Hygrothermal Modelling of the Differences between Single versus Variable Relative Humidity Vapour Diffusion Resistivity Properties of Pliable Membranes

Abstract

:1. Introduction

2. Materials and Methods

- creating user defined material data for the pliable membranes within the WUFI Pro 6.5 data library,

- completing the hygrothermal simulations using WUFI Pro 6.5, followed by

- bio-hygrothermal simulations the WUFI VTT post processing software to analyse differences in Mould Index results.

2.1. Creating New User-Defined Material Data

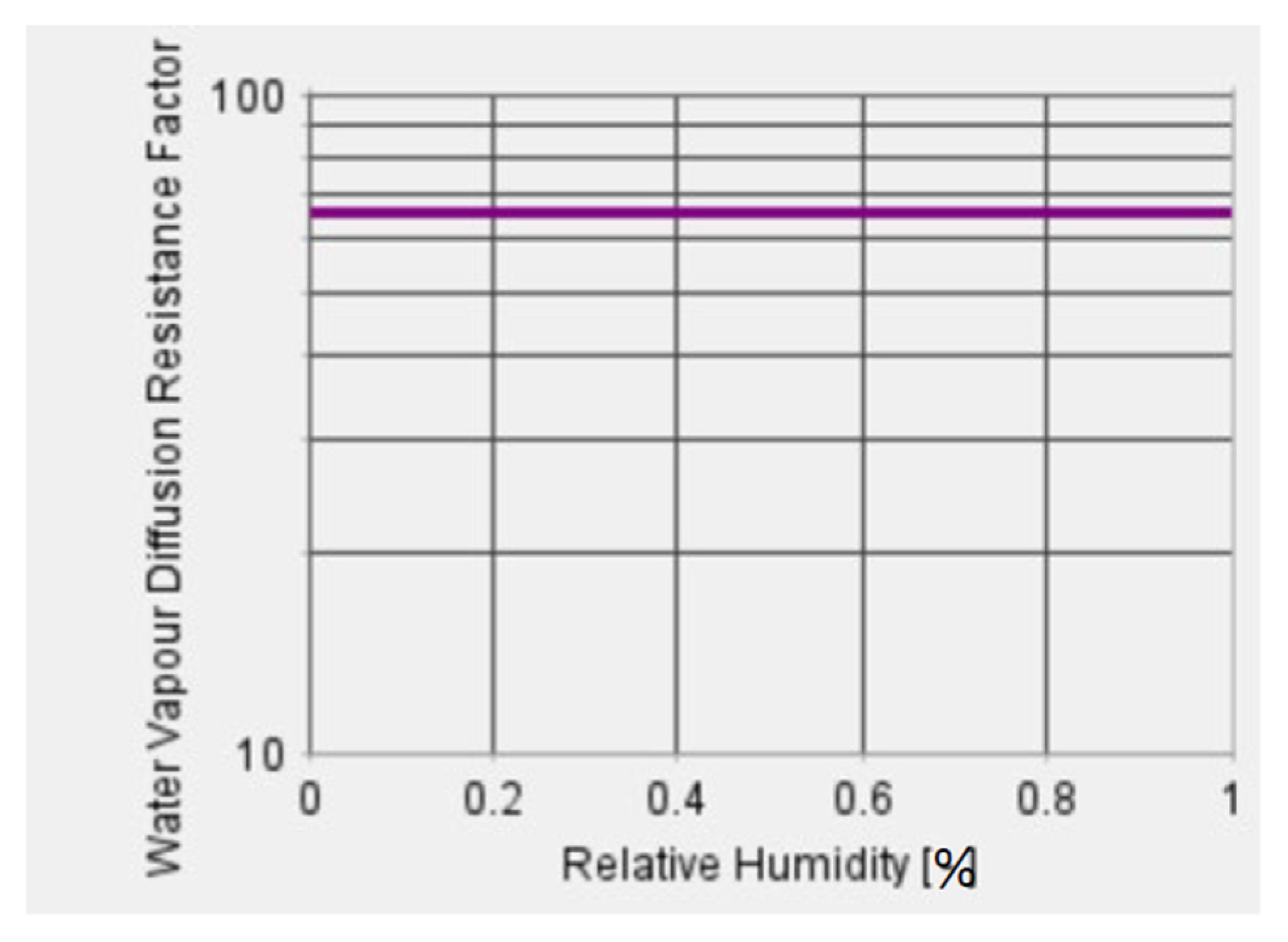

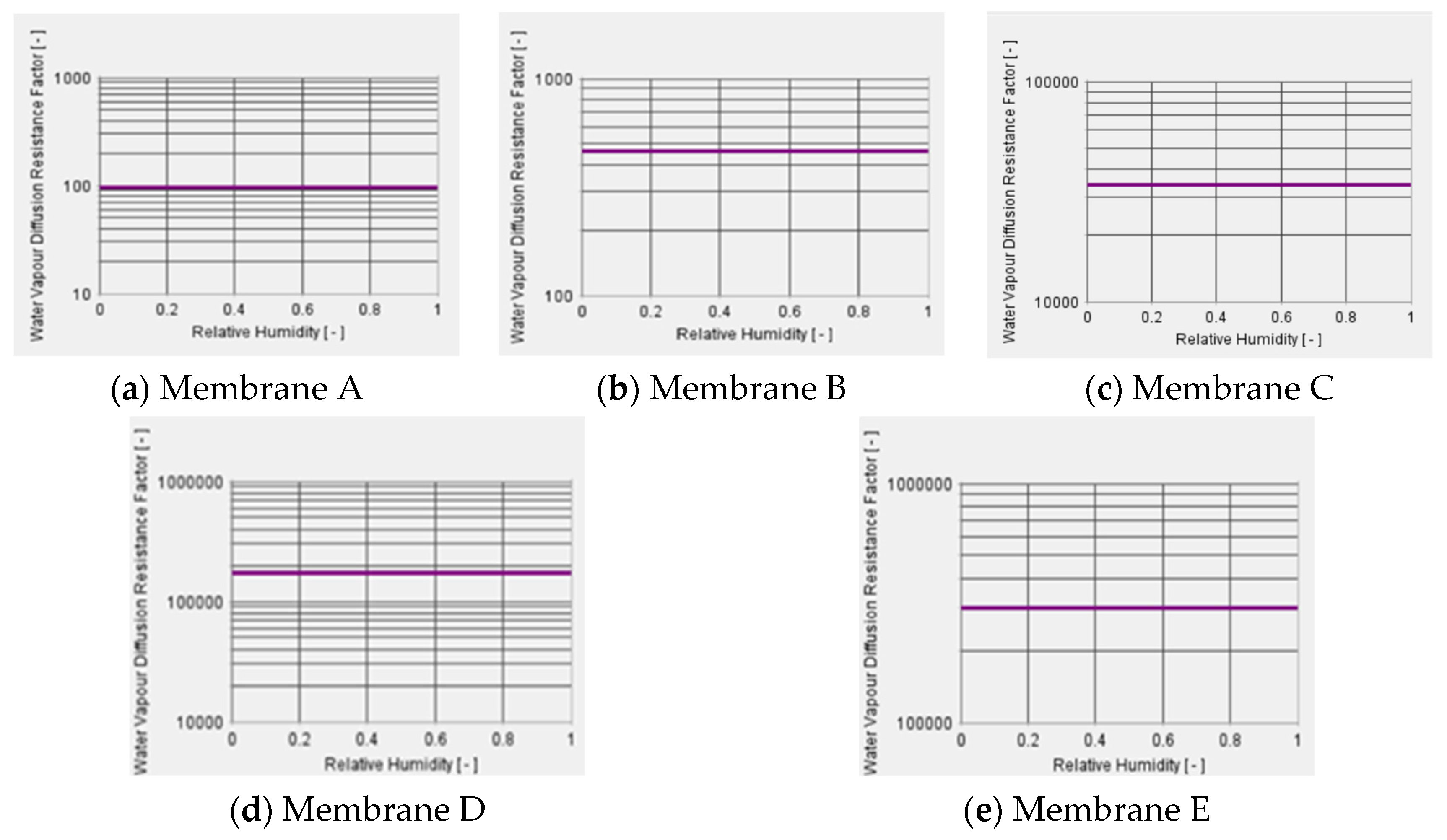

2.2. Single Point Values

2.3. Establishing and Plotting the Variable Relative Humidity Multipoint Water Vapour Diffusion Resistivity Values after Harmonic Adjustment

2.4. Simulation, Procedures, and Input Parameters

“Moisture will not accumulate interior to the primary water control layer within a building envelope; or on the interior surface of the water control layer.”

2.5. Selection of Construction Components for Hygrothermal Modelling

- − CR 1 which simulated the timber-framed clay masonry veneer wall with the five different pliable membranes using the single-point value for vapour diffusion resistance factor, and

- − CR 2 which simulated the timber-framed clay masonry veneer wall with the five different pliable membranes using the harmonic balanced multipoint values for vapour diffusion resistance factor.

2.6. Simulation’s Orientation, Initial Condition, and Surface Transfer Co-Efficient

2.7. Exterior environmental conditions

- − Darwin—Australia’s most northern capital city, located in a hot and humid climate, with no hourly rain data (tropical savannah; Köppen climate classification—Aw)

- − Sydney—Australia’s most populous city, with a temperate climate and no hourly rain data (humid subtropical; Köppen climate classification—Cfa), and

- − Holzkirchen—southern Germany, as shown in Figure 8, a humid temperate, but cooler climate with rain and climate data that include values for hourly rainfall (oceanic/marine west coast climate; Köppen climate classification—Cfb).

2.8. Interior Environmental Conditions

- − between 7:00 a.m. and 9:00 a.m., the room is to be conditioned between 20 °C and 23 °C,

- − between 10:00 a.m. and 3:00 p.m. the room is unconditioned,

- − between 4:00 p.m. and 11:00 p.m., the room is to be conditioned between 18 °C and 23 °C, and

- − between midnight and 6:00 a.m. the room is to be conditioned to between 15 °C and 23 °C.

