Overview of Cement Bond Evaluation Methods in Carbon Capture, Utilisation, and Storage (CCUS) Projects—A Review

Abstract

1. Introduction

1.1. Brief Overview of Carbon Capture, Utilisation, and Storage (CCUS)

1.2. Importance of Cement Bond Evaluation in CCUS Projects

1.3. Objectives of This Review

2. Cement Bond Evaluation Techniques

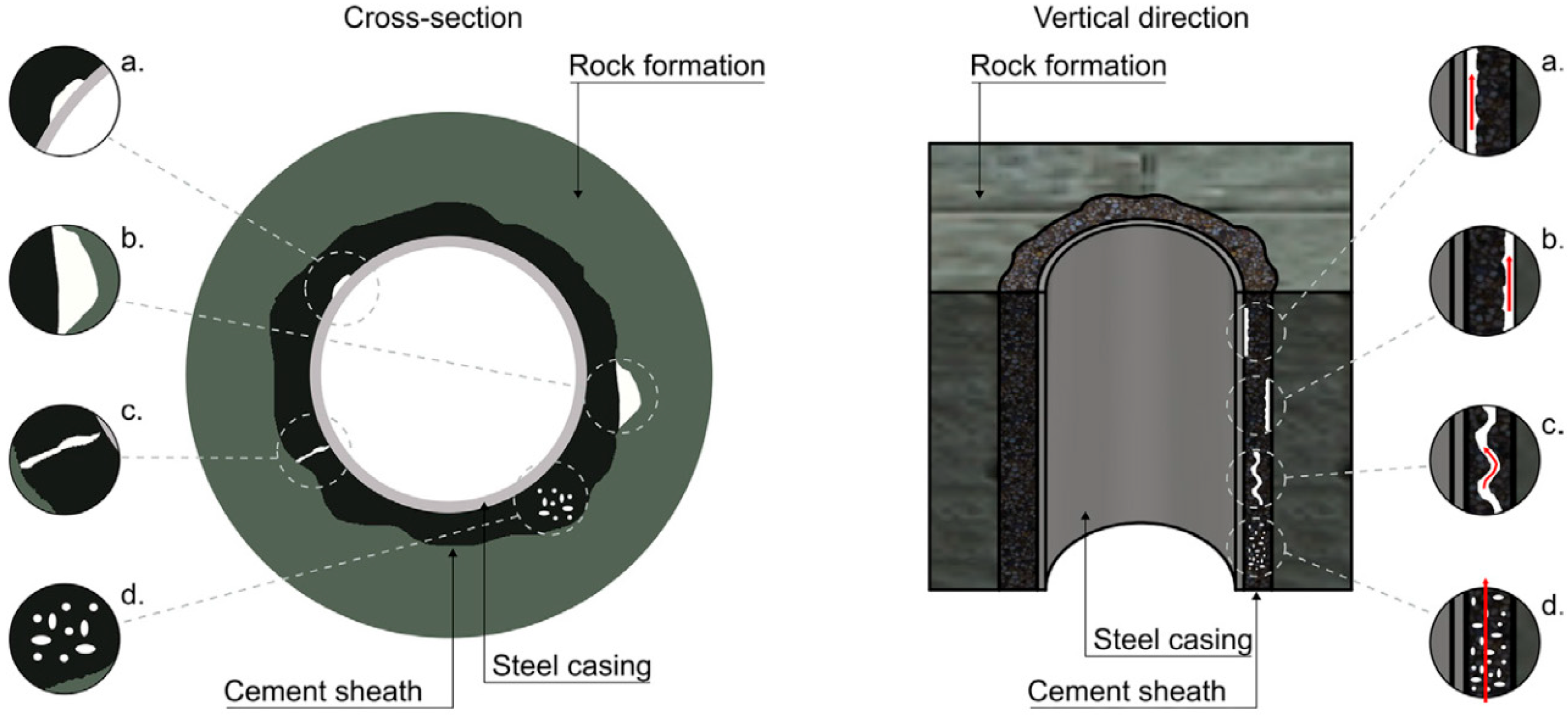

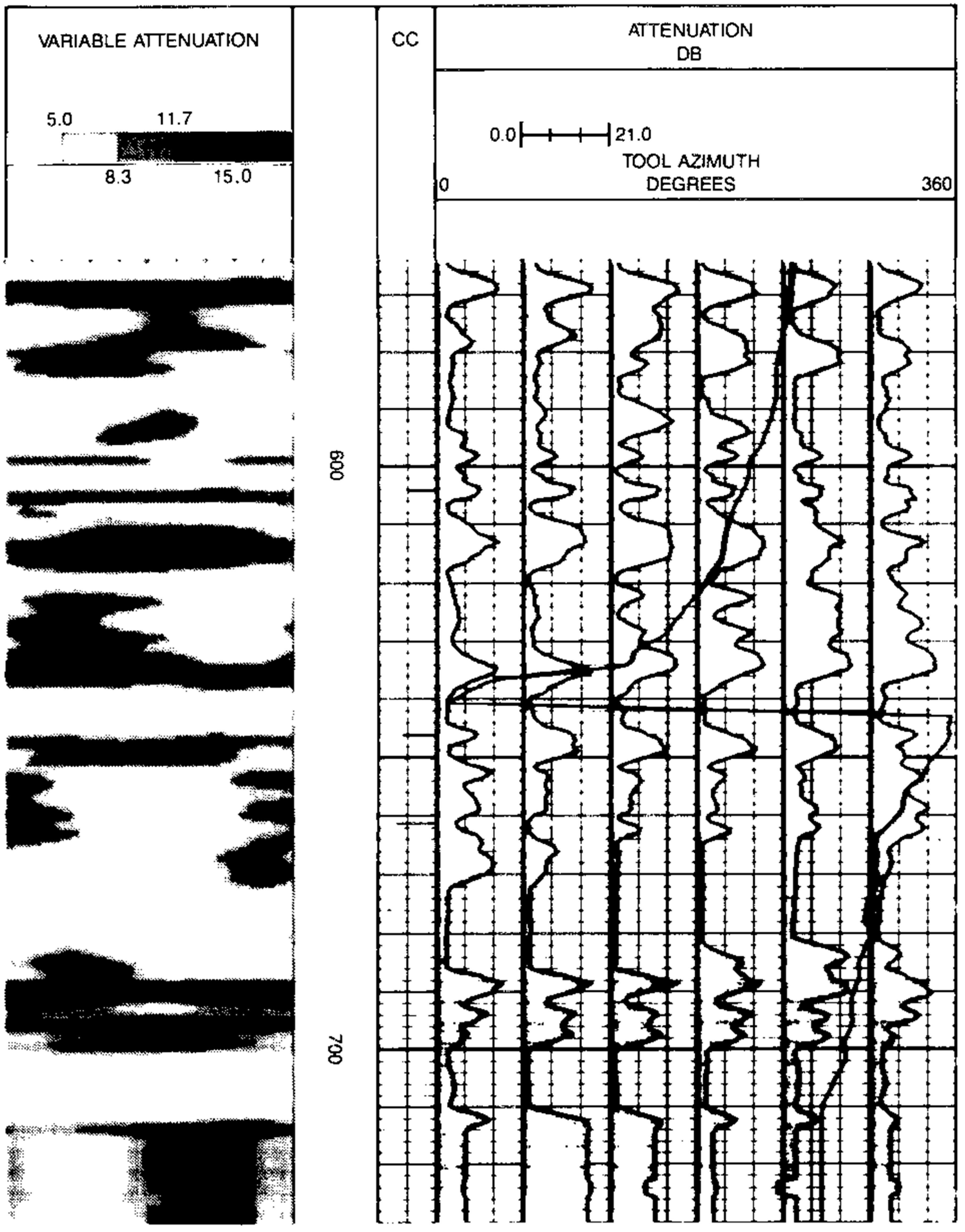

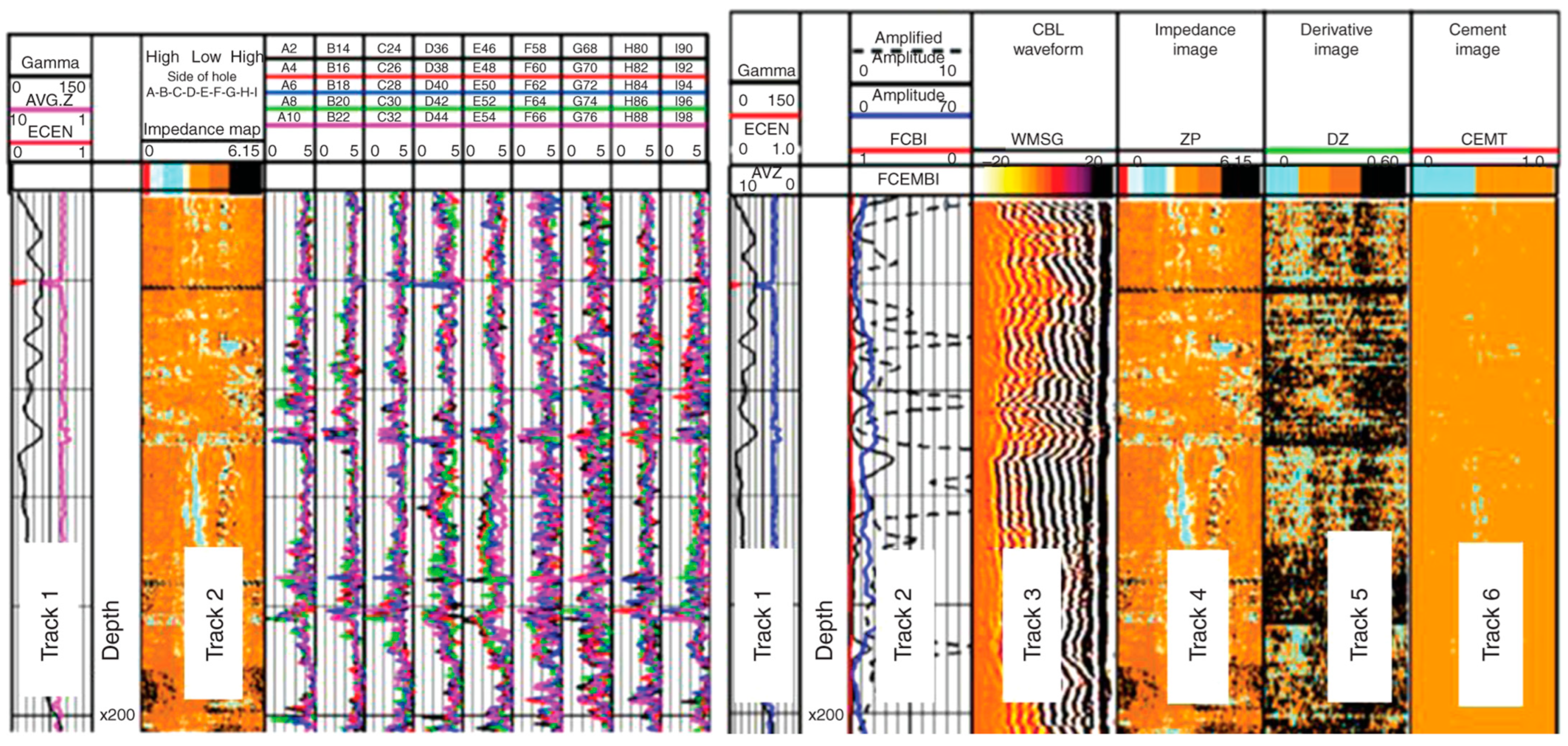

2.1. Description of Cement Bond Logging Tools

2.2. Principles of Acoustic Logging and Ultrasonic Imaging Tools

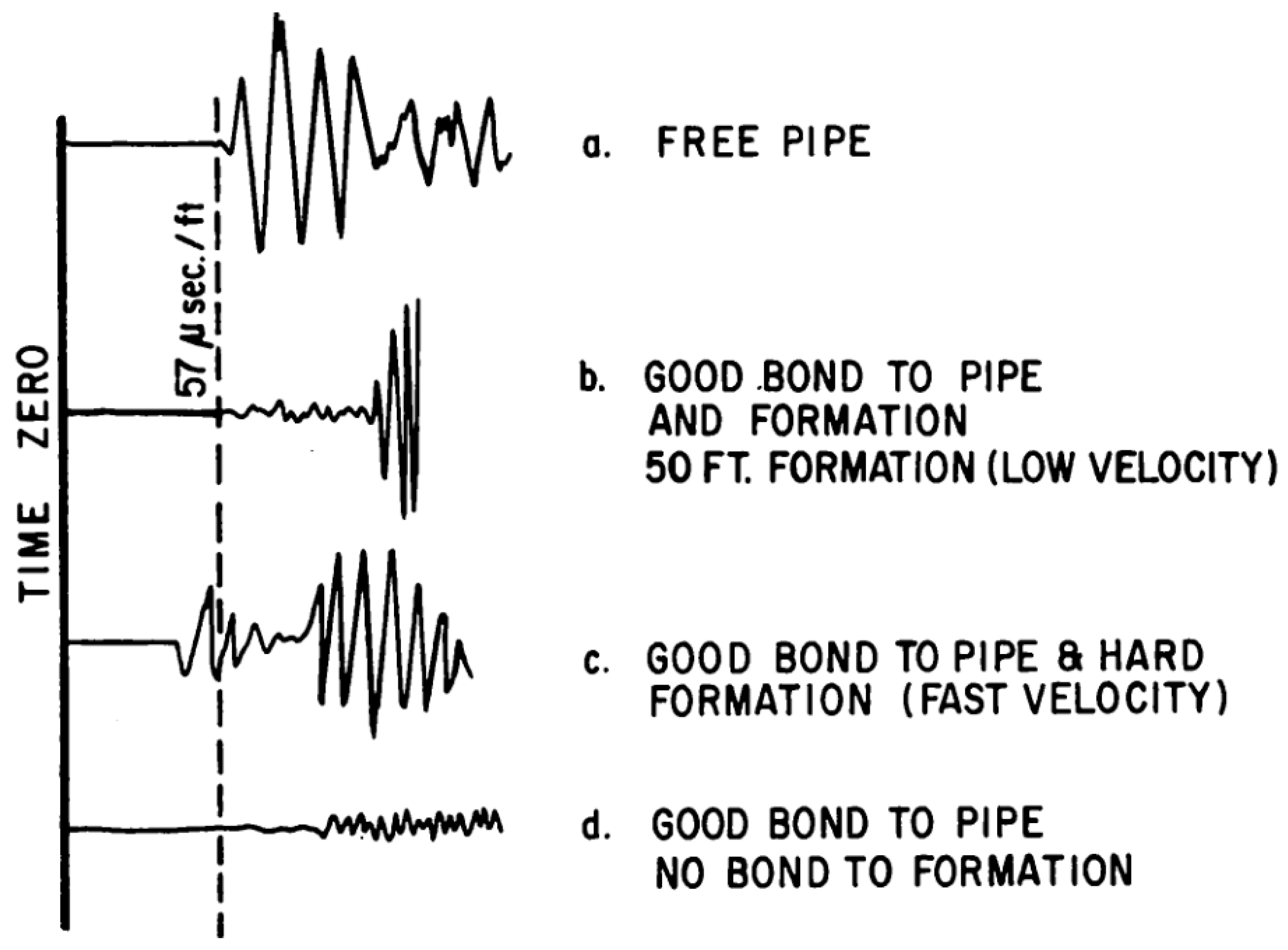

- Transit Time: This parameter reflects the acoustic impedance of the encountered materials, with variations indicating changes in material properties, such as bonding strength. In CCUS wells, lower acoustic impedance can accompany debonding or channelling created by thermal/pressure cycling.

- Amplitude: The strength of the received acoustic signal correlates with material density and integrity. Lower amplitudes suggest poor bonding or the presence of a microannulus in the cement sheath. Azimuthal low-amplitude sectors are consistent with localised CO2 migration risks.

- Attenuation: This parameter provides information about the material’s acoustic properties and cement bond quality based on the reduction in the strength of the signal as it propagates through the wellbore, casing, and cement. Elevated attenuation may reflect scattering from carbonation-induced microcracks.

- Oscilloscope Pictures: Visual representations of acoustic signals help to interpret cement bond quality and identify issues such as fluid annulus thickness or poor bonding.

