Optimization of the Borehole Wall Protection Slurry Ratio and Film-Forming Mechanism in Water-Rich Sandy Strata

Abstract

1. Introduction

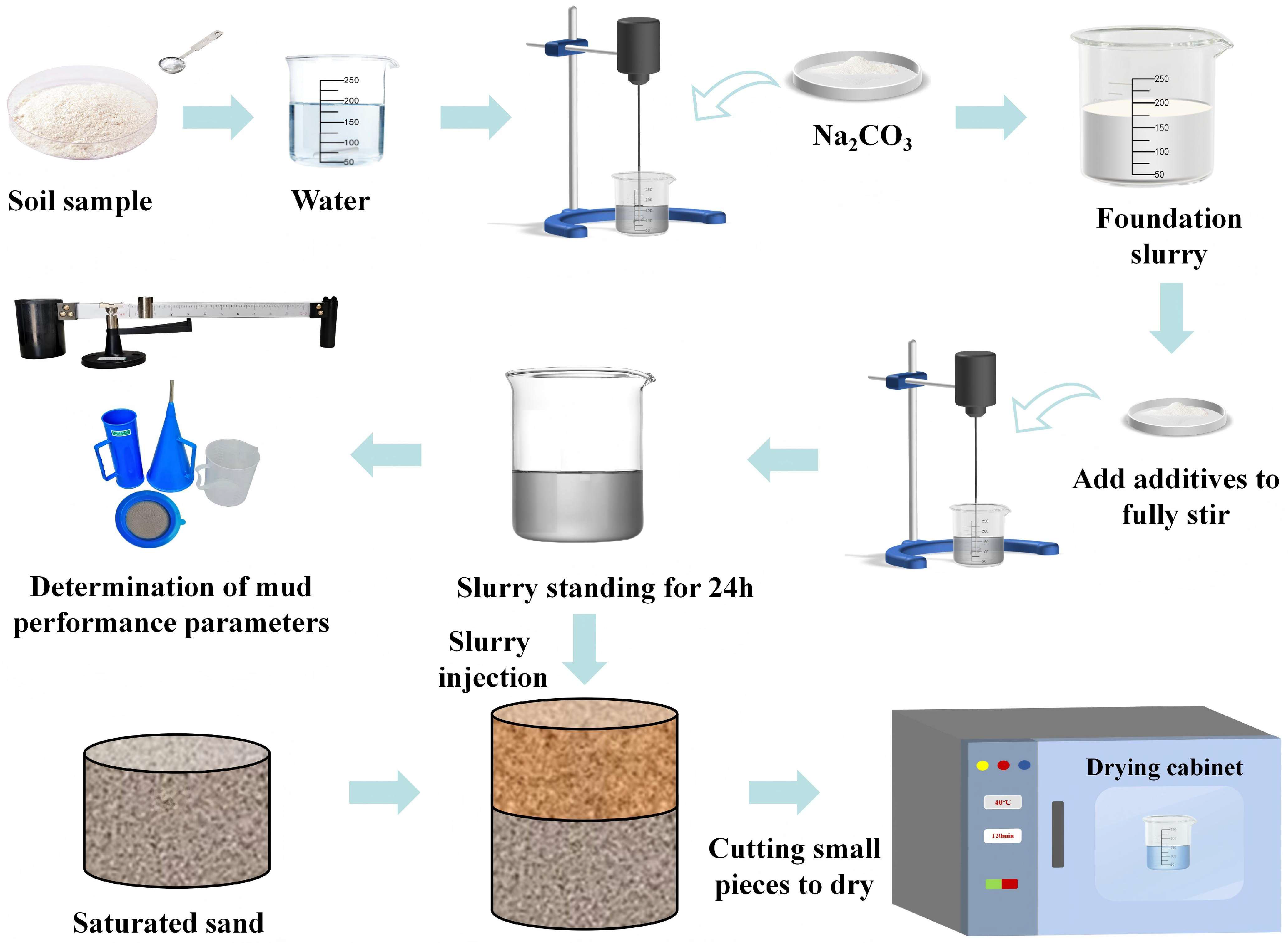

2. Optimization Scheme of the Slurry for Wall Protection of Saturated Sand Layers

2.1. Project Overview and Slurry Performance

2.1.1. Project Overview

2.1.2. Basic Properties of the Slurry

2.2. Performance Index and Influencing Factors of the Wall Protection Slurry

2.2.1. Slurry Performance Index

2.2.2. Influence Factors of the Slurry Performance Index

- (1)

- Bentonite (sodium type): Sourced from Zhejiang Hongyu New Materials Co., Ltd. (Huzhou, China), bentonite serves as the primary solid-phase material in the slurry system. Its high hygroscopicity and adsorption capacity enable it to absorb water and various inorganic substances, forming colloidal particles that seal gaps and fractures to prevent fluid loss. Additionally, bentonite increases slurry density and viscosity, thereby aiding in pore pressure control and borehole wall stabilization. As an economical and environmentally benign material, it offers both technical and operational advantages.

- (2)

- Clay: Collected from the construction site of the Weihe River, the clay particles exhibit adsorption and hydration properties, which enhance the stability of the slurry dispersion system. By adjusting the clay content, varying adsorption and hydration effects can be achieved, thereby producing slurries with distinct properties.

- (3)

- Na2CO3: Certified as food-grade by Binhu, Na2CO3 primarily functions to neutralize organic acids and acidic gases, thereby mitigating slurry corrosion. Additionally, it maintains slurry fluidity and prevents water loss.

- (4)

- CMC: Produced by Chongqing Lihong Fine Chemicals Co., Ltd. (Chongqing, China), this polymeric organic material functions as a viscosifier to mitigate excessive slurry water loss. Additionally, it exhibits colloidal protective properties and serves as an engineering material to prevent slurry contamination.

- (5)

- PAM: Produced by Chongqing Lihong Fine Chemicals Co., Ltd., these water-soluble polymers exhibit dissolution characteristics influenced by molecular weight, ionic type, and particle fineness. Complete dissolution requires prolonged stirring. The aqueous solutions demonstrate high viscosity, with viscosity positively correlated to molecular weight. While stable at room temperature, the polymers undergo thermal degradation at elevated temperatures, resulting in viscosity reduction.

