Abstract

PC steel material inside pre-stressed concrete bridges is prone to corrosion due to the effect of salt, which leads to cross-sectional losses and fractures if proper maintenance is not carried out, affecting the girders’ structural performance. In Japan, pre-tensioned girders incorporating small-diameter PC steel material with a span length of 13 m or less were used until the early 1980s. Thus, it is essential to understand the fracture conditions of PC steel material and the factors affecting section loss due to corrosion, in order to properly assess the residual strength of salt-affected pre-tensioned girders. Hence, the current research clarifies the accuracy of techniques used for detecting deterioration in a pre-tensioned PC girder that had been out of service for about 40 years, caused by exposure to the severely saline environment of the Okinawa coast. Visual and hammer-tapping investigation of the actual bridge in addition to fracture investigation of the PC steel material using the triaxial magnetic method and destructive investigation of the concrete cover on the bottom of the girder were carried out and correlated. The final results confirmed that the triaxial magnetic method could detect PC steel material fractures accurately, and valuable information was obtained regarding fracture-detection technology for application in PC girders via non-destructive testing.

1. Introduction

Early degradation of pre-stressed concrete (hereafter referred to as “PC”) bridges due to corrosion of PC steel material (hereafter referred to as “PC steel”) poses a challenge to structural performance. If proper maintenance is not carried out, the PC steel inside the concrete will undergo cross-sectional losses and fracturing due to corrosion, which will affect the performance of the girder [1]. Proper management and maintenance of PC bridges requires evaluation of residual capacity through prediction of the deterioration progress. Pre-tensioned girders using small diameter PC steel with span lengths of 5 to 13 m were used in Japan from 1959 to the early 1980s [2]. Pre-tensioned girders with single-strand PC steel are deteriorated by airborne salt; this can be assessed by finite element analysis if the fracturing or loss of the PC steel is known about, but the residual bearing capacity for structural safety may be underestimated based on visual investigation results [3]. Therefore, to properly evaluate the residual strength of salt-air damaged pre-tensioned girders, it is essential to understand fracturing and corrosion loss.

One non-destructive inspection technique for detecting fractures in PC steel is the magnetic flux leakage method. Furthermore, a magnetic flux leakage method using electromagnets (hereafter referred to as the “RM method”) has been investigated and studied for detecting fractures and cross-section losses in concrete due to the corrosion of steel materials [4,5,6,7,8]. The density and regularity of the rebars affect measurements acquired via the RM method. Large electromagnets have been developed to ensure accurate measurement of PC steel behind rebars [9]. In a previous study, a yoke-type magnet (minimum mass 35 kg, length ca. 400 mm) was used to detect single wire failures in tendons with 40 small cross-sections (ca. 20 mm2, e.g., 5 mm diameter (nominal cross-sectional area 19.64 mm2)) with a cover of less than 100 mm and arranged with mild steel reinforcement. A large yoke-type electromagnet (mass approx. 1.5 t, length 3.5 m) was developed, because the tendons behind the rebars were difficult to magnetize when arranged vertically and horizontally near the concrete surface. Excessive amounts of magnetization make it difficult to achieve uniformity of magnetization and increase the influence of rebars and stirrups; so, spacers must be placed on the surface of the model specimen to adjust the distance of the magnetization [10]. Thus, the magnetic flux leakage method is considered to have measurement accuracy issues when rebars or stirrups are placed close to the concrete surface, although detection of ruptures in PC steel in the vicinity of the rebar was not clearly indicated. On the other hand, non-destructive inspection methods using three-axis magnetic sensors have been studied to improve the accuracy of corrosion damage assessment in the steel-bottom plates of steel pipes and tanks in pipelines [11]. Recently, non-destructive inspection using the magnetic flux leakage method employing permanent magnets has been adopted in Japan as an inspection method for detecting corrosion fractures in PC steel at the bottoms and sides of post-tensioned girders [12]. This magnetic flux leakage method uses a magnet to magnetize the steel in the concrete and measure the flux density perpendicular to the concrete measurement plane. Although failure can be detected down to a single strand of bundled PC steel wire or PC steel stranded wire [9,10], the detection of strand fractures in PC steel stranded wire has not been clarified [13].

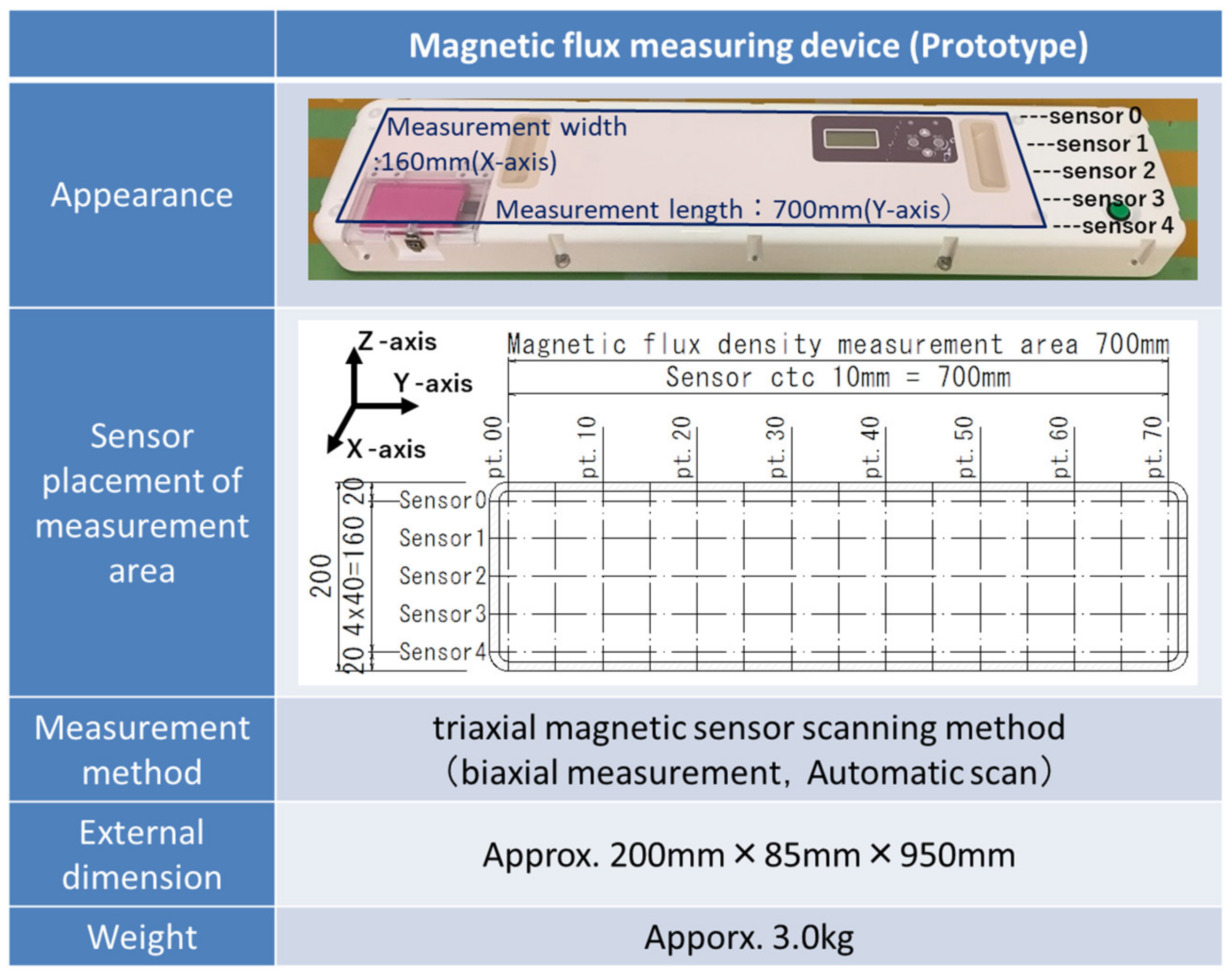

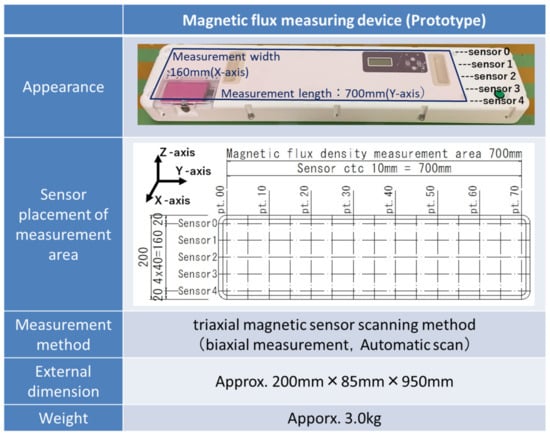

This study focuses on the magnetic flux leakage method (hereinafter referred to as the triaxial magnetic method) using a lightweight permanent magnet and a measurement device with a three-dimensional magnetic sensor (hereinafter referred to as the triaxial sensor) [14]. This type of lightweight permanent magnet (approx. 2 kg) and measuring equipment (approx. 3 kg) can be carried by measuring crews, enabling them to manoeuvre around the underside and sides of the girders. Measurement with a triaxial sensor improves accuracy of fracture detection in PC steel, as the magnetic flux density in three directions can be analyzed.

The aim of this study was to determine the accuracy of using magnetic flux leakage for detecting PC steel fractures and cross-sectional defects in an actual salt-damaged pre-tensioned girder. The practical material investigation was conducted on a pre-tensioned girder that had been exposed to salt damage on the coast for about 40 years and was no longer in service. Firstly, the damage status was evaluated by close visual inspection and hammer tapping, and a damage map was prepared to determine the area to be investigated. Next, triaxial magnetic investigation was conducted, and the corrosion fracture points of the PC steel were determined from the triaxial graphs obtained by analyzing the measured data. Subsequently, destructive investigation of the cover concrete (hereafter referred to as “destructive investigation”) was conducted to confirm the internal conditions of the investigated area. The results of these investigations were used to compare and verify the results of the triaxial magnetic method and the destructive survey.

2. Investigation Method

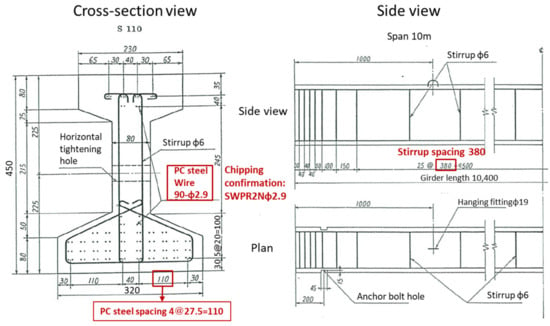

2.1. Description of the Material

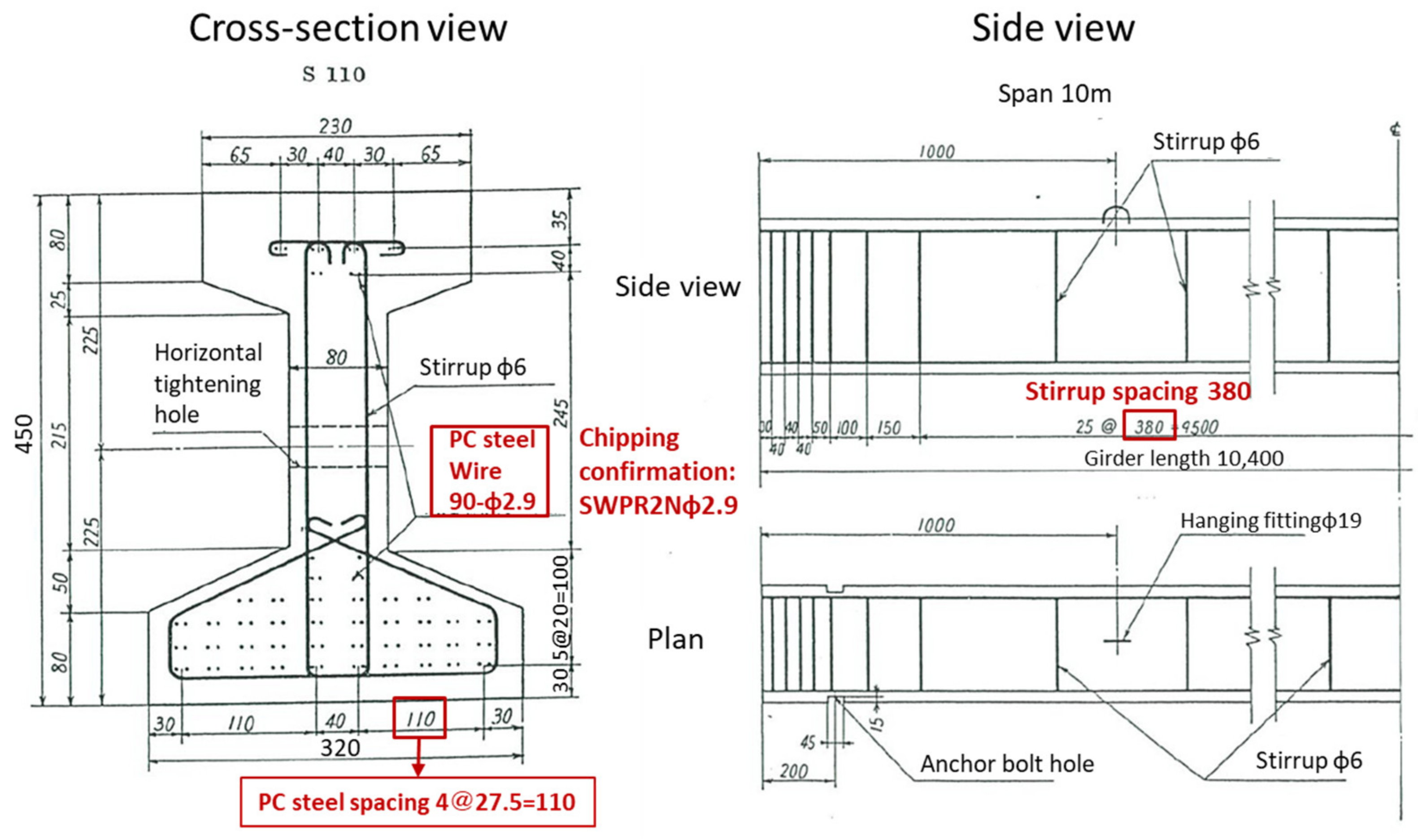

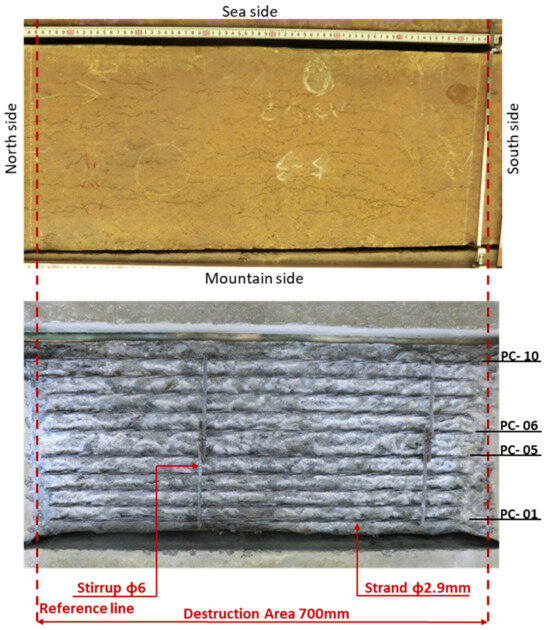

The target sample was a 10.4 m long, 10.1 m wide PC simple pre-tensioned I-girder slab bridge on the west coast of northern Okinawa Island in Japan (hereafter referred to as “K-bridge”). The main girder is illustrated in cross-section and side view in Figure 1 [2]. The PC steel consisted of strands made of two wires of 2.9 mm diameter. The K-bridge was cracked and spalled due to the severe salt damage caused by seawater splashes. Figure 2 indicates the damage on the side of the K-bridge facing the sea. For this analysis, 10 double strands of 2.9 mm dia. were placed in the girder direction on the K-bridge at a covering distance of 30 mm on the underside of the girder, and stirrups of 6 mm dia. were placed at intervals of 380 mm.

