A New Algorithmic Method for Reverse Osmosis Desalination Analysis: Design Optimization and Parametric Study

Abstract

1. Introduction

2. Research Objectives

- –

- Introduction of an algorithmic flowchart to assist in parameter selection, elaborated upon in Section 3.4.

- –

- Validation of both the technical report and proposed algorithm through an extensive case study employing ROSA software version 6.1.3. This validation fills a significant gap in the literature, as no published article has previously verified this procedure or presented parameter classification in such a simplified manner.

- –

- Conducting a comparative analysis of parameter variations, systematically isolating one parameter at a time while examining the influence of others. This approach sheds light on the intricate relationships between variables in the design process.

3. RO System Design

3.1. Design Background

- Listing up-to-date membrane models.

- Focusing on spiral-wound membranes per market developments.

- Setting a reasonable safety margin under the following considerations:

- –

- The recommended pressure of the pump should be higher than the feed pressure by 10% of the Net Driving Pressure (NDP), taking the entry losses into account.

- –

- A safety margin of about 10% is taken for system design for fouling rate prediction.

- –

- A 10% increase in the number of membrane elements is taken as a contingency procedure.

- –

- The feed pressure should be specified for the assumed flow with 90% of the calculated membrane elements.

- Permeate flow rate at the concentrate end is usually lower than the flow rate of the primary elements. Good design tends to balance the flow rate through the elements in all positions. This can be carried out by the following:

- –

- Boosting the feed pressure.

- –

- –

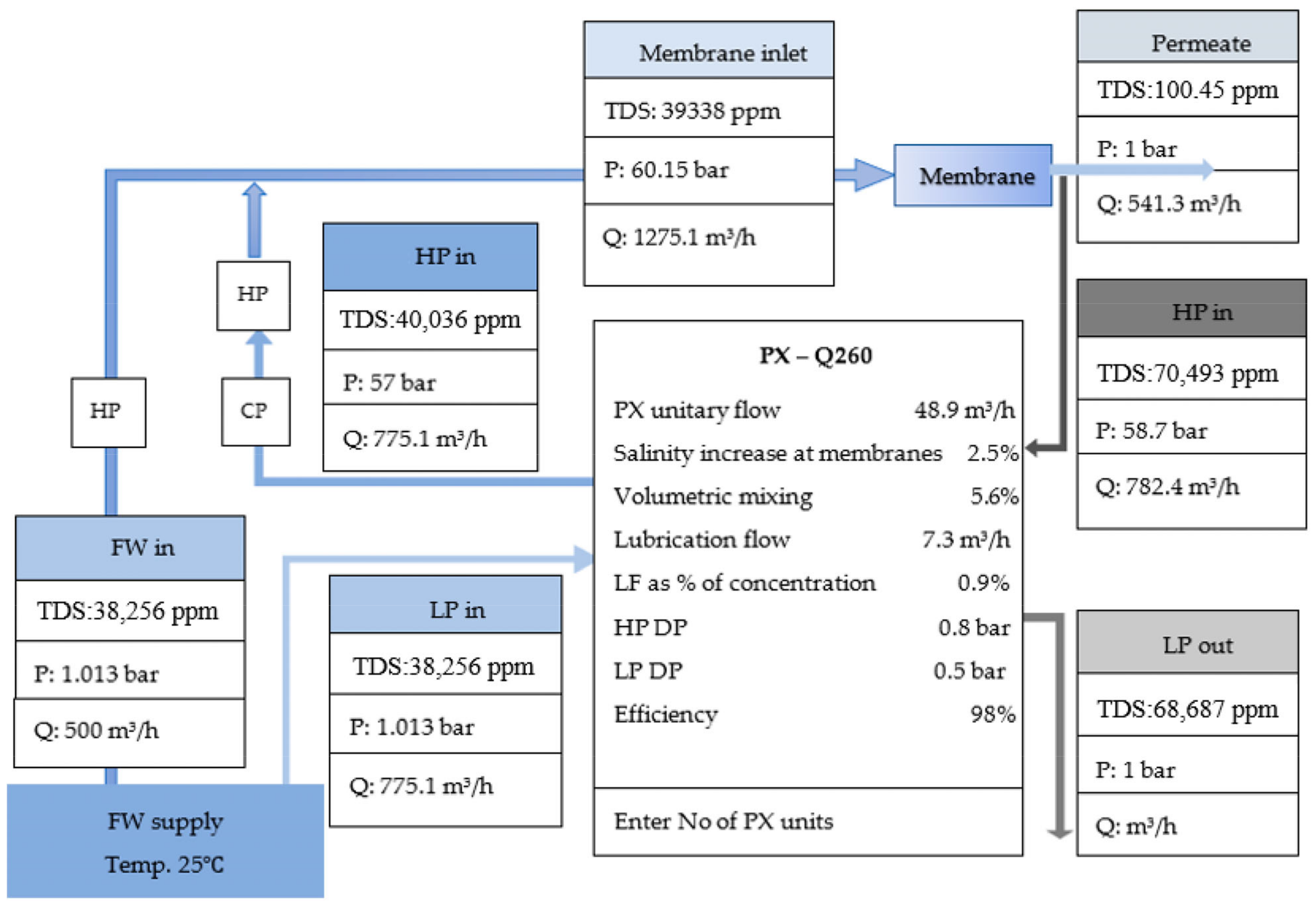

- Using energy recovery devices (ERDs) to recover the lost pressure from the brine. ERDs are used to minimize specific energy consumption (SEC) [25].

- –

- Applying a permeate backpressure only to the first stage of a two-stage system.

3.2. Classification of Design Parameters

- –

- Input parameters: These parameters constitute the design; they are mainly design parameters such as feedwater type, TDS, T, pH, flow factor, and pump efficiency.

- –

- Desired parameters: These are defined according to the user’s interest such as permeate salinity, permeate output flow rate, or feed water pressure. Desired parameters are the first to be defined, and then, the other parameters are obtained.

- –

- Dependent parameters: Parameters that depend on the input and desired parameters such as membrane area and SR that depend on the chosen feed water type, recovery ratio, permeate flux that depends on both water type and membrane, and several elements that depend on the size of the RO plant. Similarly, the pressure vessels and number of stages depend on the number of elements.

- –

- Output parameters: These are the values obtained from the software such as feedwater pressure, permeate salinity, average flux, system recovery, and specific energy.

3.3. Twelve Steps for a Good Design with a Case Study

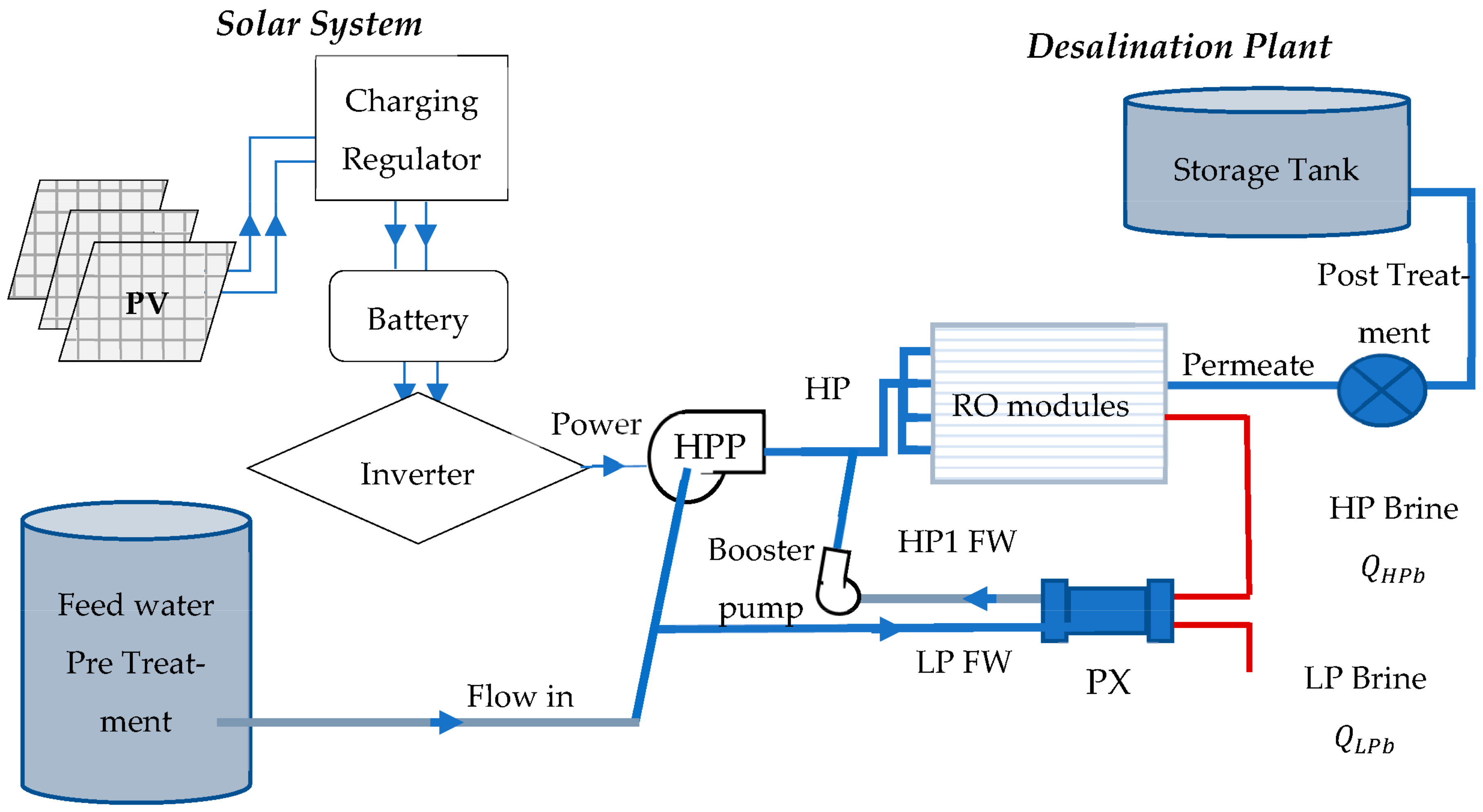

- –

- An electrical source could be a solar PV system, wind, or other sources.

- –

- Seawater pretreatment system.

- –

- RO desalination plant.

- –

- Post-treatment plant, potable water storage, and distribution.

- –

- PX to save energy, which is being taken highly into consideration lately [33].

- (A)

- (B)

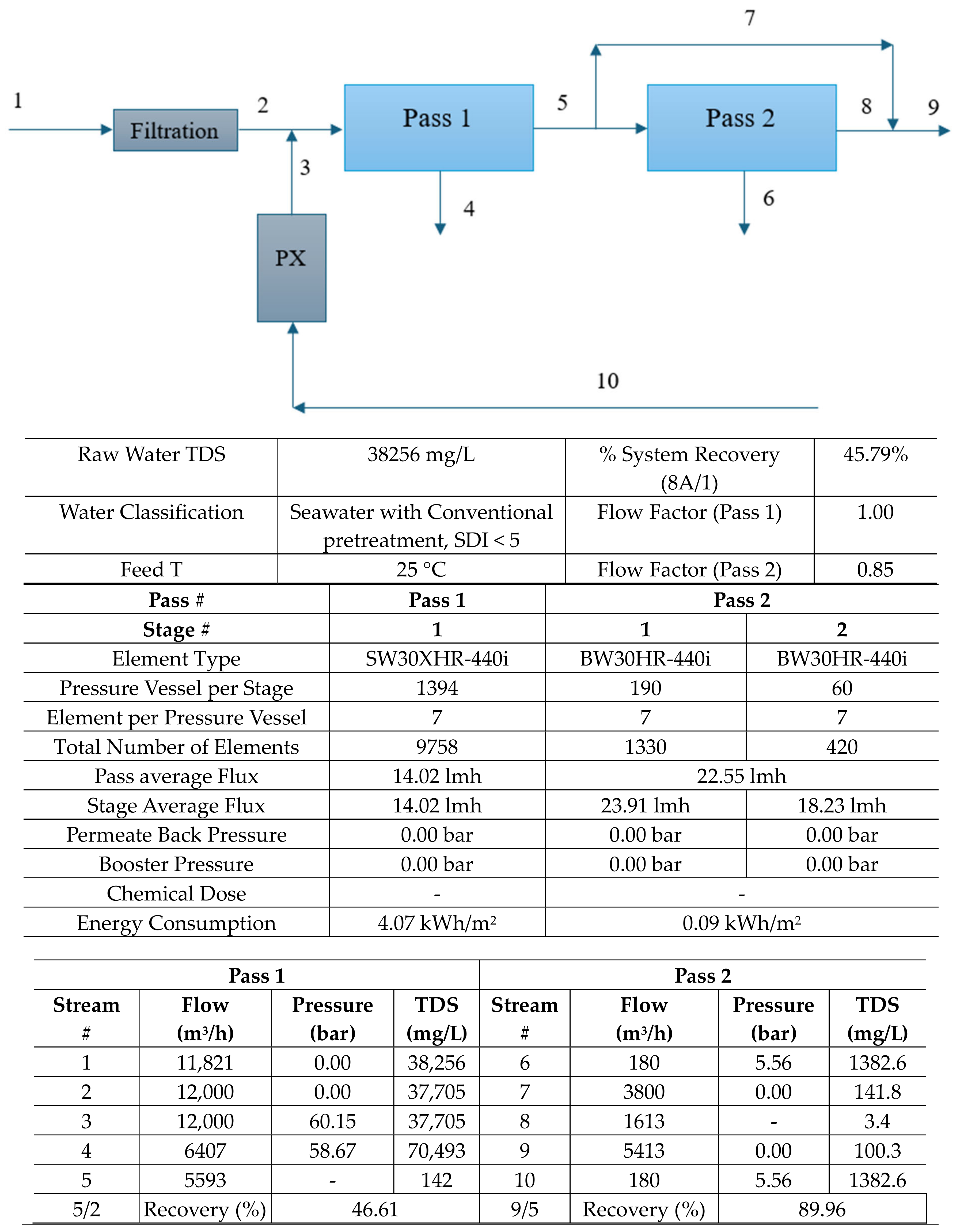

- Specifying overall feed water concentration in TDS (ppm) is shown in Table 3.