2.3. Optimization Analysis of Slurry Polymer Additives

2.4. Optimization Analysis of Slurry Ratio Parameters

2.4.1. Multiple Regression Model Establishment and Result Analysis

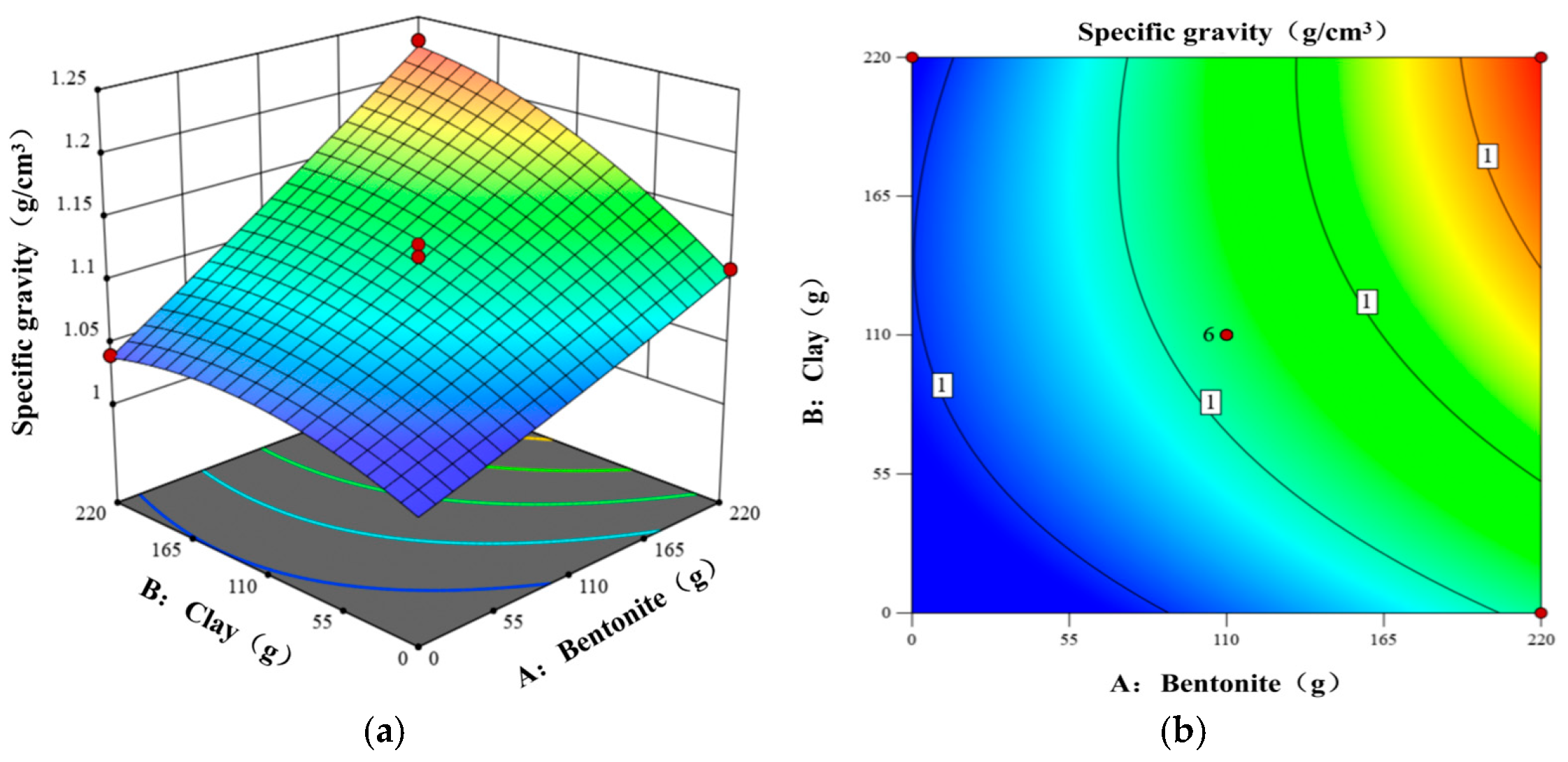

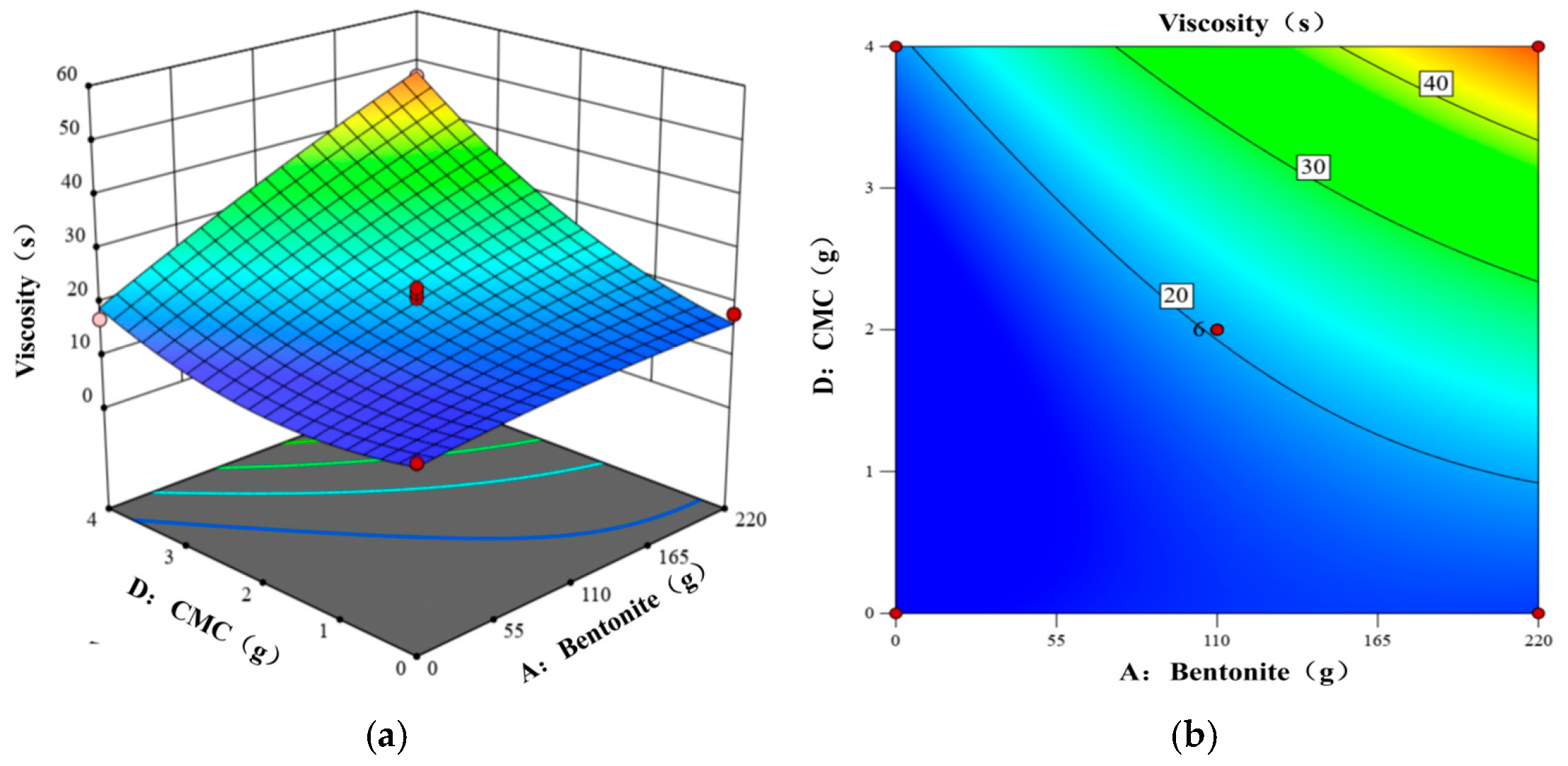

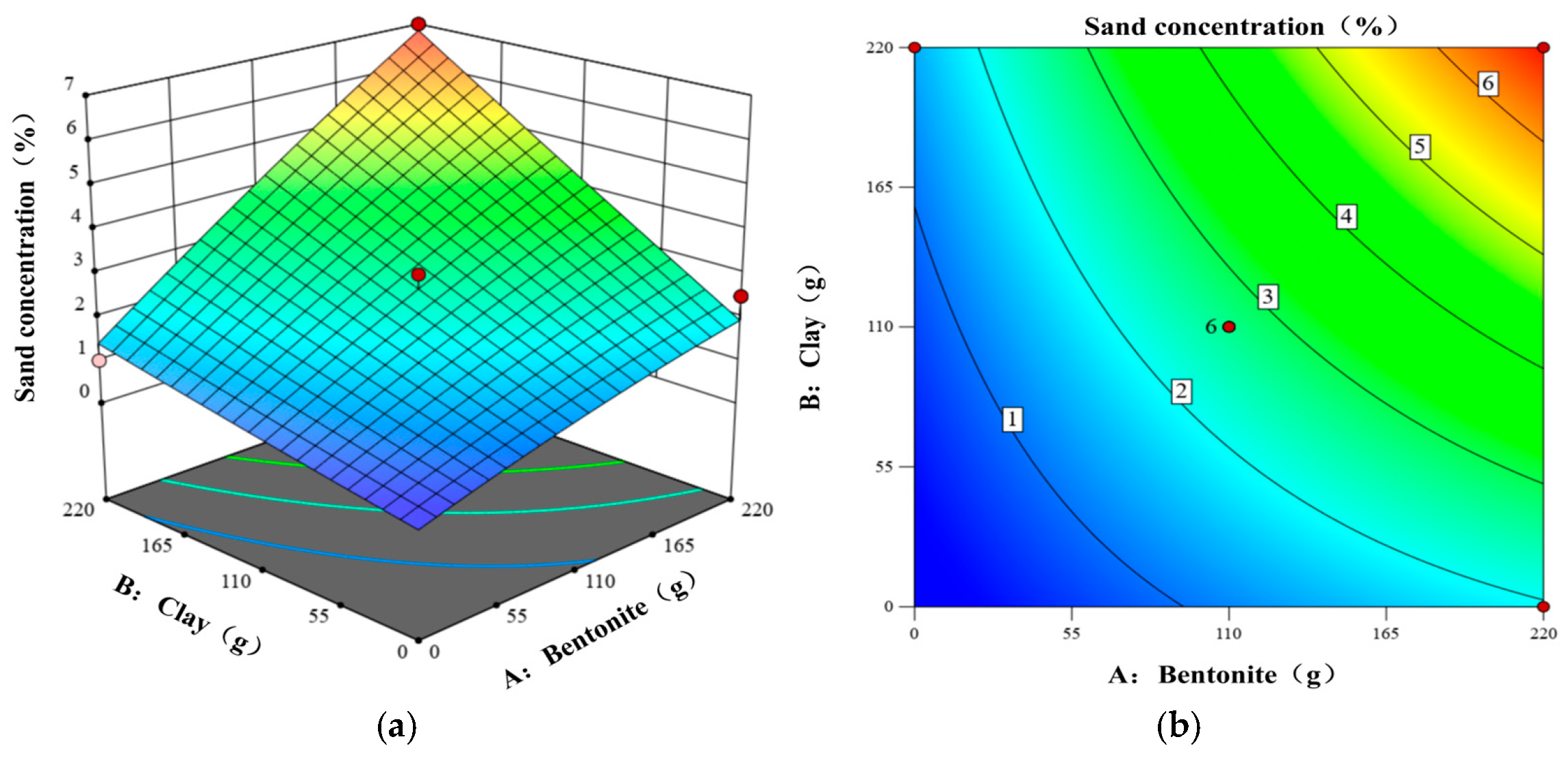

2.4.2. Two-Factor Interaction and Ratio Parameter Optimization

3. Analysis of the Film-Forming Mechanism of the Saturated Sand Slurry

3.1. Test Scheme

3.1.1. Slurry Material and Preparation

3.1.2. Test Method

3.2. Test Result Analysis

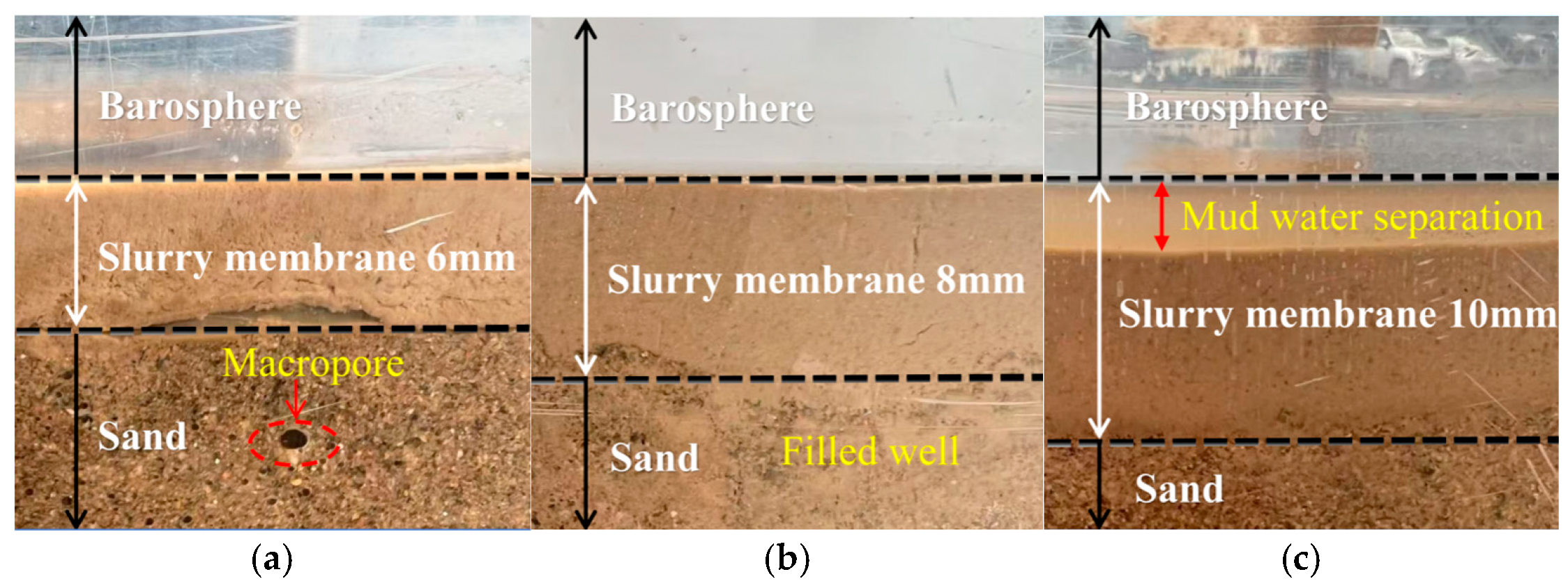

3.2.1. Slurry Film Formation Morphology

3.2.2. Mechanism of Slurry Film Action

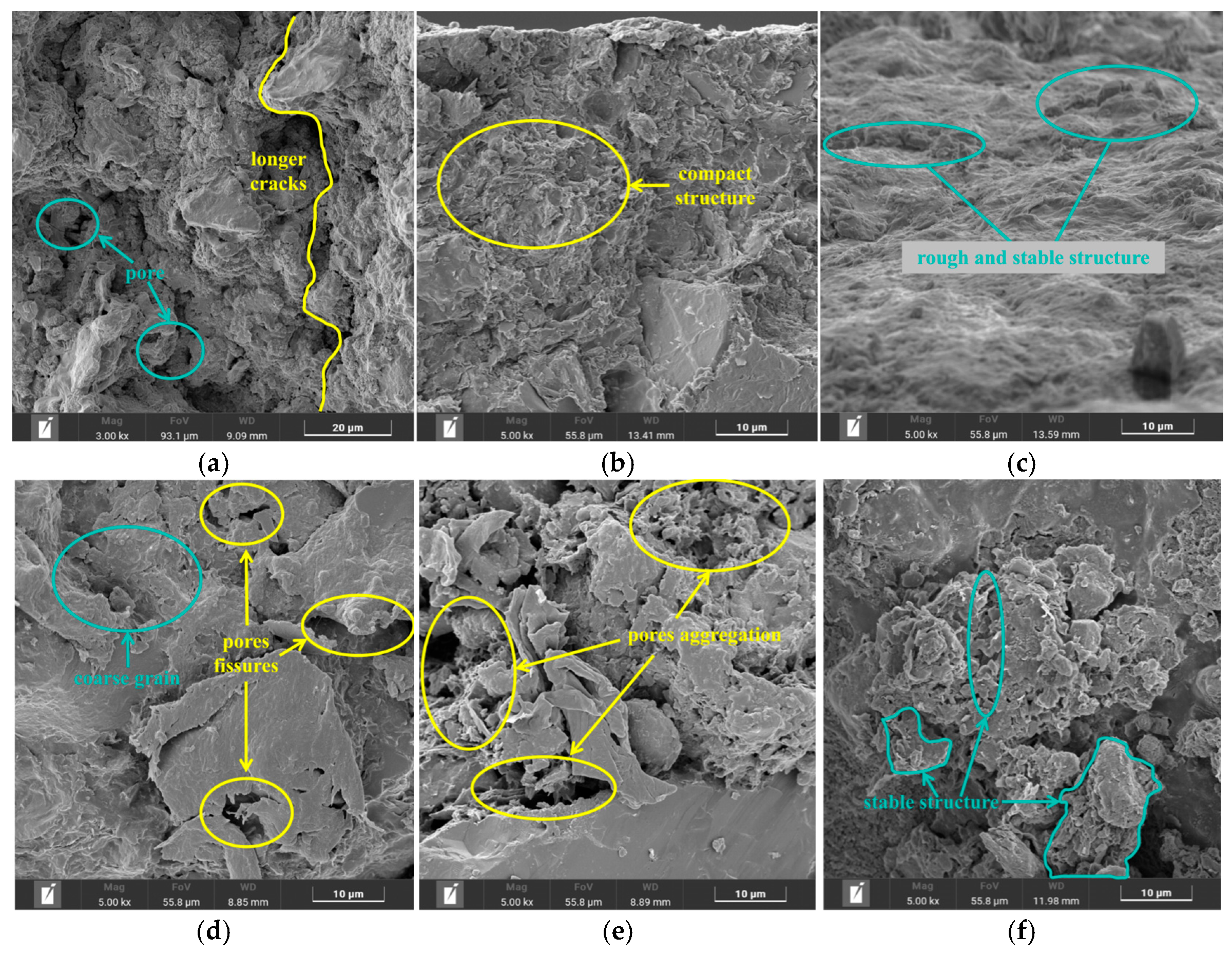

3.2.3. Analysis of the Film Forming Mechanism

4. Discussion

5. Conclusions

- (1)

- Comprehensive testing revealed bentonite and clay as the primary drivers of slurry performance, increasing specific gravity by 15–20% (from 1.14 g/cm3 to 1.20–1.25 g/cm3) and viscosity by 45–100% (from 19 s to 29–49 s) compared to the baseline slurry. Suboptimal ratios (e.g., clay–CMC > 220:1) showed diminished returns, with viscosity plateauing beyond 2 g CMC due to particle agglomeration. The interaction between bentonite and clay particularly enhanced the sand content by 150–200% at optimal ratios, while CMC addition reduced filtration loss by 35–40% and improved film formation time by 25–30%.

