Abstract

A typical halogen-free flame-retardant (HFFR) formulation for electric cables may contain polymers, various additives, and fire-retardant fillers. In this study, composites are prepared by mixing natural magnesium hydroxide (n-MDH) with linear low-density polyethylene (LLDPE) and a few types of ethylene–octene copolymers (C8-POE). Depending on the content of LLDPE and C8-POE, we obtained composites with different crystallinities that affected the final mechanical properties. The nucleation effect of the n-MDH and the variations in crystallinity caused by the blending of C8-POE/LLDPE/n-MDH were investigated. Notably, in the C8-POE/LLDPE blend, we found a decrease in the crystallization temperature of LLPDE compared to pure LLDPE and an increase in the crystallization temperature of C8-POE compared to pure C8-POE. On the contrary, the addition of n-MDH led to an increase in the crystallization temperature of LLDPE. As expected, the increase in the crystallinity of the polyolefin matrix of composites led to higher elastic modulus, higher tensile strength, and lower elongation at break. It has been observed that crystallinity also influences fire performance. Overall, these results show how to obtain the required mechanical features for halogen-free flame-retardant compounds for electric cable applications, depending on the quantities of the two miscible components in the final blend.

1. Introduction

With the development of the polymer industry, polymeric materials have found a wide range of applications, such as medicine, construction, automotive, electronics, etc. Nevertheless, most polymeric materials have the disadvantage of being flammable. Smoke and even toxic gases released during combustion are the main cause of the loss of human lives in the event of a fire. Combustion is a radical exothermic oxidation reaction that leads to the development of heat, flames, smoke, and gas. The combustion of any material requires three components: heat, oxygen, and the combusting material or fuel [1].

Flame retardants are introduced to limit the material’s flammability and the flame spread of polymers [2]. The main applications for flame-retardant polymers are in the construction and electrical cable industries and the transportation sector, where electronics are expanding. Halogen-based flame retardants are the most representative flame retardants in the polymer industry because they are highly cost- and performance-effective, despite the related environmental and toxicity issues [3]. In response to the negative impacts of halogen-based flame retardants, the industry has moved towards halogen-free flame retardants (HFFR), which are considered safer alternatives. Halogen-free flame-retardant (HFFR) polyolefin compounds, also named LZSH or LS0H (Low Smoke Zero Halogen), or even NHFR (Non-halogen flame retardant), have gained great popularity in the last two decades as the preferred materials in safe electrical cable applications, especially in Europe, the Middle East, and Asia. Halogen-free flame retardants (HFFRs) are available in several forms, including metal hydroxides, phosphorus-based compounds, nitrogen-based compounds, and nanocomposites. Among these, phosphorus-based compounds work by creating a protective barrier on the cable surface, insulating the underlying material from heat and oxygen, thus limiting combustion. These include organic and inorganic phosphates, phosphonates, and phosphinates, as well as red phosphorus [4].

Recent advances in phosphorus-based fire retardants, especially phosphates, have seen significant progress in their application within cable insulation to enhance fire safety. Researchers have been focusing on developing more effective and environmentally benign phosphorus-containing compounds [5]. For instance, recent studies have explored the use of nano-sized phosphorus-based materials, which not only improve the dispersion of the fire retardant within the polymer matrix but also enhance the overall flame retardancy and thermal stability of the material. These nano-phosphates create a more stable char layer, which is crucial for preventing the spread of fire.

Additionally, bio-based phosphorus fire retardants are gaining attention due to their reduced environmental impact compared to traditional halogenated fire retardants. For instance, a study demonstrated that the incorporation of bio-based phosphate into polypropylene cables not only improved flame retardancy but also maintained the mechanical properties of the cables, making it a promising approach for future applications in the electrical and electronics industries [6]. Another recent study focused on the development of novel phosphorus–nitrogen synergistic flame retardants, which showed remarkable efficiency in enhancing the fire resistance of polyolefin cables [7].

Metal hydroxides, on the other hand, function through an endothermic reaction that releases nonflammable molecules, such as water (H2O), and provides charring through the decomposition by-products [8]. The majority of current halogen-free flame retardant compounds for wire and cable are based on metal hydroxides due to their combination of low cost, environmentally friendly nature, low smoke generation, and flame retardancy. However, the main disadvantage of these FRs is the high dosage required to achieve an appreciable improvement in flame retardancy (at least 40–50% by weight, but in some applications up to 65–70% by weight), which often leads to processing issues and deterioration in the mechanical properties of the compound [9,10].

The most commonly used are aluminum trihydroxide (ATH), Al(OH)3, magnesium hydroxide (MDH), and Mg(OH)2 [11,12]. ATH and MDH endothermically decompose at T > 200 °C and T > 300 °C, respectively, with the release of water vapors, thus resulting in a fire retardancy effect due to cooling and dilution of the oxygen near the burning areas [13].

In this work, a natural magnesium hydroxide obtained by mining, selecting, and milling natural brucite was used as a flame retardant. During thermal decomposition, MDH releases MgO and water vapors (Equation (1)), with the first forming protective layers on the burning polymer surface, preventing heat and oxygen from reaching the polymer [14,15].

Mg(OH)2 (s) + Heat → MgO (s) + H2O (g)

Polyolefins, with their many desirable properties such as excellent electrical properties, easy processability, and a wide range of mechanical properties, are among the most interesting polymer matrices for highly filled composites for insulation and sheathing of electrical cables. Polyolefin elastomers (POE), such as copolymers of ethylene with 1-octene (C8), were selected as the preferred polymeric matrix obtained by metallocene catalysis. The physical properties of C8-POE, such as crystallinity, melting point, and density, depend upon comonomer content [16,17], whose increase leads to a decrease in the degree of crystallinity. This is because the short-chain branches interfere with the ability of the polymer backbone to organize into regular crystals. The advantages of C8-POEs include good impact resistance, high flexibility, and recyclability [18]. They can also withstand a large percentage of filler (up to over 65% by weight) thanks to their low crystallinity [19]. In addition, to comply with all the performance requirements of a thermoplastic HFFR compound for cable applications (i.e., elongation at break > 150% and tensile strength > 10–12.5 MPa or 12.5 MPa for sheathing and insulating applications, respectively [10]), C8-POE is generally used in synergistic combination with linear low-density polyethylene (LLDPE). The LLDPE has the aim of increasing the tensile strength and thermal stability up to 90 °C [19] due to its high flexural modulus and melting point > 110 °C.

Moreover, the incorporation of a high amount of inorganic fillers leads to a substantial increase in nucleating sites, which influences the crystallization level and the internal morphology of the composite and mechanical properties [20,21,22]. This work aims to study the influence of the introduction of LLDPE and MDH fillers on the crystallization behavior of C8-POE. The variation in mechanical properties caused by the different compositions was also investigated.

