Stabilization of Clay Subgrade Soil by Using Waste Foundry Sand with a Geogrid

Abstract

1. Introduction

2. Literature Review

3. Material Used

3.1. Subbase Material

3.2. Clay Subgrade Soil Layer

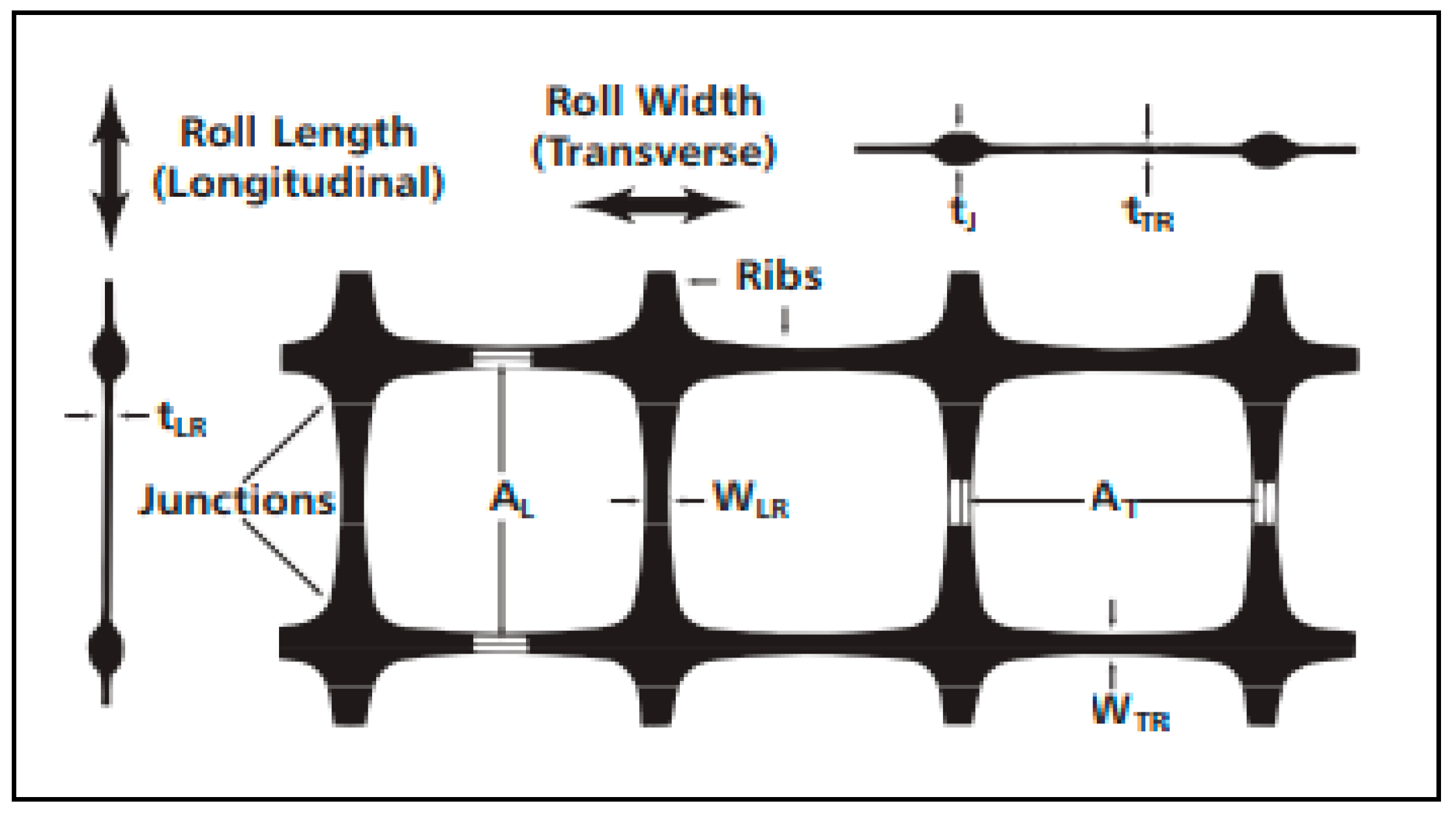

3.3. Biaxial Geogrid BX1100 (G1)

3.4. Waste Foundry Sand

4. Laboratory Testing Program

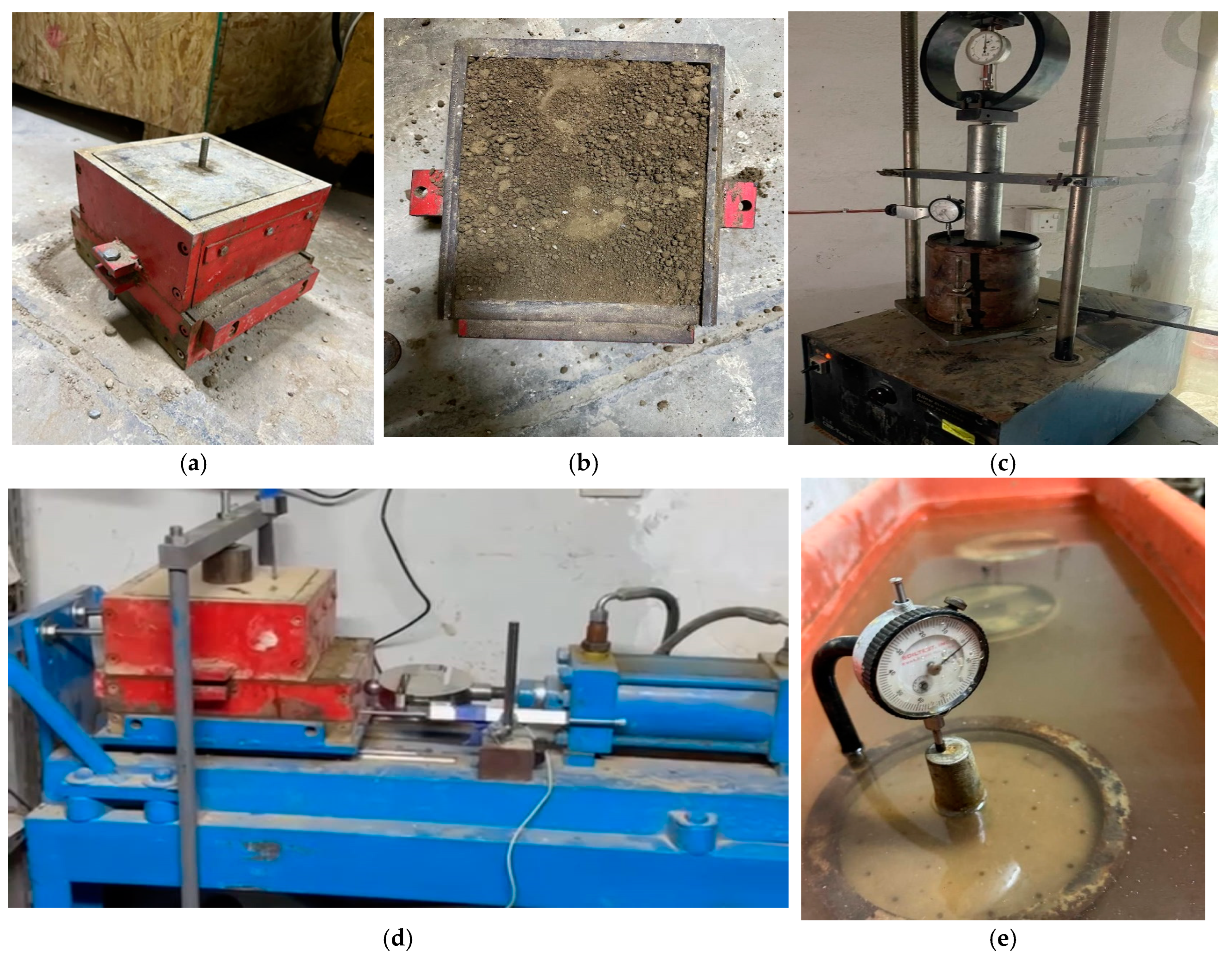

4.1. Standard Proctor Compaction Test

4.2. California Bearing Ratio Test

4.3. Direct Shear Test

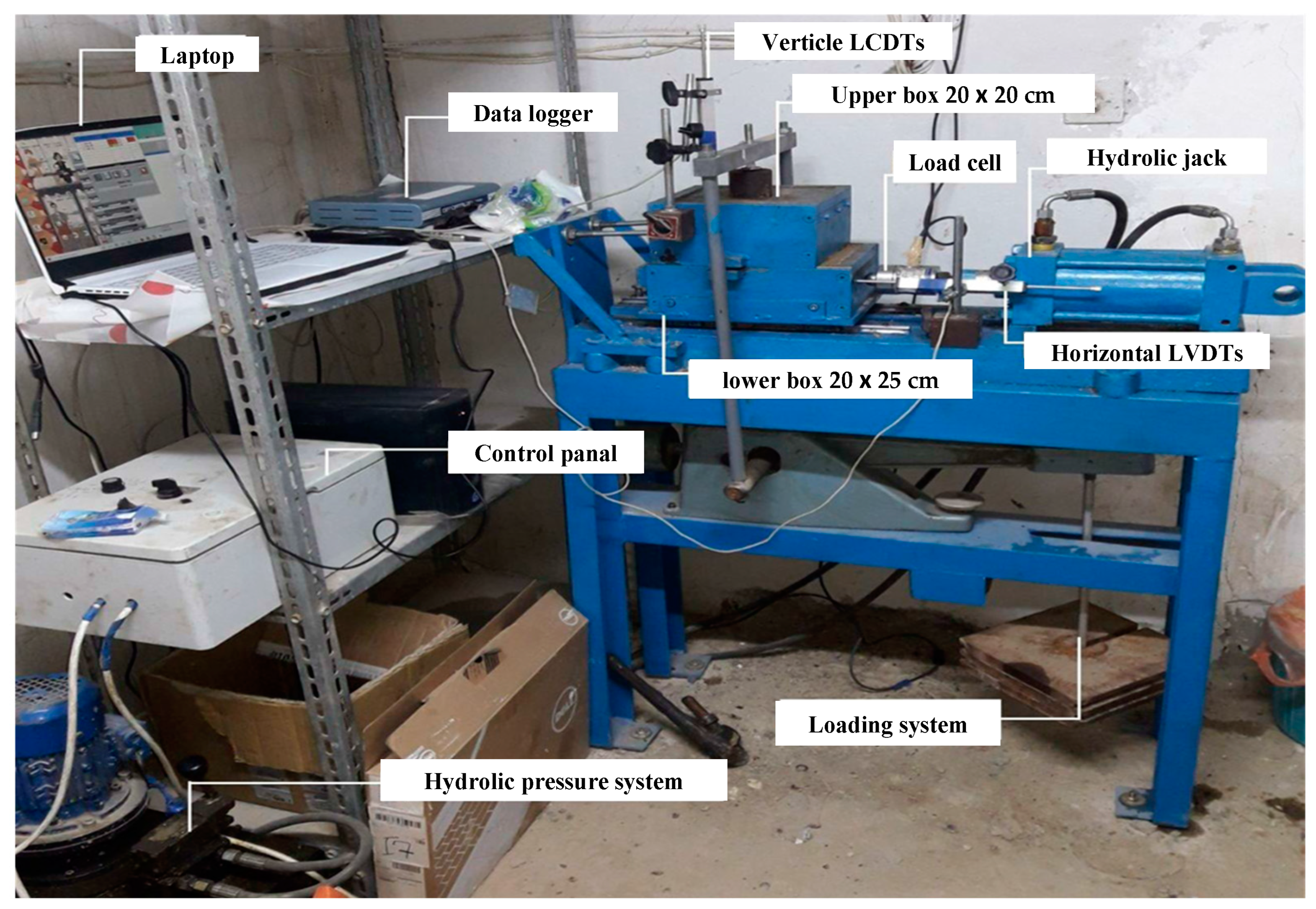