- (2)

- The response surface methodology yielded an optimized slurry ratio (water–bentonite–Na2CO3–clay–CMC = 1000:220:32:110:1), demonstrating superior performance characteristics, namely, a viscosity of 29 s (45% improvement), a specific gravity of 1.20 g/cm3, and a sand content of 3%, along with 30% faster film formation and 38 ± 2% reduced filtration loss compared to conventional formulations. In contrast, high-clay formulations (e.g., 220:0, Group e) increased specific gravity but reduced film uniformity, while CMC-deficient groups (e.g., 110:0, Group b) exhibited 20–25% higher filtration loss. Field validation showed that these parameters effectively balanced stability and workability requirements for saturated sand conditions.

- (3)

- The 1: 110 CMC–clay ratio relatively enhanced film density and stability compared to the other tested formulations, as evidenced by SEM morphology and filtration tests. Absolute quantification of mechanical properties requires advanced characterization tools in future work. Microstructural analysis provided mechanistic insights, with SEM revealing that the optimized slurry reduced film porosity by 40–50% and narrowed pore size distribution from 10–50 μm to 5–20 μm. The CMC–clay synergy at a 1:110 ratio decreased surface roughness by 60% and crack density by 70–80% through enhanced particle bridging and pore-filling effects, explaining the improved sealing performance.

