A Review on the Use of Plastic Waste as a Modifier of Asphalt Mixtures for Road Constructions

Abstract

1. Introduction

2. Literature Review

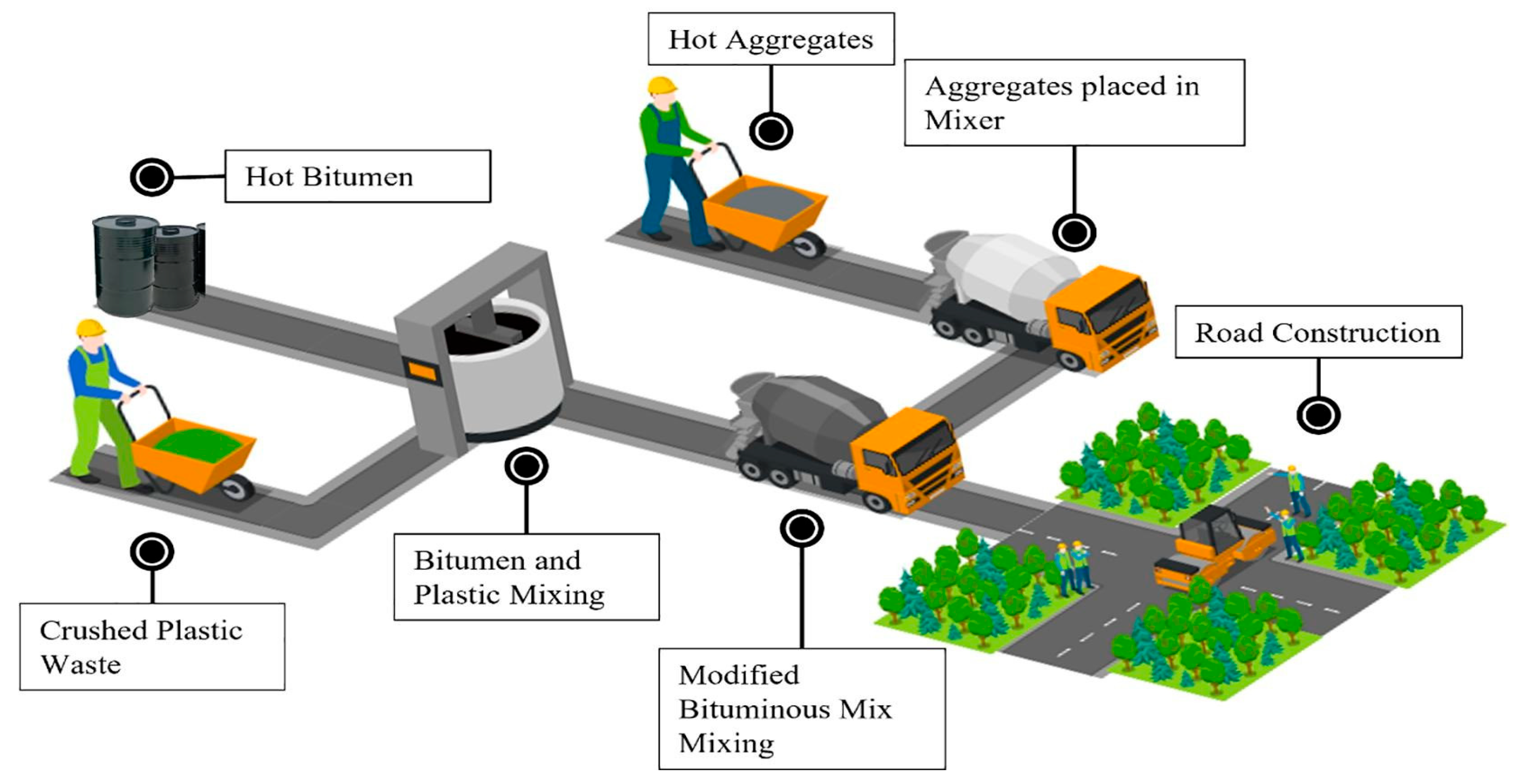

2.1. Wet Process

2.2. Dry Process

2.3. Modified Process

3. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- EN ISO 472:2013; Plastics—Vocabulary. ISO: Geneva, Switzerland, 2013. Available online: https://www.iso.org/obp/ui/#iso:std:iso:472:ed-4:v1:en (accessed on 1 January 2024).

- GESAMP. Sources, Fate and Effects of Microplastics in the Marine Environment: A Global Assessment. Available online: http://www.gesamp.org/publications/reports-and-studies-no-90 (accessed on 3 January 2024).

- Al-Salem, S.M.; Lettieri, P.; Baeyens, J. Recycling and recovery routes of plastic solid waste (PSW): A review. Waste Manag. 2009, 29, 2625–2643. [Google Scholar] [CrossRef] [PubMed]

- Singh, M.; Kamboj, S. Review on Usage of Waste Plastic in Bituminous Roads. J. Univ. Shanghai Sci. Technol. 2020, 22, 1387–1392. [Google Scholar]

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics recycling: Challenges and opportunities. Philos. Trans. R. Soc. Lond B Biol. Sci. 2009, 364, 2115–2126. [Google Scholar] [CrossRef]

- Gao, G.; Zhu, Y.; Zhang, Y.; Zhang, Y. Improved Storage Stability of LDPE/SBS Blends Modified Asphalts. Polym. Polym. Compos. 2002, 10, 229–236. [Google Scholar] [CrossRef]

- De Smet, M.; Linder, M. A Circular Economy for Plastics: Insights from Research and Innovation to Inform Policy and Funding Decisions. Available online: https://op.europa.eu/s/zj4u (accessed on 20 January 2024).

- Green Paper on a European Strategy on Plastic Waste in the Environment. Available online: https://op.europa.eu/s/zj4s (accessed on 20 January 2024).

- Briassoulis, D.; Hiskakis, M.; Babou, E. Technical specifications for mechanical recycling of agricultural plastic waste. Waste Manag. 2013, 33, 1516–1530. [Google Scholar] [CrossRef]

- Hong, R. Plastic Waste Recycling and Greenhouse Gas Reduction Taking Copenhagen as an Example from Life Cycle Assessment Perspective. Master’s Thesis, Aalborg University, Aalborg, Denmark, 2022. [Google Scholar]

- Plastic Waste in the Environment, Bio-Inteligence Service and AEA Technology. Available online: https://op.europa.eu/s/zj4o (accessed on 15 January 2024).