4.4. Large Size Direct Shear Device

4.5. Program for Contact Testing

4.6. Test Setup and Procedure

4.7. Failure Criterion

5. Results and Discussion

5.1. Evaluation of the Engineering Properties of the Stabilized Soil Results

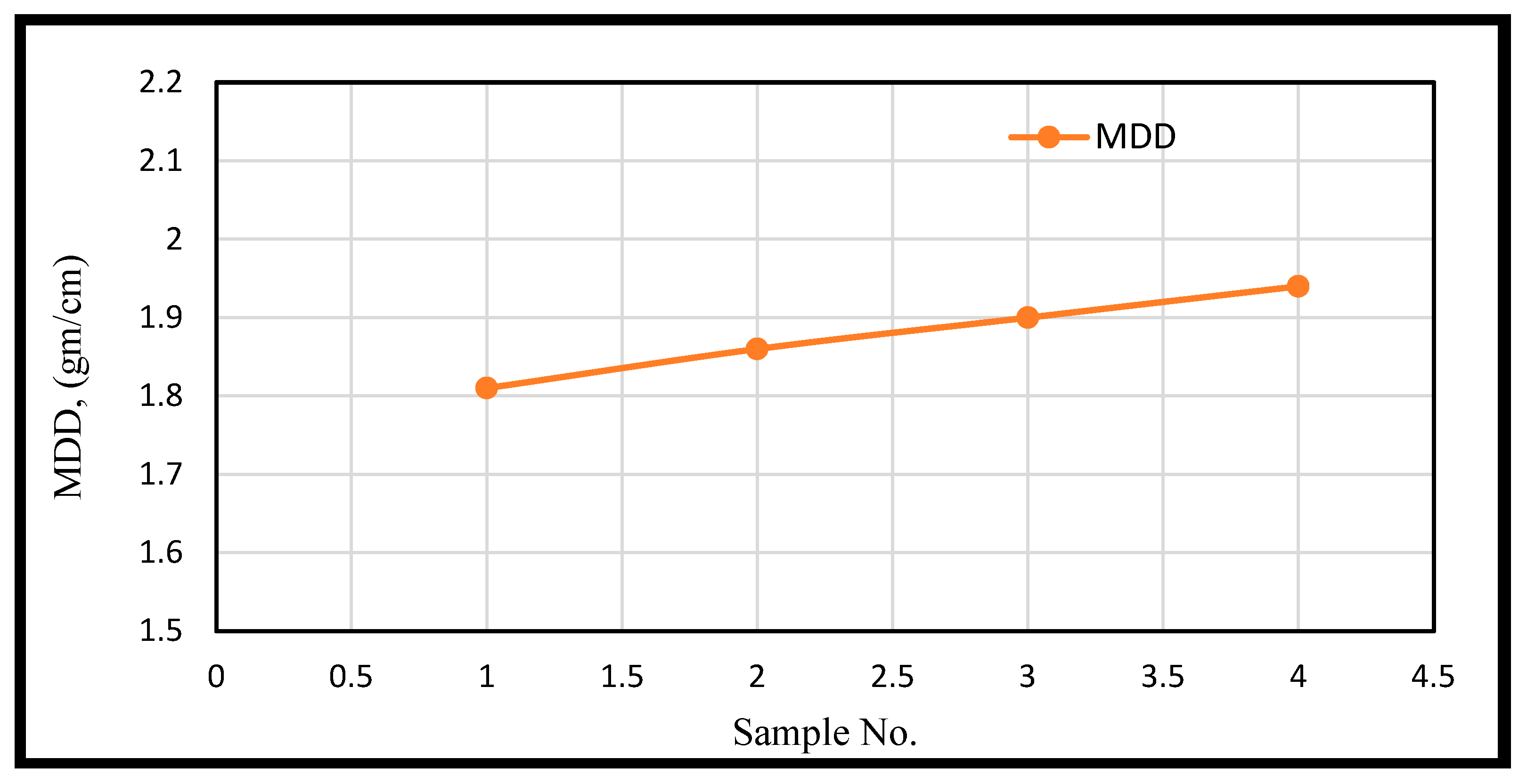

5.1.1. Peak Dry Density and Optimal Moisture Content

5.1.2. Results of the California Bearing Ratio Test

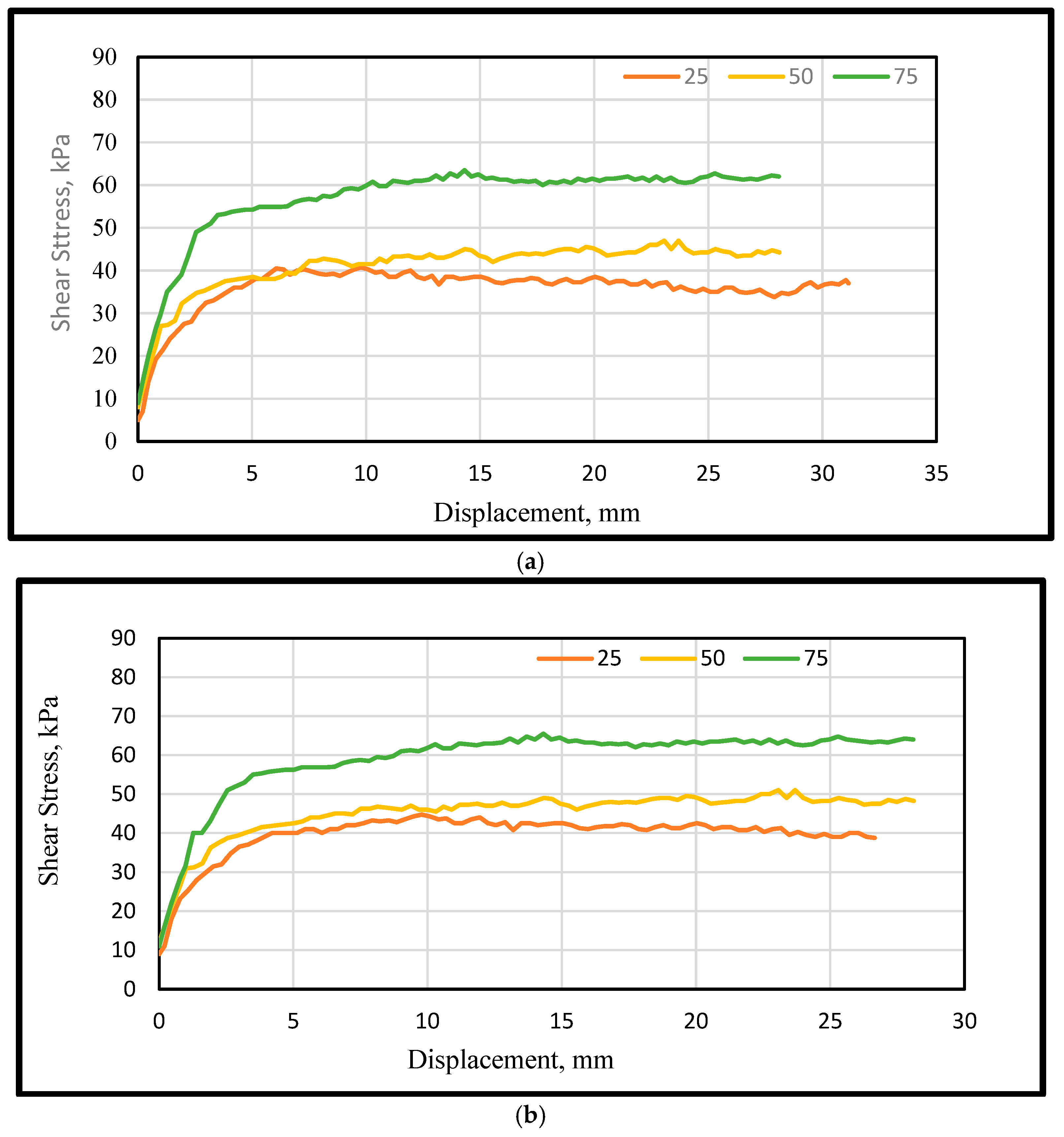

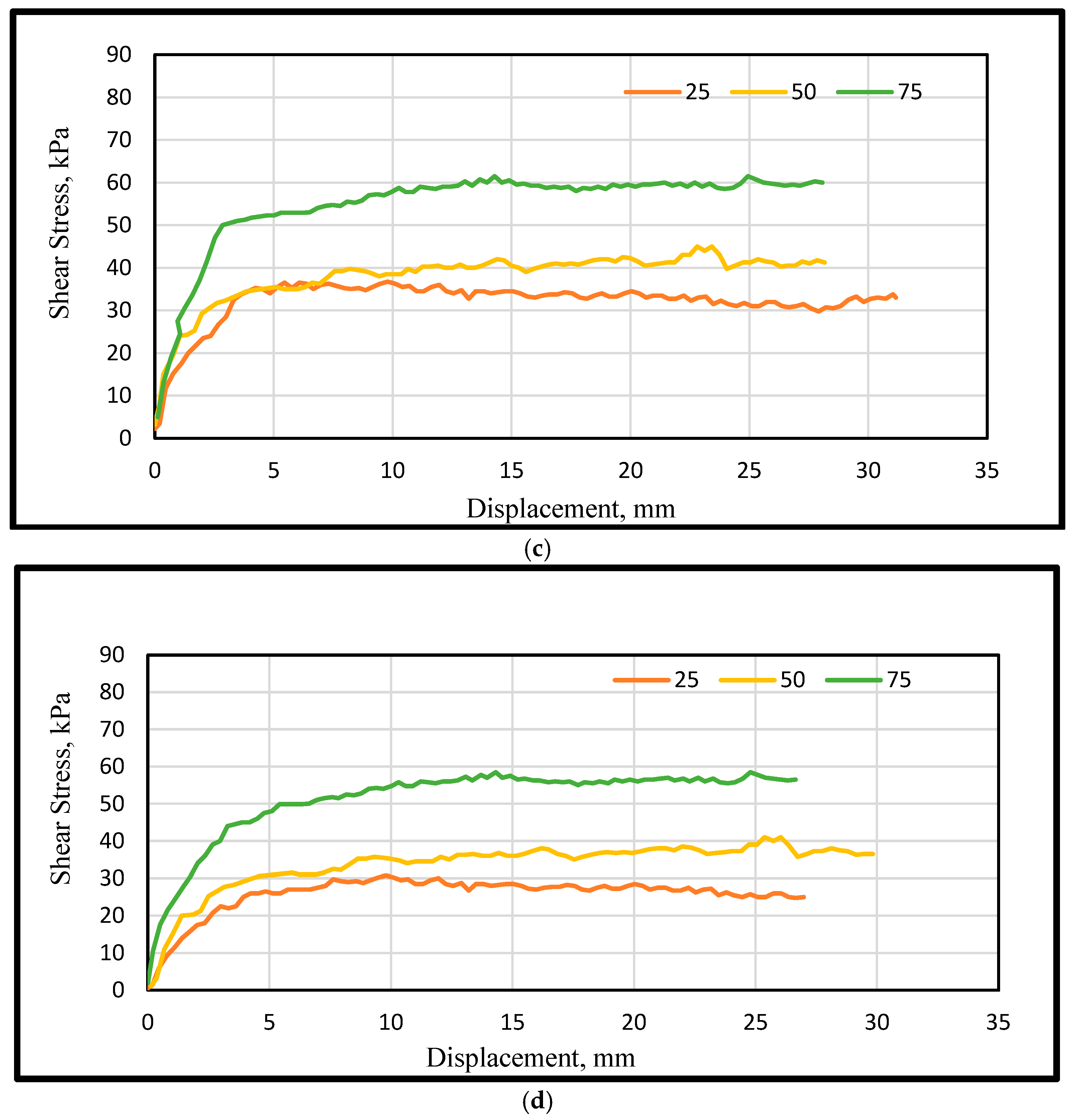

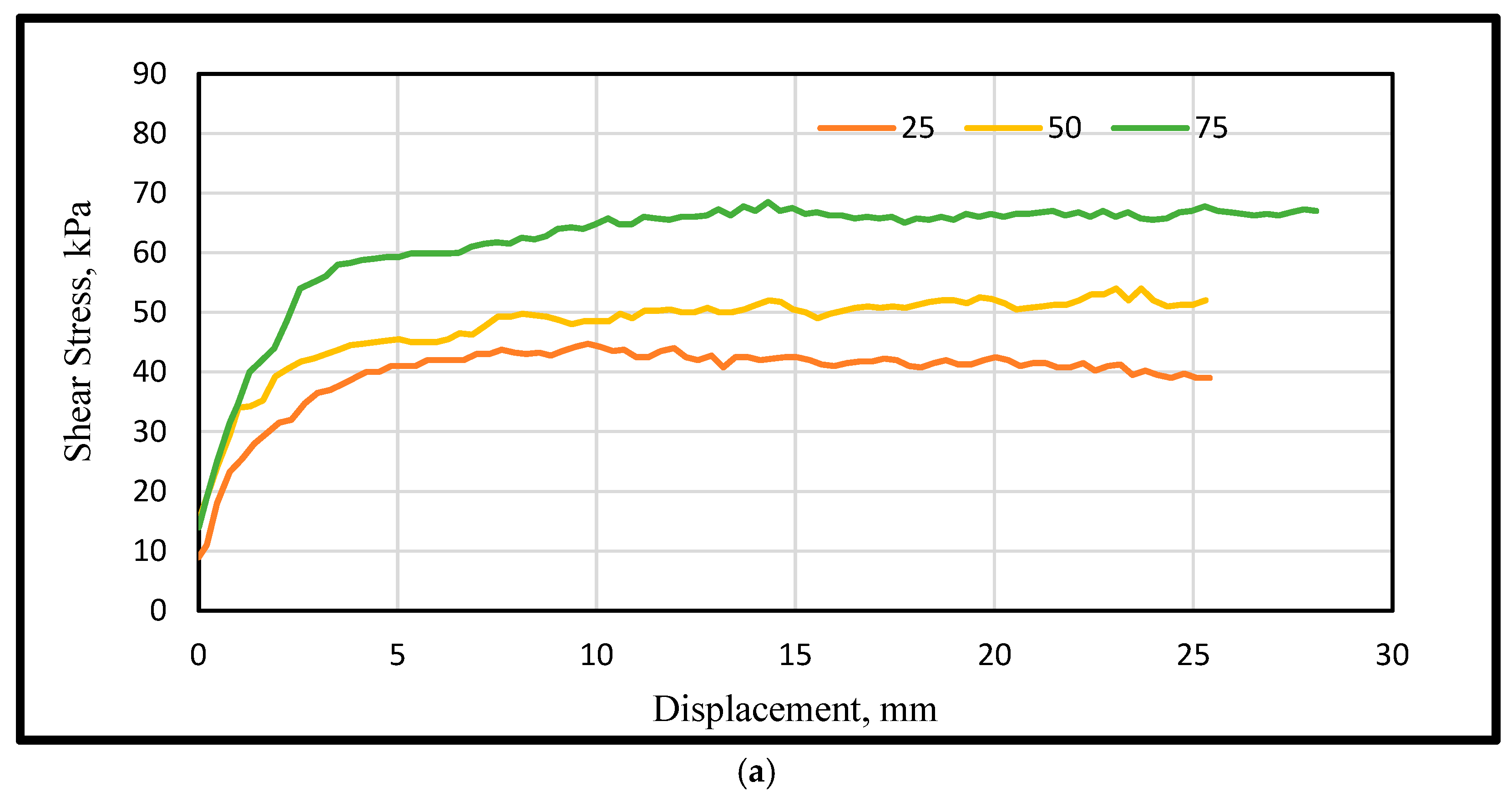