Figure 1.

Placement of PC steel and rebar for target PC girder.

Figure 2.

Damage at the bottoms of girders in the K-bridge (seaward side).

2.2. Magnetic Flux Leakage Method Using a Triaxial Sensor

2.2.1. Principle of Magnetic Flux Leakage Method Using Triaxial Sensor

The magnetic flux leakage method uses a magnet to magnetize the steel near the measurement surface and measures the magnetic flux density using a magnetic sensor to detect the location of fractures in the steel [9,15]. The measurement system is shown in Figure 3; triaxial sensors were placed on five parallel lines spaced 40 mm apart, and the magnetic flux density was measured at 10 mm intervals.

Figure 3.

Magnetic flux measuring device (prototype).

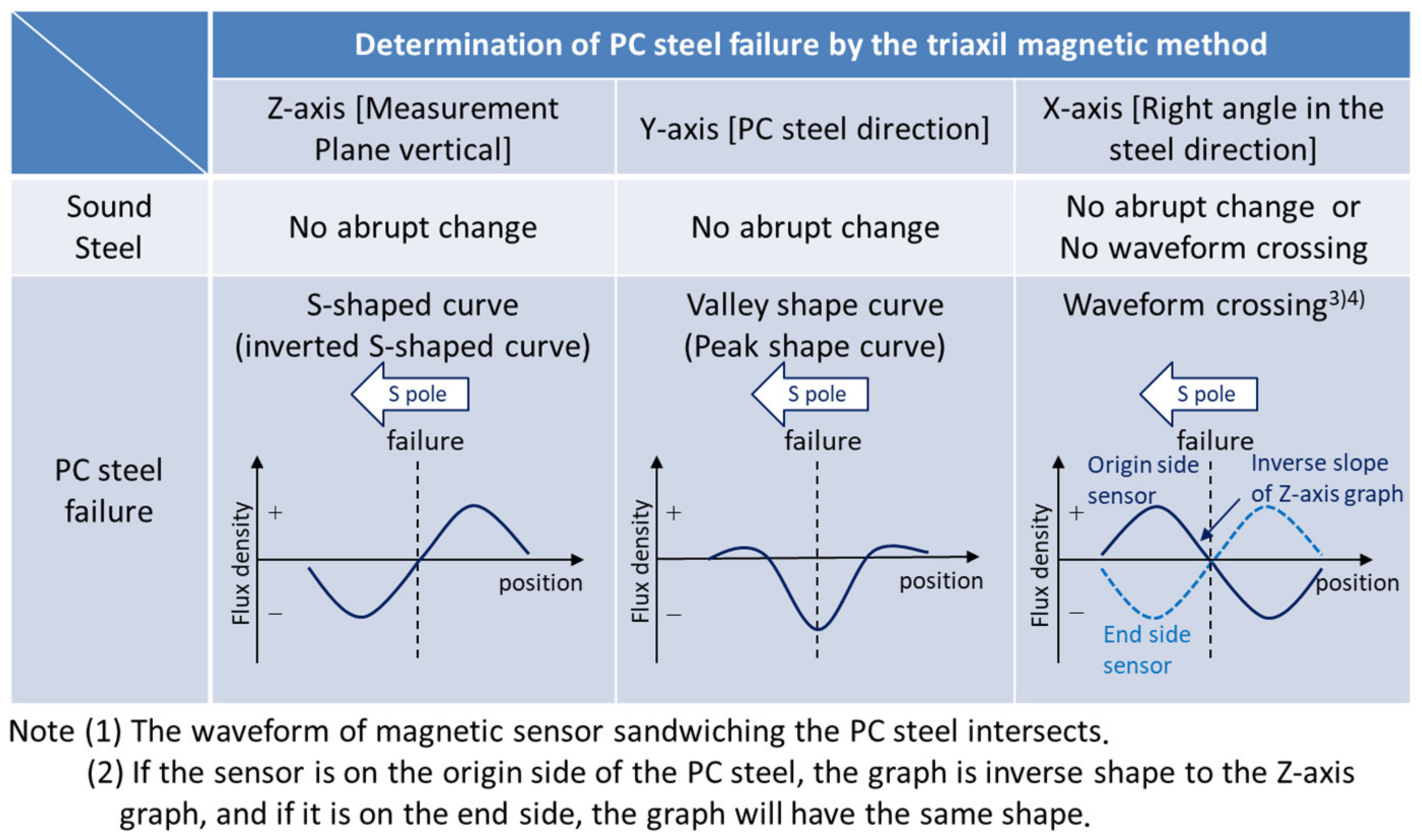

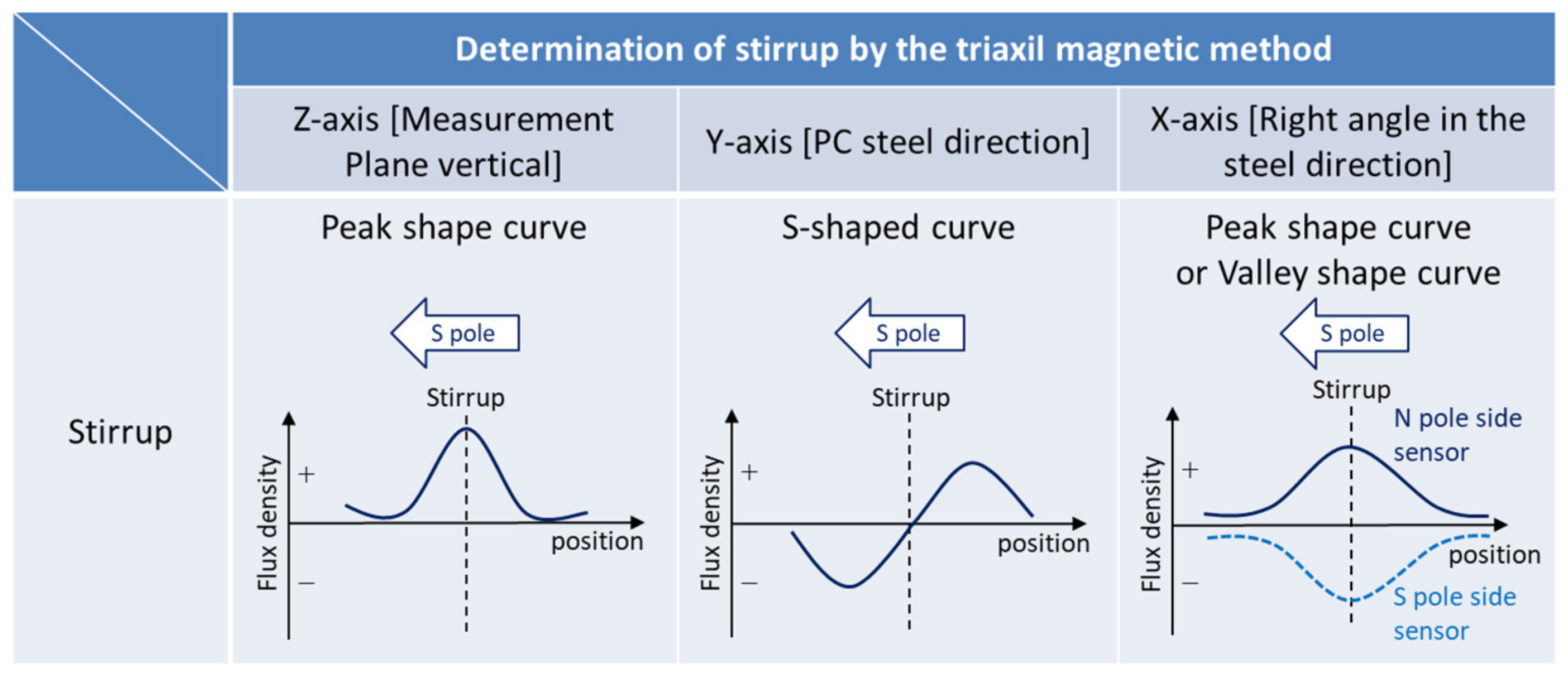

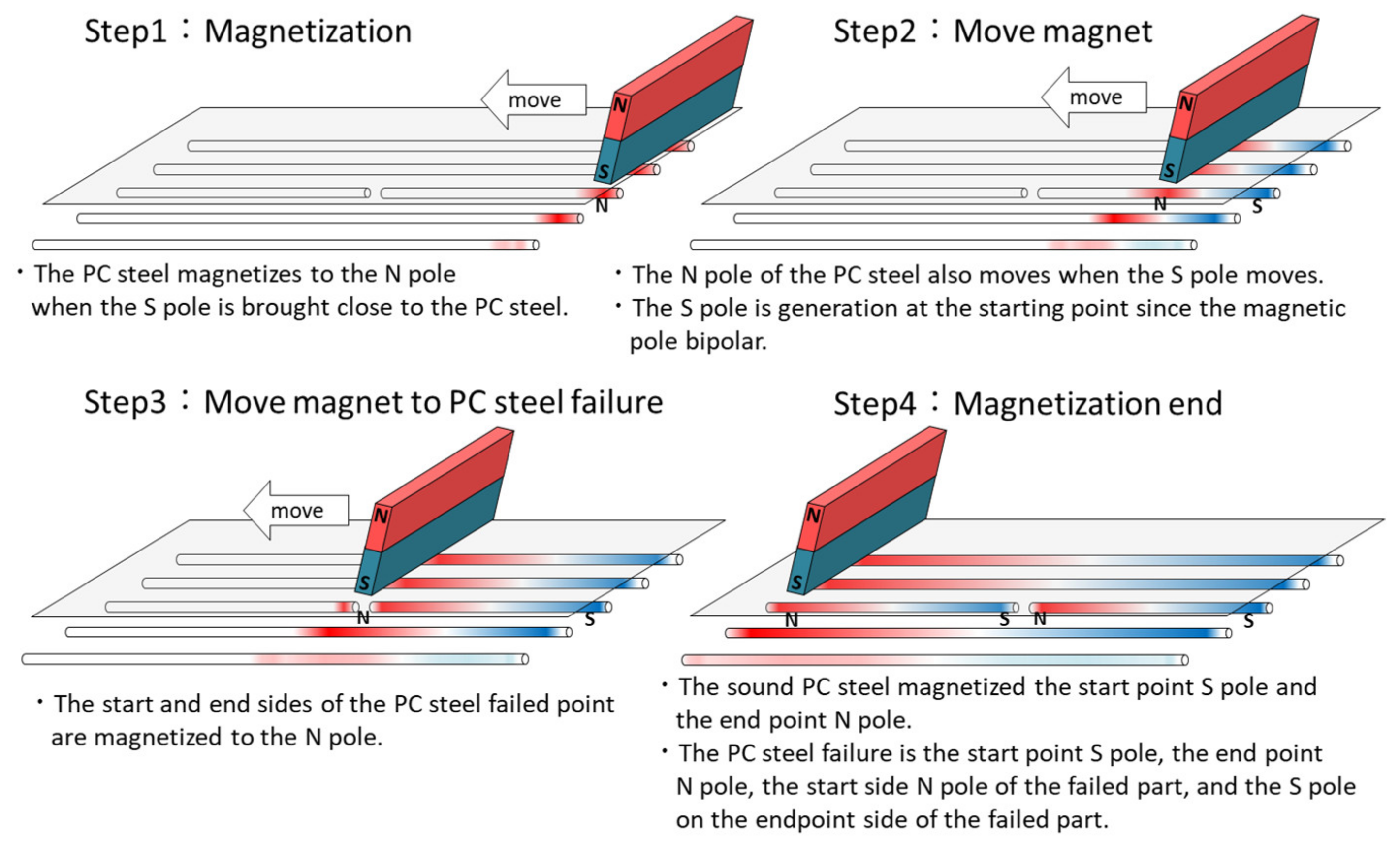

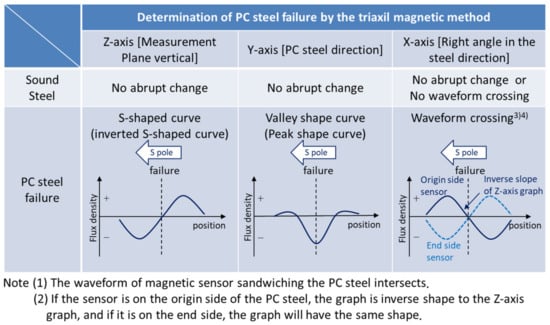

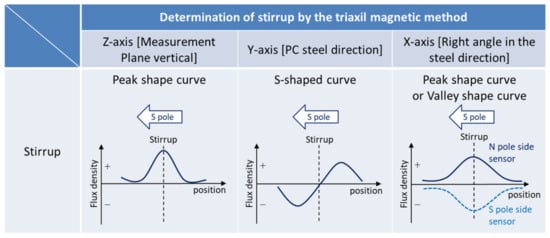

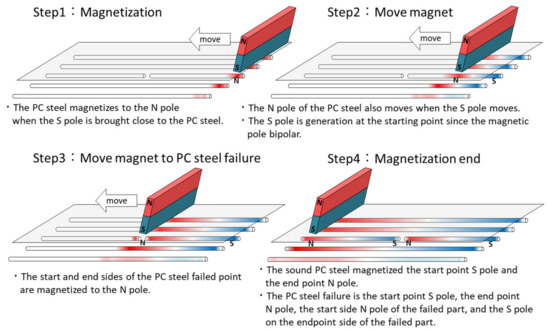

Figure 4 indicates the detection of steel fracture, and Figure 5 shows the detection of stirrups, i.e., steel bars placed around and intersecting the main bars and PC steel to reinforce the shear of the girders. When the S-pole of the magnet is placed at the magnetization start point on the surface of the concrete and moves to the magnetization end point, an S pole is formed at the magnetization start point and an N pole at the magnetization end point above the sound PC steel in the concrete. If the PC steel located in the concrete is fractured, an S pole is formed at the magnetizing start point and an N pole at the magnetizing end point, but an N pole is formed on the steel on the magnetizing start side and an S pole on the magnetizing end side at the point of fracture (see Figure 6). If stirrups are present in the concrete, placing the S pole of the magnet on the concrete surface at the magnetization start point and moving to the magnetization end point will form an N pole on the stirrup that the magnet passes through and an S pole on the stirrup that the magnet does not pass through. Near the magnetized stirrups, the magnetic fields of the PC steel and those on the stirrups overlap [16,17], creating a magnetic field specific to the stirrups.

Figure 4.

Determination of PC steel failure via the triaxial magnetic method.

Figure 5.

Detection of stirrups via triaxial magnetic method.

Figure 6.

Magnetization mechanism at the fracture in the PC steel material.