2. Materials and Methods

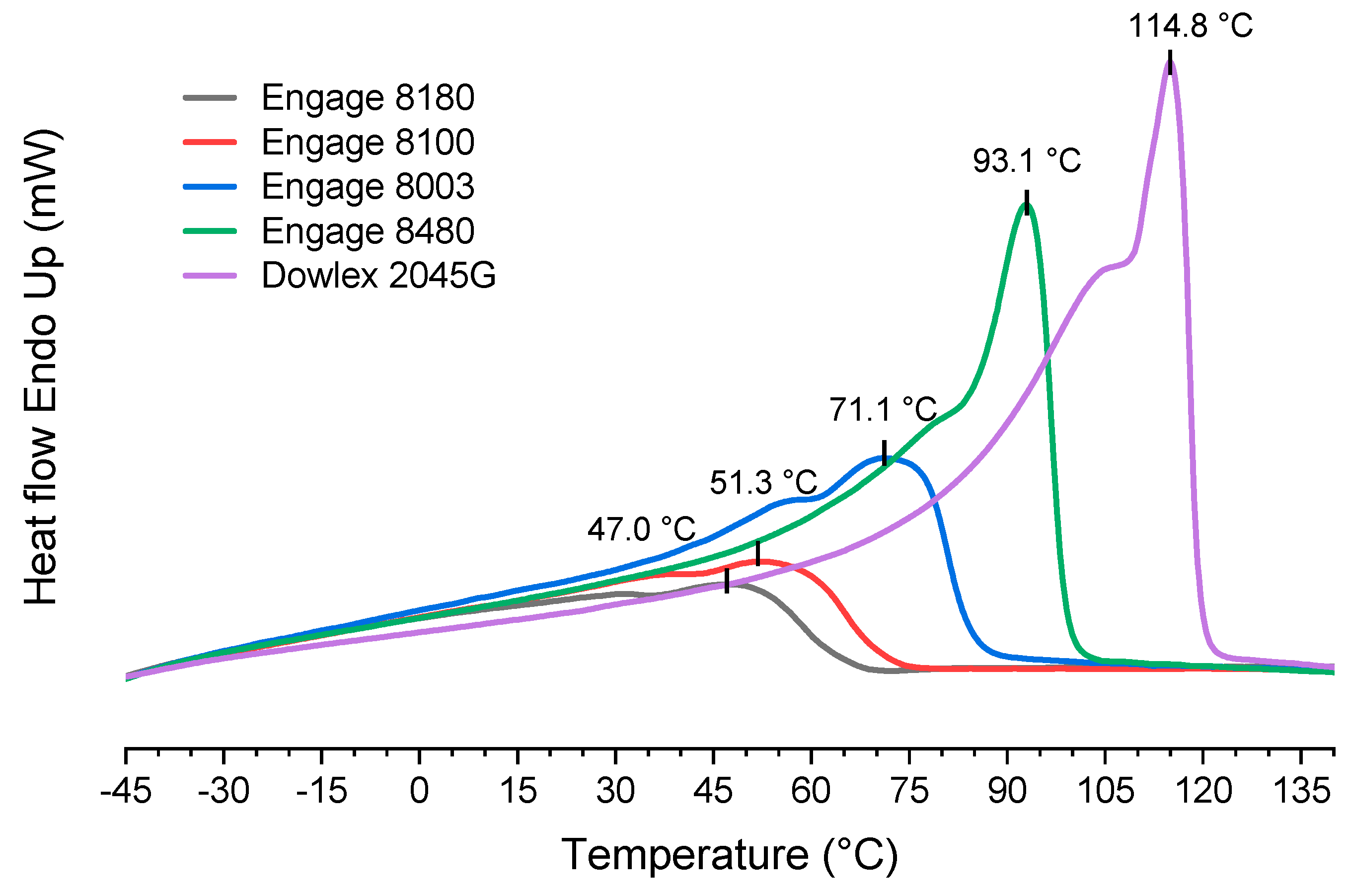

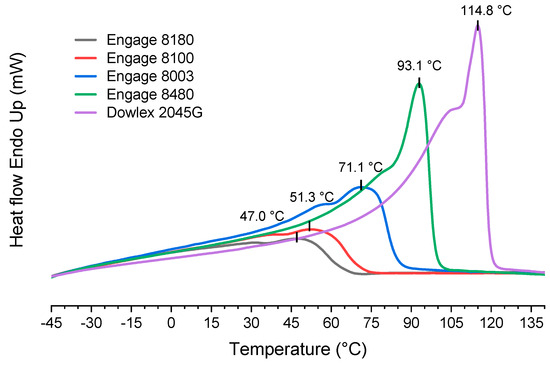

Four grades of poly(ethylene-co-octene), supplied by Dow Chemical (Dow Europe GmbH, Horgen, Switzerland) under the trade name ENGAGE™ [23,24] and characterized by different contents of comonomer, were selected. As LLDPE, Dowlex 2045G, was selected, a C8-LLDPE ethylene–octene copolymer from Dow Chemical was produced with metallocene catalysis in the solution process. The characteristics of the polyolefins are summarized in Table 1, and the second DSC heating scan is shown in Figure 1.

Table 1.

Characteristics of C8-POE samples.

Figure 1.

DSC second heating scans of C8-POE and LLDPE.

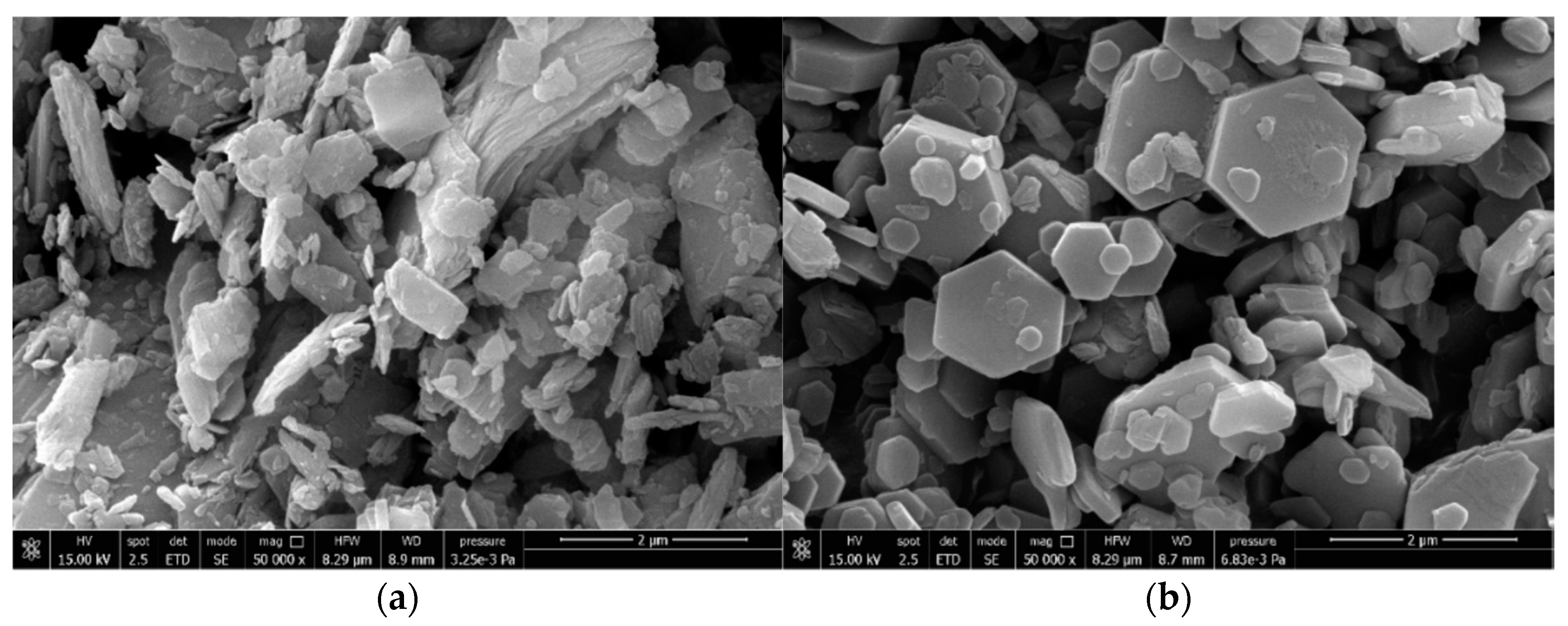

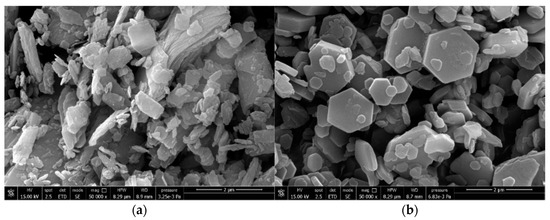

The used MDH was Ecopiren 3.5 (micronized brucite, n-MDH), supplied by Europiren (Rotterdam Science Tower, Rotterdam, The Netherlands) at 92% purity, D50 = 3.5–4 μm, and a surface area of 11 m2/g. Figure 2 compares the needle-like morphological structure of natural magnesium hydroxide in comparison to the hexagonal structure of synthetic magnesium hydroxide (s-MDH).

Figure 2.

SEM micrographs of (a) n-MDH and (b) s-MDH (scale bar 2 μm).

Fusabond N525™ (Dow Europe GmbH, Horgen, Switzerland) was used as a coupling agent (maleic anhydride modified LLDPE), supplied by Dow Chemical, with a density of 0.880 g/cm3, MFI = 3.7 g/10 min 2.16 kg@190 °C and a grafting level in the range of 0.5–1 wt.%.

All blends and composites were prepared using a twin-roll mixer to obtain a good dispersion of MDH in the polymer at a temperature of 150–160 °C for 10 min.

The crystallinity of blends and composites was measured with a DSC 4000 Perkin Elmer (PerkinElmer, U.S. LLC., Shelton, CT, USA) at a heating rate of 10 °C/min under a dry nitrogen atmosphere. About 5 mg of the sample was sealed in an aluminum pan for each measurement. A heat–cool–heat cycle was used, heating up from −65 to 160 °C, then cooling to −65 °C, followed by a second heating ramp to 160 °C. The heat flow versus temperature was recorded, and the peak melting temperatures of PEO and LLDPE were obtained from the heating scans. The degree of crystallinity (XC, %) was finally calculated using Equation (2).

where ΔHfus is the melting enthalpy of the sample, ΔH0 is the melting enthalpy of the 100% crystalline polyethylene (292 J/g) [12], ΔHgraft is the melting enthalpy of the Fusabond N525, xmix is the mass fraction of polymer in the composites [27], and xgraft is the mass fraction of Fusabond N525 in the composites. The equation’s correction is because adding filler reduces the measured crystallinity.

Mechanical properties were measured with a Lloyd Instruments LS 500 dynamometer using an elongation speed of 250 mm/min at 23 °C. The width and thickness of the specimens were 4.0 mm and 2.0 mm ± 0.2 mm, respectively, and the stretched length was 20 mm ± 0.5 mm, according to the standard ISO 37 [28].

Fire properties were verified with the vertical burning test, an internal laboratory-scale test referring to the modified DIN 4102 [29] B2 test. The measurements were carried out on samples with a dimension of 200 × 140 × 1.4 mm and a graduation line of 150 mm, as shown in Figure 3. The specimen was fixed to a specimen holder, and a Bunsen burner (Fisher Scientific Italia, Segrate, Italy) flame was applied to the bottom of the sample for 2 min.

Figure 3.

Scheme of the vertical burning test.

3. Results

3.1. Crystallization Behavior of C8-POE/LLDPE Blends

Each grade of Engage™ was blended in a 3:1 (POE:LLDPE) ratio to produce four blends (Table 2).

Table 2.

Blends of C8-POE and LLDPE in a 3/1 ratio with each Engage™.

This is considered the optimum concentration in agreement with what is commonly used as the polymeric base in flame-retardant compounds for electrical cable applications. Furthermore, it provides an adequately diluted concentration to investigate the impact of a predominantly amorphous matrix (C8-POE) on LLDPE crystallization while still maintaining a high sensitivity to detect the signal of LLDPE crystallization.