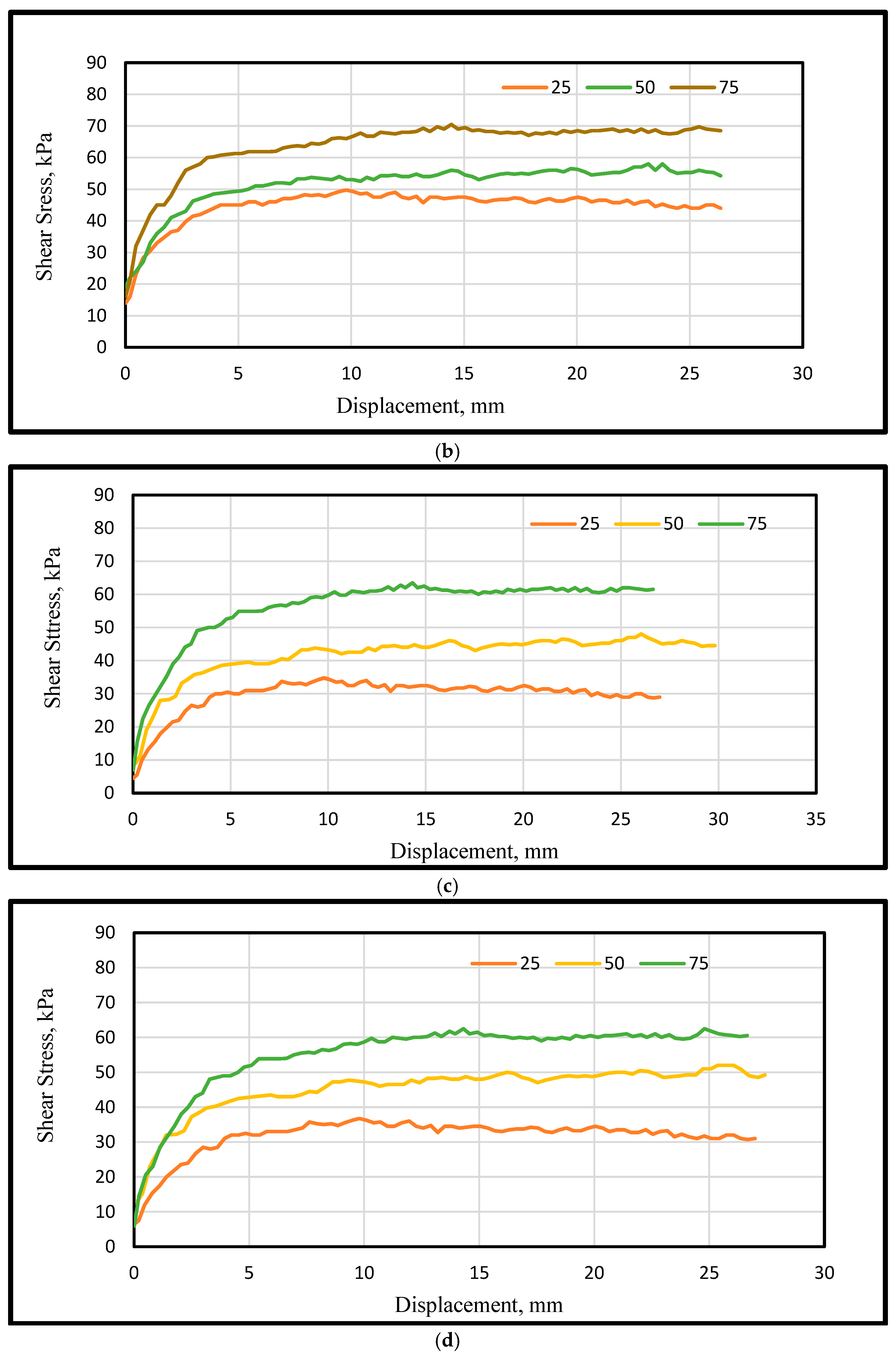

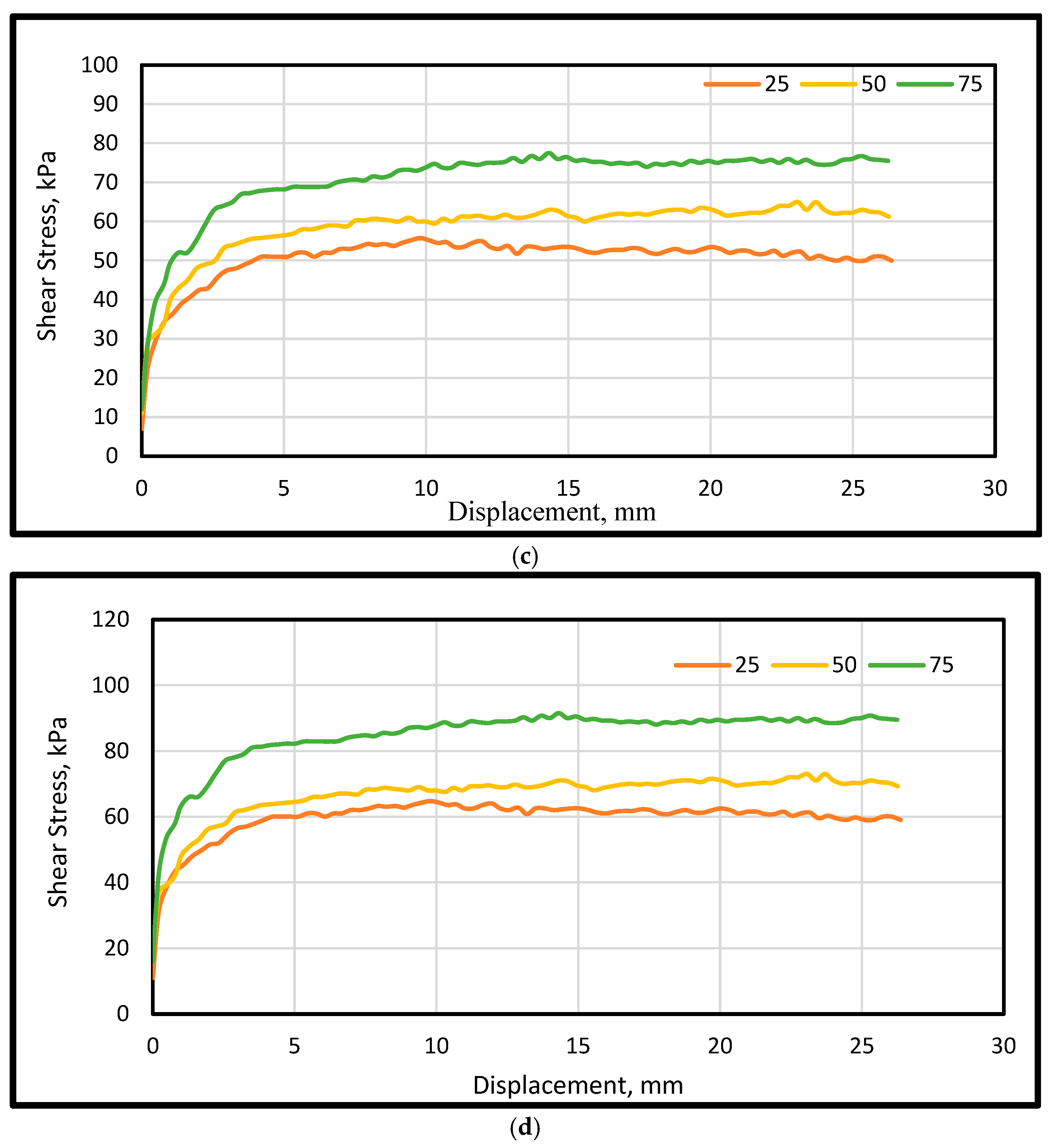

5.2. Evaluation of the Results of Interface Shear Strength of Stabilized Soil

6. Conclusions

- The interface shear strength increases as the moisture content decreases, with the highest strength observed at 10% water content. Above this, shear strength declines, reaching a minimum at 14%.

- Maximum shear strength was achieved at 95% compaction, indicating that a dry-side compaction strategy is more effective than full compaction.