3. Results

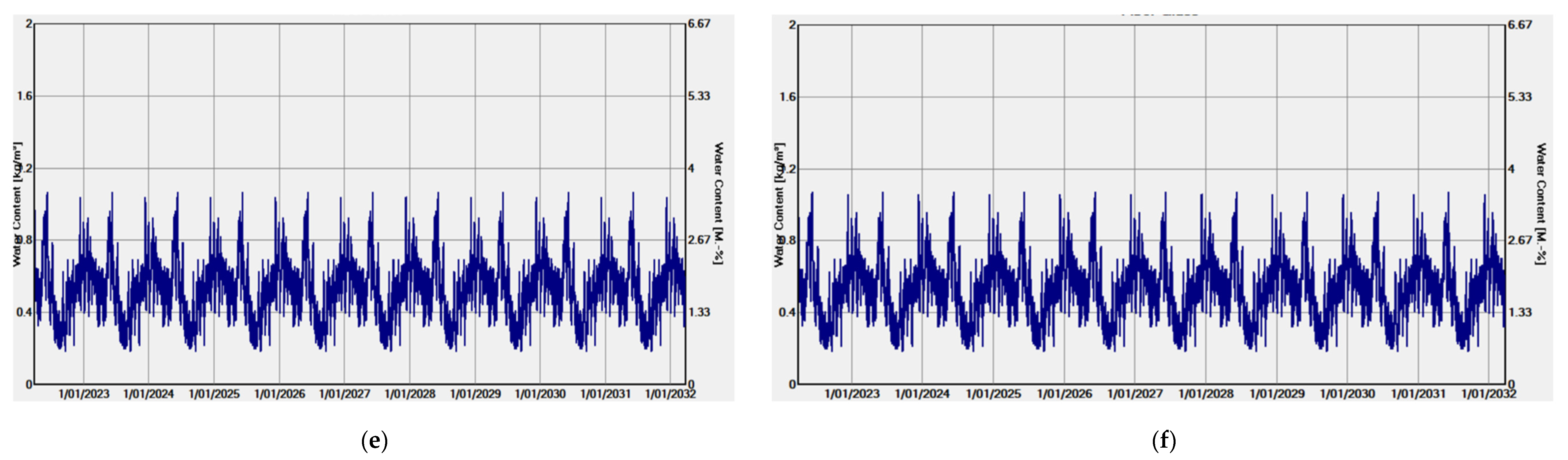

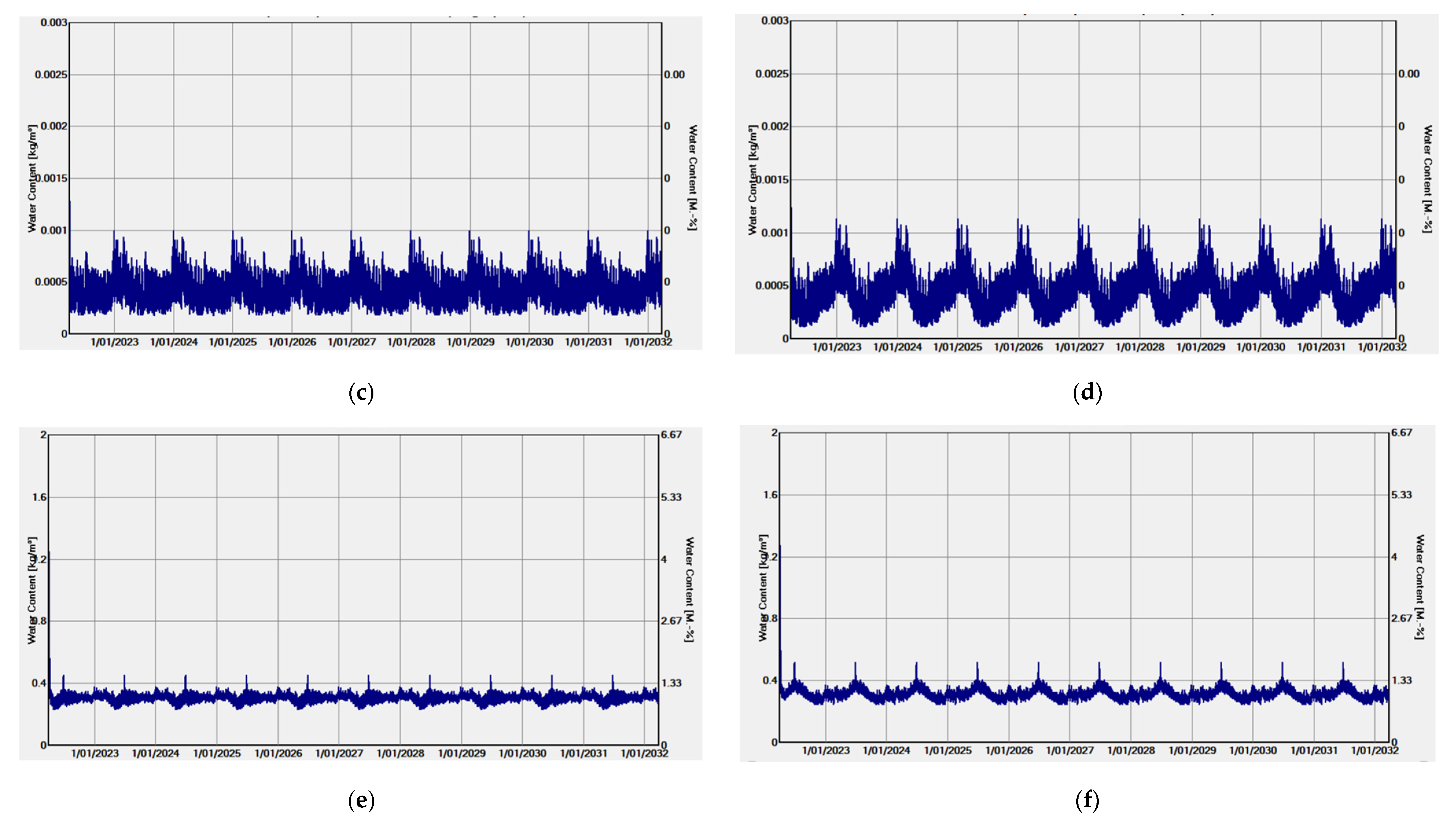

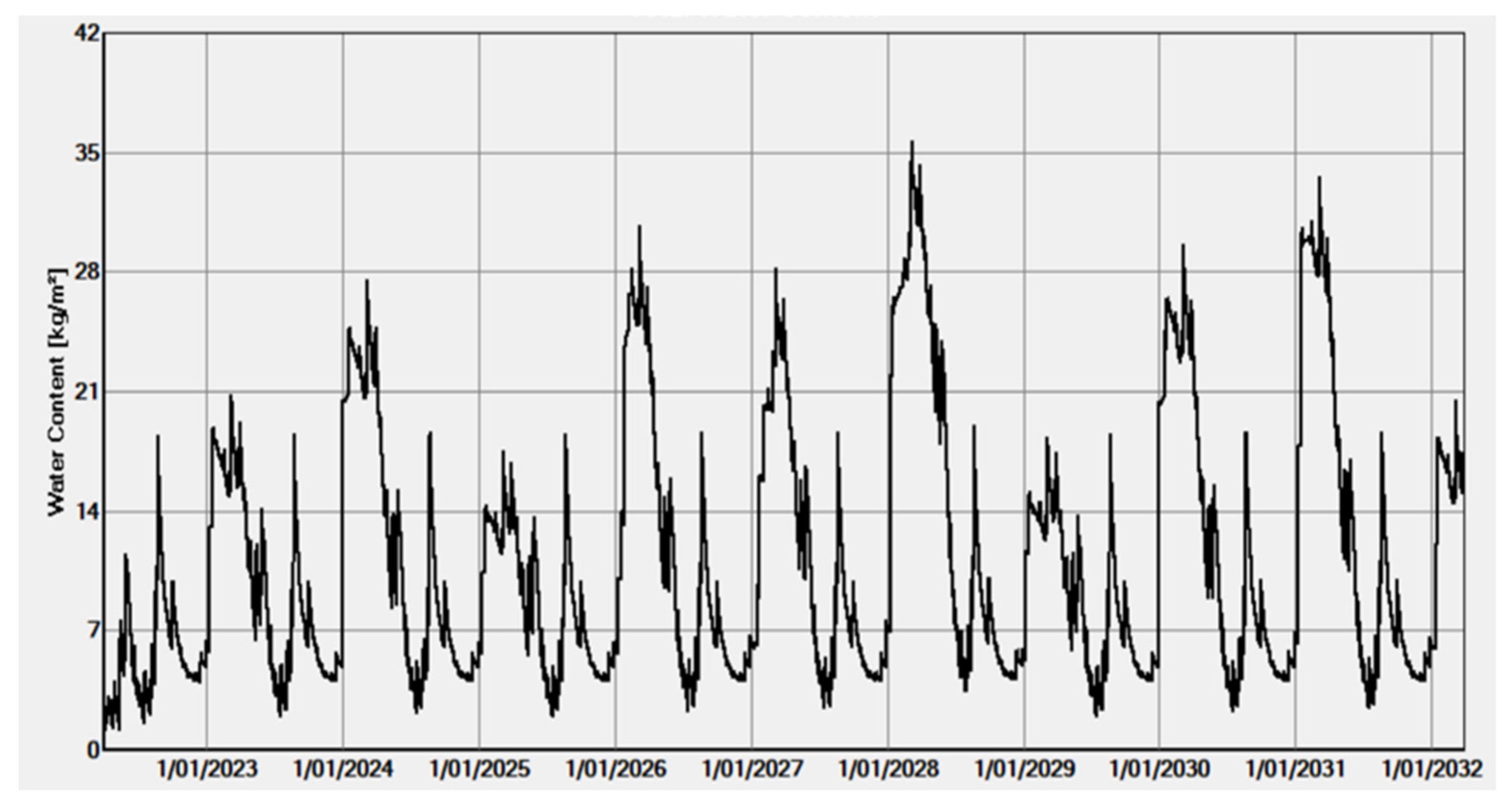

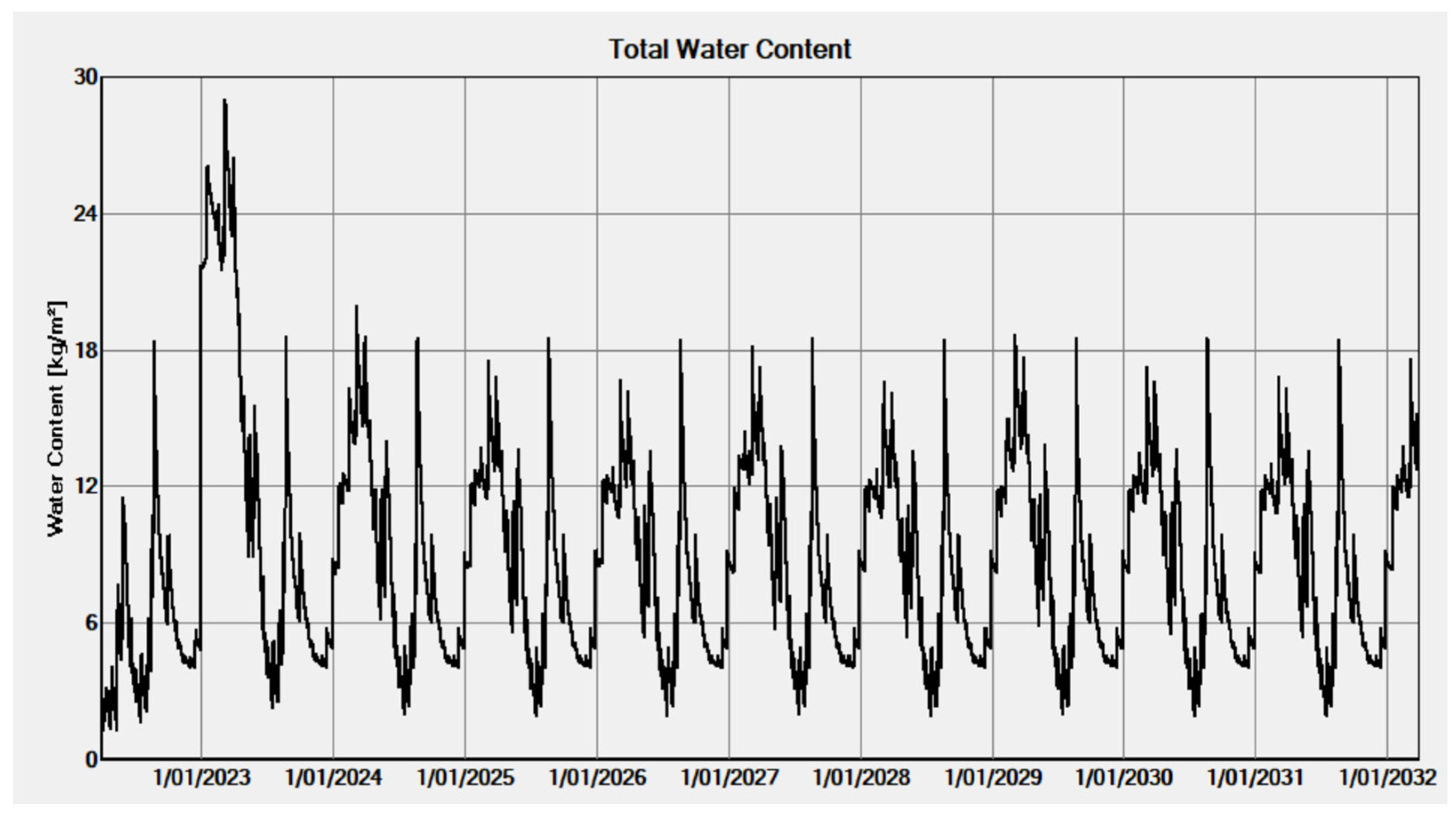

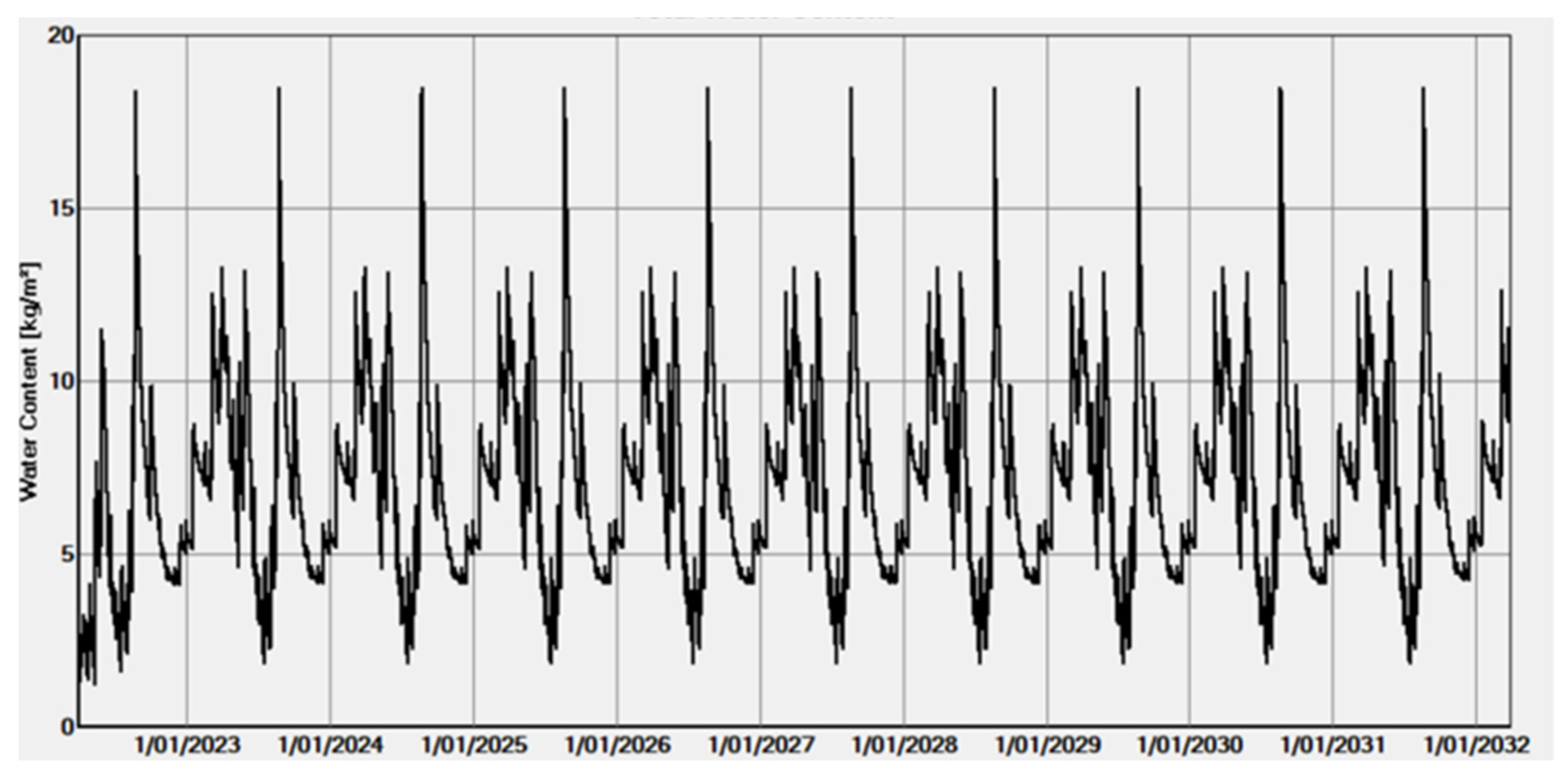