- Echo amplitude: This is an indicator of casing conditions. Reduced echo amplitude can flag debonding or fluid behind pipe in CO2 injectors.

- Internal radius of the casing: This is calculated from the transit time of the main echo.

- Casing thickness: This value is calculated from the resonant frequency.

- Acoustic impedance of the material behind the casing: This is calculated from the resonance form. Azimuthal maps of impedance enable targeted remediation where channelling is suspected.

2.3. Advantages and Limitations of Acoustic Logging and Ultrasonic Imaging Tools

3. Challenges in Cement Bond Evaluation for CCUS

3.1. Presence of CO2 and Other Reactive Fluids

3.2. Impact of Cement Sheath Deterioration over Time

4. Advances in Cement Bond Evaluation Techniques

5. Conclusions and Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Forster, P.M.; Smith, C.J.; Walsh, T.; Lamb, W.F.; Lamboll, R.; Hauser, M.; Ribes, A.; Rosen, D.; Gillett, N.P.; Palmer, M.D.; et al. Indicators of Global Climate Change 2023: Annual update of key indicators of the state of the climate system and human influence. Earth Syst. Sci. Data 2024, 16, 2625–2658. [Google Scholar] [CrossRef]

- IPCC. Climate Change 2023: Synthesis Report. In Contribution of Working Groups I, II and III to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; IPCC: Geneva, Switzerland, 2023; p. 184. [Google Scholar]

- Nanthakumar, C.; Sakthikumaran, M.; Sivashankar, G. Carbon Dioxide—The Frontline Greenhouse Gas. Int. J. Comput. Algorithm (IJCOA) 2021, 10, 47–53. [Google Scholar] [CrossRef]