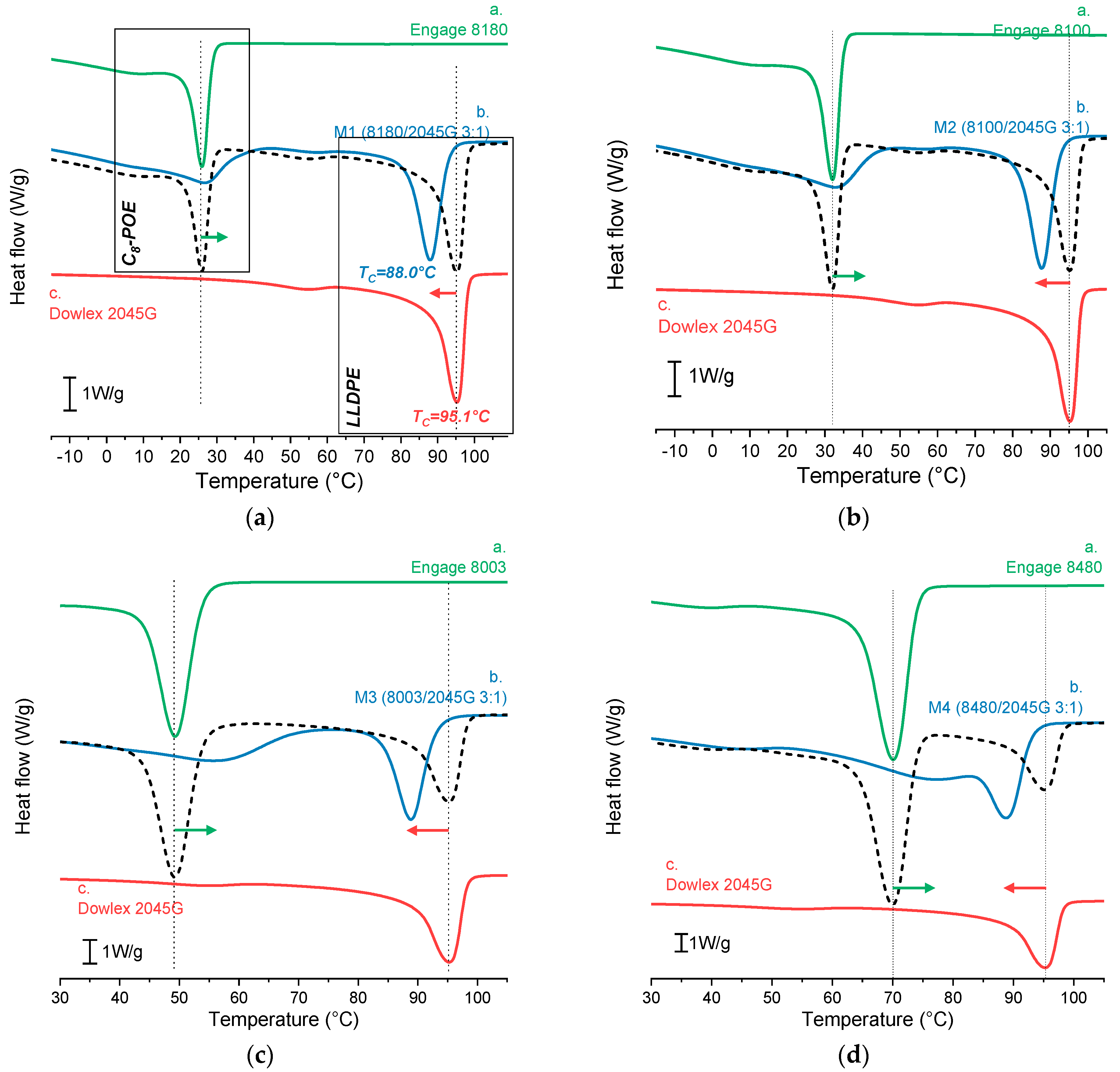

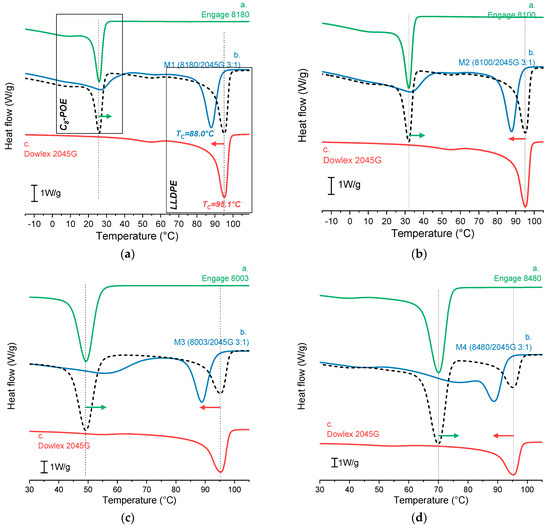

Figure 4 shows the cooling DSC curves of C8-POE, LLDPE, and their 75:25 blend, whereas Table 3 reports the crystallization temperatures (TC) of the POE and LLDPE fractions in the blend. These TC values are compared with those obtained by a linear combination of the pure polymer curves, assuming no interaction.

Figure 4.

DSC cooling traces curves a. (green line) and c. (red line) represent the pure polymers; curve b. (blue line) is the POE/LLDPE blend with a 3:1 ratio, whereas the black dashed curve is purely theoretical, and it is calculated using Origin software (version 2021) as a linear combination by multiplying each point of the curve of pure polymers (a. and c.) by its weight fraction and then summing. (a) Data for Engage 8180, M1 blend, C8-POE and Dowlex 2045G; (b) Data for Engage 8480, M4 blend, C8-POE and Dowlex 2045G; (c) Data for Engage 8003, M3 blend, C8-POE and Dowlex 2045G and (d) Data for Engage 8480, M4 blend, C8-POE and Dowlex 2045G.

Table 3.

Temperature of crystallization peaks of C8-POE/LLDPE blends.

In all figures, it is evident that the crystallization temperature (TC) of the LLDPE fraction blended with C8-POE (peak at the higher temperature of blue line b.) shifts toward lower values compared to the TC of pure LLDPE (red line c.), as evidenced by the red arrow. The shift at a lower crystallization temperature is explained as a delay in LLDPE crystallization because the concentration of LLDPE in the PEO-rich matrix is too low to form nuclei [30]. No broadening of the LLDPE crystallization peak is observed.

On the contrary, for the C8-POE fraction within the blend, the crystallization temperature (peak at the lower temperature of line b.) is shifted to higher values than the TC of pure C8-POE (green line a.). In this case, the crystallites of the already solidified LLDPE act as nucleating agents for the C8-POE (less crystalline and with a lower Tc), causing it to crystallize at a higher temperature [31]. Furthermore, the C8-POE signal in the blend is significantly broader than the calculated signal, indicating a strong influence of the intermixing with the LLDPE and the co-crystallization with the C8-POE.

Additionally, it can be observed that the advance of the C8-POE crystallization temperature (ΔTPOE = TC (MX) − TC (MX calculated)) increases as the comonomer content decreases: for C8-POE copolymers with a lower comonomer concentration (=higher ethylene content), co-crystallization with LLDPE is the favorite, and the Tc is higher than for more amorphous C8-POE.

Similarly, Table 4 shows the crystallization enthalpies for all C8-POE/LLDPE blends.

Table 4.

Enthalpy of the crystallization peaks of C8-POE/LLDPE blends.

In this case, it can be observed that the crystallization enthalpies of POE and LLPDE are slightly lower than those calculated as a linear combination of the two pure polymers, and there is no trend as the comonomer content changes.

3.2. Crystallization Behavior of C8-POE/LLDPE/n-MDH Composites

Mineral particles may trigger the nucleation and growth of C8-POE crystals. This could also be the case of n-MDH, which is obtained by micronizing brucite and used as a flame retardant in HFFR polyolefin compounds for electric cables. Table 5 shows the twelve formulations prepared, containing 36.8 wt.% C8-POE+LLDPE, 60 wt.% MDH, 3 wt.% coupling agent (Fusabond N525), and 0.2 wt.% phenolic antioxidant stabilizer (Irganox 1010 (BASF Corporation, Dispersions and Pigments, Charlotte, NC, USA)). Among these, the A series is based on neat C8-POE, and the B and C series have a POE/LLDPE ratio of 3:1 and 1:1, respectively. The latter ratio was investigated because a higher concentration of LLDPE gives both economic and performance benefits. The economic advantages are due to the lower cost of the polymer, while the performance benefits are associated with a higher tensile strength. These formulations were studied in previous work [32], but no studies about the contribution of the C8-POE and LLDPE contents to the ultimate properties of the composites were investigated.

Table 5.

Compounds based on neat C8-POE (series A), C8-POE/LLDPE mix 3/1 ratio (series B), and C8-POE/LLDPE mix 1/1 ratio (series C), with the relative characteristics (density and MFI).

DSC thermograms were recorded for each C8-POE/LLDPE/n-MDH composite and compared with related C8-POE/LLDPE blends with the same C8-POE/LLDPE ratio and pure polymers.