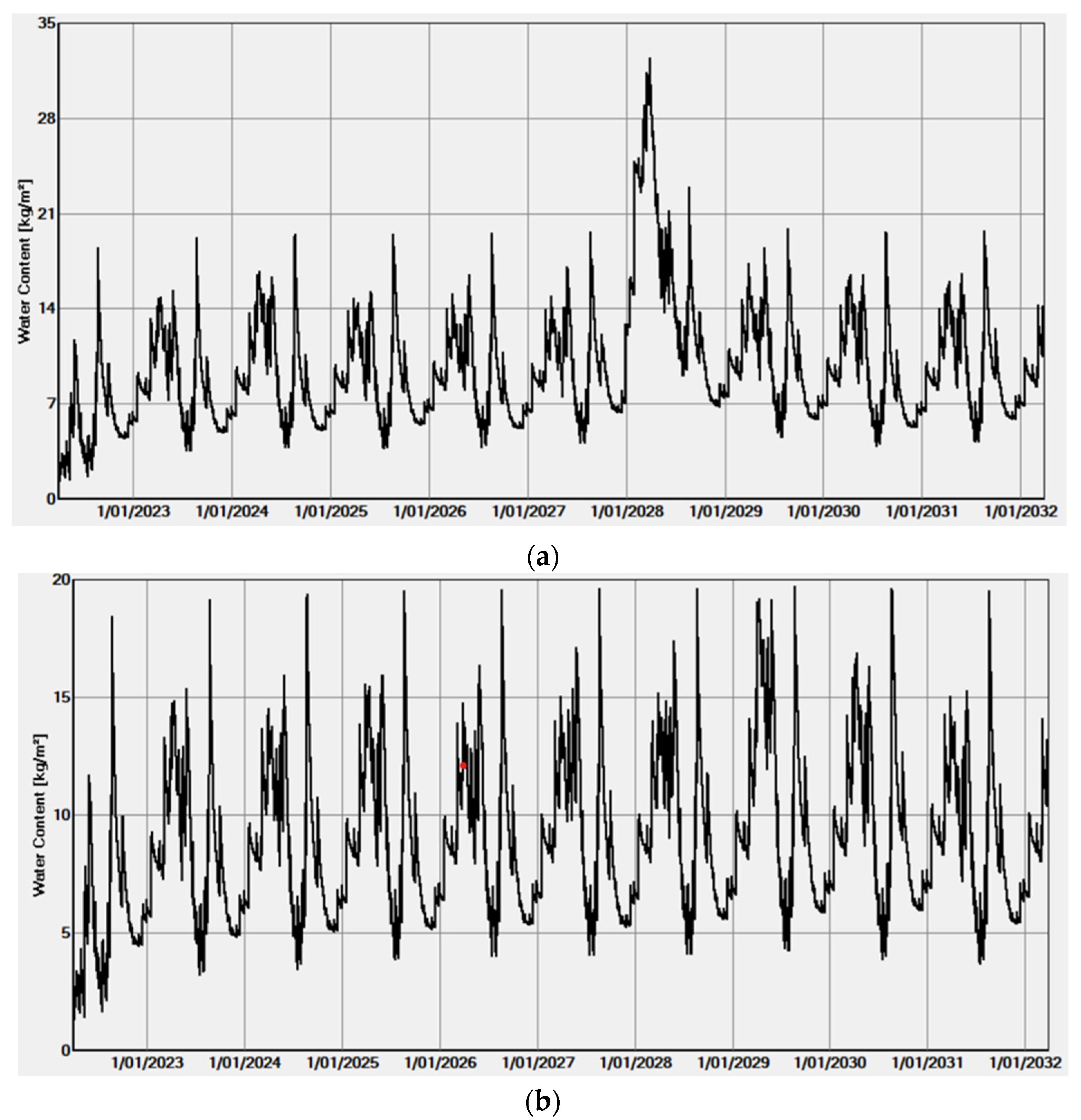

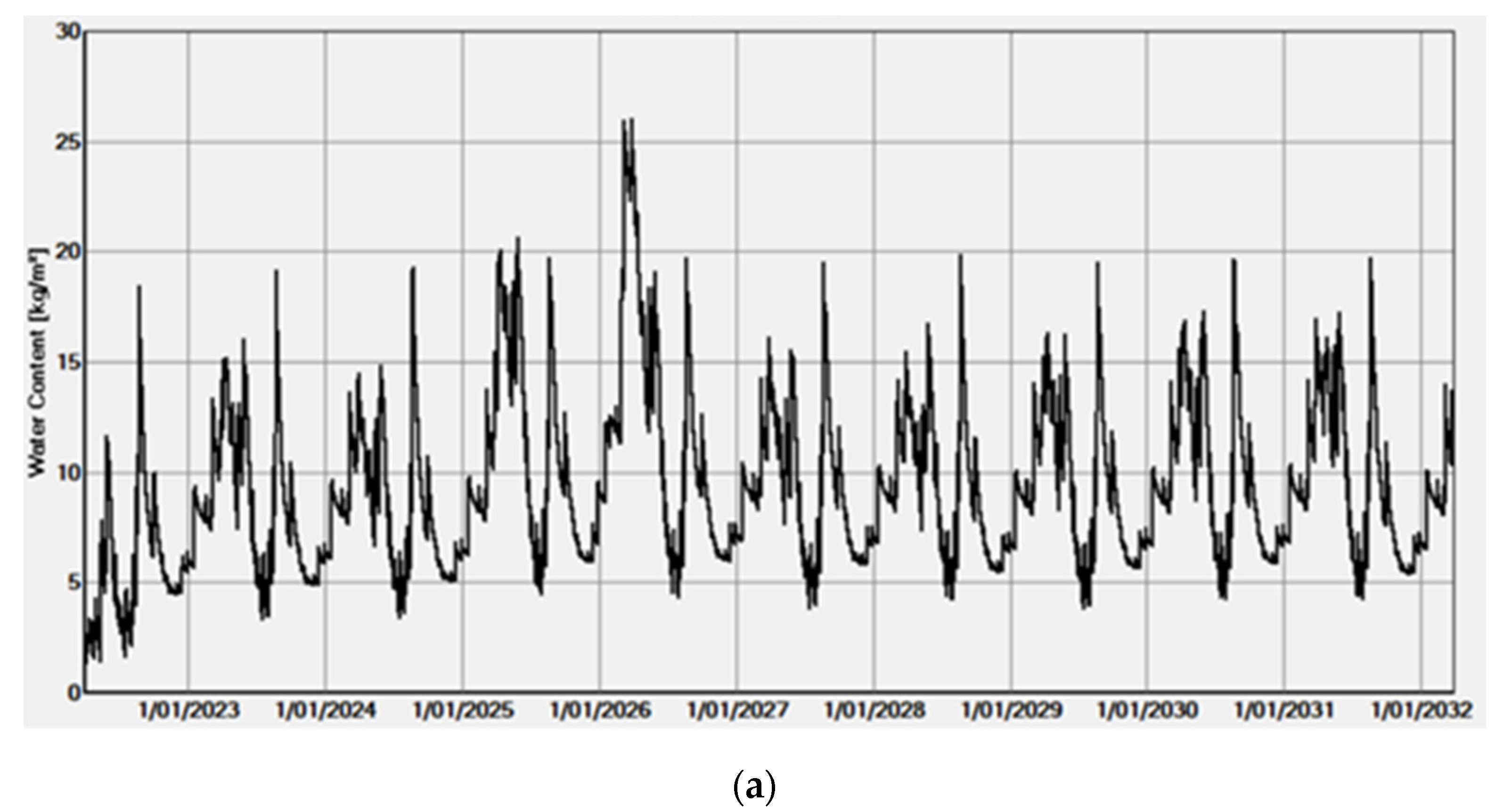

3.1. Result for the Risk of Moisture Accumulation for Two Australian Climates

3.2. Result for the Risk of Moisture Accumulation for Holzkirchen Climate