- Step 2: Required permeate flow.

- Step 3: Select the configuration flow and number of passes.

- Step 4: Select the membrane.

- System capacity (element diameter, element length)

- Feedwater TDS:

- –

- <1000 mg/L: NF270, NF90, XLE, LE, LP, TW30, BW30

- –

- 1000–10,000 mg/L: BW30

- –

- 10,000–30,000 mg/L: SW30XLE, SW30ULE

- –

- 30,000–50,000 mg/L: SW30HR, SW30XHR, SW30HRLE, SW30XLE

- Feedwater fouling potential (feed spacer thickness, fouling resistance)

- Required product water quality and energy requirements (a salt passage, feed pressure)

- Step 5: Calculate the required units of SWRO.

- Step 6: Select membrane average design flux.

- Step 7: Calculate the number of membrane elements needed.

- Step 8: Calculate the number of pressure vessel arrays needed.

- Step 9: Select the number of stages.

- Step 10: Select the staging ratio.

- Step 11: Balance the permeate flow rate.

- Step 12: Reverse Osmosis System Analysis (ROSA).

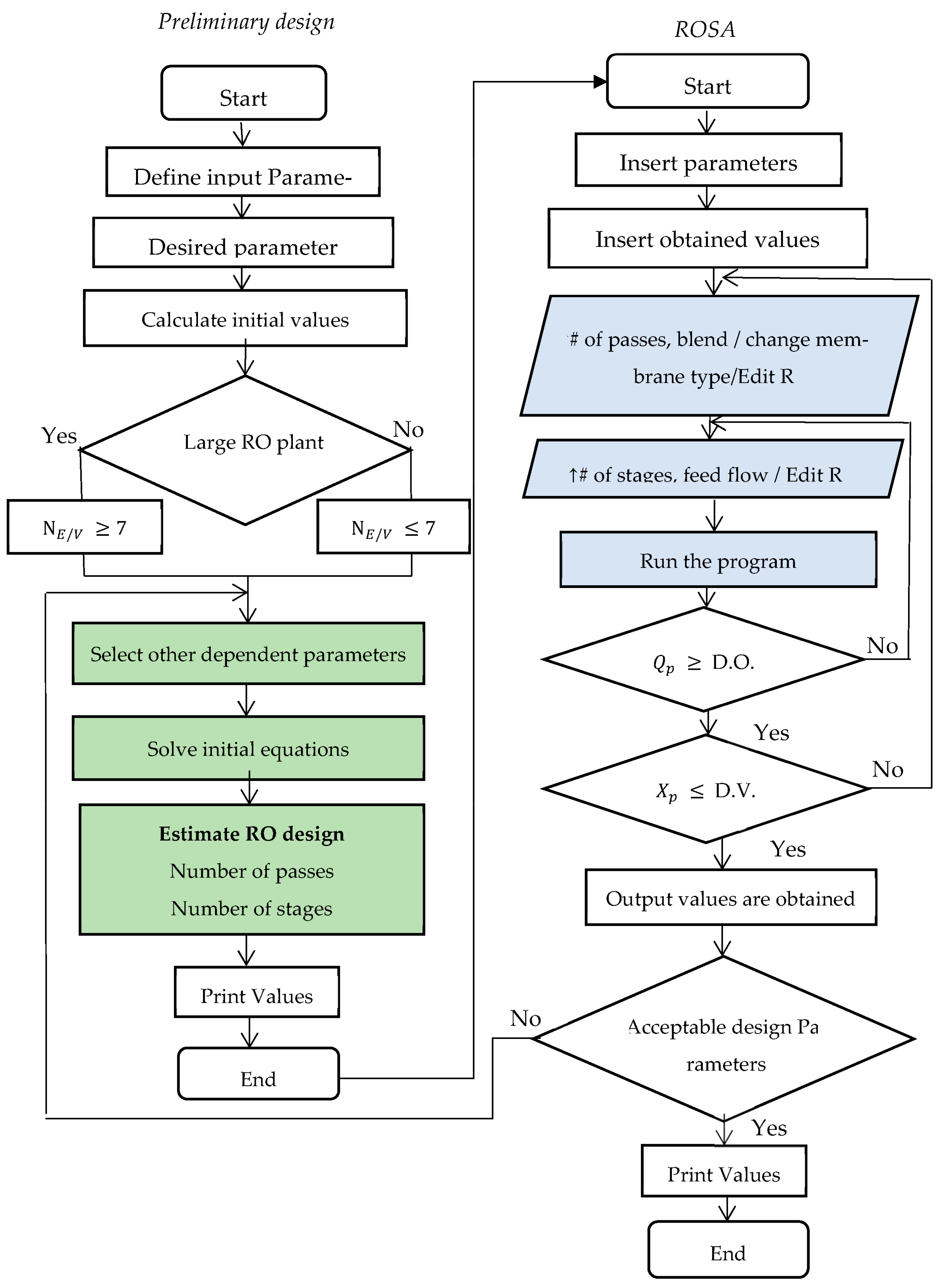

3.4. Flow Chart

- –

- Editing is performed on the dependent parameters so they can be changed within the given range which is indicated in the blue boxes in Figure 3. For example, if the results show high salinity, then membrane type or blending quantity can be changed, and the number of passes or stages within the pass can be increased. If the results show low output, then an increase in feed flow rate, number of stages, or recovery ratio can be made.

- –

- Editing is performed mainly on the design input parameters which are indicated in green boxes in Figure 3. For example, changing the temperature or feed water type membrane area requires recalculations before using the software and determining the dependent parameters.