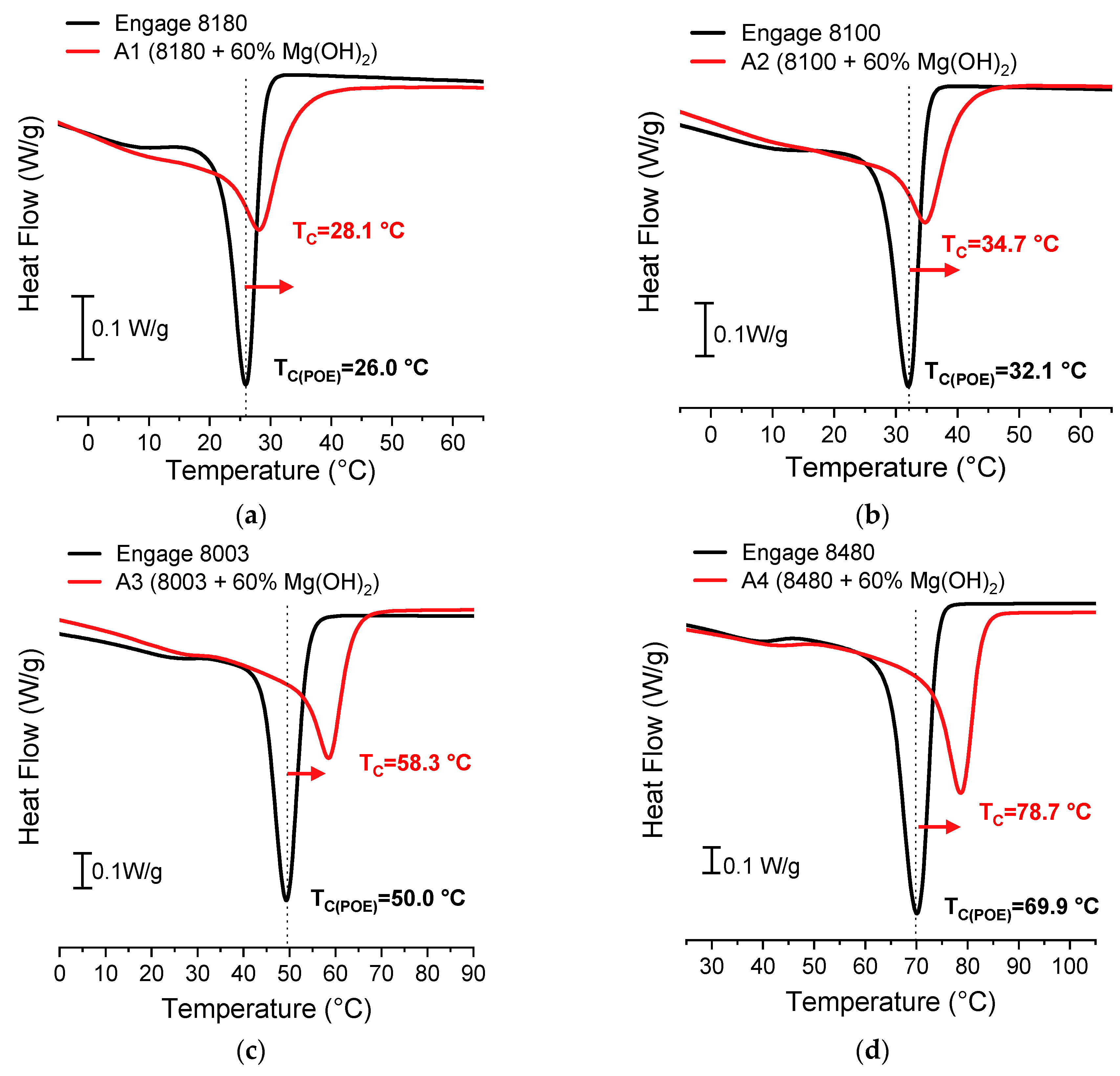

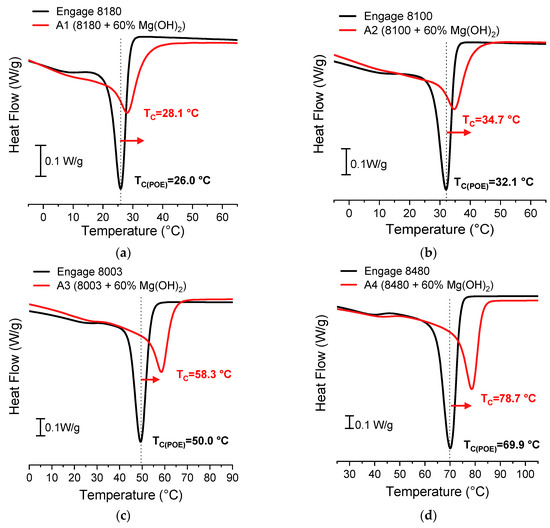

Figure 5 shows cooling DSC curves of the type “A” formulations based on C8-POE versus the respective pure polymers.

Figure 5.

Zoom of cooling scans of pure C8-POE (black line) and Engage/60% MDH composites (red line, type “A” formulations as in Table 5): (a) Engage 8180; (b) Engage 8100; (c) Engage 8003; and (d) Engage 8480.

As expected, an increase in crystallization temperature can be observed in the presence of MDH particles, which may be attributed to the heterogeneous nucleation caused by the fillers [33].

Table 6 shows the TC and ΔHC values recorded for all C8-POE+n-MDH composites compared to pure C8-POE. It can be observed that the addition of MDH increases the peak crystallization temperatures by 2.1 °C for the low crystallinity formulation (A1) and by 8.8 °C for the high crystallinity formulation (A4), following a regular trend by moving from amorphous to more crystalline C8-POE grades. Similarly, the ΔHC of formulation “A” is influenced by the comonomer content. In particular, there is a greater deviation from the enthalpy of the pure polymer as the comonomer content decreases. This greater sensitivity of highly crystalline polymers to filler could be due to the fact that filler disturbs the alignment of the molecular chains more significantly. However, in all cases, lower enthalpy values are obtained compared to pure polymers due to the high concentration of filler that disturbs crystallization; this is in line with the study of Chen et al. [34].

Table 6.

TC and ΔHC of “A” formulations and pure polymers and crystallinity (XC) of “A” formulations.

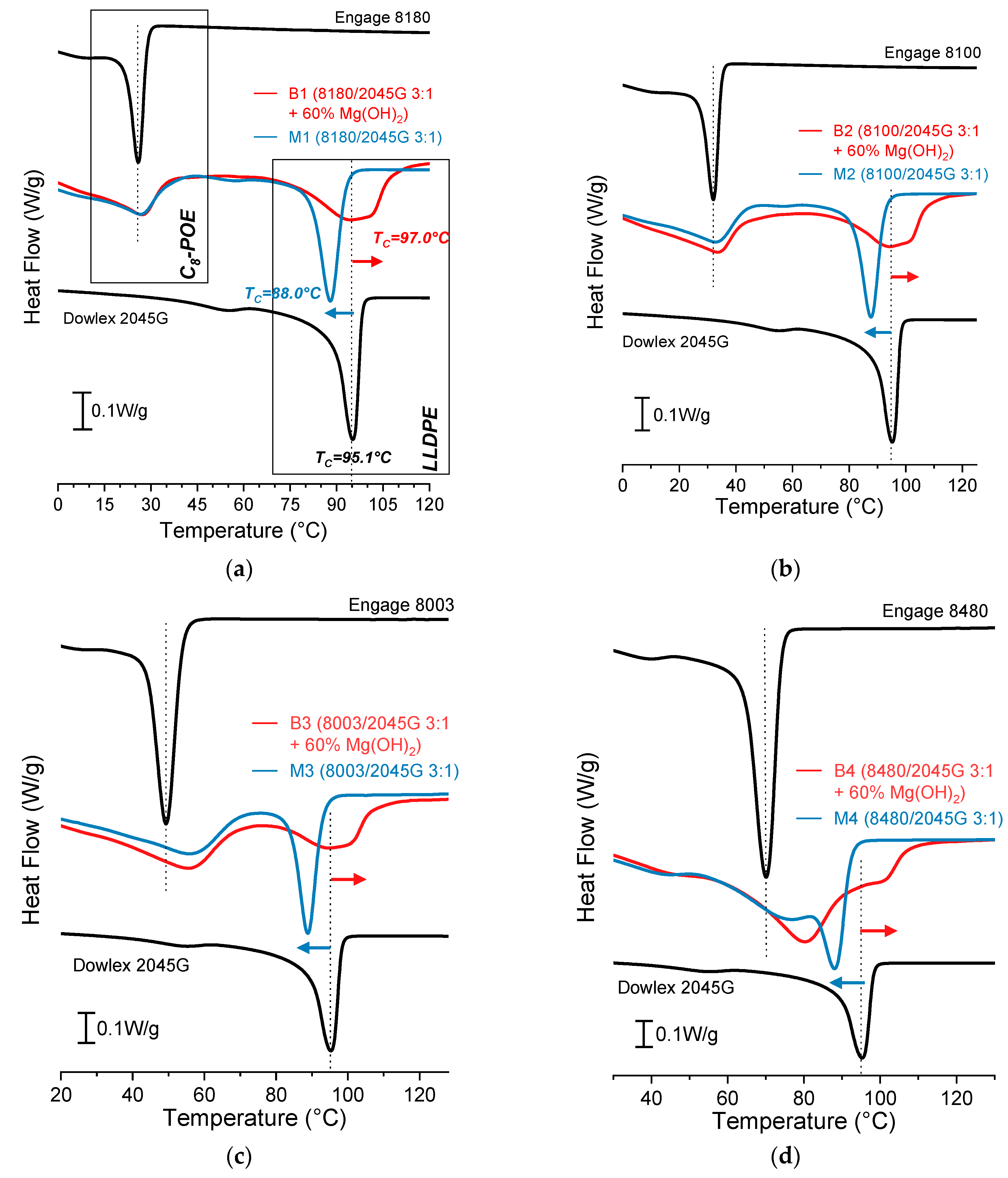

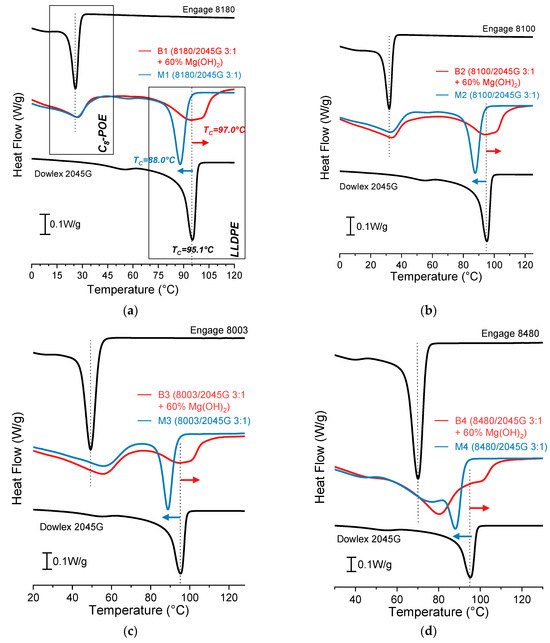

Figure 6 shows cooling DSC curves of the type “B” formulations (filled C8-POE/LLDPE blends) and the respective pure polymers and polymer blends.

Figure 6.

DSC cooling scans of pure polymer (black line), C8-POE/LLDPE blends 3/1 ratio (blue line), and C8-POE/LLDPE/60% MDH compounds (red line), type “B” formulations as in Table 5: (a) Engage 8180; (b) Engage 8100; (c) Engage 8003; and (d) Engage 8480.