When the direction of magnetization is from left (south) to right (north) in relation to the concrete surface, the Z-axis graph shows an S-shaped waveform with the N pole at the maxima and the S pole at the minima in relation to the fracture point of the PC steel on the magnetic flux density graph obtained via the measuring device whose origin is at the left end. The Y-axis graph shows a minimal (valley) graph shape at the point of the PC steel fracture and a maximal (peak) graph shape when the magnetization direction is reversed. In the X-axis graph, if the magnetic sensor is on the left (sea) side of the broken PC steel, towards the end point of the measuring device, the graph shape is a peak on the N-pole side and a trough on the S-pole side at the point of fracture in the PC steel. If the magnetic sensor is on the right (mountain) side of the PC steel, the graph shape shows a valley on the N-pole side and a peak on the S-pole side at the point of fracture, and the graph shapes of the two magnetic sensors therefore intersect. However, the graphs may not intersect, due to variations in the magnetization of the PC steel and stirrups. For this reason, the graphs in the Z- and Y-axis were checked, and the fractures in the PC steel were measured.

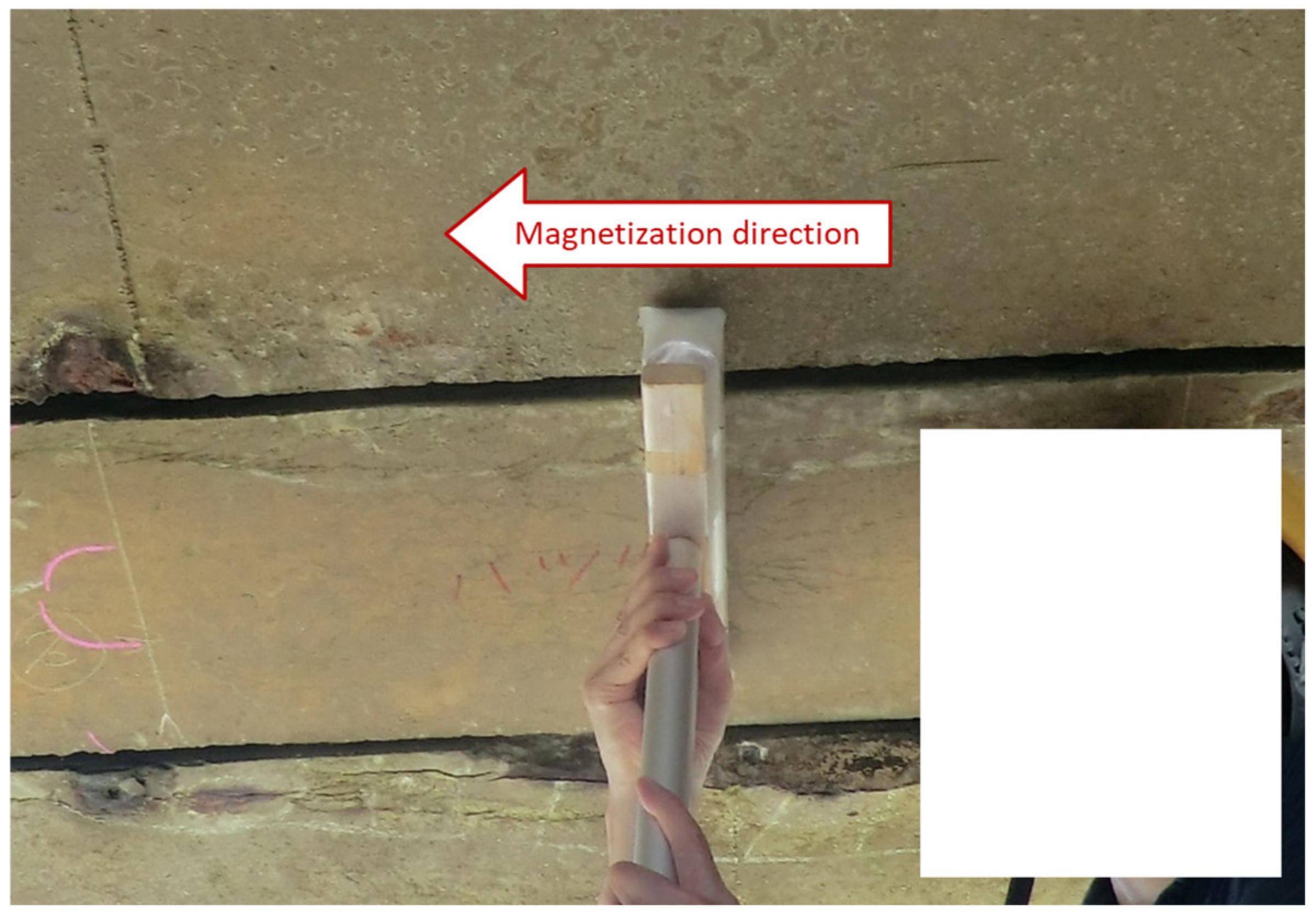

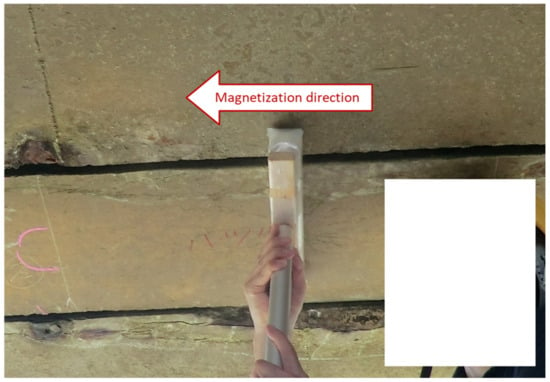

2.2.2. Methodology for Conducting the Investigation in This Study

The investigation area for the triaxial magnetic investigation carried out on the K-bridge was the same as that for the destructive investigation, to enable comparison and verification of the results. Before the destructive investigation, the measurement area was marked at the bottom of the girder (see Figure 7) and an area of about 500 mm north–south from the measurement area was magnetized by the S pole of the magnet. The magnetization was carried out twice in total, moving from south to north, with the edge of the magnet aligned with the edge of the bottom of the girder on both the mountain side and the seaward side. After magnetization, the origin of the measurement device was aligned with the northern position of the measurement area on the bottom of the girder and two separate measurements were taken. For the first of these, the edge of the girder on the seaward side was aligned with the edge of sensor 0 on the measurement device, and the second time, the edge of the girder on the mountain side was aligned with the edge of sensor 4 on the measurement device. Using the results of the post-chipping PC steel corrosion deterioration study, the measurement of the cross-sectional defects, and the visual investigation results, the detected locations of PC steel failure revealed by the triaxial waveform in the triaxial magnetic method were compared and analyzed.

Figure 7.

Magnetization status.

2.3. Visual and Hammer-Tapping Investigation of the Bottom of the Girder

In the investigation, the lines of the cracks detected by close visual inspection were chalked onto the bottom of the girder, and the area detected by a simple hammer tapping was marked. Based on this, a damage map was created using computer-aided drafting (hereafter referred to as “CAD”). In addition, pictures of the bottom of the girder were taken and converted to ortho-images, which were then converted to a crack damage map so that the crack length could be measured using CAD.

2.4. Destructive Investigation of the Bottom of the Girder

The destructive depth was about 40 mm, which was enough to confirm the entire circumference of the first volume of PC steel from the bottom of the girder. The results of these investigations were used to identify the locations of corrosion failure and cross-sectional defects in the PC steel after destructive investigation.

3. Investigation Results

3.1. Selection of the Investigation Area

This study assessed the use of non-destructive testing equipment on bridges to estimate the position of PC steel fractures according to crack widths and rust marks on the bottoms of girders, including close visual and hammer-tapping inspection of the bottoms of the girders, using survey equipment to investigate whether the PC steel was fractured at these positions. Efficient non-destructive testing can be carried out if it is possible to use information from the bottom of the girder to estimate where the PC steel has ruptured.

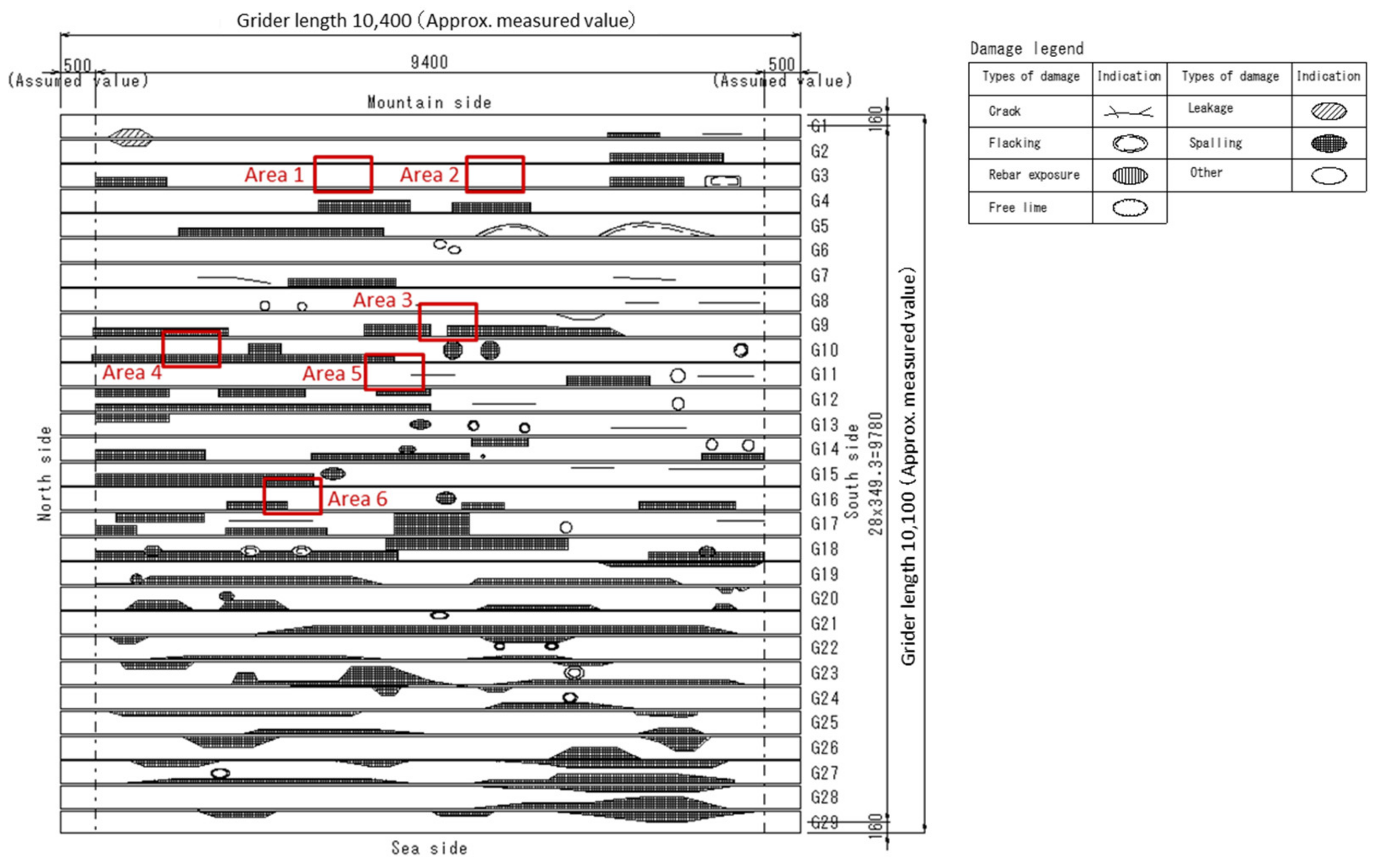

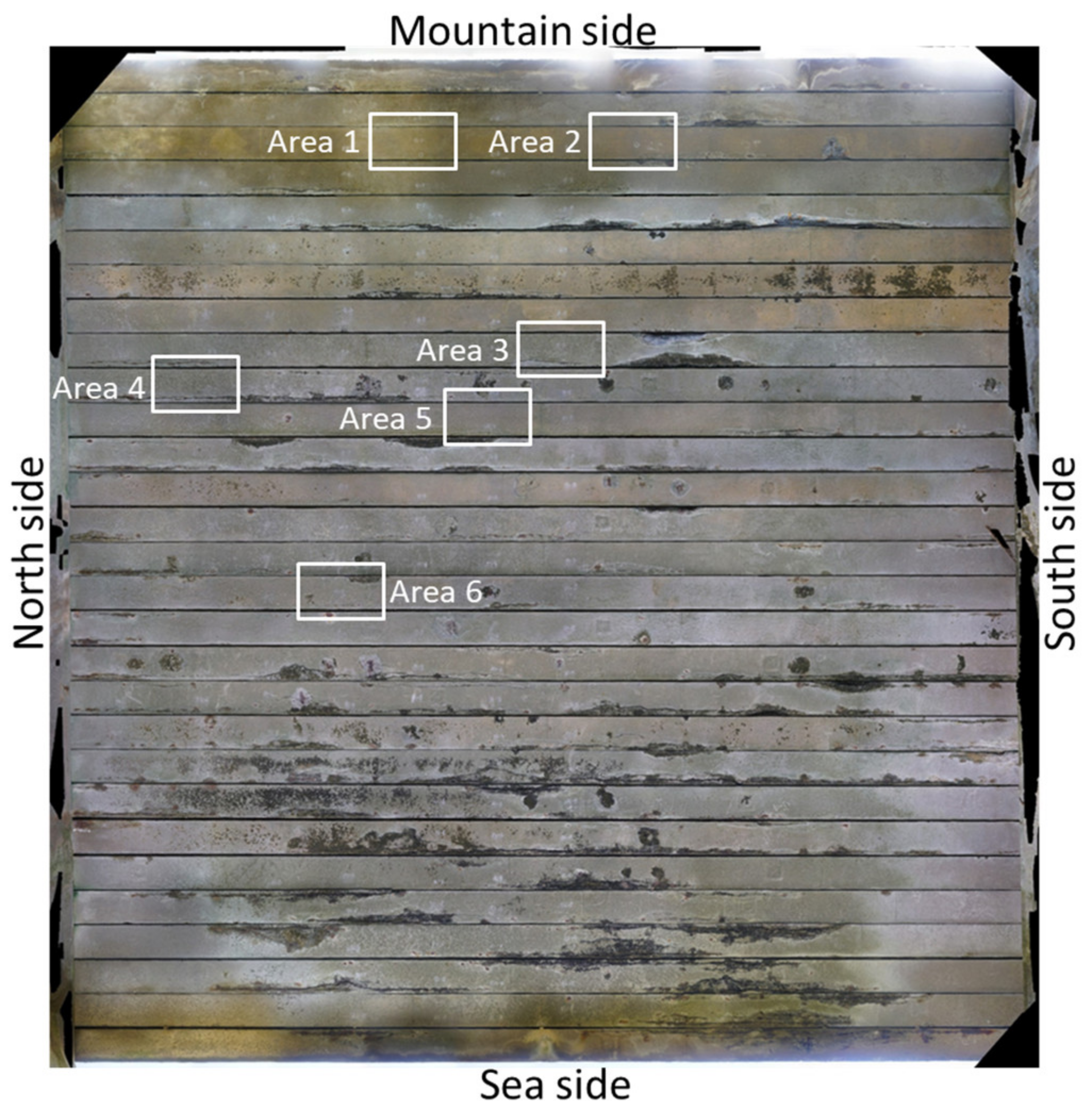

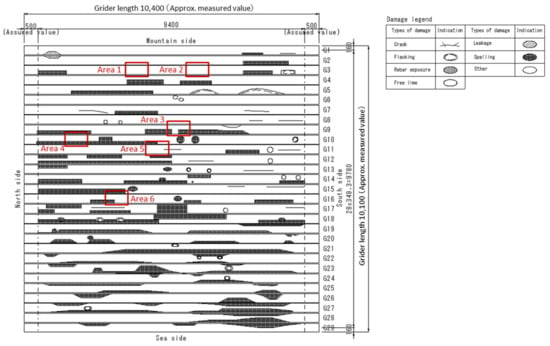

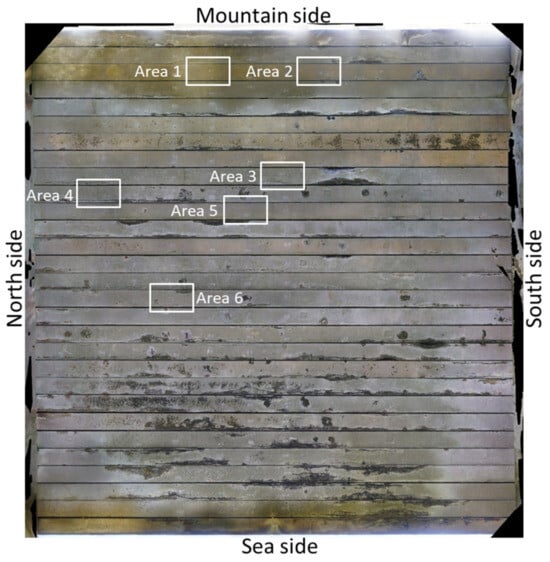

Figure 8 shows the damage map of the bottom of the girder, which was prepared based on the close visual and hammer-tapping investigations conducted on the K-bridge. Figure 9 presents an ortho-image showing the actual damage to the entire bottom of the girder. Figure 8 and Figure 9 indicate the areas of destructive investigation. For this investigation, the following areas were selected from among the many damaged areas: sound area, area with crack width of about 0.4 mm, area with crack width of about 0.55 mm, area with crack width of about 2.0 mm, area with crack width of about 2.5 mm, area with crack width of about 4.0 mm, and area with crack width of about 5.0 to 6.0 mm. The area numbers were assigned in order starting from the mountain side.