3.5. Reducing Energy Consumption

4. Results and Discussion

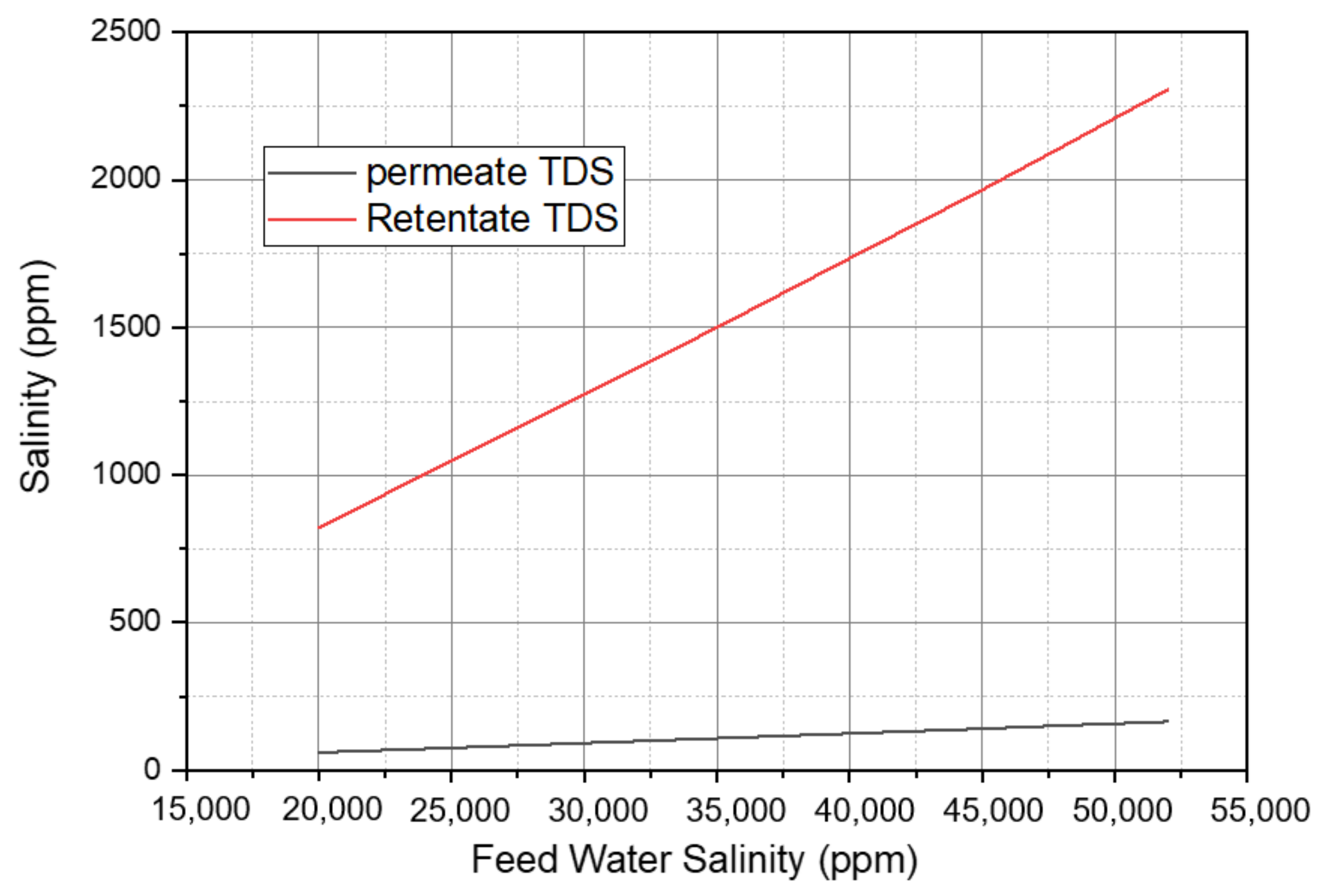

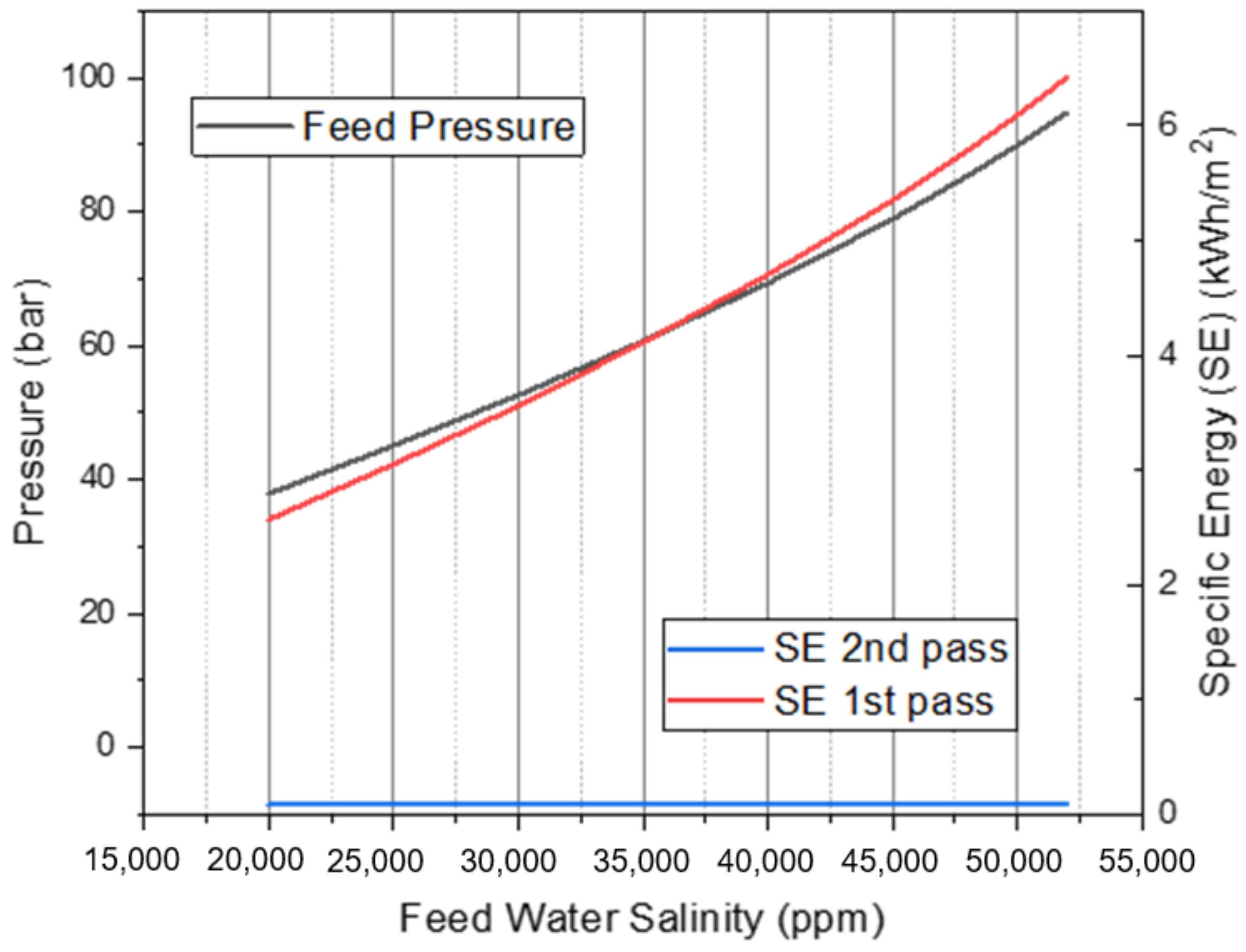

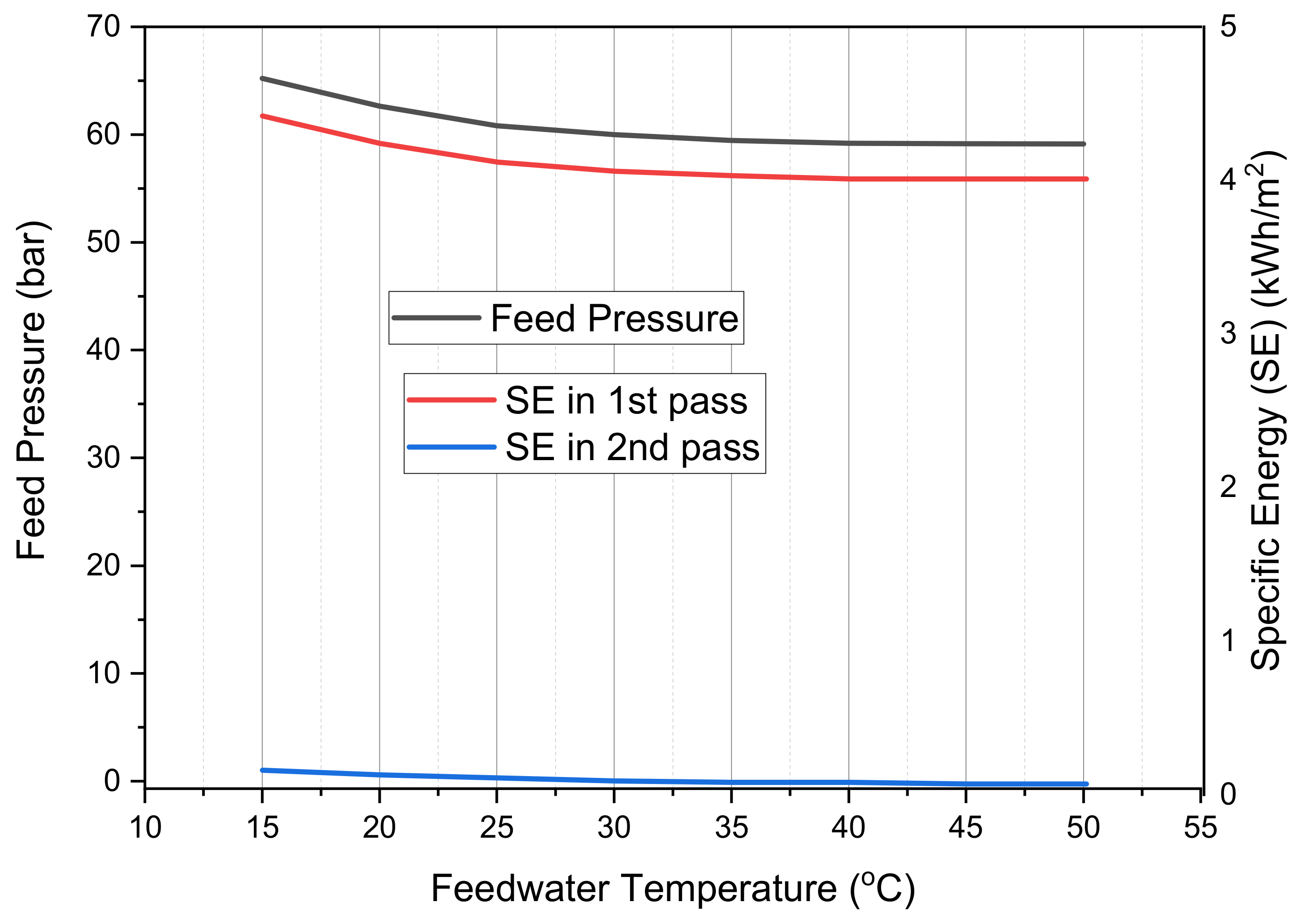

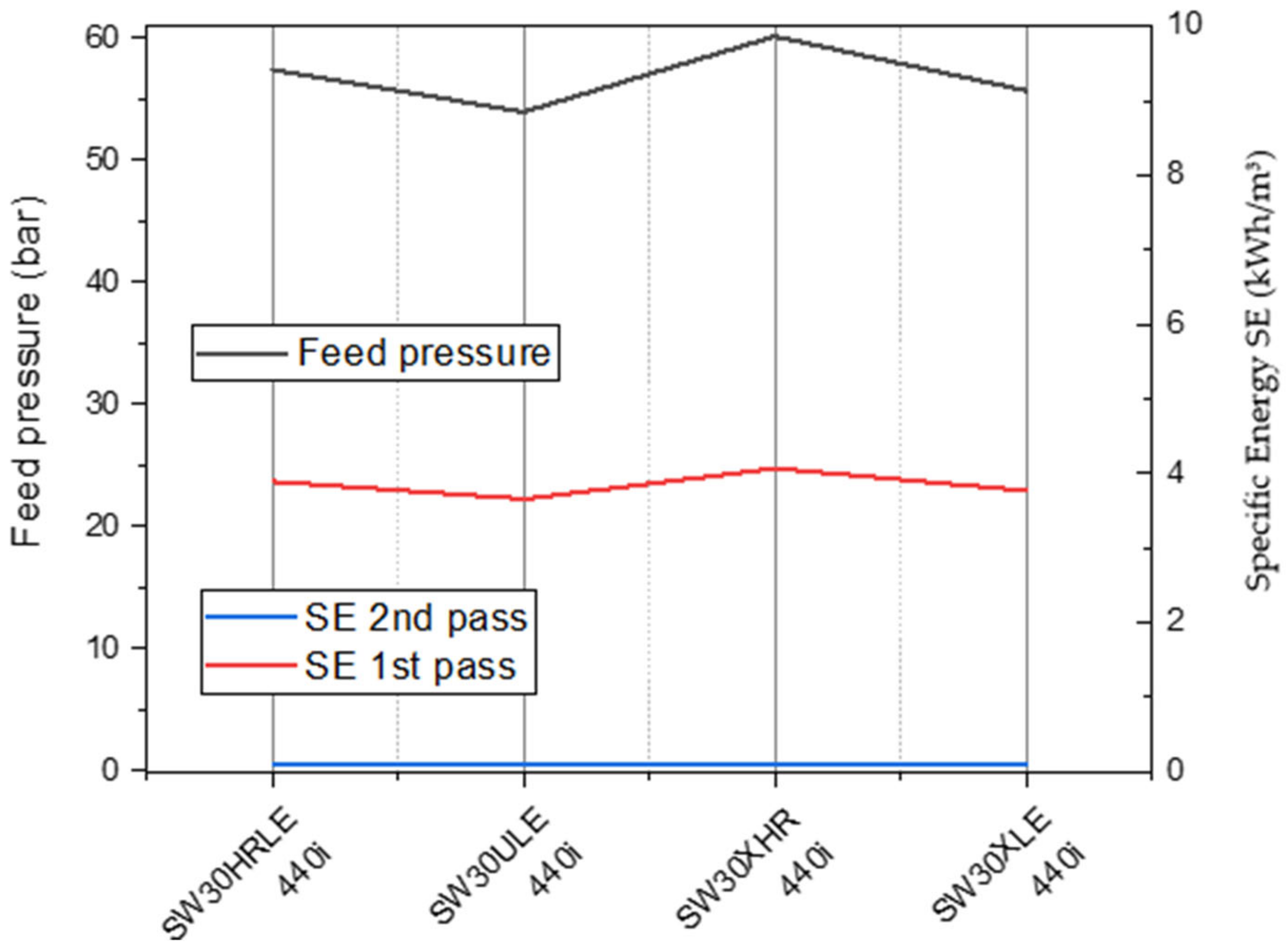

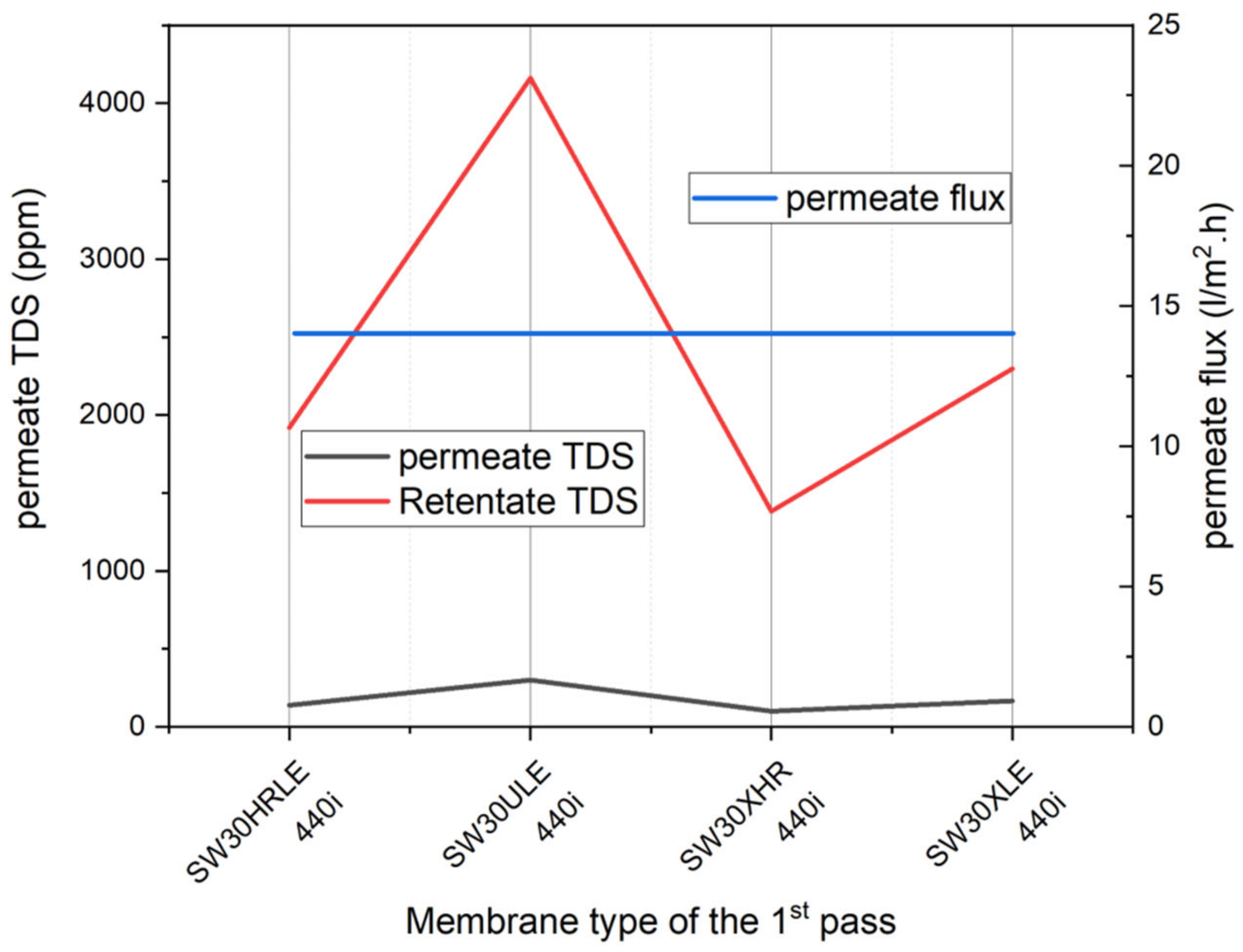

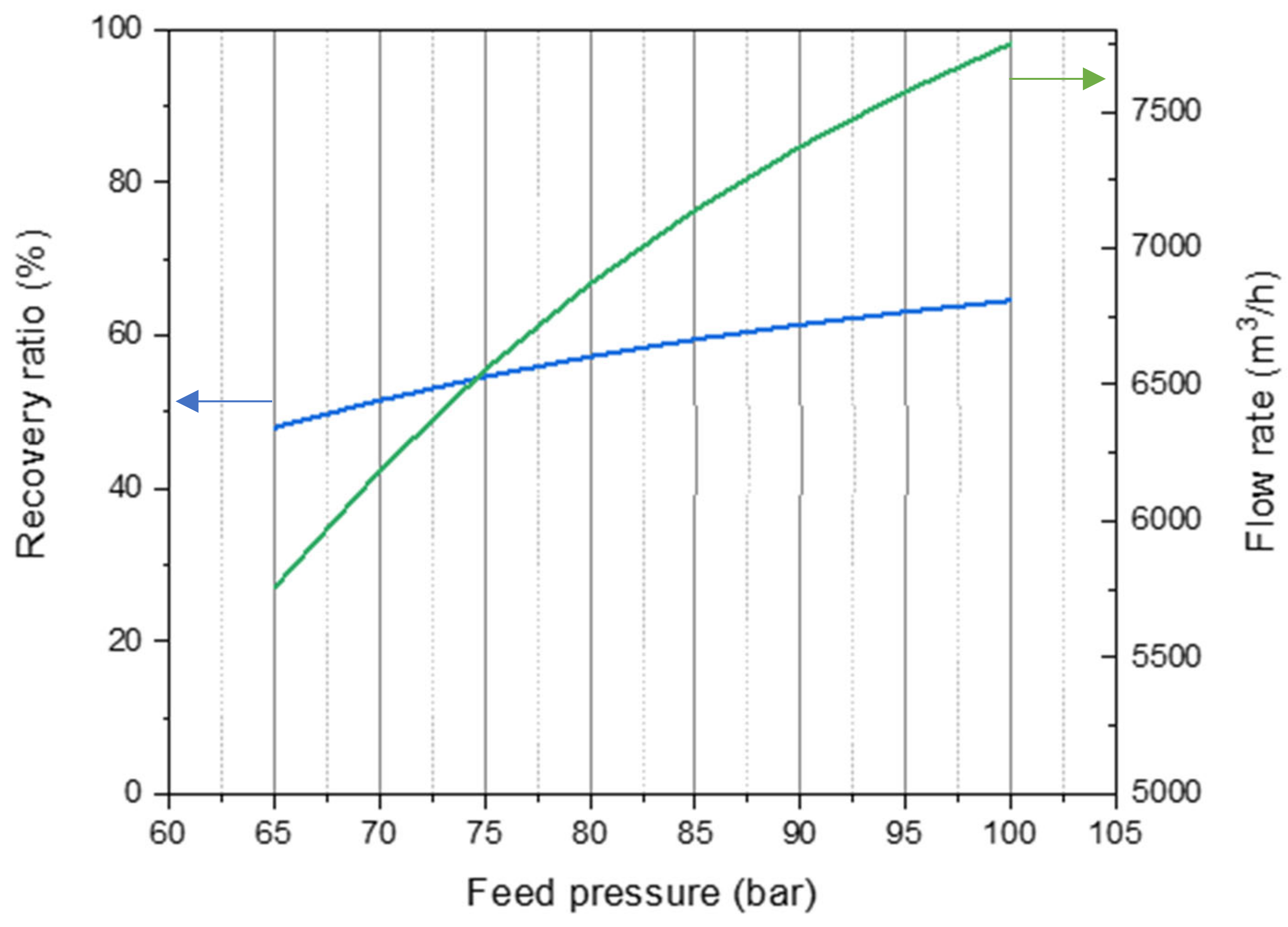

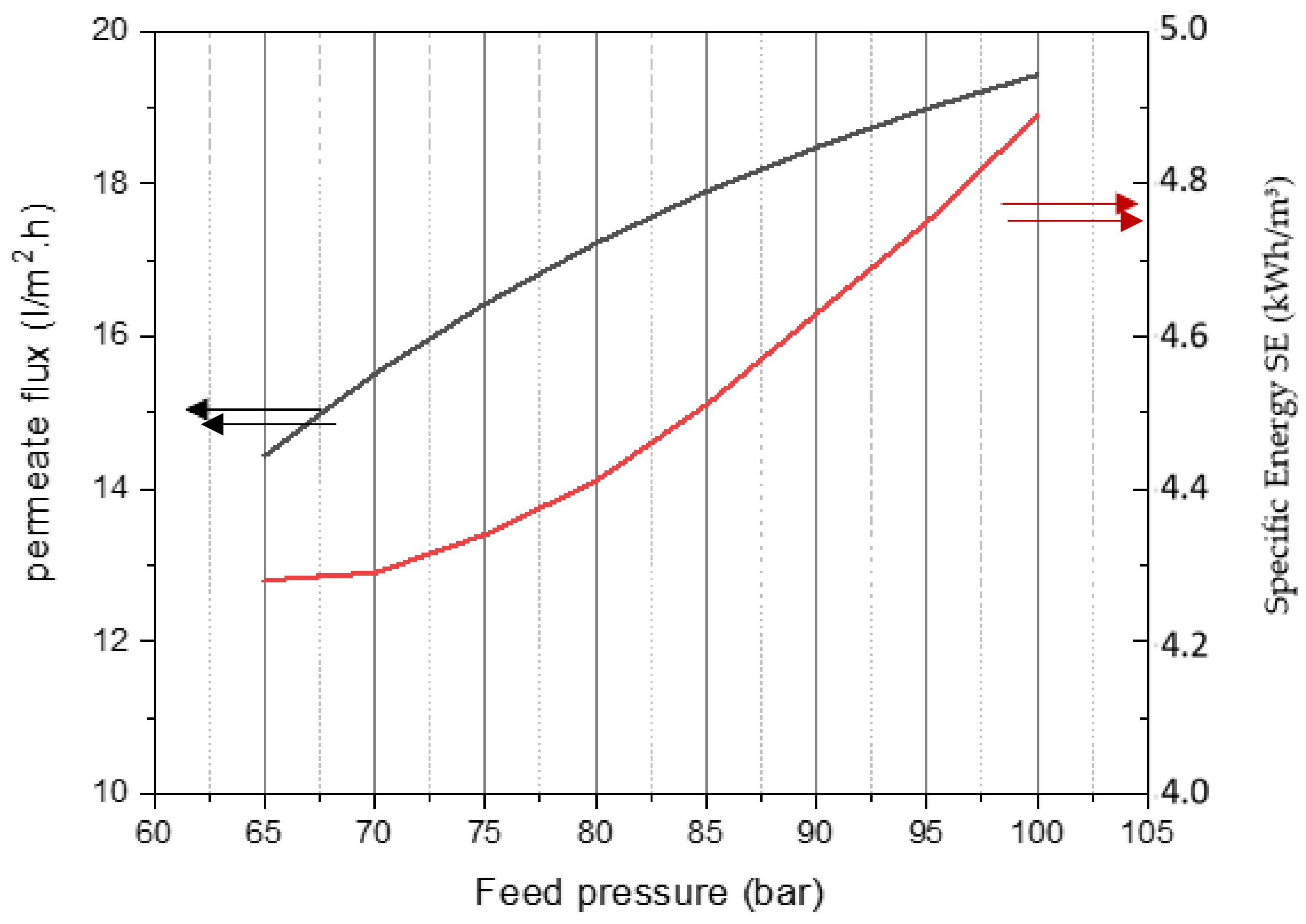

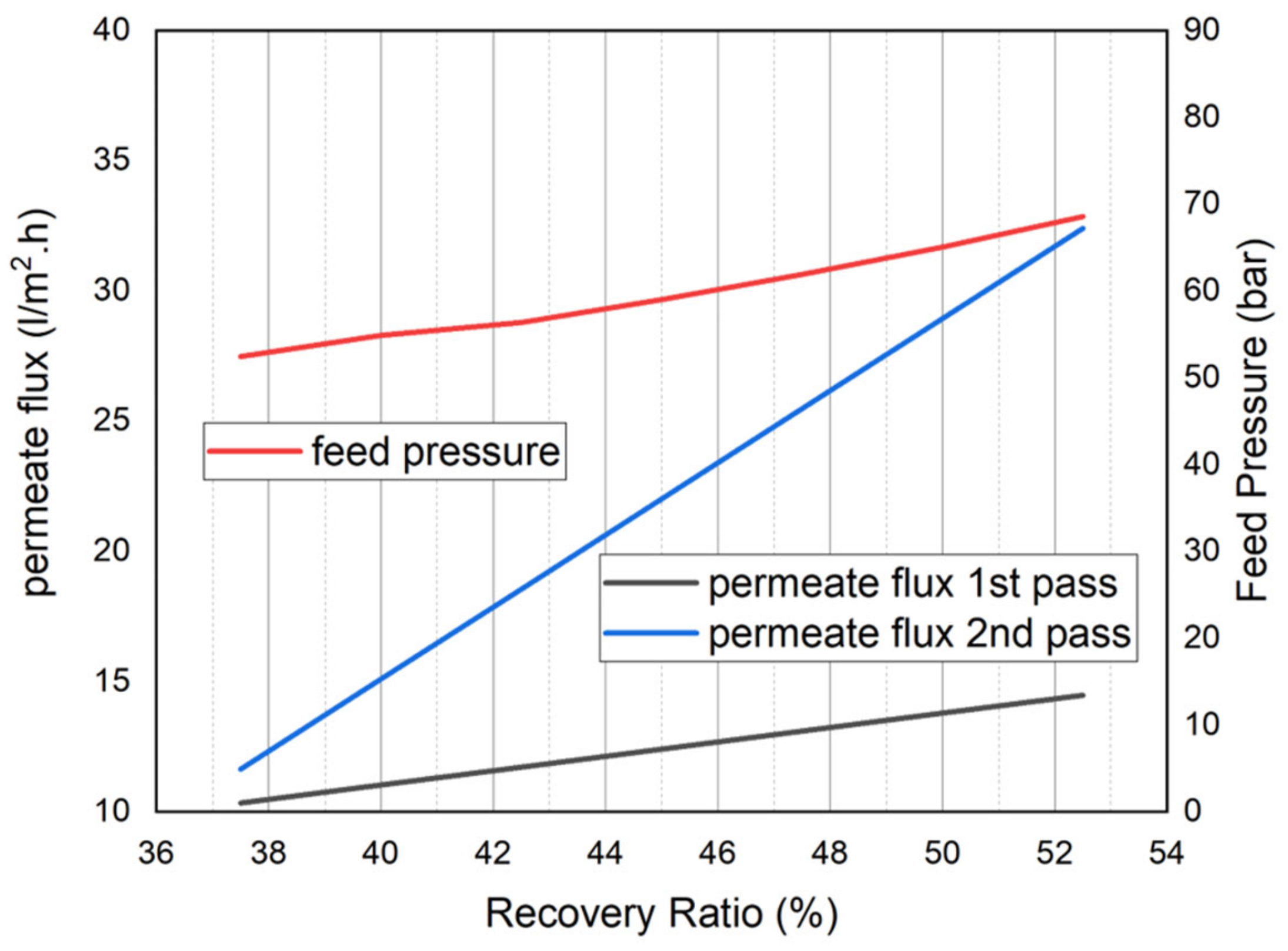

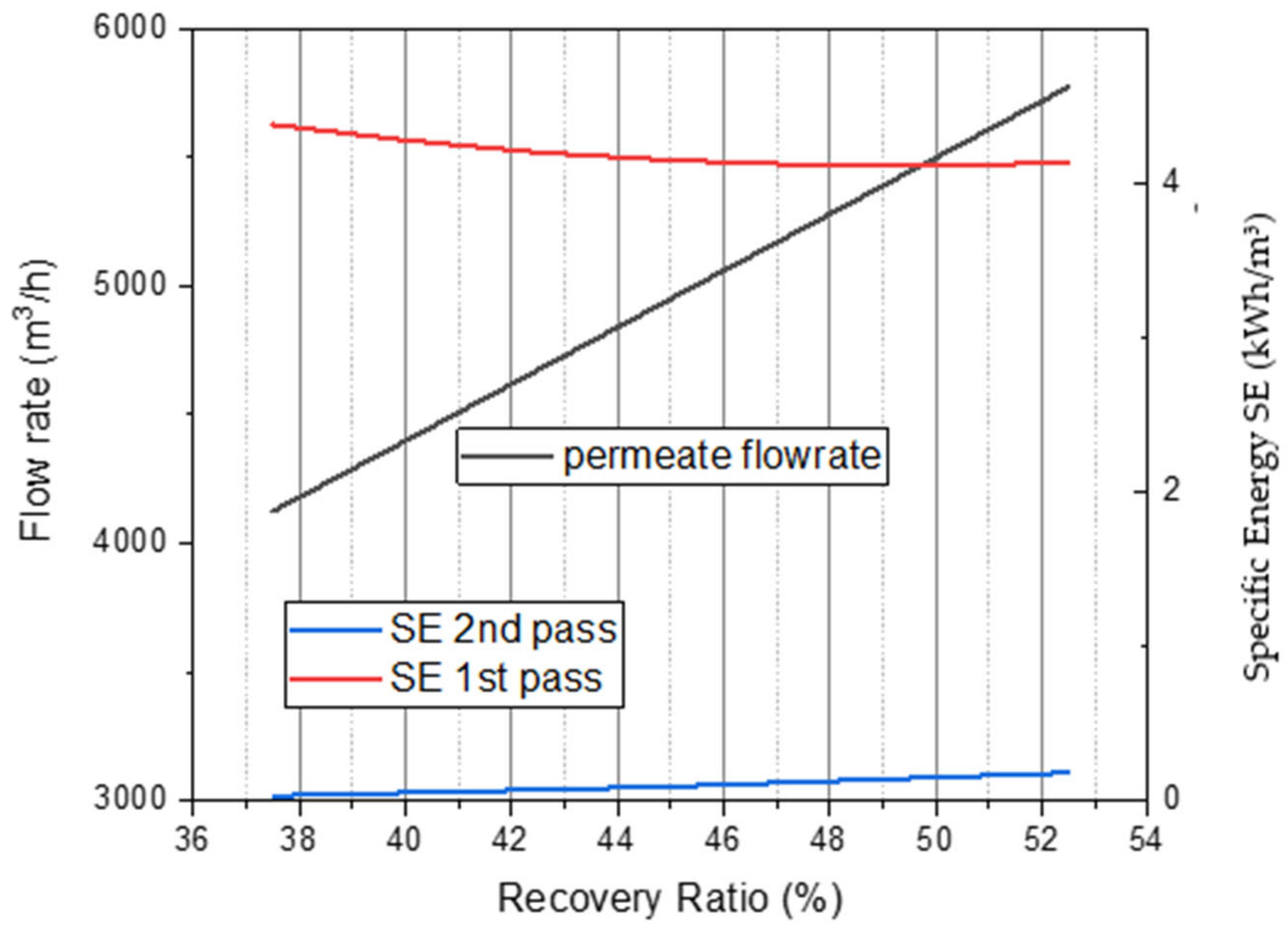

4.1. Comparison between the Main Parameters

- Case 1:

- Case 2:

- Case 3:

- Case 4:

- Case 5:

- Case 6:

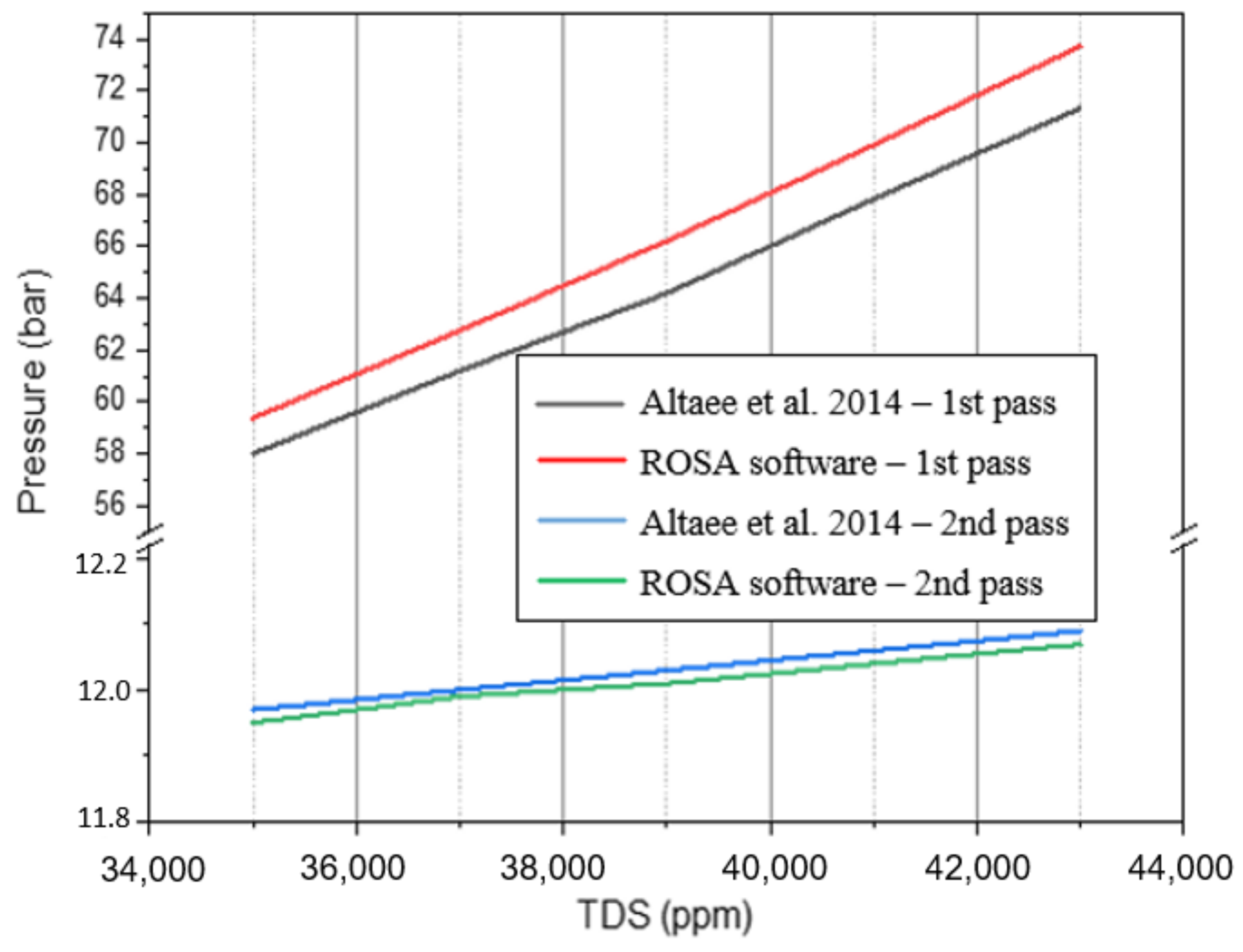

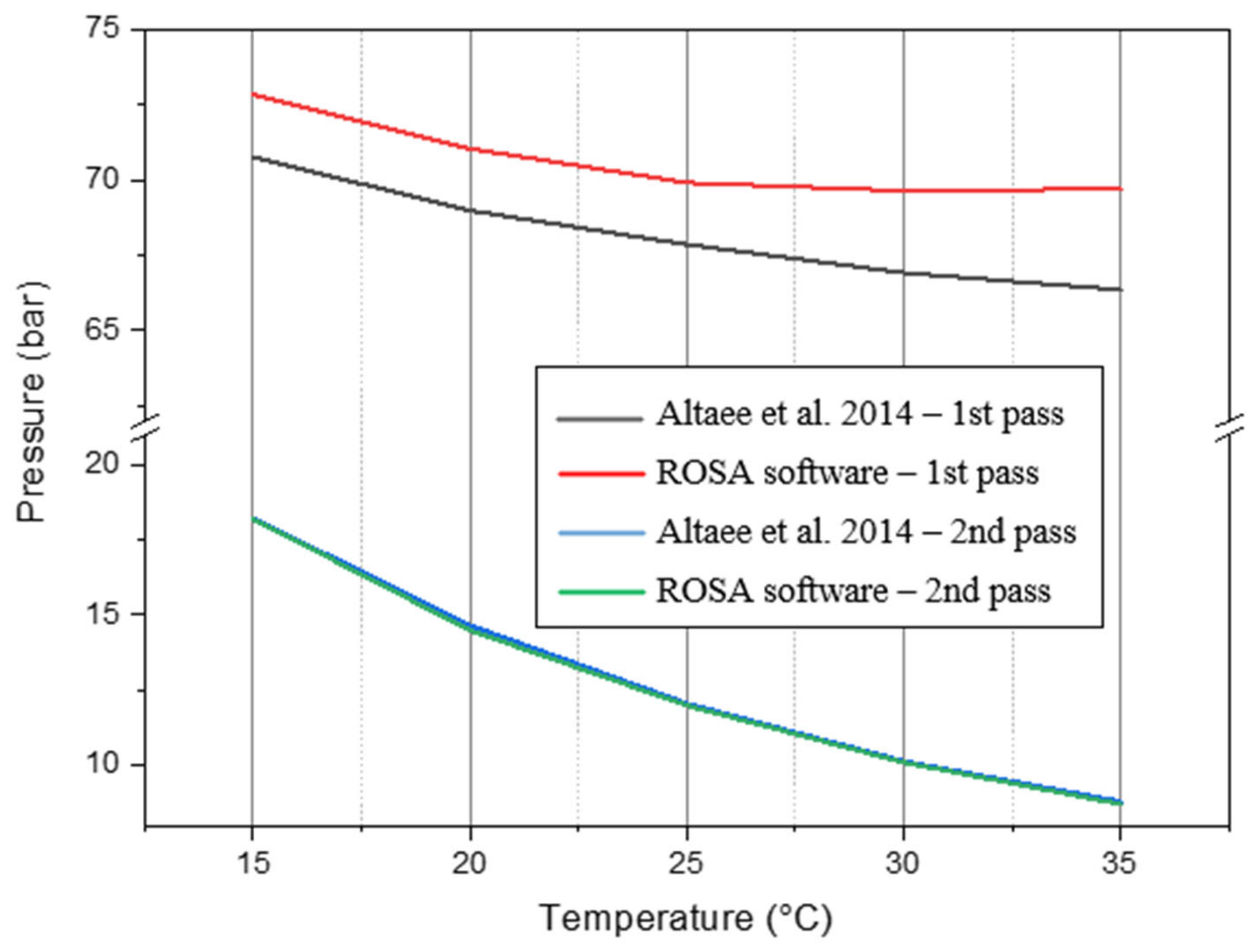

4.2. Validating the ROSA Software

5. Conclusions

- –

- More than one output can be obtained from the same design due to two main changing parameters: dependent parameters when varying within a specific range as noticed in the results, and input parameters that affect the results such as temperature and feed pressure.

- –

- Energy recovery methods, such as selecting high-efficiency pumps and membranes, optimizing their configuration, and implementing advanced control and monitoring systems, are crucial for reducing the energy consumption of an RO plant.

- –

- There are major factors that affect the design to achieve lower power consumption:

- The parametric effect, which is the result of chosen parameters mentioned in Table 12.

- The optimizing effect, which is the result of balancing the design after testing it on the software (high-pressure pumps, energy recovery devices).