- The optimal condition for stabilization using G1 geogrid occurs at 95% compaction with a moisture content approximately 2% below the optimum.

- The interaction coefficient (η) exceeded 1 for all WFS contents, indicating strong bonding between the reinforced layers.

- At 15% WFS, the optimum moisture content decreased by 13% compared to untreated clay soil.

- Peak dry density and CBR increased progressively with WFS content, reaching 7% and 63% improvements, respectively, at 15% WFS.

- Interface shear strength improved by 14%, 36%, and 55% for 5%, 10%, and 15% WFS, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Glossary/Nomenclature

References

- Al-Neami, M.A.; Alsoudany, K.Y.H.; Dawod, A.A.; Ehsan, E.A. Remediation of Cohesive Soils Using Waste Glass. In Proceedings of the International Journal of Arts and Sciences, Freiburg, Germany, 29 November–2 December 2016; Volume 9, pp. 125–138. [Google Scholar]

- Jing, X.; Wu, S.; Qin, J.; Li, X.; Liu, X.; Zhang, Y.; Mao, J.; Nie, W. Multiscale mechanical characterisations of ultrafine tailings mixed with incineration slag. Front. Earth Sci. 2023, 11, 1123529. [Google Scholar] [CrossRef]

- Abichou, T.; Benson, C.; Edil, T. Foundry Green Sand as Hydraulic Barriers: Field Study. J. Geotech. Geoenviron. Eng. 2002, 128, 206–215. [Google Scholar] [CrossRef]

- Shiva Kumar, K.; Vidyaranya, V.; Bharadwaj, S.; Prathibha, K.N.; Yuvaraj, C. Soil Stabilization Using Waste Plastic Strips. Int. J. Recent Sci. Res. 2016, 7, 11356–11358. [Google Scholar]