- Kaps, R. Comparative Environmental Evaluation of Plastic Waste Management at National Level on Example of Polish and Austrian Systems. Ph.D. Thesis, Faculty of Commodity Science, Poznan University of Economics, Poznan, Poland, 2008. [Google Scholar]

- Sutharat, M.; Chiemchaisri, W.; Chiemchaisri, C. Microbial consortium involving biological methane oxidation in relation to the biodegradation of waste plastics in a solid waste disposal open dump site. Int. Biodeterior. Biodegrad. 2015, 102, 172–181. [Google Scholar] [CrossRef]

- Wang, M.H.; He, Y.; Sen, B. Research and management of plastic pollution in coastal environments of China. Environ. Pollut. 2019, 248, 898–905. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, Y.; Huang, B.; Chen, Z.; Zhong, M.; Wang, W.; Liu, X.; Fan, Y.n.; Hu, W. Atmospheric phthalate pollution in plastic agricultural greenhouses in Shaanxi Province, China. Environ. Pollut. 2021, 269, 116096. [Google Scholar] [CrossRef] [PubMed]

- Brasileiro, L.; Moreno-Navarro, F.; Tauste-Martínez, R.; Matos, J.; Rubio-Gámez, M.d.C. Reclaimed Polymers as Asphalt Binder Modifiers for More Sustainable Roads: A Review. Sustainability 2019, 11, 646. [Google Scholar] [CrossRef]

- Mashaan, N.; Chegenizadeh, A.; Nikraz, H. Laboratory Properties of Waste PET Plastic-Modified Asphalt Mixes. Recycling 2021, 6, 49. [Google Scholar] [CrossRef]

- Zhu, J.; Birgisson, B.; Kringos, N. Polymer modification of bitumen: Advances and challenges. Eur. Polym. J. 2014, 54, 18–38. [Google Scholar] [CrossRef]

- Nikolaides, A.F.; Manthos, E. Bituminous Mixtures and Pavements VII; CRC Press: Thessaloniki, Greece, 2019. [Google Scholar]

- White, G.; Reid, G. Recycled waste plastic for extending and modifying asphalt binders. In Proceedings of the Conference: 8th Symposium on Pavement Surface Characteristics: SURF 2018, Brisbane, QLD, Australia, 2–4 May 2018. [Google Scholar]

- Prata, J.C.; Costa, J.P.d.; Lopes, I.; Andrady, A.L.; Duarte, A.C.; Rocha-Santos, T. A One Health perspective of the impacts of microplastics on animal, human and environmental health. Sci. Total Environ. 2021, 777, 146094. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Zhang, M.; Rong, H.; Zhang, X.; He, L.; Han, P.; Tong, M. Transport and deposition of plastic particles in porous media during seawater intrusion and groundwater-seawater displacement processes. Sci. Total Environ. 2021, 781, 146752. [Google Scholar] [CrossRef]

- Movilla-Quesada, D.; Raposeiras, A.C.; Silva-Klein, L.T.; Lastra-González, P.; Castro-Fresno, D. Use of plastic scrap in asphalt mixtures added by dry method as a partial substitute for bitumen. Waste Manag. 2019, 87, 751–760. [Google Scholar] [CrossRef]

- Huang, Y.; Bird, R.; Heidrich, O. A review of the use of recycled solid waste materials in asphalt pavements. Resour. Conserv. Recycl. 2007, 52, 58–73. [Google Scholar] [CrossRef]

- Duarte, G.M.; Faxina, A.L. Asphalt concrete mixtures modified with polymeric waste by the wet and dry processes: A literature review. Constr. Build. Mater. 2021, 312, 125408. [Google Scholar] [CrossRef]

- Mishra, B.; Gupta, M.K. Use of plastic waste in bituminous mixes by wet and dry methods. Proc. Inst. Civ. Eng. Munic. Eng. 2020, 173, 87–97. [Google Scholar] [CrossRef]

- Flynn, L. Recylced plastic finds home in asphalt binder. Roads Bridges 1993, 31, 41–47. [Google Scholar]

- Haider, S.; Hafeez, I.; Ullah, R. Sustainable use of waste plastic modifiers to strengthen the adhesion properties of asphalt mixtures. Constr. Build. Mater. 2020, 235, 117496. [Google Scholar] [CrossRef]

- El-Naga, I.A.; Ragab, M. Benefits of utilization the recycle polyethylene terephthalate waste plastic materials as a modifier to asphalt mixtures. Constr. Build. Mater. 2019, 219, 81–90. [Google Scholar] [CrossRef]

- Dhriyan, S.S.; Bhardwaj, A. Application of Waste Plastic in Modifying Bitumen Properties. Int. J. Sci. Res. (IJSR) 2017, 6, 1824–1827. [Google Scholar]

- Ayesha, N.; Atiq Ur Rehman, M. A mini-review on the use of plastic waste as a modifier of the bituminous mix for flexible pavement. Clean. Mater. 2022, 4, 100059. [Google Scholar] [CrossRef]

- Tuncan, A.; Tuncan, M.; Cetin, A. Reuse of Crumb Rubber and Plastic on Hot-Mixed Asphalt Concrete. In Proceedings of the 2nd Eurasphalt & Eurobitume Congress, Barcelona, Spain, 20–22 September 2000; pp. 661–667. [Google Scholar]

- Yousefi, A.A. Rubber-polyethylene Modified Bitumens. Iran. Polym. J. 2003, 13, 101–112. [Google Scholar]

- Hinislioglu, S.; Agar, E. Use of Waste High Density Polyethylene as Bitumen Modifier in Asphalt Concrete Mix. Mater. Lett. 2004, 58, 267–271. [Google Scholar] [CrossRef]

- Polacco, G.; Berlincioni, S.; Biondi, D.; Stastna, J.; Zanzotto, L. Asphalt modification with different polyethylene-based polymers. Eur. Polym. J. 2005, 41, 2831–2844. [Google Scholar] [CrossRef]

- Ho, S.; Church, R.; Klassen, K.; Law, B.; MacLeod, D.; Zanzotto, L. Study of Recycled Polyethylene Materials as Asphalt Modifiers. Can. J. Civ. Eng. 2006, 33, 968–981. [Google Scholar] [CrossRef]

- Asphalt PG 52-34. Available online: https://asphalts.moeveglobal.com/en/products/pg-52-34 (accessed on 12 February 2025).