- Bashir, A.; Ali, M.; Patil, S.; Aljawad, M.S.; Mahmoud, M.; Al-Shehri, D.; Hoteit, H.; Kamal, M.S. Comprehensive review of CO2 geological storage: Exploring principles, mechanisms, and prospects. Earth-Sci. Rev. 2024, 249, 104672. [Google Scholar] [CrossRef]

- Carpenter, C. Study Describes Challenges, Opportunities of CO2 EOR in China. J. Pet. Technol. 2022, 74, 87–89. [Google Scholar] [CrossRef]

- Davoodi, S.; Al-Shargabi, M.; Wood, D.A.; Mehrad, M.; Rukavishnikov, V.S. Carbon dioxide sequestration through enhanced oil recovery: A review of storage mechanisms and technological applications. Fuel 2024, 366, 131313. [Google Scholar] [CrossRef]

- Gür, T.M. Carbon Dioxide Emissions, Capture, Storage and Utilization: Review of Materials, Processes and Technologies. Prog. Energy Combust. Sci. 2022, 89, 100965. [Google Scholar] [CrossRef]

- Li, N.; Mo, L.; Unluer, C. Emerging CO2 utilization technologies for construction materials: A review. J. CO2 Util. 2022, 65, 102237. [Google Scholar] [CrossRef]

- Che, X.; Yi, X.; Dai, Z.; Zhang, Z.; Zhang, Y. Application and Development Countermeasures of CCUS Technology in China’s Petroleum Industry. Atmosphere 2022, 13, 1757. [Google Scholar] [CrossRef]

- Hou, Z.; Luo, J.; Xie, Y.; Wu, L.; Huang, L.; Xiong, Y. Carbon Circular Utilization and Partially Geological Sequestration: Potentialities, Challenges, and Trends. Energies 2022, 16, 324. [Google Scholar] [CrossRef]

- Global CCS Institute, Facility Data. Available online: https://app.powerbi.com/view?r=eyJrIjoiM2ZiOGM4ODMtYzU0ZS00NzVlLTkyNjgtY2EwYzg0ZWVmMGI1IiwidCI6IjRlMjRkMDI2LWI5MTYtNGNiMS04YWZmLTI1ZmZhNzA1ZWVhMSIsImMiOjEwfQ%3D%3D (accessed on 9 June 2024).