- Abu-Farsakh, M.; Coronel, J.; Tao, M. Effect of Soil Moisture Content and Dry Density on Cohesive Soil–Geosynthetic Interactions Using Large Direct Shear Tests. J. Mater. Civ. Eng. 2007, 19, 540–549. [Google Scholar] [CrossRef]

- Xu, Y.; Yan, G.; Williams, D.J.; Serati, M.; Scheuermann, A.; Vangsness, T. Experimental and numerical studies of a strip footing on geosynthetic-reinforced sand. Int. J. Phys. Model. Geotech. 2020, 20, 267–280. [Google Scholar] [CrossRef]

- Mendes, M.J.A.; Palmeira, E.M.; Matheus, E. Some Factors Affecting the In-Soil Load–Strain Behaviour of Virgin and Damaged Nonwoven Geotextiles. Geosynth. Int. 2007, 14, 39–50. [Google Scholar] [CrossRef]

- Mohammad, L.N.; Herath, A.; Rasoulian, M.; Zhang, Z. Laboratory Evaluation of Untreated and Treated Pavement Base Materials: Repeated Load Permanent Deformation Test. Transp. Res. Rec. 2006, 1967, 78–88. [Google Scholar] [CrossRef]

- Nazzal, M.; Abu-Farsakh, M.; Mohammad, L. Laboratory Characterization of Reinforced Crushed Limestone under Monotonic and Cyclic Loading. J. Mater. Civ. Eng. 2007, 19, 772–783. [Google Scholar] [CrossRef]

- Nareeman, B.J.; Fattah, M.Y. Effect of Soil Reinforcement on Shear Strength and Settlement of Cohesive Frictional Soil. GEOMATE J. 2012, 3, 308–313. [Google Scholar] [CrossRef]

- Ferreira, F.B.; Vieira, C.S.; Lopes, M.L. Experimental Investigations on Shear Strength of Soil-Geogrid Interfaces. In Proceedings of the 5th European Geosynthetics Congress, EUROGEO, Valencia, Spain, 16–20 September 2012; Volume 5, pp. 211–217. [Google Scholar]

- Vieira, C.S.; Lopes, M.D.L.; Caldeira, L.M. Sand-Geotextile Interface Characterization through Monotonic and Cyclic Direct Shear Tests. Geosynth. Int. 2013, 20, 26–38. [Google Scholar] [CrossRef]

- Banyhussan, Q.S.; Mosa, A.M.; Hussein, A.N.; Sigar, E.J. Evaluating the Shear Strength of Subbase-Subgrade Interface Using Large Scale Direct Shear Test. Int. J. Innov. Eng. 2023, 3, 35–47. [Google Scholar] [CrossRef]

- Sharaky, A.M.; Mohamed, N.S.; Elmashad, M.E.; Shredah, N.M. Application of microbial biocementation to improve the physico-mechanical properties of sandy soil. Constr. Build. Mater. 2018, 190, 861–869. [Google Scholar] [CrossRef]

- Bak, H.M.; Kariminia, T.; Shahbodagh, B.; Rowshanzamir, M.A.; Khoshghalb, A. Application of bio-cementation to enhance shear strength parameters of soil-steel interface. Constr. Build. Mater. 2021, 294, 123470. [Google Scholar]

- Xiao, Y.; He, X.; Zaman, M.; Ma, G.; Zhao, C. Review of strength improvements of biocemented soils. Int. J. Geomech. 2022, 22, 03122001. [Google Scholar] [CrossRef]

- Abichou, T.; Benson, C.H.; Edil, T.B. Foundry Green Sands as Hydraulic Barriers: Laboratory Study. J. Geotech. Geoenviron. Eng. 2000, 126, 1174–1184. [Google Scholar] [CrossRef]

- Sharma, R.K.; Kumar, A. Compaction and Sub-grade Characteristics of Clayey Soil Mixed with Foundry Sand and Fly Ash. Int. J. Eng. Res. Technol. 2013, 2, 1504–1509. [Google Scholar]

- Kumar, P.; Paliwal, M.C.; Jain, A.K. Stabilization of Sub Grade Soil by Using Foundry Sand Waste. Int. J. Eng. Sci. Res. Technol. 2016, 5, 300–308. [Google Scholar]

- Banyhussan, Q.S.; hassan, H.A.; Hamad, B.A. Investigation of Shear Strength of Subbase-Subgrade Interface with Geosynthetics Reinforcement Utilizing A Large-Scale Direct Shear Test. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2023; Volume 427, p. 03007. [Google Scholar] [CrossRef]

- Youwei, X.; Williams, D.J.; Serati, M. Investigation of shear strength of interface between road base and geosynthetics using large-scale single-stage and multi-stage direct shear test. Road Mater. Pavement Des. 2020, 21, 1588–1611. [Google Scholar] [CrossRef]

- ASTM D3080/D3080M-11; Standard Test Method for Direct Shear Test of Soils Under Consolidated Drained Conditions. American Society for Testing and Materials: West Conshohocken, PA, USA, 2011. Available online: https://www.astm.org/d3080_d3080m-11.html (accessed on 15 January 2025).

- Youwai, S.; Bergado, D.T.; Supawiwat, N. Interaction between Hexagonal Wire Reinforcement and Rubber Tire Chips with and without Sand Mixture. Geotech. Test. J. 2004, 27, 260–268. [Google Scholar] [CrossRef]

- ASTM D5321/D5321M-13; Standard Test Method for Determining the Shear Strength of Soil-Geosynthetic and Geosynthetic-Geosynthetic Interfaces by Direct Shear. American Society for Testing and Materials: West Conshohocken, PA, USA, 2014. Available online: https://www.astm.org/d5321_d5321m-13.html (accessed on 15 January 2025).