In the presence of n-MDH particles, only the LLDPE fraction of the C8-POE/LLDPE/n-MDH composite shows an increase in crystallization temperature. There is no significant effect on the TC of the C8-POE. The nucleating role of the additives is, therefore, evident only for the LLDPE, that is, the polyolefin with the highest crystallinity [35]. There is also a broadening of the crystallization peaks of the composites compared to pure polymers: the presence of the mineral particles leads to the formation of crystals of several different sizes, which is reflected in their different thermal stability. These results possibly indicate a certain interaction between the polymeric matrix and the mineral triggered by the presence of the LLDPE-g-MAH coupling agent.

Table 7 and Table 8 show the TC and ΔHC values of C8-POE/LLDPE/n-MDH composites in comparison with pure C8-POE and C8-POE/LLDPE blends (M). The overlapping DSC peaks were deconvoluted using peakfit software v4.12 (systat) in order to calculate the enthalpy of crystallization provided by each of the two polymers present. The integration ranges for formulations B1/M1 and B2/M2 were between 115 °C and −15 °C, those for formulations B3/M3 were between 115 °C and −5 °C, and those for formulations B4/M4 were between 115 °C and 10 °C.

Table 7.

Crystallization temperature of C8-POEs, LLDPE, C8-POE+LLDPE blends, and C8-POE+LLDPE+n-MDH composites.

Table 8.

Crystallization enthalpy of C8-POEs, LLDPE, C8-POE+LLDPE blends, and C8-POE+LLDPE+n-MDH composites and crystallinity (XC) of “B” formulations.

The TC of the C8-POE fraction in C8-POE+LLDPE+n-MDH composites and C8-POE+LLDPE blends (peaks at lower temperatures of the red and blue lines, respectively) are similar and higher than that of pure C8-POE (upper black line). Therefore, the main evident nucleating effect is addressed to the already crystallized LLDPE rather than to mineral particles. Regarding the LLDPE fraction, it can be observed that the TC of C8-POE+LLDPE polymer blends (peak at a higher temperature of the blue line) is significantly lower than that of pure LLDPE (lower black line). However, the opposite behavior occurs for C8-POE+LLDPE+n-MDH composites (peak at a higher temperature in the red line), with a TC higher than that of pure LLDPE (lower black line). This means that the nucleating effect of mineral particles of n-MDH (that is, TC increasing) is more than enough to compensate for the “dilution” effect of amorphous C8-POE (that is, TC reducing), as demonstrated by that measured for C8-POE+LLDPE polymer blends. Furthermore, in all formulations (C8-POE+LLDPE+n-MDH composites and C8-POE+LLDPE blends), the crystallinity enthalpies of both C8-POE and LLDPE fractions are lower than those of the pure polymer.

3.3. Influence of n-MDH Content on Composites TC

Two new formulations, reported in Table 9, were produced and analyzed by DSC. The values of TC and crystallization enthalpy are shown in Table 10.

Table 9.

Formulations of C8-POE+LLDPE+n-MDH composites with C8-POE:LLDPE = 3:1 and different n-MDH contents.

Table 10.

Crystallization temperature and enthalpy of Engage 8003+LLDPE blends and Engage 8003+LLDPE+n-MDH composites with different MDH content (20%, 40%, and 60%).

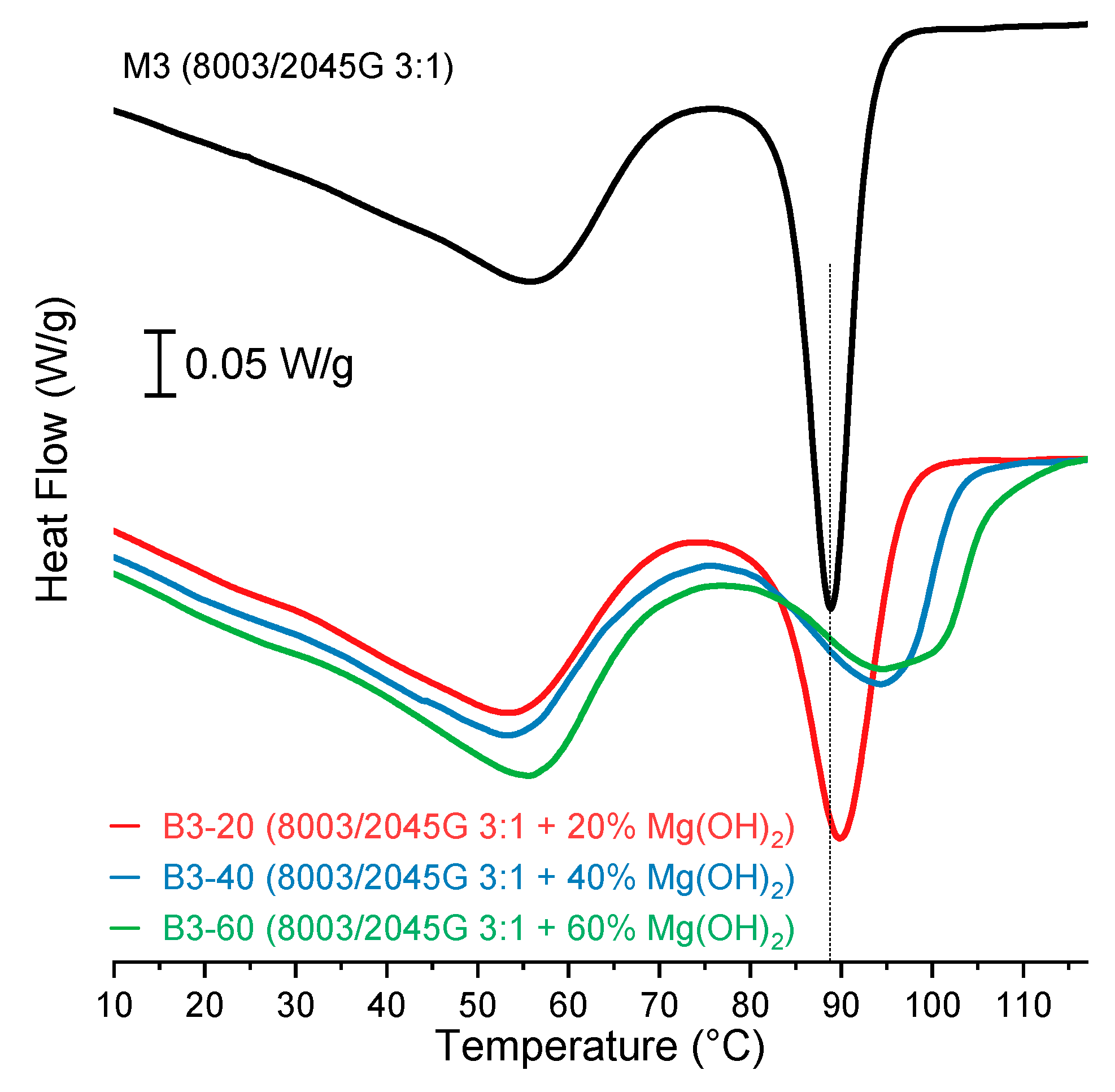

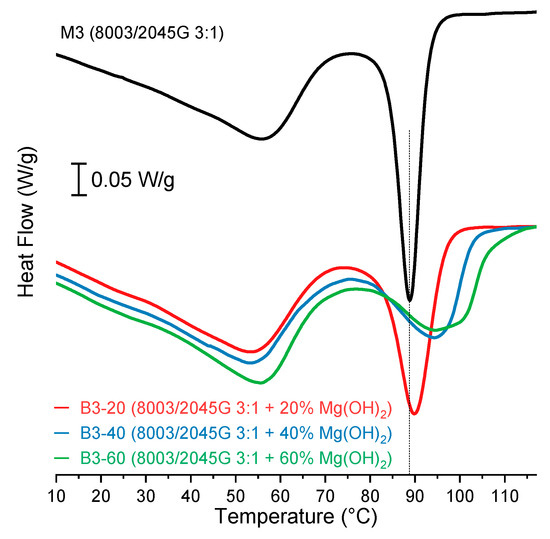

The cooling thermograms of the B3-60, B3-20, and B3-40 formulations were reported in Figure 7.

Figure 7.

Effect of MDH content on the crystallization temperature of the prepared formulations.

It can be observed that the TC of the LLDPE fraction increases in agreement with the quantity of filler (TC (B3-60) > TC (B3-40) > TC (B3-20)). Also, the broadening of the crystallization peak of the LLDPE fraction is apparent as the filler fraction increases. This phenomenon may be ascribed to different heterogeneous nucleation mechanisms [33] leading to the formation of LLDPE crystals of different sizes and, as already noted, possibly addressed to the effective interaction between the polymeric matrix and the mineral provided by the LLDPE-g-MAH coupling agent. On the other hand, with increasing mineral content, there is no significant effect on the TC of the C8-POE fraction or on the crystallization enthalpy of the C8-POE and LLDPE fractions.

3.4. Tensile Properties of C8-POE+LLDPE+n-MDH Composites

Depending on the degree of crystallinity, polymers have different mechanical properties. In the C8-POE+LLDPE+n-MDH composites, the presence of the maleated LLDPE-g-MAH coupling agent influences the final mechanical behavior.