- Dimabuyu, A. Upscaling CCUS in Asia Pacific—A look at upstream synergy projects and potential for multi-user hubs. APPEA J. 2023, 63, S371–S374. [Google Scholar] [CrossRef]

- Picha, M.S. Carbon Capture Storage (CCS) Drilling & Completion Well Integrity Lifecycle Challenges & Mitigations. In Proceedings of the SPE/IADC Asia Pacific Drilling Technology Conference and Exhibition, Bangkok, Thailand, 7–8 August 2024. [Google Scholar]

- Picha, M.S.; Abu Bakar, M.A.B.; Patil, P.A.; Abu Bakar, F.A.; Das, D.P.; Tiwari, P.K. Overcoming CO2 Injector Well Design and Completion Challenges in a Carbonate Reservoir for World’s First Offshore Carbon Capture Storage CCS SE Asia Project. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, United Arab Emirates, 15–18 November 2021. [Google Scholar]

- Picha, M.S.; Chuttani, A. Storage Development Plan SDP for Abandoning High Risk Development Wells and Drilling Fit-For-Purpose CO2 Injectors Offshore Carbon Capture Storage CCS Project. In Proceedings of the IADC/SPE Asia Pacific Drilling Technology Conference and Exhibition, Bangkok, Thailand, 9–10 August 2022. [Google Scholar]

- Askar, A.H.; Illangasekare, T.H. Controlling potential far-field brine leakage from CO2 storage formations using deep extraction wells: Numerical and experimental testing. Greenh. Gases Sci. Technol. 2023, 13, 3–30. [Google Scholar] [CrossRef]

- Okwen, R.T.; Frailey, S.M. Challenges of designing, operating, and managing brine extraction at a carbon dioxide storage site. Int. J. Greenh. Gas Control. 2021, 109, 103354. [Google Scholar] [CrossRef]

- Bathija, A.P.; Sengupta, M.; Eichmann, S.L. Method of evaluating cement-to-formation bond strength with computed tomography image analysis. Lead. Edge 2022, 41, 611–616. [Google Scholar] [CrossRef]

- Santos, L.; Taleghani, A.D. On Quantitative Assessment of Effective Cement Bonding to Guarantee Wellbore Integrity. J. Energy Resour. Technol. 2021, 144, 013001. [Google Scholar] [CrossRef]

- Gholami, R.; Raza, A.; Iglauer, S. Leakage risk assessment of a CO2 storage site: A review. Earth-Sci. Rev. 2021, 223, 103849. [Google Scholar] [CrossRef]

- Iyer, J.; Lackey, G.; Edvardsen, L.; Bean, A.; Carroll, S.A.; Huerta, N.; Smith, M.M.; Torsæter, M.; Dilmore, R.M.; Cerasi, P. A Review of Well Integrity Based on Field Experience at Carbon Utilization and Storage Sites. Int. J. Greenh. Gas Control 2022, 113, 103533. [Google Scholar] [CrossRef]

- Yousuf, N.; Olayiwola, O.; Guo, B.; Liu, N. A comprehensive review on the loss of wellbore integrity due to cement failure and available remedial methods. J. Pet. Sci. Eng. 2021, 207, 109123. [Google Scholar] [CrossRef]

- Anunciação Jaculli, M.; Choueri, N., Jr.; da Mata, C.R.; Aparecida Silva Leite, A.G.; Pelaquim Mendes, J.R.; Colombo, D. Well safety and integrity evaluation of offshore wells: A review of past, present, and future. J. Pet. Sci. Eng. 2022, 212, 110329. [Google Scholar] [CrossRef]

- Chen, B.; Li, Q.; Tan, Y.; Yu, T.; Li, X.; Li, X. Experimental measurements and characterization models of caprock breakthrough pressure for CO2 geological storage. Earth-Sci. Rev. 2024, 252, 104732. [Google Scholar] [CrossRef]

- Mura, M.; Sharma, M.M. Mechanisms of Degradation of Cement in CO2 Injection Wells: Maintaining the Integrity of CO2 Seals. In Proceedings of the SPE International Conference and Exhibition on Formation Damage Control, Lafayette, LA, USA, 21–23 February 2024; p. D011S006R004. [Google Scholar]

- Ceyhan, I.; Pilisi, N.; Suryanarayana, P.V.; Krishnamurthy, R.M. Design of Carbon Capture and Sequestration CCS Wells. In Proceedings of the IADC/SPE International Drilling Conference and Exhibition, Galveston, TX, USA, 8–10 March 2022; p. D021S018R001. [Google Scholar]

- Alberdi-Pagola, P.; Fischer, G. Review of Integrity Loss Detection and Quantification Due to Cracking in Cemented Wells. SPE J. 2023, 28, 965–982. [Google Scholar] [CrossRef]

- Meng, M.; Frash, L.P.; Carey, J.W.; Mehana, M.; Li, W.; Chen, B. Effect of stress-dependent microannulus aperture on well leakage. J. Rock Mech. Geotech. Eng. 2024, 16, 1967–1976. [Google Scholar] [CrossRef]

- Song, X.; Wu, W.; Zhang, H.; He, L.; Dong, D.; Fu, X.; Wang, R. Improving the accuracy of CO2 sequestration monitoring in depleted gas reservoirs using the pulsed neutron-gamma logging technique. Int. J. Greenh. Gas Control 2024, 132, 104080. [Google Scholar] [CrossRef]

- Well Integrity in Drilling and Well Operations; Report Number: NORSOK D-010:2021+AC2; NORSOK/Standards Norway: Lysaker, Norway, 2021.

- ISO 16530-1:2017(E); Petroleum and Natural Gas Industries—Well Integrity—Part 1: Life Cycle Governance. International Organization for Standardization: Geneva, Switzerland, 2017.

- ISO 27914:2017(E); Carbon Dioxide Capture, Transportation and Geological Storage—Geological Storage. International Organization for Standardization: Geneva, Switzerland, 2017.

- Ministerial Council on Mineral and Petroleum Resources. Regulatory Guiding Principles for Carbon Dioxide Capture and Geological Storage; Ministerial Council on Mineral and Petroleum Resources: Canberra, Australia, 2005.

- Offshore Petroleum and Greenhouse Gas Storage Act 2006; Commonwealth of Australia: Canberra, Australia, 2006.