- Danial, E.; Kianoosh, H.; Gerald, A.M. Influence of Matric Suction on Geotextile Reinforcement-Marginal Soil Interface Strength. Geotext. Geomembr. 2014, 42, 139–153. [Google Scholar] [CrossRef]

- Kianoosh, H.; Jaime, E.G.; Danial, E.; Gerald, A.M. Reinforcement Pullout Capacity in Mechanically Stabilized Earth Walls with Marginal-Quality Soils. Transp. Res. Rec. 2013, 2363, 66–74. [Google Scholar] [CrossRef]

- Nasser, K. Guidelines for the application of effective stress principle to shear strength and volume change determination in unsaturated soils. Aust. Geomech. J. 2018, 53, 37–47. [Google Scholar]

- Garakani, A.A.; Pirjalili, A.; Yoosefi, S.; Khoshghalb, A. Assessing the stress–deformation and safety factor against sliding in reinforced deep urban excavations in unsaturated soils. Int. J. Geomech. 2024, 24, 04024130. [Google Scholar] [CrossRef]

- Koutsourais, M.; Sandri, D.; Swan, R. Soil Interaction Characteristics of Geotextiles and Geogrids. In Proceedings of the 6th International Conference on Geosynthetics, Atlanta, Georgia, 25–29 March 1998; pp. 739–744. [Google Scholar]

- Sahib, B.Q.; Jaafar, A.; Anmar, D. Effect of Water Content and Degree of Compaction of Clay Subgrade Soil on the Interface Shear Strength Using Geogrid. J. Adv. Res. Appl. Sci. Eng. Technol. 2025, 52, 262–280. [Google Scholar]

- Nilay, T.; Edil, T.B.; Benson, C.H. Interaction between reinforcing geosynthetics and soil-tire chip mixtures. J. Geotech. Geoenviron. Eng. 1998, 124, 1109–1119. [Google Scholar] [CrossRef]

| Weight Percentage Passing | ||

|---|---|---|

| Sieve Size (mm) | Passing (%) | Limits of SCRB/R6, 2003 |

| 50 | 100 | 100 |

| 25 | 88.5 | 75–95 |

| 9.5 | 74.5 | 40–75 |

| 4.75 | 51.2 | 30–60 |

| 2.36 | 41.4 | 21–47 |

| 0.3 | 27 | 14–28 |

| 0.075 | 14.3 | 5–15 |

| Properties | Values | Limits to SCRB/R6, 2003 |

|---|---|---|

| MDD (gm/cm3) | 2.24 | Not limited |

| Optimum moisture content (OMC) (%) | 7.00 | Not limited |

| Organic matter (%) | 0.84 | Maximum = 2 |

| T.S.S. (%) | 7.58 | Maximum =10 |

| SO3 content (%) | 2.60 | Maximum = 5 |

| Gypsum content (%) | 5.59 | Maximum = 10.75 |

| Properties | Results | Requirement for Specifications |

|---|---|---|

| MDD (gm/cm3) | 1.81 | AASHTO T99-95 |

| OMC (%) | 11.2 | AASHTO T99-95 |

| Liquid limit (%) | 32 | AASHTO T89-96 |

| Plastic limit (%) | 21 | AASHTO T90-96 |

| Physical Properties | Information | ||

|---|---|---|---|

| Type | Biaxial geogrid | ||

| Color | Black | ||

| Polymer | PP | ||

| Rib shape | Rectangular | ||

| Guide properties | Units | MD | XMD |

| Rib thickness | mm | 0.76 | 0.76 |

| Opening dimensions | mm | 25 | 33 |

| Tensile strength * | kN/m | 12.4 | 19 |

| Tensile strength ** | kN/m | 8.5 | 13.4 |

| Tensile strength *** | kN/m | 4.1 | 6.6 |

| Sample No. | WFS (%) | OMC (%) | Comparison (%) | MDD (%) | Comparison (%) | CBR (%) | Comparison (%) |

|---|---|---|---|---|---|---|---|

| 1 | 0 | 11.2 | 1.81 | 5.1 | |||

| 2 | 5 | 10.5 | −6.25 | 1.86 | +2.7 | 5.8 | +17.6 |

| 3 | 10 | 10.1 | −9.8 | 1.90 | +4.9 | 7.7 | +50.9 |

| 4 | 15 | 9.7 | −13.39 | 1.94 | +7.1 | 8.3 | +62.7 |

| State | Density | W (%) | WFS (%) | σ (kPa) | π (kPa) | c (kPa) | δ (°) | Comparison (%) |

|---|---|---|---|---|---|---|---|---|

| clay-subbase | 1.71 | 10 | 0 | 25 | 35 | 25 | 22 | |

| 50 | 45 | |||||||

| 75 | 55 | |||||||

| clay-G1-subbase | 1.71 | 10 | 0 | 25 | 39.5 | 30 | 20.8 | |

| 50 | 49 | |||||||

| 75 | 58.5 | |||||||

| 5 | 25 | 45 | 35 | 23 | +14 | |||

| 50 | 56 | |||||||

| 75 | 66.8 | |||||||

| 10 | 25 | 54 | 42 | 25.6 | +36 | |||

| 50 | 66 | |||||||

| 75 | 78 | |||||||

| 15 | 25 | 63 | 50 | 27.5 | +55 | |||

| 50 | 76 | |||||||

| 75 | 89 |

| WFS (%) | η |

|---|---|

| 0 | 1.06 |

| 5 | 1.21 |

| 10 | 1.41 |

| 15 | 1.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Banyhussan, Q.S.; Abdulrazzaq, J.; Hussein, A.A.; Dulaimi, A.; Andrade, J.M.d.A.; Bernardo, L.F.A. Stabilization of Clay Subgrade Soil by Using Waste Foundry Sand with a Geogrid. CivilEng 2025, 6, 26. https://doi.org/10.3390/civileng6020026

Banyhussan QS, Abdulrazzaq J, Hussein AA, Dulaimi A, Andrade JMdA, Bernardo LFA. Stabilization of Clay Subgrade Soil by Using Waste Foundry Sand with a Geogrid. CivilEng. 2025; 6(2):26. https://doi.org/10.3390/civileng6020026

Chicago/Turabian StyleBanyhussan, Qais Sahib, Jaafar Abdulrazzaq, Ahmed A. Hussein, Anmar Dulaimi, Jorge Miguel de Almeida Andrade, and Luís Filipe Almeida Bernardo. 2025. "Stabilization of Clay Subgrade Soil by Using Waste Foundry Sand with a Geogrid" CivilEng 6, no. 2: 26. https://doi.org/10.3390/civileng6020026

APA StyleBanyhussan, Q. S., Abdulrazzaq, J., Hussein, A. A., Dulaimi, A., Andrade, J. M. d. A., & Bernardo, L. F. A. (2025). Stabilization of Clay Subgrade Soil by Using Waste Foundry Sand with a Geogrid. CivilEng, 6(2), 26. https://doi.org/10.3390/civileng6020026