- Casey, D.; McNally, C.; Gibney, A.; Gilchrist, M.D. Development of a Recycled Polymer Modified Binder for Use in Stone Mastic Asphalt. Resour. Conversat. Recycl. 2008, 52, 1167–1174. [Google Scholar] [CrossRef]

- Moatasim, A.; Cheng, P.; Al-Hadidy, A.I. Laboratory Evaluation of HMA with High Density Polyethylene as a Modifier. Constr. Build. Mater. 2011, 25, 2764–2770. [Google Scholar] [CrossRef]

- Villegas-Villegas, R.E.; Loria-Salazar, L.G.; Aguiar-Moya, J.P.; Fernandez-Gomez, W.D.; Reyes-Lizcano, F.A. Recycling of Banana Production Waste Bags in Bitumens: A Green Alternative. In Proceedings of the 5th Eurasphalt & Eurobitume Congress, Istambul, Turkey, 13–15 June 2012. [Google Scholar]

- Harrigan, E.T.; Leahy, R.B.; Youtcheff, J.S. The SUPERPAVE Mix Design System Manual of Specifications, Test Methods, and Practices; Strategic Highway Research Program, National Academy of Sciences: Washington, DC, USA, 1994; p. 253. [Google Scholar]

- Costa, L.M.B.; Silva, H.M.R.D.; Oliveira, J.R.M.; Fernandes, S.R.M. Incorporation of Waste Plastic in Asphalt Binders to Improve their Performance in the Pavement. Int. J. Pavement Res. Technol. 2013, 6, 457–464. [Google Scholar] [CrossRef]

- Behl, A.; Sharma, G.; Kumar, G. A sustainable approach: Utilization of waste PVC in asphalting of roads. Constr. Build. Mater. 2014, 54, 113–117. [Google Scholar] [CrossRef]

- Dalhat, M.A.; Wahhab, H.I.A.-A. Performance of recycled plastic waste modified asphalt binder in Saudi Arabia. Int. J. Pavement Eng. 2015, 18, 349–357. [Google Scholar] [CrossRef]

- Li, Q.; Xiao, D.; Wang, K.C.P.; Hall, K.D.; Qiu, Y. Mechanistic-empirical pavement design guide (MEPDG): A bird’s-eye view. J. Mod. Transp. 2013, 19, 114–133. [Google Scholar] [CrossRef]

- Khan, I.M.; Kabir, S.; Alhussain, M.A.; Almansoor, F.F. Asphalt Design using Recycled Plastic and Crumb-rubber Waste for Sustainable Pavement Construction. Procedia Eng. 2016, 145, 1557–1564. [Google Scholar] [CrossRef]

- Bansal, S.; Misra, A.K.; Bajpai, P. Evaluation of modified bituminous concrete mix developed using rubber and plastic waste materials. Int. J. Sustain. Built Environ. 2017, 6, 442–448. [Google Scholar] [CrossRef]

- Leng, Z.; Sreeram, A.; Padhan, R.K.; Tan, Z. Value-added application of waste PET based additives in bituminous mixtures containing high percentage of reclaimed asphalt pavement (RAP). J. Clean. Prod. 2018, 196, 615–625. [Google Scholar] [CrossRef]

- Yu, H.; Zhu, Z.; Zhang, Z.; Yu, J.; Oeser, M.; Wang, D. Recycling waste packaging tape into bituminous mixtures towards enhanced mechanical properties and environmental benefits. J. Clean. Prod. 2019, 229, 22–31. [Google Scholar] [CrossRef]

- Papagiannakis, A.T. Mechanistic-Empirical Pavement Design; A Brief Overview. Geotech. Eng. 2013, 44, 75–82. [Google Scholar]

- White, G. Evaluating recycled waste plastic modification and extension of bituminous binder for asphalt. In Proceedings of the Eighteenth Annual International Conference on Pavement Engineering, Asphalt Technology and Infrastructure, Liverpool, UK, 27–28 February 2019. [Google Scholar]

- Hake, S.L.; Damgir, R.M.; Awsarmal, P.R. Utilization of Plastic waste in Bitumen Mixes for Flexible Pavement. Transp. Res. Procedia 2020, 48, 3779–3785. [Google Scholar] [CrossRef]

- Santhanam, N.; Ramesh, B.; Agarwal, S. Experimental investigation of bituminous pavement (VG30) using E-waste plastics for better strength and sustainable environment. Mater. Today Proc. 2020, 22, 1175–1180. [Google Scholar] [CrossRef]

- Elnaml, I.; Liu, J.; Mohammad, L.N.; Wasiuddin, N.; Cooper, S.B., III; Cooper, S.B., Jr. Developing Sustainable Asphalt Mixtures Using High-Density Polyethylene Plastic Waste Material. Sustainability 2023, 15, 9897. [Google Scholar] [CrossRef]

- Louisiana Standard Specifications for Roads and Bridges; Louisiana Department of Transportation and Development: Baton Rouge, LA, USA, 2016.

- Tušar, M.; Kakar, M.R.; Poulikakos, L.D.; Pasquini, E.; Baliello, A.; Pasetto, M.; Porot, L.; Wang, D.; Falchetto, A.C.; Dalmazzo, D.; et al. RILEM TC 279 WMR round robin study on waste polyethylene modified bituminous binders: Advantages and challenges. Road Mater. Pavement Des. 2023, 24, 311–339. [Google Scholar] [CrossRef]

- Radadiya, A.A.; Swami, G.; Sutariya, J.; Sidhdhapara, T.; Desai, N.P. Experimental Study of Dry Mix Process in Road Construction by Adding Recycled Polypropylene. Int. J. Res. Appl. Sci. Eng. Technol. IJRASET 2018, 6, 2358–2363. [Google Scholar] [CrossRef]

- Vasudevan, R.; Sekar, A.R.C.; Sundarakannan, B.; Velkennedy, R. A technique to dispose waste plastics in an ecofriendly way—Application in construction of flexible pavements. Constr. Build. Mater. 2012, 28, 311–320. [Google Scholar] [CrossRef]

- Gangwar, P.K.; Pandey, S.P. Utilization of plastics in road construction. Int. J. Res. Appl. Sci. Eng. Technol. IJARIIE 2016, 2, 1440–1445. [Google Scholar]

- Kamada, O.; Yamada, M. Utilization of Waste Plastics in Asphalt Mixtures; Memoirs of the Faculty of Engineering, Osaka City University: Osaka, Japan, 2002; pp. 111–118. [Google Scholar]

- Hassani, A.; Ganjidoust, H.; Maghanaki, A.A. Use of plastic waste (poly-ethylene terephthalate) in asphalt concrete mixture as aggregate replacement. Waste Manag. Res. 2005, 23, 322–327. [Google Scholar] [CrossRef]

- Awwad, M.T.; Shbeeb, L. The Use of Polyethylene in Hot Asphalt Mixtures. Am. J. Appl. Sci. 2007, 4, 390–396. [Google Scholar] [CrossRef]

- Khan, T.A.; Sharma, D.K. Effect of waste polymer modifier on the properties of bituminous concrete mixes Constr. Build. Mater. 2011, 25, 3841–3848. [Google Scholar] [CrossRef]