Figure 8.

Damage map.

Figure 9.

Ortho-image showing the bottom surface of the girder from the top surface of the girder.

In this paper, we verify the status of the fracturing and cross-sectional loss of PC steel identified via the corrosion observed in photographs of the bottoms of the girders, in comparison with the accuracy of detection of fracturing and cross-sectional loss in PC steel as indicated by the waveforms of each axis according to triaxial magnetic measurements. The width of the corrosion cracks was measured using a crack gauge or a scale, with each crack width indicated by the maximum value of the crack (near the point indicated by the arrow in the photograph of the bottom of the girder). The crack widths are shown in order of decreasing crack width.

3.2. Comparison and Verification of the Results of Non-Destructive Investigation and Destructive Investigation

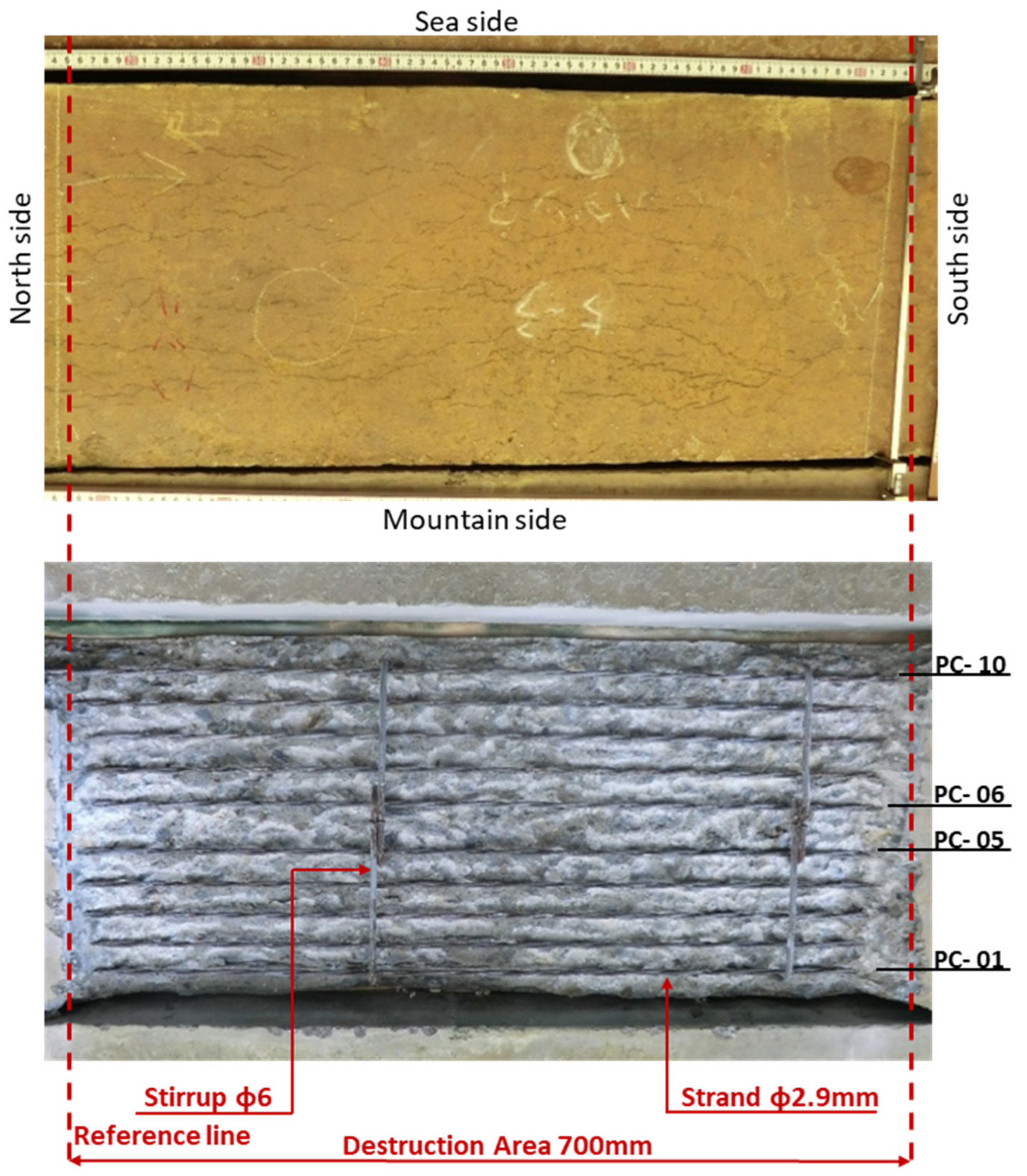

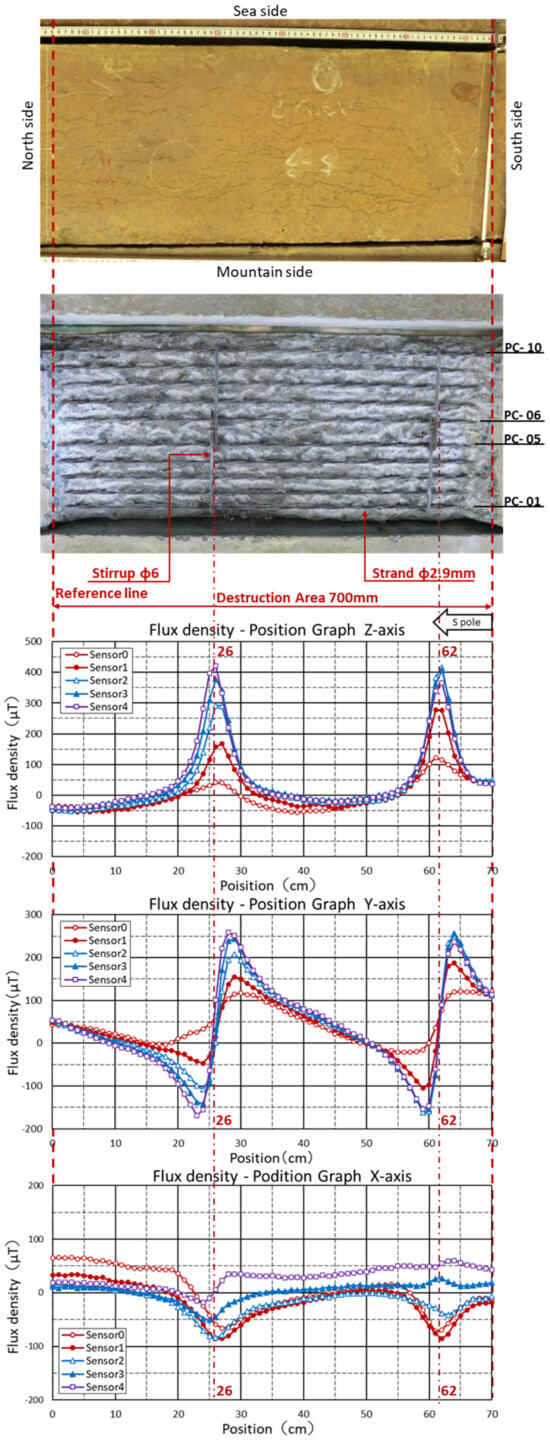

3.2.1. Sound Case (Seaward Side, Area 1)

Figure 10 and Figure 11 show the bottom of the girder before and after destruction and the waveform of the triaxial magnetic method in the sound area, where no cracks were observed on close visual inspection and no detection was observed via the hammer-tapping investigation. Cracks in the axial direction are often observed near the sides of the bottoms of girders deteriorated by salt damage; in this case, none were observed in the investigated area. The bottom of the PC steel, which had a sound cover, showed light rusting throughout, but there were no areas of localized corrosion, indicating that the PC steel was in the early stages of corrosion.

Figure 10.

Before and after destruction at the bottom of the girder (Area 1).

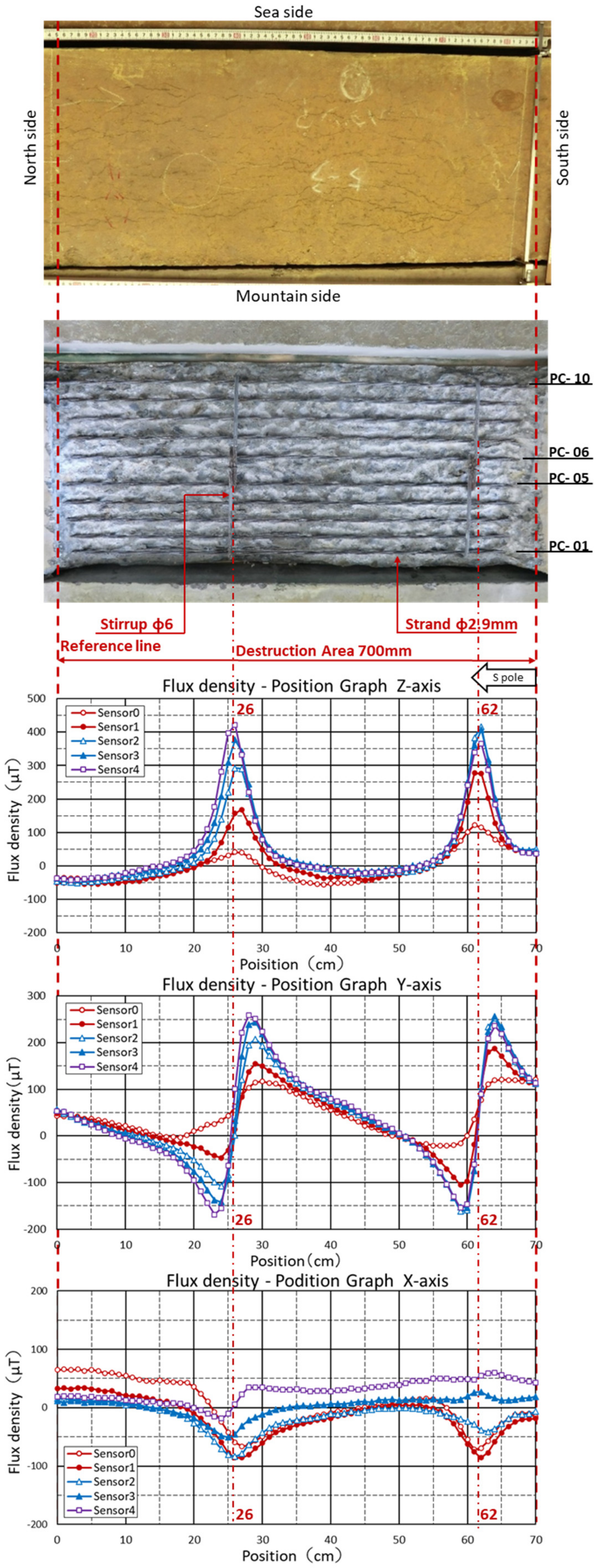

Figure 11.

Before and after destruction at the bottom of the girder, and results of the triaxial magnetic method (Area 1).

The triaxial magnetic method revealed waveforms that could be judged as stirrups at points 26 and 62. In comparison with the photos taken after destruction, stirrups could be seen around measuring points 26 and 62. This indicates that the triaxial magnetic method can detect stirrups with high accuracy. The strong response of sensor 4 indicated on the Z-axis and Y-axis graphs is assumed to have been due to the difference in magnetic force between the centre and the edge on the long side of the permanent magnet that was used, which weakened the magnetic field of the PC steel near the side of the girder, along with the interaction of the magnetic fields of the PC steel, which strengthened the field near the centre of the bottom surface of the girder. The strong responses of sensors 0 and 1 shown on the x-axis graph is assumed to have been due to the magnetic poles at the edges of the stirrups caused by the magnetization, resulting in the stronger response of the sensors closer to the magnetic poles.

