord. J. Rock Mech. Eng. 2024, 43, 2081–2091. [Google Scholar]

- Li, J.; Niu, J.; Wan, C.; Liu, X.; Jin, Z. Comparison of flexural property between high performancepolypropylene fiber reinforced lightweight aggregate concrete and steel fiber reinforced lightweight aggregate concrete. Constr. Build. Mater. 2017, 157, 729–736. [Google Scholar] [CrossRef]

- Wang, S.; Zhu, H.; Liu, F.; Cheng, S.; Wang, B.; Yang, L. Effects of steel fibers and concrete strength on flexural toughness of ultra-high performance concrete with coarse aggregate. Case Stud. Constr. Mater. 2022, 17, e01170. [Google Scholar] [CrossRef]

- Zhang, J.C.; Li, B.J.; Chen, W.Y.; Guo, R.X. Experimental investigations on tensile strength and fracture toughness of a polyoxymethylene fiber reinforced concrete. Theor. Appl. Fract. Mech. 2024, 130, 104250. [Google Scholar] [CrossRef]

- Lee, J.H.; Cho, B.; Choi, E. Flexural capacity of fiber reinforced concrete with a consideration of concrete strength and fiber content. Constr. Build. Mater. 2017, 138, 222–231. [Google Scholar] [CrossRef]

- Jin, L.; Jia, L.; Zhang, R. Mesoscopic numerical study on fracture behavior of steel fiber reinforced concrete at low temperature. Eng. Mech. 2023, 40 (Suppl. S1), 200–206. [Google Scholar]

- Huang, J.; Chen, H. Effect of basalt fiber length on mechanical properties and frost resistance of concrete. J. Funct. Mater. 2025, 56, 3194–3201. [Google Scholar]

- Xia, W.; Lu, S.; Bai, E.; Xu, J.; Du, Y.; Yao, A. Study on the mechanical properties of carbon nanotube-carbon fiber composite modified concrete. J. Mater. Rep. 2023, 37, 110–118. [Google Scholar]

- He, Y.; Huang, W.; Guo, J.; Chen, X.; Yan, M.; Wang, J. Residual mechanical properties of co-polyoxymethylene fiber ultra-high performance concrete after high temperature. Silic. J. 2022, 50, 839–848. [Google Scholar]

- Yue, J.; Wang, J.; Wu, Y.; Zhang, H.; Ye, Z.; Zhang, R. Experimental study and numerical simulation on fracture mechanical properties of 3D printed carbon fiber reinforced concrete J/OL. J. Build. Struct. 2023, 45, 243–252. [Google Scholar]

- Zheng, S.; Hu, J.; Zhang, X.; Yang, F.; Zhou, L.; Ruan, S. Experimental study on mechanical properties of green high performance fiber reinforced concrete. J. Hunan Univ. 2024, 51, 155–164. [Google Scholar]

- Chen, Y.; Li, H.; Ye, P.; Chen, Z.; Xu, H. Experiment on mechanical properties of steel fiber recycled concrete under cyclic loading. J. Compos. Mater. 2022, 39, 5574–5585. [Google Scholar]

- Zou, Q.; Chen, J.; Fu, B.; Teng, J. Mechanical properties of glass fiber composite solid waste reinforced concrete. J. Compos. Mater. 2025, 42, 1489–1501. [Google Scholar]

- Liu, C.Y.; Wang, H.Q.; Liu, X.F.; Niu, M.X.; Wu, J.F. Experimental study and numerical simulation of the effect of different fiber types on the basic mechanical properties of shotcrete. Sci. Rep. 2024, 14, 26573. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, Y.; Duan, L. Bending performance test of ultra-high performance cement-based composites with copolyformaldehyde fiber. J. Compos. 2024, 41, 373–382. [Google Scholar]

- Qin, N.; Li, Q.; Xu, B. Pore characteristics and dynamic mechanical properties of polyformaldehyde fiber reinforced high strength concrete. J. Yangtze River Acad. Sci. 2023, 40, 180–186. [Google Scholar]

- Huang, D.; Niu, D.; Liu, Y.; Su, L.; Xia, Q. Study on mechanical properties, permeability and pore structure of basalt-polypropylene fiber reinforced concrete. Proc. Yangtze River Acad. Sci. 2023, 40, 147–152. [Google Scholar]

- Wang, Z.; Guo, R.; Guo, L.; Xia, H.; Zhang, J. Study on mechanical properties of polyformaldehyde fiber airport pavement concrete based on orthogonal test. Road Traffic Sci. Technol. 2023, 40, 57–65. [Google Scholar]

- Zhang, Z.; Zhu, X.; Zhang, Y.; Gong, R. Experimental and numerical investigation on flexural and fracture performance of steel fiber reinforced shotcrete. Constr. Build. Mater. 2022, 315, 125645. [Google Scholar] [CrossRef]

- Banjara, N.K.; Ramanjaneyulu, K. Experimental Investigations and Numerical Simulations on the Flexural Fatigue Behavior of Plain and Fiber-Reinforced Concrete. J. Mater. Civ. Eng. 2018, 30, 04018151. [Google Scholar] [CrossRef]