- –

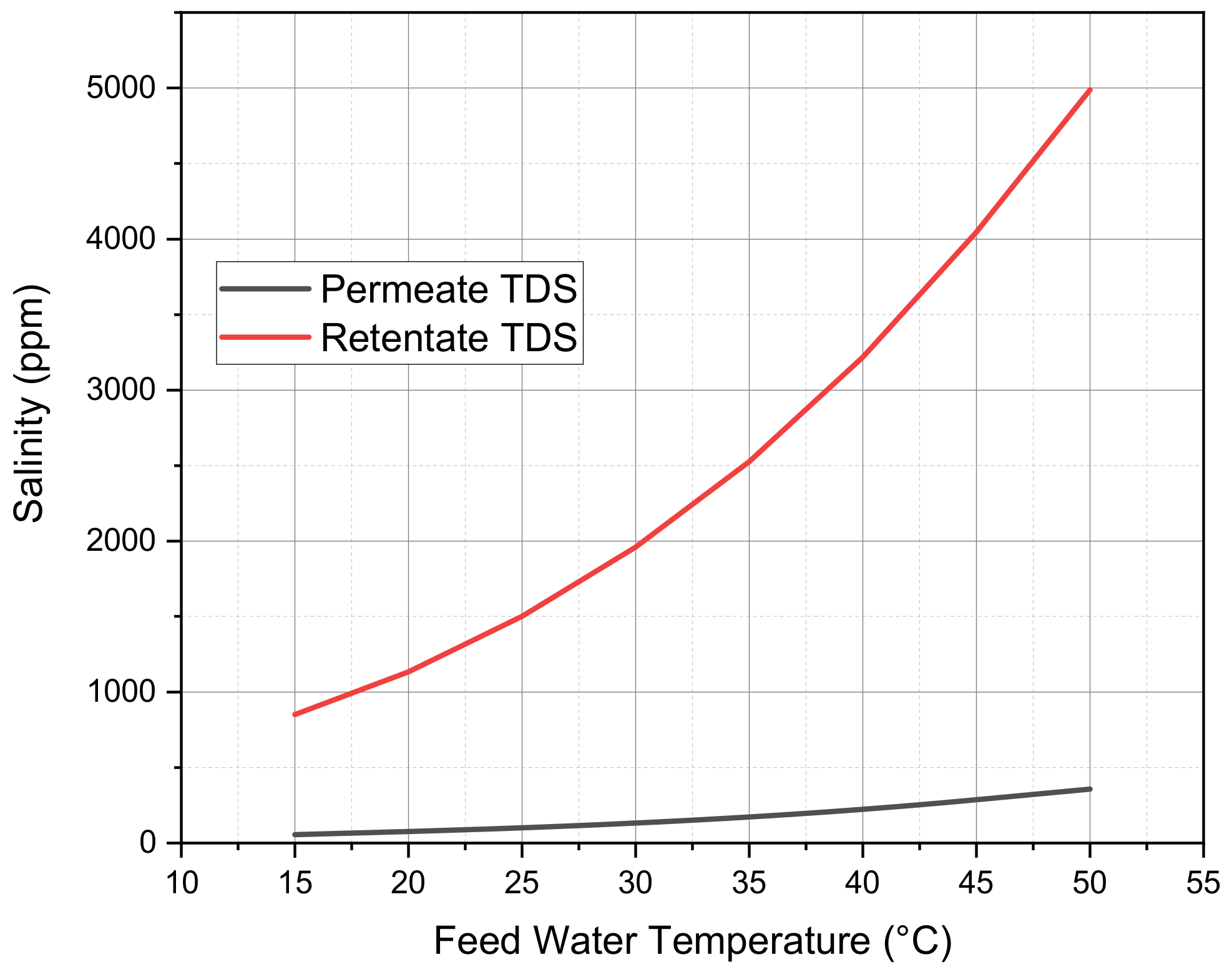

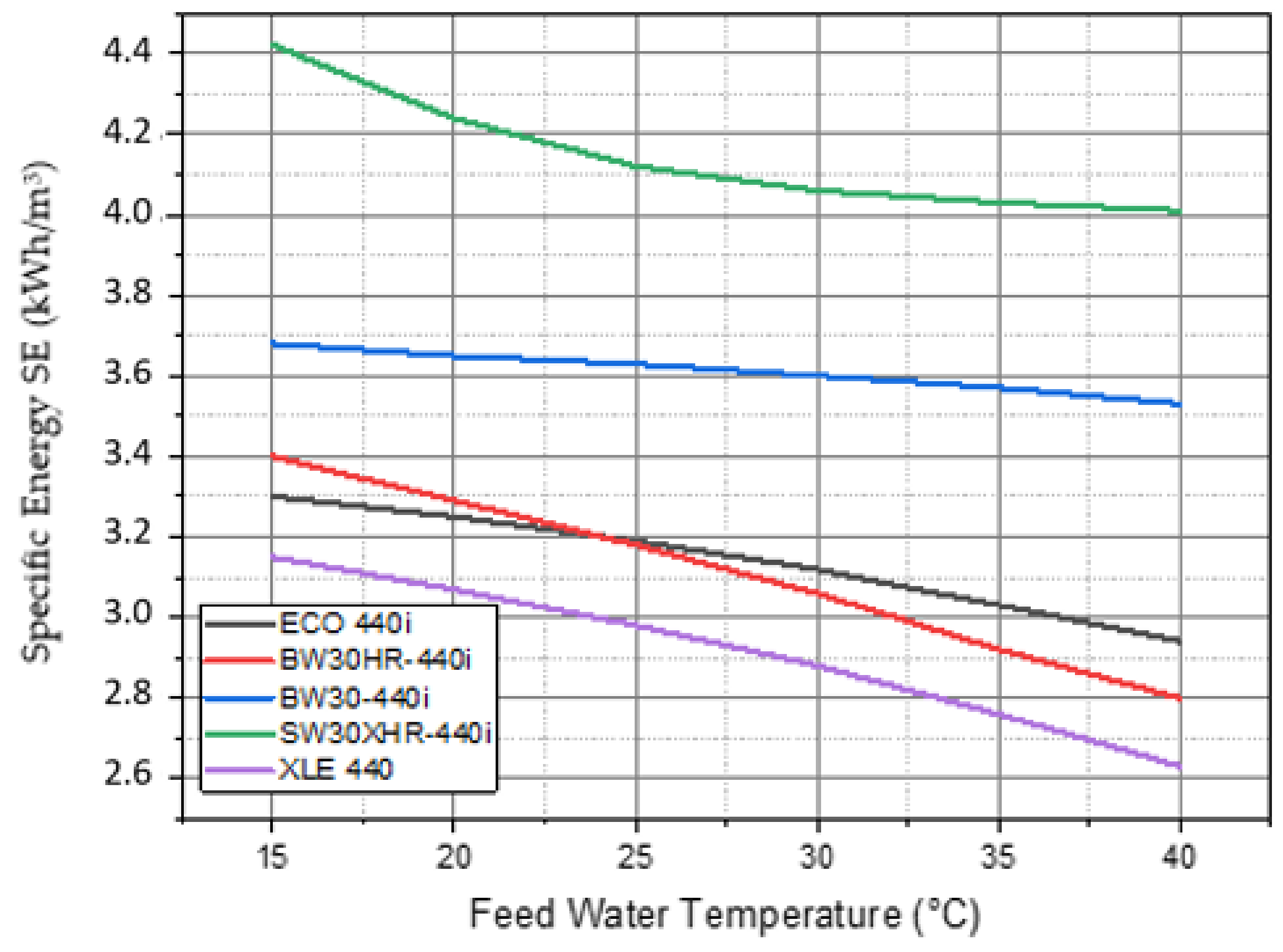

- It is found that the higher temperature of feedwater causes better RO operation, where, as the feedwater temperature increases for a constant permeate flow, feed pressure decreases, and the salinity of permeate increases. Hence, as a result of the lower pressure required, specific energy consumption (SEC) decreases. However, the rate of decrease in FW pressure and SEC depends on the type of membrane used.

- –

- Increasing recovery has a significant effect on the design. As the recovery rate is reduced, the concentration of reject water decreases; hence, the osmotic pressure in the membrane elements decreases. Decreasing recovery dilutes the concentrate flow, which reduces the membrane feed pressure, which reduces the load on the high-pressure pump motor.

- –

- ERDs mainly depend on the operating parameters (flow and pressure) for better performance.

- –

- The active area, salt rejection, and flow capacity are the main affecting parameters of membrane performance.

- –

- Membrane types do not affect membrane system flux because the quality of feed water defines the ultimate flux.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shafieian, A.; Rizwan Azhar, M.; Khiadani, M.; Kanti Sen, T. Performance improvement of thermal-driven membrane-based solar desalination systems using nanofluid in the feed stream. Sustain. Energy Technol. Assess. 2020, 39, 100715. [Google Scholar] [CrossRef]

- Topaloglu, D.; Tilki, Y.M.; Aksu, S.; Yilmaz, T.N.; Celebi, E.E.; Oncel, S.; Aydiner, C. Novel technological solutions for eco-protective water supply by economical and sustainable seawater desalination. Chem. Eng. Res. Des. 2018, 136, 177–198. [Google Scholar] [CrossRef]

- Anis, S.F.; Hashaikeh, R.; Hilal, N. Reverse osmosis pretreatment technologies and future trends: A comprehensive review. Desalination 2019, 452, 159–195. [Google Scholar] [CrossRef]

- Kadhom, M. A review on the polyamide thin film composite (TFC) membrane used for desalination: Improvement methods, current alternatives, and challenges. Chem. Eng. Res. Des. 2023, 191, 472–492. [Google Scholar] [CrossRef]

- Rodríguez-Calvo, A.; Silva-Castro, G.A.; Osorio, F.; González-López, J. Reverse osmosis seawater desalination_ current status of membrane systems_ Desalination and Water Treatment. Desalination Water Treat. 2015, 56, 849–861. [Google Scholar] [CrossRef]

- Edokali, M.; Bocking, R.; Mehrabi, M.; Massey, A.; Harbottle, D.; Menzel, R.; Hassanpour, A. Chemical modification of reduced graphene oxide membranes: Enhanced desalination performance and structural properties for forward osmosis. Chem. Eng. Res. Des. 2023, 199, 659–675. [Google Scholar] [CrossRef]

- Al-Obaidi, M.A.; Rasn, K.H.; Aladwani, S.H.; Kadhom, M.; Mujtaba, I.M. Flexible design and operation of multi-stage reverse osmosis desalination process for producing different grades of water with maintenance and cleaning opportunity. Chem. Eng. Res. Des. 2023, 182, 525–543. [Google Scholar] [CrossRef]

- Slocuma, A.H.; Haji, M.N.; Trimble, A.Z.; Ferrara, M.; Ghaemsaidi, S.J. Integrated Pumped Hydro Reverse Osmosis systems. Sustain. Energy Technol. Assess. 2016, 18, 80–99. [Google Scholar] [CrossRef]

- Li, M.; Chan, N.; Li, J. Novel dynamic and cyclic designs for ultra-high recovery waste and brackish water RO desalination. Chem. Eng. Res. Des. 2022, 179, 473–483. [Google Scholar] [CrossRef]

- Qasim, M.; Badrelzaman, M.; Darwish, N.N.; Darwish, N.A.; Hilal, N. Reverse osmosis desalination: A state-of-the-art review. Desalination 2019, 459, 59–104. [Google Scholar] [CrossRef]

- Ali, I.B.; Turki, M.; Belhadja, J.; Roboam, X. Systemic design and energy management of a standalone battery-less PV/Wind driven brackish water reverse osmosis desalination system. Sustain. Energy Technol. Assess. 2020, 42, 100884. [Google Scholar]

- Mostafaeipour, A.; Qolipour, M.; Rezaei, M.; Babaee-Tirkolaee, E. Investigation of off-grid photovoltaic systems for a reverse osmosis desalination system: A case study. Desalination 2019, 454, 91–103. [Google Scholar] [CrossRef]

- Naseri, A.; Bidi, M.; Ahmadi, M.H.; Saidur, R. Exergy analysis of a hydrogen and water production process by a solar-driven transcritical CO2 power cycle with Stirling engine. J. Clean. Prod. 2017, 158, 165–181. [Google Scholar] [CrossRef]

- Shaaban, S.; Yahya, H. Detailed analysis of reverse osmosis systems in hot climate conditions. Desalination 2017, 423, 41–51. [Google Scholar] [CrossRef]

- Greenlee, L.F.; Lawler, D.F.; Freeman, B.D.; Moulin, P. Reverse osmosis desalination: Water sources, technology, and today’s challenges. Water Res. 2009, 43, 2317–2348. [Google Scholar] [CrossRef]

- Datta, S.; Baul, A.; Sarker, G.C.; Sadhu, P.K.; Hodges, D.R. A Comprehensive Review of the Application of Machine Learning in Fabrication and Implementation of Photovoltaic Systems. IEEE Access 2023, 11, 77750–77778. [Google Scholar] [CrossRef]