- (4)

- Practical implementation demonstrated 25–30% greater borehole stability and a 40% reduction in collapse incidents versus the conventional slurry while achieving 15–20% cost savings through optimized additive usage. Suboptimal mixes (e.g., excessive clay without CMC) required 10–15% more material to achieve comparable stability, negating cost benefits. These results provide both theoretical understanding and practical guidelines for slurry design in challenging hydrogeological conditions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CMC | Sodium Carboxymethyl Cellulose |

| PAM | Polyacrylamide |

| NMR | Nuclear Magnetic Resonance |

| XRD | X-Ray Diffraction |

| SEM | Scanning Electron Microscopy |

References

- Mo, H.; Liao, H.; Guo, X.; Zhou, M. Influence of Construction-Induced Effects and Post-Grouting on the Performance of Mud-Protected Bored Piles: A Numerical Investigation. Buildings 2025, 15, 1457. [Google Scholar] [CrossRef]

- Lei, H.Y.; Shi, F.S.; Liu, X.; Cui, W. Experimental study on properties of vegetable gum-modified mud and filtercake forming in sandy stratum. Chin. J. Geotech. Eng. 2023, 45, 394–401. [Google Scholar]

- Li, Z.C.; Liu, B.W.; Han, D.D.; Xie, Y.C.; Zhao, Y.L. Study on the influence of microcracks of coarse aggregate with specific particle size on crushing strength. Comput. Part. Mech. 2024, 11, 705–719. [Google Scholar] [CrossRef]

- Gupta, S.; Kumar, S. Dynamic behavior of geopolymer stabilized kaolin clay under long-term cyclic loading. Constr. Build. Mater. 2023, 407, 133562. [Google Scholar] [CrossRef]

- Zhou, J.X.; Zha, L.C.; Meng, S.Y.; Zhang, Y. Optimization on overall performance of Modified Ultrafine Cementitious Grout Materials (MUCG) and hydration mechanism analysis. PLoS ONE 2024, 19, e0309312. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.; Song, G.Y.; Liu, Y.; Hu, H.J. Investigation on Modification of Bentonite to Improve Performance for Civil Engineering Mud. Conserv. Util. Miner. Resour. 2023, 43, 96–100, (In Chinese with English abstract). [Google Scholar]

- Ding, W.T.; Guo, W.J.; Cao, K.; Li, Z. Rheological properties and film-forming mechanism of anti-seawater deterioration slurry for slurry shield. Chin. J. Geotech. Eng. 2024, 46, 2484–2491, In Chinese with English abstract. [Google Scholar]

- Ekeinde, E.B.; Okoro, E.E.; Dosunmu, A.; Lyuke, S. Optimizing aqueous drilling mud system viscosity with green additives. J. Pet. Explor. Prod. Technol. 2019, 9, 315–318. [Google Scholar] [CrossRef]