- Li, X.; Zeng, Y.; Muchiri, N.D.; Yan, W.; Feng, Y. The use of distributed acoustic sensing (DAS) in monitoring the integrity of cement-casing system. J. Pet. Sci. Eng. 2022, 208, 109690. [Google Scholar] [CrossRef]

- Paluruan, F.; Azevedo, V. Integrated Wireless Barrier Monitoring Prevents Greenhouse Gas Emission During Extended Well Suspension in Carbon Capture and Storage (CCS) Field. In Proceedings of the ADIPEC, Abu Dhabi, United Arab Emirates, 2–5 October 2023; p. D031S114R005. [Google Scholar]

- Wydiabhakti, T.B.; Hati, S.; Das, B.; Kumar, A.; Thorat, A.; Singh, A.; Sherratt, P.J. A Fit-For-Purpose Workflow for In-Situ Stress Characterization in Carbon Capture and Storage Formations. In Proceedings of the Offshore Technology Conference Brasil, Rio de Janeiro, Brazil, 24–26 October 2023; p. D021S027R006. [Google Scholar]

- Patil, P.A.; Hamimi, A.M.; Abu Bakar, M.A.B.; Das, D.P.; Tiwari, P.K.; Chidambaram, P.; Jalil, M.A. Scrutinizing Wells Integrity for Determining Long-Term Fate of a CO2 Sequestration Project: An Improved and Rigorous Risk Assessment Strategy. In Proceedings of the International Petroleum Technology Conference, Riyadh, Saudi Arabia, 21–23 February 2022; p. D032S163R004. [Google Scholar]

- Zulkipli, S.N.F.; Johare, D.; Dangfa, D.N.; Amin, M.F.M.; Yang, S.; Razak, M.Z.A.; Omar, I.S. Redefining Well Abandonment Strategy: Tipping the Scale Towards Greater Cost and Operational Efficiency Through a Novel Multi-Layer Steel Barriers Cement Bond Logging. In Proceedings of the SPE Asia Pacific Oil & Gas Conference and Exhibition, Adelaide, Australia, 17–19 October 2022; p. D031S015R001. [Google Scholar]

- Zausa, F.; Rossi, N.; Morcella, T.H. Blowout Probability Estimation for CCS New and Converted Wells and Risk Assessment on Well Barriers Integrity. In Proceedings of the SPE Europe Energy Conference and Exhibition, Turin, Italy, 26–28 June 2024; p. D011S004R003. [Google Scholar]

- Laronga, R.; Swager, L.; Bustos, U. Time-Lapse Pulsed-Neutron Logs for Carbon Capture and Sequestration: Practical Learnings and Key Insights. Petrophysics-SPWLA J. Form. Eval. Reserv. Descr. 2023, 64, 680–699. [Google Scholar] [CrossRef]

- Khalifeh, M.; Gardner, D.; Haddad, M.Y. Technology Trends in Cement Job Evaluation Using Logging Tools. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, United Arab Emirates, 13–16 November 2017; p. D041S116R001. [Google Scholar]

- Wilson, A. Technology Trends in Evaluating Cement Jobs Using Logging Tools. J. Pet. Technol. 2018, 70, 74–77. [Google Scholar] [CrossRef]

- Zuo, C.; Qiao, W.; Che, X.; Yang, S. Evaluation of azimuth cement bond quality based on the arcuate phased array acoustic receiver station. J. Pet. Sci. Eng. 2020, 195, 107902. [Google Scholar] [CrossRef]

- Nathan, K.; Kamarudin, M.A.; Devadass, L.; Mohammed, M.J.; Yen, K.K.; Amat, H.; Choon, T.B. Comparison of Cement Evaluation Utilizing Different Logging Tools and Cementing Best Practices: A Case Study in Middle East. In Proceedings of the ADIPEC, Abu Dhabi, United Arab Emirates, 2–5 October 2023; p. D031S086R004. [Google Scholar]

- Albert, L.E.; Standley, T.E.; Tello, L.N.; Alford, G.T. A Comparison of CBL, RBT, and PET Logs in a Test Well With Induced Channels. J. Pet. Technol. 1988, 40, 1211–1216. [Google Scholar] [CrossRef]

- Gai, H.; Lockyear, C.F. Cement Bond Logging—A New Analysis to Improve Reliability. SPE Adv. Technol. Ser. 1994, 2, 34–42. [Google Scholar] [CrossRef]

- Bigelow, E.L.; Domangue, E.J.; Lester, R.A. A New and Innovative Technology for Cement Evaluation. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 23–26 September 1990; p. SPE-20585-MS. [Google Scholar]

- Thomas, S.; Smith, C.H.; Williams, B.W.; Hamilton, L. Ultrasonic-Log Response in Lightweight-Cement Conditions. SPE Drill. Complet. 2015, 30, 326–333. [Google Scholar] [CrossRef]

- Bicalho, L.; Barbosa, A.; Wu, L.; Salazar, J.; Rodrigues, A. LWD Acoustic Application for Cement Bond Evaluation: A Case Study in Brazil. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 4–7 May 2020; p. D031S038R003. [Google Scholar]

- Blyth, M.; Hupp, D.; Whyte, I.; Kinoshita, T. LWD Sonic Cement Logging: Benefits, Applicability, and Novel Uses for Assessing Well Integrity. In Proceedings of the SPE/IADC Drilling Conference, Amsterdam, The Netherlands, 5–7 March 2013; p. SPE-163461-MS. [Google Scholar]

- Anderson, W.L.; Walker, T. Research Predicts Improved Cement Bond Evaluations with Acoustic Logs. J. Pet. Technol. 1961, 13, 1093–1097. [Google Scholar] [CrossRef]

- Bigelow, E.L. A Practical Approach to the Interpretation of Cement Bond Logs. J. Pet. Technol. 1985, 37, 1285–1294. [Google Scholar] [CrossRef]

- Fa, L.; Xie, W.Y.; Tian, Y.; Zhao, M.S.; Ma, L.; Dong, D.Q. Effects of electric-acoustic and acoustic-electric conversions of transducers on acoustic logging signal. Chin. Sci. Bull. 2012, 57, 1246–1260. [Google Scholar] [CrossRef]

- Chaney, P.E.; Zimmerman, C.W.; Anderson, W.L. Some Effects of Frequency Upon the Character of Acoustic Logs. J. Pet. Technol. 1966, 18, 407–411. [Google Scholar] [CrossRef]

- Ridha, S.; Lubis, L.A.; Setiawan, R.A.; bin Mohar, J.M. Investigation on Mixed Oil-Cement for Wellbore Integrity Using Acoustic Velocity. Key Eng. Mater. 2017, 740, 190–194. [Google Scholar] [CrossRef]

- Winn, R.H.; Anderson, T.O.; Carter, L.G. A Preliminary Study of Factors Influencing Cement Bond Logs. J. Pet. Technol. 1962, 14, 369–372. [Google Scholar] [CrossRef]

- Fertl, W.H.; Pilkington, P.E.; Scott, J.B. A Look at Cement Bond Logs. J. Pet. Technol. 1974, 26, 607–617. [Google Scholar] [CrossRef]

- Che, X.-H.; Qiao, W.-X.; Ju, X.-D.; Wang, R.-J. Azimuthal cement evaluation with an acoustic phased-arc array transmitter: Numerical simulations and field tests. Appl. Geophys. 2016, 13, 194–202. [Google Scholar] [CrossRef]

- Zemanek, J.; Caldwell, R.L.; Glenn, E.E.; Holcomb, S.V.; Norton, L.J.; Straus, A.J.D. The Borehole TeleviewerA New Logging Concept for Fracture Location and Other Types of Borehole Inspection. J. Pet. Technol. 1969, 21, 762–774. [Google Scholar] [CrossRef]