- Delgado-Torres, A.M.; García-Rodríguez, L.; del Moral, M.J. Preliminary assessment of innovative seawater reverse osmosis (SWRO) desalination powered by a hybrid solar photovoltaic (PV)—Tidal range energy system. Desalination 2020, 477, 114247. [Google Scholar] [CrossRef]

- Saleem, H.; Zaidi, S.J. Nanoparticles in reverse osmosis membranes for desalination: A state of the art review. Desalination 2020, 475, 114171. [Google Scholar] [CrossRef]

- Mahlangu, O.T.; Nthunya, L.N.; Motsa, M.M.; Morifi, E.; Richards, H.; Mamba, B.B. Fouling of high pressure-driven NF and RO membranes in desalination processes: Mechanisms and implications on salt rejection. Chem. Eng. Res. Des. 2023, 199, 268–295. [Google Scholar] [CrossRef]

- Bani, N.A.; Noordin, M.K.; Hidayat, A.A.; Kamil, A.S.A.; Amran, M.E.; Kasri, N.F.; Muhtazaruddin, M.N.; Muhammad-Sukki, F. Development of Predictive Maintenance System for Haemodialysis Reverse Osmosis Water Purification System. In Proceedings of the 2022 4th International Conference on Smart Sensors and Application (ICSSA), Kuala Lumpur, Malaysia, 26–28 July 2022; pp. 23–28. [Google Scholar] [CrossRef]

- Du, C.; Zhao, X.; Du, J.R.; Feng, X.; Yang, H.; Cheng, F.; Ali, M.E.A. A field study of desalination of high-salinity surface brackish water via an RO-NF hybrid system. Chem. Eng. Res. Des. 2022, 182, 133–144. [Google Scholar] [CrossRef]

- FILMTEC Membranes—Steps to Design a Reverse Osmosis System. Dow Water & Process Solutions, 13 March 2018. [Online]. Available online: https://www.dupont.com/content/dam/dupont/amer/us/en/water-solutions/public/documents/en/RO-NF-FilmTec-Manual-45-D01504-en.pdf (accessed on 24 May 2024).

- 10 Steps to Design an RO/NF Membrane System. Desal Supplies, [Online]. Available online: https://fr.scribd.com/document/414151608/10-Steps-to-Design-an-RO-NF-Membrane-System (accessed on 24 May 2024).

- Oren, S.; Biesheuvel, M. Theory of Ion and Water Transport in Reverse-Osmosis Membranes. Phys. Rev. Appl. 2018, 9, 024034. [Google Scholar] [CrossRef]

- Haryati, S.; Hamzah, A.B.; Goh, P.S.; Abdullah, M.S.; Ismail, A.F.; Bustan, M.D. Process intensification of seawater reverse osmosis through enhanced train capacity and module size—Simulation on Lanzarote IV SWRO plant. Desalination 2017, 48, 92–101. [Google Scholar] [CrossRef]

- Aridi, R.; Faraj, J.; Ali, S.; Lemenand, T.; Khaled, M. Innovative concept of vortex generator-equipped multi-drain heat recovery systems–Numerical study and energetic analysis. Int. J. Thermofluids 2023, 20, 100455. [Google Scholar] [CrossRef]

- Aridi, R.; Faraj, J.; Ali, S.; Lemenand, T.; Khaled, M. Thermoeconomic and environmental impacts of vortex generator-equipped multi-drain heat recovery systems under various renewable sources. Energy Convers. Manag. X 2023, 20, 100431. [Google Scholar] [CrossRef]

- Aridi, R.; Yehya, A. Review on the sustainability of phase-change materials used in buildings. Energy Convers. Manag. X 2022, 15, 100237. [Google Scholar] [CrossRef]

- Aridi, R. Advanced Heat Recovery Systems: Use of Vortex Generators and Hybridization with Thermoelectric Generators, Considering Renewable Energy Sources and Life Cycle Assessment; Polytech Angers: Angers, France, 2023. [Google Scholar]

- Aridi, R.; Faraj, J.; Ali, S.; El-Rab, M.G.; Lemenand, T.; Khaled, M. Energy Recovery in Air Conditioning Systems: Comprehensive Review, Classifications, Critical Analysis, and Potential Recommendations. Energies 2021, 14, 5869. [Google Scholar] [CrossRef]

- Aridi, R.; Faraj, J.; Ali, S.; Lemenand, T.; Khaled, M. Thermoelectric Power Generators: State-of-the-Art, Heat Recovery Method, and Challenges. Electricity 2021, 2, 359–386. [Google Scholar] [CrossRef]

- Aridi, R.; Faraj, J.; Ali, S.; Lemenand, T.; Khaled, M. A comprehensive review on hybrid heat recovery systems: Classifications, applications, pros and cons, and new systems. Renew. Sustain. Energy Rev. 2022, 167, 112669. [Google Scholar] [CrossRef]

- Das, A.; Rao, A.K.; Alnajdi, S.; Warsinger, D.M. Pressure exchanger batch reverse osmosis with zero downtime operation. Desalination 2024, 547, 117121. [Google Scholar] [CrossRef]

- Stover, R. Expansion Retrofit of the Via Maris Palmachim Seawater Reverse Osmosis Plant; International Desalination Association World Congress: Dubai, United Arab Emirates, 2021. [Google Scholar]

- Abdel-Fatah, M.A.; Elsayed, M.M.; Al Bazedi, G.A. Design of Reverse Osmosis Desalination Plant in Suez City (Case Study). J. Sci. Eng. Res. 2016, 3, 149–156. [Google Scholar]

- Ezzeghni, U.A. Designing and Optimizing 10,000 m3 Conventional SWRO Desalination Plant; First Conference for Engineering Sciences and Technology (CEST): Libya, North Africa, 2018. [Google Scholar]

- Prakash, N.; Chaudhuri, A.; Das, S.P. Numerical modelling and analysis of concentration polarization and scaling of gypsum over RO membrane during seawater desalination. Chem. Eng. Res. Des. 2023, 190, 497–507. [Google Scholar] [CrossRef]

- Ghoujdi, I.E.; Hadiannasab, H.; Bidi, M.; Naeimi, A.; Ahmadi, M.H.; Nazari, M.A.; Ming, T. Multiobjective optimization design of the solar field and reverse osmosis system with preheating feed water using Genetic algorithm. Energy Sci. Eng. 2018, 6, 624–642. [Google Scholar] [CrossRef]

- Stover, R.L.; Martin, J. Reverse Osmosis and Osmotic Power Generation with Isobaric Energy Recovery. Desalination Water Treat. 2010, 15, 267–270. [Google Scholar] [CrossRef]

- Altaee, A.; Sharif, A. A conceptual NF/RO arrangement design in the pressure vessel for seawater desalination. Desalination Water Treat. 2014, 54, 624–636. [Google Scholar] [CrossRef]

- Version 5.01-9.1. DOW, 23 April 2019. [Online]. Available online: https://dowac.custhelp.com/app/answers/detail/a_id/19181/~/filmtec-membranes---rosa-version-history (accessed on 8 May 2019).

| # | Parameter | Symbol (Unit) | Physical Meaning | |

|---|---|---|---|---|

| 1 | FW type | Brackish water | BW | It is important to select the best membranes for each type of water, according to the salinity. For example, well waters of low salinity involve less treatment than SW when used for drinking. Therefore, membranes and numbers of stages need to be defined for each specific case. |

| Sea water | SW | |||

| Tap water | TW | |||

| 2 | Feed flow rate | (m3/h) | The flow of the feed water depends on the source flow. | |

| 3 | Feed pressure | PF (Pa) | The pressure of the feed water, depends on the source. | |

| 4 | Temperature | T (°C) | The T of the FW. | |

| 5 | Flow Factor | FF | Flow Factor or Fouling Factor is a value used in ROSA to compute the feed pressure of the system. It depends on the type of FW; for instance, FF of BW is 0.95. | |

| 6 | Flux average flux | (L/m2·h) | Flux defines the rate at which water permeates a RO membrane. | |

| 7 | Salt flux | (L/m2·h) | The quantity of TDS that has gone through a particular area of membrane in a specific time. | |

| 8 | Membrane area | A (m2) | The area of the membrane affects the number of elements membrane to reach the permeate of specific salinity. | |

| 9 | Membrane type | Membranes are used to remove saline FW from freshwater. The membrane type depends on the type of FW. | ||

| 10 | Number of elements | The total number of membrane elements is determined by dividing the design permeate flow. | ||

| 11 | Number of elements in the pressure vessel | NE/V | When the total number of elements is calculated, the total number of vessels in the system can be obtained by dividing by the number of elements in the pressure vessel. | |

| 12 | Number of stages | NS | A stage in RO is a line, where the FW comes into the RO system as one stream and leaves as either a permeate water or concentrate. In the case of more than one stage, the concentration coming out from the 1st stage becomes the FW to the 2nd stage. | |

| 13 | Osmotic pressure | P (Pa) | The change in water level is due to the addition of a particular quantity of salt. | |

| 14 | Permeate flow | (m3/h) | Is proportional to the Net Driving Pressure (NDP) differential across the membrane, the water flowing over the membrane. | |

| 15 | Permeate salinity | (ppm) | The salt concentration in the permeate. | |

| 16 | pH | Amount of acidity/basicity of the water. | ||

| 17 | Pressure exchanger | PX | It is used to transfer the energy of pressure from a fluid stream with high pressure to another fluid stream with low pressure | |

| 18 | Recovery ratio | RR (%) | The ratio of permeate water volume to the FW volume. | |

| 19 | Retentate flow | (m3/h) | Is defined as the rate of flow which has not passed through the RO membrane and comes out from the RO system with rejected ions. | |

| Concentrate flow | ||||

| Brine flow | ||||

| 20 | Retentate TDS | (ppm) | The salt concentration in the retentate. | |

| 21 | Staging ratio | R | The relation of the number of pressure vessels in succeeding stages. | |

| 22 | Salinity | (ppm) | The concentration of salt, for example, sodium in water. | |

| 23 | Salt passage | Salt passage over the membrane wall layer is defined as “salt passage”. | ||

| 24 | Salt rejection | SR | Lack of passage over the membrane wall layer is defined as “salt rejection”. | |

| 25 | Specific energy | SE (kWh/m3) | The measure of the energy usage in desalination processes, and relies on various water quality, design, operational and factors. | |

| 26 | System recovery | Y (%) | The system recovery is the amount of recovered water from the FW, which depends on the type of FW and the number of stages and element vessels. | |

| 27 | Total dissolved solids | TDS (mg/L) | TDS represents the sum of all organic and inorganic substances dissolved in a liquid. | |

| 28 | High-pressure brine | HP B | Brine leaves the system with high pressure, to recover the high pressure that would be rather lost. A pressure EX is employed so that the high pressure is transferred to the FW. | |

| 29 | Low-pressure FW | LP FW | FW has low pressure, so part of this FW passes through the pressure EX to recover the high pressure from the HP brine. | |

| 30 | Low-pressure brine | LP B | After transferring the high pressure, the brine leaves the pressure EX with low pressure. | |

| 31 | High-pressure FW | HP FW | FW leaves the pressure EX with higher pressure and then passes through a pump to reach the required pressure. | |

| Seawater Constituent | Concentration (mg/L) | Seawater Constituent | Concentration (mg/L) |

|---|---|---|---|

| Cations | Anions | ||

| Calcium () | 450 | Chloride () | 22,100 |

| Magnesium () | 1450 | Sulfate () | 3410 |

| Sodium () | 12,500 | Boron (B) | 4–5 |

| Potassium () | 450 | Bicarbonate () | 160 |

| Total Cations | 14,850 | Total Anions | 25,670 |

| Boron (B) | 4–5 | ||

| Total dissolved solids (TDS) | 40,525 | ||

| Component/Parameter | Specifications/Design Criteria |

|---|---|

| Feedwater | |

| Design flow rate | 1000,000 m3/day |

| TDS | 38,468 mg/L |

| T | 25 °C |

| Intake type | open-intake |

| Criteria | Level | |

|---|---|---|

| Chloride Concentration | 70 ppm (Max) | |

| Salinity | TDS | 400 ppm (Max) |

| Na | 60 ppm (Max) | |

| Boron | 0.3 ppm (Max) | |

| pH | 7.5–8.5 max | |

| Desired Parameters | Permeate Salinity Permeate Flow Rate |

|---|---|

| Input parameters | FW type FW TDS T Flow Factor FW pressure |

| Dependent parameters | Membrane type Salt rejection |

| Output parameters | FW pressure FW flow rate Average flux System recovery Specific energy |

| Membrane Type | Membrane Main Characterization | Permeate Flow (m3/day) | Salt Rejection (%) | Active Area (m2) |