- Deng, Z.; Chen, P.; Liu, X.; Du, L.; Tan, J.; Liang, N. Study on the tensile and compressive mechanical properties of multi-scale fiber-reinforced concrete: Laboratory test and mesoscopic numerical simulation. J. Build. Eng. 2024, 86, 108852. [Google Scholar] [CrossRef]

- Chira, A.; Kumar, A.; Vlach, T.; Laiblová, L.; Škapin, A.S.; Hájek, P. Property improvements of alkali resistant glass fibers/epoxy composite with nanosilica for textile reinforced concrete applications. Mater. Des. 2015, 89, 146–155. [Google Scholar] [CrossRef]

- Liang, X.; Wu, C. Meso-scale modelling of steel fiber reinforced concrete with high strength. Constr. Build. Mater. 2018, 165, 187–198. [Google Scholar] [CrossRef]

- Hu, H.; Liu, J.; Wang, J. Analysis of Toughness and Acoustic Emission Characteristics of Fiber-reinforced Concrete. J. China Coal Soc. 2023, 48, 1209–1219. [Google Scholar]

- Zhang, W.; Xu, X.; Wang, H.; Wei, F.; Zhang, Y. Experimental and numerical analysis of interfacial bonding strength of polyoxymethylene reinforced cement composites. Constr. Build. Mater. 2019, 207, 1–9. [Google Scholar] [CrossRef]

- GB/T 50081-2019; Standard for Test Methods of Physical and Mechanical Properties of Concrete. China Construction Industry Publishing House: Beijing, China, 2019.

- JGJ/T 372-2016; Technical Specification for Application of Shotcrete. China Construction Industry Press: Beijing, China, 2016.

- GB 50086-2015; Technical Code for Rock and Soil Anchor and Shotcrete Support Engineering. China Construction Industry Press: Beijing, China, 2015.

- GB 50164-92; Concrete Quality Control Standard. China Construction Industry Publishing House: Beijing, China, 1993.

- Deng, Z.; Wang, H.; Liu, Y. Flexural toughness and fracture properties of eco-steel fiber reinforced concrete. J. Build. Sci. Eng. 2017, 34, 111–118. [Google Scholar]

- ASTM C1609/C1609M-19; Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete (Using Beam with Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2012.

- Ding, Y.; Wang, Y.; Sun, X. Test method and evaluation standard for flexural toughness of steel fiber reinforced concrete. J. Build. Mater. 2014, 17, 76–82. [Google Scholar]

- Xu, H.; Deng, Z. Experimental Study on Mechanical Properties of New Ultra-High Performance Concrete. Concrete 2016, 4, 20–23. [Google Scholar]

- Wang, W.; Zhu, J.; Cheng, X.; Liu, S.; Jiang, D.; Wang, W. Numerical simulation of strength of basalt fiber permeable concrete based on CT technology. Case Stud. Constr. Mater. 2022, 17, e01348. [Google Scholar] [CrossRef]

- Yao, Y.; Zhong, Y.; Su, Z.; Muhammad, R.; Wang, D.; Li, Y.; Li, S.; Sun, G. Micromechanical analyses of unidirectional (UD) discontinuous flax fiber reinforced composites. Compos. Sci. Technol. 2024, 258, 110893. [Google Scholar] [CrossRef]

- Zhong, Y. Study on the Properties of Self-Compacting Vibration-Damping Soil for Fat Groove Backfilling. Master’s Thesis, Guangzhou University, Guangzhou, China, 2025. [Google Scholar]

- Mu, X. Study on the Bearing Capacity of Thin-Layer Comb Tenon Steel-Concrete Joints. Master’s Thesis, Northwest A&F University, Xianyang, China, 2025. [Google Scholar]

- GB/T 50010-2010; Design Standard of Concrete Structure. China Building Industry Press: Beijing, China, 2010.

- Sidoroff, F. Description of Anisotropic Damage Application to Elasticity; Springer: Berlin, Germany, 1981; pp. 237–244. [Google Scholar]

- Hillerborg, A.; Modéer, M.; Petersson, P.E. Analysis of crack formation and crack growth in concrete by means of fracture mechanics and finite elements. Cem. Concr. Res. 1976, 6, 773–781. [Google Scholar] [CrossRef]

- Wang, Z.; Niu, D.; Zhang, G. Comparison and parameter analysis of simulation and test on flexural performance of SFRC beams. J. Chin. Ceram. Soc. 2020, 39, 1401–1408. [Google Scholar]

- Xiao, J.; Li, Y.; Wang, Y. Numerical simulation analysis on seismic performance of recycled concrete shear walls. China Civ. Eng. J. 2016, 49, 21–30. [Google Scholar]

- Ding, Y.; Wang, Y. Experimental Study on Workability of Fiber Self-Compacting High-Performance Concrete. China Civ. Eng. J. 2015, 11, 51–57. [Google Scholar]

- Liu, Z.; Xiao, Y.; Li, J. Study on single fiber pull-out test and numerical simulation of steel fiber reinforced concrete. Eng. Mech. 2018, 35, 118–127. [Google Scholar] [CrossRef]