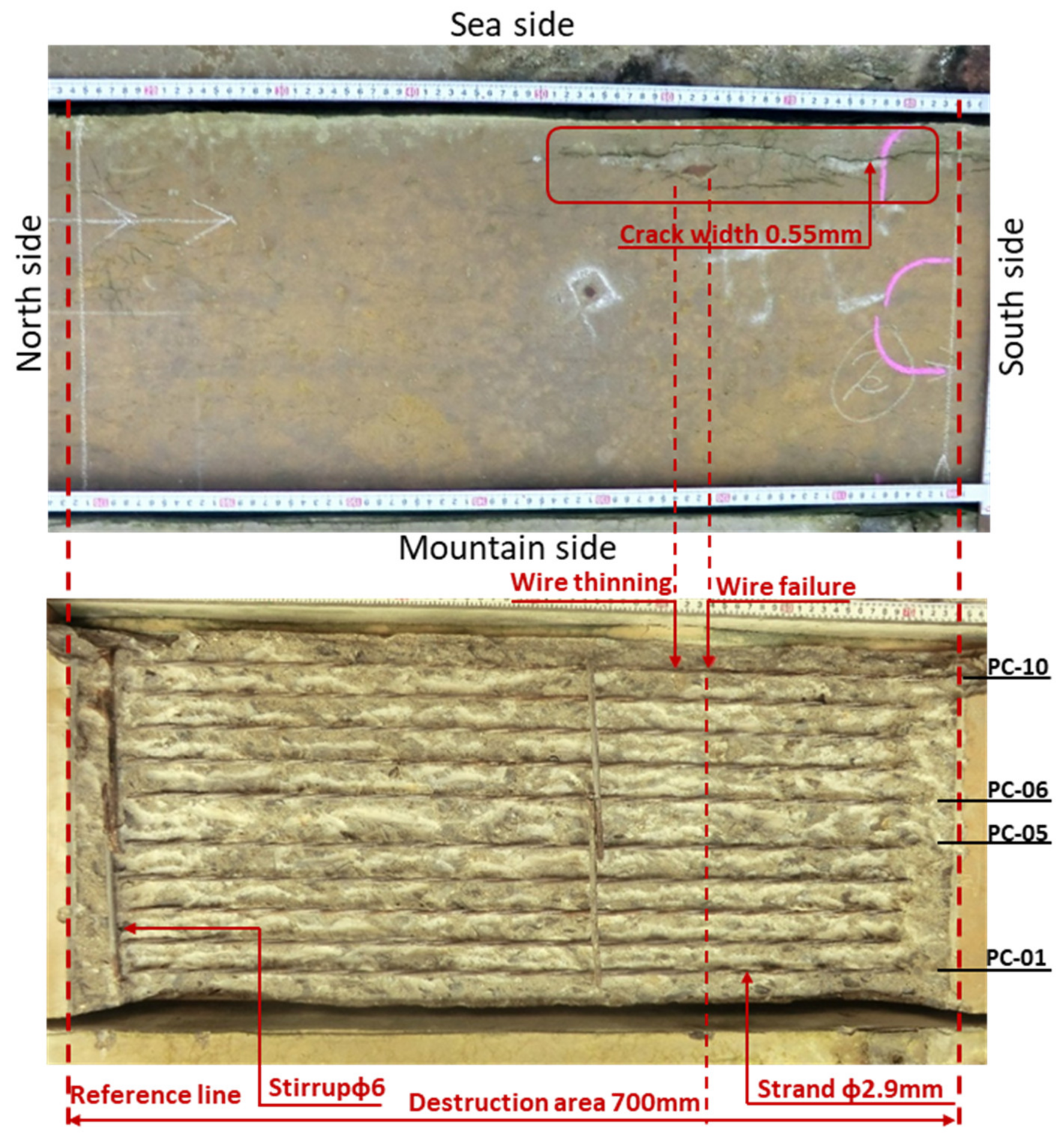

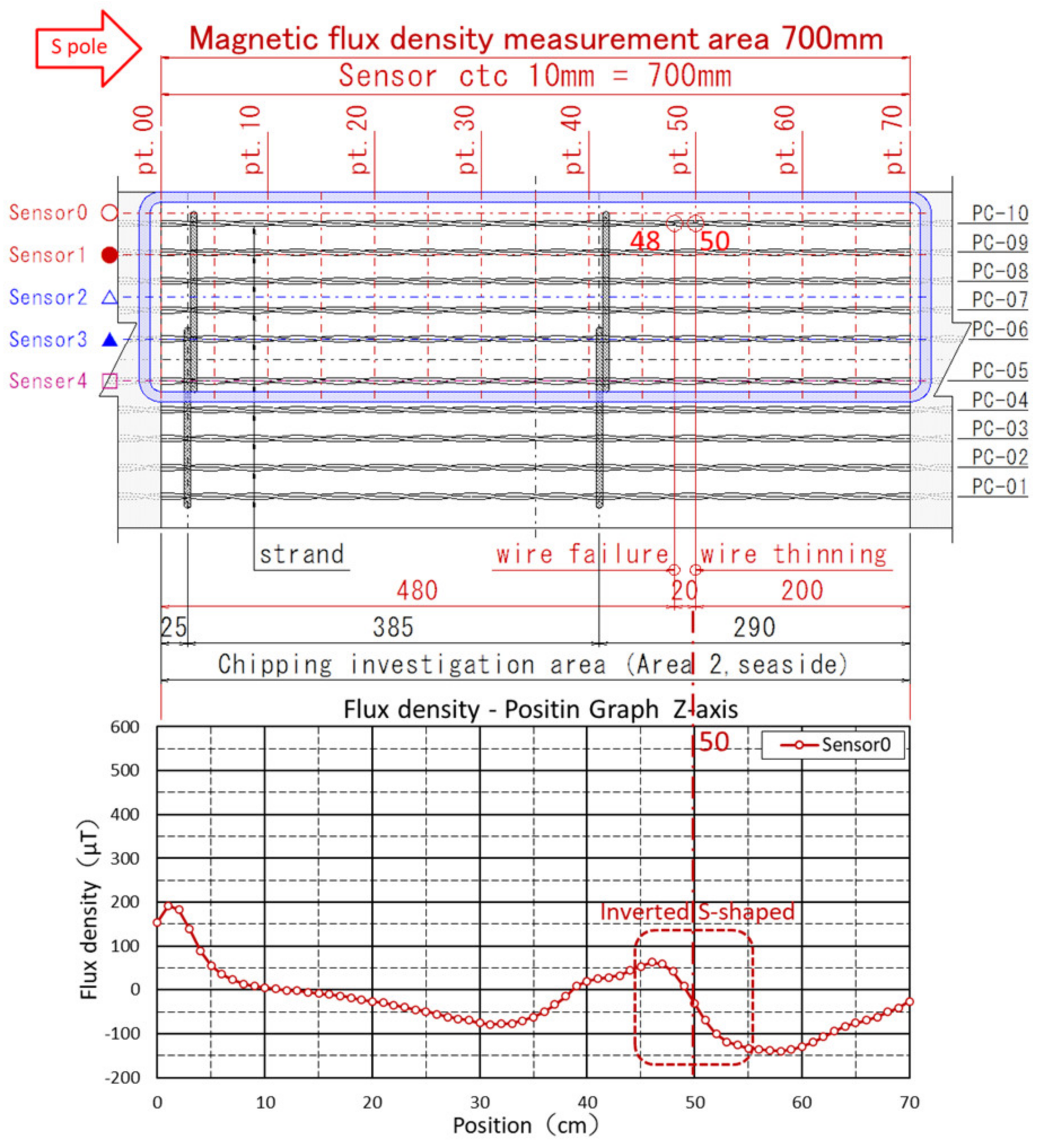

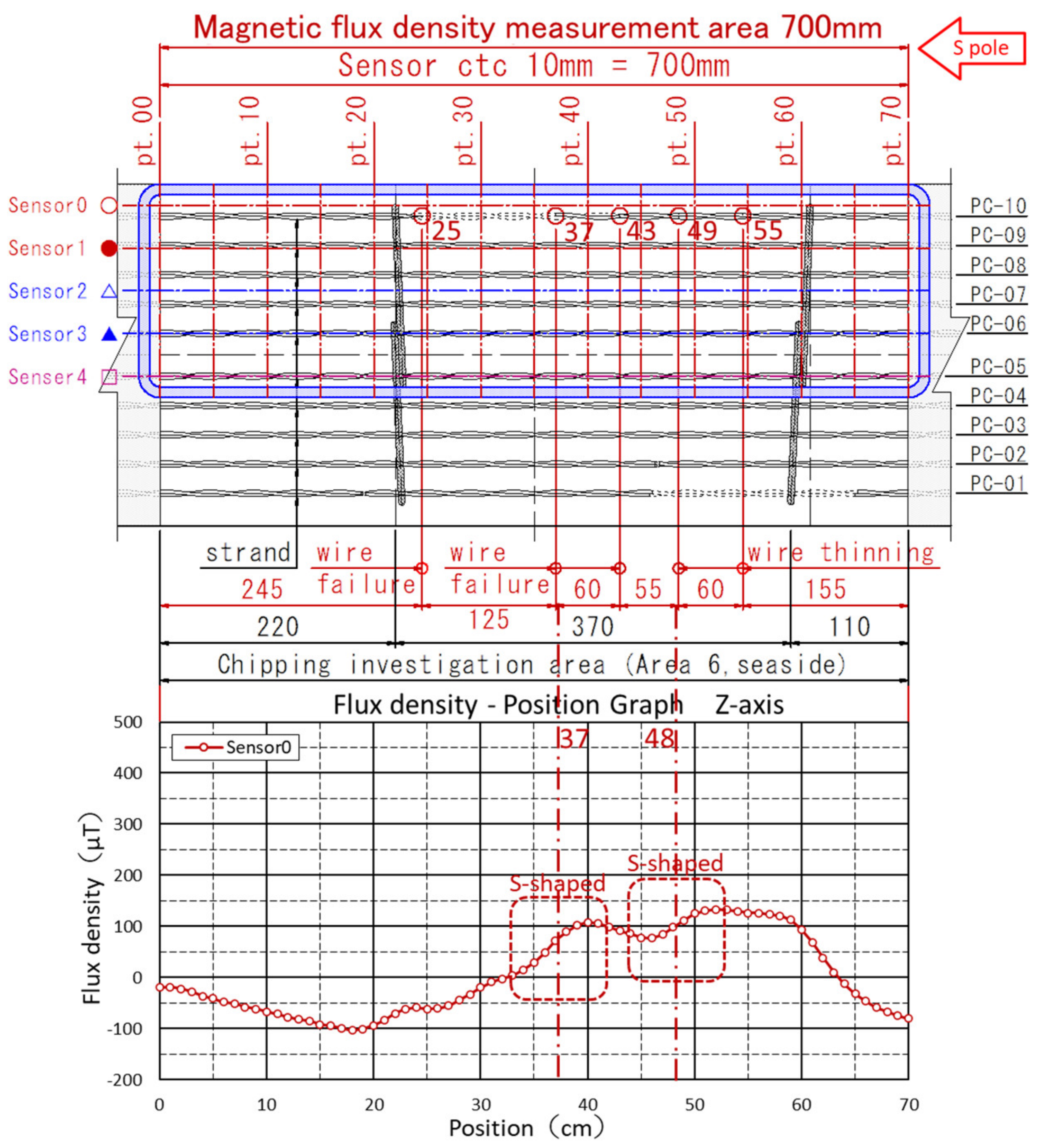

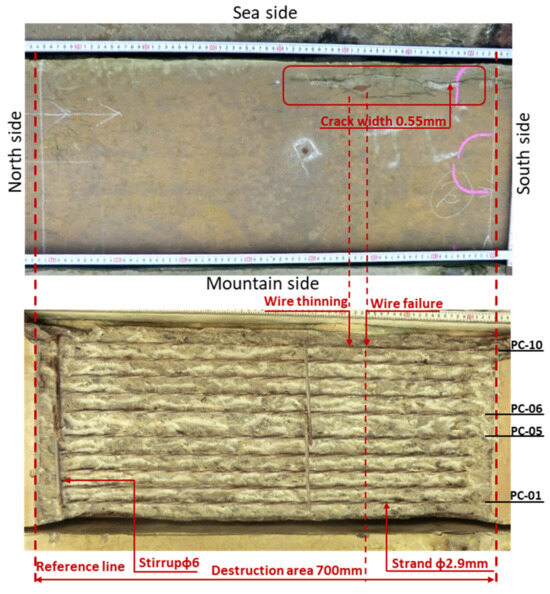

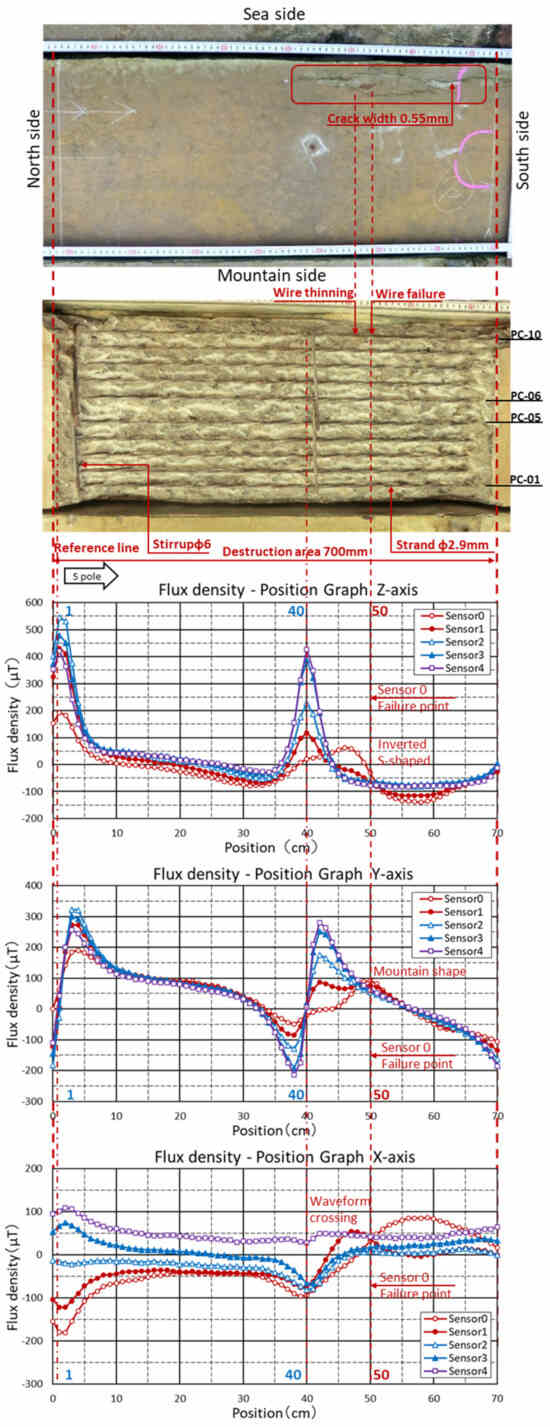

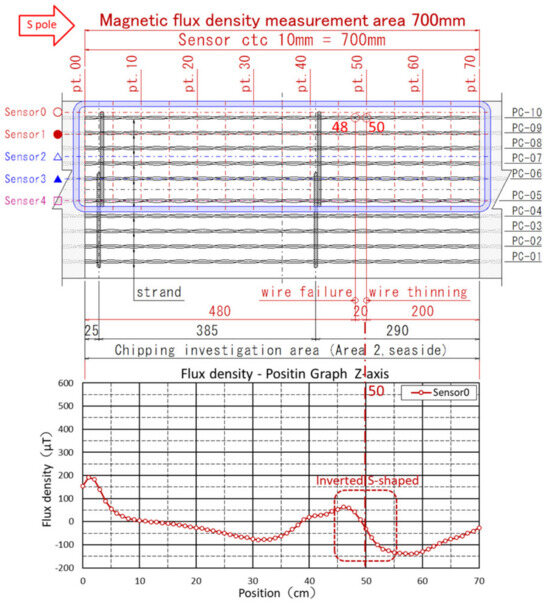

3.2.2. Case of Crack Width 0.55 mm (Seaward Side, Area 2)

Figure 12 and Figure 13 show the bottom of the girder before and after destruction, and the triaxial magnetic waveform of a corrosion crack with a width of 0.55 mm. Cracks were observed on the bottom of the girder in the direction of the girder, starting around 370 mm from the reference line and extending beyond the investigation area, within 20 to 30 mm from the edge of the girder on the seaward side. The maximum crack width was about 0.55 mm, and a crack length of about 180 mm was observed about 40 to 50 mm from the edge of the girder on the seaward side, starting at about 450 mm from the reference line. In between the two cracks, there was a rusty layer about 30 mm long and 10 mm wide. Failure of a single wire (hereafter referred to as a “wire failure”) and a cross-sectional defect of about half of the wire (hereafter referred to as “wire thinning”) were observed on the two-wire strand (hereafter referred to as the “strand”) at the same position as the corrosion crack with a width of 0.55 mm (Figure 14). Except for in the PC steel immediately below the cracks, there was no fracturing or thinning of the strands due to corrosion.

Figure 12.

Before and after destruction at the bottom of the girder (Area 2).

Figure 13.

Before and after destruction at the bottom of the girder, and results of the triaxial magnetic method (Area 2).

Figure 14.

Failure status due to corrosion of strand (Area 2).