- Gökçe, H.S.; Andiç-Çakır, Ö. Bleeding characteristics of high consistency heavyweight concrete mixtures. Constr. Build. Mater. 2019, 194, 153–160. [Google Scholar] [CrossRef]

- Han, J.; Wang, K. Influence of bleeding on properties and microstructure of fresh and hydrated Portland cement paste. Constr. Build. Mater. 2016, 115, 240–246. [Google Scholar] [CrossRef]

- Lu, Z.; Zhou, W.H.; Yin, Z.Y. Effect of viscosity on slurry infiltration in granular media. Int. J. Geomech. 2022, 22, 04022138. [Google Scholar] [CrossRef]

- Zhao, Q.X.; Xie, L.L.; Cao, P.; Zhang, Z.Y.; Li, K.H.; Lin, H.; Huang, C. A Study on the Borehole Wall Stability Analysis and Slurry Ratio Optimization for Construction of Pile in Complex Marine Strata. Materials 2024, 17, 1984. [Google Scholar] [CrossRef] [PubMed]

- Min, F.; Song, H.; Zhang, N. Experimental study on fluid properties of slurry and its influence on slurry infiltration in sand stratum. Appl. Clay Sci. 2018, 161, 64–69. [Google Scholar] [CrossRef]

- Yuan, H.Z.; Zhang, Z.X.; Huang, X.; Li, Y. Comparing, slurry infiltration characteristics between calcareous and silica sands based on slurry infiltration column tests and CT scanning. Tunn. Undergr. Space Technol. 2024, 152, 105919. [Google Scholar] [CrossRef]

- Lu, Z.; Zhou, W.H.; Yin, Z.Y.; Yang, J. Numerical modeling of viscous slurry infiltration in sand. Comput. Geotech. 2022, 146, 104745. [Google Scholar] [CrossRef]

- Kai, C.; Zhang, F.; Cheng, C.; Chen, Q. Design Synthesis and Performance of Anti-Collapse Drilling Polymer Mud with Higher Stability. Pigm. Resin. Technol. 2021, 51, 101–109. [Google Scholar] [CrossRef]

- Rita, N.; Khalid, I.; Ridho, E.M. Drilling mud per-formances consist of CMC made by carton waste and Na2CO3 for reducing lost circulation. Mater. Today Proc. 2021, 39, 1099–1102. [Google Scholar] [CrossRef]

- Liu, D.S.; Liu, X.R.; Lin, C.Q.; Xiong, F.; Han, Y.F.; Meng, Q.J.; Zhong, Z.L.; Chen, Q.; Weng, C.X. Experimental study and engineering application of slurry permeability mechanism of slurry shield in circular-gravel stratum. Arab. J. Geosci. 2020, 13, 1000. [Google Scholar] [CrossRef]

- Edalatfar, M.; Yazdani, F.; Salehi, M.B. Synthesis and identification of ZnTiO3 nanoparticles as a rheology modifier additive in water-based drilling mud. J. Pet. Sci. Eng. 2021, 201, 108415. [Google Scholar] [CrossRef]

- Yang, Y.L.; Du, Y.J.; Reddy, K.R.; Fan, R.D. Phosphateamended sand/Ca-bentonite mixtures as slurry trench wall backfills: Assessment of workability, compressibility and hydraulic conductivity. Appl. Clay Sci. 2017, 142, 120–127. [Google Scholar] [CrossRef]

- Al-Hameedi, A.T.T.; Alkinani, H.H.; Alkhamis, M.M.; Dunn-Norman, S. Utilizing a new eco-friendly drilling mud additive generated from wastes to minimize the use of the conventional chemical additives. J. Pet. Explor. Prod. Technol. 2020, 10, 3467–3481. [Google Scholar] [CrossRef]

- Bagum, M.; Ahammad, J.M.; Husain, T.; Husain, M.E. An experimental study to develop an environmental friendly mud additive of drilling fluid using Aloe Vera. J. Pet. Sci. Eng. 2022, 211, 110135. [Google Scholar] [CrossRef]

- AlAwad, M.N.J.; Fattah, K.A. Characterization of Oil Well Cement–Formation Sheath Bond Strength. Eng 2025, 6, 117. [Google Scholar] [CrossRef]

- Nashed, S.; Moghanloo, R. Replacing Gauges with Algorithms: Predicting Bottomhole Pressure in Hydraulic Fracturing Using Advanced Machine Learning. Eng 2025, 6, 73. [Google Scholar] [CrossRef]

- Chen, X.; Wang, C.W.; Xue, Y.C.; Chen, Z.H.; Jin, J.Z.; Wang, R.H. A novel thermo-thickening viscosity modifying admixture to improve settlement stability of cement slurry under high temperatures. Constr. Build. Mater. 2021, 295, 123606. [Google Scholar] [CrossRef]

- Qin, S.; Zhou, W.H.; Xu, T. Effects of seawater on the infiltration behavior of bentonite slurry into sand. Constr. Build. Mater. 2023, 371, 130759. [Google Scholar] [CrossRef]

- Gao, Q.; Hu, Q.; Zhang, J.; Ren, Z.; Liu, C.; Liu, J.; Wang, S.; Cheng, G.; Zhang, R.; Ren, C. Experimental study on wall-protecting mud modification of super-long bored pile in the alluvial plain region of the Yellow River. Constr. Build. Mater. 2023, 368, 130395. [Google Scholar] [CrossRef]

- DZ/T 0155-95; Construction Specifications for Drilled Cast-in-Place Piles. Ministry of Geology and Mineral Resources of China: Beijing, China, 1995; In Chinese.

- JGJ/T 225-2010; Technical Specification for Large-Diameter Belled Cast-in-Place Pile Foudation. Ministry of Housing and Urban-Rural Development of China: Beijing, China, 2010; In Chinese.

- T/CECS 592-2019; Technical Standard for Construction of Bored Pile. China Association for Engineering Construction Standardization: Beijing, China, 2019; In Chinese.