- Havira, R.M. Ultrasonic Cement Bond Evaluation. In Proceedings of the SPWLA 23rd Annual Logging Symposium, Corpus Christi, TX, USA, 6–9 July 1982; Volume 1. [Google Scholar]

- Hayman, A.J.; Hutin, R.; Wright, P.V. High-Resolution Cementation and Corrosion Imaging by Ultrasound. In Proceedings of the SPWLA 32nd Annual Logging Symposium, Midland, TX, USA, 16–19 June 1991; p. SPWLA-1991-KK. [Google Scholar]

- Graham, W.L.; Silva, C.I.; Leimkuhler, J.M.; De Kock, A.J. Cement Evaluation and Casing Inspection with Advanced Ultrasonic Scanning Methods. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 5–8 October 1997; p. SPE-38651-MS. [Google Scholar]

- Acosta, J.; Barroso, M.; Mandal, B.; Soares, D.; Milankovic, A.; Lima, L.; Piedade, T. New-Generation, Circumferential Ultrasonic Cement-Evaluation Tool for Thick Casings: Case Study in Ultradeepwater Well. In Proceedings of the OTC Brasil, Rio de Janeiro, Brazil, 24–26 October 2017; pp. 1841–1854. [Google Scholar]

- Patterson, D.; Ingram, S.; Matuszyk, P.J.; Yao, X.; Das, R.; Steinsiek, R. Enhanced Cement Bond Evaluation in Thick Casing Utilizing Guided Acoustic Modes Generated by Electromagnetic Acoustic Transducers. In Proceedings of the OTC Brasil, Rio de Janeiro, Brazil, 24–26 October 2017; pp. 1107–1128. [Google Scholar]

- Thierry, S.; Klieber, C.; Lemarenko, M.; Le Calvez, J.-L.; Brill, T.M.; Barrou, T.; Hayman, A.; Mege, F.; Van Os, R. New-generation ultrasonic measurements for quantitative cement evaluation in heavy muds and thick-wall casings. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dubai, United Arab Emirates, 26–28 September 2016; Volume 2016. [Google Scholar]

- Zhao, G.; Zhang, D.; Lu, Z.; Wang, B. Detection of Defects in Reinforced Concrete Structures Using Ultrasonic Nondestructive Evaluation with Piezoceramic Transducers and the Time Reversal Method. Sensors 2018, 18, 4176. [Google Scholar] [CrossRef]

- Zulkipli, S.; Das, S.; Smith, E. Cement Evaluation in Highly Laminated and Multi-Stacked Sandstone Reservoirs: The World First Novel Approach Using Dual-Physics Cement Bond Assessment. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, United Arab Emirates, 15–18 November 2021; p. D021S046R004. [Google Scholar]

- Udebhulu, O.D.; Aladeitan, Y.; Azevedo, R.C.; De Tomi, G. A review of cement sheath integrity evaluation techniques for carbon dioxide storage. J. Pet. Explor. Prod. Technol. 2024, 14, 1–23. [Google Scholar] [CrossRef]

- Al Menhali, S.J.; Ibeziako, C.; Ramadhan, T.M.; Al Sabi, H.J.; Arbadov, G.; Anwar, M.; Paun, B.; Ziganshin, R.; Al Shamsi, E.; Hamdy, I.; et al. Engineering Innovation of Sustainable Ideation for Supper Corrosive Environment CO2—First Non-Portland Cement for Primary Barrier in Middle East and First Non-Portland Cement Application for CCS Well in World. In Proceedings of the International Petroleum Technology Conference, Dhahran, Saudi Arabia, 12–14 February 2024; p. IPTC-23513-EA. [Google Scholar]

- Freire, A.L.; José, H.J.; Moreira, R.D.F.P.M. Potential applications for geopolymers in carbon capture and storage. Int. J. Greenh. Gas Control 2022, 118, 103687. [Google Scholar] [CrossRef]

- Abid, K.; Gholami, R.; Mutadir, G. A pozzolanic based methodology to reinforce Portland cement used for CO2 storage sites. J. Nat. Gas Sci. Eng. 2020, 73, 103062. [Google Scholar] [CrossRef]

- Kaminskas, R.; Kubiliute, R.; Prialgauskaite, B. Smectite clay waste as an additive for Portland cement. Cem. Concr. Compos. 2020, 113, 103710. [Google Scholar] [CrossRef]

- Tiong, M.; Gholami, R.; Li, Y. A Novel Portland Cement for CO2 Sequestration by Nanoparticles. In Proceedings of the International Petroleum Technology Conference, Riyadh, Saudi Arabia, 21–23 February 2022; p. D032S152R003. [Google Scholar]

- Barría, J.C.; Manzanal, D.; Ghabezloo, S.; Pereira, J.-M. Effect of supercritical carbonation on porous structure and mechanical strength of cementitious materials modified with bacterial nanocellulose. Mater. Struct. 2023, 56, 180. [Google Scholar] [CrossRef]

- Mei, K.; Zhang, L.; Cai, Y.; Xiao, T.; Xue, Q.; Wang, Y.; Sun, Q.; McPherson, B. Investigation of chemical processes in cement exposed to wet ScCO2 and CO2-saturated brine in geological CO2 storage conditions. Int. J. Greenh. Gas Control 2024, 135, 104143. [Google Scholar] [CrossRef]

- Neves, A.V.; Lima, V.N.; Lima, I.N.; Letichevsky, S.; de Avillez, R.R.; de Andrade Silva, F. The influence of H2S and CO2 on the triaxial behavior of class G cement paste under elevated temperature and pressure. Geoenergy Sci. Eng. 2024, 240, 213084. [Google Scholar] [CrossRef]

- Zhang, W.; Liao, W.; Eckert, A.; Ma, H.; Prevallet, A.; Goedde, T.; Wronkiewicz, D.; Meng, M. Wellbore Integrity Evaluation for CO2 Sequestration Wells: An Integrated Experimental, Geochemical, and Numerical Investigation. In Proceedings of the 56th U.S. Rock Mechanics/Geomechanics Symposium, Santa Fe, NM, USA, 26–29 June 2022; p. ARMA-2022-0816. [Google Scholar]

- Gu, T.; Zheng, Y.C.; Zheng, Y.Z.; Xia, H.W.; Cheng, X.W.; Guo, X.Y. Effects of Compressive Stress on Carbonation-Induced Degradation of Oil Well Cement under CO2 Storage Environment. MSF 2020, 993, 1303–1318. [Google Scholar] [CrossRef]

- Gonzalez-Estrella, J.; Ellison, J.; Stormont, J.C.; Shaikh, N.; Peterson, E.J.; Lichtner, P.; Cerrato, J.M. Saline Brine Reaction with Fractured Wellbore Cement and Changes in Hardness and Hydraulic Properties. Environ. Eng. Sci. 2021, 38, 143–153. [Google Scholar] [CrossRef]