- Rongali, U.; Singh, G.; Chourasiya, A.; Jain, P.K. Laboratory Investigation on Use of Fly Ash Plastic Waste Composite in Bituminous Concrete Mixtures. Procedia Soc. Behav. Sci. 2013, 104, 89–98. [Google Scholar] [CrossRef]

- Moghaddam, T.B.; Soltani, M.; Karim, M.R. Evaluation of permanent deformation characteristics of unmodified and Polyethylene Terephthalate modified asphalt mixtures using dynamic creep test. Mater. Des. 2014, 53, 317–324. [Google Scholar] [CrossRef]

- Moghaddam, T.B.; Soltani, M.; Karim, M.R.; Shamshirband, S.; Petković, D.; Baaj, H. Estimation of the rutting performance of Polyethylene Terephthalate modified asphalt mixtures by adaptive neuro-fuzzy methodology. Constr. Build. Mater. 2015, 96, 550–555. [Google Scholar] [CrossRef]

- Angelone, S.; Martinez, F.; Cauhape Casaux, M.L. Green pavements: Reuse of plastic waste in asphalt mixtures. Mater. Struct. 2016, 49, 1655–1665. [Google Scholar] [CrossRef]

- Badejo, A.A.A.; Adekunle, A.; Adekoya, O.O.; Ndambuki, J. Plastic waste as strength modifiers in asphalt for a sustainable environment. Afr. J. Sci. Technol. Innov. Dev. 2017, 9, 173–177. [Google Scholar] [CrossRef]

- Pasetto, M.; Baliello, A.; Pasquini, E.; Poulikakos, L. Dry Addition of Recycled Waste Polyethylene in Asphalt Mixtures: A Laboratory Study. Materials 2022, 15, 4739. [Google Scholar] [CrossRef]

- Poulikakos, L.D.; Pasquini, E.; Tusar, M.; Hernando, D.; Wang, D.; Mikhailenko, P.; Pasetto, M.; Baliello, A.; Falchetto, A.C.; Miljkovic, M.; et al. RILEM interlaboratory study on the mechanical properties of asphalt mixtures modified with polyethylene waste. J. Clean. Prod. 2022, 375, 134124. [Google Scholar] [CrossRef]

- Martin-Alfonso, J.E.; Cuadri, A.A.; Torres, J.; Hidalgo, M.E.; Partal, P. Use of plastic wastes from greenhouse in asphalt mixes manufactured by dry process. Road Mater. Pavement Des. 2019, 20, S265–S281. [Google Scholar] [CrossRef]

- Chavez, F.; Marcobal, J.; Gallego, J. Laboratory evaluation of the mechanical properties of asphalt mixtures with rubber incorporated by the wet, dry, and semi-wet process. Constr. Build. Mater. 2019, 205, 164–174. [Google Scholar] [CrossRef]

- Ahmadinia, E.; Zargar, M.; Karim, M.R.; Abdelaziz, M.; Shafigh, P. Using waste plastic bottles as additive for stone mastic asphalt. Mater. Des. 2011, 32, 4844–4849. [Google Scholar] [CrossRef]

- Jafar, J.J. Utilisation of Waste Plastic in Bituminous Mix for Improved Performance of Roads. KSCE J. Civ. Eng. 2016, 20, 243–249. [Google Scholar] [CrossRef]

- Bary, E.M.A.; Farag, R.K.; Ragab, A.A.; Abdel-monem, R.M.; Abo-shanab, Z.L.; Saleh, A.M.M. Green asphalt construction with improved stability and dynamic mechanical properties. Polym. Bull. 2020, 77, 1729–1747. [Google Scholar] [CrossRef]

- Russo, F.; Eskandarsefat, S.; Venturini, L.; Viscione, N. A complete study on an asphalt concrete modified with graphene and recycled hard-plastics: A case study. Case Stud. Constr. Mater. 2022, 17, e01437. [Google Scholar] [CrossRef]

- Mino, G.D.; Vijayan, V.; Eskandarsefa, S.; Venturini, L.; Mantalovas, K. Investigating the Multi-Recyclability of Recycled Plastic-Modified Asphalt Mixtures. Infrastructures 2023, 8, 84. [Google Scholar] [CrossRef]

- Ecopals: Tomorrows Construction Materials. Available online: https://www.ecopals.de/en (accessed on 12 February 2025).

- Duroflex: Asphalt Additive. Available online: https://www.yumpu.com/en/document/read/11786122/duroflex-r-asphalt-additive-from-germany (accessed on 13 February 2025).

| Abbreviation | Definition | Abbreviation | Definition | Abbreviation | Definition |

|---|---|---|---|---|---|

| ABS | Acrylonitrile–butadiene–styrene terpolymer | LDPE | Low-density polyethylene | PE | Polyethylene |

| AM | Asphalt mixture | LLDPE | Linear low-density polyethylene | PWM | Plastic waste materials |

| Cd | Cadmium | LAS | Linear Amplitude Sweep | RAP | Reclaimed asphalt pavement |

| CDI | Construction Densification Index | MDPE | Medium-density polyethylene | SBR | Styrene–butadiene–styrene random copolymer |

| CO | Carbon monoxide | MEPDG | Mechanistic-Empirical Pavement Design Guide | SBS | Styrene–butadiene–styrene block copolymer |

| DEG | Diethylene glycol | MSCR | Multiple stress Creep recovery | SEBS | Styrene-ethylene-butylene-styrene triblock copolymers |

| DETA | Diethylenetriamine | NR | Natural rubber | SMA | Stone mastic asphalt |

| DSR | Dynamic shear rheometer | Pb | Lead | TEG | Triethylene glycol |

| EVA | Poly (ethylene-vinyl acetate) | PBR | Polybutadiene rubber | TGA | Thermal gravimetrical analysis |

| FTIR | Fourier-transformed infrared spectroscopy | PCA | Plastics coated aggregates | TSR | Tensile strength ratio |

| FT-wax | Fischer–Tropsch wax | PET | Polyethylene terephthalate | UP | Unsaturated polyester |

| GMA | Glycidyl methacrylate | PG | Propylene glycol | VMA | Voids in mineral aggregates |

| GPC | Gel-permeation chromatography | PG | Performance-grade | WPET | Waste poly (ethylene terephthalate) |

| GRP | Graphene-enhanced recycled plastic | PMB | Polymer-modified binders | WPM | Waste polymer modifier |

| GWP | Graphene and waste hard plastic | POP | Dioxin | WPT | Waste packing tape |

| HDPE | High-density polyethylene | PP | Polypropylene | WSBS | Warm Mix with SBS Binder |

| HSBS | Hot Mix with SBS Binder | PPA | Polyphosphoric acid | WTT | Wheel-tracking test |