- Jin, J.; Du, X.; Liu, J. Numerical simulation of mechanical properties of steel fiber high-strength concrete based on mesomechanics. China Civ. Eng. J. 2012, 45 (Suppl. S1), 102–107. [Google Scholar]

- Pan, H.; Li, G.; Yao, J. Mesoscopic numerical simulation and experimental study on flexural performance of steel fiber reinforced concrete. J. Build. Struct. 2016, 37, 121–128. [Google Scholar]

| Density (g/cm3) | Length (mm) | Equivalent Diameter (mm) | Tensile Strength (MPa) | Elongation at Break (%) | Elastic Modulus (GPa) | Temperature (°C) |

|---|---|---|---|---|---|---|

| 1.41 | 30, 36, 42 | 0.44 | >1000 | 13~15% | >10 | 45~100 °C |

| Grouping | Cement (kg/m3) | Aggregate (kg/m3) | Water (kg/m3) | Fiber Length (mm) | Fiber Content (kg/m3) | Rapid Setting Admixture (kg/m3) |

|---|---|---|---|---|---|---|

| P0L0 | 300 | 1260 | 185 | - | - | 15 |

| P5L30 | 300 | 1260 | 185 | 30 | 5 | 15 |

| P7L30 | 300 | 1260 | 185 | 30 | 7 | 15 |

| P9L30 | 300 | 1260 | 185 | 30 | 9 | 15 |

| P5L36 | 300 | 1260 | 185 | 36 | 5 | 15 |

| P7L36 | 300 | 1260 | 185 | 36 | 7 | 15 |

| P9L36 | 300 | 1260 | 185 | 36 | 9 | 15 |

| P5L42 | 300 | 1260 | 185 | 42 | 5 | 15 |

| P7L42 | 300 | 1260 | 185 | 42 | 7 | 15 |

| P7L42 | 300 | 1260 | 185 | 42 | 9 | 15 |

| Group | ff/MPa | Grouping | ff/MPa | ||||||

|---|---|---|---|---|---|---|---|---|---|

| xi | μ | σ | cv(%) | xi | μ | σ | cv(%) | ||

| P0L0 | 2.84 | 2.94 | 0.07 | 2.38% | P7L36 | 5.34 | 5.40 | 0.04 | 0.74% |

| 3.00 | 5.43 | ||||||||

| 2.99 | 5.43 | ||||||||

| P5L30 | 3.28 | 3.39 | 0.08 | 2.36% | P9L36 | 5.48 | 5.57 | 0.07 | 1.26% |

| 3.47 | 5.59 | ||||||||

| 3.42 | 5.64 | ||||||||

| P7L30 | 3.50 | 3.52 | 0.03 | 0.85% | P5L42 | 5.20 | 5.22 | 0.02 | 0.38% |

| 3.57 | 5.22 | ||||||||

| 3.50 | 5.25 | ||||||||

| P9L30 | 3.92 | 3.9 | 0.08 | 2.05% | P7L42 | 5.33 | 5.41 | 0.06 | 1.11% |

| 3.99 | 5.48 | ||||||||

| 3.80 | 5.42 | ||||||||

| P5L36 | 3.94 | 4.10 | 0.12 | 2.93% | P9L42 | 5.63 | 5.71 | 0.09 | 1.58% |

| 4.17 | 5.65 | ||||||||

| 4.20 | 5.84 | ||||||||

| Dilatation Angle | Eccentricity | fb0/fc0 | K | Viscous Parameter |

|---|---|---|---|---|

| 38 | 0.1 | 1.16 | 0.66667 | 0.0005 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, Y.; Wang, G.; Zhao, B.; Wang, M.; Li, Y.; Li, S.; Yuan, M.; Wang, M.; Ma, Y. Polyformaldehyde Fiber Shotcrete Bending Fracture Test and Finite Element Simulation Research. Eng 2025, 6, 322. https://doi.org/10.3390/eng6110322

Zheng Y, Wang G, Zhao B, Wang M, Li Y, Li S, Yuan M, Wang M, Ma Y. Polyformaldehyde Fiber Shotcrete Bending Fracture Test and Finite Element Simulation Research. Eng. 2025; 6(11):322. https://doi.org/10.3390/eng6110322

Chicago/Turabian StyleZheng, Yuelong, Guangjin Wang, Bing Zhao, Menglai Wang, Yanlin Li, Shujian Li, Mingli Yuan, Mingqiang Wang, and Yubo Ma. 2025. "Polyformaldehyde Fiber Shotcrete Bending Fracture Test and Finite Element Simulation Research" Eng 6, no. 11: 322. https://doi.org/10.3390/eng6110322

APA StyleZheng, Y., Wang, G., Zhao, B., Wang, M., Li, Y., Li, S., Yuan, M., Wang, M., & Ma, Y. (2025). Polyformaldehyde Fiber Shotcrete Bending Fracture Test and Finite Element Simulation Research. Eng, 6(11), 322. https://doi.org/10.3390/eng6110322