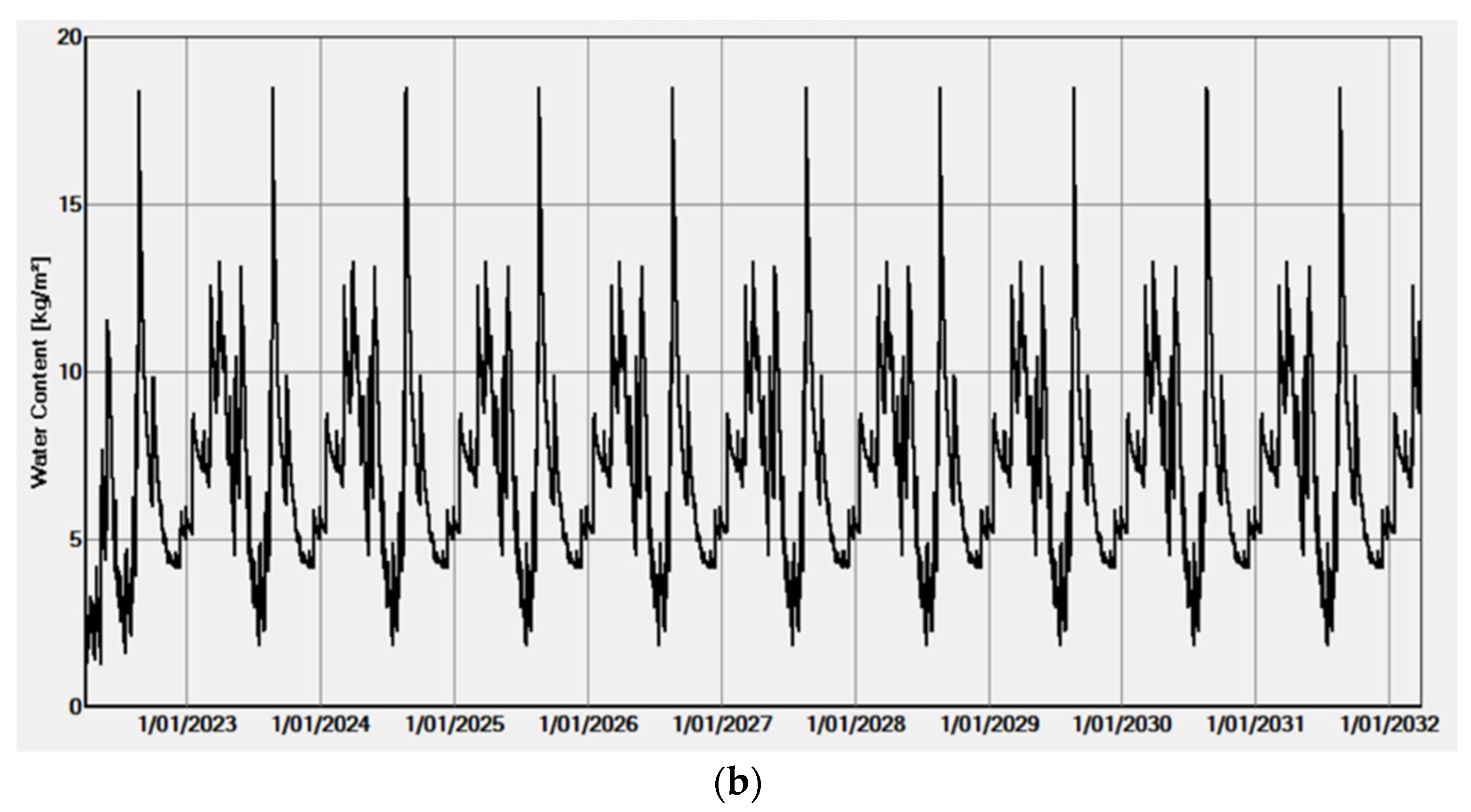

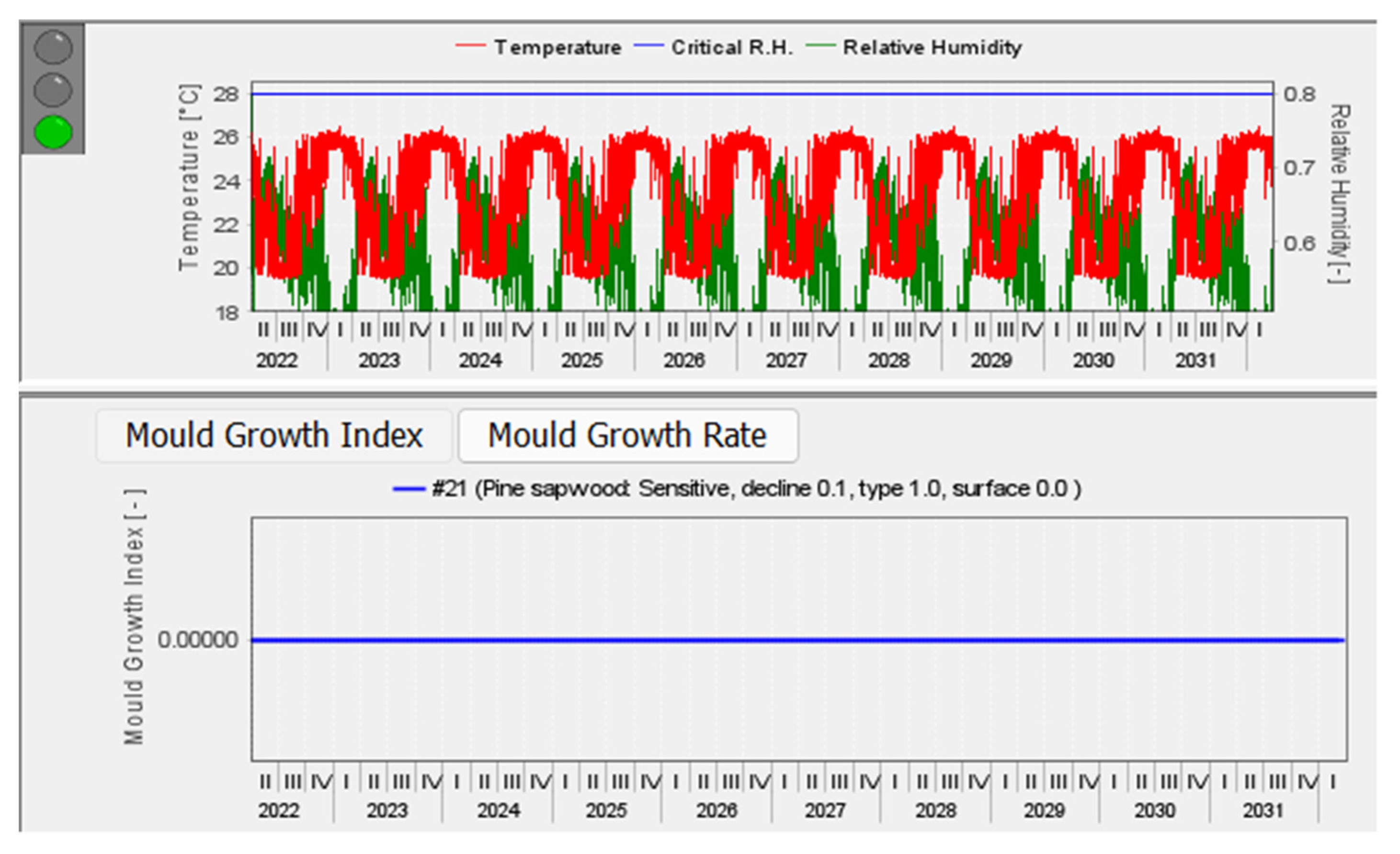

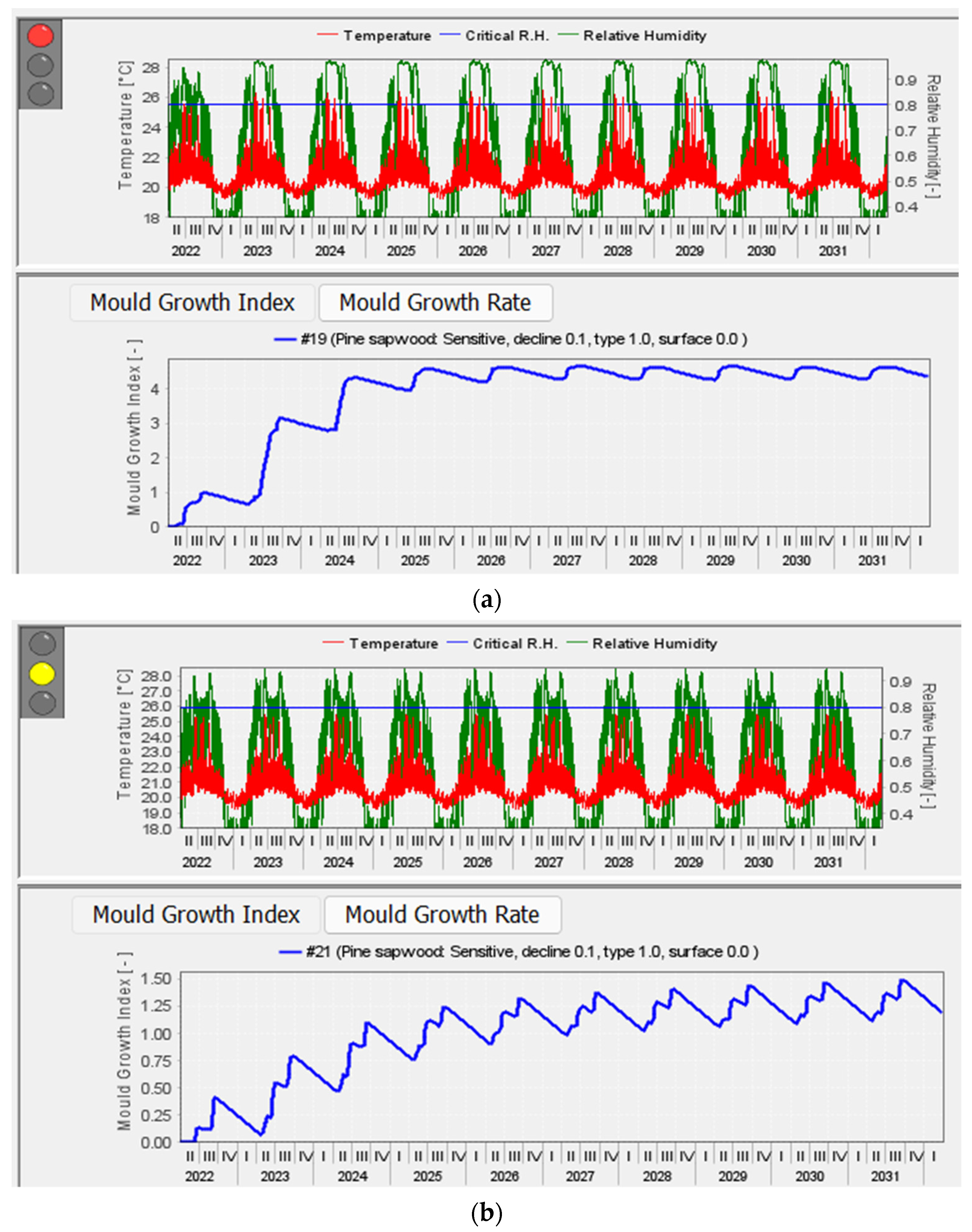

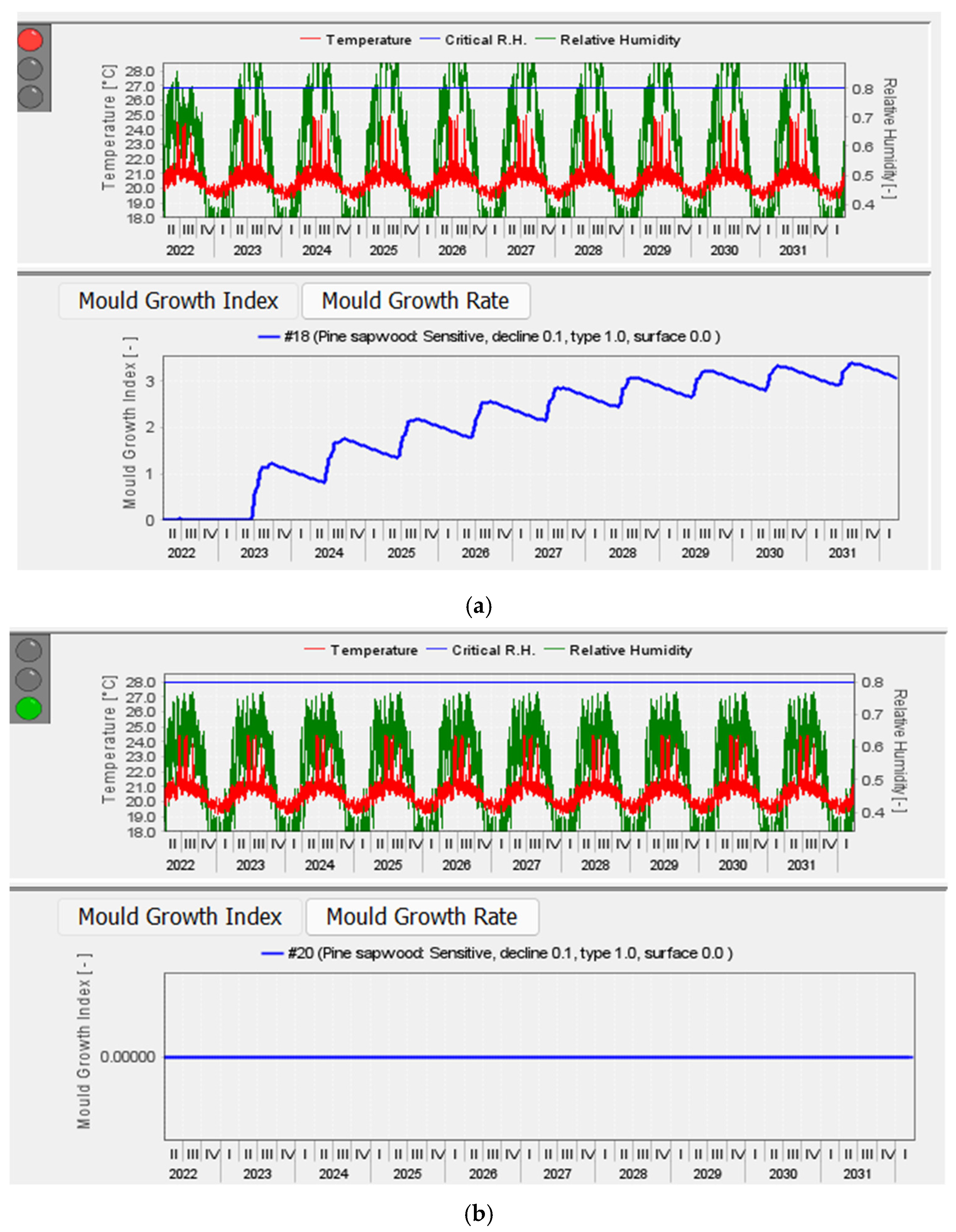

3.3. Results of Mould Growth Simulation for Sydney and Darwin Climate with No Rain Data

3.4. Results of Mould Growth Simulation for Holzkirchen Cliamte with Rain Data

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| ABCB | Australian Building Codes Board |