- Wang, H. Study on Preparation and Permeability Performance of Slurry for Bored Piles in Calcareous Cemented Strata; Shenyang University of Technology: Shenyang, China, 2021. [Google Scholar]

- API RP 13B-1; Recommended Practice for Field Testing Water-Based Drilling Fluids. American Petroleum Institute: Washington, DC, USA, 2019.

- ISO 3071; Textiles—Determination of pH of aqueous extract. International Organization for Standardization: Geneva, Switzerland, 2020.

- Box, G.E.P.; Behnken, D.W. Some new three level designs for the study of quantitative variables. Technometrics 1960, 2, 455–475. [Google Scholar] [CrossRef]

- Angela, D.; Daniel, V.; Danel, D. Design and Analysis of Experiments; Springer: New York, NY, USA, 1999. [Google Scholar]

- Alyamac, K.E.; Ghafari, E.; Ince, R. Development of eco-efficient self-compacting concrete with waste marble powder using the response surface method. J. Clean. Prod. 2017, 144, 192–202. [Google Scholar] [CrossRef]

- Zhou, Y.S.; Xie, L.; Kong, D.W.; Peng, D.D.; Zheng, T. Research on optimizing performance of desulfurization-gypsum-based composite cementitious materials based on response surface method. Constr. Build. Mater. 2022, 341, 127874. [Google Scholar] [CrossRef]

- ASTM D6910/D6910M; Standard Test Method for Marsh Funnel Viscosity of Clay Construction Slurries. ASTM International: West Conshohocken, PA, USA, 2023.

- Ye, W.T.; Wang, J.Y.; Fu, L.L.; Zhou, S.H.; Ning, J.W. Laboratory test and characteristic of filter film formation of slurry shield in medium-coarse sand stratum in Fuzhou. Chin. J. Rock Mech. Eng. 2018, 37, 1260–1269, (In Chinese with English abstract). [Google Scholar]

| Specific Gravity (g/cm3) | Viscosity (s) | Sand Content (%) | pH |

|---|---|---|---|

| 1.20–1.40 | 20–45 | <4 | 8–12 |

| Number | CMC (g) | PAM (g) | Specific Gravity (g/cm3) | Viscosity (s) |

|---|---|---|---|---|

| 1 | 0 | 0 | 1.14 | 19 |

| 2 | 1 | 1.20 | 25 | |

| 3 | 2 | 1.20 | 29 | |

| 4 | 3 | 1.20 | 44 | |

| 5 | 4 | 1.20 | 49 | |

| 6 | 0 | 1 | 1.20 | 28 |

| 7 | 2 | 1.21 | 44 | |

| 8 | 3 | 1.21 | 76 | |

| 9 | 4 | 1.21 | 113 |

| Serial Number | Factor | Specific Gravity (g/cm3) | Viscosity (s) | Sand Content (%) | pH * | |||