| HVS | Heavy vacuum slopes | PS | Polystyrene | WWPT | Warm Mix with WPT Binder |

| HWPT | Hot Mix with WPT Binder | PUR | Polyurethane | ||

| ITS | Indirect tensile strength | PVC | Polyvinyl chloride |

| Year | Author | Type of Recycled Plastic Used | Recycled Plastic (%) | Impact on Properties | Refs. |

|---|---|---|---|---|---|

| 2000 | A. Tuncan et al. | LDPE | 5, 10, and 20% by weight of bituminous binder | Marshall stability: Improved stability was achieved by adding plastic, indicating enhanced bonding between the modified binder and aggregates. Indirect tensile strength: Significant boost, with a 69% increase when 20% plastic was added to the binder. | [32] |

| 2002 | Gao et al. | LDPE | 0.5 to 1.5% by weight of bituminous binder | Storage stability: Improved storage stability using pre-blended LDPE/SBS. Softening-point variations were reduced through the addition of sulfur, but viscosity differences at higher LDPE dosages were not eliminated. Rheological properties: Improved high-temperature rutting resistance, as evidenced by dynamic shear rheometer (DSR) temperature-sweep tests. | [6] |

| 2003 | A.A Yousefi | HDPE, LDPE, LLDPE | 1 and 3% by weight of bituminous binder | Physical network formation: A physical network was formed via PBR-PE blends, unlike SBR, NR, and SEBS blends. Elastic recovery and film-forming properties: Superior elastic recovery and film-forming properties were exhibited by SBR-PE blends. Effectiveness of LDPE types: Bituminous binder properties were more effectively altered through LLDPE compared to LDPE and HDPE. Incorporation of HVS oil: Enhanced low-temperature characteristics are offered via HVS oil. Expansion of rubber particles with HVS oil: The volume of rubber particles was expanded by adding HVS oil, contributing to improved material performance. | [33] |

| 2004 | S. Hinislioglu et al. | Recycled HDPE | 4, 6, and 8% by weight of bituminous binder | Marshall stability: Decreasing values were observed in the Marshall stability test with increasing HDPE dosage, except for 4% HDPE mixtures. Marshall flow: An inverse pattern was observed in Marshall flow findings. Rutting resistance: A 50% increase in rutting resistance for the 4% HDPE mixture. | [34] |

| 2005 | G. Polacco et al. | PE-based polymers | 6% by weight of bituminous binder | Storage instability and phase separation: Storage instability and phase separation were exhibited by all PE-based polymer-modified binders. Effect of polymer types: Enhanced compatibility for ethylene-based reactive terpolymers and GMA functional groups. The highest compatibility with the bituminous binder was shown for LLDPE. Rheological and viscosity characteristics: Noticeable differences in rheological and viscosity characteristics were observed in LLDPE, suggesting potential crosslinking during high-shear mixing. | [35] |

| 2006 | S. Ho et al. | Recycled (PE) wax, recycled LDPE | Up to 4% by weight of bituminous binder | Rutting resistance and thermal cracking resistance: Improved rutting resistance but reduced thermal cracking resistance with added PE wax and LDPE was exhibited. Suitability of LDPE for asphalt enhancement: LDPE with a reduced molecular weight and broader molecular weight distribution was identified as better suited for asphalt enhancement. | [36] |

| 2008 | D. Casey et al. | Recycled LDPE, recycled MDPE, recycled HDPE, recycled PP, recycled PVC, recycled PET | Up to 6% by weight of bituminous binder | Impact of DETA on storage stability: Decreased storage stability was exhibited by binders modified with 1 and 2% DETA. Performance enhancement with PPA: Performance properties and storage stability were enhanced through the addition of 0.8% PPA, identifying the binder with 0.8% PPA and 4% HDPE as optimal. Indirect tensile fatigue and rutting tests: Better performance was achieved using an HDPE-plus-PPA modified mixture. | [38] |

| 2011 | A. Moatasim et al. | HDPE | 1 to 7% by weight of bituminous binder | Effects on binder properties: The bituminous binder was stiffened through the addition of HDPE, as indicated by increased softening points and reduced penetration and ductility values, especially at higher dosages. Resistance to temperature fluctuations and mass loss: Improved resistance to temperature fluctuations and decreased mass loss attributed to heat and air were demonstrated by HDPE-modified binders. Stability and rutting resistance in asphalt mixtures: Increased stability and rutting resistance were observed in asphalt mixtures with higher HDPE dosages. Moisture resistance and stiffness: Superior moisture resistance, increased stiffness at 25 °C, and improved thermal cracking resistance at low temperatures were exhibited by HDPE-modified mixtures, particularly the 5% HDPE-modified mixture. | [39] |

| 2012 | R.E. Villegas-Villegas et al. | Recycled HDPE | 3% by weight of bituminous binder | Impacts on high-temperature deformation: Enhanced resistance to high-temperature permanent deformation compared to the base binder. Impact on fatigue resistance: No notable impact on fatigue resistance was observed. Mixture-performance tests: Increased stiffness and improved resistance to rutting and moisture damage were noted. | [40] |

| 2013 | Costa et al. | Recycled HDPE, recycled LDPE | 5% by weight of bituminous binder | Effect on binder properties: Raised softening points and reduced penetration were shown with the incorporation of polymers, particularly with HDPE, EVA, and SBS. Resilience and elasticity of modified binders: Comparable or better resilience was exhibited by modified binders, especially binders modified with EVA, SBS, and crumb rubber. Impact on binder viscosity: Increased binder viscosity was exhibited by polymer addition, with SBS-modified binders exhibiting the highest viscosity. | [42] |

| 2014 | Ambika Behl et al. | Recycled PVC | 3 and 5% by weight of bituminous binder | Increased binder stiffness and viscosity: Increased binder stiffness and viscosity with PVC waste addition after chemical modification and blending were observed. Enhanced rutting resistance: Enhanced resistance against permanent deformation (rutting) was exhibited with 5% PVC waste-modified binder. High consistency and elasticity of modified binders: Increased retained stability and improved moisture susceptibility were demonstrated by modified asphalt mixtures in mechanical tests. Enhanced rutting and cracking resistance: Enhanced resistance against permanent deformation and cracking was observed, with decreased rutting values and increased fatigue life, particularly with higher PVC waste percentages. | [43] |