| ACH | Air Exchange |

| AIRAH | Australian Institute for Refrigeration, Air-conditioning, and Heating |

| ASHRAE | American Society for Heating, Refrigeration, and Air-conditioning Engineers |

| ASTM | American Society for Testing and Materials |

| BOM | Bureau of Meteorology, Australia |

| BS | British Standards |

| CEN | European committee for Standardisation (in French: Comité Européen de Normalisation) |

| CSIRO | Commonwealth Scientific and Industrial Research Organisation, Australia |

| DIN | Deutsches Institut für Normung |

| EN | European standard (in German: Europaische Norm) |

| EPW | Energy Plus Weather |

| HAM | Heat, Air, and Moisture |

| HRA | Hygrothermal Risk Assessment |

| HVAC | Heating, Ventilation, and Air-Conditioning |

| IAQ | Indoor Air Quality |

| IEQ | Indoor Environmental Quality |

| ISO | International Organisation for Standardisation |

| MI | Mould Index |

| NatHERS | National House Energy Rating Scheme, Australia |

| NCC | National Construction Code, Australia |

| ϕ | Relative Humidity (RH) (%) |

| q | Heat Flux (J/m2s) |

| l | Thermal Conductivity (J/msK) |

| RMY | Reference Meteorological Year |

| R-values | Thermal Resistance (m2 K)/W |

| SD | Diffusion Air layer Thickness (m) |

| STC | Surface Transfer Coefficient |

| T | Temperature (°C) |

| μ | Water Vapour Resistance Factor |

| WDR | Wind-Driven Rain |

| WHO | World Health Organisation |

| WUFI | Wärme Und Feuchte Instationär (heat and moisture transiency) |

| WV | Water Vapour |

| WVTR | Water Vapour Transmission Rate |

Appendix A

| Moisture Content in Layer after Simulation | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Materials | Pliable Membrane A | Pliable Membrane B | Pliable Membrane C | |||||||||

| Single Point | Multipoint | Single Point | Multipoint | Single Point | Multipoint | |||||||

| Orientation | North | West | North | West | North | West | North | West | North | West | North | West |

| External brick veneer (kg/m2) | 4.38 | 4.84 | 4.38 | 4.84 | 4.40 | 4.87 | 4.40 | 4.86 | 4.43 | 4.89 | 4.42 | 4.88 |

| 40 mm air cavity layer (kg/m2) | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

| 1 mm vapour control layer (kg/m2) | 0.00 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 4.47 | 4.96 |

| Insulation layer (kg/m2) | 0.55 | 0.59 | 0.55 | 0.59 | 0.49 | 0.53 | 0.50 | 0.53 | 0.44 | 0.48 | 0.44 | 0.48 |

| Interior plaster (kg/m2) | 3.62 | 3.77 | 3.64 | 3.79 | 3.47 | 3.58 | 3.47 | 3.58 | 3.31 | 3.44 | 3.31 | 3.44 |

| Total water content after simulation (kg/m2) | 1.24 | 1.24 | 1.24 | 1.24 | 1.24 | 1.24 | 1.24 | 1.24 | 1.24 | 1.24 | 1.25 | 1.25 |

| Simulation numerical qualities | ||||||||||||

| Balance 1 (kg/m2) | −0.68 | −0.62 | −0.68 | −0.62 | −0.68 | −0.62 | −0.68 | −0.63 | −0.68 | −0.63 | −0.69 | −0.63 |

| Balance 2 (kg/m2) | −0.70 | −0.61 | −0.69 | −0.61 | −0.70 | −0.62 | −0.70 | −0.64 | −0.73 | −0.64 | −0.72 | 0.63 |

| Number of convergence errors | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Moisture Content after Simulation | ||||||||

|---|---|---|---|---|---|---|---|---|

| Materials | Pliable Membrane D | Pliable Membrane E | ||||||

| Single Point | Multipoint | Single Point | Multipoint | |||||

| Orientation | North | West | North | West | North | West | North | West |

| External brick veneer (kg/m2) | 9.2 | 4.89 | 4.43 | 4.89 | 4.43 | 4.89 | 4.44 | 4.89 |

| 40 mm air cavity layer (kg/m2) | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

| 1 mm vapour control layer (kg/m2) | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| Insulation layer (kg/m2) | 1.87 | 0.48 | 0.44 | 0.48 | 0.44 | 0.48 | 0.39 | 0.48 |

| Interior plaster (kg/m2) | 8.75 | 3.44 | 3.31 | 3.44 | 3.31 | 3.44 | 3.01 | 3.31 |

| Total water content after simulation (kg/m2) | 1.24 | 1.24 | 1.24 | 1.24 | 1.24 | 1.24 | 1.24 | 1.24 |

| Simulation | Numerical | Qualities | ||||||

| Balance 1 (kg/m2) | 0.67 | −0.63 | −0.68 | −0.63 | −0.68 | −0.63 | −0.63 | −0.63 |

| Balance 2 (kg/m2) | 0.71 | −0.64 | −0.73 | −0.64 | 0.64 | −0.64 | −0.64 | −0.64 |

| Number of convergence errors | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Moisture Content in Layer after Simulation | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Materials | Pliable Membrane A | Pliable Membrane B | Pliable Membrane C | |||||||||

| Single Point | Multipoint | Single Point | Multipoint | Single Point | Multipoint | |||||||

| Orientation | North | West | North | West | North | West | North | West | North | West | North | West |

| External brick veneer (kg/m2) | 4.66 | 4.93 | 4.56 | 4.93 | 4.67 | 4.95 | 4.67 | 4.95 | 9.2 | 9.2 | 9.2 | 9.2 |

| 40 mm air cavity layer (kg/m2) | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

| 1 mm vapour control layer (kg/m2) | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Insulation layer (kg/m2) | 0.96 | 1.00 | 0.99 | 1.03 | 0.71 | 0.73 | 0.72 | 0.75 | 1.87 | 1.87 | 1.87 | 1.87 |

| Interior plaster (kg/m2) | 6.56 | 6.43 | 6.74 | 6.59 | 5.7 | 5.70 | 5.74 | 5.74 | 8.75 | 7.39 | 8.73 | 7.34 |

| Total water content after simulation (kg/m2) | 1.24 | 1.24 | 1.24 | 1.24 | 1.24 | 1.24 | 1.24 | 1.24 | 1.24 | 1.24 | 1.24 | 1.25 |

| Simulation numerical qualities | ||||||||||||

| Balance 1 (kg/m2) | −0.57 | −0.54 | −0.57 | −0.54 | −0.60 | −0.57 | −0.60 | −0.57 | 0.67 | 0.61 | 0.67 | 0.61 |

| Balance 2 (kg/m2) | −0.83 | −0.76 | −0.83 | −0.76 | −0.84 | −0.75 | −0.84 | −0.75 | 0.71 | 0.62 | 0.71 | 0.61 |

| Number of convergence errors | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Moisture Content after Simulation | ||||||||

|---|---|---|---|---|---|---|---|---|

| Materials | Pliable Membrane D | Pliable Membrane E | ||||||

| Single Point | Multipoint | Single Point | Multipoint | |||||

| Orientation | North | West | North | West | North | West | North | West |

| External brick veneer (kg/m2) | 4.74 | 5.03 | 4.74 | 5.03 | 4.74 | 5.03 | 4.74 | 5.03 |

| 40 mm air cavity layer (kg/m2) | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

| 1 mm vapour control layer (kg/m2) | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| Insulation layer (kg/m2) | 0.30 | 0.31 | 0.30 | 0.31 | 0.30 | 0.30 | 0.30 | 0.30 |

| Interior plaster (kg/m2) | 3.42 | 3.44 | 3.41 | 3.44 | 3.41 | 3.43 | 3.41 | 3.44 |

| Total water content after simulation (kg/m2) | 1.24 | 1.24 | 1.24 | 1.24 | 1.24 | 1.24 | 1.24 | 1.24 |

| Simulation | Numerical | Qualities | ||||||

| Balance 1 (kg/m2) | −0.65 | −0.62 | −0.65 | −0.62 | −0.65 | −0.62 | −0.65 | −0.62 |

| Balance 2 (kg/m2) | −0.80 | −0.70 | −0.8 | −0.7 | −0.8 | −0.70 | −0.80 | −0.7 |

| Number of convergence errors | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Moisture Content in Layer during Simulation | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Materials | Pliable Membrane A | Pliable Membrane B | Pliable Membrane C | |||||||||

| Single Point | Multipoint | Single Point | Multipoint | Single Point | Multipoint | |||||||

| Orientation | North | West | North | West | North | West | North | West | North | West | North | West |

| External brick veneer (kg/m2) | 7.41 | 146.39 | 7.01 | 88.59 | 7.01 | 88.59 | 7.24 | 89.58 | 6.11 | 89.42 | 14.86 | 89.32 |

| 40 mm air cavity layer (kg/m2) | 0.01 | 0.02 | 0.01 | 0.02 | 0.01 | 0.02 | 0.01 | 0.02 | 0.01 | 8.34 | 0.01 | 0.02 |

| 1 mm vapour control layer (kg/m2) | 0.00 | 0.02 | 0.01 | 0.02 | 0.01 | 0.02 | 0.01 | 0.0 | 0.00 | 0.08 | 29.24 | 48.71 |