Figure 15 presents a comparison between the destruction results and the Z-axis waveform obtained using the triaxial magnetic method. The Z-axis waveform is an inverted S-shape, and the Y-axis waveform is a flank; so, this was judged to indicate a PC steel failure point. In the X-axis waveform, the intersection of sensor 0 and sensor 1 was confirmed at measuring point 50. In the X-axis waveform, the polarity differed between sensors 0–2 and 3–4 near the reference line. A magnetic pole was generated at the edge of the stirrup during magnetisation, but due to the significant unevenness of the magnetization, this was assumed to have been caused by another magnetic pole generated near sensors 3–4. Next, the results after destruction were compared with the waveform generated by the triaxial magnetic method. Wire failure was confirmed near measurement point 50 in the PC steel closest to sensor 0. The wire thinning near point 48 was not detected by the triaxial magnetic method. At point 50, wire failure was detected with good accuracy, even though there was corrosion thinning at point 48.

Figure 15.

Comparison of Z-axis waveform using the triaxial magnetic method; PC steel fracture and sensor arrangement (Area 2).

During magnetization, a local magnetic field is generated at the thinning point of the wire. A magnetic flux is generated inside the magnetized steel in a direction that cancels the magnetic field generated outside the steel. In addition, magnetic fluxes are generated in the magnetized steel in a direction that cancels the magnetic fluxes generated in the defective areas. It can be inferred that these fluxes reduce the influence of the magnetic fluxes generated in the defective parts of the steel. From these results, it is assumed that wire failure can be detected accurately using this method, while in the current study, wire thinning could not be detected. It is possible that sectional defects could be detected via analysis of the thickness of the steel, the amount of magnetization in the steel, and the quantity of sectional defects, but this has not been clarified and is an issue for the future.

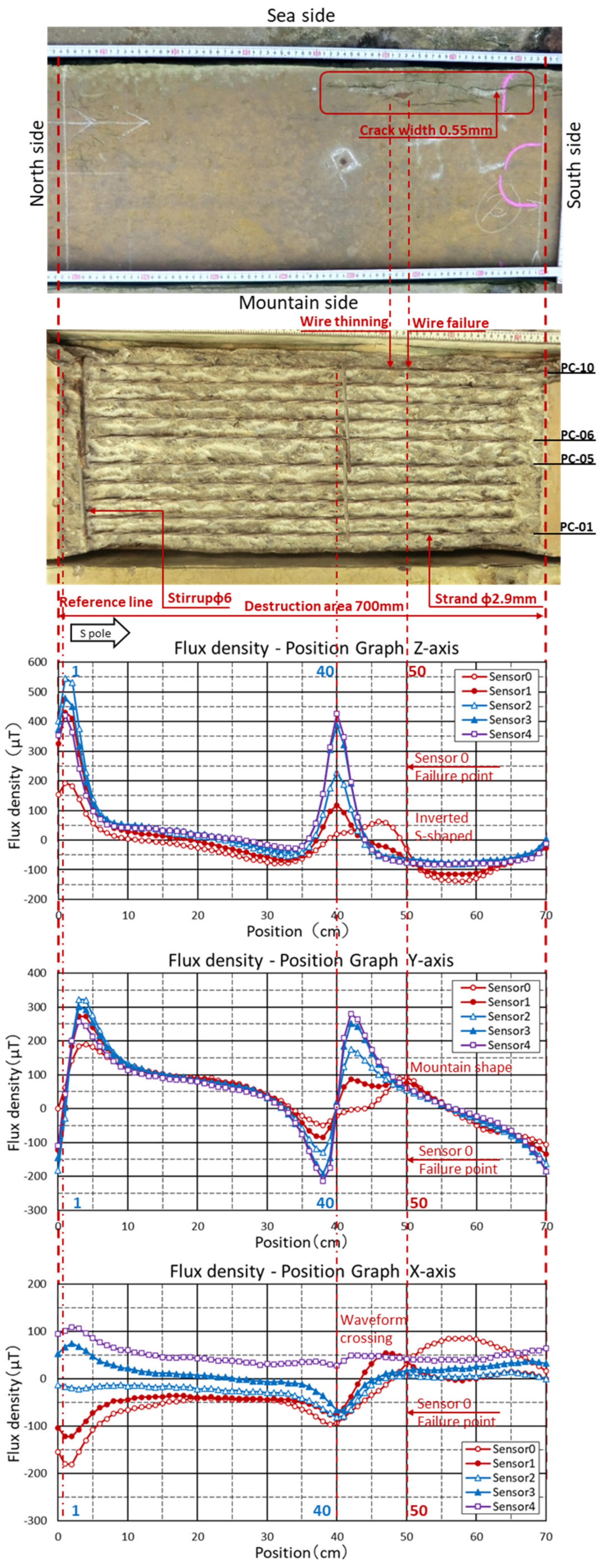

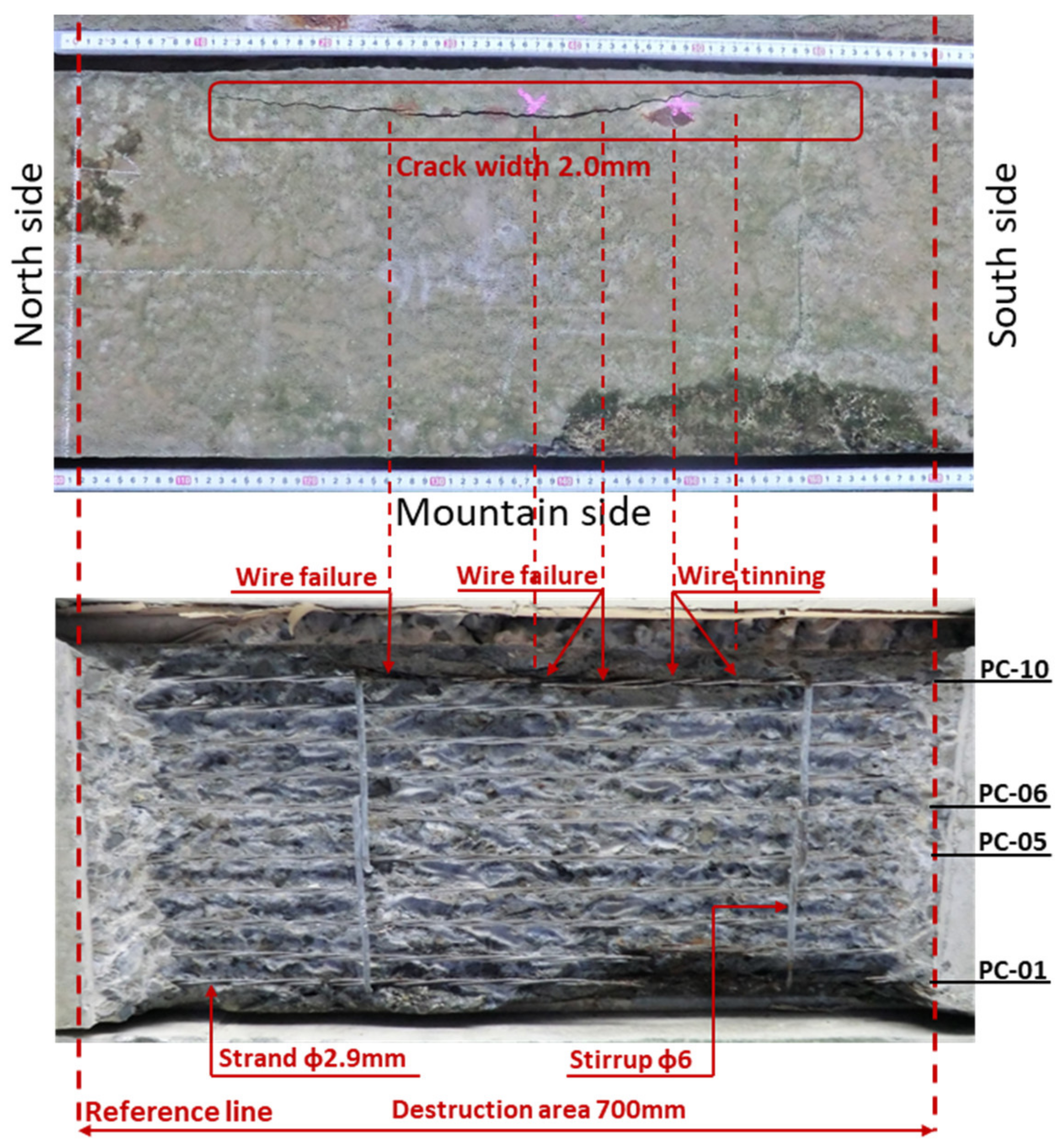

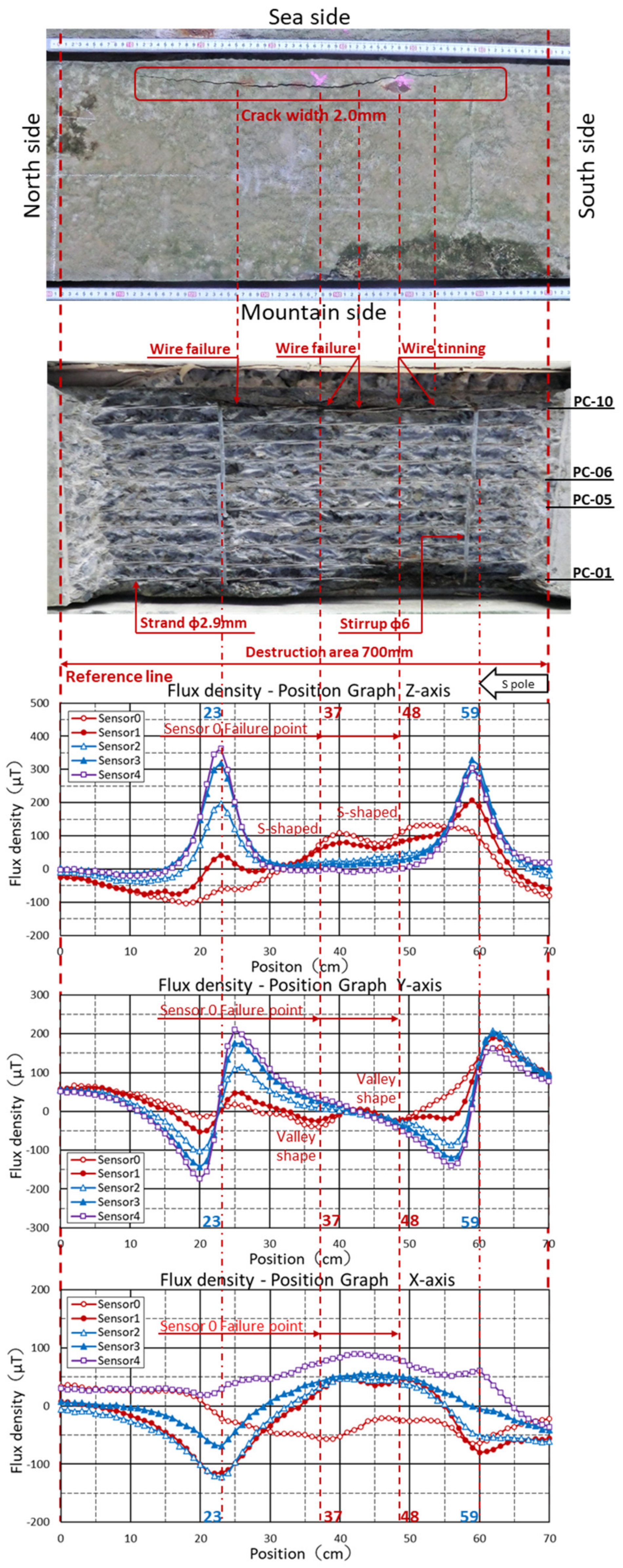

3.2.3. Case of Crack Width 2.0 mm (Seaward Side, Area 6)

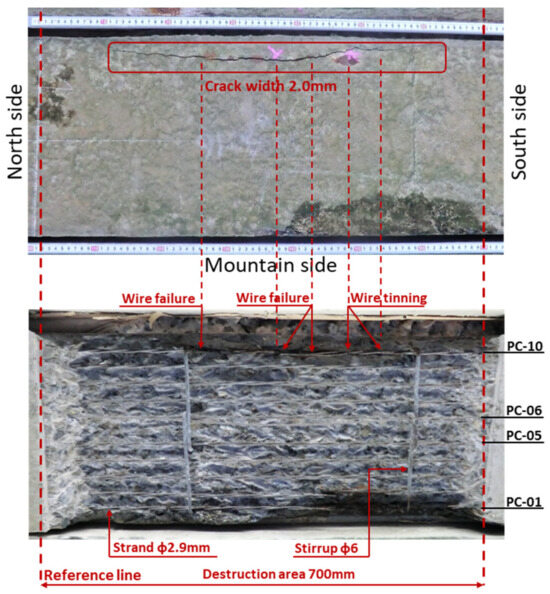

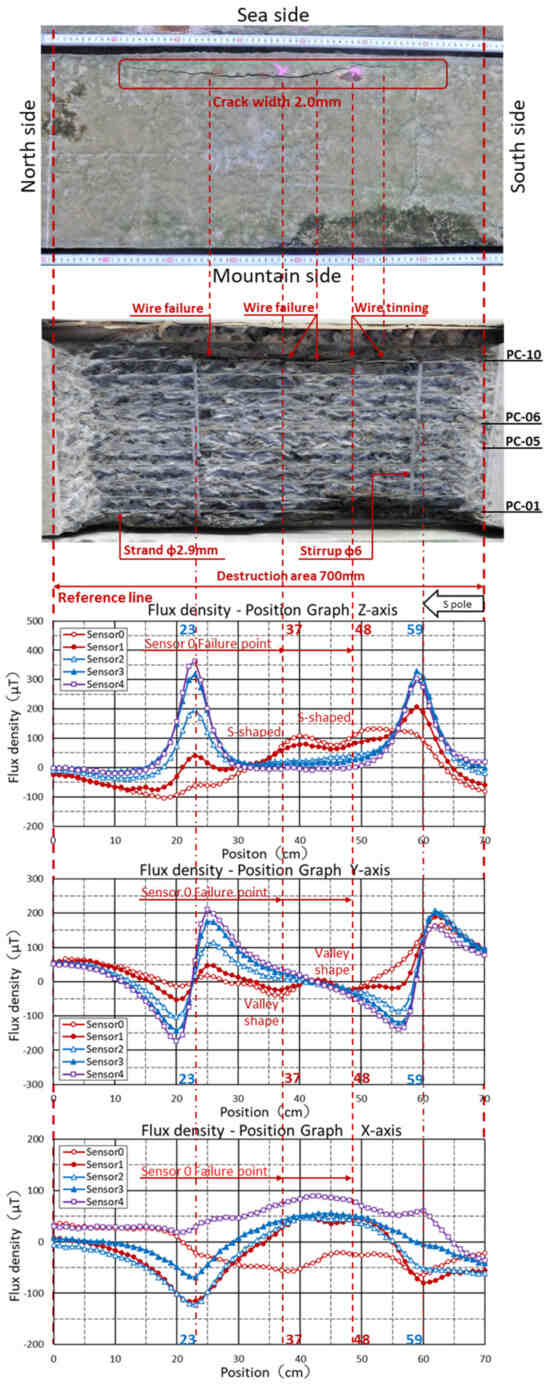

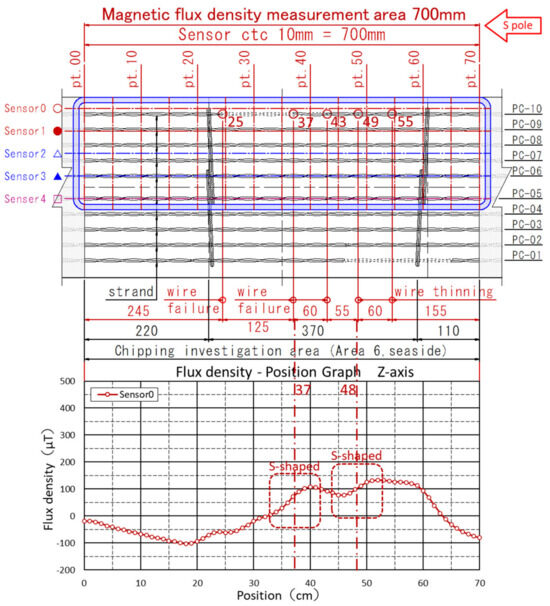

Figure 16 and Figure 17 show the bottom of the girder before and after destruction, and the waveform of the triaxial magnetic method applied for a corrosion crack with a width of 2.0 mm. In the investigation area on the bottom of the girder, cracks with rusty efflorescence were observed within 10 to 40 mm from the seaward side of the girder, starting around 110 mm from the reference line and extending about 530 mm in the direction of the girder. The maximum crack width was about 2.0 mm. Three wire failures and several areas of wire thinning were observed in the two strands at approximately the same position as the crack with a width of 2.0 mm (Figure 18). Except for the PC steel immediately below the corrosion crack, no corrosion fracture nor wire thinning were observed.