| 2015 | M.A. Dalhat and H.I. Al-Abdul Wahhab | Recycled PP, recycled HDPE, recycled LDPE | 4% by weight of bituminous binder | Increased viscosity in modified binders: Increased viscosity was observed in all modified binders, with more significant viscosity changes noted in HDPE and PP compared to LDPE. Enhanced rutting resistance: Improved viscoelastic behavior was displayed by the plastic-modified binders, indicating enhanced rutting resistance. Bitumen hardening and stiffness: Bitumen hardening was evidenced due to plastic modification, with the mixture containing 2% PP demonstrating the greatest stiffness. Predicted performance in asphalt pavements: Enhanced predicted rutting and fatigue performance in asphalt pavements, with PP showing a more pronounced improvement compared to HDPE and LDPE were displayed. | [44] |

| 2016 | I.M. Khan et al. | Recycled HDPE, recycled LDPE | 2, 4, 8, and 10% by weight of bituminous binder | Enhancements in elastic behavior and rutting resistance: Enhancements in the elastic behavior and resistance to rutting of the base binder were displayed via the inclusion of HDPE and LDPE. Optimal blends for modifying bitumen: The most effective resistance against rutting was exhibited with the inclusion of 4% HDPE and 10% LDPE | [46] |

| 2017 | Shubham Bansal et al. | Not specified | 4, 6, 8, and 10% by weight of bituminous binder | Increase in strength with partial replacement of bitumen: An increase in strength by up to 16% was observed with the partial replacement of bitumen with plastic waste, while rubber materials showed a remarkable 50% improvement. Flow values and air void content standards: High flow values were exhibited by mixtures with over 10% rubber replacement, and allowable air void content standards were met using both modified and non-modified mixes. Environmental benefits and cost reduction: Enhancements in strength and durability, as well as the potential to reduce environmental pollution and minimize construction costs, were achieved by incorporating post-service life material wastes in asphalt–concrete mixtures. | [47] |

| 2018 | Zhen Leng et al. | Recycled PET | 1, 1.5, and 2% by weight of bituminous binder | Improvements in binder properties: Improvements in softening point, permanent deformation, resistance to stripping, and fatigue cracking resistance were indicated in PET-modified binders with RAP. Influence on elastic characteristics and low-temperature performance: Positive influence on the elastic characteristics and low-temperature performance of the mixtures was observed with the addition of PET-derived additives. Impact on rutting resistance and fatigue crack resistance: A 15% improvement in rutting resistance and a 60% enhancement in fatigue crack resistance were achieved by incorporating PET-based additives. | [48] |

| 2019 | Huayang Yu et al. | Not specified | 6% by weight of bituminous binder | Mechanical performance: Comparable mechanical performance was noted between WPT and SBS asphalt mixtures. Enhanced long-term service performance: Enhanced long-term service performance was exhibited by WPT asphalt mixtures. Prediction by MEPDG: High rutting resistance and smoother pavement were indicated by the results of the MEPDG prediction for WPT asphalt mixtures. | [49] |

| 2019 | G. White | Products from MacRebur | 6% by weight of bituminous binder | Assessment of environmental impact: Leachability and fume generation were assessed in the study, with no adverse impacts found on either. Improvements in asphalt mixtures: Significant improvements in stiffness and rutting resistance were observed in stone mastic asphalt (SMA) mixtures incorporating plastic products, with higher fracture toughness noted under stress-control conditions. Impact on moisture damage resistance and fatigue life: Increased fatigue life was noted with MR6 and MR10, while MR8 showed no improvement over the control mixture under strain-control conditions, although there was no substantial impact on moisture damage resistance. | [51] |

| 2020 | S. L. Hake et al. | Recycled PET | 5, 7.5, 10, 12.5, and 15% by weight of bituminous binder | Improved properties in plastic-modified asphalt mixtures: Improved properties in plastic-modified semi-dense asphalt–concrete mixtures, including a 1.6% decrease in Marshall stability and an 8.1% reduction in air voids. Increase in bulk density: A 0.43% increase in bulk density was observed in neat mixtures, meeting the set limits for voids in mineral aggregates and bitumen-filled voids. Road durability and cost reduction: Enhanced road durability was observed through the inclusion of plastic waste, resulting in an extended service life capable of withstanding heavier loads and a 5.18% reduction in construction and maintenance costs. | [52] |

| 2020 | Needhidasan Santhanam et al. | Not specified | 5 to 20% by weight of bituminous binder | Effect on ductility, penetration, and softening point: A decrease in ductility values was observed with increasing e-waste powder, reaching a maximum at 5% penetration and softening tests indicated lower values in the absence of e-waste plastic, which increased significantly with higher percentages. Impact on viscosity and bitumen need: A gradual increase in viscosity was revealed with more e-waste plastic, reaching a minimum without any addition. Substituting 10% of e-waste resulted in a 10% reduction in bitumen needs, leading to an enhancement in flexibility and strength by 11.28%. Effect on binder stability and Marshall stability: Binder stability was decreased when exceeding 7.5% e-waste, and Marshall stability was improved by up to 25% with the incorporation of fly ash. | [53] |

| 2023 | I.Elnaml et al. | Recycled HDPE | 3% by weight of bituminous binder | Stiffness and Rutting Resistance of HDPE-Modified Asphalt Mixture: Greater stiffness and rutting resistance compared to conventional mixtures M76 and M70 were exhibited by the HDPE asphalt mixture. Resistance to Moisture and Crack Resistance: Enhanced resistance to moisture was observed in the M673H mixture due to the inclusion of HDPE plastic waste. | [54] |

| 2023 | M. Tušar al. | Polyethylene (PE) | 5% by weight of bituminous binder | Temperature-Dependent Behavior: Elastic properties were exhibited by the mix at low temperatures, while at high temperatures, bitumen became viscoelastic, leading to inhomogeneity and instability. Filler-Like Effect: PE was observed to act as a filler above 34–40 °C, influencing viscosity trends. Resistance to Permanent Deformation: Improved resistance to permanent deformation was indicated through MSCR tests. Fatigue Performance and Stress Resistance: Enhanced fatigue performance and stress resistance were demonstrated through LAS tests. Feasibility of Secondary Waste Usage: No significant performance difference was observed between shreds and pellets, making secondary waste a viable alternative. | [56] |

| Year | Author | Type of Recycled Plastic Used | Recycled Plastic (%) | Impact on Properties | Refs. |

|---|---|---|---|---|---|

| 2002 | O. Kamada et al. | Recycled PE, recycled PP | Up to 10% by volume of asphalt mixture | Fatigue, rutting, and stripping Resistance in dense-graded mixtures: Enhanced fatigue, rutting, and stripping resistance in dense-graded mixtures were achieved with the incorporation of PE, with outcomes varying based on the specific type of recycled PE. Rutting resistance in PP-modified dense-graded mixtures: Enhanced rutting resistance was observed in PP-modified dense-graded mixtures, with no improvements in fatigue and stripping resistance. Resistance to rutting, stripping, and gasoline immersion in open-graded mixtures: Improved resistance to rutting, stripping, and gasoline immersion in open-graded mixtures was achieved with the addition of PE. | [60] |