| Insulation layer (kg/m2) | 0.65 | 3.29 | 6.04 | 12.92 | 6.04 | 12.92 | 3.15 | 10.74 | 60.53 | 30.70 | 6.27 | 9.89 |

| Interior plaster (kg/m2) | 3.09 | 3.81 | 3.98 | 3.93 | 3.98 | 3.93 | 3.95 | 3.92 | 4.01 | 3.85 | 6.30 | 3.92 |

| Total water content after simulation (kg/m2) | 1.24 | 1.07 | 1..35 | 10.95 | 1.35 | 10.95 | 1.12 | 1086 | 6.16 | 12.97 | 1.82 | 10.8 |

| Simulation numerical qualities | ||||||||||||

| Balance 1 (kg/m2) | −0.34 | 15.06 | 0.11 | 9.54 | 0.11 | 9.54 | −0.13 | 9.45 | 4.92 | 11.56 | 0.05 | 9.38 |

| Balance 2 (kg/m2) | −0.23 | −153.36 | 0.20 | −6.8.4 | 0.2 | 6.84 | −0.03 | 7.37 | 4.9 | −67.92 | 0.11 | 10.24 |

| Number of convergence errors | 0 | 12462 | 0 | 5102 | 1 | 5102 | 1 | 4958 | 40 | 990 | 0 | 2535 |

| Moisture Content after Simulation | ||||||||

|---|---|---|---|---|---|---|---|---|

| Materials | Pliable Membrane D | Pliable Membrane E | ||||||

| Single Point | Multipoint | Single Point | Multipoint | |||||

| Orientation | North | West | North | West | North | West | North | West |

| External brick veneer (kg/m2) | 6.10 | 90.70 | 6.11 | 88.29 | 6.10 | 89.26 | 6.11 | 89.32 |

| 40 mm air cavity layer (kg/m2) | 0.01 | 17.04 | 0.01 | 0.02 | 0.01 | 2.50 | 0.01 | 2.46 |

| 1 mm vapour control layer (kg/m2) | 0.00 | 0.05 | 0.00 | 0.02 | 0.00 | 0.04 | 0.01 | 0.07 |

| Insulation layer (kg/m2) | 65.19 | 31.04 | 63.73 | 30.53 | 66.08 | 30.68 | 61.54 | 30.43 |

| Interior plaster (kg/m2) | 4.01 | 3.85 | 4.01 | 3.93 | 4.01 | 3.85 | 4.01 | 3.85 |

| Total water content after simulation (kg/m2) | 6.588 | 13.49 | 6.45 | 12.5 | 6.68 | 12.72 | 6.25 | 12.7 |

| Simulation | Numerical | Qualities | ||||||

| Balance 1 (kg/m2) | 5.33 | 12.08 | 5.20 | 11.09 | 5.41 | 11.31 | 5.01 | 11.29 |

| Balance 2 (kg/m2) | 5.32 | −78.20 | 5.19 | −45.06 | 5.40 | −49.71 | 4.99 | −65.08 |

| Number of convergence errors | 40 | 964 | 42 | 800 | 32 | 910 | 39 | 1090 |

References

- Olaoye, T.; Dewsbury, M.; Künzel, H. Empirical Investigation of the Hygrothermal Diffusion Properties of Permeable Building Membranes Subjected to Variable Relative Humidity Condition. Energies 2021, 14, 4053. Available online: https://www.mdpi.com/1996-1073/14/13/4053 (accessed on 10 July 2022). [CrossRef]

- AS/NZS 4200:1; Pliable Building Membranes and Underlays. Council of Standards Australia: Sydney, NSW, Australia, 2017.

- Künzel, H. Adapted vapour control for durable building enclosures. In Proceedings of the 10th International Conference on Durability of Building Materials & Components, Lyon, France, 17–20 April 2005. [Google Scholar]

- Olaoye, T.S.; Dewsbury, M. Establishing an environmentally controlled room to quantify water vapour resistivity properties of construction materials. In Revisiting the Role of Architecture for ’Surviving’ Development. In Proceedings of the 53rd International Conference of the Architectural Science Association 2019, Roorkee, India, 28–30 November 2019; pp. 675–684. [Google Scholar]

- Hens, H.L. Combined heat, air, moisture modelling: A look back, how, of help? Build. Environ. 2015, 91, 138–151. [Google Scholar] [CrossRef]

- Olaoye, T.S.; Dewsbury, M.; Künzel, H. Laboratory Measurement and Boundary Conditions for the Water Vapour Resistivity Properties of Typical Australian Impermeable and Smart Pliable Membranes. Buildings 2021, 11, 509. [Google Scholar] [CrossRef]

- Künzel, H.M. Simultaneous Heat and Moisture Transport in Building Components. One-and Two-Dimensional Calculation Using Simple Parameters; IRB-Verlag: Stuttgart, Germany, 1995. [Google Scholar]

- Olaoye, T.; Dewsbury, M.; Kunzel, H.; Nolan, G. An empirical measurement of the water vapour resistivity properties of typical australian pliable membrane. In Proceedings of the The 54th International Conference of the Architectural Science Association (ANZAScA), Auckland, New Zealand, 25–28 November 2020; pp. 161–170. [Google Scholar]

- WHO. Who Guidelines for Indoor Air Quality: Dampness and Mould; WHO Regional Office for Europe Scherfigsvej 8 DK-2100 Copenhagen Ø; WHO: Copenhagen, Denmark, 2009. [Google Scholar]

- Ramos, N.M.; Delgado, J.Q.; Barreira, E.; De Freitas, V.P. Hygrothermal properties applied in numerical simulation: Interstitial condensation analysis. J. Build. Apprais. 2009, 5, 161–170. [Google Scholar] [CrossRef]

- Defo, M.; Lacasse, M.; Laouadi, A. A comparison of hygrothermal simulation results derived from four simulation tools. J. Build. Phys. 2021, 45, 432–456. [Google Scholar] [CrossRef]

- Mendes, N.; Oliveira, R.C.L.F.; Santos, G.D. Domus 2.0: A whole-building hygrothermal simulation program. Proc. Build. Simul. 2003, 2003, 863–870. [Google Scholar]

- Olaoye, T.S.; Dewsbury, M.; Kunzel, H. A Method for Establishing a Hygrothermally Controlled Test Room for Measuring the Water Vapor Resistivity Characteristics of Construction Materials. Energies 2020, 14, 4. [Google Scholar] [CrossRef]

- Langmans, J.; Klein, R.; Roels, S. Numerical and experimental investigation of the hygrothermal response of timber frame walls with an exterior air barrier. J. Build. Phys. 2013, 36, 375–397. [Google Scholar] [CrossRef]

- Lelievre, D.; Colinart, T.; Glouannec, P. Hygrothermal behavior of bio-based building materials including hysteresis effects: Experimental and numerical analyses. Energy Build. 2014, 84, 617–627. [Google Scholar] [CrossRef]

- López, O.; Torres, I.; Guimarães, A.; Delgado, J.; de Freitas, V.P. Inter-laboratory variability results of porous building materials hygrothermal properties. Constr. Build. Mater. 2017, 156, 412–423. [Google Scholar] [CrossRef]

- Mukhopadhyaya, P.; Kumaran, M.K.; Lackey, J.; Normandin, N.; Reenen, D.V.; Tariku, F. Hygrothermal Properties of Exterior Claddings, Sheathing Boards, Membranes, and Insulation Materials for Building Envelope Design. In ASHRAE; 2007. Available online: https://web.ornl.gov/sci/buildings/conf-archive/2007%20B10%20papers/121_Mukhopadhyaya.pdf (accessed on 4 November 2021).

- Slimani, Z.; Trabelsi, A.; Virgone, J.; Freire, R.Z. Study of the Hygrothermal Behavior of Wood Fiber Insulation Subjected to Non-Isothermal Loading. Appl. Sci. 2019, 9, 2359. [Google Scholar] [CrossRef] [Green Version]

- Freire, R.Z.; Dos Santos, G.H.; Coelho, L.D.S. Hygrothermal Dynamic and Mould Growth Risk Predictions for Concrete Tiles by Using Least Squares Support Vector Machines. Energies 2017, 10, 1093. [Google Scholar] [CrossRef] [Green Version]

- Muñoz-González, C.M.; León-Rodríguez, Á.L.; Medina, R.C.S.; Teeling, C. Hygrothermal performance of worship spaces: Preservation, comfort, and energy consumption. Sustainability 2018, 10, 3838. [Google Scholar] [CrossRef] [Green Version]

- Akkurt, G.; Aste, N.; Borderon, J.; Buda, A.; Calzolari, M.; Chung, D.; Costanzo, V.; Del Pero, C.; Evola, G.; Cardenas, H.E.H.; et al. Dynamic thermal and hygrometric simulation of historical buildings: Critical factors and possible solutions. Renew. Sustain. Energy Rev. 2019, 118, 109509. [Google Scholar] [CrossRef]

- Hansen, T.K.; Bjarløv, S.P.; Peuhkuri, R.H.; Harrestrup, M. Long term in situ measurements of hygrothermal conditions at critical points in four cases of internally insulated historic solid masonry walls. Energy Build. 2018, 172, 235–248. [Google Scholar] [CrossRef]

- Coelho, G.B.; Silva, H.E.; Henriques, F.M. Calibrated hygrothermal simulation models for historical buildings. Build. Environ. 2018, 142, 439–450. [Google Scholar] [CrossRef]

- Strang, M.; Leardini, P.; Brambilla, A.; Gasparri, E. Mass Timber Envelopes in Passivhaus Buildings: Designing for Moisture Safety in Hot and Humid Australian Climates. Buildings 2021, 11, 478. [Google Scholar] [CrossRef]

- Setter, L.; Smoorenburg, E.; Wijesuriya, S.; Tabares-Velasco, P.C. Energy and hygrothermal performance of cross laminated timber single-family homes subjected to constant and variable electric rates. J. Build. Eng. 2019, 25, 100784. [Google Scholar] [CrossRef]