- Srivastava, A.; Ahmed, R.; Shah, S. Carbonic Acid Resistance of Hydroxyapatite Based Cement. In Proceedings of the SPE International Conference on Oilfield Chemistry, Galveston, TX, USA, 8–9 April 2019; p. D012S016R002. [Google Scholar]

- Nguyen, V. Well Cement Degradation and Wellbore Integrity in Geological CO2 Storages: A Literature Review. PPEJ 2021, 5, 000269. [Google Scholar] [CrossRef]

- Omosebi, O.A.; Ahmed, R.M.; Shah, S.N. Mechanisms of Cement Degradation in HPHT Carbonic Acid Environment. In Proceedings of the SPE International Conference on Oilfield Chemistry, Montgomery, TX, USA, 3–5 April 2017; p. D021S006R004. [Google Scholar]

- Schütz, M.K.; Baldissera, A.F.; Coteskvisk, P.M.; Vecchia, F.D.; Menezes, S.C.; Miranda, C.R.; Einloft, S. Chemical degradation of reinforced epoxy-cement composites under CO2-rich environments. Polym. Compos. 2018, 39, E2234–E2244. [Google Scholar] [CrossRef]

- Saini, P.; Kumar, H.; Gaur, T. Cement bond evaluation using well logs: A case study in Raniganj Block Durgapur, West Bengal, India. J. Petrol. Explor. Prod. Technol. 2021, 11, 1743–1749. [Google Scholar] [CrossRef]

- Bazaid, A.; Jawed, R.; Kumar, A.; Benslimani, A. Innovative Approach to Enhance Evaluation of Well Integrity in Unconventional Completions With FBE Coating. Petrophys.—SPWLA J. 2025, 66, 594–615. [Google Scholar] [CrossRef]

- Izadi, M.; Chaparian, E.; Trudel, E.; Frigaard, I. Squeeze cementing of micro-annuli: A visco-plastic invasion flow. J. Non-Newton. Fluid Mech. 2023, 319, 105070. [Google Scholar] [CrossRef]

- Yang, H.; Zhou, P.; Xiong, C.; Yu, S.; Li, J. Integrity Evaluation of Cement Ring during Fracturing and Flowback of Horizontal Well in Jimsar Shale Oil. Lithosphere 2021, 2021, 6519109. [Google Scholar] [CrossRef]

- Carpenter, C. Polyaramide Vesicles Prove Effective for Wellbore Integrity and CO2 Sequestration. J. Pet. Technol. 2022, 74, 87–89. [Google Scholar] [CrossRef]

- Orujov, A.; Coddington, K.; Aryana, S.A. A Review of CCUS in the Context of Foams, Regulatory Frameworks and Monitoring. Energies 2023, 16, 3284. [Google Scholar] [CrossRef]

- de Souza, L.P.B.; Ferreira, G.R.B.; Camerini, I.G.; Correia, T.D.M.; Ribeiro, M.G.D.C.; Hidalgo, J.A.S.; de São João, B.L.D.; Llerena, R.W.A.; Kubrusly, A.C.; Ayala, H.V.H.; et al. Machine learning-based cement integrity evaluation with a through-tubing logging experimental setup. Geoenergy Sci. Eng. 2023, 227, 211882. [Google Scholar] [CrossRef]

- Li, X.-R.; Gu, C.-W.; Ding, Z.-C.; Feng, Y.-C. THM coupled analysis of cement sheath integrity considering well loading history. Pet. Sci. 2023, 20, 447–459. [Google Scholar] [CrossRef]

- Zhang, Y.; Xie, J.; Zhao, W.; Dai, J.; Gao, F. Corrosion Characteristics of Polymer-Modified Oil Well Cement-Based Composite Materials in Geological Environment Containing Carbon Dioxide. Polymers 2024, 16, 2187. [Google Scholar] [CrossRef] [PubMed]

- Itikawa, M.A.; Ahón, V.R.R.; Souza, T.A.; Carrasco, A.M.V.; Neto, J.C.Q.; Gomes, J.L.S.; Cavalcante, R.R.H.; Ribeiro, I.B.; Rocha, J.M.S.; Carvalho, C.P.C.; et al. Automatic Cement Evaluation Using Machine Learning. In Proceedings of the Offshore Technology Conference Brasil, Rio de Janeiro, Brazil, 24–26 October 2023; p. D021S020R007. [Google Scholar]

- Kalyanraman, R.S.; Van Kuijk, R.; Hori, H. Making Sense of Why Sometimes Logs Do Not See Cement in the Annulus. In Proceedings of the SPE Western Regional Meeting, Bakersfield, CA, USA, 23–27 April 2017; p. D041S011R001. [Google Scholar]

- Qi, Z.B.; Feng, L.; Xin, Z.; Han, S.Y.; Li, L. A Novel and Efficient Method for Quantitative Cement Logging Using a Logging-While-Drilling Acoustic Tool. In Proceedings of the SPE Kuwait Oil & Gas Show and Conference, Kuwait City, Kuwait, 15–18 October 2017; p. D021S003R003. [Google Scholar]

- Saumya, S.; Singh, J.; Vij, J.; Sarkar, S.; Das, B.; Shedde, P. Evaluating Cement Integrity Through Industry’s First LWD Full Range Quantitative Cement Bond Index: A Game Changer in Deepwater Wells. In Proceedings of the International Petroleum Technology Conference, Beijing, China, 26–28 March 2019; p. D031S064R004. [Google Scholar]