| 2005 | A. Hassani et al. | PET | 5 to 15% by weight of asphalt mixture | Marshall stability and flow: With increasing PET dosage, decreased stability, and increased flow were exhibited by Plastiphalt mixtures. Marshall-quotient values: Except for the 5% dosage, lower stability and Marshall-quotient values were consistently observed with Plastiphalt, attributed to reduced friction between PET granules. Density: The lower density values of all Plastiphalt mixtures compared to the control mixture were attributed to the reduced specific gravity of PET. Aggregate replacement: Natural resources could be saved by substituting 5% of aggregates with PET in the construction of a 1 km road. | [61] |

| 2007 | M.T. Awwad et al. | HDPE, LDPE | 6 to 18% by weight of bituminous binder | Bulk density: Reduced bulk density was consistently exhibited by blends containing PE modifications, with the highest bulk density observed at a 12% dosage for both HDPE and LDPE. Marshall stability and flow: Marshall stability flow was improved with the addition of HDPE and LDPE with ground HDPE. Air voids and VMA: Air voids and VMA were elevated in blends with PE modifications, decreasing up to a 12% dosage and increasing at higher dosages. | [62] |

| 2011 | Sangita et al. | Blend of recycled PE and shredded nitrile rubber | 6, 8, 12, and 15% by weight of bituminous binder | Marshall stability: An optimal dosage of 8% WPM was identified. Indirect tensile strength, creep stiffness, resilient modulus: The optimal modified mixture with WPM was observed to have augmented stiffness, thereby enhancing its ability to resist permanent deformation and moisture damage. Retained stability and rutting resistance: Improved resistance to permanent deformation and moisture damage in the asphalt mixture was exhibited. | [63] |

| 2012 | R. Vasudevan et al. | Recycled PE, recycled PP, recycled PS | 5 to 20% by weight of bituminous binder | Enhanced properties of plastics coated aggregates (PCA): Various properties, such as crushing resistance, soundness, impact resistance, abrasion resistance, and reduced water absorption, were improved via the introduction of waste plastics to aggregates. Improved Marshall stability: Enhanced Marshall stability, indicating improved resistance to deformation and structural integrity, was exhibited. Performance of paving projects: Comparable or superior performance in terms of smoothness, field density, rebound deflection, texture depth, and skid resistance was observed. Absence of pavement defects: Instances of rutting, cracking, potholes, or edge flaws commonly associated with conventional asphalt mixtures were absent in projects utilizing PCA. Cost savings: Potential material cost savings of around 10% were suggested by a cost analysis for asphalt mixtures incorporating PCA, indicating economic benefits associated with this approach. | [58] |

| 2013 | Umadevi Rongali et al. | Not specified | 0.25 to 1% by weight of asphalt mixture | Enhanced indirect tensile strength: A 10.3% greater indirect tensile strength ratio was exhibited by AC B compared to AC A, indicating enhanced durability against moisture damage. Higher deformation and recovery: Higher deformation and recovery percentages were revealed via static creep tests for AC B at elevated temperatures, suggesting improved resistance to deformation under thermal stress. Higher resilient modulus values: Higher resilient modulus values were exhibited by AC B compared to AC A, indicating greater stiffness and structural integrity. Lower rut depth: A 15.9% lower rut depth was demonstrated by AC B than AC A, highlighting improved resistance to rutting, a common distress mechanism in asphalt pavements. Suitability for asphalt pavement structure: Enhanced properties were displayed by asphalt–concrete pavement containing a composite of plastic waste and fly ash, making it suitable for use in asphalt road construction. | [64] |

| 2014–2015 | T.B. Moghaddam et al. | Recycled PET | 0.2 to 1% by weight of aggregate | Improvement in rutting resistance: Significant improvements in rutting resistance were observed in PET-modified SMA mixtures at higher PET contents and stress levels. | [65] |

| 2016 | S. Angelone et al. | Recycled PE, recycled PP | 2, 4, and 6% by weight of asphalt mixture | Stability enhancement: Increased stability values with rising plastic content were demonstrated by PE-modified mixtures, whereas decreased stability was shown for PP-modified mixtures. Rutting Resistance: Comparable permanent deformation resistance to control mixtures was exhibited by PE-modified mixtures, while lower performance in this aspect was shown by PP-modified mixtures. Fatigue and thermal cracking resistance: Better fatigue and thermal cracking resistance were exhibited by PE-modified mixtures, whereas lower performance in these aspects was shown for PP-modified mixtures. Water immersion resistance: Good resistance to water immersion was shown for both PE and PP-modified mixtures. Thermal susceptibility: Low thermal susceptibility was exhibited by PE-modified mixtures, whereas similar dynamic modulus results in control mixtures at 2% and 4% PP were displayed by PP-modified mixtures. | [67] |

| 2017 | A.A. Adedayo Badejo et al. | Recycled PET | 1 to 5% by weight of bituminous binder | Marshall stability and flow: Decreased Marshall stability was shown for mixtures enhanced with PET compared to the unmodified mixture. Increased Marshall flow values, indicating the decreased stability and deformation resistance of the mixture, were exhibited by mixtures enhanced with PET. | [68] |

| 2018 | G. White et al. | Not specified | 6% by volume of bituminous binder | Impact on AC20 mixture: Enhanced stiffness, improved rutting resistance, and superior resistance to moisture damage were displayed by the AC20 mixture when modified with MR6 compared to the unmodified mixture. Impact on SMA10 mixture: Increased rutting resistance, fracture toughness, and stiffness resulted from the incorporation of MR6, MR8, and MR10 in the SMA10 mixture. Moisture damage resistance: The impact on moisture damage resistance varied between the three plastic products. Economic evaluation: A financially viable option compared to typical modified binders in Australia could be presented by employing MR6 and MR10 as a replacement for 6% of the volume, as indicated through economic evaluation analysis. | [20] |

| 2022 | M. Pasetto et al. | Recycled PE | 0, 0.25, and 1.5% by weight asphalt mixture | Impact on workability: No notable impact on the workability of the asphalt mixture under the investigated production conditions was shown via the incorporation of waste PE up to 1.5% of the mixture’s weight. Rheological characteristics: Significant alterations in the rheological characteristics of the asphalt mixtures were observed when the maximum recycling rate was utilized. Stiffness and rutting resistance: Significantly higher stiffness and resistance to permanent deformation, with improved material response as the PE dosage increased, were exhibited by mixtures incorporating recycled waste plastic. Fracture resistance: A proportional increase in fracture resistance and strength with the addition of plastic waste was revealed by indirect tensile tests. Resistance to moisture: No detrimental impacts on the resistance to moisture of the asphalt mixture with the inclusion of PE waste were found through the investigation. | [69] |