- Busser, T.; Pailha, M.; Piot, A.; Woloszyn, M. Simultaneous hygrothermal performance assessment of an air volume and surrounding highly hygroscopic walls. Build. Environ. 2019, 148, 677–688. [Google Scholar] [CrossRef]

- Chang, S.J.; Yoo, J.; Wi, S.; Kim, S. Numerical analysis on the hygrothermal behavior of building envelope according to CLT wall assembly considering the hygrothermal-environmental zone in Korea. Environ. Res. 2020, 191, 110198. [Google Scholar] [CrossRef]

- Schmidt, E.; Riggio, M. Monitoring Moisture Performance of Cross-Laminated Timber Building Elements during Construction. Buildings 2019, 9, 144. [Google Scholar] [CrossRef] [Green Version]

- Lackey, J.C.; Marchand, R.G.; Kumaran, M.K. A logical extension of the astm standard e96 to determine the dependence of water vapour transmission on relative humidity. In Insulation Materials: Testing and Applications, 3rd Volume; ASTM International: West Conshohocken, PA, USA, 1997. [Google Scholar]

- Feng, C.; Janssen, H.; Feng, Y.; Meng, Q. Hygric properties of porous building materials: Analysis of measurement repeatability and reproducibility. Build. Environ. 2015, 85, 160–172. [Google Scholar] [CrossRef]

- Glass, S.V.; Gatland, S.D., II; Ueno, K.; Schumacher, C.J. Analysis of improved criteria for mold growth in ashrae standard 160 by comparison with field observations. In Advances in Hygrothermal Performance of Building Envelopes: Materials, Systems and Simulations, ASTM STP1599; Mukhopadhyaya, P., Fisler, D., Eds.; ASTM International: West Conshohocken, PA, USA, 2017; pp. 1–27. [Google Scholar]

- Künzel, H.M.; Zirkelbach, D. Advances in hygrothermal building component simulation: Modelling moisture sources likely to occur due to rainwater leakage. J. Build. Perform. Simul. 2013, 6, 346–353. [Google Scholar] [CrossRef]

- Künzel, H.M. Accounting for unintended moisture sources in hygrothermal building analysis. In Proceedings of the 10th Nordic Symposyum of Building Physics, Lund, Sweden, 15–19 June 2014; pp. 947–953. [Google Scholar]

- Ashrae Standard 160; Criteria for moisture-control design analysis in buildings. American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHARE): Atlanta, GA, USA, 2016.

- ABCB. Ncc 2019 Building Code of Australia—Volume Two; Australia Building Code Board: Canberra, Australia, 2019; Volume 2. [Google Scholar]

- AIRAH. Criteria for moisture control design analysis in buildings. In Da07; Australian Institute of Refrigeration, Air Conditioning and Heating: Melbourne, Australia, 2020. [Google Scholar]

- Nath, S.; Dewsbury, M.; Watson, P.; Lovell, H.; Kunzel, H. A bio-hygrothermal mould growth analysis of typical australian residential wall systems. In Proceedings of the 54th International Conference of the Architectural Science Association (ANZAScA) 2020, School of Future Environments, Built Environment Engineering, Auckland University of Technology, Architectural Science Association, Virtual, Auckland, New Zealand, 26–27 November 2020; pp. 1–10. [Google Scholar]

- Commonwealth Scientific Industrial Research Organisation. Australian Housing Data: Wall Construction. Available online: https://ahd.csiro.au/dashboards/construction/ (accessed on 28 December 2021).

- The NatHERS National Administrator. NatHERS Software Accreditation Protocol. Available online: https://www.nathers.gov.au/sites/default/files/2019-10/2019%20NatHERS%20Software%20Accreditation%20Protocol.pdf2019 (accessed on 15 June 2022).

- Dewsbury, M.; Soudan, A.; Su, F.; Geard, D.; Cooper, A.; Law, T. Condensation Risk Mitigation for Tasmanian Housing; University of Tasmania: Tasmania, Australia, 2018. [Google Scholar]

- Din 1946-6; Ventilation and Air Conditioning—Part 6: Ventilation for Residential Buildings—General Requirements, Requirements for Design, Construction, Commissioning and Handover as Well as Maintenance. Deutsches Institut für Normung: Berlin, Germany, 2019.

- Viitanen, H.; Krus, M.; Ojanen, T.; Eitner, V.; Zirkelbach, D. Mold Risk Classification Based on Comparative Evaluation of Two Established Growth Models. Energy Procedia 2015, 78, 1425–1430. [Google Scholar] [CrossRef]

- Vandemeulebroucke, I.; Defo, M.; Lacasse, M.A.; Caluwaerts, S.; Van Den Bossche, N. Canadian initial-condition climate ensemble: Hygrothermal simulation on wood-stud and retrofitted historical masonry. Build. Environ. 2021, 187, 107318. [Google Scholar] [CrossRef]

- Karagiozis, A.N.; Salonvaara, M.; Holm, A.; Kuenzel, H. Influence of wind-driven rain data on hygrothermal performance. In Proceedings of the Eighth International IBPSA Conference, Eindhoven, The Netherlands, 11–14 August 2003; pp. 627–634. [Google Scholar]

- Nascimento, M.L.M.; Bauer, E.; De Souza, J.S.; Zanoni, V.A.G. Wind-driven rain incidence parameters obtained by hygrothermal simulation. J. Build. Pathol. Rehabil. 2016, 1, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Schöner, T.; Zirkelbach, D. Zirkelbach. Development of hygrothermal reference years for Germany. In Proceedings of the Central European Symposium on Building Physics (CESBP), Dresden, Germany, 14–16 September 2016; pp. 133–140.

| Properties | Membrane A | Membrane B | Membrane C | Membrane D | Membrane E |

|---|---|---|---|---|---|

| Porosity (m3/m3) | 0.41 | 0.411 | 0.086 | 0.001 | 0.001 |

| Specific Heat Capacity, Dry (J/(kg K)) | 850 | 850 | 2500 | 2300 | 2300 |

| Thermal Conductivity, Dry (W/(m K)) | 0.6 | 0.6 | 2.4 | 2.3 | 2.3 |

| Temp-dep. Thermal Conductivity (W/(m K2)) | 2.0000 × 10−4 | 2.0000 × 10−4 | 2.0000 × 10−4 | 2.0000 × 10−4 | 2.0000 × 10−4 |

| Properties | Membrane A | Membrane B | Membrane C | Membrane D | Membrane E |

|---|---|---|---|---|---|

| Bulk Density (kg/m3) | 272 ± 10 | 159 ± 6 | 115 ± 25 | 212 ± 6 | 373 ± 5 |

| Water Vapour Diffusion Resistance Factor | 90 ± 5.98 | 369 ± 41.62 | 64,755 ± 1980 | 174,600 ± 10323 | 307,317 ± 16,850 |

| Material | Thickness (m) | R-Value ((m2 K)/W) |

|---|---|---|

| Exterior surface film | 0.06 | |

| Clay brick | 0.110 | 0.18 |

| Ventilated cavity | 0.039 | 0.16 |

| Pliable membrane | 0.001 | 0.00 |

| Bulk insulation | 0.090 | 2.70 |

| Plasterboard | 0.010 | 0.07 |

| Interior surface film | 0.12 | |

| Totals | 0.250 | 3.29 |

| No | Material Layers | Dimension (m) | Initial Water Content (kg/m3) |

|---|---|---|---|

| 1 | Red veneer brick | 0.110 | 9.2 |

| 2 | Air layer; without additional moisture capacity | 0.04 | 0.01 |

| 3 | Pliable membrane | 0.001 | 0.0 |

| 4 | Fibre glass insulation | 0.090 | 1.86 |

| 5 | Gypsum plaster | 0.010 | 6.3 |

| Australia Cities | NatHERS Climate Zone | Building Location | Time Period (Hours) | Heating Thermostat Set Point (°C) | Cooling Thermostat Set Point (°C) |

|---|---|---|---|---|---|

| Sydney | 17 | Living room/Dining and Kitchen Bedroom | 07:00 to 24 07:00 to 09:00 10:00 to 15:00 24:00 to 06:00 | 20 18 Unconditioned 15 | 25.5 25.5 Unconditioned 25.5 25.5 |

| Darwin | 1 | Living room/Dining and Kitchen Bedroom | 07:00 to 24 07:00 to 09:00 10:00 to 15:00 24:00 to 06:00 | 20 18 Unconditioned 15 | 26.5 26.5 Unconditioned 26.5 26.5 |

| Location | Koppen Climate Classification | Northern Orientation | Western Orientation |

|---|---|---|---|

| Darwin | Aw | 3 of 5 | 5 of 5 |

| Sydney | Cfa | 4 of 5 | 5 of 5 |

| Holzkirchen | Cfb | 5 of 5 | 5 of 5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olaoye, T.S.; Dewsbury, M.; Wallis, L.; Küenzel, H. Hygrothermal Modelling of the Differences between Single versus Variable Relative Humidity Vapour Diffusion Resistivity Properties of Pliable Membranes. CivilEng 2022, 3, 687-716. https://doi.org/10.3390/civileng3030040

Olaoye TS, Dewsbury M, Wallis L, Küenzel H. Hygrothermal Modelling of the Differences between Single versus Variable Relative Humidity Vapour Diffusion Resistivity Properties of Pliable Membranes. CivilEng. 2022; 3(3):687-716. https://doi.org/10.3390/civileng3030040

Chicago/Turabian StyleOlaoye, Toba Samuel, Mark Dewsbury, Louise Wallis, and Hartwig Küenzel. 2022. "Hygrothermal Modelling of the Differences between Single versus Variable Relative Humidity Vapour Diffusion Resistivity Properties of Pliable Membranes" CivilEng 3, no. 3: 687-716. https://doi.org/10.3390/civileng3030040

APA StyleOlaoye, T. S., Dewsbury, M., Wallis, L., & Küenzel, H. (2022). Hygrothermal Modelling of the Differences between Single versus Variable Relative Humidity Vapour Diffusion Resistivity Properties of Pliable Membranes. CivilEng, 3(3), 687-716. https://doi.org/10.3390/civileng3030040