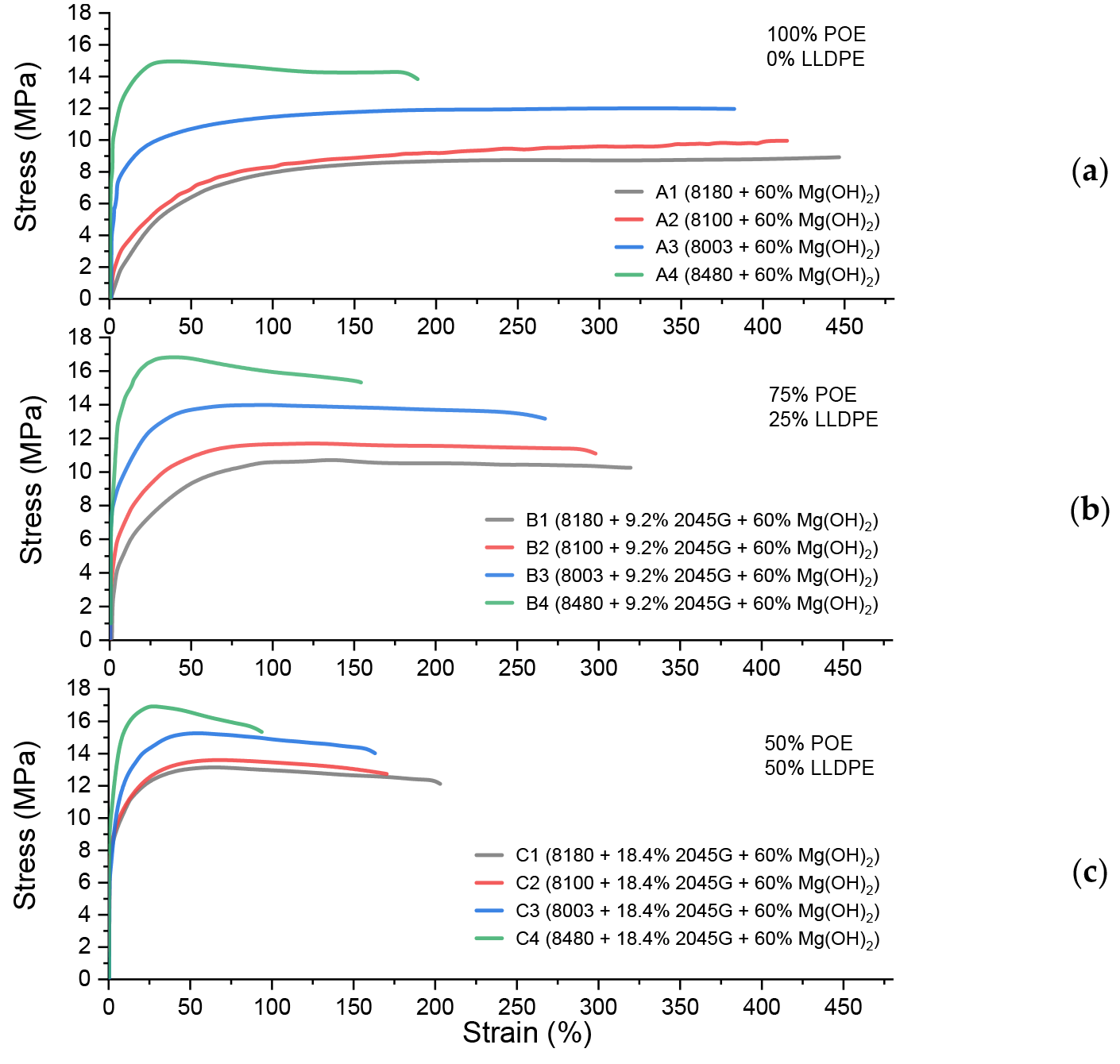

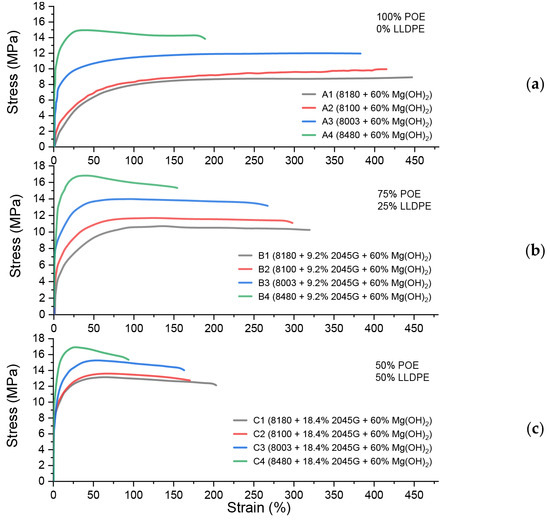

The C8-POE/LLDPE/n-MDH composites were tested via stress–strain experiments, and the curves are shown in Figure 8. Table 11 reports the values of elongation at break, Young’s modulus, and tensile strength in relation to crystallinity values.

Figure 8.

Stress-strain curve of (a) type “A” formulation, (b) type “B” formulation, and (c) type “C” formulation (for the thermal properties, refer to Figure S1 and Table S1).

Table 11.

Physical properties (DSC crystallinity, tensile strength (TS), elongation at break (E@B), Young’s modulus) of the C8-POE+LLDPE+n-MDH composites.

As expected, the composites without LLDPE and based only on C8-POE (A1, A2, A3, and A4) show higher elongation at break in comparison to composites containing LLDPE, thanks to the more amorphous polymeric matrix. For the same reason, by comparing the A1 vs. A2 vs. A3 vs. A4 composites, we observe a clear increase in tensile properties and a decrease in elongation [36]. As expected, the introduction of LLDPE leads to a decrease in E@B and an increase in tensile properties due to the higher crystallinity of the composite.

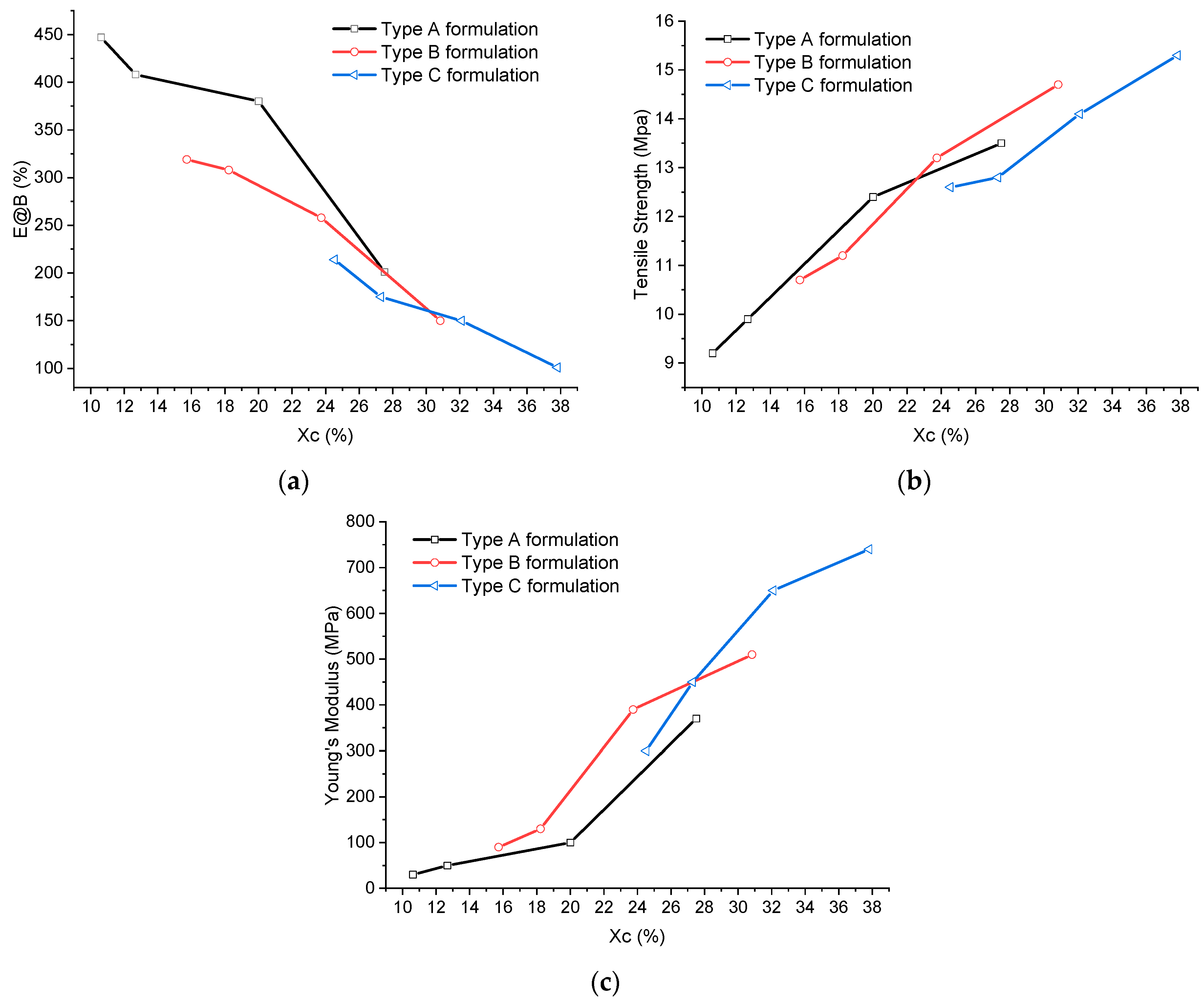

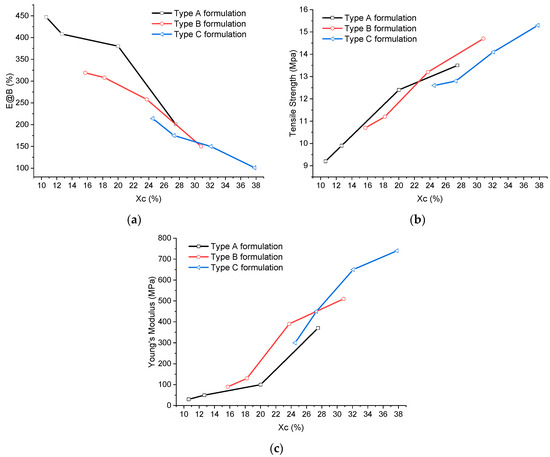

Figure 9 shows the mechanical properties of all the formulations as a function of the crystallinity.

Figure 9.

Trend of mechanical properties as a function of crystallinity: (a) elongation at break, (b) tensile strength, and (c) Young’s modulus.