| 2022 | L.D. Poulikakos et al. | Polyethylene (PE) | 0.25%, 0.5%, 1%, 1.5%, and 5% by weight of asphalt mixture | Compaction Efficiency: A lower construction densification index (CDI) was exhibited by PE-modified mixtures, indicating improved workability and easier compaction. Strength Enhancement: Indirect tensile strength (ITS) was increased through the addition of PE, suggesting improved cohesion in the mastic phase. A slight but consistent increase in ITS was observed with a higher PE content. Moisture Sensitivity: Moisture resistance in PE-modified mixtures (≤1.5% PE) was found to be similar to that of the reference mixtures, except when water-sensitive granite aggregates were used. Stiffness Variation: Stiffness was generally increased through higher PE content (up to 5%), with 1.5% PE showing reduced time dependency under axial sinusoidal loading. Viscoelastic Behavior: Enhanced elasticity was demonstrated by PE-modified mixtures compared to the reference mixture. Creep Performance: Lower creep rates and a higher creep modulus were observed in PE-modified mixtures. Resistance to Permanent Deformation: Resistance to rutting was improved via PE. Stable or improved results were shown in wheel-tracking tests in air with 1.5% PE, while increased deformation was observed in water at higher PE doses (>5%), indicating that caution should be exercised with excessive PE content. Optimal PE Content: Based on the findings, 1.5% PE was identified as the optimal dosage for balancing performance improvements without compromising stability. | [70] |

| Year | Author | Type of Recycled Plastic Used | % Recycled Plastic | Impact on Properties | Refs. |

|---|---|---|---|---|---|

| 2011 | E. Ahmadina et al. | Recycled PET | 2, 4, 6, 8, and 10% by weight of bituminous binder | Impact on asphalt mixture characteristics: Improved characteristics by incorporating plastic were noted, particularly with only a 6% addition. Potential to lower construction costs: The potential of incorporating plastic into flexible pavement construction to lower construction costs was acknowledged. | [73] |

| 2016 | J. Jafar | Not specified | 8% by weight of total aggregate | Stiffness of chemically treated plastic: Higher stiffness was observed by incorporating chemically treated plastic as a partial replacement for aggregate in asphalt mixtures, indicating increased adhesion between bitumen and surface particles of chemically treated plastic. Retained tensile strength under soaked conditions: A 10% higher retained tensile strength was shown by the chemically treated plastic–modified asphalt mixtures, indicating enhanced stability due to chemical additives improving the adhesion between aggregates and bitumen. | [74] |

| 2018 | Leng et al. | Recycled PET | 1, 1.5, and 2% by weight of bituminous binder | Improved rutting and fatigue resistance: Superior effectiveness was exhibited when incorporating both RAP and PET-sourced additives, with a minimum 15% boost in resistance to rutting and up to a 60% enhancement in resistance to fatigue cracking. | [48] |

| 2019 | Martin-Alfonso et al. | Recycled low-density polyethylene (LDPE) | 0.5, 1, and 3% by weight of asphalt mixture | Mixing time and integration: Mixing time was reduced, and the integration of waste plastic into asphalt mixtures was enhanced via additives comprising recycled LDPE pre-swollen with mineral oil or bitumen. Mitigation of long-term aging: Mitigation of long-term aging of the bituminous binder was achieved using a blend containing 72.2% recycled LDPE and 27.8% mineral oil. Viscosity limits and compaction: Viscosity limits were exceeded with binders incorporating recycled polymer. Achievable compaction was demonstrated when incorporating 0.5% recycled LDPE through a dry process. Rutting and moisture sensitivity: Improvements in resistance to rutting and moisture sensitivity were observed, especially for asphalt mixtures. Air voids in porous mixtures: Air voids in porous asphalt mixtures were reduced via the introduction of recycled LDPE through the dry method. Durability and fatigue resistance: Different levels of overall durability and fatigue resistance were demonstrated by LDPE-modified porous mixtures. | [71] |

| 2020 | Bary et al. | Recycled polyethylene terephthalate (PET) | 4 and 8% by weight of asphalt mixture | Enhancement in bitumen characteristics: An enhancement in bitumen characteristics was demonstrated, showing increased temperature stability and improved resistance to rutting and plastic deformation. Increased toughness of modified bitumen: An increased toughness of modified bitumen was exhibited due to the strong interaction between bitumen and USP. | [75] |

| 2022 | Francesca Russo et al. | GWP and graphene | 6% by weight of bituminous binder | Enhanced strength, stiffness, and rutting resistance: Enhanced strength and stiffness were demonstrated by the asphalt modified with waste hard plastic (GWP) and graphene, with remarkably similar resistance to permanent deformation observed in both laboratory and field tests. Fatigue life and sustainability of GWP modification: Greater or comparable fatigue life of the GWP-modified bituminous binder was demonstrated, proving to be sustainable and eco-friendly with no logistical or compaction issues. Long-term monitoring and environmental Benefits: No distress signs were observed, underscoring the efficacy of utilizing recycled waste plastics as a viable bitumen modifier. | [76] |

| 2023 | Gaetano Di Mino et al. | GRP | 6% by weight of bituminous binder | Effects of recycled plastic bitumen modifier: The equi-shear modulus temperature, softening point, and upper PG of the asphalt mixtures were increased via the recycled plastic bitumen modifier. Performance of recycled mixtures: Similar or comparable properties to binders in control mixtures were showcased by binders derived from reclaimed asphalt with the recycled plastic modifier throughout all recycling cycles. | [77] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ameur, A.B.; Valentin, J.; Baldo, N. A Review on the Use of Plastic Waste as a Modifier of Asphalt Mixtures for Road Constructions. CivilEng 2025, 6, 17. https://doi.org/10.3390/civileng6020017

Ameur AB, Valentin J, Baldo N. A Review on the Use of Plastic Waste as a Modifier of Asphalt Mixtures for Road Constructions. CivilEng. 2025; 6(2):17. https://doi.org/10.3390/civileng6020017

Chicago/Turabian StyleAmeur, Amira Ben, Jan Valentin, and Nicola Baldo. 2025. "A Review on the Use of Plastic Waste as a Modifier of Asphalt Mixtures for Road Constructions" CivilEng 6, no. 2: 17. https://doi.org/10.3390/civileng6020017

APA StyleAmeur, A. B., Valentin, J., & Baldo, N. (2025). A Review on the Use of Plastic Waste as a Modifier of Asphalt Mixtures for Road Constructions. CivilEng, 6(2), 17. https://doi.org/10.3390/civileng6020017