|---|---|---|---|---|

| DOW–SW 30HRLE–440i | SW—high rejection | 31 | 99.8 | 41 |

| DOW–SW 30ULE–440i | SW—low energy | 45.4 | 99.7 | 41 |

| DOW–SW 30HRLE–370/34i | SW—fouling resistant | 25.3 | 99.8 | 34 |

| DOW–HRLE–440i | BW—low energy | 48 | 99.5 | 41 |

| DOW–BW 30HR–440i | BW—high rejection | 48 | 99.7 | 41 |

| Plant daily capacity | 1,000,000 m3/day |

| Plant yearly capacity | 1,000,000 × 365 = 365,000,000 m3/yr |

| Number of hours in a year | 365 × 24 = 8760 h |

| Plant average flow | 365,000,000/8760 = 41,666.7 m3/h |

| Operation hours per year, 8000 h | downtime for maintenance, 760 h |

| Plant flow with an availability factor | 365,000,000/8000 = 45,625 m3/h |

| Plant flow 10% availability and redundancy factor | 45,625 × 1.1 = 50,187.5 m3/h |

| No | Feed Type | Permeate Flux (L/m2·h) | Recovery Ratio R (%) |

|---|---|---|---|

| 1 | SW from open intake | 10–15 | 40–50 |

| 2 | SW from beach wells | 10–17 | 40–50 |

| 3 | BW | 20–29 | 75–85 |

| 4 | TW, low salinity well water | 24–29 | 80–88 |

| System Recovery (%) | # of Serial Element Positions | # of Stages (6-Element Vessels) | # of Stages (7-Element Vessels) | # of Stages (8-Element Vessels) |

|---|---|---|---|---|

| 35–40 | 6 | 1 | 1 | --- |

| 45 | 7–12 | 2 | 1 | 1 |

| 50 | 8–12 | 2 | 2 | 1 |

| 55–60 | 12–14 | 2 | 2 | --- |

| Cases | Feed Salinity (ppm) | T (°C) | Membrane Type | Feed Pressure | Recovery (%) | Feed Flow (m3/h) | Design |

|---|---|---|---|---|---|---|---|

| 1 | Varies | 25 | Fixed | Output | 46.6 | 12,000 | 1st pass 1 stage 2nd pass 2 stages = 88% # of elements # of pressure vessels |

| 2 | 38,225 | Varies | Fixed | Output | 46.6 | 12,000 | |

| 3 | 38,225 | 25 | Varies | Output | 46.6 | 12,000 | |

| 4 | 38,225 | 25 | Fixed | Varies | 46.6 | 12,000 | |

| 5 | 38,225 | 25 | Fixed | Output | Varies | 12,000 | |

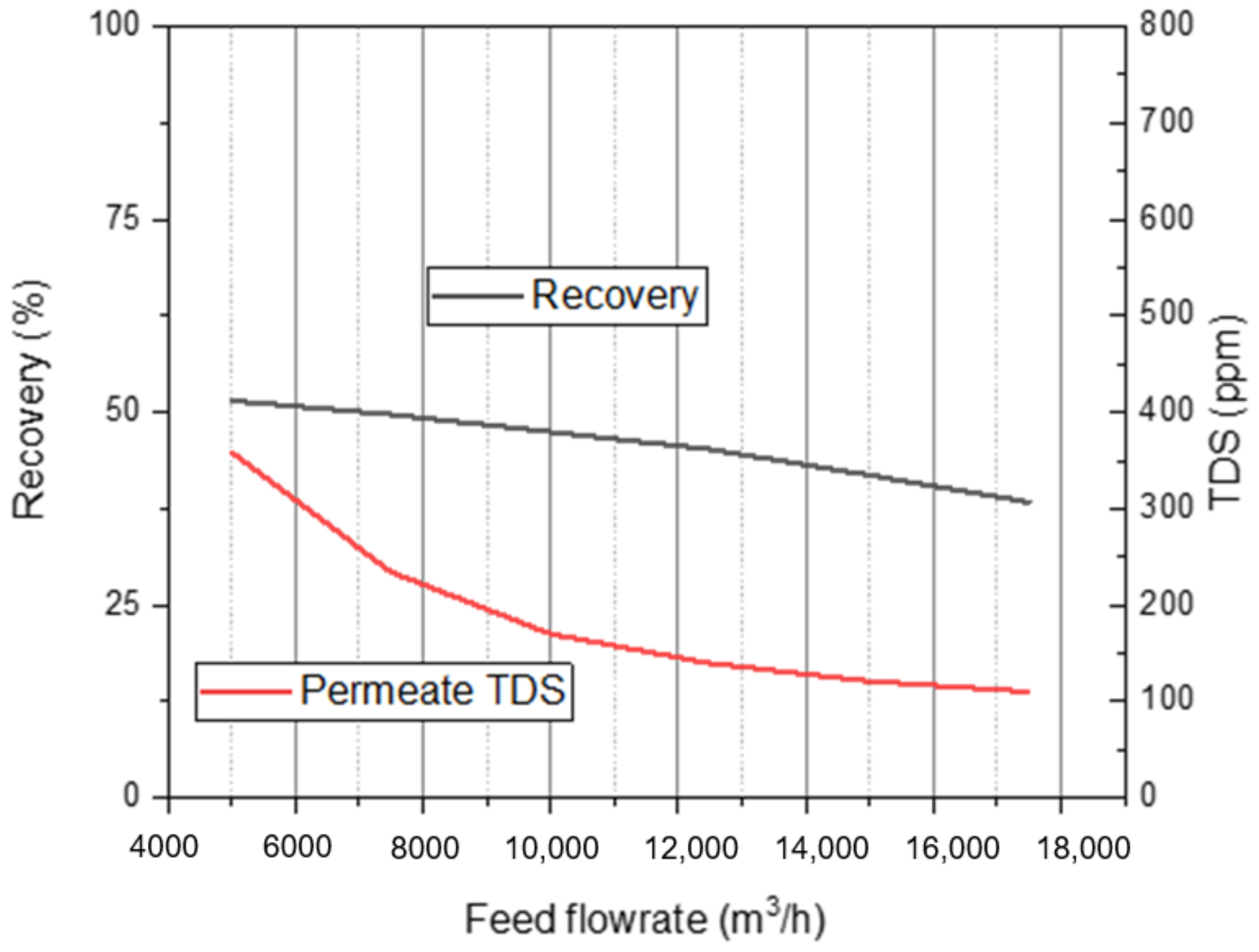

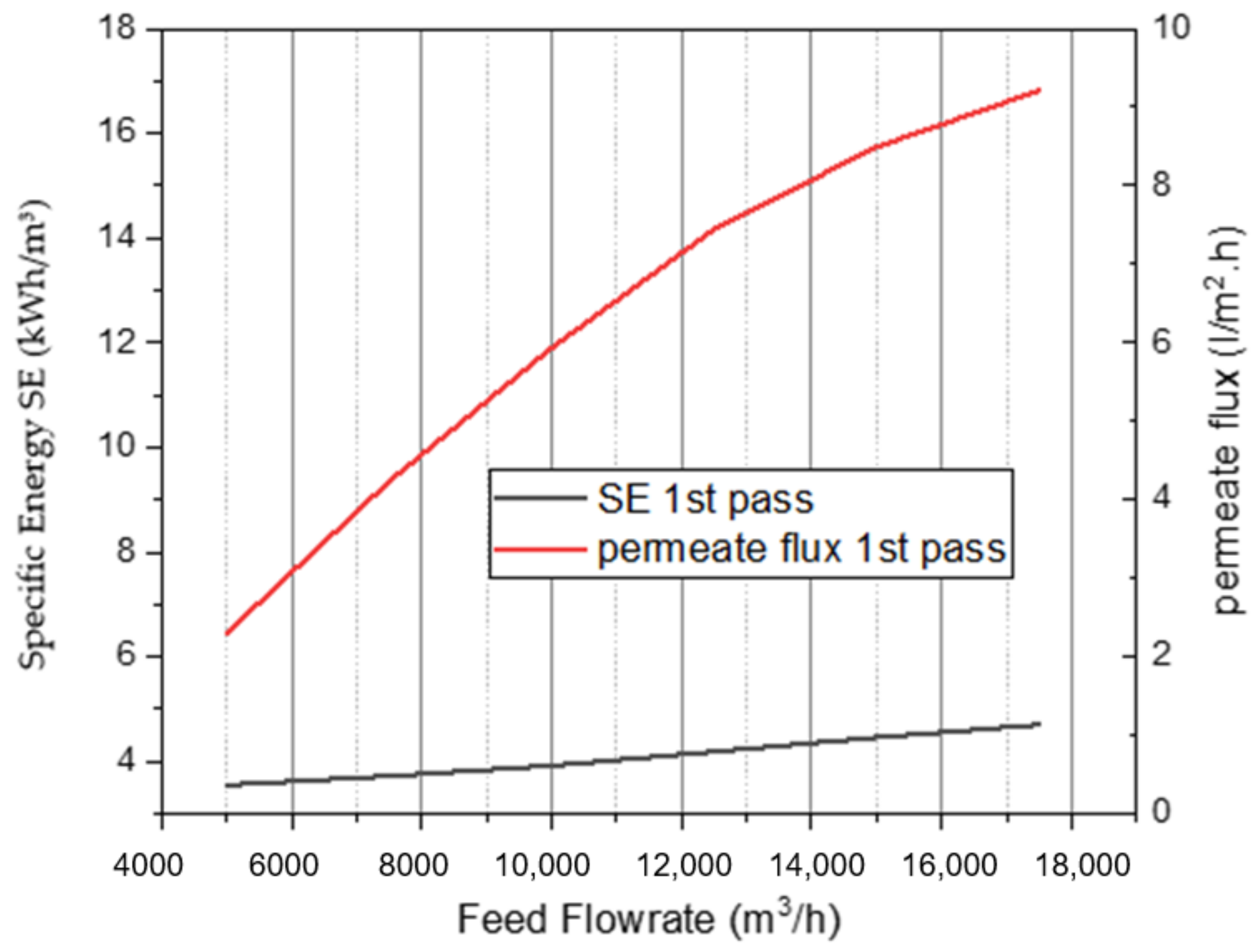

| 6 | 38,225 | 25 | Fixed | Output | 46.6 | Varies |

| Membrane | Area (m2) | SR (%) | Flow Rate (m3/h) | Pressure (bar) |

|---|---|---|---|---|

| SW30HRLE440i | 40.9 | 99.8 | 31 | 55.2 |

| SW30ULE440i | 40.9 | 99.7 | 45.4 | 55.2 |

| SW30XHR440i | 40.9 | 99.82 | 25 | 55.2 |

| SW30XLE440i | 40.9 | 99.8 | 37.5 | 55.2 |

| Case | Permeate Flux (L/m2·h) | Feed Pressure (Pa) | Specific Energy (kWh/m3) | Permeate TDS (ppm) | |

|---|---|---|---|---|---|

| ↑ Feed | Pressure | ↑ | ↑ | ↑ | ↑ |

| Salinity | ↓ | ↑ | ↑ | ↑ | |

| Temperature | Constant | ↓ | ↓ | ↑ | |

| Flow rate | ↑ | Constant | ↑ | ↓ | |

| ↑ Recovery | ↑ | ↑ | ↓ | ↓ | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aridi, R.; Al Mawla, M.; Harika, E.; Lemenand, T.; Khaled, M.; Gad El-Rab, M. A New Algorithmic Method for Reverse Osmosis Desalination Analysis: Design Optimization and Parametric Study. Eng 2024, 5, 1183-1208. https://doi.org/10.3390/eng5030065

Aridi R, Al Mawla M, Harika E, Lemenand T, Khaled M, Gad El-Rab M. A New Algorithmic Method for Reverse Osmosis Desalination Analysis: Design Optimization and Parametric Study. Eng. 2024; 5(3):1183-1208. https://doi.org/10.3390/eng5030065

Chicago/Turabian StyleAridi, Rima, Mohamad Al Mawla, Elias Harika, Thierry Lemenand, Mahmoud Khaled, and Mostafa Gad El-Rab. 2024. "A New Algorithmic Method for Reverse Osmosis Desalination Analysis: Design Optimization and Parametric Study" Eng 5, no. 3: 1183-1208. https://doi.org/10.3390/eng5030065

APA StyleAridi, R., Al Mawla, M., Harika, E., Lemenand, T., Khaled, M., & Gad El-Rab, M. (2024). A New Algorithmic Method for Reverse Osmosis Desalination Analysis: Design Optimization and Parametric Study. Eng, 5(3), 1183-1208. https://doi.org/10.3390/eng5030065