Figure 16.

Before and after destruction at the bottom of the girder (Area 6).

Figure 17.

Before and after destruction at the bottom of the girder, and results of the triaxial magnetic method (Area 6).

Figure 18.

Failure status due to corrosion of strand (Area 6).

Figure 19 presents a comparison between the destruction results and the Z-axis waveform acquired via the triaxial magnetic method. The triaxial waveforms showed that sensor 0 had a different waveform from the other sensors at measurement points 37 and 48. The Z-axis waveform was S-shaped, and the Y-axis waveform was valley-shaped. Next, the results after the destruction were compared with the waveforms for the points 37 and 48. The Z-axis waveform was S-shaped, and the Y-axis waveform was valley-shaped. Then, the results after the destruction were compared with the waveform generated using the triaxial magnetic method. Wire failure was observed at point 37 of the PC steel closest to sensor 0, and thinning of each of the two wires was observed at point 48. Strand failure was observed at point 25 near the stirrup, wire failure at point 43, and wire thinning at point 55; however, these could not be detected by the triaxial magnetic method. At measurement point 48, each of the two wires showed evidence of thinning, and the magnetic field was the same as that for wire failure; so, it was assumed that wire thinning had been detected. In the case of the strand rupture at point 25, there was a stirrup about 25 mm from the starting point, and the magnetic fields of the stirrup and a strand rupture overlapped, making it difficult to detect the failure. Detection of failure in the vicinity of stirrups needs future research.

Figure 19.

Comparison of Z-axis waveform using the triaxial magnetic method; PC steel fracture and sensor arrangement (Area 6).

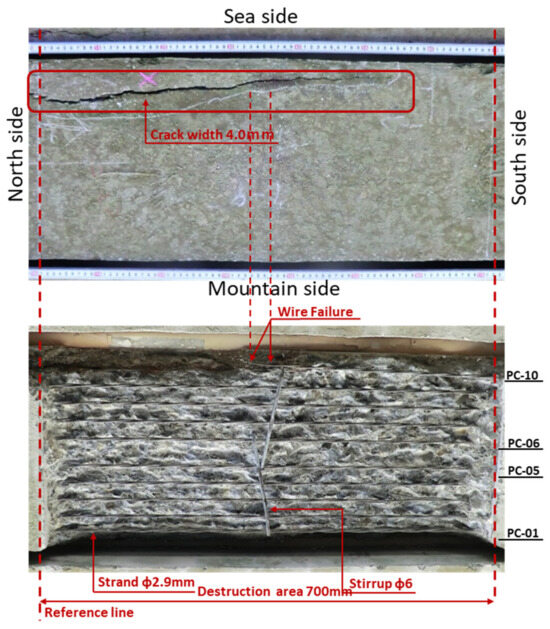

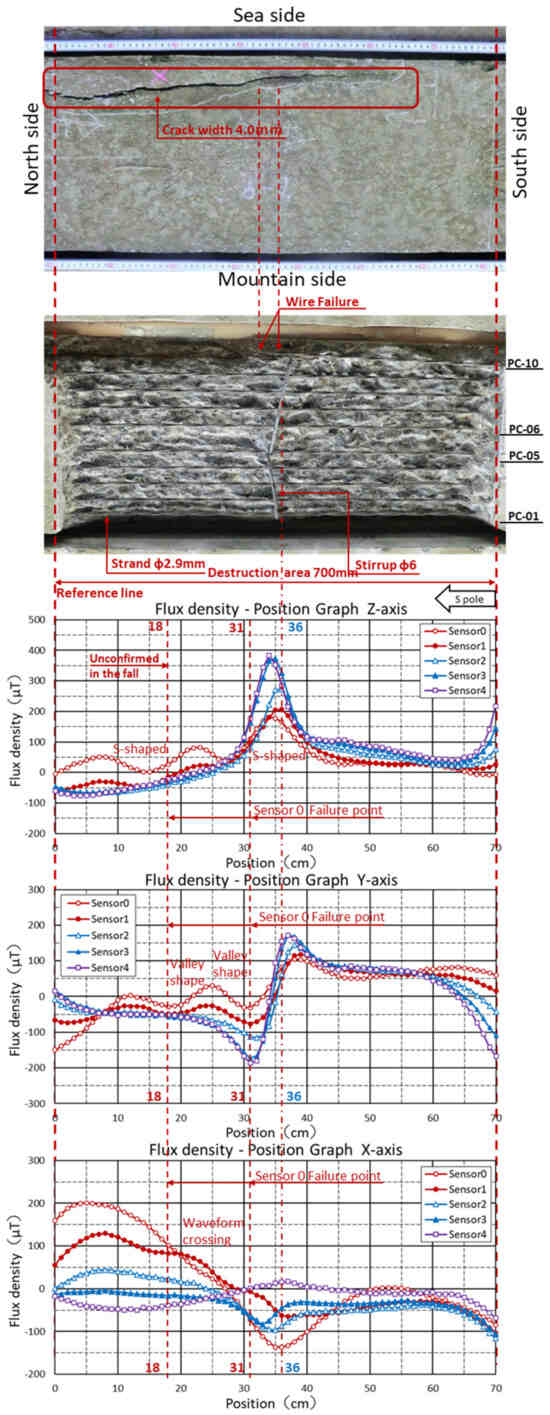

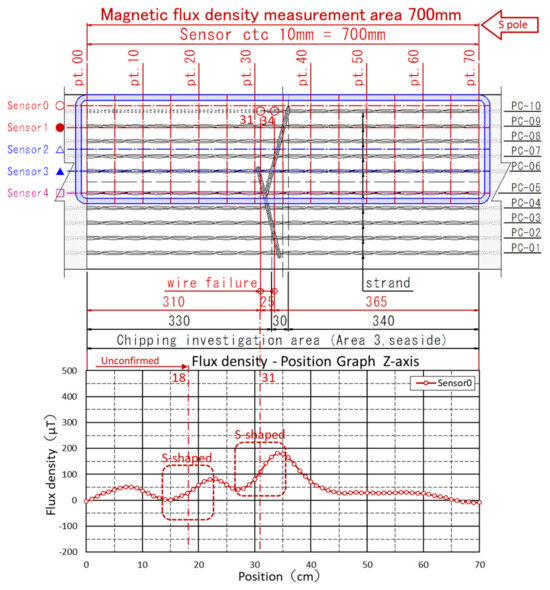

3.2.4. Case of Crack Width 4.0 mm (Seaward Side, Area 3)

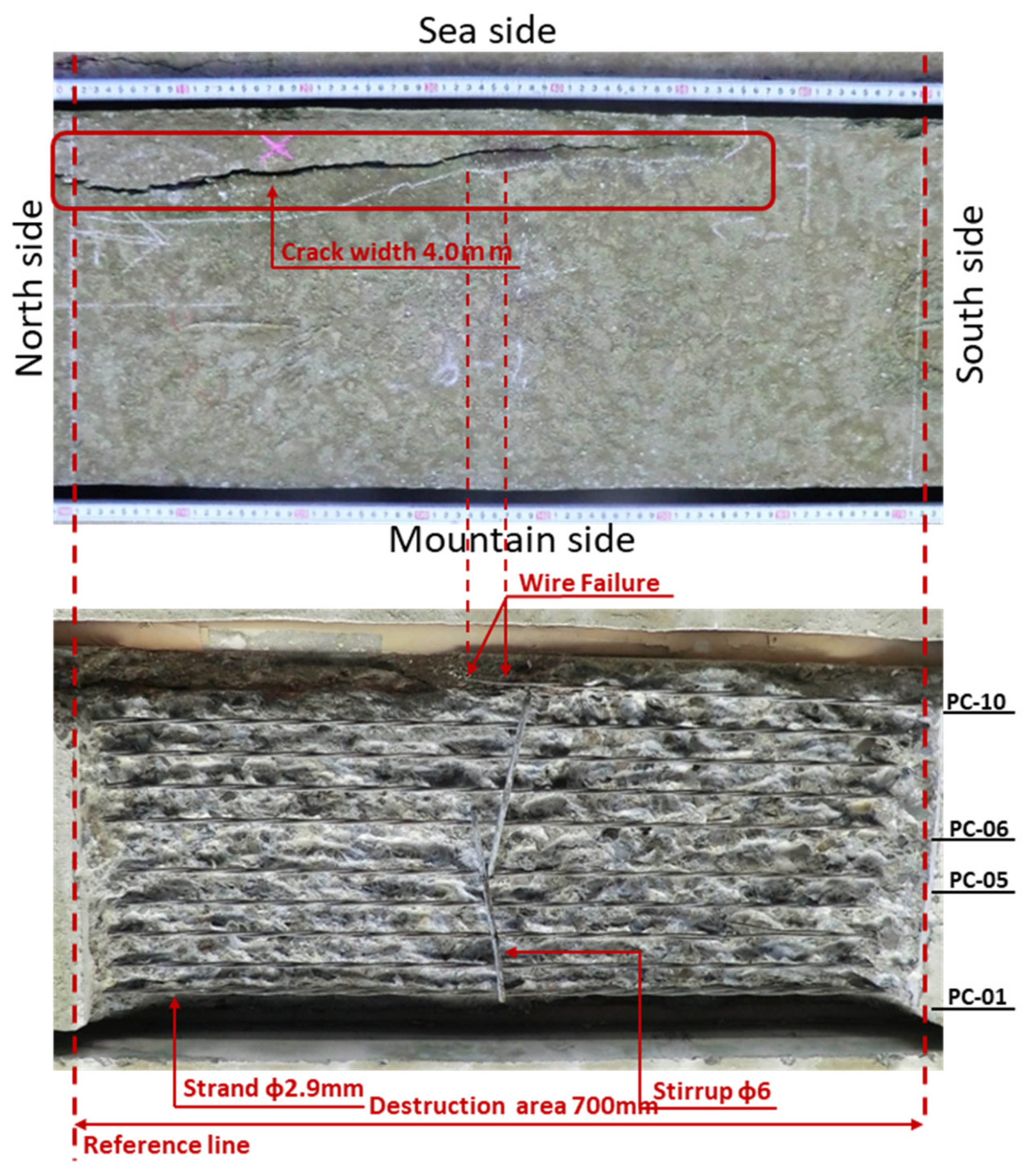

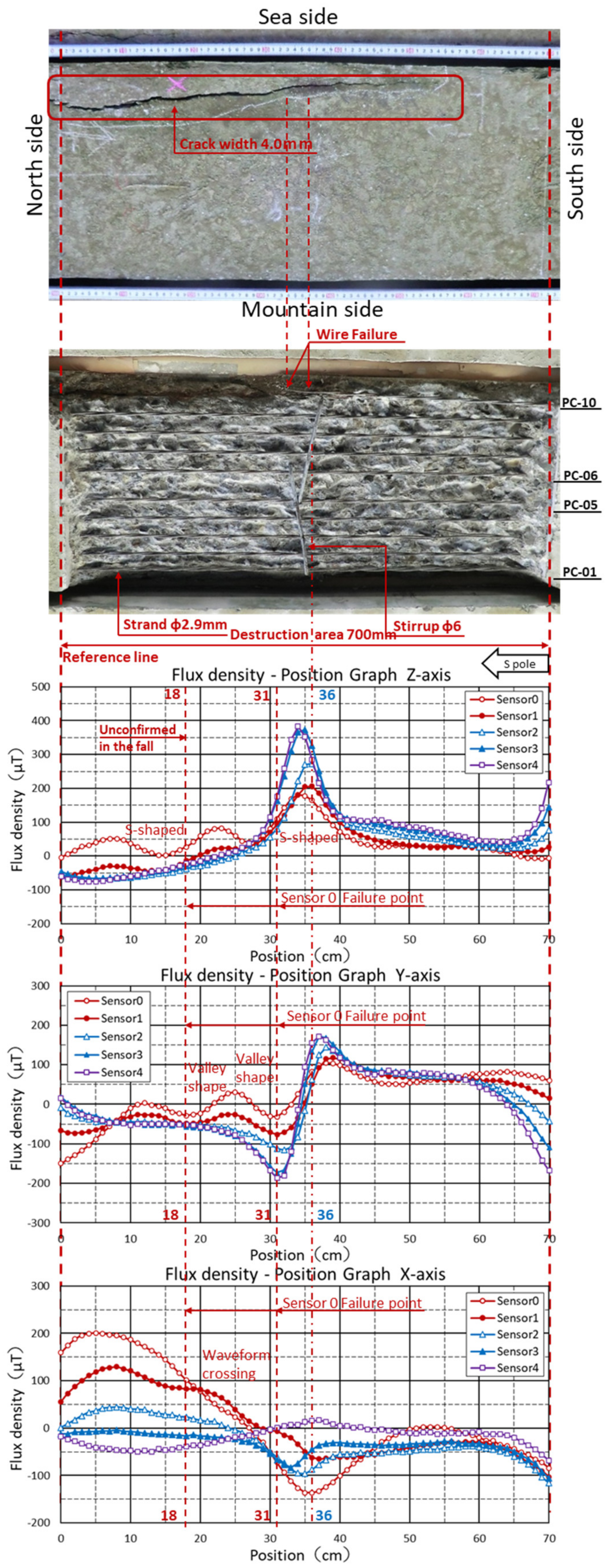

Figure 20 and Figure 21 show the bottom of the girder before and after destruction, and the waveform generated by the triaxial magnetic method for a corrosion crack with a width of 4.0 mm. On the bottom of the girder in the investigation area, cracks were observed with rust efflorescence in the direction of the girder, starting at a point 300 mm beyond the reference line and extending to 530 mm from the reference line, with a length of 830 mm, within a range of 20 to 70 mm from the seaward side of the girder on the seaward side. The maximum crack width was about 4.0 mm. Two wire failures and evidence of a missing strand were observed at about the same position as the corrosion crack with a width 4.0 mm. Figure 22 indicates the state of the wire failure. There were no wire failures or wire thinning due to corrosion, except for in the PC steel just below the corrosion cracks that we focused on.

Figure 20.

Before and after destruction at the bottom of the girder (Area 3).

Figure 21.

Before and after destruction at the bottom of the girder, and results of the triaxial magnetic method (Area 3).

Figure 22.

Failure status due to corrosion of strand (Area 3).