|---|---|---|---|---|---|---|---|---|

| A | B | C | D | |||||

| 1 | 110 | 0 | 32 | 2 | 1.07 | 21 | 1.5 | 12 |

| 2 | 110 | 0 | 16 | 4 | 1.05 | 18 | 1 | 11 |

| 3 | 0 | 110 | 16 | 0 | 1.04 | 14 | 1 | 10 |

| 4 | 220 | 110 | 32 | 2 | 1.20 | 29 | 4 | 12 |

| 5 | 220 | 220 | 16 | 2 | 1.23 | 35 | 7 | 11 |

| 6 | 220 | 110 | 16 | 4 | 1.21 | 47 | 3 | 10 |

| 7 | 0 | 110 | 32 | 2 | 1.05 | 16 | 1 | 12 |

| 8 | 110 | 220 | 16 | 0 | 1.09 | 16 | 5 | 9 |

| 9 | 110 | 110 | 0 | 0 | 1.08 | 19 | 3.5 | 8 |

| 10 | 110 | 220 | 0 | 2 | 1.13 | 27 | 4.5 | 7 |

| 11 | 220 | 0 | 16 | 2 | 1.11 | 24 | 2.5 | 10 |

| 12 | 110 | 110 | 32 | 4 | 1.16 | 51 | 2 | 12 |

| 13 | 0 | 110 | 0 | 2 | 1.05 | 17 | 0.5 | 8 |

| 14 | 110 | 0 | 16 | 0 | 1.05 | 15 | 0.25 | 11 |

| 15 | 220 | 110 | 16 | 0 | 1.14 | 18 | 5 | 10 |

| 16 | 0 | 110 | 16 | 4 | 1.05 | 17 | 0.5 | 10 |

| 17 | 110 | 220 | 32 | 2 | 1.14 | 29 | 4 | 13 |

| 18 | 0 | 220 | 16 | 2 | 1.04 | 17 | 1 | 10 |

| 19 | 110 | 110 | 16 | 2 | 1.11 | 21 | 2.5 | 11 |

| 20 | 110 | 110 | 16 | 2 | 1.12 | 22 | 3 | 10 |

| 21 | 110 | 0 | 0 | 2 | 1.06 | 20 | 1 | 8 |

| 22 | 110 | 110 | 16 | 2 | 1.11 | 19 | 2.5 | 11 |

| 23 | 110 | 110 | 32 | 0 | 1.08 | 19 | 2.5 | 11 |

| 24 | 220 | 110 | 0 | 2 | 1.19 | 28 | 4.5 | 7 |

| 25 | 110 | 110 | 0 | 4 | 1.15 | 38 | 2.5 | 8 |

| 26 | 110 | 110 | 16 | 2 | 1.10 | 17 | 3 | 10 |

| 27 | 110 | 220 | 16 | 4 | 1.15 | 43 | 3.5 | 10 |

| 28 | 110 | 110 | 16 | 2 | 1.13 | 20 | 2.5 | 9 |

| 29 | 110 | 110 | 16 | 2 | 1.12 | 23 | 2.5 | 9 |

| Source | Degree of Freedom | Mean Square | F | p | |||

|---|---|---|---|---|---|---|---|

| Y1 | Y2 | Y1 | Y2 | Y1 | Y2 | ||

| Model | 14 | 0.0057 | 180.13 | 41.99 | 12.89 | * | * |

| A | 1 | 0.0484 | 625.42 | 357.16 | 44.77 | * | * |

| B | 1 | 0.0125 | 283.56 | 92.53 | 20.30 | * | 0.0005 |

| C | 1 | 0.0001 | 21.33 | 0.9835 | 1.53 | 0.3382 | 0.2369 |

| D | 1 | 0.0070 | 1064.08 | 51.7 | 76.17 | * | * |

| AB | 1 | 0.0014 | 0.1266 | 10.4 | 0.0091 | 0.0061 | 0.9255 |

| AC | 1 | 0.0000 | 1 | 0.1844 | 0.0716 | 0.6741 | 0.7929 |

| AD | 1 | 0.0009 | 169 | 6.64 | 12.10 | 0.0220 | 0.0037 |

| BC | 1 | 0.0000 | 0.25 | 0 | 0.0179 | 1 | 0.8955 |

| BD | 1 | 0.0009 | 144 | 6.64 | 10.31 | 0.0220 | 0.0063 |

| CD | 1 | 0.0000 | 42.25 | 0.1844 | 3.02 | 0.6741 | 0.1040 |

| A2 | 1 | 0.0000 | 7.11 | 0.2837 | 0.5091 | 0.6026 | 0.4873 |

| B2 | 1 | 0.0028 | 3.02 | 20.5 | 0.2158 | 0.0005 | 0.6494 |

| C2 | 1 | 0.0003 | 152.8 | 2.32 | 10.94 | 0.1496 | 0.0052 |

| D2 | 1 | 0.0003 | 160.88 | 2.32 | 11.52 | 0.1496 | 0.0044 |

| Lack of fit | 9 | 0.0001 | 19.14 | 1.36 | 4.10 | 0.3841 | 0.0673 |

| Source | Degree of Freedom | Mean Square | F | p | |||

|---|---|---|---|---|---|---|---|

| Y3 | Y4 | Y3 | Y4 | Y3 | Y4 | ||

| Model | 14 | 5.05 | 4.36 | 33.04 | 8.81 | * | 0.0001 |

| A | 1 | 33.38 | 0.1778 | 218.56 | 0.359 | * | 0.5586 |

| B | 1 | 24.22 | 0.9 | 158.57 | 1.82 | * | 0.199 |

| C | 1 | 0.1875 | 56.33 | 1.23 | 113.75 | 0.2865 | * |

| D | 1 | 1.88 | 0.3333 | 12.31 | 0.6731 | 0.0035 | 0.4257 |

| AB | 1 | 2 | 1.06 | 13.07 | 2.13 | 0.0028 | 0.1663 |

| AC | 1 | 0.25 | 0.25 | 1.64 | 0.5048 | 0.2216 | 0.4891 |

| AD | 1 | 0.5625 | 0 | 3.68 | 0 | 0.0756 | 1 |

| BC | 1 | 0.25 | 1 | 1.64 | 2.02 | 0.2216 | 0.1772 |

| BD | 1 | 1.27 | 0.25 | 8.29 | 0.5048 | 0.0121 | 0.4891 |

| CD | 1 | 0.0625 | 0.25 | 0.4092 | 0.5048 | 0.5327 | 0.4891 |

| A2 | 1 | 0.1027 | 0.1094 | 0.6722 | 0.2209 | 0.4260 | 0.6456 |

| B2 | 1 | 0.0045 | 0.9043 | 0.0296 | 1.83 | 0.8660 | 0.198 |

| C2 | 1 | 0.016 | 0.6685 | 0.1046 | 1.35 | 0.7511 | 0.2647 |

| D2 | 1 | 0.1922 | 0.0296 | 1.26 | 0.0598 | 0.2808 | 0.8103 |

| Lack of fit | 9 | 0.2005 | 0.3259 | 3.01 | 0.4074 | 0.1190 | 0.8856 |

| Group Number * | Clay (g) | CMC (g) | Viscosity (s) | Specific Gravity (g/cm3) |

|---|---|---|---|---|

| a | 0 | 0 | 18 | 1.14 |

| b | 0 | 1 | 22 | 1.14 |

| c | 110 | 1 | 26 | 1.20 |

| d | 110 | 2 | 29 | 1.20 |

| e | 220 | 1 | 30 | 1.25 |

| f | 220 | 2 | 36 | 1.25 |

| Specific Gravity (g/cm3) | Film Formation Time (min) | Final Filtration Loss (mL) | Average Filtration Rate * (mL/min) | Slurry Film Thickness (mm) |

|---|---|---|---|---|

| 1.14 | 1.33 | 526 | 6.6 | 6 |

| 1.20 | 1.00 | 456 | 5.7 | 8 |

| 1.25 | 1.67 | 904 | 7.5 | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Li, M.; Qiu, P.; Tang, L.; Liu, Z.; Zhang, F. Optimization of the Borehole Wall Protection Slurry Ratio and Film-Forming Mechanism in Water-Rich Sandy Strata. Eng 2025, 6, 251. https://doi.org/10.3390/eng6100251

Liu X, Li M, Qiu P, Tang L, Liu Z, Zhang F. Optimization of the Borehole Wall Protection Slurry Ratio and Film-Forming Mechanism in Water-Rich Sandy Strata. Eng. 2025; 6(10):251. https://doi.org/10.3390/eng6100251

Chicago/Turabian StyleLiu, Xiaodong, Meng Li, Peiyue Qiu, Liyun Tang, Zhenghong Liu, and Fusheng Zhang. 2025. "Optimization of the Borehole Wall Protection Slurry Ratio and Film-Forming Mechanism in Water-Rich Sandy Strata" Eng 6, no. 10: 251. https://doi.org/10.3390/eng6100251

APA StyleLiu, X., Li, M., Qiu, P., Tang, L., Liu, Z., & Zhang, F. (2025). Optimization of the Borehole Wall Protection Slurry Ratio and Film-Forming Mechanism in Water-Rich Sandy Strata. Eng, 6(10), 251. https://doi.org/10.3390/eng6100251