An almost linear trend with increasing crystallinity can be observed for all the investigated mechanical properties. Notably, there is an increase in tensile strength and modulus and a decrease in elongation at break. The desired mechanical properties can be achieved by controlling the total crystallinity of the polymer matrix. This is independent of the method employed to achieve crystallinity: it is possible to combine the more crystalline POE with a smaller amount of LLDPE or the more amorphous POE with a larger amount of LLDPE.

3.5. Fire Performance of the Highly Filled POE Compounds

In the field of electrical cables, vertical burning tests are widely used as a screening method to assess their relative flammability and performance relatively quickly.

The results of the vertical burning test are shown in Table 12.

Table 12.

Experimental results obtained from the vertical burning test of all formulations.

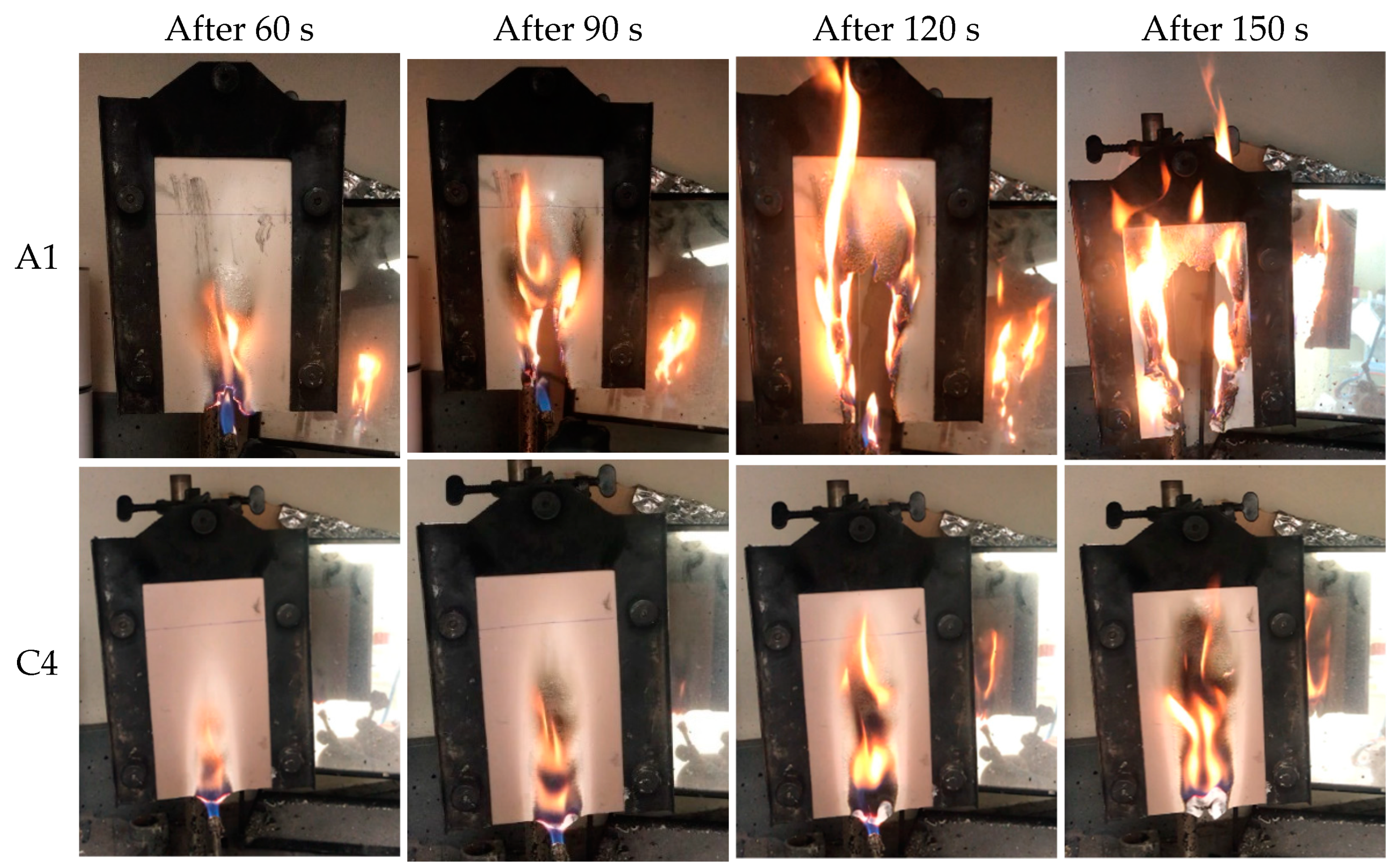

A delay in flame propagation (higher t2) and dripping can be observed as crystallinity increases. This may be due to a combination of higher thermal resistance and a more compact structure than more amorphous polymers, which limits dripping. A decrease in t1 is also observed, but this value is influenced by various factors, such as the height of the flame. The same value can be obtained for a composite that burns slowly but with a long flame or for a composite that burns quickly but with a short flame. On the other hand, there are no significant differences in the height and width of the flame.

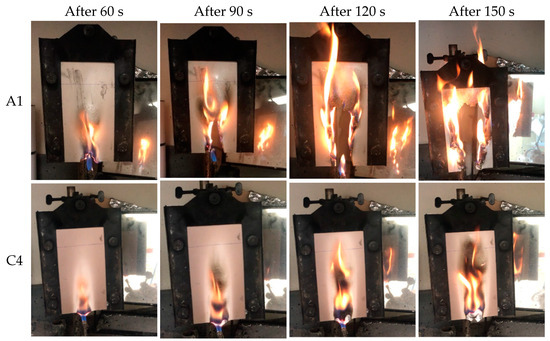

Figure 10 shows the photos of the fire test to better appreciate the marked difference between the lower crystallinity formulation (A1) and the higher crystallinity formulation (C4).

Figure 10.

Vertical burning comparison between compounds with lower crystallinity (A1 = Engage 8180/60% Mg(OH)2) and compounds with higher crystallinity (C4 = Engage 8480/Dowlex 2045G/60% Mg(OH)2 with 1:1 polymer ratio).

It can be observed that after 150 s, the flame base of formulation A1 has already reached the graduation line, while the flame base of formulation C4 is still at the beginning of the specimen.

4. Conclusions

Electrical cable compounds require strong mechanical properties and flame resistance. This performance is achieved using POE with different comonomer (1-octene) content combined with LLDPE and through the incorporation of flame-resistant metal hydroxides into the polymer matrix.

Firstly, the effect of blending LLDPE and various POEs with different 1-octene contents was investigated. Our studies suggested that there is a delay in the crystallization of the LLDPE fraction. This delay is independent of the type of POE used and is merely due to the dilution effect of the POE fraction on the LLDPE fraction. An advance in the crystallization of the POE fraction was also observed. This advance correlated with comonomer content: for POE with a lower 1-octene content, the advance was more significant than for POE with a higher 1-octene content. This phenomenon is due to the already-formed LLDPE crystals acting as nucleating agents for the POE fraction.

For the C8-POE/n-MDH composites, the influence of filler addition on the crystallization of each POE with different 1-octene contents was investigated. Our studies demonstrated that, in general, the introduction of n-MDH provided a strong nucleating effect, significantly accelerating the crystallization process of the polyolefin matrices examined in this work. Specifically, it was observed that the lower the comonomer content in the POE, the higher the increase in the crystallization temperature of C8-POE.

For C8-POE+LLDPE+n-MDH composites, the combined effect of filler addition and blending LLDPE with each POE at different 1-octene contents was studied. Among the two opposing effects of C8-POE (reducing TC) and n-MDH (increasing TC) on the TC of LLDPE, the nucleating effect provided by the inorganic particles was predominant. On the other hand, there is no effect of the filler on the crystallization of the POE fraction. The TC of LLDPE was also influenced by the amount of n-MDH: the lower the amount of n-MDH, the lower the measured TC.

In terms of crystallization enthalpy, both polymer blending and the introduction of n-MDH reduced the crystallinities of the pure polymers.

As expected, the higher the crystallinity of the polymer matrix, the higher the tensile strength and Young’s modulus, and the lower the elongation at break. The increase in crystallinity also results in a delay in the propagation of the flame and in the drip time.

These compounds are suitable for designing cables complying with the EN 50399 [37] fire test as per CPR (Construction Production Regulation) in Europe for building power cables. The tests for electrical cables in Europe are conducted under highly demanding conditions, typically lasting around 40 mi, with powerful burners. This extended application of fire allows the magnesium hydroxide to reach the necessary temperature to decompose, releasing water and acting as an effective flame retardant. In a future study, we will use cone calorimeters for the evaluation of the flame retardancy of this kind of compound, as we did in the past [38].

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/eng5030109/s1, Figure S1: DSC cooling scans of type “C” formulations (C8-POE/LLDPE/60% MDH compounds with 1:1 polymer ratio), as in Table 5, Table S1: Crystallization temperature of C8-POEs, LLDPE, and C8-POE+LLDPE+n-MDH composites with 1:1 polymer ratio.

Author Contributions

Conceptualization, V.M.; formal analysis, V.M. and M.M.; investigation, V.M.; data curation, S.H.; writing—original draft preparation, V.M.; writing—review and editing, A.P.; supervision, C.C.; project administration, C.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data available upon request.

Acknowledgments

Europiren B.V. and Dow Europe are kindly acknowledged for supplying the raw materials Ecopiren® and ENGAGE®, respectively, and related information. Figures were created with BioRender.com.