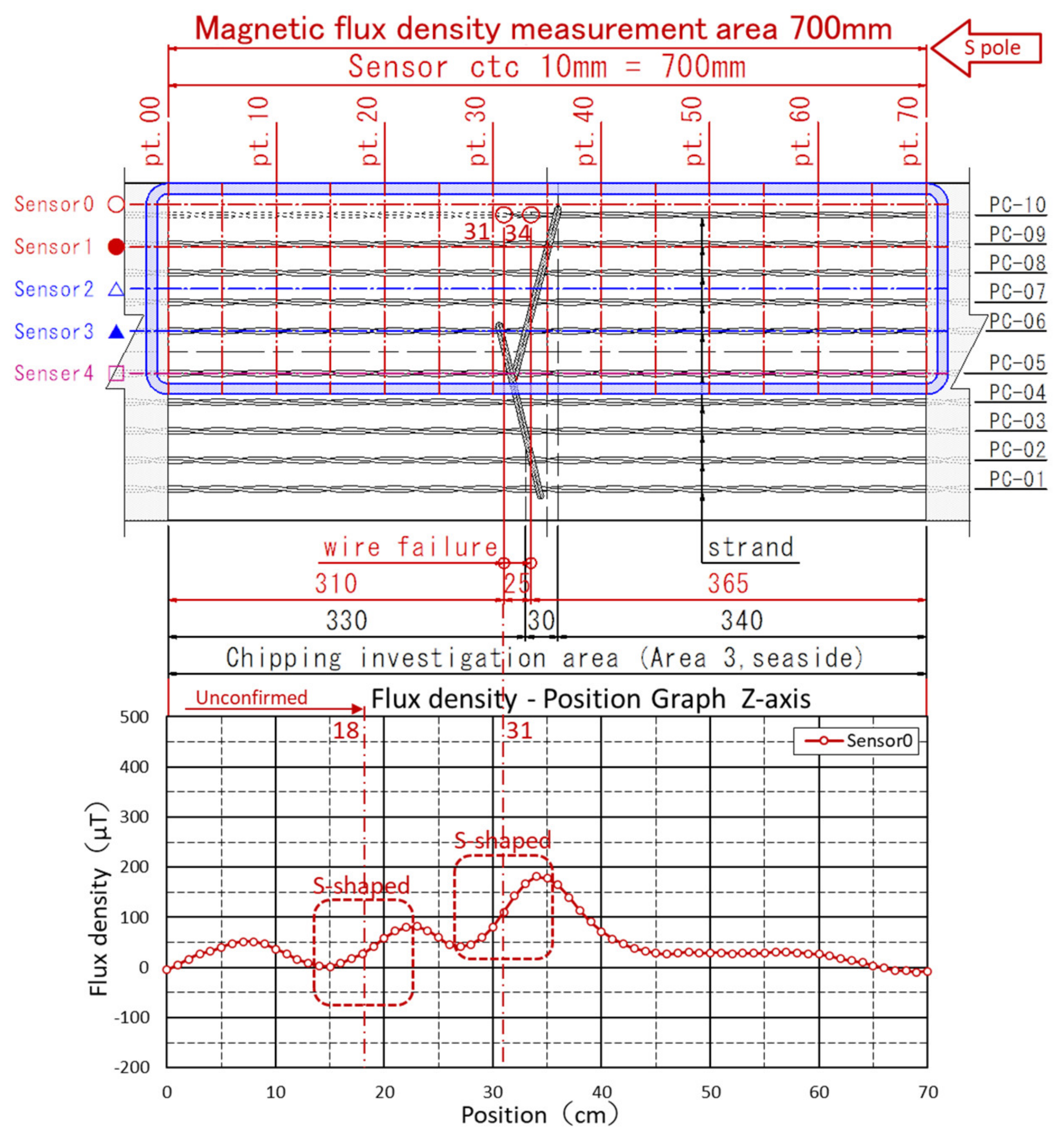

Figure 23 presents a comparison of the destruction results and the Z-axis waveform generated via the triaxial magnetic method. The triaxial waveform results show that sensor 0 had a different waveform compared with the other sensors at measurement points 18 and 31. The Z-axis waveform is S-shaped, and the Y-axis waveform is valley-shaped. The X-axis waveform shows an intersection between sensor 0 and sensor 1 around measurement point 18, but no waveform was found at measurement point 31 that could be judged as a fracture. Next, the results after destruction were compared with the waveform obtained through the triaxial magnetic method. The PC steel closest to sensor 0 was missing from measuring points 0 to 31, and the damage at measuring point 18 could not be confirmed. Wire failure was observed at points 31 and 34 near the stirrup. However, there was also wire failure at points 31 and 34, and it was not possible to determine which instance of failure was being detected. At measuring point 31, there were two wire failures about 30 mm apart. It is thought that the magnetic field generated by the two failures and the stirrup overlapped and formed a magnetic field that looked like that of a single failure.

Figure 23.

Comparison of Z-axis waveform using the triaxial magnetic method; PC steel fracture and sensor arrangement (Area 3).

At the location where the triaxial magnetic method detected a PC steel failure, a strand of two wires and wire failure were confirmed. However, following the triaxial magnetic method, two wire ruptures in close proximity were detected as a single PC steel fracture, but it was difficult to detect each rupture and the rupture in the PC steel near the stirrups. This study verified the detection of failure and thinning in two-wire twisted strands. From the results of this verification, considering cases of PC steel with seven or more stranded wires, such as have frequently been used in recent years, it is estimated that about half of strand failures can be detected. In cases of tendons with bundles of PC steel strands, it is estimated that half of strand failures can be detected. However, as model test measurements have not been carried out, the accuracy of detection of these strand fractures is an issue for the future.

Based on the measurement results from the actual bridge, it was possible to detect one strand break (nominal cross-sectional area 6.606 mm2) out of two strands (ø 2.9 mm (nominal cross-sectional area 13.21 mm2)) with a cover of 30 mm. Full-scale test measurements of steel fractures in three-strand twisted wires carried out by equipment manufacturers have confirmed that total steel fracturing can be measured. Since failure in a single strand can be detected, failure in a two-wire twisted strand, where the magnetic flux density is greater, can also be detected sufficiently. Although single-strand failure was detected near stirrups, there were two single-strand failures nearby and it was not possible to determine which failure had been detected. Regarding ruptures in PC steel, it was confirmed that a single line failure with a cross-sectional area of 7 mm2 could be detected. If PC steel strand failure occurs within 30 mm of a stirrup, misalignment of 20–30 mm may occur even if the failure can be detected. The magnetic field generated at the point of PC steel rupture can be affected by the stirrup’s magnetic field, causing the position of the rupture signal to shift. As the magnetic force generated by magnetizing steel depends on the cross-sectional area of the steel, it can be inferred that the degree of influence depends on the ratio of the cross-sectional area of the PC steel and stirrups. Therefore, it is possible to detect rupture points in PC steel accurately around stirrups by investigating the degree of shift in the position of the rupture signal according to the relationship between the rupture point in the PC steel and the stirrup position, depending on the ratio of the cross-sectional area of the PC steel and the stirrup.

Generally, pre-tensioned girders include multiple tiers of PC steel from the undersides of the girders. Corrosion of steel due to salt damage occurs when salt blown on the wind adheres to the undersides and sides of girders and moisture is supplied (moisture absorption, rainwater, etc.), which penetrates into the concrete, causing the PC steel closest to the concrete surface to corrode and crack, and the supply of oxygen and moisture causes localized fracturing or, to a certain extent, thinning of the steel. The magnitude of the measured magnetic flux density depends on the amount of magnetization of the PC steel by the permanent magnet and the distance between the steel break point and the magnetic sensor. We speculate that the second layer of PC steel can be detected by investigating and analyzing how the magnetic flux density graph changes depending on the magnetic force of the permanent magnet used for magnetization, the distance between the steel rupture point and the magnetic sensor, and the positional relationship between the first and second layers of ruptured steel.

In pre-tensioned T-girders, the PC steel is placed in a bent-up arrangement from the underside of the girder towards the girder ends. When magnetized from the underside of the girder, the bent-up steel is presumed to become a magnetic pole at the bend-up point because there is no PC steel within the magnetic field range of the magnet at the bend-up point. However, it is not known what shape the flux density graphs will take, as no model or real-world measurements have been carried out on bridges comprising pre-tensioned T-girders. These are issues to be addressed in the future.

4. Conclusions

In this study, the results of destructive and nondestructive investigations into PC steel material failure were analyzed to determine the accuracy of the magnetic flux leakage method for detailed detection of fractures and cross-sectional defects in PC steel. The tests were conducted on a pre-tensioned I-girder exposed to a severe salt environment on the coast for about 40 years. The main conclusions of this study are as follows:

- (1)

- Using the triaxial magnetic method, it was confirmed that two-wire failure and one-wire failure in a pre-tensioned girder could be accurately detected using a thin strand of two wires.

- (2)

- Using the magnetic flux leakage method with permanent magnets, it was difficult to detect cross-sectional defects due to corrosion in the wire, because the magnetic field properties of the wire defects did not correspond with the cross-sectional defects;

- (3)

- In the magnetic flux leakage method with permanent magnets, when two wire failures occur close to each other, the magnetic fields overlap and form a magnetic field that can be regarded as a single break; so, it is considered difficult to detect each individual break;

- (4)

- When applying the magnetic flux leakage method with permanent magnets, if there is a failure in the PC steel material near the stirrup, the magnetic fields formed by the failure and the stirrup overlap, causing the magnetic field specific to the failure to move or disappear, which may cause positional error or make detection impossible.

As described above, despite some issues, the triaxial magnetic method for investigating ruptures in PC steel material can detect the rupture of PC steel material with good accuracy. These findings are based on the pre-tensioned girders analyzed in this study, and it is necessary to increase the quantity of research carried out to improve the accuracy of rupture detection in PC steel material via non-destructive investigation. It is expected that the findings of this study will be useful for the inspection and evaluation of similar pre-tensioned girders.

Author Contributions

Conceptualization, H.K. and T.S.; validation, H.K.; formal analysis, H.K.; investigation, H.K.; resources, T.S. and Y.T. (Yoshiaki Tamaki); data curation, H.K. and Y.T. (Yuko Tanabe); writing—original draft preparation, H.K.; writing—review and editing, Y.T. (Yoshiaki Tamaki) and T.S.; visualization, H.K. and Y.T. (Yuko Tanabe); supervision, T.S.; project administration, H.K.; funding acquisition, H.K. and T.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data used in this paper can be provided. Please contact the author.

Conflicts of Interest

Authors Hisashi Kakinohana and Yuko Tanabe were employed by Kawada Construction Co., Ltd., Hisashi Kakinohana and Yuko Tanabe declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest. The company had no role in the design of the study; in the collection, analysis, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Virmani, Y.P.; Clemera, G.G. Corrosion Protection: Concrete Bridge (Report No. FHWA-RD-98-088); U.S. Department of Transportation, Federal Highway Administration, Turner-Fairbank Highway Research Center: McLean, VA, USA, 1998. [Google Scholar]

- JIS A 5313-1959; Prestressed Concrete Beams for Slab Bridges. Japan Industrial Standards Research Association Deliberation: Japanese Standards Association: Tokyo, Japan, 1971.

- Takeda, K.; Tanaka, Y.; Shimomura, T.; Yamaguchi, T.; Kuga, S.; Ibayashi, K.; Murakami, Y. Loading test and numerical evaluation of the residual strength of pre-tension PC beam affected by chloride attack. J. Jpn. Soc. Civ. Eng. Ser. E2 Mater. Concr. Struct. 2015, 71, 303–322. [Google Scholar]

- Singh, S.W.; Rao, B.P.C.; Thirunavukkarasu, S.; Jayakumar, T. Flexible GMR sensor Array for Magnetic Flux leakage Testing of Steel Track Ropes. J. Sens. 2012, 2012, 129074. [Google Scholar]

- Wu, J.; Wu, W.; Kang, Y. Magnetic Flux Leakage Course of Inner Defects and Its Detectable Depth. Chin. J. Mech. Eng. 2021, 34, 63. [Google Scholar] [CrossRef]

- Jones, L.; Pessiki, S.; Naito, C.; Hodgson, I. Inspection Methods & Techniques to Determine Non-Visible Corrosion of Prestressing Strands in Concrete Bridge Components: Task 2—Assessment of Candidate NDT Methods (ATLSS REPORT NO.09-09); Lehigh University, ATLSS Engineering Research Center, Pennsylvania. Dept. of Transportation: Bethlehem, PA, USA, 2010. [Google Scholar]

- Nims, D.K.; Devabhaktuni, V. Magnetic Sensor for Nondestructive Evaluation of Deteriorated Prestressing Strand—Phase II: (Final Report); The University of Toledo, University Transportation Center: Toledo, OH, USA, 2011. [Google Scholar]

- Myakushev, K.; Slearev, D.; Sukhorukov, D. Magnetic flux leakage (MFL) method for nondestructive testing of pre-stressed steel reinforcement strands. In Proceedings of the 12th European Conference on Non-Destructive Testing, Gothenburg, Sweden, 11–15 June 2018. [Google Scholar]

- Hillemeier, B.; Walther, A. Fast Non-Destructive Localisation of Prestressing Steel Fractures in Post-Tensioned Concrete Bridges. In Advances in Construction Materials 2007, 1st ed.; Springer Nature: Heidelberg, Germany, 2007; pp. 563–574. [Google Scholar]

- Yokoyama, T.; Aoki, K.; Miyanaga, K.; Hirose, M. Experiments measuring PC steel rupture by flux leakage method. In Proceedings of the 23rd Symposium on Developments in Prestressed Concrete, Morioka, Japan, 23–24 October 2014; Japan Prestressed Concrete Institute: Tokyo, Japan, 2014; pp. 425–428. [Google Scholar]

- Peng, L.; Huang, S.; Wang, S.; Ahao, W. Three-dimensional magnetic flux leakage signal analysis and imaging for tank floor detect. Inst. Eng. Technol. 2018, 2018, 1865–1870. [Google Scholar]

- Japan Prestressed Concrete Institute. Investigation and Repair and Reinforcement Guidelines for PC Steel Materials for Existing Post-Tension Bridges; Japan Prestressed Concrete Institute: Tokyo, Japan, 2016. [Google Scholar]

- Kato, R.; Nakamori, S.; Hirose, M.; Yamamoto, T. Detection of corroded PC steel in under-grouted areas by the flux leakage method and its effect on beam load-bearing capacity. In Proceedings of the 25th Symposium on Developments in Prestressed Concrete, Kitakyushu, Japan, 20–21 October 2016; Japan Prestressed Concrete Institute: Tokyo, Japan, 2016; pp. 277–282. [Google Scholar]

- Morita, H.; Maruyama, K.; Abe, S.; Hashimoto, Y. Non-destructive inspection solution for detecting internal steel failure in PC bridges by magnetic stream method. In Overview of the 8th Technical Research Presentation of the Okinawa Association of the Japan Society of Civil Engineers; Japan Society of Civil Engineers, Western Branch, Okinawa Chapter: Urasoe-shi, Japan, 2019; pp. 152–157. [Google Scholar]

- Sagradyan, A.; Takaya, S.; Yamamoto, T.; Miyagawa, T. Development of testing procedure for magnetic flux leakage based method of corrosion detection for reinforcement in post-tensioned concrete structures. In Proceedings of Japan Concrete Institute; Japan Prestressed Concrete Institute: Tokyo, Japan, 2015; Volume 37, pp. 1717–1722. [Google Scholar]

- Yamada, N.; Katurai, M. Electromagnetism, rev., 3rd ed.; The Institute of Electrical Engineers of Japan: The Institute of Electrical Engineers of Japan: Tokyo, Japan, 2002; pp. 242–246, 250–252. [Google Scholar]

- Griffiths, D.J. Introduction to Electrodynamics, Forth Education; Pearson Education, Inc.: Glenview, IL, USA, 2013; pp. 59–60, 241–242. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).