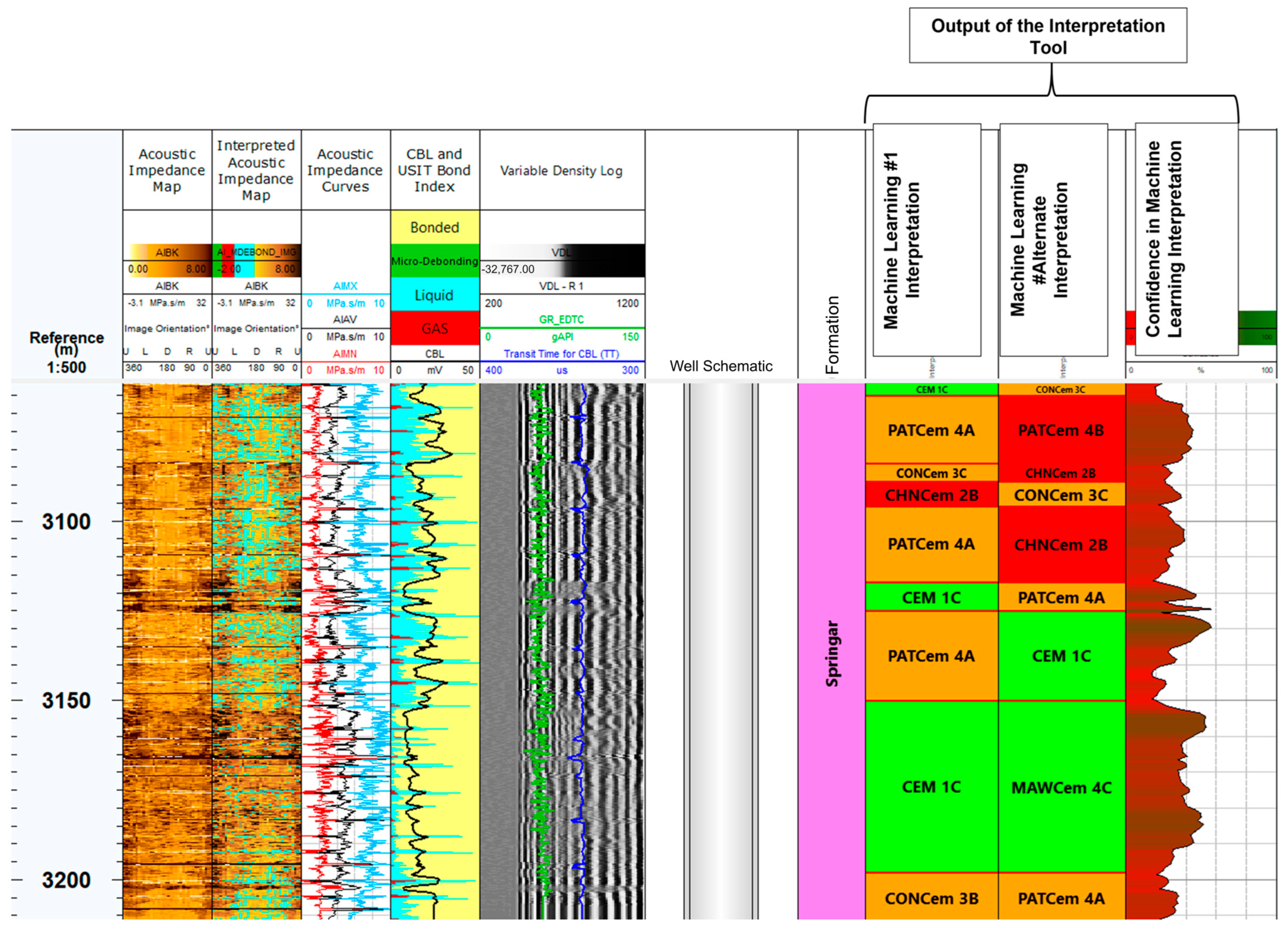

- Viggen, E.M.; Singstad, B.-J.; Time, E.; Mishra, S.; Berg, E. Assisted Cement Log Interpretation Using Machine Learning. SPE Drill. Complet. 2023, 38, 220–234. [Google Scholar] [CrossRef]

- Kalyanraman, R.S.; Chen, X.; Wu, P.-Y.; Constable, K.; Govil, A.; Abubakar, A. Autonomous Interpretation Methods of Ultrasonic Data Through Machine Learning Facilitates Novel and Reliable Casing Annulus Characterization. In Proceedings of the SPE/IADC International Drilling Conference and Exhibition, Virtual, 8–12 March 2021; p. D041S016R001. [Google Scholar]

- Salehabadi, M.; Mohamad Yakup, M.A.; Chung, S.J.; Buang, A.; Jaafar, I.; Thanoon, D.; Patel, C. Machine Learning Cement Quality Risk Assessment. In Proceedings of the Offshore Technology Conference Asia, Kuala Lumpur, Malaysia, 27 February–1 March 2024; p. D021S015R008. [Google Scholar]

| Tool | Key Advantages | Key Disadvantages |

|---|---|---|

| Cement Bond Log (CBL) | Widely used standard sonic log; simple amplitude and travel-time measurements give an intuitive overall bond assessment. | No azimuthal coverage (only provides an average bond measurement), so it can miss narrow channels. Results are sensitive to tool decentralisation and microannulus (small casing-cement gaps), which can lead to misleading poor-bond indications. |

| Segmented Bond Tool (SBT) | Measures bond quality in multiple circumferential sectors (e.g., six 60° segments), enabling detection of non-uniform cement and channels around the casing. Particularly useful in eccentric or irregular wells, since each sector is logged independently to pinpoint localised bonding defects. | Discrete sector coverage means lower spatial resolution than fully azimuthal imaging (defects smaller than a sector can be overlooked). The tool’s design is more complex than a standard CBL, and like other acoustic logs it requires continuous fluid coupling to transmit signals. |

| Azimuthally Acoustic Bond Tool (AABT) | Employs phased-array acoustic transmitters for full 360° coverage, greatly improving azimuthal resolution to locate channels and quantify their orientation/extent. Offers a detailed circumferential bond map, so small channels or partial bond issues can be identified more reliably than with older tools. | Higher complexity and cost—AABT’s advanced phased-array hardware and data processing make it less common and require specialised expertise. As a newer technology, it may rely on proprietary equipment and has limited public field validation data compared to conventional tools. |

| Ultrasonic Imaging Tool (USIT) | High-frequency pulse-echo imaging provides much finer vertical and radial resolution than sonic tools, delivering a detailed 360° map of casing cement coverage. Measures acoustic impedance of the annulus, which allows direct identification of liquid vs. solid behind casing (less dependent on cement properties and more effective at detecting channels or voids). | Requires liquid in the wellbore for acoustic coupling (cannot transmit through gas). Logging is slower with dense data and the equipment is more expensive than a basic CBL, increasing operational cost. Like other acoustic methods, its signals can be distorted by heavy mud or multiple casing strings, complicating interpretation in such conditions. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Allo, P.T.; Rezaee, R.; Clennell, M.B. Overview of Cement Bond Evaluation Methods in Carbon Capture, Utilisation, and Storage (CCUS) Projects—A Review. Eng 2025, 6, 303. https://doi.org/10.3390/eng6110303

Allo PT, Rezaee R, Clennell MB. Overview of Cement Bond Evaluation Methods in Carbon Capture, Utilisation, and Storage (CCUS) Projects—A Review. Eng. 2025; 6(11):303. https://doi.org/10.3390/eng6110303

Chicago/Turabian StyleAllo, Paulus Tangke, Reza Rezaee, and Michael B. Clennell. 2025. "Overview of Cement Bond Evaluation Methods in Carbon Capture, Utilisation, and Storage (CCUS) Projects—A Review" Eng 6, no. 11: 303. https://doi.org/10.3390/eng6110303

APA StyleAllo, P. T., Rezaee, R., & Clennell, M. B. (2025). Overview of Cement Bond Evaluation Methods in Carbon Capture, Utilisation, and Storage (CCUS) Projects—A Review. Eng, 6(11), 303. https://doi.org/10.3390/eng6110303