Conflicts of Interest

Michela Meucci, Sara Haveriku and Camillo Cardelli were employed by Ipool Srl, Spin-Off Company of National Council of Research Institute (CNR). Vanessa Matteucci is a PhD student that conducts her work in collaboration with Ipool Srl. The remaining author declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Bar, M.; Alagirusamy, R.; Das, A. Flame retardant polymer composites. Fibers Polym. 2015, 16, 705–717. [Google Scholar] [CrossRef]

- Hu, Y.; Qian, X.; Song, L.; Lu, H. Polymer/Layered compound nanocomposites: A way to improve fire safety of polymeric materials. Fire Saf. Sci. 2014, 11, 66–82. [Google Scholar] [CrossRef]

- Kim, Y.; Lee, S.; Yoon, H. Fire-Safe polymer composites: Flame-retardant effect of nanofillers. Polymers 2021, 13, 540. [Google Scholar] [CrossRef] [PubMed]

- Nilsson, N.; Fischer, C.H.; Lassen, C.; Møller, C.; Brogaard, N.L. Fire Safety Requirements and Alternatives to Brominated Flame- Retardants. Minist. Environ. Food Den. 2016, 1822, 1–72. [Google Scholar]

- Konstantinova, A.; Yudaev, P.; Shapagin, A.; Panfilova, D.; Palamarchuk, A.; Chistyakov, E. Non-Flammable Epoxy Composition Based on Epoxy Resin DER-331 and 4-(β-Carboxyethenyl)phenoxy-phenoxycyclotriphosphazenes with Increased Adhesion to Metals. Sci 2024, 6, 30. [Google Scholar] [CrossRef]

- Li, Y.; Qi, L.; Liu, Y.; Qiao, J.; Wang, M.; Liu, X.; Li, S. Recent Advances in Halogen-Free Flame Retardants for Polyolefin Cable Sheath Materials. Polymers 2022, 14, 2876. [Google Scholar] [CrossRef]

- Sharma, V.; Agarwal, S.; Mathur, A.; Singhal, S.; Wadhwa, S. Advancements in nanomaterial based flame-retardants for polymers: A comprehensive overview. J. Ind. Eng. Chem. 2024, 133, 38–52. [Google Scholar] [CrossRef]

- Wei, M.; Murphy, D.; Barry, C.; Mead, J. Halogen-Free Flame Retardants for Wire and Cable Applications. Rubber Chem. Technol. 2010, 83, 282–302. [Google Scholar] [CrossRef]

- PINFA. Flame Retardants in Electric and Electronic. 2017. Available online: https://www.pinfa.eu/wp-content/uploads/2018/05/PINFA_EE_brochure_Edition_2017-11.pdf (accessed on 1 January 2022).

- Haveriku, S.; Meucci, M.; Badalassi, M.; Cardelli, C.; Pucci, A. Rheological and Aesthetical Properties of Polyolefin Composites for Flame Retardant Cables with High Loading of Mineral Fillers. Micro 2022, 2, 524–540. [Google Scholar] [CrossRef]

- Gupta, V.; Jain, D. Optimization of Halogen Free Flame Retardant Wire and Cable Compounds; Pluss Polymer: Bawal, India, 2007. [Google Scholar]

- Haveriku, S.; Meucci, M.; Badalassi, M.; Cardelli, C.; Ruggeri, G.; Pucci, A. Optimization of the Mechanical Properties of Polyolefin Composites Loaded with Mineral Fillers for Flame Retardant Cables. Micro 2021, 1, 102–119. [Google Scholar] [CrossRef]

- Prabhakar, M.N.; Shah, A.U.R.; Song, J.-I. A Review on the Flammability and Flame Retardant Properties of Natural Fibers and Polymer Matrix Based Composites. Compos. Res. 2015, 28, 29–39. [Google Scholar] [CrossRef]

- Hornsby, P.R. Fire retardant fillers for polymers. Int. Mater. Rev. 2001, 46, 199–210. [Google Scholar] [CrossRef]

- Rothon, R.N.; Hornsby, P.R. Flame retardant effects of magnesium hydroxide. Polym. Degrad. Stab. 1996, 54, 383–385. [Google Scholar] [CrossRef]

- Bamford, D.; Dlubek, G.; Lüpke, T.; Kilburn, D.; Stejnv, J.; Menke, T.J.; Alam, M.A. Free volume, glass transition and degree of branching in ethylene/α-olefin copolymers: Positron lifetime, differential scanning calorimetry, wide-angle X-ray scattering, and density studies. Macromol. Chem. Phys. 2006, 207, 492–502. [Google Scholar] [CrossRef]

- Quijada, R.; Dupont, J.; Miranda, M.S.L.; Scipioni, R.B.; Galland, G.B. Copolymerization of ethylene with 1-hexene and 1-octene: Correlation between type of catalyst and comonomer incorporated. Macromol. Chem. Phys. 1995, 196, 3991–4000. [Google Scholar] [CrossRef]

- Simanke, A.G.; Galland, G.B.; Freitas, L.; Da Jornada, J.A.H.; Quijada, R.; Mauler, R.S. Influence of the comonomer content on the thermal and dynamic mechanical properties of metallocene ethylene/1-octene copolymers. Polymer 1999, 40, 5489–5495. [Google Scholar] [CrossRef]

- Dow Chemical, Dow Wire and Cable. Cable Formulations ENGAGE Polyolefin Elastomers (POE) in Halogen Free Flame Retardant Cable Formulations; Dow Europe GmbH: Horgen, Switzerland, 2000. [Google Scholar]

- Camino, G.; Maffezzoli, A.; Braglia, M.; De Lazzaro, M.; Zammarano, M. Effect of hydroxides and hydroxycarbonate structure on fire retardant effectiveness and mechanical properties in ethylene-vinyl acetate copolymer. Polym. Degrad. Stab. 2001, 74, 457–464. [Google Scholar] [CrossRef]

- McGenity, P.M.; Hooper, J.J.; Paynter, C.D.; Riley, A.M.; Nutbeem, C.; Elton, N.J.; Adams, J.M. Nucleation and crystallization of polypropylene by mineral fillers: Relationship to impact strength. Polymer 1992, 33, 5215–5224. [Google Scholar] [CrossRef]

- Rothon, R.N. Particulate-Filled Polymer Composites, 2nd ed.; iSmithers Rapra Publishing: Shrewsbury, UK, 2003; Volume 554. [Google Scholar]

- Batistini, A. New polyolefin plastomers and elastomers made with insiteTM technology: Structure—Property relationship and benefits in flexible thermoplastic applications. Macromol. Symp. 1995, 100, 137–142. [Google Scholar] [CrossRef]

- Chum, P.S.; Swogger, K.W. Olefin polymer technologies-History and recent progress at the Dow Chemical Company. Prog. Polym. Sci. 2008, 33, 797–819. [Google Scholar] [CrossRef]

- Hsu, Y.C.; Truss, R.W.; Laycock, B.; Weir, M.P.; Nicholson, T.M.; Garvey, C.J.; Halley, P.J. The effect of comonomer concentration and distribution on the photo-oxidative degradation of linear low density polyethylene films. Polymer 2017, 119, 66–75. [Google Scholar] [CrossRef]

- ASTM D1238/ISO 1133; Standard Test Method for Melt Flow Rates of Thermoplastics by Extrusion Plastometer. ASTM International: West Conshohocken, PN, USA, 2013.

- Kalantar Mehrjerdi, A.; Åkesson, D.; Skrifvars, M. Influence of talc fillers on bimodal polyethylene composites for ground heat exchangers. J. Appl. Polym. Sci. 2020, 137, 49290. [Google Scholar] [CrossRef]

- ISO 37:2017; International Standard Tensile Stress-Strain Properties. ISO: Geneva, Switzerland, 2017.

- DIN 4102; Fire Behavior of Building Materials and Elements. Deutsches Institut für Normung (DIN): Berlin, Germany, 1998.

- Li, J.; Shanks, R.A.; Olley, R.H.; Greenway, G.R. Miscibility and isothermal crystallisation of polypropylene in polyethylene melts. Polymer 2001, 42, 7685–7694. [Google Scholar] [CrossRef]

- Dikobe, D.G.; Luyt, A.S. Comparative study of the morphology and properties of PP/LLDPE/wood powder and MAPP/ LLDPE/wood powder polymer blend composites. Express Polym. Lett. 2010, 4, 729–741. [Google Scholar] [CrossRef]

- Meucci, M.; Haveriku, S.; Badalassi, M.; Cardelli, C.; Ruggeri, G.; Pucci, A. Effect of Polyolefin Elastomers’ Characteristics and Natural Magnesium Hydroxide Content on the Properties of Halogen-Free Flame-Retardant Polyolefin Composites. Micro 2022, 2, 164–182. [Google Scholar] [CrossRef]

- Karrad, S.; Lopez Cuesta, J.M.; Crespy, A. Influence of a fine talc on the properties of composites with high density polyethylene and polyethylene/polystyrene blends. J. Mater. Sci. 1998, 33, 453–461. [Google Scholar] [CrossRef]

- Chen, X.; Yu, J.; Guo, S.; Luo, Z.; He, M. Effects of Magnesium Hydroxide and Its Surface Modification on Crystallization and Rheological Behaviors of Polypropylene. Polym. Compos. 2009, 30, 941–947. [Google Scholar] [CrossRef]

- Luyt, A.S.; Malik, S.S.; Gasmi, S.A.; Porfyris, A.; Andronopoulou, A.; Korres, D.; Vouyiouka, S.; Grosshauser, M.; Pfaendner, R.; Brüll, R. Halogen-free flame-retardant compounds. Thermal decomposition and flammability behavior for alternative polyethylene grades. Polymers 2019, 11, 1479. [Google Scholar] [CrossRef] [PubMed]

- Shan, C.L.P.; Soares, J.B.P.; Penlidis, A. Mechanical properties of ethylene/1-hexene copolymers with tailored short chain branching distributions. Polymer 2001, 43, 767–773. [Google Scholar] [CrossRef]

- EN 50399; Common Test Methods for Cables under Fire Conditions—Heat Release and Smoke Production Measurement on Cables during Flame Spread Test—Test Apparatus, Procedures, Results. CENELEC: Brussels, Belgium, 2022.

- Cardelli, A.; Ruggeri, G.; Calderisi, M.; Lednev, O.; Cardelli, C. Effects of poly(dimethylsiloxane) and inorganic fillers in halogen free flame retardant poly(ethylene-co-vinyl acetate) compound: A chemometric approach. Polym. Degrad. Stab. 2012, 97, 2536–2544. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).